WEST VIC REGION

FOOT IN THE DOOR

Hamish Milne had the choice of managing a dairy farm or coming on board as a sharefarmer. He had no hesitation about choosing the latter. Page 3.

Hamish Milne had the choice of managing a dairy farm or coming on board as a sharefarmer. He had no hesitation about choosing the latter. Page 3.

BY BRENDAN REA

IT HAS certainly been a challenging season, and the upcoming months will determine if we receive enough rainfall to provide more than the short-term relief received to date.

As dairy farmers, we have all faced less-than-ideal circumstances at some point. However, with good information, a strong team, and decisive actions, we can navigate challenges effectively.

WestVic Dairy is committed to supporting the region’s farmers by providing technical information to manage dry conditions and recognises the need for decision making support.

Personalised one-on-one assistance is available for anyone seeking practical help, offered through a new delivery model of the Our Farm, Our Plan program.

This new model brings the program directly to your farm.

For those who find it hard to commit the time to leave the farm, this approach makes it easier to participate and benefit from the support the program can offer.

WestVic Dairy staff, along with

a consultant, facilitate the process and conduct a series of one-onone meetings directly with you over two years. This approach is designed to fit your availability and needs.

The program combines a straightforward review and planning process with flexible oneon-one support, to help you work towards achieving your personal and farm business goals.

As we plan to manage the challenges created by the dry conditions and make the most of spring, this is an ideal time to begin the program.

Consultants will help you

address any immediate concerns brought by the dry spell and then look at long-term goals, improving business performance and managing risk.

Additionally, resources like the Farm Fitness Checklist are available to help farmers assess their current situation, with the option to delve deeper into these tools in focused sessions.

WestVic Dairy strives to advance the south-western Victorian dairy industry and will report on its activities to achieve this at this year’s Annual General Meeting.

I would like to invite you and other interested community

members to WestVic Dairy’s AGM on Tuesday, October 8, at the Killara Centre, Manifold St, Camperdown at 1pm.

The AGM provides an overview of WestVic Dairy’s operations over the 2023-24 financial year and provides you with the opportunity to ask questions.

Questions for the board will be taken on notice and should be submitted in writing to: The Chair, WestVic Dairy Inc, PO Box 174, Camperdown, 3260 or email info@westvicdairy.com.au by close of business on Friday, October 4.

Prior to this year’s AGM a regional consultation forum for Dairy Australia’s strategic plan will be held from 11.30am to 12.30pm.

This is your chance to share your thoughts about the direction of the organisation and its investments for the next five years.

If you are interested in receiving personalised support for you and your farm business, or would like to attend the AGM or consultation session, call the WestVic Dairy team on 5557 1000.

I wish you all good spring rains and bountiful silage harvest.

– Brendan Rea is the WestVic Dairy chair.

BY RICK BAYNE

WHEN HAMISH Milne was offered an opportunity to manage a dairy farm or come on board as a sharefarmer, he had no hesitation about opting for the latter.

Hamish, 32, sees sharefarming as the first step towards his ultimate goal of running his own dairy farm, even though he was raised on a family beef-sheep property and already has his own beef operation.

Being a sole worker on the farm has its challenges, but Hamish is up for it. He’s working up to 12 hours every day but takes it in his stride.

“It doesn’t bother me,” he said. “I’ve got a goal in mind to have my own dairy and you have to work hard to achieve that.”

Hamish is on an 85-15 sharefarming agreement with Aran Gleeson at his Kirkstall farm.

Aran’s main farm is about 10km away at Illowa, a beef-to-dairy conversion that continues to perform well, milking about 500 Friesians.

The Kirkstall property had been owned by a client of Aran’s contracting business and when it came up for sale about three years ago, he and wife Taliah were quick to buy it for more out paddocks to raise dairy heifers and grow more silage.

The dairy that had been operational under the previous owner was put into hibernation as Aran concentrated on growing the Illowa business.

After getting the opportunity to buy more land next to his Illowa farm, Aran decided to grow numbers and work two dairies. He reactivated the Kirkstall dairy and called on Hamish to help.

The dairy went back into use in July and Hamish is now milking 253 Holsteins.

