WEST VIC REGION

Ten years ago, Mat and Renee Whitehead set out on a path to farm ownership, and today they have a string of new investments to show for it. Story, page 6.

OCTOBER, 2023 ISSUE 156

INVESTING IN THEIR FUTURE

ALL THINGS RURAL ...That’s what we do better!

Bega Cobram Cohuna Fuel available at these stores.

Colac Corryong Dumbalk VICTORIA & NSW STORE LOCATIONS - TRADING HOURS MON-FRI 8AM-5PM SAT 9AM -12PM. Times may vary - contact store. îs. 32519

Eskdale Finley Foster Korumburra Leongatha

Heywood Kiewa Koroit

Maffra FARM SUPPLIES

Numurkah Orbost Rochester & CROP

Simpson Swan Hill Wangaratta

Warragul Wonthaggi Yarram

PASTURE

ANIMAL MANAGEMENT

GENERAL MERCHANDISE

VISIT OUR WEBSITE agwarehouse.com.au

AG Warehouse™ aims to support our customers in the areas of cropping, dairy, livestock, equine and lifestyle farming with the latest technologies and best products available in the market through our strategic vendor partners. Our team is experienced, knowledgeable and focused on servicing the farming needs of our customers.

BY JACQUI SUARES

DAFFODILS HERALD the arrival of spring in my garden, and already we have had some beautiful sunny days after a relatively mild winter.

As we prepare for what will hopefully be a bountiful silage and hay season, signs of very dry conditions are already playing out in the northern regions of Australia.

Now might be a good time to revisit our bushfire plans in the event of an El Niño summer; the CFA website has a very useful template that prompts preparation.

It’s been a busy social calendar in the southwest with another amazing Ladies Lunch presented to a sell-out crowd, Myf Warhurst reminiscing about her country childhood and the terrific panel session hosted by Belinda and Carol Doolan talking all things ice-cream with the incredible Caroline Simmons from Timboon Fine Ice-cream.

Whether you’re a local or a visitor, a trip to Timboon is always a great idea, and the icecream highly recommended!

The WestVic Dairy Young Dairy Network held its annual Trivia Night at Noorat, with many thanks to local legends — Gary Ross as MC and quizmaster Jason Smith.

Not only a great social night, the event raised much-needed funds for BlazeAid and Need for Feed, two charities very close to every farmer’s heart.

Congratulations to all the people who help make these events so successful — and the team at WestVic Dairy are a very big contributor!

Spring has certainly sprung Chair’s message

I spend an awful lot of time in the car, and have been taking full advantage by listening to podcasts.

Obviously I’m not the only one — Australia officially leads the world when it comes to podcast listening.

I particularly valued the Humans of Agriculture four-part Carbon Shortcut series with Professor Richard Eckard. I’ve even replayed them to pick up the bits I missed the first time!

We also have a south-west local, Chloe Brown, creating an informative and entertaining series of stories on the More Than Milk podcast — featuring stories of the farmers and industry professionals that showcase the diversity, challenges, successes and the passion for all things dairy. (You can read about Chloe on page 6 in the main section of this edition of Dairy News Australia .)

Check these podcasts out — it’s a neat way of learning on the run.

Spring also means annual meeting season. The WestVic AGM will be held on October 17, and our Annual Report together with our new Strategic Plan will be available.

Both documents will also be on the website for ready access.

We will be welcoming new directors to the

board, so watch our communication channels for announcements.

My thanks to Brad Collins, who has completed his term on the board, for his candid and enthusiastic commitment to WestVic over the past three years.

Jacqui Suares is the WestVic Dairy chair.

2 // WEST VIC REGION DAIRY NEWS AUSTRALIA OCTOBER 2023

Jacqui enjoys listening to Chloe Brown’s More Than Cows podcast.

Crash forces wake-up call

BY RICK BAYNE

MOST FARMERS look back at the milk price crash of 2016 as one of the worst times in their lives — Rodney and Chloe Brown see it as the best thing that happened to their dairy careers.

Prior to the crash, they were sharefarming with Rodney’s parents Jim and Lynette at Kirkstall, but not really thinking about the future or minding their spending.

“Upon reflection, the crash was the best thing that ever happened to us … it gave us direction,” Chloe said.

“It was a wake-up call, an eye-opener about what we spend,” Rodney said.

Rodney admits he likes buying, but didn’t really give much thought to his purchases.

