A spreading improvement

Reuling strives for efciency in bedding

By Grace Jeurissen grace.j@star-pub.com

CLARKSVILLE, Iowa

Reading up on worldwide dairy practices and technology has been something Eduard Reuling has always enjoyed.

And, beyond his enjoyment, Reuling’s reading led him to invest in a robotic bedding system on his farm near Clarksville.

“I always try to know what is happening in the world,” Reuling said. “Coming from the Netherlands, I like to know what is going on over there since I still have many friends there.”

Reuling and his wife, Resy, and their children, Jenny, Ryanne, Nick and Wouter, milk 500 cows in a swing-32 parlor three times a day.

In 2005, the Reulings moved from the Netherlands to start Snow Rock Dairies LLC.

They began milking 350 cows and slowly grew the herd to where it is today.

The Reulings spent a number of years trying different bedding options.

“When we rst started, we used rubber mats and sawdust, but the sawdust would get wasted by the cows, and we had to bed regularly,” he said.

“This became expensive and time consuming so we tried manure solids.”

Reuling said manure solids were not efcient for his operation.

In 2017, waterbeds were installed in the freestall barns. At rst, they spread hydrated

Turn to

|

8

A bright future Rolling the dice

Buying dairy farm 20 years ago pays off

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

VERGAS, Minn. –

Zumbrota DFA plant completes expansion

By Taylor Jerde taylor.j@star-pub.com

By Taylor Jerde taylor.j@star-pub.com

ZUMBROTA, Minn.

– The Dairy Farmers of America plant in Zumbrota has grown in size not only to meet customers’ demands but to better serve the dairy farmers in the area and the communities it serves.

“What really drove this decision was the needs of the customers,” said Terry Johnson, plant manager.

“When you make this investment, there is a continued demand and a process of creating value-added products that also help add value to our dairy farmer owners and end product that goes out.”

The $90 million expansion added an additional 86,000 square feet to the facility which initially boasted

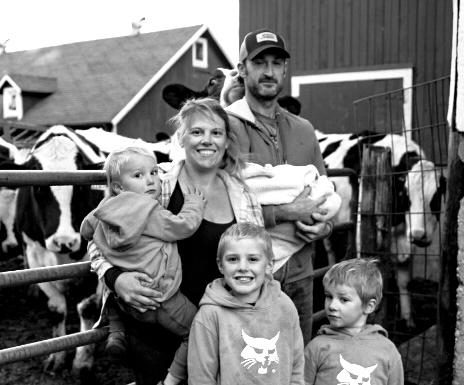

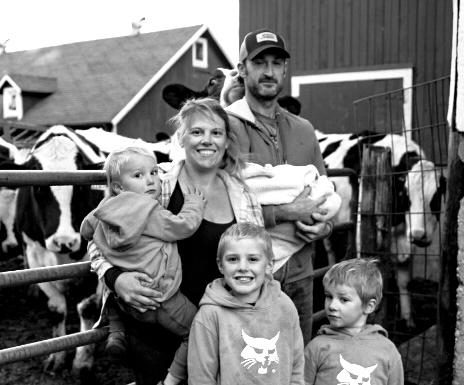

When the Schlauderaff family bid on a dairy farm near Vergas during an auction in 2002, it was a big move. When their bid won, it took a while to sink in.

“After the auction ended, we had to get back because we had corn chopping to do,” Casey Schlauderaff said. “The reality didn’t set in until later when we had to do nancing and try to put the whole project together and make it work.”

In the 20 years since then, the family has done just that – made it work.

Today, Schlauderaff Enterprises milks 650 Holsteins three times a day in

a double-12 parallel parlor, which is a big change from the 150 cows they milked on their home farm near Detroit Lakes prior to purchasing the second farm.

Family members live

on or near the home farm. A 15-minute commute is all that separates the two farm sites. At the Vergas farm,

DAIRY ST R October 29, 2022Volume 24, No. 17 “All dairy, all the time”™

AARON THOMAS/DAIRY STAR

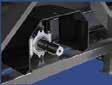

Eduard Reuling checks the se�ngs on his Astor bedding robot Oct. 21 at his farm Snow Rock Dairies LLC near Clarksville, Iowa. They milk 500 cows in a swing-32 parlor.

TAYLOR JERDE/DAIRY STAR

Plant manager Terry Johnson stands in front of the Dairy Farmers of America sign Oct. 20 at the plant in Zumbrota, Minnesota. The Zumbrota loca�on is one of the largest plants for DFA.

REULING

Page

Turn to DFA | Page 9

Turn to SCHLAUDERAFF | Page 6

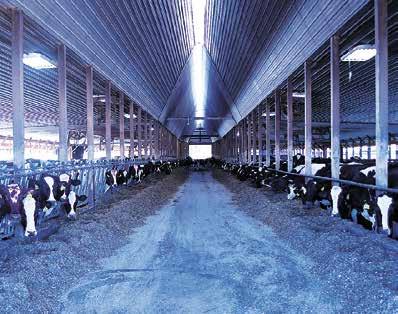

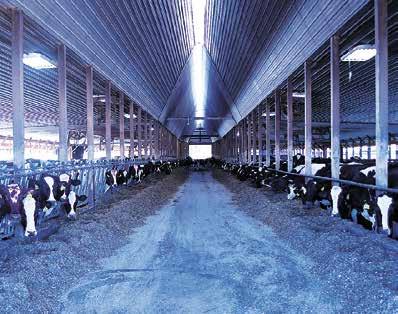

JAN LEFEBVRE/DAIRY STAR

Some of the 650 Holsteins eat Oct. 18 in one of two freestall barns at Schlauderaff Enterprises near Vergas, Minnesota. The Schlauderaffs milk three �mes a day in a double-12 parallel parlor.

Sign up for our Newsletterup for our Dairy St r Milk Break Visit dairystar.com to sign up!

ISSN

Phone:

Published by Star Publications LLC General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor 320-352-6303

• tiffany.k@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101

• danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666

• stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812

• abby.w@dairystar.com

Grace Jeurissen - Staff writer 320-352-6303

• grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980

• jan.l@star-pub.com

Taylor Jerde - Staff Writer 507-403-1680

• taylor.j@star-pub.com

Maria Bichler - Copy Editor maria.b@dairystar.com • 320-352-6303 Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks 320-352-6303

• joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217

• fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260

• jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825

• mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884

• amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202

• megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284

• kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739

• julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The

One

Our

Milk pricing system scrutinized

Last year, Secretary of Agriculture Tom Vilsack requested the U.S. dairy industry get into one room and build consensus to nd solutions to the shortfalls in the federal order system. American Farm Bureau economist Danny Munsch said the system has not been updated in 20 years in a major way. “In that time, we’ve gone from a uid milk-focused market to more of the manufactured goods driving the market, and the Federal Milk Marketing Order system doesn’t reect those changes,” Munsch said. Due to other market disruptions, like COVID-19, farmers faced massive negative producer price differentials on their milk check. The AFBF hosted the weekend forum in Kansas City, Missouri.

AFBF outlines farm bill priorities

That list includes the continuation of current farm bill funding, prioritization of crop insurance, and adequate stafng and resources for U.S. Department of Agriculture technical assistance. “We also believe that transparency is needed in our dairy system,” said Zippy Duvall, president, American Farm Bureau Federation. “We believe that because higher costs of production, it justies the increase in the reference prices for the Title I commodities to ensure farmers remain economically viable.” The AFBF board of directors unanimously approved the policy recommendations, but the nal approval will come during the group’s annual meeting in January 2023.

A new perspective on trade

The White House newly-released National Security Strategy includes a change in trade policy. The report said the United States’ focus on fair and open trade has helped corporations rather than workers. The Biden administration said it will seek new trade opportunities that protect labor

standards and the environment. To combat food insecurity, the administration plans to keep agricultural markets open, increase fertilizer production and invest in climate-smart agriculture.

WTO predicts trade downturn

Insider

Insider

The

takers

Deadlines

Subscriptions

Letters

Sauk Centre, MN

The World Trade Organization is forecasting a signicant decline in global trade growth next year. Growth is forecast at 1%, compared to a previous estimate of 3.4%. The WTO director-general urged member-countries to avoid trade restrictions to counter supply chain problems.

By Don Wick Columnist

Dairy industry seeks better ocean freight service

Federal Maritime Commission Chairman Daniel Maffei sat down with representatives of the U.S. Dairy Export Council and National Milk Producers Federation to discuss supply chain issues. The dairy groups emphasized the continuing problems with high costs, unreliable scheduling and the need for better service from the ocean freight system.

