At ProviCo Rural, we’re Australia’s only milk replacer manufacturer, sourcing premium milk from local dair y farmers. Our range of high-quality Australian milk powders delivers optimal protein for infant animals , giving them the best start in life.

Explore Australia’s leading Calf Milk Replacer range, ProfeLAC, with solutions tailored for all your needs.

1300 380 343

admin@provicorural.com.au

www.provicorural.com.au

BY ELIZA REDFERN

IF THE past few seasons have taught us anything, it’s that dairy markets are not immune to global pressures.

Although Australia’s just-finished season has come with some decided improvements, there will always be challenges to navigate.

Australia’s milk production increased 3.1 per cent (to 8.376 billion litres) over the 2023-24 season, largely attributed to the lower comparable figures of the previous season and more favourable weather conditions.

This beat initial expectations, however, increased milk flows were occurring at a time when economic pressures created difficulty in both global and domestic markets.

On the international stage, the competitiveness of Australian dairy products somewhat improved over the 2023-24 season — tighter global supply supported international export pricing and shipping challenges along key routes diverted additional demand towards Oceania product.

Nevertheless, Australian dairy exports only increased one per cent last season, totalling almost 705,000 tonnes.

Purchasing activity from importers globally has become more price sensitive as costs bite across the supply chain, and China’s own economic woes (and strong local production) continue to weigh on the dairy export market.

As such, Chinese buyers purchased 30 per cent less Australian dairy over the season, with other key markets soaking up the balance.

Product shipped to Japan increased 22 per cent, supporting total cheese exports, and buyers across the South- East Asia region imported 23 per cent more Australian dairy than in the 2022-23 season.

At the same time, Australian dairy remained under pressure from overseas product domestically.

Almost 312,000 tonnes of dairy was imported into Australia over the 2023-24 season; while this was nine per cent lower than the previous season, it was still higher than the two seasons prior.

There are a variety of reasons overseas dairy products are imported into Australia, with

economic factors being a key driver in recent years.

Considering Australia’s modest milk production recovery, improved product competitiveness and shipping challenges (impacting the flow of product into Australia, not just out), less dairy was sourced from New Zealand (-7 per cent), Europe (-7 per cent) and the United States (-24 per cent) over the 2023-24 season.

The 2024-25 season is now under way, bringing with it some new developments (lower farm gate milk prices) and some old aspects (weather and economic challenges).

Considering the impacts these may carry for milk flows this season, Dairy Australia is forecasting total production to drop slightly, maintaining a national milk pool around 8.3 billion litres.

Economic challenges will likely remain a feature of dairy markets in the months to come — with limited recovery in export markets foreseen in the near term, regaining domestic market share will likely be a focus for many manufacturers.

Eliza Redfern is Dairy Australia’s Analysis and Insights manager.

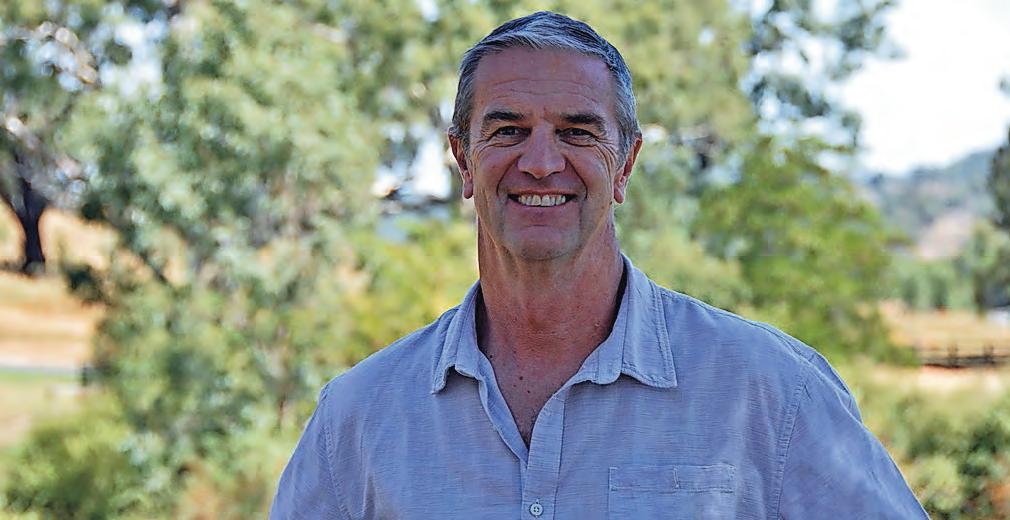

QUEENSLAND DAIRY farmer Paul Roderick

has been designated as Dairy Australia’s chairelect and will formally step into his role as chair following the Dairy Australia Annual General Meeting.

The board have also recommended two board nominees to stand for election at the AGM, which will be held on November 26 in Warrnambool, Victoria.

Current Dairy Australia chair James Mann will retire from the board at the AGM, following nine years as a director, including four-anda-half-years as chair.

“Paul’s contributions so far during his time on the board have been deeply valued, and I am confident his extensive knowledge of and passion for dairy will make him an outstanding chair,” Mr Mann said.

“Designating Paul as chair-elect provides a seamless transition as we continue to deliver for farmers and work towards developing Dairy Australia’s next five-year strategic plan.”

Mr Roderick thanked Mr Mann for his leadership and impact over his term as chair.

“James has contributed greatly to Australia’s dairy industry through a wide variety of leadership roles for more than 20 years, championing strategies and activities that support the profitability and sustainability of dairy farmers,” Mr Roderick said.

“I’m grateful for the board’s support and confidence in becoming the chair-elect, and I’m excited for the opportunity to build on James’ legacy by driving strategies that further advance dairy farm businesses and the profitability of our industry.”

First elected to the Dairy Australia Board in November 2020, Mr Roderick has operated his family dairy farm at Harrisville in south-east Queensland for more than 30 years.

He has held a number of industry roles including chair of Subtropical Dairy and was involved in establishing the Young Dairy Network in Queensland.

The terms of two directors — the retiring Mr Mann and Euberta dairy farmer Simone Jolliffe — expire at the AGM, meaning there are two vacancies for the board.

In accordance with its constitution, the board is required to have an appropriate balance of skills and experience that relate to the nature of the business and affairs of Dairy Australia, with at least four directors having milk producer skills.

Both vacancies this year are for directors with milk producer skills.

“After a comprehensive selection process, the two candidates recommended by the Board Selection Committee are Dr James Neal

and Ms Simone Jolliffe,” committee chair Alan Bell said.

Dr Neal has been chair of the Dairy NSW Board since 2020. He farms with his wife and parents near Taree, milking up to 800 cows year-round.

He has extensive skills in agricultural research, development and extension, with a PhD in water use efficiency, yield, nutritive value, and profitability of different dairy forages.

Appointed to the Dairy Australia Board in 2021, Ms Jolliffe has been farming near Wagga Wagga in NSW with her husband since 2000.

Ms Jolliffe has nearly 25 years’ industry involvement outside their farm business in local, state and national roles. She has held various leadership roles in industry research, development and extension as well as advocacy and representation.

Dairy Australia members will vote for directors at the AGM or in advance by proxy.

To be successfully elected to the vacant director roles, each nominee will require a

majority of the votes cast.

All dairy farm business operators are eligible to become members of Dairy Australia and vote at the AGM.

Farmers can contact the Dairy Australia member line on 1800 004 377 or email at membership@dairyaustralia.com.au to become a member or confirm that their details are correct.

Information about participating in the forum and AGM, as well as instructions for voting, will be provided closer to the date. For more information on the director election process, go to: https://www. dairyaustralia.com.au/directorelections#. ZGGx8E9ByHs

BY GEOFF ADAMS

BEGA CHEESE milk suppliers may have to wait for a recovery in farm gate milk prices.

In an interview marking Bega Cheese’s 125th anniversary, executive chairman Barry Irvin noted the disappointment with the low opening prices for the 2024-25 season compared to last year.

“We have had two strong years of pricing, and probably last year was not reflective of global markets but it did reflect the strong competition for milk,” Mr Irvin said.

“I have to say we would have expected global commodity prices to have begun to improve a little more than they have over the last few months.

“We have been seeing a downward trend for some time.

“We still expect an improvement ... but it’s probably likely to be a little later in the financial year we are currently in, or late in the first half of the next calendar year.”

The Bega Group marked the 125th anniversary with some celebrations around the Bega Valley.

For most of the past century, the milk co-operative enjoyed modest growth, but in the past

10 years, thanks to an energetic expansion policy under Mr Irvin’s stewardship, the company revenue has increased from the $1 billion mark to $3.3 billion.

Their brands include the iconic Vegemite and Bega Peanut Butter, acquired in 2017, as well as Dairy Farmers, Dare, Farmers Union Greek Style Yogurt, Farmers Union Iced Coffee, Pura, Masters, Big M, Daily Juice, Zooper Dooper, Mildura, Prima and others through the 2021 acquisition of the Lion Dairy and Drinks business.

The company is leading the Bega Valley’s push to improve sustainability with a Regional Circularity Co-operative (RCC) and the ‘Bega Circular Valley 2030’ program, aiming to make the Bega Valley the most circular regional economy in Australia by 2030.

“Can we get better outcomes in terms of costs, or better environmental outcomes,”

Mr Irvin said they were asking.

