2 minute read

MICRO RUN - The Evolution of digital

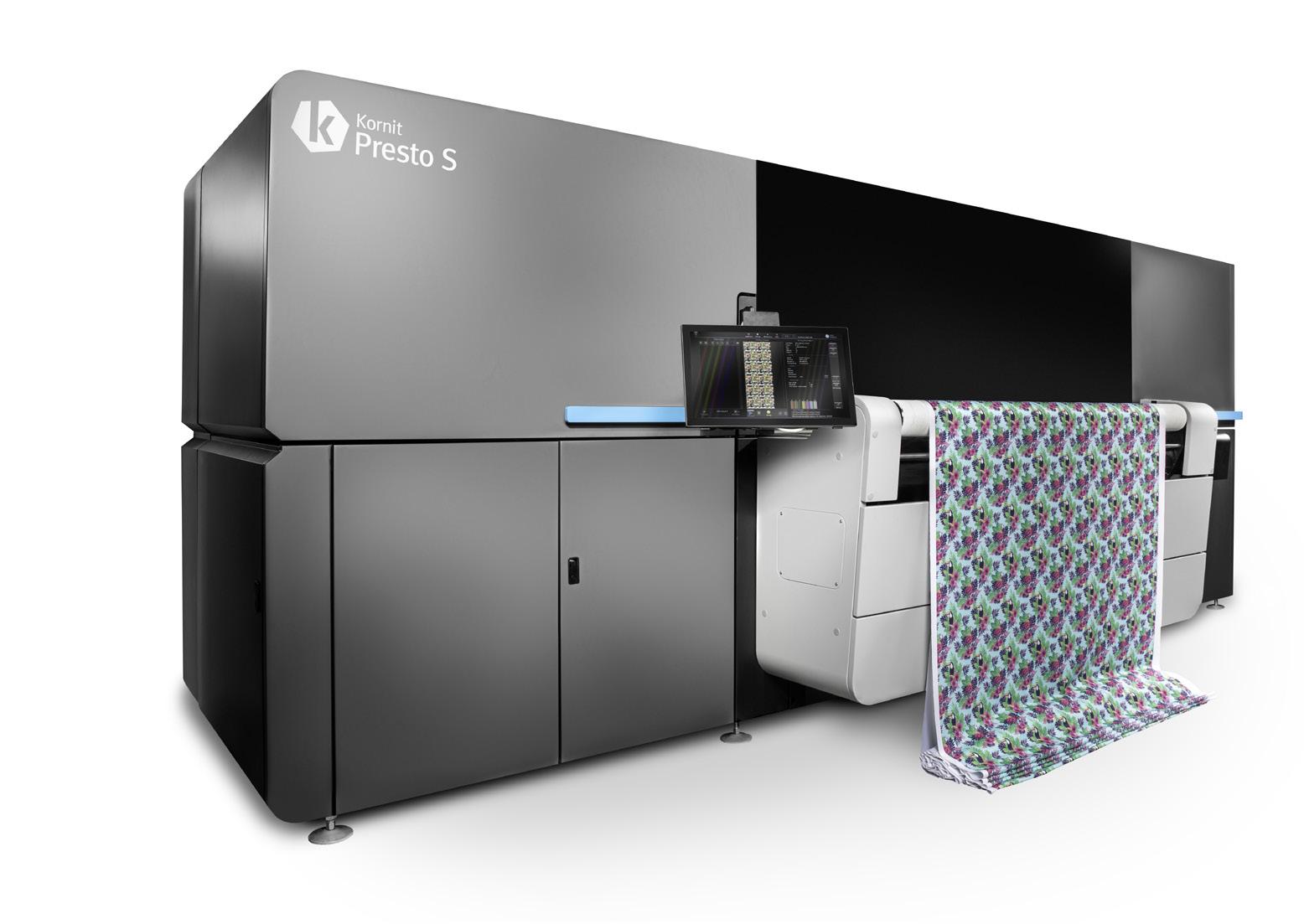

eliminate the need for external process steps, so users can achieve the best results from PFP (Prepared-For-Print) to finished digitally printed fabric faster than ever.

Designed for end-to-end garment manufacturers, the Presto offers the quickest file-to-finished goods process for short and micro-runs. It additionally offers low-cost micro-run production and has the shortest run cycle in the industry.

Kornit Presto leverages patented technologies for added benefits. It utilises award-winning NeoPigment Robusto ink, which is water-based, non-toxic, and 100% biodegradable. It is able to print on all fabric types with just one ink set, and results in excellent hand-feel and vivid colour combinations.

With the Presto, it eliminates pre- and post- care. Users just need to load files and print. All energy- and waterconsuming steps are also eliminated. Manpower needs is reduced. Files are loaded and queued at setup, without any mid-run intervention.

“With the Kornit Presto, we bring all the benefits of textile pigment printing to the digital world by combining Kornit Digital’s advanced technology with our revolutionary NeoPigment process. We provide you with an unprecedented colour gamut and the ability to print any design, in any number of colour combinations, at any level of detail,” said Andy Yarrow, president for Kornit Asia Pacific.

“Our NeoPigment process eliminates the need for external process steps, making the Kornit Presto a true standAndy Yarrow, president for Kornit Asia Pacific

alone solution. Digitally print on a wide variety of fabrics with just one printer and one NeoPigment Robusto ink set. By eliminating energy- and waterconsuming steps, and using our 100% biodegradable inks, you benefit from the most eco-friendly solution in the textile printing industry.”

The Microrun in Action: a case study Established in 2008, Spoonflower is a growing web-to-print business in the US. The company caters to the largest community of independent fabric designers in the world, serving 2,000 orders each day with an average print of 1 to 2 yards. Customers upload and print their own designs on a range of fabrics, or choose from a wide range of ready-made independent design options.

With the Kornit, the entire manufacturing process happens in one step. It essentially consolidates the entire textile industry into one machine.