Managing the three-headed dragon

knowledge to manage the three-headed

Virginia Tech professor emeritus David Kohl said it takes solid

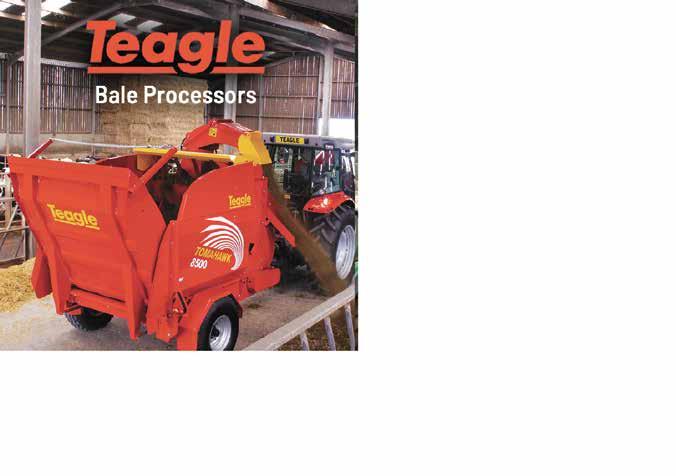

Page 2 • Dairy Star • Saturday, October 29, 2022 Dairy Prole brought to you by your North America dealers.

Ag

Turn to AG INSIDER | Page 5 DAIRY ST R

020355 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

320-352-6303 Fax: 320-352-5647 www.dairystar.com

deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising

ad

have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave.,

56378-1246.

nancial

INVEST IN QUALITY ® www.kuhn.com KuhnNorthAmerica.com QUALIT Y www.k u hn.com KuhnNorthAmeric Visit your local KUHN livestock dealer today! INVEST IN QUALITY ® www.kuhn.com Lindell Sales & Service Cannon Falls, MN Hammell Equipment Eitzen, MN Adkins Equipment Detroit Lakes, MN Isaacson Sales & Service Lafayette, MN Blue Hilltop Lake Wilson, MN Schlauderaff Implement Fluegge’s Ag Mora, MN Northland Farm Systems Owatonna, MN Lake Henry Implement Paynesville, MN Minnesota Ag Group Plainview, MN Dairyland Supply Sauk Centre, MN Woller Equipment Swanville, MN Werner Implement Vermillion, MN Anderson Bros. Edgeley, ND Duppong's, Inc. Glen Ullin, ND Enerbase Cooperative Minot, ND Roeder Brothers Inc. Bellevue, IA Maquoketa, IA Kunau Implement DeWitt, IA Bodensteiner Implement Elkader, IA J. P. Scherrman, Inc. Farley, IA Burco Sales Independence, IA Kunau Implement Preston, IA Engel Agri-Sales Sac City, IA Dee Implement of Waukon Waukon, IA HIGH-USAGE , HIGH-CAPACITY SPREADING Withstand heavy loads with stout, commercial-grade undercarriage Multiple discharge options to best suit the needs of your operation Reversible apron easily clears any unforeseen obstruction or blockage Guillotine endgate increases material PXL 100 SERIES PROSPREAD ® CommercialApron Box Spreader 865-1,230 cu. ft. capacity truck & trailer models

When did you start and nish corn silage harvest? First Section: Pages 15-16 FROM OUR SIDE OF THE FENCE: www.automatedwastesystems.com (712) 439-2081 Watertown, SD (605) 753-0300 Hull, IA COMPLETE MANURE EXPERTS For additional stories from our other zone, log on to www.dairystar.com Dairy Star • Saturday, October 29, 2022 • Page 3 Stearns County dairy judging team places high at nationals Second Section: Page 25 Stearns Co., MN Redhead Creamery ages well, opens distillery First Section: Pages 12 - 13 Brooten, MN Zumbrota DFA plant completes expansion First Section: Pages 1, 9 Zumbrota, MN Pasture walk event demonstrates PaddockTrac Third Section: Pages 10 - 11 Villard, MN Buying dairy farm 20 years ago pays off First Section: Pages 1, 6 Vergas, MN Zone 2 Zone 1 Columnists Ag Insider Pages 2, 5 First SectionF Dear County Agent Guy Page 36 First Section Dea Ag P Firs The “Mielke” Market Weekly Pages 6 - 7 Second Section A Day in the Life of the Mauks Second Section: Pages 12, 14 Howard Lake, MN Middendorfs install robotic milking system, see herd improvement First Section: Pages 26 - 27 Melrose, MN Harvesting Quality Forages First Section: Pages 18, 20 Sauk Centre, MN Reuling strives for efciency in bedding First Section: Pages 1, 8 Clarksville, IA Just Thinking Out Loud Page 38 First Section Jus O F Fir Something to Ruminate On Page 34 First Section S to Fi Dairy Good Life Page 39 First Section

Page 4 • Dairy Star • Saturday, October 29, 2022 FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Advanced Dairy Systems 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 Anderson Dairy Systems, Inc. 1312 13 1/2 Ave. • Barron, WI 54812 (715) 537-3300 Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 295 East Main Street • Lewiston, MN 55952 (507) 452-5532 Leedstone 222 E Co Rd 173, Melrose, MN 56352 (320) 256-3303 24260 Cty. Rd. 27 • Plainview, MN 55964 (507) 534-3161 Athman Dairy Inc. 238 Main Street North • Pierz, MN 56364 (320) 468-2494 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Professional Dairy Systems 1449 Homecrest Ave. • Wadena, MN 56482 (218) 632-5416 Leedstone 1720 Freitag Dr. • Menomonie, WI 54751 (715) 231-8090 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Fuller’s Milker Center, Inc. 423 U.S. 61 • Lancaster, WI 53813 (608) 723-4634 278 W. Court St. • Richland Center, WI 53581 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 • Dual Germicide: Primary: Chlorine Dioxide promotes a quick kill. Secondary: LAS promotes a long-lasting kill. • Effective against ALL Mastitis-Causing Organisms • Contains Lactic Acid to promote Teat Exfoliation • Teat skin conditioning – 12.4% skin conditioning package • Green coloring for easy identification BEFORE Exfoliation AFTER Exfoliation TEAT END ISSUES? The BEST protocol is Valiant Pre-Post during the day & Recover during the night. It speeds up the exfoliation process keeping teat ends soft & in TOP CONDITION! 78% TRI-BLEND SKIN CONDITIONING PACKAGE is HUGE! GERMICIDE:1.5% HEPTANOIC ACID Be sure your herd is PROTECTED...Set up a Plan Today! Cold Weather is Coming...Are you Prepared? DO YOU HAVE A WINTER TEAT OPTION? Featuring LANOLIN (Top Skin Conditioner) EASIER, FASTER & LESS MESSY than most salves & creams! COLD WEATHER Udder Health Solution! ONE NAME STANDS ALONE. HEALMAX. FAST RESULTS WITHOUT FORMALDEHYDE SAFER THAN FORMALDEHYDE for cows and crew WORKS FAST WORKSFAST with proven results in about one week withprovenresultsinaboutoneweek FEATURES A PATENTED MODE-OF-AC TION you won’t get with any other hoof care product. With HEALMAX® in your footbath, you’ll avoid formaldehyde which is PAINFUL, IRRITATING, LESS EFFECTIVE at extreme temperatures and is a known CARCINOGEN. ALDEHYDE forcowsand BEFORE BEFOAFTER RE E 20 DFESGF 0086 Progress ve Da ryman US H PerChi 5 Ad 4 66x6 5 indd 1 1 30 20 5:41 PM (800) 887-4634 • Lancaster, WI (608) 647-4488 • Richland Center, WI fullersmilkercenter.com Northland Farm Systems Owatonna, MN Lake Henry Implement Paynesville, MN Brunkan Equipment Worthington, IA CALL YOUR AREA MUSTANG BY MANITOU DEALER TODAY! PUSHING THE LIMITS OF CONSTRUCTION PERFORMANCE Ready to work, Mustang by Manitou Compact Equipment comes standard with the right power loaders have pushed the limits of durability, setting new industry standards. GENUIN CHOOSE FOR YOUR MUSTANG EQUIPMENT PLAYIN’ IN THE DIRT SINCE 1965 HINGTHELIMITSOFCONS www.mustang-by-manitou.com

“If it’s not well managed, that will take liquidity, prot and equity off the balance sheet, but those with a high business IQ will actually put prot, liquidity and equity on the balance sheets,” Kohl said. Over the rest of this decade, Kohl said “the better will get better and the worst are going to fall behind.” Good relationships are also key during tough times.

Ination disrupts farm, food sector

The Federal Reserve banks, of Minneapolis and Kansas City, hosted a virtual symposium to discuss food costs and the long-term outlook. During the forum, Federal Reserve Bank of Kansas City Vice President Nathan Kauffman said the current increase in food and commodity prices is similar to what happened in 2013. “Price surges are usually driven by severe production disruptions,” Kauffman said. “Occasionally, price surges are driven by demand growth, like in 2013 where we saw rapid economic growth in China and the establishment of biofuel policies in the U.S.” Land O’Lakes President and CEO Beth Ford was also

part of the conference and said farmers are feeling the impact of high input costs. “Transportation, trucking, rail and warehousing are all facing interruptions that are driving up prices.”

Environmental benets of dairy production

The Association of Equipment Manufacturers, the National Milk Producers Federation and Dairy Farmers of America unveiled a study on the benets of modern dairy technologies during World Dairy Expo. “If you look at the role technology has played, we’ve seen a tremendously positive impact on milk yield,” said Chad Huyser, president, Lely North America. “We believe the technology adoption can be attributed to a milk yield increase of about 6% and the data supports that we’ve been able to reduce the feed usage by what’s the equivalent of 3,200 NFL football stadiums full of feed.”