“Can we use our resources better? It’s a heavy duty collaboration with the community and all levels of government.

“It’s a way of thinking about your entire community.”

Barry Irvin talks about Bega’s past and future, and what energises him in his key position, in a podcast recorded by Country News, a sister publication of

https://www.dairynewsaustralia. com.au/news/bega-boss-says-wait-forbetter-milk-prices/

Australian Dairy Farmers has welcomed the new Federal Agriculture Minister Julie Collins.

ADF president Ben Bennett said he was pleased to welcome a minister from a strong state for agricultural production, including dairy. Ms Collins is a Tasmanian MP.

“We appreciate Minister Collins’ acknowledgement of the vital role that agriculture plays in our country,” Mr Bennett said.

“The Australian dairy industry is the third largest agricultural industry in Australia and dairy farmers are world leaders in quality, innovation and sustainability, producing milk and dairy products that are in high demand both domestically and internationally.

“However, the dairy industry faces serious challenges, including the ongoing issues of profitability, sustainability and regulation.

“Those challenges require strategic policy support and robust collaboration between government and industry stakeholders.

“We look forward to working collaboratively to address the challenges and harness the opportunities ahead.”

Mr Bennett said ADF was inviting the minister on a farm tour, providing the opportunity for her to engage directly with industry experts and local farmers, witness first-hand the innovative practices that make dairy a global leader and discuss the issues impacting the dairy sector.

The National Farmers’ Federation has also welcomed Ms Collins’ appointment.

The NFF’s Jolyon Burnett said having a minister from a state where primary industries remained a significant contributor to the local economy should ensure a keener ear would be given to the needs of the sector.

AT JUST 19, Holly Anderson might be the youngest Australian cattle breeder to have a bull placed in the artificial insemination system.

Empire Banks P has been picked up by Genetics Australia and is expected to have semen available from this spring.

While Holly’s Empire Jerseys stud is relatively new, she hails from a family that has been producing top-quality Jerseys for decades.

Holly’s parents Rob and Kerrie operate Kings Ville Jerseys, which has sold 28 bulls into AI and was last year named one of Jersey Australia’s inaugural master breeders.

Kings Ville was started in 1987 by Rob with the support of his parents, Bert and Winsome, who established Kings View Jerseys in 1961.

Holly was keen to go one step further and came up with the name Empire to reign over the Kingdom.

“I always joked with Dad whenever one of my cows had a girl that my empire was growing and that’s how Empire Jerseys was created,” Holly said.

“My family has Kings in their stud names, I still wanted my stud to be connected with them but to be separate at the same time.”

Holly says there is some friendly rivalry within the family — and she beat her dad who was 24 when he sold his first bull to AI — but she acknowledges their support.

“I must be close to being the youngest to get a bull into AI,” Holly said.

“I’m happy to get that goal ticked off and hopefully I’ll get more in the future, but I’m very thankful to Mum and Dad because it wouldn’t be possible if it wasn’t for them.”

Holly’s journey to AI breeding success started when she was 12 and got to take her pick of any heifer in the calf shed, an offer that was extended to her older sisters Em and Meg.

“I chose Archer Belle — she had Matt Belle, the dam of Empire Banks,” Holly said.

“I didn’t base it off what she looked like; I chose her because she had the highest BPI in the calf shed. It was a case of mind over heart.”

In 2021, Holly started Empire Jerseys and in 2023 she started fulltime work on the farm. She now has full control over what bulls she uses.

“Because I’m relatively new to the game, when it comes to my breeding objectives, I aim for polled as well as creating more efficient and productive cows.

“When Matt Belle was born and I saw that she had ideal numbers being the highest BPI Jersey heifer in Australia, it gave me the hope that one day she would put a bull into AI.

“When I looked at the number of bulls Mum and Dad had sent into AI, getting my own bull in the system definitely became a goal of mine.

“When Matt Belle had her first son, he was just a couple short on BPI which taught me the value of genomics, the challenges that come

with a changing criteria base and to focus on important reliant traits for the Jersey breed.

“I was fortunate enough for Matt Belle to have another son — Banks. When his genomics arrived, it was an exciting moment and I thought he had a good chance.

“I’m a bit biased due to the strong relationship I have created with Banks but I do hope he goes on to do well.”

While Belles are the main family within Empire Jerseys, the budding stud also boasts Banks, Melmiss and Eran among others, including several Fernleafs she owns by herself as well as co-owns with her sisters.

“I’d love to get a bull from the Fernleaf family into AI,” Holly added.

“I’ve got a real soft spot for Jerseys due to being a fifth-generation dairy farmer.

Northern Victorian dairy farmer and industry leader Monique Bryant is the new programming chair for the 2025 Australian Dairy Conference in Queensland.

A third-generation farmer, Monique grew up passionate about the dairy industry.

After completing an agribusiness degree at the University of Melbourne she worked at Rural Finance (Rural Bank) and Tatura Milk (Bega) in dairy-focused roles before purchasing the family farm at Kaarimba (husband Mark’s side of the family) in 2007.

Since then they have added more land, irrigation water and cows to the business.

Despite the many challenges that have been thrown at the business, being involved in the dairy industry still makes Monique smile every day.

“There have been a lot of challenges as a dairy farmer but I get to work alongside my family every day doing something I really enjoy. How lucky am I,” she said.

ADC 2025 will be held on the Gold Coast from February 12 to 14.

“ADC has a reputation for raising the bar each year regarding content, speakers and the delegate experience, and I am honoured to lead the Programming Committee for Gold Coast 2025,” Monique said.

“We aim to strive high and think differently as we curate Australia’s premier dairy event.

“I really hope that dairy farmers across the country take some time to invest in ADC as a platform to explore opportunities, get out of their comfort zone and

“I see the Jersey cow playing a big part into the sustainable future due to their size and production and can see Australian Jersey genetics going very far around the world.”

Holly has embraced the industry and is vice-president of Gippsland Dairy Youth Group.

“I enjoy organising events and helping to encourage the next generation,” she said.

“It’s important to have a supported environment and build relationships with like-minded people.”

Genetics Australia CEO Anthony Shelly said no-one on the GA team could recall a younger breeder supplying a bull to the team.

“It’s exciting news for the Jersey breed, not only have enthused youth but to have Holly leading the way,” he said.

“No doubt she has been mentored by some strong family influences, yet Holly has still had the vision and passion to create her own herd and breeding program.

“We are proud to be associated with such an inspirational young achiever and look forward to many more Empire bulls joining the Genetics Australia team.”

Empire Banks P is a particularly well-balanced bull with BPIg $342, and an excellent production profile with strong kilos and components along with appealing health traits, Survival +110, Cell Count +134, Mastitis Resistance +105, combined with linear scores that excel for strength and udders.

gather with colleagues in an empowering and progressive forum.

“I hope they take the opportunity to head to Gold Coast for some sun, fun and celebrate our great industry.”

Close to the dairy regions of southern Queensland and northern NSW, the Gold Coast will be the hub for exploration, knowledge-sharing, and a whole lot of fun, according to ADC president and NSW dairy farmer Rose Philipzen.

“Dairy farmers and people involved in the industry are incredibly hard workers with ongoing demands operating dairy businesses,” Rose said.

“ADC is seeking to combine one of the key learning and knowledge-sharing forums with the opportunity for some much-needed time off or family vacation.”