“I used to just go and buy a tractor, but now I think do I really need it? I’d never been cautious about spending, but now we have to justify every expense.

“In sharefarming, if we had cash in the bank, we could afford it. There were no contingency plans. We didn’t sit down and make business decisions, but we do now.”

After the crash, they left the share agreement and took five months to re-evaluate their lives and their future in the industry.

Rodney took a job with another dairy farm, Chloe worked off-farm.

They had been on a 50-50 share and owned the cows and an outpaddock at Hawkesdale, but had too much debt on the outpaddock and their house.

It was also a difficult transition period for decision making and they had to buy a lot of hay to cover dry seasons.

Rodney and Chloe got out of the share agreement and sold most of their cows and the outpaddock and Jim and Lynette returned to milking.

However, Jim soon fell ill, and after five months they returned on a lease agreement.

By this time, the young couple had started their agriculture diplomas, which built their business skills.

“We wanted to do it ourselves and do it properly,” Chloe said.

“Rodney’s parents were hesitant and wanted to know that we would be able to pay the bills.

“We hired a consultant who did a business plan and we took on the lease five months after the crash.

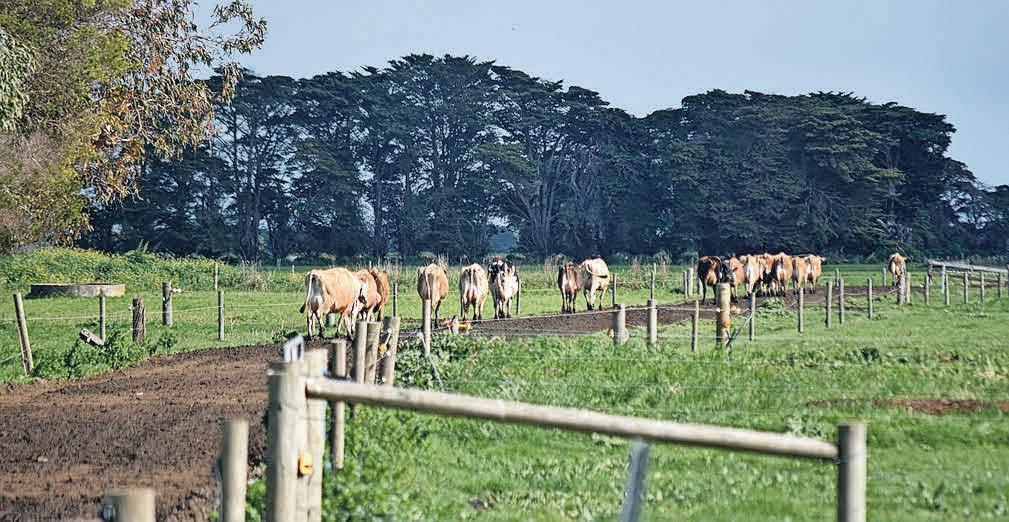

Today they run 220 mostly registered Jerseys on the farm at Kirkstall with a 22-a-side swingover herringbone dairy.

The dairy was built in the 1980s but has been

updated with Allflex monitoring collars, Easy Dairy and Auto Draft gate, along with a milk taxi for feeding calves that saves three hours each morning and evening, sound investments geared to the future and allowing the ability to run as a single-person operation.

They have built good equity in the business on the back of good seasons and milk prices and their ultimate plan is to buy the farm, although there is no timeline for that.

“We want to build enough wealth in our business to make investments to make it easier and more efficient,” Chloe said.

They joined off the Allflex collars for the first time this year and say the heat detection and animal health benefits have been terrific.

When Rodney and Chloe returned in 2016, they couldn’t get cows in-calf so tried calving in February, May and September.

“It was the worst decision of our lives — we didn’t know if we were coming or going,” Rodney said.

However, it did show February-March had the better conception rate so they stuck with that.

They had 60 empty cows last year, including some recently purchased from NSW, but after joining off the collars this year the empty rate was cut by more than half.

“I’ve always thought a cow will get in-calf better to a natural heat than a brought-on heat and we’re saving money on tail paint, PGs and scratchies, plus the time we could be investing somewhere else,” Chloe said.

This year they invested in sexed semen on cows for the first time.

“We picked out cows to rear heifer calves from and put sexed semen in them; anything we didn’t want to rear a calf out of just got conventional,” Rodney said.

After six weeks everything went to beef as a strategic move.

“If I have a calf, I’d rear it but I can’t milk a beef calf,” Rodney said.