New faces coming to St. Paul in 2023

Ahead of the election, it’s known that 41 Minnesota legislators will not be returning to St. Paul in 2023.

Agricultural lobbyist Cory Bennett

said it will be a time of change. “No matter who’s in control, Republican or Democrat, we’re going to have new leadership; we’re going to have new committee chairs, new committee staff,” Bennett said. There is a budget surplus, which will get attention in the upcoming legislative session. The upcoming year is a budget-setting one which will be a priority. “With that, I think you’re going to hear a lot about taxes and a lot of talk about a bonding bill,” Bennett said.

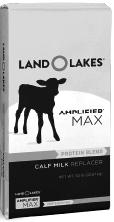

Consumer misconceptions

While 98% of U.S. farms are family-owned and operated businesses, most Americans believe less than half of the farms are family farms. A survey of 1,000 adults nationwide was conducted by Land O’Lakes. This research found 87% of those surveyed are interested in knowing where their food comes from. Millennials were at the top of that list.

Beyond Meat cuts jobs

Beyond Meat, which produces plant-based meat substitutes, is cutting 200 jobs and has issued a warning to investors about its revenue outlook. Beyond Meat Chief Financial Ofcer

Douglas Ramsey is also leaving the company. Ramsey was suspended in September after an altercation at a college football game.

Meatless no more

After two years in operation, JBS USA is shutting down its U.S. plantbased food business. The meatpacking company will put its focus on its plantbased business in Brazil and Europe.

Trivia challenge

Switzerland consumes more chocolate on a per-capita basis than any other country in the world. That answers our last trivia question. For this week’s trivia, when did October Co-op Month become a national celebration? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Dairy Star • Saturday, October 29, 2022 • Page 5 www.midwestlivestock.com ZUMBROTA, MN 800-233-8937 RENNER, SD 605-274-3656 MENOMONIE, WI 715-235-5144 Baier Creek Farms, Elmwood, WI • 2x12 Lift Parlor w/ GEA Dematron 70 milk meters & (2) 6400 gal. Mueller Tanks Celebrating 50 years in business! NEW, UPDATE, OR REMODEL? REMODEL?We can do that! dragon of price volatility, higher input costs and rising interest rates.

Con nued from AG INSIDER | Page 2

cows are housed in two freestall barns. The herd maintains a rolling herd average of 28,000 pounds.

The Schlauderaffs also farm 1,000 owned acres and 800 rented, manage a hay and silage chopping business, and raise and feed out 50 bull calves each year.

Schlauderaff said they knew the choice to bid on the Vergas farm was a gamble, but the timing was right, even though he and his brothers, Chad and Kelly, were only in their 20s. The youngest brother, Kory, was in high school at the time.

“We thought if we’re considering building a new barn in any sort of time, we should probably be at that auction,” Schlauderaff said. “We thought it might be a fair deal, and it was already complete and close enough.”

The family did not hold a formal meeting, but they often discussed buying the second farm.

“We talked on the phone constantly about it,” Schlauderaff said. “It was pretty stressful.”

They also talked with a banker to determine if they could secure the funds needed to be allowed to bid at the auction.

“There were so many unknowns,” Schlauderaff said. “What’s it going to go for? Can you leverage to do it? You’ve got to buy cattle. You’re basically putting money down on the chance that you’re going to be able to pull it off.”

Once they made the decision and won with a bid of $500,000, it took at least ve years to get the whole family better arranged in the jobs that best suited them.

“Your original vision changes as you nd out that people’s personalities t better in certain places,” Schlauderaff said. “I can’t speak for my brothers, but they would probably say that I’m a bossy person. Then, you gravitate toward telling employees what to do.”

Since purchasing the farm, all four boys have married and now have children. Chad and Jennifer have two children. Chad handles all crop decisions and does equipment repairs. Schlauderaff, who manages the dairy, and his wife, Paige, have three children. Kelly and Jamaica have ve children. Kelly works off the farm but helps when needed. He also handles feed purchases and milk contracts. Kory and Lindsay have three children. Kory manages the farm’s 550 heifers, drives the chopper and sprayer, and helps Chad with repairs. Their parents, Barb and Gary, help on the farm.

Barb spent many years managing newborn calves, and Gary did eldwork and pile packing. Both helped with milking. Today, they spend the winter in Florida but help in many ways.

“There’s a lot of farms where families can’t work together,” Schlauderaff said. “Being as spread out as we are probably helps us do it because we’re not right on each other every day.”

Originally, the plan was to avoid having employees beyond hiring a herdsman right after the purchase of the Vergas farm. That person, Paul Kasowski, is still with them today.

“We did most of the milking ourselves for the rst several years,” Schlauderaff said. “Mom and Dad would start in the morning. I was on the later shifts and got home at 2 in the morning. That was probably the rst 10 years. We added even more cows and realized that we needed to add more people.”

The farm’s growth has brought on the purchase of tractors, equipment and farm structures, such as a sand separator purchased in 2014 and a new feedlot added at the beginning of this year.

Page 6 • Dairy Star • Saturday, October 29, 2022 www.LangeAgSystems.com Specializing in Livestock Equipment and Construction, New and Used Bagging Machines, Silage Bags, Bunker Covers and Grain Storage! We Have What You’re Looking For! W7246 Hwy 68 Waupun, WI 53963 | 920-324-3537 M-F 7:30 am -7 pm, Sat 7:30 am -3 pm , Sunday 11:00 am - 1:00 pm ’21 Kubota SSV65CH Diesel, 64 HP, 2 Spd HVAC Cab, Hyd Quick Tach $49,995 ‘21 Meyer SXI865, Large 1000 PTO, 3rd Auger, LED Lights - $65,900 NH 28, 540 PTO, Whirl-A-Feed-Hopper $1,195 MORE INVENTORY AT WWW.BALLWEG.BIZ ‘14 JD 6140R 140 HP, 1823 Hrs., 3 SCV’s, 3 Pt Hitch $127,900 ’16 JD 323E 2 Spd, 74 HP, 18 GPM, Boom Breakout Force 4300 lbs, 740 hrs., $63,900 ’22 J&M 555 16 Ton Gear, Hyd. Drum Brakes, Roll Tarp w/ Frame & Crank $22,700 Con�nued from SCHLAUDERAFF | Page 1

PHOTO SUBMITTED

Chad, Kory, Kelly and Casey Schlauderaff a�end a Minnesota Vikings game Dec. 8, 2019, at U.S. Bank Stadium in Minneapolis, Minnesota. The brothers and their parents, Barb and Gary, have grown the family’s dairy business, Schlauderaff Enterprises, to include two farm sites.

Turn to SCHLAUDERAFF | Page 7

bedding has been huge over original

as to cow comfort and better production,” Schlauderaff said.

There have also been challenges along with the growth.

“We bought expensive cattle in 2008, and then the milk price crashed in 2009,” Schlauderaff said. “A lot of people went out of business that year.”

Through the years, Schlauderaff said he has become more certain the farm will withstand volatility.

“I don’t think you ever get to that point of thinking you’ve made it,” he said. “You still have daily stress and wonder if this thing will make it or not. It was rough when the milk price crashed, but the next time there was a milk price drop I thought, ‘Well, we’ve done it before.’ You’ve got to gure out what you’re going to do and ride through it.”

Today, some of the next generation of Schlauderaff children are showing an interest in agriculture, and Kelly’s son is already working on the farm. The future of Schlauderaff Enterprises looks bright.

“It’s been a crazy ride,” Schlauderaff said. “We’ve met so many people and learned so much. I like the process. I think that’s what makes successful farms … guring out how systems relate and work together.”

Schlauderaff said he is happy with how the family business is evolving.

“I like the days I show up here,” he said. “For the most part, it’s a pretty rewarding job.”

Dairy Star • Saturday, October 29, 2022 • Page 7 www.TridentPulsation.com Trident@TridentPulsation.com TridentPulsation™ System 607-849-3880 • 607-759-1037 TridentPulsation™ Specifically designed to work with positive pressure fresh air, TridentPulsation™ ensures a consistent gentle massage over a wide range of vacuum levels yielding very fast milking while eliminating backwash. TridentPulsationtm holds the liner fully open on attach to ensure every liner properly pulls up onto the teat and again holds it full open on detach for a quick and gentle slide off the teat. 70% milk yield in the first two minutes with start to finish milking in 3 to 4 minutes. The power of positive pressure How to make your cows disappear... Sell it in the classieds! 320-352-6303 Receive unmatched performance all year long. Only AGCO Genuine lubricants guarantee proven performance. We’re prepared for every season, so you can be too. Designed and field tested by engineers, our lubricants are formulated with high quality base oil and additives to consistently provide the highest performance required by agricultural demands. There’s no cutting corners when it comes to AGCO Genuine lubricants. [][] ©2021 AGCO Corporation. AGCO Parts is a worldwide brand of AGCO Corporation. AGCO and AGCO Parts are trademarks of AGCO. All rights reserved. 20084 Del-Clay Farm Equipment 1003 210th Ave | Edgewood, IA 52042 www.delclay.com | 563-928-6445“Sand

mattresses

Con�nued from SCHLAUDERAFF | Page 6

JAN LEFEBVRE/DAIRY STAR

Casey Schlauderaff stands by his tractor Oct. 18 on the family’s dairy farm near Vergas, Minnesota. The Schlauderaffs bought the dairy 20 years ago to expand their original farm near Detroit Lakes, Minnesota.