Aran owns the cows, the land and the dairy and provides other equipment, while Hamish supplies a motorbike and pays for a few things including chemicals in the dairy.

“It’s a way to get into the industry without too much risk,” Hamish said.

“Aran offered farm manager or share farmer and we thought this agreement would work better at the start and we can review later on once things progress, and hopefully I can start getting my own dairy cows.

“It was easier to do it this way. It’s an opportunity to work for myself and to get my foot in the door of the dairy industry while continuing to work on my beef farm.”

The beef farm is being run on his family’s farm at Mepunga. His parents, both recently retired, are helping with the beef while Hamish

progresses his dairy career.

The Milne family farm has been in beef and sheep over recent decades, but had earlier been home to several smaller dairy farms.

Hamish has long-term plans to revive dairy on the 283-hectare home farm.

“I grew up with beef and sheep but I’ve always worked in dairies,” Hamish said,

He did relief milking while at school and later worked with dairy farming neighbours Barry and Andrea Smith for more than seven years.

“They taught me what I needed to know and I enjoyed being outside working with animals.

Getting the 38-a-side swingover dairy up and running again in Kirkstall was easy, especially with Aran’s previous experience at the Illowa beef conversion.

“Aran had people come in to upgrade the dairy where needed and replace all the cups and lines,” Hamish said.

“It was right to go when I did the first milking in early July.”

Hamish hasn’t needed to learn much since taking on the additional responsibilities.

“Aran set it up and said how he wanted it to run.”

Some of the cows on the Kirkstall farm came from Aran’s farm but they were topped up with a new herd from Colac, with more are on the way.

The cows are mostly pasture fed but they also get access to almond hauls on the feed pad in the morning and get roughly 7kg of wheat-canola mix per milking.

They return straight to the paddocks after the evening milking.

Hamish enjoys working with the Holsteins.

“I’ve always liked the Holsteins,” he said.

“Every farm I’ve worked on has been Holsteins and I like how you get more litres in the vat.”

They cope well on the flat farm, which is known to get very wet after heavy rain, though Hamish says this season has been good.

Aran calves most of the year at the home farm and the calves will be taken to be raised at the Kirkstall property.

In February, Hamish will start calving in Kirkstall. “We’ve got two calving sheds and calving paddocks so we can do it here,” he said.

He will also rear close to 100 Friesian bull calves for mop-ups that will be trucked back to be raised at the Mepunga beef farm before being sold as two-year-olds, continuing a trade he has developed over the past four years.

While he has been doing most of the work on his own so far, Hamish has access to a shared worker with Aran.

“I have to pay a worker if I want to put one on, but that’s up to me,” he said.

With two people, the milkings would be kept to under two hours, though Hamish has been getting them done in less than 2.5 hours on his own.

“It’s fine,” he said. “It just takes an extra 20 minutes and you get whatever other jobs are needed done when you can.

“I knew it would be hard by myself. It would

be a lot easier with a second person doing jobs but that will have to wait for a few pay cheques to come in after a few start-up costs.

“It’s still early days here but so far, this deal is working well for me. So far so good.”

BY RICK BAYNE

WHEN MILKING stretched out to 10 hours every day, Alex and Robert Robertson knew something had to change at their Simpson farm. That change has now arrived in the form of an 80-bail rotary dairy, cutting the milking period down to two hours in morning and again in the evening.

More than halving the milking time has been good for the cows and the brothers and their four milkers, but the giant new shed has many additional advantages.

“Flexibility is the name of the game,” Alex said. “We wanted something that was easy to use and quick to milk in and we got it.”

The automation, cleaning and safety features are added bonuses – and even the walls are staying clean thanks to the massive setback zone!

The brothers had been milking in their old 44-bail dairy for the past 21 years.

“We decided milking was getting a bit long at 10 hours a day,” Alex said.

“At one stage we were putting through 1200 cows in a 44-bail dairy and it was too long. Everyone was getting tired.”

The old dairy is being used for lead feeding cattle prior to calving but the new dairy is taking pride of place, but it could have been superseded by a barn.

The brothers are still keen to get a barn, but some sage advice from a bank manager set the dairy as the priority.

“We both wanted a barn but could see that the dairy was more of a pressing issue in terms of the long hours for staff,” Alex said.