BY SOPHIE BALDWIN

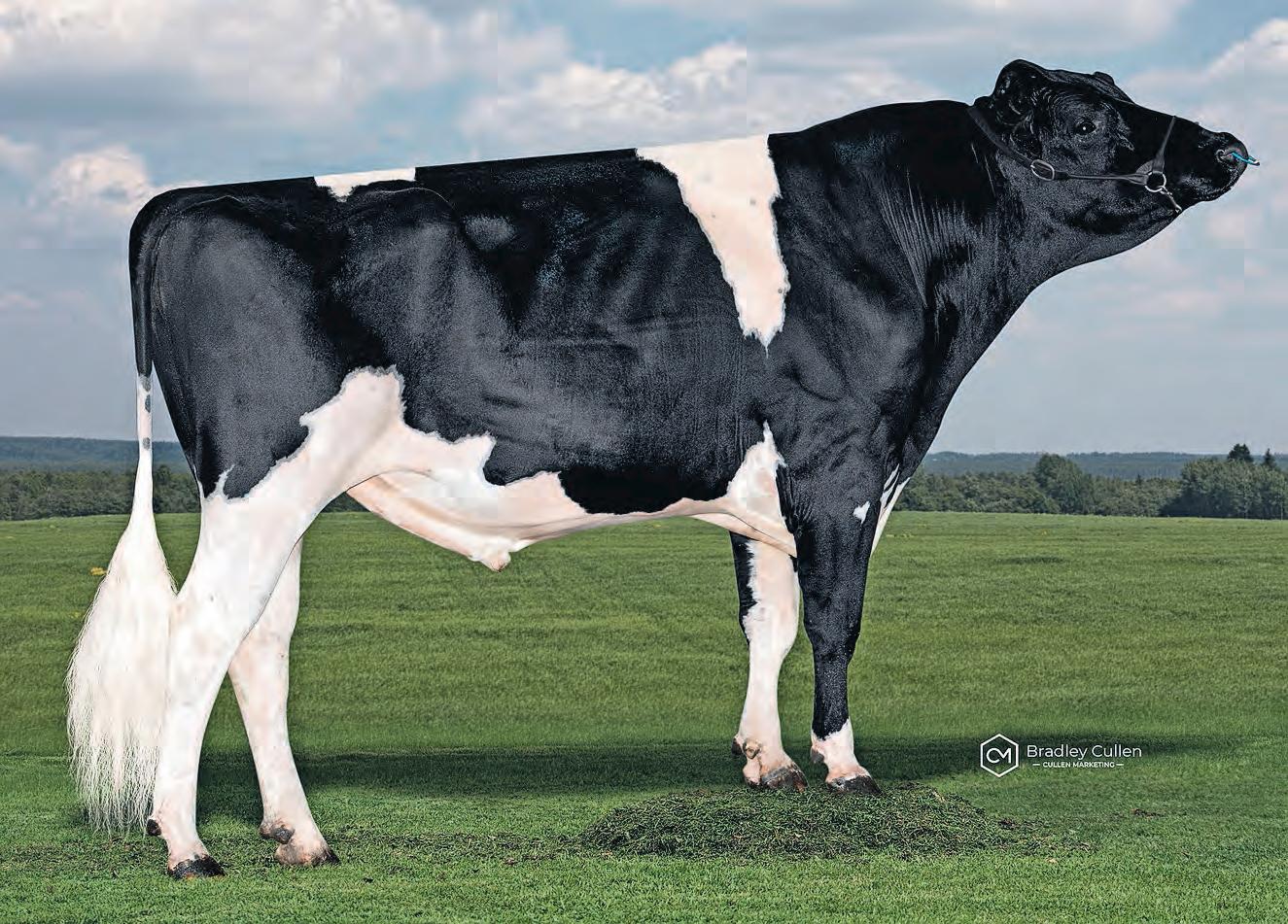

THERE MIGHT be a new group behind the organisation, but for five young dairy farmers the opportunity will still be the same, as they take the trip of a lifetime to visit some industry sights and compete at the Young Breeders School in Belgium.

The Young Breeders School provides an opportunity for attendees to test out their showing and fitting skills over two days, culminating in a competition where the Australian team will compete against other young farmers from 19 countries.

More than 180 young farmers participate in the school and 30,000 people visit the show every year.

Ryan Barker, Tasmania; Bridget Liebelt, South Australia; Elly Simms, NSW; and Hayden King and Patrick Anderson, both from Victoria, represented Australia on the trip which kicked off on August 24.

For 25-year-old Bridget, who grew up on a dairy farm and has been showing cows since she was eight years old, the trip will be an awesome opportunity to work on her showmanship skills.

“I am grateful to be chosen and I am really looking forward to the trip,” she said.

“I haven’t been overseas at all and I can’t wait to get to the school, meet other young farmers and experience everything the trip has to offer.”

Organiser Justin Johnston said the trip was a great experience for young dairy farmers and it was something he

wanted to see continue in the future.

Not only do the team get the opportunity to compete at the breeders school, they also get to take a look at some different farms in Holland including a barn, grazing and robot system.

They will also take a tour of a seed facility, among other things.

“I was part of the first original trip back in 2019 and I thought the experience was invaluable so along with the committee (Simon Tognola, Julia Paulger and Brent Mitchell) we have made it happen, along with help from our sponsors,” Justin said.

The organising team raised $32,000 — half in cash donations and half from an auction from donated goods held at the Bendigo Winter Fair.

Justin said 19 young farmers put their hands up to be involved in the trip, eight were pre-selected for an interview by the panel and then the final five were chosen.

“The team will get the chance to show off their cattle skills to over 30,000 people, network with other industry professionals and also get to tour around Belgium — there are not too many opportunities left for young farmers in the industry these days so it is important we keep what we have so we encourage them to stay in the industry,” he said.

Callum McPhee, 32, from Deniliquin has the job of mentoring the Australian team.

His family has been running Hillview Park Holsteins since 1956 and he has been showing cows

himself since he was a young boy.

His family milk 300 cows and Callum said he is always looking to improve the next generation.

“The goal is always to breed an animal good enough to compete in the show ring,” Callum said.

He is looking forward to heading to Belgium and taking on the role of a mentor.

“I guess my role will be to use my experience to help the team if they run into a problem and to drive them around as well,” he said.

“It will be great to travel to Belgium and the networking and learning opportunities for the team will be amazing.

“It is still a competition, a bit like the cow Olympics, and we will be competitive and do Australia proud.”

The dual-listed dairy company a2 Milk has agreed to pay its New Zealand supplier almost $NZ25 million ($A22.7 million) to settle a long-running dispute between the two parties.

A2 Milk Company and Synlait Milk had been at loggerheads since October when a2 tried to cancel its arrangement to exclusively use Synlait milk for its a2 Platinum infant formula product.

A2 said it had the right to cancel the deal after Synlait failed to meet product volume targets for 2022-23, while Synlait said the notice was not valid under their supply agreement and issues regarding prices and intellectual property of a2 Milk baby formula product specifications.

Following a process of binding arbitration, the companies agreed the October cancellation notice was valid and that a2

The Young Breeders School is an international event created in 1999. It is aimed at young people aged 13 to 25 years, with the main aim to teach

Milk had the right to source milk from any supplier, although Synlait said it expected a2 would still use it in the short term.

“Settling these disputes is another positive step forward in our business recovery plan," Synlait chief executive Grant Watson said.

As part of the deal, a2 Milk will make a one-off payment to Synlait of $NZ24.75 million.

For 60 years the heart of the RENN Roller Mill has been its precisionmachined 16” diameter rolls which provide more grain rolling area per revolution compared to other brands of roller mills with smaller diameter rolls.

RENN Roller Mills save time and money year after year by rolling more grain per hour with less horsepower.

young breeders their way around a dairy cow and improve their knowledge on optimising selection and show preparation.

Cash-strapped Synlait has also agreed to hold a capital raise as part of the deal and a2, a major shareholder, has agreed to participate.

The parties also agreed that a2 Milk owns the intellectual property rights for its infant milk formula product specifications and that Synlait would continue to meet annual product targets.

BY JEANETTE SEVERS

LELY INTERNATIONALLY founded the Red Cow Community in 2017, to recognise dairy farmers who are using at least eight of their robot milking units and milking 500 cows, at a minimum.

Australian dairy farmers were recently recognised, in Gippsland, Victoria, at Lely Australia’s Connect, Care and Grow conference in late July.

The first Lely robot milking units installed in Australia were on a Gippsland dairy farm, in 2001. On this farm, 300 cows were milked through four Lely Astronaut A2 milking robots on a pasture grazing system.

Eventually those robots were on-sold, and installed on a Tasmanian dairy farm, where they are still working.

Gaining the Red Cow award brings Australian dairy farmers into a community that includes farmers across Canada, Argentina, Belarus, Italy, Denmark, Japan, Sweden, Russia, Germany, Turkey, the United Kingdom and the United States.

Lely Oceania cluster manager Wil van Vorstenbosch said the Red Cow Community enabled dairy farmers to network with others who were also managing large dairy farms, to discuss common challenges and learn about each others’ systems.

“We at Lely care about our farmers,” Wil said. “We aim to grow together with our dairy farmers to achieve continuous improvement.”

The Australian dairy farmers who have now

joined the Red Cow community are a mix of owners and sharefarmers. They are:

Josh Bishop and Rowan Stokes, Wild Dog Dairy, Stokes, Tasmania.

Rachel Millhouse and Matthew Radford with Andrew Radford, Radford Bros, Riana, Tasmania.

Grant and Leesa Williams, Willora Farms, Hallora, Victoria.

Peter and Lisa Vening, Hedley, Victoria.

Stuart Seabrook and Ray Howe, Bonnie View Pastoral Co P/L, Drouin, Victoria.

Michael, Jodie and Jake Connor, Nangkita Dairies P/L, Mt Compass, South Australia.

Perrin Hicks and Asher Jacobs, Hicks-Jacobs Dairies, Mt Compass, South Australia.

Jacinta and Josh Clark, Fiander-Moor Partnership, Mt Gambier, South Australia.

Margaret, Gordon, Ben, Ashley and Justin Lockett, Stanvale Farms, Neerim North,

Victoria.

For more photos of Red Cow farmers, go to: https://www.dairynewsaustralia.com.au/news/

farmers-join-global-network/

For more stories and photos from the Lely Australia Conference go to pages 11, 16 and 17.

BY JEANETTE SEVERS

THE FARMER panel at the Lely conference in Gippsland represented a diversity of dairy farmers who have installed Lely robot milking units.

It comprised Lisa and Shawn Vening from Hedley in Victoria, Asher Jacobs from Fleerieu in South Australia and John van Adrichem from Togari in Tasmania. Dale Serong from Lely Center Gippsland was the facilitator.

Asher said he “looked over the fence” at what his neighbour was doing and was impressed enough to contact Lely and compare the cost of upgrading his herringbone system to installing robot units.

Lifestyle and labour were big factors in his and his partner’s decision-making.

“Our young children were a key driver for us to change to robot units,” Asher said.

“The cost replaced a workers wage.”

He said they installed the RUs next to the swingover herringbone platform.

This enabled them to train their cows after milking on the herringbone platform to access grain

through the RU system, in readiness for change.

“This meant they knew where the grain was from day one,” Asher said.

“Pre-training helped a lot for when we switched over.”

There were some issues in the first few weeks.