Dairy St r Milk Break Sign up for ourup for our Newsletter Sign up at www.dairystar.com

lime on top of the stalls, but it was not keeping the cows dry and clean.

Not wanting to go back to hauling bedding, Reuling purchased the bedding robot in 2021 and began preparing the barn to house the technology.

“I will never ever go back to hauling bedding in four days a week,” Reuling said. “The dual chamber waterbeds have improved cow comfort, and the robot spreading sawdust twice each day keeps them dry and clean.”

Reuling set up the frame himself over the course of a few months. He fastened approximately 1,600 feet of Ibeam to a T that is attached to his posts in the middle of the stalls. Reuling chose to put the hopper and conveyor for the robot at the center of the freestall barn so there was no need for additional construction.

Once construction of the track and frame were done, technicians from AMS Galaxy USA installed and programmed the robot. The robot has been running since early August 2021.

Other than a short-lived mishap with the robot’s wiring in August, caused by a lightning strike, Reuling said the technology has been running

well.

“It’s so convenient,” he said. “All I have to do is ll the hopper a few times each week, and the rest is done by the robot. If we need to reprogram the timing, I just go into the computer to change it. It’s simple.”

The robot is programmed to spread bedding while the cows are being milked. Bedding is spread across 400 stalls in the older existing freestall barn. The barn that houses the fresh cows is bedded with sawdust using a manual spreader.

For 500 cows, Snow Rock

Dairies goes through one semitruck load of sawdust a month.

The sawdust is loaded into the storage container three times per week and from there runs up a conveyor to equipment that shreds the bedding further.

The bedding is then conveyed to a robot that delivers the bed-

ding to the stalls.

Once the timing is right, the robot runs the bedding along the stalls, and in about 30 minutes, it travels back to the hopper to charge and reloaded for the next group.

Milking at the farm is done by employees, while much of the herd health and management is done by Reuling with the help of his family. Crops are purchased out of the eld from neighbors, and heifers are sent at 4 months to a heifer raiser.

“I do nearly everything, the breeding, feeding calves, feeding cows, hoof trimming and ultrasounding,” Reuling said.

Because milking is hired and feed is purchased, the Reulings focus on minimizing the extensive list of tasks that have to be done or at least ease the way they are being done.

“If we want to automate something, it needs to take labor away from me,” he said.

Reuling’s whole life has been surrounded by dairy, and his ultimate goal with the farm has been to improve animal well-being and do so efciently.

“This is always what I’ve done,” Reuling said. “I’ve never thought of doing something else.”

Page 8 • Dairy Star • Saturday, October 29, 2022 CALL OR SEE YOUR LOCAL DEALER FOR COMPLETE DETAILS! MINNESOTA A & C Farm Service, Inc. (TMR Mixer Dealer) Paynesville, MN Fluegge’s Ag, Inc. Mora, MN Gorter’s Clay & Dairy Equip. Pipestone, MN Hammell Equipment Inc. Chat eld, MN Eitzen, MN Harmony, MN Rushford, MN Midwest Machinery Co. (Full Line) Glencoe, MN Glenwood, MN Howard Lake, MN Princeton, MN Midwest Machinery Co. (Forage Boxes Only) Alexandria, MN Sauk Centre, MN Schlauderaff Implement Co. Litch eld, MN Werner Implement Co., Inc. Vermillion, MN Wingert Sales & Service Plainview, MN Johnson Tractor, Inc. Janesville, WI Luxemburg Moter CompanyLuxemburg, WI Price Equipment Sales, Inc. Bloomington, WI Tractor Central Arcadia, WI Cameron, WI Chippewa Falls, WI Durand, WI Granton, WI Menomonie, WI Mondovi, WI Sheldon, WI West Salem, WI Westby, WI IOWA Engel Agri Sales Sac City, IA SOUTH DAKOTA Pfeifer Implement Co. Sioux Falls, SD WISCONSIN Hupf’s Repair Center Beaver Dam, WI Meyer Manufacturing Corp. Dorchester, WI • 800-325-9103 Visit our website! meyermfg.com Manure, litter, sludge — superior coverage! Wagon, trailer or truck versions. Advanced engineering provides consistent batches day after day. More sizes, more options, more performance! Load after load, we never lose sight of what’s important. INDUSTRIAL & CROSSFIRE MODELS FORAGE DELIVERY IS OUR SPECIALTY FORMULA TMR QUALITY PRODUCTS & HAPPY CUSTOMERS FOR MORE THAN 75 YEARS, MEYER IS DRIVEN BY YOUR SUCCESS QUALITY NEVER GOES OUT OF STYLE

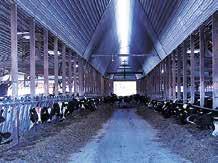

Con nued from REULING | Page 1

AARON THOMAS /DAIRY STAR

The bedding robot spreads sawdust across 400 stalls in the Reulings’ freestall barn. Reuling lls the robot’s hopper three mes a week with sawdust, and the robot does the rest of the work on a set schedule.

110,000 square feet. The expansion also allows the plant to grow from 140 employees to 160.

The expansion, completed in July and celebrated in September along with the Zumbrota plant’s 50th anniversary, includes a waste water treatment facility, drying tower, wet mixing system, lab upgrades and utility upgrades. The dairy powder drying tower has the capacity to dry an additional 25% per year.

The Zumbrota location takes in 1.5 million pounds of raw milk each day. The milk is used to create cheese, condensed whey and cheese powders. Johnson said the recent increase in production capabilities delivers value back to the farmer owners.

“We’re able to highlight farmers and market their milk globally,” he said.

The expansion stems from a want to be better stewards to the community. The waste water treatment facility enables DFA to discharge clean waste water to the city. They also added a column that eliminates odor from the air when being discharged from the plant.

Johnson said such improvements will increase plant efciency and production capabilities while

also lowering the cost of water discharge.

The addition also added safety measures for employees.

“We had to be mindful of the community and community concerns,” Johnson said. “It makes us a better neighbor.”

Johnson has been the plant manager since 2020 when the expansion began. He was a dairy farmer from Wisconsin but became interested in food production. He started working in a small cheese plant in Wilson, Wisconsin, and then took a job at Nestle before coming to DFA.

Johnson said he feels fortunate to have been part of the expansion.

“It is important for me to contribute to DFA,” he said.

As DFA expanded its presence in Zumbrota, Johnson said they took care to use local products and businesses whenever possible. They worked with local contractors and had new equipment for the plant made in Minnesota.

“My hope is to see the things we put in to make ourselves better for our customers and for the community continue to do exactly what we project it to do: to set a standard for our site and encourages future investments,” Johnson said.

Dairy Star • Saturday, October 29, 2022 • Page 9 ONE NAME STANDS ALONE. HEALMAX. FAST RESULTS WITHOUT FORMALDEHYDE SAFER THAN FORMALDEHYDE for cows and crew WORKS FAST with proven results in about one week. FEATURES A PATENTED MODE-OF-ACTION you wont get with any other hoof care product youwon’tgetwithanyotherhoofcareproduct HEALMAX® in your footbath, you’ll avoid formaldehyde which is PAINFUL, IRRITATING, LESS EFFECTIVE at extreme temperatures and is a known CARCINOGEN. ALDEHYDE forcowsandcrew BEFORE BEFOAFTER RE Wit W “With the traditional footbath, we had issue of it not being filled/not being filled correctly. Now with the automated footbath, we can ensure it is filled correctly and on time. Just 3 months in and we have already seen a large improvement in hoof health and reduction in hooftrimming costs” Brandon Meddaugh, Dairy Manager Bella Vista Dairy Belmont, WI 900 Cows 20 DFESGF 0086 P ogress ve Da ryman US H PerCh 5 Ad 4 66x6 5 indd 1 1/30 20 5:41 PM (800) 887-4634 • Lancaster, WI (608) 647-4488 • Richland Center, WI fullersmilkercenter.com From Our Yard to Yours. AGRICULTURAL | RESIDENTIAL | LIGHT COMMERCIAL Decks | Barns | New Home Construction | Remodeling | Additions Industrial Buildings | Pole Sheds | Garages | So Much More! 320-243-7815 Paynesville, MN | BorkLumber.com Traditional Values. Continuing Excellence. www.norbco.com67962 State Hwy 55, Watkins, MN 55389 • 320-764-5000 MA KING COW COMFORT OUR PRIORITY Curtain SystemsVentilation SystemsFreestall SystemsHeadlocks

TAYLOR JERDE/DAIRY STAR

This dry tower is part of the expansion of the Dairy Farmers of America plant in Zumbrota, Minnesota. It has the capacity to dry an addi onal 25% per year.

Passing the farm onto the next generation

By Jan Lefebvre jan.l@star-pub.com

Editor’s note: This is part one of a two-part feature regarding farm transitions. In the next issue of Dairy Star, we will cover examples of what has worked well for some farm families and where to nd assistance with farm transitions.