“We went to the bank manager and he advised us to build the dairy.”

They still want a barn but it might be a couple of years away.

“It would be good for ease of handling with big numbers,” Alex said.

“The cows are happy if they get spoon fed all the time. If you get a terrible day, I don’t like to be out in the rain or heat and they don’t like it either.

“We’ve got all the equipment to do barn feeding and there are a lot of people around who have proven they make a lot more milk with a barn, but we’ve put it on hold for a while.”

Planning for the new 80-bail dairy started about two years ago.

“We wanted to create a system that didn’t make the mistakes of the old dairy in terms of keeping it clean, and making it flow easily,” Alex said.

“In the old dairy, the walls were too close to the table so you were forever cleaning them. The first thing was to make the walls 4-5 metres away from the table so it took that

cleaning problem away.

“The second thing was to fully enclose the table so no effluent gets inside making it easier to clean and one less job to do.”

Although Alex built the old dairy, this time they wanted to outsource the task and turned to GreenCon based in Cobden. GreenCon managing director James Green showed them a recent construction and they were keen to emulate it.

“We liked it and said we want something like that but bigger,” Alex said.

“I would have been happy with 60 or 70 bails but Rob saw dairies in Tasmania and spoke to other farmers and they said make sure you build the right size because everyone grows bigger after you build it.”

They had already experienced such growth, having started with 320 cows in the old dairy.

“It was going to cost more but would be worth it in the long-term,” Alex said.

“We wanted a table that was easy to run, easy to clean and easier to train people if we have backpackers. We wanted it simple, fast and efficient.”

Then there was the matter of the setback.

“The dairy James showed us had three-metre setback but I wanted five,” Alex said.

“He said we were going a bit big so we compromised to 4.5 metres. I just didn’t want shit on the walls. You’re going to spend time in the dairy so you’ve got to make it comfortable. You don’t want something where you hate going to work every day.”

They looked at robotics but ultimately decided to stay conventional.

“We felt we would need a barn and 18 robots for up to 1400 cows,” Alex said.

“Here we’ve got a shed up and running for $3.5 million whereas the robots and barn would have cost us in excess of $10 million.

“We had the staff and figured it would be easier to retain staff if we had a good set up that they like to milk in.”

Milking on the new rig started in July and after the first day, the cows felt right at home.

A lot of the problems from the old dairy have disappeared – such as cows slipping off the edge of the table, lifting their heads and knocking equipment.

There’s no slipping in the yards thanks to a new grooved surface, or on the exit ramp thanks to a flat surface.

“They seem very calm,” Alex said.

“We don’t have trouble getting them on; if anything, we have trouble getting them off.

“The shed flows really well. We haven’t had any trouble since we started. Milkings are now down to two hours, or even a bit less.”

The Jantec dairy system records fat, litres, protein and cell count, and a coding system flashes white to show when cows are on heat and red if they are on antibiotics and their milk has to be separated.

If a cow doesn’t milk out to its average, it will send the cow around again.

“It’s very simple,” Alex said.

“In the other dairy, the staff would have to put in codes and it would take ages to get someone trained. Here someone can learn within five minutes.”

In just two months, production has lifted,

the cell count has improved and there’s a slight reduction in mastitis.

The cows are sprayed with iodine before they go on the table and 10 seconds after being milked. The spray is mixed automatically in the adjoining chemical room.

“We hardly have to do a thing,” Alex said.

“Once, they’re cupped, we just stand around and watch them. They look like normal milking machines but they do a lot of stuff you don’t realise.”

“They draft automatically, spray automatically and any unwell cows are drafted automatically. It’s streamlined everything.”

There are two races for the cows to enter, though this can be reduced to one.

Cleaning and maintenance are also controlled with equipment and rubber wear on the outside of the table. There’s no oil with the rotary running on nylon rollers.

An overhead platform allows for safe observation and any repairs that may be needed.

The vats are enclosed for safety and cleanliness and there’s a big staff kitchen and even a shower.

The large new yards are flanked by three big silos, with capacity to add three more as cow numbers grow.

“We’re currently around 900 but just starting to calve again and will probably peak at 1100 to 1200,” Alex said.