“Getting the draft gates right for grazing would have been good from the start, but the infrastructure was still arriving,” Asher said.

Lisa and Shawn Vening are the fourth and fifth generation working in the dairy industry.

Lisa and her husband Paul wanted to invest in a new dairy that incorporated the ambitions of their three sons.

“The boys wanted to work on the farm and were interested in the dairy industry,” Lisa said.

“We didn’t want the boys busting their guts, and we wanted them to spend time with their young families.”

The entire family worked together to build the infrastructure — a new shed, cattle yards and drafting set-up, laneways, reconfiguring paddocks, a feed pad and effluent dam.

Their commitment saw them working 20-hour days, building the infrastructure, continuing to farm,

and milking in the old dairy.

“Don’t do everything yourself,” Shawn said.

“We were working all day then stopping at 6pm to milk cows.”

He also recommended simplifying

the amount of herd management data available.

“I can spend hours going through information to decide who to join to who,” Shawn said. In contrast, Lisa enjoys sifting

through the data.

“I’ve got six generations of pedigrees in some cow families,” Lisa said.

Shawn said the robot milking system had changed for the better how the entire family farmed.

“We enjoy doing the other farm work, but we’re not stuck milking twice a day,” Shawn said.

John van Adrichem was the first Tasmanian dairy farmer to install Lely RUs, and he took himself to technician school to learn how to service the units.

His family farm transitioned from a herringbone to a rotary platform, before John inquired about the RUs.

“After four days, seeing the cows walking to the dairy on their own, I knew I’d done the right thing,” John said.

He recommended being open to changing your farming systems.

“I started with ABC grazing, but it didn’t work,” John said.

“It needed perseverance. You need a bit of lolly. We started feeding a biscuit of hay. You have to be open to change.

“In particular, training the heifers to three grazings per day was very important. They don’t know what to do.”

BY JEANETTE SEVERS

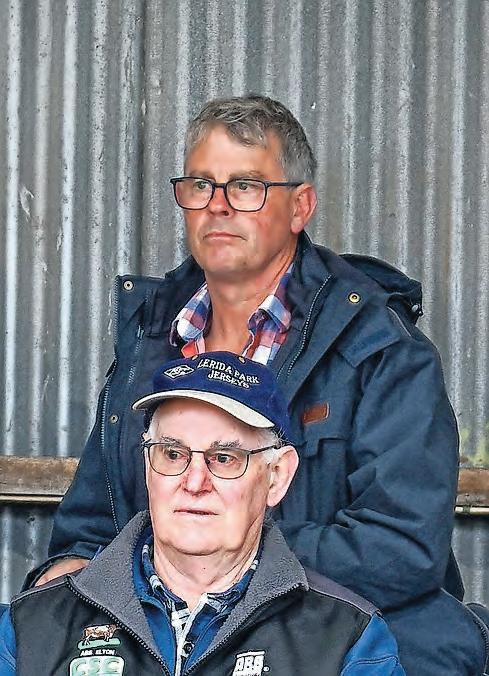

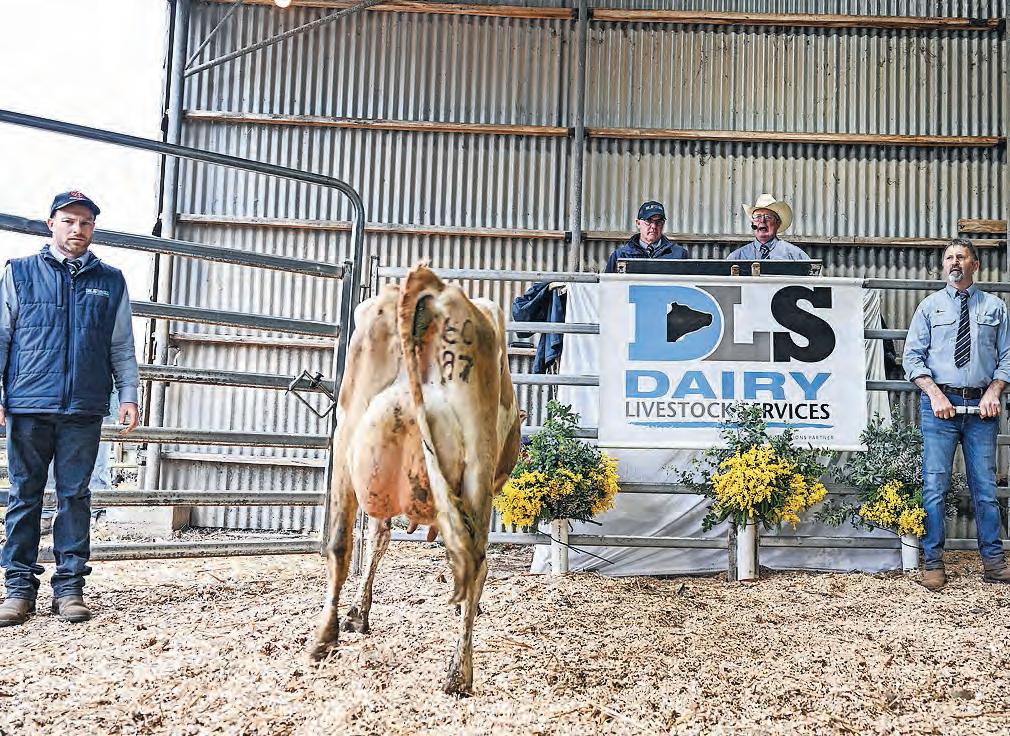

RETIREMENT PREDICATED the dispersal sale of Lerida Park Jersey cows and in-calf heifers on August 15.

Rhys and Lauren Smethurst sold their dairy farm at Princetown, in south-west Victoria. Then their renowned registered milking herd were sold in the on-property sale.

“The neighbour was looking for another farm to buy, and none of our children wanted to succeed to the farm,” Rhys told Dairy News Australia

“Lauren and I want to spend more time with our children and grandchildren, who all live some distance away.”

Those considerations correlated with the couple’s decision to sell and finish their long association with the dairy industry and breeding Jersey cattle.

Rhys and Lauren will continue to live in the local district, on a smallholding at Camperdown.

While the milking herd was sold in August, Rhys and Lauren are raising the yearlings and calves on their new property and an outblock, and expect to sell them in-calf in two sales in 2025.

“The yearlings will be available as autumn calvers, and we’ll join the heifer calves for spring-calving next year,” Rhys said.

“It means we’ll have two more sales, unless these young cattle are sold privately.”

The Lerida Park prefix will continue, with purchases by some significant studs and a Smethurst family member, as well as a new buyer.

“My cousin, Troy, bought 23 cattle and they’ll go to Smethurst Park at Athlone,” Rhys said.

Rhys’ father, Bruce, established Lerida Park stud in 1966, with a nucleus of cows from the herd of his brother, Jim.

“It’s great that someone in the family will continue on with these cows,” Rhys said.

Troy Smethurst is adding the Lerida Park Jerseys to his registered Holstein and Brown Swiss herds on his farm at Athlone, Victoria.

He paid the sale top of $11,500 for lot 39, the recently calved Lerida Park Raceway Sabina 78, born 2021, A2A2, and classified VG86 as a two-year-old.

Troy competed for this young cow against a lot of bids from the floor of the sale, while he

“Troy decided to take the opportunity of this dispersal to buy the very best of many decades of selective breeding, and keep the bloodlines in the Smethurst family.”

Troy also purchased lot 54, the five-year-old and recently calved cow Lerida Park Pilgrim Rose 419, EX93 and milking 8000 litres, for $10,000; as well as a number of animals ranging in price from $6500 to $8000.

“Indeed, these selections will form a wonderful foundation for the Jersey section of what is already a tremendous herd of cows at Smethurst Park,” Brian said.

“I think the Lerida Park dispersal sale is one of the great Jersey herds that’s ever been sold, and I know these cows will go away and do a tremendous job for their new owners,” he said.

“We advertised it as the ‘Jersey Dispersal Sale of the Year’. These cows are big production, high genomics, great type and the cows are in great form.”

Some of the bidders have been long-term clients of Lerida Park, buying young cows and joined heifers over many years to add their genetics to their own herds.

These bidders included Graeme and Lisa

Among their purchases, Sandra and Daniel Bacon, Brookbora Jerseys, Tennyson, Victoria, paid $6000 for lot 20, Lerida Park Woodside Lucy 235, a four-year-old due to calve in September, joined to sexed semen from Roulette.

Corey Couch, Ocean Acres Jerseys, Laang, Victoria, purchased lot 9, Lerida Park Tahbilk Lucy 182, EX92, born 2019 and due in September to Broadway, for $9250.

The Couch, Bell and Ferrari syndicate paid $9000 for lot 145, Lerida Park Eclipse Selley 2-ET, EX92. She is a daughter of Royal Show Champion Fleurieu Astound Selley, EX93.

Robbie Salter and Danny Griffiths, Kerang, paid $9000 for lot 116, Lerida Park Malachi Countess 409, EX92, born 2018, calved March this year and rejoined by AI to Big Red.

Helena Brown, HD Farming, Jindivick, added to her nucleus herd. Dairy News Australia has previously published a story about her growing investment in dairy [https:// www.dairynewsaustralia.com.au/news/ starting-to-build-her-dream/].