When considering a farm transition, how does the older generation value the next generation’s investment? Should sweat earn equity? Do children who put time and effort into the success of the farm deserve a larger share of farm inheritance than nonfarming siblings?

These, and many other, questions can be tricky when passing on a family farm. It is also a private matter to most families and can be difcult to discuss with others or even within the family itself.

Jim Molenaar is aware of how difcult it can be to navigate a farm transition. For the past 41 years, he has worked as an instructor in farm business management, the past eight years at St. Cloud Technical and Community College. A specialist in farm succession planning, he rst gained experience while working as a mediator in a farmer lender program during the 1980s farm crisis.

“For so many farmers, transitioning is something they need help with,” Molenaar said. “Some do this very well, but I’ve also seen some failures.”

Molenaar grew up on a farm and went through a farm transition himself.

“There is a big difference between an estate plan and a farm succession plan,” he said. “An estate plan is what happens with my assets when I pass away. A farm succession plan is what I can do during my lifetime to make sure the farm continues with the next generation.”

Many farmers are uncomfortable talking with others about their farm transition struggles. If they do wish to say something, they may rather remain anonymous. Even those who have had successful transitions are uncomfortable talking about the experience because they do not want to seem like they are bragging; they want to avoid sharing private nancial information about family members.

Off the record, farmers of both generations may talk about the difculties they are facing in communicating their wishes for the future of their farm. Younger farmers may say things such as, “I can’t talk to my dad about this,” or “I’m putting in lots of sweat equity and not receiving much pay, but I still have no say in anything.” Older farmers may say, “I’m near retirement and can’t afford to invest major money in big changes right now,” or “I’ve worked my whole life for the farm and deserve to make the big decisions.”

Molenaar said one farmer talked about a family near him that has to hold two separate Christmas holidays because two brothers fought over their family’s farm transition and will no longer attend the gathering at the same time. Another farmer spoke about going into debt before retirement for a son who wanted to take over the farm and expand, but the son changed his mind a few years later when high debt remained. There are also numerous stories about siblings suing siblings over farm transitions.

Besides farmers not sharing stories with outsiders, a bigger problem is when farm families are uncomfortable discussing a farm’s transition within the family itself. Then it can be difcult to get through the transition successfully and keep the family intact.

“You hear stories about farms where somebody dies, the will is read and somebody gets it all and the others didn’t get any,” Molenaar said. “There are families who will never talk to each other again, and this is real. It happens way too often.”

One pitfall, according to Molenaar, is for the retiring or leaving generation not to plan what their retirement will look like and what their retirement needs will be. This includes living arrangements such as who will live in the farmhouse or on the farm.

“What is fair versus what is equal?” Molenaar said. “Let’s say there are ve children. One stays to farm; the others move elsewhere. Is the fairest thing that everyone receives an equal share, or does the one staying on the farm need some assistance so that the farm will continue? There are some ways to look at that such as what is the contribution versus how have they been compensated.”

Shawn Meyer is a farm business management instructor at Minnesota West Community and Technical College in Hutchinson, Minnesota. He has more than 17 years of experience in farm nance and working with farm families as they plan for the future.

“I’ve sat at so many tables where I know what one of the parties is thinking, but, for whatever reason, they just won’t say it to the other one,” he said. “How do we move forward without ever communicating what my hopes, my wants, my thoughts are. Some people just give up because they have gotten nowhere for so long.”

Meyer said the process is challenging but necessary.

“It’s not fun by any means, but it has to be dealt with in order to be successful,” he said.

Attorney Shayna W. Borakove, of Borakove Osman LLC in Middleton, Wisconsin, has more

Page 10 • Dairy Star • Saturday, October 29, 2022 Quality portable roasting since 1989 800 366 3402 midwestgrainroasters.com Roa st Your Bean sRoast Your Beans Be Your Own protein SupplierBe Your Own protein Supplier Quality Roasted and steeped for By-pass protein Value Stop paying trucking, elevator fees, grain bank charges and excessive shrinks Experience We’ve roasted millions of bushels Convenience Fully equipped with fuel, electricity, boom auger discharge and operator. It only takes minutes to set up and then we roast 10 tons per hour. Hydrostatic & Hydraulic Repair Skidsteer Attachments For Sale 320-634-4360 www.stoens.com 16084 State Hwy. 29 • Glenwood, MN 56334 • Repair & Sales • Troubleshooting • Hose Assemblies • Design • Service Calls • Cylinders Toll Free 866-634-4360 320-200-1221 Visit us at www.justinaddy.com Avon, MN Covering MN, SD, IA, & WIDrink Milk Graduate of the Dairyland Hoof Care Institute Proud member of We do wide grooving and mini grooving Help keep your cows safe. Hoof trimming since 2003 WE OFFER COMPLIMENTARY: UDDER SINGEING TAIL TRIMMING Keep your cows cleaner, healthier & save time! MINI GROOVER Grooves concrete that has been already grooved. CALL FOR ALL YOUR CONCRETE GROOVING NEEDS

ADOBE STOCK PHOTO

Transi oning a farm to the next genera on involves many conversa ons and detailed planning. It’s important for families to approach a transi on with open minds.

Turn to TRANSITIONS | Page 11

Shawn Meyer West Community & Technical College

Jim Molenaar

St. Cloud Technical & Community College

than 14 years of experience as a farm continuation practice leader at her rm.

“I regularly am called in as a consult by other attorneys throughout Wisconsin regarding farm succession strategies and structure,” she said. “I have spent the majority of my life either living on a farm or planning to ensure farm families continue living on theirs.”

Borakove knows farm transition planning is different from most other kinds of estate planning.

“The farm is more than land, cows, crops, ups and downs,” she said. “It is a piece of the farmer; it’s family; it’s a belief and a core value. Farm transition planning is so difcult to begin as it is hard to put words down about something so hard to describe.”

Borakove realizes the emotions attached to a family farm add an extra challenge in farm transitions.

“This one is a big one … the failure to address and anticipate family dynamics in the planning,” she said. “The cracks and breaking points of the family and the farm should be weighed and considered. The way it was when the patriarch/matriarch acquired the farm is not the way it has

to be, nor the way it necessarily can be today.”

Molenaar said addressing family dynamics is important as well.

“It’s hard for parents to communicate plans to their children, especially if it’s not equal shares,” he said. “But, it’s really important to do if you want your family to like each other. Maybe they won’t like you, but they will like each other.”

Even though farm families know communication is key in transitions, it is often an intimidating hurdle.

“Talking about it does make one face one’s own mortality,” Molenaar said. “That can be hard. Giving up control can be really hard.”

Also, the next generation struggles to bring up the topic.

“Sometimes the younger generation is uncomfortable pushing the conversation,” Molenaar said. “Whoever has the gold gets to make the rules. The option the young person has is to say, ‘OK, I don’t want to do this.’ Other than that, it is the parents’ responsibility to start the conversation or get help in planning. If you have a plan, you can transfer management over time.”

Meyer agreed.

“It sounds so cliché, but it’s just communication,” Meyer said. “We have to be open and honest about what’s there, whether it’s good or bad.”

Molenaar agreed.

“It’s never too late to communicate,” he said.

Dairy Star • Saturday, October 29, 2022 • Page 11 Quality Consistency KLC Farms Roasting, Inc. 320-352-3326 Visit www.roastedbeans.com Preferred By Bovines Everywhere Get your cows attention • Energy • Protein • Amino acids • Bypass protein Protein Feed them KLC Roasted Soybeans! Con nued from TRANSITIONS | Page 10

Shayna W. Borakove Borakove Osman LLC.

GREENWALD FARM CENTER Greenwald, MN • 320-987-3177 WWW.GREENWALDFARMCENTER.COM DMI 530 Ecolo-Tiger ..............................$12,000 DMI 530 ripper w/leads..........................$14,000 DMI 530B w/lead ...................................$16,500 HAYING & FORAGE EQUIP. Sitrex QR12, QR10, QRS rakes ....................New Sitrex MKE 12-wheel rake ......................$11,000 H&S HM2000 9’ Inverter........................$11,000 ‘13 Vermeer 604SM rnd baler, 4,518 bales .$33,000 Ogden 12-wheel cart rake .............................$4,500 Many sizes of rakes available All Sizes of Sitrex Rakes.........................On Hand GRAVITY BOXES (2) Demco 365 ..........................$7,800 & $5,000 Many Sizes of Gravity Boxes ..................on Hand (2) Brent 644 box .......................................$18,000 J&M 385 ......................................................$6,500 Killbros 555..................................................$8,500 Killbros 555, tarp & fender ...........................$9,500 MISCELLANEOUS New Red Devil & Agro Trend Snowblowers USED TRACTORS CIH 8940, FWA, 5200 hrs ......................$89,000 CIH 8930, 2100 hrs., 2WD .....................$92,000 CIH 8910, 2WD, 4,100 hrs .....................$72,000 CIH 8920, 2WD, 3,300 hrs .....................$82,000 CIH 8920, FWA, 4,400 hrs. ....................$79,000 CIH 7220, FWA, 1700 hrs. ..................Coming In CIH 7140 Magnum, 3700 hrs .................$74,000 CIH 7130, FWA, 3500 hrs ......................$74,000 IH 806 ....................................................$11,000 IH 460 diesel ............................................$5,000 TILLAGE CIH RMX 340, 25’ ..................................$31,000 CIH 530B w/lead ....................................$18,000 CIH 527B ripper .....................................$13,500 CIH Tigermate 255, 24’ ..........................$41,000 CIH Tigermate 200, 25’ ..........................$28,000 CIH Tigermate 200, 28’ field cult. ...........$24,000 CIH RMX 340, 26’ ..................................$33,000 CIH 6750, 4 shank, 3 twist w/lever.........$15,500 CIH 530C $38,000 We have many sizes of used gravity boxes on hand Various Sizes of Rock Wagons On Hand Twine, Wrap & Net Wrap IN STOCK! DMI 530B $18,000 CIH 26’ Tigermate II 28’ rolling basket $30,000