“GreenCon, Walsh Plumbing, Newcome Electrical, Yarroweyah Engineering (platform), Southwest Dairy (milking machines) and Coweld engineering (feed system) did a great job,” Alex added.

NOT

“Best decision I’ve made since taking over the farm was going with SWDS. Damian and his team are a powerhouse and worked with our small timeframe to get the job done even better than I could have expected”

“Our upgrade made our goal of moving to a one person shed a reality. The Waikato gear is fantastic and makes milking easy with its functionality and reliability. The best part about SWDS is when you do run out or break something, they are always just around the corner and can get you going again straight away”

“We have built three dairies on different farms now with SWDS and Waikato. Damian doesn’t make a promise he can’t deliver. His honestly and open communication made the design and build process stress free, there were no hidden extras and his team have done a superb installation every time”

“We built with SWDS in 2019 and our dairy is an absolute dream”

“The new dairy is exactly what I expected from SWDS. It’s perfect”

“SWDS are complete professionals. The dairy is going great”

“After looking at other dairy builds, we were con dent to go with SWDS and they have not disappointed. They were great to deal with, we really like the Waikato gear as it’s both reliable and easy to operate. We can highly recommend Damian and his team for any dairy build”

To chat about your new dairy, give us a call 1300 00 SWDS

BY RICK BAYNE

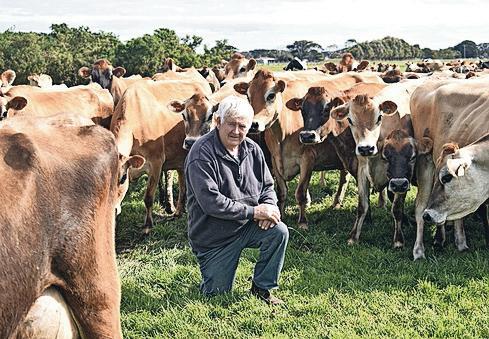

PAUL LENEHAN is considered a master when it comes to breeding Jersey cows, but his focus has always been grounded in commercial outcomes.

Earlier this year Paul was named as a Jersey Australia Master Breeder but he admits he never went looking for show success or awards, even though the honour was much appreciated.

“I’ve always been a commercial breeder,” he said.

“I like a good-looking type cow, but you’ve got to pay the bills. I’ve always chased production; not an extreme show cow.

“In a tough season like this, it pays to have well-bred cattle that continue producing when you put costly feed into them.”

Paul and his wife Lynette established Murray Brook Jerseys in 2000 at Crossley near Koroit, though the farm itself was started by Paul’s father Pat in 1946.

Paul and Lynette have retired into Koroit but their son Adam continues the business. Now aged 73, Paul makes daily trips to the farm and continues to hold the reins of the breeding program.

His love for dairying has never diminished and the family business continues to progress.

Last year they started running a second dairy on their long, thin farm which is linked by a leased property, and they added a sharefarmer, Lewis Ferguson.

The farm was milking 430 cows on one dairy but they aim to get up to 480-500 next year across the two dairies, with 140 heifers to calve this season.

The new dairy was needed to address the shape of the farm and the central leased link.

“The farm is really long and skinny and there was a lot of time walking cows,” Paul said.

“Because of its shape, it needed two people to bring in the cows and milk.

“We have 70 acres of leased land in the middle and having two dairies means that if anything happened to the lease, we’d still have the option to keep most of the cows.”

The second block linked to the home farm through the leased land was purchased about 10 years ago and the dairy on it hadn’t been used for about 10 years before that.

“It had been out of action for about 20 years so we had to refit it all but that went well,” Paul said.

It’s a small dairy, 12-a-side double-up herringbone, and the existing main dairy is also a relatively small 18-a-side herringbone.

“We never had a rotary because of the lease land in the middle,” Paul said. “The home farm is 250 acres and it would be too costly to put a rotary on a 250-acre block.”

Paul was 14 when he started milking with his father and his focus from the start was on big, high-quality cows with strong production.

“I was always very keen on the breeding side of things,” Paul said.

“When the herd was registered in 2000, it was all home grown and I’d kept all the records over the previous 35 years, so we could do genetic recovery.”

Paul’s breeding goals haven’t changed much over time. “I love a big-bodied, balanced cow with high and wide rear udders so they fill up with milk,” he said.