“We don’t need to keep all the calves. We could see the cows we wanted to rear out of because we had the figures to select from.”

They milk about 220, but aim to reduce to about 200. About 90 per cent of the herd are registered and many were classified last spring.

“That worked in our benefit this year when we joined them and we will do the next batch this year,” Rodney said.

They bought 53 Jerseys from NSW last year and are filtering Friesians and cross-breds out of the herd.

Continued on page 8

GPS Farm Mapping

Australian Mapping produces an accurate farm map to assist farmers in the management of their land and their business. An accurate farm map has many and varied uses including:

• Quality assurance purposes

• Irrigation planning can help increase yields and save $$ by putting water only where needed

• Save on your inputs with accurate mapping for fertilizer and spray applications

Phone: 0429 171 685

• Whole farm planning

• Whiteboards up to 1.2 × 2.4 metres available.

| email: sam.baulch@gmail.com

An easy to use app that allows you to map your farm and maintain your paddock and livestock records. Increase farm ef ciency, and reduce costly mistakes by giving your whole team access to the latest paddock and livestock records

w: farmap.com.au

e: info@farmap.com.au

Chloe and Rodney Brown were forced to take a break from the dairy industry after the milk price crash of 2016 but returned with better business sense and better spending protocols.

Although a relatively small farm, Rodney and Chloe say it is well suited to a family operation.

A milk taxi has eased the burden for Chloe during calving season, cutting hours off each feeding session.

Chloe and Rodney Brown were forced to take a break from the dairy industry after the milk price crash of 2016 but returned with better business sense and better spending protocols.

Although a relatively small farm, Rodney and Chloe say it is well suited to a family operation.

A milk taxi has eased the burden for Chloe during calving season, cutting hours off each feeding session.

WEST VIC REGION // 3 DAIRY NEWS AUSTRALIA OCTOBER 2023

96572

www.australianmapping.com.au

Compost is dairy industry’s saviour

BY RICK BAYNE

TONY EVANS had the dairy world at his feet as a teenager, but he became more interested in what was going onto the land under his feet.

Tony gave up a promising career in dairy to focus on a compost business which has grown into a major success in south-west Victoria and continues to work with dairy farmers across the region.

When he started, compost was rarely considered on dairy farms, today he said it might be the industry’s saviour when it came to adapting to climate change requirements.

His farming experience just set the scene for the real love of his life — making the most out of the land and creating healthier, more productive soils.

After moving from Melbourne as a 17-yearold, Tony started his dairy apprenticeship at Bookar near Camperdown in the early 1980s.

He wasn’t a stranger to the region — his grandparents were born in the district before moving to Melbourne and he had local relatives — and he was always keen to work outdoors and with cattle.

He started working in March 1981 and moved to a farming apprenticeship in 1982.

Despite being a city boy, his aptitude for farming was quickly acknowledged and Tony won the Victorian Farm Apprentice award in 1985.

As a prize, he got to spend three months working on dairy farms in Minnesota in 1986.

“I showed initiative in purchasing 256 acres of land at 21, I wasn’t born and bred on a farm and probably presented myself reasonably well as someone who could represent Australia in the US,” Tony said.

“It wasn’t just about being a good farmer.”

He said it was a great experience, including addressing 900 people at the Minnesota State Fair.

“It broadened my horizons as I’d only experienced farming in western Victoria. In those days, we didn’t have access to US genetics in the dairy industry and I saw and milked cows that had phenomenal production.

“Shortly after I came back, we got access to US genetics and saw a leap in productivity.”

After returning to Australia, Tony was married the following January to Angie.

They bought a herd of cows and went sharefarming, next door to his own land which was used for young stock.

They later sharefarmed on a bigger farm at Simpson and grew their herd to 220.

After six years of sharefarming, they leased a farm near Camperdown, but Tony was burnt out.

“We had taken on more leased land and trying to get bigger and better, but I had three young kids and I couldn’t work any harder,” he said.

“We sold the cows and wound back the leases and took some time off.”

That’s when he stumbled upon the composting and waste business, establishing Camperdown Compost Company in 1997 with business partner Nick Routson to process organic waste, including from dairy companies, and build alternative fertiliser programs to assist dairy farmers.

“My father was a printer and did some work for a guy who was trading in worms. We looked at it and saw the potential so we set up a commercial size worm farm,” Tony said.