Curds and whey

Redhead Creamery ages well, opens distillery

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

BROOTEN, Minn. –

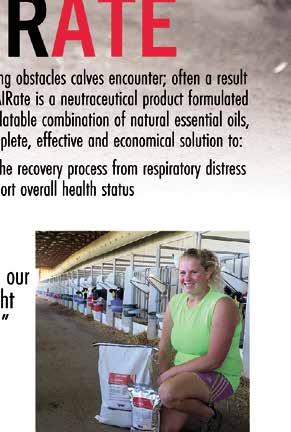

For almost a decade, JerLindy Farms has been the site of Redhead Creamery near Brooten.

From when the creamery rst began crafting cheese curds, cheddar and brie in 2013 to now being available nationwide, Redhead Creamery’s products have won the way into consumers’ taste buds.

The farm and creamery are co-owned by Alise and Lucas Sjostrom and Alise’s parents, Jerry and Linda Jennissen. The majority of the creamery’s cheese is sold through a distributor to stores such as Lunds & Byerlys, Jerry’s Foods and Kowalski’s Markets. Redhead Creamery’s cheese is also shipped to stores nationwide.

Taking things a step further, Redhead Creamery is

in the process of creating an on-site distillery in order to use the whey that is a byproduct of cheese making.

“We will be getting a lter machine that will allow us to separate the lactose from the protein that’s left

in the whey,” Alise Sjostrom said. “Then, we will ferment that lactose.”

The distillery will create and market what Sjostrom calls a clear, whey-based spirit.

With a distillery in the works and Redhead Cream-

ery growing, Sjostrom values taking time to reect.

“It’s weird to have people driving out to the middle of nowhere to come and see the cows and buy our cheese,” she said. “I get to go to stores where I dreamed of seeing my products, and

there they are. I need to stop and think about it a second, and I don’t do that enough because we are trying to get the next thing going.”

At Jer-Lindy Farms, 190 cows are milked in a double-8 herringbone parlor. The herd is comprised of registered Holsteins and Brown Swiss. Redhead Creamery uses about 12% of the farm’s milk in the production of artisan cheeses.

“I always knew, if I ever had my own family, I wanted them to grow up the way I did,” Sjostrom said. “But, I didn’t really want to milk cows, so I had to gure out what I was going to do instead.”

Three full-time and four part-time employees help with making cheese, running the on-farm store and working events. The creamery also offers delivery service, which became necessary during the coronavirus pandemic.

“There was a point where we had zero wholesale sales because restaurants closed and everything closed,” Sjostrom said. “Out

Page 12 • Dairy Star • Saturday, October 29, 2022 Bio-Vet’s quality Direct Fed Microbial supplements can provide an even greater return on investment. Bio-Vet’s quality Direct Fed Microbial supplements Improved gut health Obtain more nutrients from feed intakes Utilize high fermentation acid loads Reduce negative effects of acidosis Maintain microbial balance Also Available: Bunker Silos Feed bunks Grain Storage Water Tanks Cattle Guards Foot Baths 1-800-325-8456 LIKE US ON FACEBOOK! Out of Sight,Out of Mind MANURE STORAGEANURE Visit us on the web: www.wieserconcrete.com UNDERBARN SLATTED FLOOR MANURE STORAGE SYSTEM

PEOPLE MOVING PRODUCT

TIFFANY KLAPHAKE/DAIRY STAR

Cheesemaker Alise Sjostrom stands at the store counter Sept. 30 in Redhead Creamery in Brooten, Minnesota. At Jer-Lindy Farms, 12% of the milk produc on is used for the creamery.

Turn to REDHEAD | Page 13

of necessity, we needed to move cheese. We started delivering door to door.”

Redhead Creamery is open to the public Friday and Saturday afternoons. The shop offers pan-fried cheese curds, paninis and cheese platters as well as beer, wine and cider. During store hours, the creamery offers farm tours. On the third Saturday of June, the creamery holds its biggest event called Curd Fest.

“It’s a huge celebration of agriculture and cheese curds,” Sjostrom said. “We have live music, and we bring in other food makers and vendors to sample and sell their products as well. We also have food trucks.”

Redhead Creamery aims to create the best cheese possible through a willingness to experiment and learn, always starting with quality ingredients.

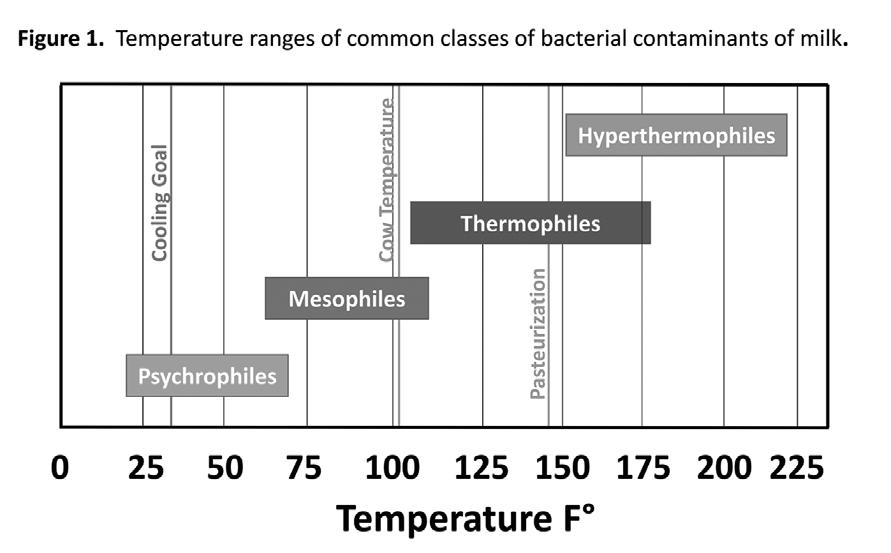

“At the very basic for making cheese, you need milk, cultures, rennet and salt,” Sjostrom said. “You have to start with good quality milk. If you start with crappy milk, you will have crappy cheese.”

Many variables are involved in creating cheese texture and avor.

“It’s not just one thing that makes the cheese what it is,” Sjostrom said. “During cheddaring, we might manipulate the avor by nishing it off differently, for instance cave aging it in a different humidity and temperature, and end up with a completely different cheese than if we vacuum sealed it and put it in a cooler.”

Redhead Creamery uses both techniques and many others.

For instance, they wash wheels of cheese to make avors such as the Tipsy Tilsiter, washed with cider from Milk and Honey Ciders. There is also the St. Anthony, which is selling well seven years after the rst was made.

“It was our rst award-winning cheese,” Sjostrom said. “We wash that one with whiskey from Panther Distillery to create a fun rind.”

Since then, other varieties of Redhead Creamery cheese have won awards at the Minnesota State Fair and in other contests.

Sjostrom said being asked to pick her favorite Redhead Creamery cheese is like being asked to pick her favorite child, but she admitted her favorite is the North Fork Munster.

“I wanted a soft, stinky, alcoholwashed cheese, and that’s what this is,” Sjostrom said. “It’s our most challenging and frustrating cheese, but when it works, it’s my favorite.”

After graduating from the University of Minnesota and moving to Vermont because of her husband’s job, Sjostrom worked in the retail shop for a cheese company and learned about European-style cheeses and specialty food marketing. The couple visited breweries and cheese companies on weekends.

“It was fun, but we were learning,” Sjostrom said. “We picked the brains of other makers and asked questions. We went to cheese companies at ve in the morning to watch them get started.”

When they moved to Wisconsin, Sjostrom worked for Crave Brothers Farmstead Cheese but made trips to Vermont to take cheesemaking classes. During these years, she continued to plan for Redhead Creamery.

“From ideation to actually making something took a good 10 years of planning,” Sjostrom said.

Today, the Sjostroms have three children: Lucy, Henry and Conan. And, like Sjostrom had hoped, the Sjostrom children are growing up on the farm.

“Originally, I imagined it would be me and my mom making cheese, and that would be it, which is nonsustainable,” Sjostrom said. “When I was not here, cheese was not made, so I had no life when we rst started. Now I have this awesome group of people who are able to help make this happen. As my kids are growing and I want to go do things with them, I can do that.”