Helena bought the 2022 Junior Champion Southwest Challenge when she paid $3000 for lot 16, Lerida Park ASKN Lucy 214, VG86, A2A2.

“I bought 12 cattle, a mix of cows and heifers in this consignment, including several in-calf with sexed semen,” Helena told Dairy News

“I now have 31 head, all in-calf, and 25 of those are registered. Given we have so many registered cows in our herd now, we think we’ll change our focus and source more, with the idea of registering our own stud prefix.”

Helena’s new purchases included the cow families Sabina, Rose, Lucy and Prim. Robbie Wilson, Jamber Farms, Jamberoo, NSW, was a keen bidder at the sale and bought a truckload, including cow families Lucy, Rosemaree, Countess and Rosebud.

Siblings Cameron Thompson and Lisa McKay of Linsand Farms, Irrewillipe, bought cows fresh in milk, including lot 60, Lerida Park Stux Rose 424, classified 85 as a two-year-old and reclassified recently as EX90, born 2019, for $9000. G. and L. Bryce of Green Pines Jerseys, Nullawarre, bought Lerida Park Chrome Sabina 74, EX, for $8250; and Lerida Park Woodside Rosemaree 226 at $7000. She was the top selling joined heifer.

The selling agents were Dairy Livestock Services, and the on-farm sale was integrated online with Stocklive.

The sale of 191 Jerseys grossed $722,600, for an average of $3785. The 24 spring-calving heifers averaged $3645, and the 167 cows averaged $3805.

For an extended report on the sale, go to: https://www.dairynewsaustralia.com.au/ news/the-jersey-sale-of-the-year/

What if you could proactively improve calf and cow health sothey can better withstandchallenges, including those caused by mycotoxins?

What if you could control calf diarrhea before an outbreak, and reduce the incidence, severity and duration of other common diseases that affectthe feedconversion efficiency of lactating cows and your bottom line?

What if you could add nutritional insurance to every stage of your cattle’s lives resulting in healthier heifer calves that join the milkingherd ready to contribute at a high level, and lactating cows that spend less time off feed.

Has been shown to:

•Agglutinates and binds E. coli and Salmonella enterica.

• Agglutinate and bind E. coli and Salmonella enterica

•Reduces the incidence, severity and duration of mastitis and cryptosporidiosis infection.

• Reduce the incidence, severity and duration of mastitis and cryptosporidiosis infection

• Reduce blood stress markers during and after transport and temperature stress.

•Reduces blood stress markers during and after transport and temperature stress.

• Minimise cytotoxic damage caused by a variety of mycotoxins and carryover of aflatoxins in milk

• Improve weight gains and performance in calves and milk yields in lactating cows

•Minimises cytotoxic damage caused by a variety of mycotoxins and carryover of aflatoxins in milk.

•Improves weight gains and performance in calves and milk yields in lactating cows.

Distributed By:

BY JEANETTE SEVERS

BUSINESS SUCCESSION in Australia will see $5 trillion of wealth transferred between generations in the next decade.

That requires a good understanding of the implications of good and bad succession planning in agriculture.

Bad succession planning is dying rather than having conversations that are sometimes hard, and refusing to make decisions that avoid unnecessary legal and tax expenses.

A good succession plan replaces assumptions, provides clarity for everyone, avoids legal challenges, and can provide a comfortable retirement for the principals.

A good succession plan identifies the property, assets and ownership structure of the business — and may lead to advice about changing the ownership structure of the business so it can be run more effectively and efficiently.

These were the messages at a farmers’ gathering near Bairnsdale recently.

Succession planning is about more than planning for the business, it is also about financial planning for retirement.

It is a risk management tool that enables the current owners to identify where their income for retirement is coming from, what insurances they need to keep paying, and where their income is being generated from.

Retirement at 67 years old for many people is unachievable now in Australia. That includes farmers.

In the next 10 years, in Australia, agriculture is one of the key industries where $5 trillion value of wealth transfer will occur through succession planning, said Ken White, one of the speakers and the principal accountant at White’s Accounting and Taxation Solutions.

A poor or non-existent succession plan affects how the assets and income of the farm business are assessed for the current and next generation.

A good succession plan enables the current farm owners to plan for an active retirement, identifies how they transition out of ownership, and how other people transition into ownership.

Ken said a number of Australian Tax Office and Centrelink concessions were available, but lack of planning put these at risk.

These included how GST, Capital Gains Tax, Stamp Duty, superannuation and gifting rules were applied.

Ken encouraged farmers to seek their accountant’s advice about how to frame their succession plans to the advantage of

themselves and their successors, whether that was inter-generational transfer or the sale of the farm and its assets.

Ken recommended not leaving the issue of inheritance until after death. For one thing, transfer of wealth into superannuation during the principal’s lifetime had clear advantages.

“The sale of assets, even to family members, realises income that can be articulated into the superannuation fund of the exiting person or people,” he said.

“The dispersal of assets should be spread over several years, if possible.”

Dispersal staggered over several years affected income and tax assessment.

But assets transferred after the principal’s death — as inheritance — were very complicated to value.

Chris Jehu, principal of Countryside Business Partners and one of the speakers at the gathering, has facilitated many families through the succession planning process.

“Planning looks after current and future ownership,” he said.

Estate planning identifies how the assets are to be distributed. Retirement planning ensures wealth is adequate enough to meet your future needs. Transitioning the family business is about identifying what components need to continue, and under what management or control methods.

“But not every business has to be succeeded,” Chris said.

Succession shouldn’t be a ‘one size fits all’ situation.

“Therefore, it’s important to identify and know what components of succession planning is relevant to you,” he said.

“First there needs to be clear communication about the expectations of everyone involved.

“Approval of the way forward means implementation could be in stages, with targets and covering clearly articulated life stages and market events.”

This might include clearing sales of equipment and machinery, valuing of stock, and sale of stock.

For example, in a livestock enterprise that focuses on breeding, the progeny still have to be sold in a timely manner. In an animal agribusiness that focuses on finishing or fattening, the finished livestock have to be sold at the targeted weights.

In a horticulture or cropping farm business, product still has to be grown, harvested and sent to market.

These are the types of ongoing business transactions that should be documented in a succession plan against market events, Chris said.

“It’s also important that if assets are distributed before the will is read, activities need to be documented.”

There were some key legal tools that helped ensure good succession planning, according to Katherine Argentino, a lawyer and director of Argentino Law.

That included a Deed of Family Arrangement, that supports the will and estate plan, and outlines the agreement between all people with an interest in an inheritance.

“It helps to lock in the agreed arrangement and is signed by every family member involved in the succession,” Katherine said.

She recommends starting the succession conversation early. Katherine also recommends regularly reviewing the succession plan.

“Succession planning should be gradual and thoughtful, with lots of sharing of information and perspective, so it’s almost a non-event when it happens,” she said.

“Communication is key to success. Open, honest conversations are vital. No one likes a [life changing] surprise, at the end of the day.

“A plan should also be reviewed every three to five years, to ensure it encompasses anything that’s changed.

“Ensure any changes or transfers that occurred during that time are documented.”

She also recommended ensuring supporting documents are reviewed and up-todate – including wills, power of attorney, end of life care, binding death nominees on superannuation.

Unparalleled heat detection.

BY JEANETTE SEVERS

MORE THAN 100 dairy farmers and service providers from across Australia, with a few overseas visitors, attended the Lely Australia Connect, Care and Grow conference, held in Gippsland in late July.

The primary regions for installation of Lely robot milking units (RUs) in Australia are Tasmania, South Australia and Gippsland.

The bulk of these installations are in Tasmania and Victoria.

Gippsland was the place of origin of the first Lely RU installation in Australia, in 2001, at the farm of Max and Evelyn Warren, who installed four Lely Astronaut A2 units at Winnindoo. They milked 300 cows.

It was a world-first in operating RUs in a pasture-based milking situation.

As well as running their dairy farm, Max and Evelyn Warren created a tourism operation where visitors could see the robot milking machinery in operation, as well as view and operating a small scale of the farm.

In 2004, they won the Hugh Mackay Innovation Award for their business.

A few years later, Max and Evelyn replaced their units with four Lely Astronaut A3 milking robots.

They have since sold that dairy farm, but those units are still in service, on the share farm of Wild Dog Dairy in Scotchtown, Tasmania, operated by Josh Bishop and Rowan Stokes.

Gippsland has always been a growth area for RUs.

Ten years ago, 14 per cent of Australian dairy farms with RUs were located in Gippsland. Lely was a significant contributor to that number.

“There are now 275 Lely RUs installed and operating in Australia, with an average of five milking robots per farm,” Lely Oceania and Asia marketing manager Rene van Dalen said.

“Tasmania and Victoria have the bulk of the installs, with approximately 220 RUs.

“In the last three years, we’ve seen a very high increase in interest in robotic milking.

“In South Australia, we have installed more than 40 RUs in the past three years.

“People see them working well on their neighbours’ farms.

“We’re expecting interest to continue to grow in the next few years.”

There are now Lely service centers in five Australian states, installing and providing support to farmers in Queensland, NSW, Victoria, South Australia and Tasmania.

At the conference, Lely recognised a cohort of Australian dairy farmers milking at least 500 cows with RUs, joining them to the global Red Cow membership.

There were several attendees attending the conference because they were considering installing RUs.

Michael and Oscar Kowald from Mt Torrens, South Australia, are converting their dairy farm to RUs.