“They were closing Warrnambool’s landfill and Bonlac Cobden had nowhere to send their waste, so we took the initiative and set up an EPA-licensed facility to accept it.”

It was a case of ‘if you build it, they will come’.

Tony and Nick started working part-time in the business in 1998, started employing people by 2004 and now have 10 to 12 employees and a $4 million annual turnover.

“There was an opportunity and we filled that gap. In our time, nine other facilities have closed, usually due to lack of compliance, so waste kept gravitating to us.”

They planned to use the waste for worm food, but found it was better for making compost.

“In 1999 we met microbiologist Dr Elaine Ingham and she opened our eyes to the opportunities,” Tony said.

“We realised we didn’t have to make worm castings to make a good product — a compost fitted with the type of waste we were taking.”

Tony Evans’ compost business evolved out of a regional need for more waste facilities.

Mountains of compost.

4 // WEST VIC REGION DAIRY NEWS AUSTRALIA OCTOBER 2023 Vetch Hay Cereal Hay Lupins Barley Wheat Grains Freight options available For Sale 95801 STOPP FAMILY TRUST Phone: Alan Stopp 0418 831 908 Email: stopp @gmail.com Address: 1115 Martin Camp Road, Keith, SA, 5267

Tony Evans gave up a promising dairy career to focus on making compost.

saviour says former farmer

Farmers approached the company about using compost on their properties so they introduced sales through agronomists on commission.

In 2005 they started to sell directly to farmers.

“The first thing I said to the farmers was you shouldn’t be buying compost from us; you should be making your own. You have all this waste on a dairy farm and you should be using it,” Tony said.

Helping farmers make compost on their farms soon grew into a big industry in itself, and they managed the process for more than 100 farms a year.

At the same time, sales increased because some of the Camperdown compost would be added as an inoculant.

“It lifted the profile of what we were doing and the acceptance of compost into the dairy industry and it demonstrated that you could make compost out of dairy waste,” Tony said.

In 2015 the business was restructured, bringing in an independent chair and board, while Tony and Nick retained shared ownership.

“The business was growing too big and Nick and I were acting as joint CEOs, but you can’t fill your head with everything so you have to delegate,” Tony said.

“The chairman brought in structure and accountability.”

Tony retired from full-time work in the business five years ago at 55, but he remains a 50 per cent owner and silent partner.

They have six board meetings a year and Tony receives monthly reports and is involved in major strategic decisions.

“I was suffering from stress — I was doing too much with the business, our land and cattle and consulting, which led me to travelling around Australia and overseas, and my brain was fried,” he said about the decision to step back from the day-to-day operation.

“My doctor diagnosed stress and said I needed to make some changes, so I stopped work and gave up consulting work.

“I got rid of everything except for the cattle which gave me a purpose and a reason to get out of bed.”

Tony and Angie will transition the cattle to two of their daughters as they continue to lighten their load.

Tony remains convinced of the value of compost.

“We pioneered the concept of composting on farms here in Australia,” he said.

“Most farms don’t use compost, but most farms should.”

While the company moved away from on-farm composting about five years ago, he said farmers needed to look for the right way to use their waste and the best way to improve their soils.

“Dairy companies want to change their carbon footprint. They know we have to look at soil carbon from a climate perspective, but also from a productivity perspective.

It is being driven by consumers and countries that import our products and the Federal Government has signed up to zero methane emissions by 2030.

“If we have to have zero methane emissions by 2030, we need to implement changes in the next 18 months and compost can help that.

“Dairy farmers with a high input system are going to have waste which is a problem if it isn’t managed effectively, but it’s actually a resource they can use as a catalyst for change.”

Tony said farmers could reduce their fertiliser inputs by utilising the resources on their farm.

“They can lower their carbon footprint by hopefully building and sequestering carbon, reducing bought-in fertilisers and by better managing their emissions from ponds.

“We stumbled into it but the more we learnt we realised this was where farmers needed to go.”

industry’s

Tony Evans grew up in Melbourne but always wanted to work outdoors.

The

in use on a south-west

WEST VIC REGION // 5 DAIRY NEWS AUSTRALIA OCTOBER 2023 88612 Phone: 1300 887 380 Email: sales@irrigatewisa.com.au Web: www.irrigatewisa.com.au Smarter irrigation for your farm • WiSA’s automated irrigation system can deliver water when required and on time • WiSA’s wireless solution means you have total control from your mobile phone or computer • WiSA improves water use efficiency and can reduce labour costs • WiSA’s automated irrigation system can improve the sustainability of your dairy farm, vineyard, orchards, and fields Contact us: FARM & IRRIGATION AUTOMATION EXPERTS WiSA - Proudly Australian owned & manufactured for 28 years

Some of the product on the move at the Camperdown Compost Company site.

compost

Victorian farm.