“I’ve always wanted a big-bodied cow with capacity to eat a lot of feed and produce a lot of milk and she had to have a good udder to carry that and to last in the herd for a long time.

“One of the main comments I get when people come here is about the size of the cattle.”

Paul likes young cows to be a good size when they calve.

“If they’re too small when they calve, you’re forever trying to catch up,” he said.

“One of the main aims these days is to grow out the young cattle with heifers coming in around 450-kilos.”

The focus on quality has been reflected in the farm’s consistent platinum milk awards and high placings in the top 10 of national herd rankings. The cows produce a bit over 7000 litres with 620-640 kg/MS.

Over the past seven years, Paul fulfilled a long-held ambition to contribute bulls to the AI system, mostly from old cow families that have been on the farm for generations. He now has six bulls in AI, and the first to be selected, Shadow Man, set the scene for the stud’s success.

“His sales were huge and he has had good daughters and has been very positive with his traits,” Paul said.

The stud’s principal home-grown cow families include the Annie and Lyn families.

“I mainly stick with my own families but in recent years had bought in a bit of a mixture,” Paul added.

He has been genomic testing since 2015 and the whole herd is now tested, opening the door for export opportunities with 90 high-genomic heifers being sold to HRM Dairies in Pakistan over the past two years.

The local success as well as the exports show the value of registering and classifying cattle, according to Paul.

“There’s real value in registering cattle,” he said.

“You just have to look at clearance sales to see the difference when selling registered cattle. We wouldn’t have had the opportunity to export to Pakistan if they weren’t registered.”

Paul classifies all two-year-old daughters and says that also adds value.

“Without that you have no proof for type so it adds value to know where you’re going with your own herd and it assists the industry.”

In the early days, Paul used a lot of American genetics but now uses mostly Australian, reflecting his positive impressions of the Australian Jersey cow.

Although they added Holsteins several years ago, more recently they have reverted back to Jerseys, with only nine old Holsteins remaining.

“I still love the Jerseys and think they are more profitable,” Paul said.

“The kilograms of solids she can produce for her body weight is much better than a Holstein.”

Murray Brook farm also qualifies for Jersey Australia’s Five Star Jerseys classifications.

Although officially retired, Paul still visits the farm every day and enjoys checking things.

Breeding remains his number one passion.

“I do that with Adam and our consultant Amy Wright. We’ve always worked closely with Amy, especially if we’re looking at overseas bulls.”

OLLIE BAKER grew up in the dairy heartland of Timboon but hadn’t really considered work in the field until a door opened for him.

Everything changed thanks to a fruitful family conversation and a scholarship from DemoDAIRY Foundation.

Ollie, 17, is now doing his dairy apprenticeship with Pinecrest Dairy, which operates three farms in the Heytesbury region, and studying his Certificate II in Agriculture at RIST.

Ollie completed Year 10 at South West TAFE in 2023 and was looking for a work opportunity this year.

“My Mum was friends with someone who knew the farm owners and they had a chat and offered me milking shifts on Sundays and it spiralled from there,” he said.

“I enjoyed doing the milkings and wanted to do more.”

He is mainly working at Pinecrest’s Curdievale farm but also does some shifts at Nullawarre, with his work now nearing a fulltime position.

“I grew up in town but I’ve always liked machinery and animals and now I’m learning a lot more about the science of farming,” Ollie said.

He’s also learning about the variety of jobs on the farm, from feeding to milking and cleaning to fencing, and he’s keen on learning more.

“I like being outside and working on my own,” he said.

“I see my future if not in dairy, hopefully something in agriculture. Right now, dairy is a

good path for me and opens up a lot of options in the Timboon area.”

Ollie said the course was helping his career progression.

“RIST runs a good program and you get to learn a lot of practical stuff,” he said.

“There’s not always time to learn everything on the farm so it’s good to have the background from the course.”

He said the DemoDAIRY Foundation scholarship was particularly helpful.

•

•

•

•

•

•

•

“It’s helping to pay for the fees for my education as well as the personal protection equipment that is required, and that doesn’t come cheap.”

for DemoDAIRY Foundation and Powell Legacy Fund