“We’re about 80 per cent along with the conversion to install two units,” Michael said.

Pauline, Marcus and Ella Young operate a herringbone dairy system at Ridgley, Tasmania. They were at the conference to listen and see what was happening on other farms.

“We’re milking 400 cows twice a day in a herringbone dairy,” Marcus said.

“There’s three generations of us involved in the farm.

“We’re at the conference because we’re thinking about how to change to robot units.”

A local participant in the farm tours was Al Grant, who has a dairy farm at Warragul South.

“I’m still milking 200 cows in a rotary dairy, but I thought it would be good to have a look at these systems,” he said.

A consistent consideration for attendees to switch to RUs was to bypass labour issues.

One of the farm tours was hosted by Leesa and Grant Williams, Willora Farms at Hallora, Victoria.

They first invested in Lely Astronaut A3 robots in 2009, upgrading them in 2013 to Astronaut A4s.

Then in 2021, they installed their second suite of RUs, the Astronaut A5s, alongside their rotary platform.

They now operate 10 RUs across their two farms, milking a combined 600 cows.

Leesa and Grant operate the longest running robotic dairy farm in Australia.

Leesa said the spread and number of dairy farms created a strong support network.

“With so many RU farmers around now, if someone in the network has a personal problem, there’s always someone who can step in

and help if you unexpectedly need to leave the farm for a while,” she said.

Her son was able to manage another farm when the owner was hospitalised, because he understood how the RUs worked.

The other farm tour was hosted by Mel and Luke Wallace, Wallacedale, Poowong North.

They installed three Lely Astronaut A5 robots to milk 210 cows, replacing a herringbone system that milked 160 cows.

“Twelve months to the day after installation we knew it was the right thing to do,” Luke said.

The couple recently returned from a holiday together overseas. Mel said the holiday was a direct result of changing their system after installing the RUs.

Luke had also started running marathons.

Globally, this year Lely has installed its 50,000th RU, a growth of 30,000 units in the past decade.

Lely Australia cluster manager Wil van Vorstenbosch told conference attendees the future of the dairy industry relied on farming practices that received the approval of consumers.

“The farm of the future needs to provide opportunities for consumers to engage in conversations about improved environments, animal welfare, and the origins of sustainable and nutritious dairy products,” he said.

“Lely systems enable farmer prosperity while achieving those consumer expectations.”

One example is how Lely systems have changed according to geographic interest.

The original design was based on European

dairy systems, with cows barn-housed for a significant portion of the year.

Wil said moving into markets in New Zealand and Australia had caused the company to change its systems to suit a pasture grazed system.

Lely the company is still privately owned by the same family – they are descendants of brothers Cornelis and Arij van der Lely, who founded it in 1948 in the Netherlands.

“Many innovations later, Lely is focused on dairy automation related products, all aimed at making our farmers’ lives easier,” Wil said.

The conference saw presentations from Lely, DLL and Rabobank staff, a farmer panel, and visits to two dairy farms in West Gippsland. For photo galleries from both days of the conference, go to: www.dairynewsaustralia. com.au

BY RICK BAYNE

SOUTH-WEST VICTORIAN dairy women

might be facing a tough season at home, but on August 16 they had a reason to smile.

The 2024 Great South West Ladies’ Luncheon in Warrnambool on August 15 was another hit, continuing a tradition that has flourished over the past 15 years.

All 320 places were sold out within two days.

“It was a juggle but we got everyone in,” Great South West Ladies’ Luncheon Committee member Belinda Doolan, who farms in Ecklin South, said.

“We’re lucky we have this venue at Deakin, because I don’t think anywhere else in town would fit us.”

Despite the demand, Belinda said there were no plans to add more luncheons.

“It’s set in the calendar now,” she said.

“We want to keep it with a majority of dairy farmers in the room and give the women an opportunity to catch up, but it’s also open to service industries and sponsors whose support makes the event possible.”

Belinda said the day was a welcome distraction from a tough season.

“We are in harsh circumstances,” she said.

“There are a few things up against dairy farmers at the moment, but we will always come through the other end, and it was great to have this opportunity today.

“Everyone is talking and smiling and it’s exactly what we need today. Dairy farming can be stressful — it is physically challenging and

“The Great South West Ladies Luncheon Committee takes pride in the fact that this event also helps address women’s mental health and wellbeing.

“The luncheon offers a chance for women to connect, relax, reflect, rejuvenate.”

ɋ To see more pictures from the event, go to: https://www.dairynewsaustralia.com.au/ news/day-out-lifts-womens-spirits/

Liz Ellis might be best known as an Australian netball legend, but she also has a connection to dairy farming.

Liz was guest speaker at the Great South West Ladies’ Luncheon in Warrnambool on August 15 and could reflect on her own farming journey, along with her notable sporting achievements.

“Apart from being big milk drinkers, my father-in-law was a dairy farmer and my husband grew up on a dairy,” she said.

“He’s a beef farmer today, so I have a bit of insight into the farming industry and a first-hand view about how much of a gamble farming is.

“With farming, you never know where the next bushfires, figuratively speaking, can start.”

Liz enjoys the farming environment.

“We travelled through this area a couple of years ago and were blown away by the beauty and lushness of the dairy country,” she said.

“We live near Byron Bay, which used to be a big dairying region, but the industry there seems to be under a bit of pressure at the moment.”

She told the crowd of 320 about the benefits of playing sport.

“Being involved in sport is so great physically and for your mental health,” she said.

And it can also contribute to self-confidence.

“It was interesting listening to the panel this morning about how to get started in the industry.

The big thing was that it’s not a lack of skills, it’s belief in yourself.

“I like to speak a bit about believing in yourself and that finding someone who believes in you can be equally as powerful.

“The great thing about a lunch like this is that you will find someone who believes in you.”

Liz is regarded by many as one the greatest defenders to play netball, winning three world titles, two Commonwealth Games gold medals, four national league titles and MVP awards with the Sydney Swifts.

She became the national captain in 2004 and remains the most capped player in Australian netball history.

Since retiring in 2007, she has forged a successful career in the media and as a coach.

NORCO RETURNED to EKKA, Queensland’s biggest agriculture show, with its fun, interactive and educational experience from August 10 to 18.

Research reveals close to half (45 per cent) of Year 6 kids don’t know their lunchbox items originate from farms and an even bigger number (80 per cent) of primary school students having no idea how modern milk is produced; data likely compounded by the fact that 55 per cent of school aged children had never visited a farm.

Back by popular demand and to help bridge this educational gap, Norco re-launched its ‘Grass to Glass’ farm experience at EKKA this year in an effort to bring a greater level of understanding about dairy farming, agriculture and food origins.

The multi-sensory ‘Grass to Glass’ display combined AR technology and real-life farm experiences to showcase each step of the farming process, via a three-zone learning trail where guests can move from the working farm to the Norco factory, while sampling Norco milk.

Norco supplier Warren Gallagher said it was important to show the next generation how farms operate and to help educate on where their food actually comes from.

“As a parent, I know how fussy kids can be with their food but they also love it when they get to choose their favourite breakfast or dinner,” Warren said.

“The dining table is a great place to start having fun and engaging conversations about where our favourite foods come from.

“I grew up on a dairy farm, so I was lucky enough to connect what I saw around me with what was being put on the table in front of me.

“But of course, that’s not the case for all kids, which is likely why there’s may be a divide between farming and the food they eat.”

To enhance education and play for all attendees, the three sensory zones also included a mix of outdoor games, a cinema experience with farm and factory tour videos, educational facts and an augmented reality game series called Cow’s Play.

There was also the opportunity to attend several milking demonstrations throughout the day, learn how to make cream and butter, and try their hand at milking a cow.

Norco’s commercial and strategy general manager Ben Menzies said Norco’s continued investment and participation at EKKA reflected its commitment to championing Aussie dairy farmers and the integral role they play in Australia’s rural communities.

“EKKA is a beloved and iconic event for Queenslanders, and to be part of it for many years is an absolute honour,” Ben said.

“It’s always a wonderful time where country and city communities come together to celebrate the best of Queensland’s agricultural industry and have some good wholesome family fun that is remembered for years to come.”

We understand that farm life’s all-consuming. So, in 1977 we were the first to invent cow monitoring solutions that not only maximise dairy herd performance, but also minimise workload and stress to restore work-life balance.

Experience why the world’s top milking equipment and genetics providers choose to partner with Nedap. “Powered by Nedap” means the most reliable and innovative cow monitoring technology, complemented by the great value arising from its integration with their unique solutions. Together, we help you get the most out of your results and life on the farm.

Learn more and find your Nedap distributor at nedap.com/farmlifeAU

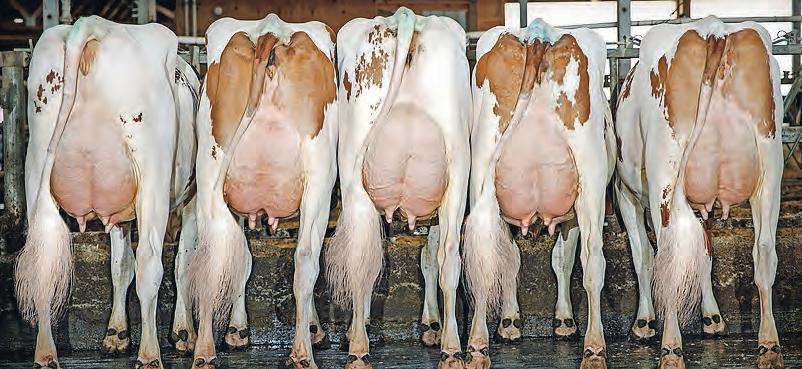

BREEDING COWS to AI from all around the world was like a fantasy come true for Goulburn Valley dairy farmer Gayle Clark.