Making a sound investment in

BY RICK BAYNE

TEN YEARS ago, Mat and Renee Whitehead set out on a path to farm ownership, and today they have a string of new investments to show for it.

From a fun logo for Whitehead Farms, designed by Renee, to a recently installed shelter, the Timboon farm has been transformed over the decade.

Mat is fourth-generation on the farm. His great-grandparents settled in 1956, milking 28 cows on a 212 hectare lot, about one-third of the current milking platform. Today they milk close to 800.

Mat bought the original land off his grandparents while his parents John and Leanne had a separate farm next door.

They merged in 2013 and that’s where the transformation started, firstly with a central 60-stall rotary dairy and then with new dams, irrigation pivots, solar panels, concrete feed pad and most recently a shelter.

They even changed their calving system.

The farm was a Focus Farm in 2013-14 and one of the goals was succession planning which came to fruition about 18 months ago when Mat and Renee bought the business from John and Leanne.

They plan to work the farm for the next 20 years and hope another generation continues with their young children showing interest.

“They already have big dreams about what they can do,” Renee said.

Renee grew up on a dairy farm, but had worked in hospitality for 20 years and vowed not to return to farming, but the succession planning included a focus on lifestyle.

“I said I’d never be a dairy farmer again, but when we discussed being on the farm, we made an effort to get a lifestyle-work balance,” she said.

“We had to grow herd numbers and go from a family farm to a farm with staff to make that possible,” Mat said.

Whitehead Farms now employs five people. In 2013, Mat had 300 cows and his parents 250, and it has progressively grown since the merger.

They try to factor in a holiday every year, though that has been tough due to staff turnover since the pandemic.

The rotary dairy “with all the bells and whistles” has helped to make the enterprise more productive and streamlined the milking process.

They introduced collars three years ago, making milking easier and creating health benefits.

Mat and Renee Whitehead are enjoying the certainty of a three-year milk price with their mostly Holstein herd. The rotary dairy shed and shelter.

The 60-stall rotary dairy was installed in 2013, the same year the property was used as a Focus Farm and when Mat and Renee Whitehead started succession planning.

6 // WEST VIC REGION DAIRY NEWS AUSTRALIA OCTOBER 2023

A dairy shelter was installed out of necessity when another herd was parked on the farm, but Renee and Mat are already appreciating its benefits with improved production, streamlined milking and less paddock damage.

their family’s future

“They’re a time saver,” Mat said.

“It gives you peace of mind that you’re not missing cows on heat.”

The shed also has solar power, introduced about five years ago, which Mat says has been helpful, but not a game changer.

The heifers calve in November and the cows in January until the start of March, with a 71 per cent six-week in-calf rate this year.

Previously most calved in June-July.

“It was a hard slog, especially when trying to get cows and calves out of wet paddocks,” Renee said.

“Because we started employing staff and the money would be better if we calved everything in summer, we progressed to doing that.

“You have longer days and people are happier and more willing to do the work in summer.”

Summer calving has also led to improved calf health and production fits with their new Coles fresh milk contract.

The herd is mostly Holstein with a few Monbéliardes, Aussie reds and occasional Jersey crosses.

“We had Holsteins, but they were harder to get in calf, so we introduced three-way crosses,” Mat said.

The black and whites have picked up their fertility rates, but the Monbéliardes have had problems with eye cancer, so they now focus on Aussie reds for cross-breeding.

Mat and Renee like well-fed cows. They buy vetch hay and feed close to three tonnes of grain per year.

They grow maize, but no longer do summer crops after finding little success.

“They seemed to be a lot of hard work for little reward and putting 800 cows on one crop paddock is difficult to manage,” Mat said.

They added pivots last year and watered 40ha of grass, but don’t plan to return to summer cropping.

“Giving the cows a couple of kilos of green feed every day made a difference,” Mat said.

They average about 8500 litres or 600 kg/ Ms a year.

“That’s been fairly consistent and is around a kilo of milk solids per kilogram of weight which is pretty good.”

The new shelter went into use in May and came out of necessity.