Dairy Star • Saturday, October 29, 2022 • Page 13 Kreofsky Ag Systems (507) 534-3855 WWW.KBSCOMPANIES.COM COW COMFORT IS OUR PRIORITY! AQUASTAR Ultimate Waterbed and Aqua Board MAGELLAN Rubber Flooring www.brynsaas.com Lots of Used Mixers • Variety of Manure Pumps and Tanks All on Hand! 1660 Jordan West Rd., Decorah, IA 563-382-4484 2012 GEA SP-3B-9 $9,250 1979 Brenner 6200 Gallon $29,500 2014 GEA EL-48-6D-6100 $86,500 2014 GEA EL-54-4450 $39,500 2015 GEA EL-84-5000 $46,500 2014 New Holland 195 $18,000 VERTICAL TMRS LLC

Con nued from REDHEAD | Page 12

TIFFANY KLAPHAKE/DAIRY STAR

Employees of Redhead Creamery prepare to make cheese Sept. 30 in the creamery’s lower-level. Customers at the creamery can watch through the store’s interior viewing windows.

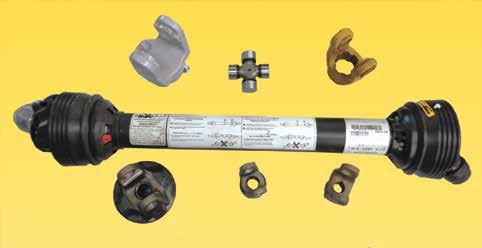

Page 14 • Dairy Star • Saturday, October 29, 2022 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH Friendly & Knowledgeable Parts Department We Understand The Frustrations of Breakdowns We Are Here To Help! SpeeDee Delivery Available! Mike, LaShana, Dan & Gene SAU M i n n e s o ta ’s LargestFeeding and ureHandli n g D e a rel Man Ifyouhavea barn, we haveasolution.www.dairylandsupply.com PTO Parts Available On Hand

F r o m O u r S i d eFrom Our Side

O f T h e F e n c eOf The Fence

Eric Otte Randolph, Minnesota Dakota County 600 cows

Eric Otte Randolph, Minnesota Dakota County 600 cows

When did you start and nish corn silage harvest? We began the second week of September, and it took two full weeks to complete.

How many acres did you harvest and what was the tonnage? We harvested around 9,500 tons on about 350 acres.

What other crops do you harvest in the fall and how is the harvest coming for those? We strictly harvest corn in the fall and began Oct. 18. This fall has been going great because of how dry it has been, but also not so great because of how dry it has been. We are getting anywhere between 220-230 bushels per acre and have about a week left of harvesting.

What other eldwork do you have left for this year? We have a lot of corn stalk bales to do. We don’t plan on doing much tillage because of how dry it has been, and we don’t want to dry the ground out any more. We’ll also do some ripping on the headlands just to break up the compaction.

What was the biggest challenge you encountered during the growing season or while harvesting this year? The biggest challenge for us has been the dryness. We had to run the irrigator so much that we had a lot of breakdowns on the irrigator. We were changing gearboxes all summer long because they were running so often.

What is your favorite part of the fall harvest? My favorite part is hauling corn and driving truck. It’s my favorite job to do in the fall.

Tell us about your farm. We milk 600 Holsteins and raise our own youngstock. We have 1,500 acres and raise our own crops. My mom, dad, brother Tyler and myself are all full time on the farm. My other brother, Bret, helps part time, and my ancée, Laura, helps and drives grain cart.

Chris Hedtke Mayer, Minnesota Carver County 70 cows

When did you start and nish corn silage harvest? We started Sept. 9 and nished Sept. 16. Then, we did a small bag a couple weeks later of some late-planted corn when we got our rst frost.

How many acres did you harvest and what was the tonnage? Normally, we do 45 acres, but this year, it took 55 because the tonnage was down. We don’t track our tons per acre. We chop until our four bags are full.

What other crops do you harvest in the fall and how is the harvest coming for those? We did our high-moisture corn Oct. 10-11. That yielded close to 200 bushels an acre at 27% moisture. We’ve been hauling our corn to the elevator for our dry corn, and it has been yielding between 170-180 bushels to the acre at 20% moisture. We have 40 acres of corn that will be combined this week.

What other eldwork do you have left for this year? We have most of our tillage left. We have a small amount of corn stalks to bale.

What was the biggest challenge you encountered during the growing season or while harvesting this year? We were wet in the spring so we planted later than normal. Then, in July, we were short of moisture, which caused the yields to be down from last year. We are happy how everything turned out. The crop could have been a lot worse. I’m thinking plowing will be a challenge this fall because the ground is so hard and dry.

What is your favorite part of the fall harvest? I enjoy when we chop silage. We have a tradition with our family to pick a night or two to have supper in the eld. The kids enjoy it.

Tell us about your farm. My wife, Kirsten, and I have four children, Maddie, Hallie, Grace and Joey. We are in partnership with my mom and dad, Joni and Curtis. We milk 70 cows and raise our replacement heifers and farm 300 acres of corn and alfalfa.

How far along are you with the fall harvest?

Duane Suess Sleepy Eye, Minnesota Brown County 200 cows

When did you start and nish corn silage harvest? We started around Sept. 10, and we were done in about a week.

How many acres did you harvest and what was the tonnage? We do about 110 acres of silage, and the tonnage was similar to last year. We chopped around 2,000 tons.

What other crops do you harvest in the fall and how is the harvest coming for those? We did 100 acres of earlage in late September. It was running around 230 bushels an acre. That’s about normal. We only had 7.5 inches of rain this summer, so I am happy with my yield. We had 100 acres of soybeans, and they ran in mid-50s.

What other eldwork do you have left for this year? We are doing grain corn now. We are on our last 90 acres, and we have 800 acres of total corn acres. When we started the corn Oct. 10, that ran 19%-20% moisture. Now, it’s down to 14%-15% so we can run it right in the bin and blow air on it. We have some fall tillage done and have a lot of round bales to do yet. We try to do around 600 rounds and have done around 300.

What was the biggest challenge you encountered during the growing season or while harvesting this year? The dryness, but I’m surprised how good the crop was. It was a wet spring, and then, it turned dry.

What is your favorite part of the fall harvest? Combining, that’s my favorite part of the whole year. It’s a joy harvesting.

Tell us about your farm. I farm with my son, Craig. He is the third generation on the farm. We milk 200 cows and farm around 1,050 acres; that includes acres my son farms. We milk our cows in a double-8 parlor. We feed our Holstein steers and buy extra as well. We ship our milk to First District Association.

Dairy Star • Saturday, October 29, 2022 • Page 15 Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant. Contact Star Blends at: 800-462-4125 or StarBlends.com Feeding your animals like they’re our own y

Turn to OUR SIDE | Page 16

Marvin Amundson

Westby, Wisconsin

County

cows

When did you start and nish corn silage harvest? We nished the rst week in October. It took two days with a custom harvesting crew.

How many acres did you harvest and what was the tonnage? We harvested 60 acres, and it came to 29 tons per acre.

What other crops do you harvest in the fall and how is the harvest coming for those? We harvest soybeans, high-moisture corn and dry corn in the fall. Everything is late this year so we have not started on any of them yet.

What other eldwork do you have left for this year? Besides harvesting the rest of the crops, we usually make about 300 shred bales for heifer bedding.

What was the biggest challenge you encountered during the growing season or while harvesting this year? Not being able to get parts when there were breakdowns.

What is your favorite part of the fall harvest? Everything. It is my favorite time of the year because it’s not too hot outside, and I love eldwork.

Tell us about your farm. I have been farming here for 47 years. We crop 375 acres. My wife, Chris, farms with me and is also a eld representative for Westby Creamery. Our son, Kyle, is transitioning into taking over the operation. We have been milking with robots since May 2021.

Brad Medek Pierz, Minnesota Morrison County 250 cows

When did you start and nish corn silage harvest? We started Sept. 10 and nished Sept. 20. We put it all in a bunker. The bunker is 80 feet by 250 feet with 8-foot side walls. We harvested it with a 6-row self-propelled and hauled with seven boxes.

How many acres did you harvest and what was the tonnage? We did about 300 acres at about 5,000 tons. It was a good year but not our best. We got a little dry at the end. We were very fortunate. The cattle will stay fed for another year.

What other crops do you harvest in the fall and how is the harvest coming for those? Two weeks ago, we did 200 acres of soybeans. That ran between 20-30 bushels an acre. That’s on sandier soil so we were happy with it. We have 350 acres of corn to combine for high moisture. We started that last week. It’s running 20%-31% and is 130140 on the yield. In between that, we were picking rocks for a couple weeks. We picked 100 acres on land we plan to seed alfalfa in. We have a lot of rocks.

What other eldwork do you have left for this year? We are working on emptying the lagoon as we are combining. We have 2.5-milliongallon lagoon. We have 1.5 million gallons to haul yet. We top applicate it and then disc it in. We have done 150 acres of tillage. We also have to do corn stalks and usually do at least 500 bales.

What was the biggest challenge you encountered during the growing season or while harvesting this year? The high fuel price and operating costs. Diesel fuel is still around $5. We got dry at the end of August, and it’s been dry through. We are really dry, but it makes harvesting really easy.