Gayle and husband Laurie’s 450-strong herd is 85 per cent Holstein, with the rest made up of Reds and Jerseys.

A lot of thought has gone into creating those cows, along with the decision to

“I was already interested in breeding kelpies, but I was like a kid in a lolly shop when we arrived here,” the Katandra West farmer said. Twenty-five years later, Gayle’s passion has led to a herd of long-lasting, trouble-free and highly productive cows.

transition the herd to VikingGenetics.

“After doing it for 25 years, we want an animal that’s easy care and that’s what we’ve got,” Gayle said.

Gayle likes to use a motor car analogy when describing her cows.

“What struck me about these animals was not only the ease with which they calved, but the speed,” Gayle said.

“I don’t think we had any that took more than 30 minutes, but most had a calf on the ground within 20 minutes of the first signs of the calving being imminent.”

“The cow’s conformation or type is her chassis; her health traits are the running gear — everything from gearbox to tyres — and her genetic productive capacity is her engine.

“She can have the most powerful engine available, but unless that’s harnessed to a chassis that can carry it and has the right running gear to go with it, it won't carry her across a chequered flag.”

Throughout the journey, she came to realise the cows that make the most money are the ones that remain in the herd year after year.

Night watches of the calving paddock are mostly a thing of the past.

They also recognised that for a cow to become an old cow in the herd, her fertility was paramount.

Cows that don’t get in calf, don’t stay in the herd very long.

Gayle hasn’t found a Holstein bull that surpasses VHSparky for daughter fertility, though VHRomello comes close.

These bulls are rated at 6.3 DPR and 4.5 DPR respectively on the United States system.

“Fertility and mastitis resistance are two of the biggest contributing factors that carry a cow through to old age,” Gayle said.

Power Systems Australia are the Australian AKSA distributor for a large range of Diesel, Gas & Hybrid generators for stand-by and prime applications. No matter what style or size of generator you are looking for, Power Systems Australia are your Generator specialists.

CONTACT US TODAY FOR

Power Systems Australia Pty Ltd 1300 453 054

3 Holcourt Road Laverton North Victoria 3026 www.powersystemsaustralia.com.au sales@powersystemsaustralia.com.au

“Choosing purely on productive capacity from a catalogue gets you a ‘sprinter’; however, if you recognise that the money is with the cows who make old age in your herd, you want a ‘stayer’.”

Gayle’s cows get in-calf repeatedly, have very few health setbacks, and “physically hold together a lot better than most, because their build quality is a house made of bricks, not straw”.

“In general, you don’t notice them until they stand out as old or last of their generation.”

The farm has experienced a few hiccups along the way, and that’s where VikingGenetics came to help.

“We had an extremely wet year in 2016 and lameness was an issue, especially on the tall cows,” Gayle said.

“At the same time, cows over 700kg were struggling to fit in the rotary bails.

“Like many across the world, we started actively seeking a smaller-statured cow; a grazing, walking kind of cow.”

They had a few Red cows in the herd and found an appealing Red bull from VikingGenetics, Foske, to use across them.

Foske made a big impression.

“His progeny were ‘wow’ — they would be the first to get to the dairy, first to the feed, and were well-built with a strong determination to thrive,” Gayle said.

In 2020, the Clarks needed more cows to deal with a huge autumn surplus of feed and purchased a late winter calving herd based on VikingGenetics and in calf to Viking bulls.

“Knowing that the Scandinavian farmer requires a vet to administer mastitis treatment, something we as farmers can do here in Australia, makes the data on health traits very real.”

In years gone by, the Clarks pursued rump correction, using some very white bulls that led to a rising incidence of cancers, mostly eye or third eyelid.

They have been able to reverse that trend thanks to bulls like VHLeyton, VHBerosus, VHNader which have mostly black pigmentation.

The Scandinavian influence has also offered relief from inbreeding.

After transitioning to VikingHolstein, Gayle is happy with the results.

“I needed smaller stature cows and we like the fertility and calving ease,” she said.

She is now handing the breeding reins over to daughter Hayley.

Their son Ethan also works part-time on the farm, along with two other staff members.

“Hayley is a keen cow enthusiast, loves her animals and her engineering background benefits the farm by way of sound decision-making,” Gayle said.

Hayley has applied sexed semen to the herd, leading to a large number of Holstein heifers being born in autumn this year.

ɋ You can read Hayley’s dairy farming story at: https://www.dairynewsaustralia.com.au/ news/excited-about-a-dairy-future/

BY JEANETTE SEVERS

A GIPPSLAND cow has been named in a local competition to appreciate cows and to measure if her performance improves over the next 12 months because she has a name.

The three-year-old Jersey cow, in James Clyne’s herd on his Newry dairy farm, milked 7717 litres, or 662kg milk solids, last year.

She is the second cow named Clarabelle in his herd. The original Clarabelle is a Holstein cow.

The competition to name a cow was promoted by Southern Rural Water as part of celebrating National Cow Appreciation Day, in July.

The competition attracted entries from across Victoria and was won by Ciele Towb, a local person living in

the Latrobe Valley.

“Clarabelle is a girl’s name of Latin origin, meaning bright and beautiful, and is the name given to Walt Disney’s cartoon cow character who was Minnie Mouse’s best friend,” Ciele said.

“It’s also one of several names used for cows years ago that ended with ‘bell’, possibly referring to the bells once worn around their necks to keep track of them.

“I’m so excited to have won this competition.”

Southern Rural Water manages water allocations for the Macalister Irrigation District, which includes dairy farms in the Newry zone in Central Gippsland.

SRW water supply manager Matt Cook said there were many good suggestions for names for a cow.

Matt said naming a cow in the

Clyne milking herd would enable SRW to measure a hypothesis that cows with names were more productive.

More than 15 years ago in the United Kingdom, Newcastle

GEA’s flush system is engineered to effectively clean dairy farm alleys and holding areas.

An effective flush system is crucial in dairy farming, according to GEA effluent equipment product manager Jaco Mostert.

He said a robust flush system regularly removes manure and waste from floors, reducing the risk of infections like mastitis and enhancing overall cow health.

“Effective waste removal also minimises unpleasant odours, creating a more comfortable and healthier living environment for livestock and personnel.”

Jaco said automated flush systems offer significant labour savings by reducing the need for manual cleaning over large areas.

“This allows farmers to focus on essential tasks, thereby boosting overall productivity. Automated systems ensure consistent and thorough cleaning, which can be challenging to achieve manually.”

He said maintaining a clean-living condition enhances cow comfort, directly correlating with increased milk production.

Regular cleaning of floors and equipment also reduces corrosion, extending facility lifespan and cutting maintenance costs.

Jaco said flush systems also help with environmental impacts and regulatory compliance.

“Efficient flush systems facilitate the collection and management of manure, which can be processed and utilised.

Modern flush systems are designed for efficient water use, reducing overall consumption and waste.”

GEA’s flush system is engineered to effectively clean dairy farm alleys and holding areas.

Automated and low maintenance, it requires minimal labour while ensuring cows remain clean and healthy.

It features:

Stainless steel base for durability.

Consistent and controlled flow.

High-volume directional flush.

Labour and time savings.

Simple, reliable controls.

Robust airbag ensures reliable valve operation.

Requires only 40 psi to shut o 8m of head pressure.

“By investing in GEA’s flush system, dairy farms can achieve cleanliness, enhance operational efficiency, manage environmental impact, boost productivity, ensure regulatory compliance, and maintain a positive public image,” Jaco said. For more information, contact Jaco Mostert on 0418 253 950. your local GEA dealer or go to: https://www. GEA.com/dairyfarming

University researchers Catherine Douglas and Peter Rowlinson published their original research stating cows with names increased production. Their research identified giving a

dairy cow a name increased production by up to 284 litres.

They measured the interaction of 516 farmers and stock managers with cows, and concluded a more caring attitude towards cows with names created a cow that was more relaxed around humans.

Herds containing cows with names measured a 258 litre/cow higher milk yield than those without.

“We’ll work with James Clyne to track the winning cow’s performance over 12 months and report on the results on National Cow Appreciation Day next year,” Matt said.

“Our new Clarabelle did well last year, producing 7717 litres, or 662kg milk solids,” James said.

“I’m interested to see if a personal touch of a name gives her an edge and helps her produce more milk this year.”

CLASS LEADING GRAIN MILLING TECHNOLOGY

UNPARALLELED MILLING EFFICIENCY AND ENERGY CONSUMPTION

BETTER UTILISATION OF YOUR GRAIN

EUROPEAN QUALITY AND MANUFACTURED

MULTIPLE DISC MILL SIZES AVAILABLE

Flexible Augers • Pencil Augers • Mixers • Cleaners • Control Systems

SPEAK TO A SKIOLD VMS REPRESENTATIVE ABOUT YOUR NEXT FEED MILL

Complete feed systems also available

BY SOPHIE BALDWIN

CHLOE BROWN, Renata

Cumming and Lucy Collins have always had a passion for women and dairy and as a result, have been hosting networking events in western Victoria for the past two years.