“We had extra cows parked here last year and we were trying to work through the logistics of not wrecking paddocks and the shelter seemed to be the best way to go,” Renee said.

It was initially planned to put half the herd in during the day and half at night, but the cows are voting with their feet.

“The cows loved it too much,” Renee said.

“They have the choice of going in the shed or down the paddock.

At night they go down the paddock and when they’ve had enough grass, they wander back to the shed and sit down.

“They love the shed. We don’t force them to go in there. They’ve got the choice and they choose the shed.”

They will look at adding shade cloth to protect them from summer heat.

Production initially increased as well, but Mat

said the biggest improvements were in the time saved at milking and protecting the paddocks which can get bogged with 900mm annual rainfall.

“Everyone got home half an hour earlier over winter and the paddocks seem to be in better condition coming into spring than they normally would be,” he said.

“We’d been looking at it for years, but it was a bite-the-bullet because of the situation we were in with the parked cows, but the necessity will have long-term benefits.”

The other herd left in August.

A concrete feed pad next to the shelter was built in 2015.

Mat and Renee have a confident outlook.

“We’re hoping to be in a steady state now and repay some debt,” Mat said.

The mandatory code of conduct for milk suppliers has made a big difference.

“We’ve got a milk price now for three years which means we can breathe easier,” Renee said.

“We can plan and budget. It makes it easier for everyone, especially with the fluctuating price of inputs,” Mat said.

investment in

The Whitehead Farms logo was designed by Renee.

The remnants of the original 1956 dairy can still be found on the land.

WEST VIC REGION // 7 DAIRY NEWS AUSTRALIA OCTOBER 2023

Mat and Renee like well-fed cows. They buy vetch hay and feed close to three tonnes of grain per year.

Crash forces wake-up call

Continued from page 3

“We needed cow numbers to get back in so we bought anything we could find, no matter what colour it was, but we had a six-year plan to phase out the others and go with Jerseys,” Rodney said.

“They’re easier to handle and feed and they’re happy to walk.”

Their feed efficiency is another attraction.

“Because we’re dryland farming with no irrigation and only milk off 298 acres, the

ultimate goal is to do 200 and do them really well,” Chloe said.

Previously heifers were agisted, but this year agistment wasn’t available so they have been raised on the home farm.

“It has been tight but we’ve just had enough feed,” Chloe said.

“We always buy vetch for the cows, but we have done really good silage and hay and even though last year wasn’t great quality, we had enough.”

Going forward the plan is to be self-sufficient

and keep all cows and heifers onsite.

They are being meticulous and strategic with their inputs, doing soil tests on every paddock and developing individual feed blends for each calf.

“It’s definitely viable as a family business on this amount of land,” Rodney said.

“We want to leave the farm in a better position if our kids want it and I want to leave it in dairy,” Chloe said.

“A pet peeve of mine is great dairy farms that have gone to beef.”

The farm is a mixture of old Vic rye-grass and native grass and they are introducing more perennials.

Under Rodney’s parents, the first half of the farm was used as night paddocks, the back half day paddocks, but Rodney follows a rotational farming system.

“Our mindset has completely changed since we got back in,” Rodney said.

“Back then I’d just put cows in a paddock

Having

8 // WEST VIC REGION DAIRY NEWS AUSTRALIA OCTOBER 2023

your farming and personal goals with Our Farm, Our Plan Got your game plan? Proudly supported by

Rodney and Chloe rebuilt their herd after briefly leaving then industry and are now concentrating on registering and classifying their Jerseys.

Set

a game plan is vital for success – on the field and on the farm. And creating one has never been easier. Our Farm, Our Plan, developed for dairy farmers, helps you put your goals down on paper, prepare for the season ahead (and beyond) and get your whole team on the same page. Ways to get started today: Contact your regional team Visit dairyaustralia.com.au/ofop Call 1800 548 073

Chloe and Rodney Brown were forced to take a break from the dairy industry after the milk price crash of 2016 but returned with better business sense and better spending protocols.

Although a relatively small farm, Rodney and Chloe say it is well suited to a family operation.

A milk taxi has eased the burden for Chloe during calving season, cutting hours off each feeding session.

Chloe and Rodney Brown were forced to take a break from the dairy industry after the milk price crash of 2016 but returned with better business sense and better spending protocols.

Although a relatively small farm, Rodney and Chloe say it is well suited to a family operation.

A milk taxi has eased the burden for Chloe during calving season, cutting hours off each feeding session.