What is your favorite part of the fall harvest? All your work is nearly done. The end is in sight. I really like to combine.

Tell us about your farm. I am in partnership with my nephew, Riley Schlegel, and we milk 250 cows and farm 1,100 acres. We typically grow corn, soybean, alfalfa and grass hay. We milk our cows in a double-10 swing parallel parlor, and we have one freestall barn. We ship our milk to First District Association.

Vernon

200

Page 16 • Dairy Star • Saturday, October 29, 2022 Con nued from OUR SIDE | Page 15 820 W. MAIN ST. • CHILTON, WI 53014 920-849-9304 www.ddequipment.com 2014 Penta 6020SD $23,000 Penta 6030 $28,500 Penta 6730 Call for Price NEW & USED Penta 5530 Call for Price Penta 9630 Just In! Call for Price Penta DB 50 1 left - $89,500 WE ALSO CARRY THESE BRANDS: Equipment We service all brands Proudly madein CENTRAL IOWA SERVING NE IOWA & SW WI MIDWEST ALKOTA 18297 LINCOLN RD. • FAYETTE, IA 563-425-3219 Doug Kiel MIDWEST ALKOTA 103 5TH ST. • GRUNDY CENTER, IA 319-215-2138 Taylor Appel pel 563-42 Dou Excellent Aluminum Cleaner! Great for livestock trailers and cleaning milk stone off bulk tanks, or any other aluminum on your dairy farm! Pressure Washers – Stationary & Portable 300° Steam Combo Units hersWasssurePre &aryStation Po lertab Put more steam into your cleanING

Target Your Customers! Advertise Online at www.dairystar.com If you would like to advertise, call 320-352-6303 for more information.

Dairy Star • Saturday, October 29, 2022 • Page 17 JOIN OUR TEAM Now Hiring Service Technician Intern Apply Now! SCAN ME bit.ly/3fwYBl6 Paid Internship +1-800-636-5581 | Proudly serving you from Brookings, SD; St. Peter, MN; and Melrose, MN! DEALER Cutting-Edge Milking Equipment | Supply Delivery | Preventive Maintenance Herd Advisory & Software Support | Manure Management Services | Feed Management farm-systems.com © 2022 Farm Syststeems. All rights ts rese re rved. A-3386648395 Need Service? Keep your operation up and running with Farm Systems Your Local Milking, Manure and Feed Management Solutions & Service Provider

Zimmermann

110 cows

Sauk Centre, Minnesota Stearns County

Describe your farm and facilities. We milk in a double-8 parallel parlor. The dry cows are in a pole barn with a bedding pack. We farm 300 acres of corn, soybean and alfalfa.

What forages do you harvest? Corn silage, haylage, dry corn, high-moisture corn and soybeans.

How many acres of crops do you raise? We have 75 acres of alfalfa, 80 acres of corn for silage, 80 acres for grain corn and 80 acres of soybean.

Describe the rations for your livestock. We feed a mixture of corn silage, haylage, dry or wet corn (depending what we have at the time), and a protein mix.

What quality and quantity do you harvest of each crop? As much and as good as we can get. Qual-

ity is important to us. We get 68% moisture for corn silage, and we get 25-30 tons per acre. We always get four cuttings of alfalfa, and sometimes, we even

get ve. We get 12-14 tons of haylage a year and harvest at 50% moisture. We chop everything and put it in a pile.

Describe your harvesting techniques for alfalfa and corn silage. We chop all the alfalfa and put it in a pile. We custom-hire someone to chop the alfalfa. We

also custom-hire someone to harvest corn silage, and we use all our equipment to pack the pile. We customhire for our harvest because it’s cheaper than owning large enough equipment to get the crops harvested fast enough at the right time to get the best quality feed.

What techniques do you use to store, manage and feed your forages? We let silage sit for three months before we open the bag. For haylage, we like it to sit a month before we use it, but sometimes we run out and will need to start using it sooner. We put everything in bags or piles. We cover the pile with tires, so that the tires are tire to tire.

How do quality forages play into the production goals of your herd? It is a must to get good quality feed for our cows. To get good quality milk, we need to feed our cows good quality feed. We work closely with a nutritionist to monitor the quality of each bag

Page 18 • Dairy Star • Saturday, October 29, 2022 Harvesting Quality Forages 507-879-3593 – 800-821-7092 Box 116, Lake Wilson, MN 56151 – www.bluehilltop.comBox 116, Lake Wilson, MN 56151 – www.bluehilltop.com Blue Hilltop, Inc. SUPERIOR LOOK, BUILD & PERFORMANCE The KUHN Knight PS 250, 260 & 270 ProSpread® apron box manure spreaders are high-capacity, noncommercial spreaders designed for feeder, cow/calf, and dairy operations that process a wide array of semi-solid and solid materials. PS 270 models feature heavy-duty vertical beaters, equipped with 5/8” (1.6 cm) flighting and hardened steel beater tips, providing a durable beater capable of handling almost anything. ENOGENFEED.COM University of Nebraska-Lincoln Research Studies, 2013-2017; Kansas State University Research Study, 2017; University Research, 2019. rch S tudies, 2013-2017; K udy, R es GET THE ENOGEN ADVANTAGE according to recent feeding trials at leading universities Enogen ® corn for feed can help deliver improved feed efficiency to help lower feed costs. Mike

TIFFANY KLAPHAKE/DAIRY STAR

Lori and Mike Zimmermann farm 300 acres and milk 110 cows near Sauk Centre, Minnesota. The Zimmermanns closely monitor their forage to ensure the quality of their milk.

Turn to FORAGE | Page 20

“Udder Comfort™ is a big help on our dairy. We use it on all fresh cows and for any cow with signs of mastitis. It helps our milk quality too. We love it!” says Brandon Grewe. He and his wife Kim met in 2010 when Brandon wanted to buy a cow from Kim and her dad. Today, they operate Valley Gem Farms, milking 180 cows near Cumberland, Wis., and the cow that brought them together was dam of homebred 7-year-old three-peat World Dairy Expo grand champion Valley Gem Atlas Malt-ET EX96 97MS

Malt’s first world championship was in 2019 as a 3-year-old. The show was canceled in 2020. Then, in 2021, Malt came back just fresh and was grand champion again. In the same lactation, she achieved the three-peat as grand champion Guernsey of WDE 2022.

Kim recalls 2021: “Malt was just 20 days fresh at Expo that year and made grand champion -- and best udder -- for the second time. Udder Comfort works!”

Dairy Star • Saturday, October 29, 2022 • Page 19

— Kim and Brandon Grewe

VALLEY GEM

FARMS, The Grewe Family, CUMBERLAND, WI 180 Guernseys, Jerseys and Holsteins 67 lbs/cow/day, high components, SCC 140,000 Home to Valley Gem Atlas Malt-ET EX96 97MS “We love it for our fresh cows... It did wonders for Malt!” Quality Udders Make Quality Milk For external application to the udder only after milking, as an essential component of udder management. Always wash and dry teats thoroughly before milking. 1.888.773.7153 uddercomfort.com Maximum Results Minimal Cost Call to locate a distributor near you. Get Your Farm Shop Stocked for the Busy Fall Season with Martin Welding! DRAG LINE Plenty in Stock! WITH OR WITHOUT FITTINGS METAL 360 FITTINGS IN STOCK! 102480 Cty Rd N, Colby, WI 54421 (715) 223-3211 Shipping available on all parts. Wholesale opportunities available. DEALER FOR Your Specialists for ANY Liquid Manure Handling PARTS | SERVICE | REPAIR High pressure hoses & couplers · Drag lines · Knife valves · Swivels Replacement parts for any liquid manure tankers or spreaders Custom galvanized gates available ALWAYS IN STOCK: Many Brands of Bearings · Balder Electric Motors · Pulleys Sprockets · PTO Parts · Gates Belts & Hydraulic Hoses—huge selection in stock (custom sizes available) Hundreds of belts, bearings, bolts, sprockets in stock! WE CAN SHIP

and pile when we open it to feed our cows so we can adjust the ration if needed.

What management of harvesting techniques have you changed that have made a notable difference in forage quality? We switched from baleage to haylage. For us, it saves a ton of time and money doing haylage versus baleage. The biggest thing we have learned is to pack the piles as best

we can. The more packing the better, so we drive over it with a tractor and blade.

Describe a challenge you overcame in reaching your forage quality goals. The biggest challenge for us each year is the weather. Getting enough rain throughout the growing season and then not raining while we are trying to harvest.

Page 20 • Dairy Star • Saturday, October 29, 2022

Con nued from FORAGE | Page 18

TIFFANY KLAPHAKE/DAIRY STAR Tony Schlangen, Mike Zimmermann’s brother-in-law, drives combine as Mike’s daughter, Daisy, drives grain cart Oct. 21 near Sauk Centre, Minnesota. The Zimmermanns worked to

ll

a bag of high-moisture corn.

Stand out from the herd. DAIRY ST R 522 Sinclair Lewis Avenue, Sauk Centre, MN | 320-352-6303 | www.dairystar.com Professional Print, Website & Sign Solutions for Farms & Small Businesses Contact your area sales representative listed in First Section, page 2 to learn how our customized services can help your farm or business!