In 2024 they decided to take it a step further, hosting their first out-of-region event.

Cream of the Crop was a twoday conference for women in the dairy industry, held in EchucaMoama at the end of July.

The organisers were blown away by the support, with more than 110 people attending, the majority of whom were farmers.

“Women play such a huge role on-farm whether they are out physically working or doing the books, and often they do it all with a family in tow,” Ms Brown said.

“We wanted our program to have something for everyone from business through to networking and mental health. We were blown away with the sharing of different stories and the camaraderie.”

The conference included a variety of guest speakers, workshops,

networking dinner and a regional tour including the GV Creamery, Mulcahys’ dairy operation and Byford Equipment.

“We had hoped for the best but at the same time we were apprehensive when we started planning because it is hard to get bums on seats, especially when we’re moving into a new region,” Ms Brown said.

She said it was great to see some faces from previous events but exciting to see so many new ones.

“Cream of the Crop is a positive initiative, and we want to collectively celebrate all the wonderful things about women and dairy and building off that positivity for the future of the industry.

“There was such a wonderful energy across the two days and the word of mouth feedback has been really encouraging.”

Murray Dairy chair Rachael Napier was a guest speaker and said it was her first time at the event. She will definitely be booking her ticket for the next one in Gippsland in 2025.

“I was so impressed by all the women in attendance who were all farmers,” Ms Napier said.

“It was such a supportive and

amazing environment and it was the first event I have been too where it was organised by women and everything on offer was for women, including babysitting.

“It was so easy to relate our own dairying journeys to her own personal experiences and it was so relatable, the whole conference was just amazing.”

Ms Brown said Gippsland had

“The topics were all relevant and the tours were great. It was interesting to be shown around by a woman at Byfords who started her career on the floor welding.

already been chose for the 2025 event, and it will now be all about finding the ideal time.

“We look at other dairy events and the region’s calving pattern and we always try to avoid those busy times so we can get as many people to attend as possible.”

&

• Next generation, iron-based, all weather slug & snail bait with technology for maximum attractiveness, palatability and persistence

•Gentle on the environment, crops and non-target organisms

•Nil withholding period for grazing and harvest

•Certified input for organic production

BY DR LES SANDLES

IN THE children’s nursery rhyme, The House

That Jack Built (origins circa 1590), we are seduced into imagining a shonky house — not because anything that is revealed by the house, but rather the improbable series of events that lead to our eventual introduction to the house.

This is not unlike our introduction to Regen Ag — too often the claims made, and the paths to soil restoration are improbable indeed.

Nevertheless, a house — but certainly not Jack’s house — is a perfect metaphor for the process of successfully creating healthy, productive soils.

We all understand the purpose and process of building an enduring house: start with a clear picture of the finished house, put the plan together (architect and builder), make sure the foundations are to spec, put up the frame, rough in the electrics and plumbing etc, clad the roof and walls, insulate, fit out and furnish.

All of this before the family moves in with the ultimate expectation that they will have a safe and happy home for a long, long time.

Building a healthy soil is no different.

The goal is clear: a soil that provides everything for our plants to thrive and produce healthy feed for the herd, and perhaps more importantly, vegies for us.

For this to occur, we have to build a cosy, safe home for the microbes that are going to

work hard to feed those plants on which we and our livestock rely.

In soil, the foundations are the mineral balances that control soil structure — the ones I’ve been banging on about in several previous articles; the plumbing and electrical make up the humus — controlling water holding and availability, and the ion exchange capacity, respectively.

And so it goes — in an orderly manner taking care to execute each step in turn. Sure, we might begin bits and pieces of the next phase before the previous is finished, but essentially we follow the plan.

In our soil health journey, the end game is a warm and cosy house for the microbes in the rhizosphere — the metabolic hot-tub

comprising the 1mm around the plant roots — NOT the plants per se.

If the microbes are happy, they will adequately supply the needs of the plants.

And this is where many soil health journeys go astray. Cherry picking, or plucking out of a hat, what piece or pieces of a soil restoration/ Regen Ag are implemented is doomed to failure.

We wouldn’t build the frame of our house without first attending to the foundations, and we certainly wouldn’t hang our electrics in fresh air while we wait for the frame to appear. This is no different.

In previous articles I have discussed soil structure and the key bits of science controlling pore space, and why that is important.

We have also gotten a better understanding of the role humus plays and where mixed species pastures fit in, and how necessary they are to both support a diverse soil microbiology and pull a heap of atmospheric carbon back into the soil through increased photosynthesis.

All of this is to prepare the home for the ‘family’ to move in.

We want a massive amount of a diverse population of microbes colonising the soil and feeding the plants.

When we achieve this, we will have a truly sustainable, healthy soil and as a result, healthy plants and healthy animals requiring very little outside inputs.

Next month, we will discover which of the soil microbes are most important and why.

DAMIEN COCKER, a dairy farmer from Sheffield in Tasmania, was struggling to fill the summer feed gap.

After losing significant milk productivity from his 600 Friesian/Jersey cross cattle throughout the drier months, Damien needed a long-lasting solution to address the seasonal instability.

“We’ve always grown conventional turnips, but we had to switch feed due to one of our usual herbicide options going off production,” Damien said.

Searching for a sustainable feed bank, Damien turned to DLF Seeds, which recently introduced the Cleancrop Brassica System to Australian farmers — and hasn’t looked back. Its cutting-edge system integrates specially bred brassica cultivars with tolerance to the herbicide Telar, offering a robust solution for weed management and crop enhancement, something DLF Seeds product development manager Isaac Berry says is the perfect answer to filling the summer feed gap.

“Despite Cleancrop being a new technology to Australia, it has been tried and tested for over a decade across the ditch in New Zealand,” Isaac said.

“The benefits of Cleancrop are really in the name. Because of the tolerance to Telar, there's great yield and regrowth capabilities, which increases grazing efficiency and ensures cleaner paddocks.”

The Cleancrop Brassica System is implemented by preparing the paddock and seed

beds, sowing the Cleancrop brassica seed as usual, before directly spraying Telar within a 48 hour period post-sowing to manage weeds.

This method allows the brassica crops to grow without competition from the 48 weeds on the label, significantly improving yield and quality, something Rodney Bakker, a dairy farmer from Timboon in Victoria, says is a game-changer.

“We planted Cleancrop Leafy turnip for the first time in October and November last year, right when the weather started to turn,” Rodney said.

“We implemented staggered planting techniques, so the crop provided about six weeks of grazing, with turnips growing knee-high.

“The cattle loved it and transitioned smoothly; now the girls sit and wait at the gate when moving paddock during the summer feed rotation.

“Importantly though, milk yields stayed consistent over the summer, which is what we set out to do with this product.”

Isaac highlighted the advantages this has for producers, noting Cleancrop provides farmers with a wider range of weed control compared to a traditional brassica.

“It allows crops to establish without competition, achieving higher yields and meeting productivity goals,” he said.

Rodney agrees.

“It’s a handy solution to have feed all year

round, maintaining milk yields and fitting perfectly into our management system,” he said.

Damien has experienced the direct benefits of switching from sowing traditional turnips to the DLF Seeds product.

“The choice of sowing Cleancrop Toto turnip, despite a bit more management, was a great change to our rotations. The weed control has been outstanding, truly living up to its name,” he said.

“We saw yields of 18 to 20 tonnes per hectare, with the cows adapting quickly to the new forage.”

Rodney said it wasa great product for paddocks with high weed pressure.

“Cleancrop minimised weeds like wireweed and fathen, making it easier to replant grass afterward,” he said.

The Cleancrop Brassica System also supports sustainability by reducing the need for multiple herbicide applications and promoting efficient forage production.

By integrating high-performance cultivars with effective weed control, the system streamlines crop management and enhances pasture quality.

“We only sowed 5.5 hectares last season, and that wasn’t nearly enough,” Rodney said.

“Given the success we had, we’re planning to more than double our planting this coming spring.”

ɋ For more information, visit: https:// dlfseeds.com.au

Tama Australia and the McGrath Foundation are celebrating 10 years of partnershipso we're giving YOU the chance to WIN two tickets,flights and accommodation to the Pink Test 2025.

All you need to do is:

1.Purchase a pallet of TrioWrap Plus Pink

2.Upload your purchase invoice* to Tama Rewards using the Submit Claim

3.Email photo's of your pink bales in the field to: support@tamarewards.com.au

So pink up your paddock, raise Breast Cancer Awareness and be in with a chance to WIN.

*Invoices must be dated 1st July30th September 2024 to be eligible.

NEW RESEARCH by Dairy UP aims to unlock the nutritive potential of kikuyu pastures used by NSW dairy farmers.

Kikuyu is fast-growing and well-adapted to subtropical areas, but generally perceived as being of poor nutritive value for dairy cattle.

However, Dairy UP project leader Professor Yani Garcia said the research team was working to change that.

“We are exploring new management options to grow and utilise more kikuyu over summer and increase the productivity of kikuyu-based pastures,” he said.

Prof Garcia said the timing of grazing had a big impact on kikuyu’s nutritive value, affecting pasture utilisation and profitability.

“Kikuyu leaves lose quality very rapidly if not consumed at the right time, and the window of opportunity is generally smaller than for temperate grasses,” he said.

Grazing intervals also affect stem content.