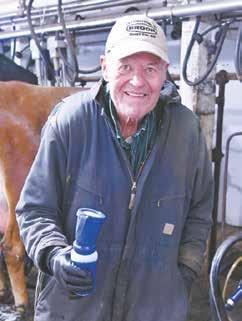

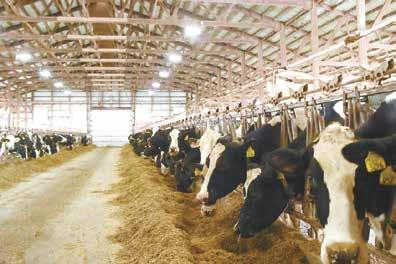

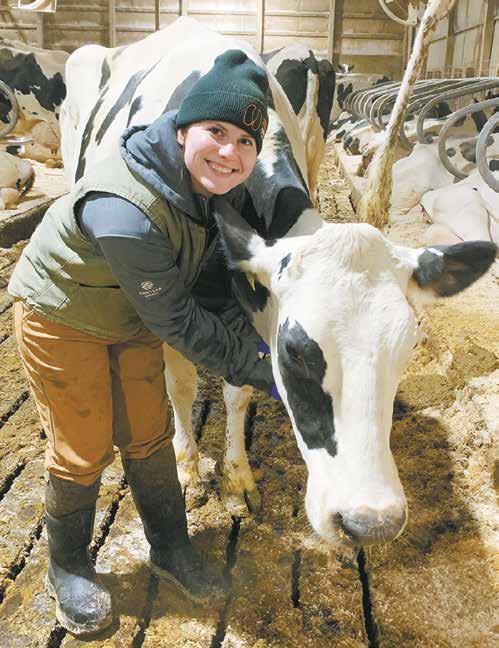

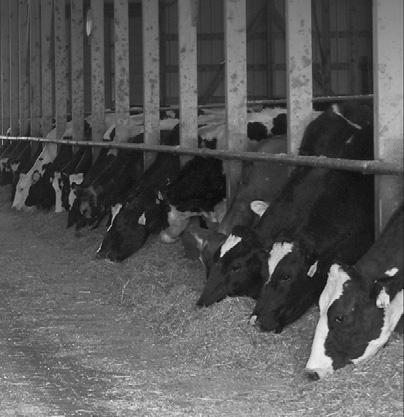

Gary Hillesheim pauses during evening milking Jan. 30 at Riverside Dairy near Sleepy Eye, Minnesota. Hillesheim starts morning chores each day at 4:30.

By Amy Kyllo amy.k@star-pub.com

SLEEPY EYE, Minn. — For over 65 years 79-year-old Gary Hillesheim has been working on his farm, Riverside Dairy, near Sleepy Eye.

“That’s all I know,” Hillesheim said. “I never thought of doing anything else.”

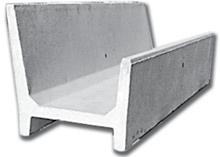

Hillesheim will turn 80 in May. He farms alongside his wife, Rosie, and daughter, Stacy Tauer, and her and her husband Ron’s children, Nick and Sidney. They milk 70-80 cows in an 8-stall stanchion at parlor. The herd is housed in a sawdust compost pack barn.

Tauer has been working full time alongside her dad for 20 years. She nishes beef on the side and plans to eventually take over the family dairy.

“All

By Dan Wacker dan.w@dairystar.com

WAUKON, Iowa — July 27, 2024, started like every other morning at Ronan Family Dairy Farm near Waukon. Jim Ronan went to the barn to move cows around and get prepared for milking and the hoof trimmer, who was coming that day. While moving a cow to the barn, he was hit by the farm’s 3,000-pound bull.

Before he knew what happened, Jim was on the ground being pushed around by the bull, who had been on the farm for over 18 months without any signs of aggression.

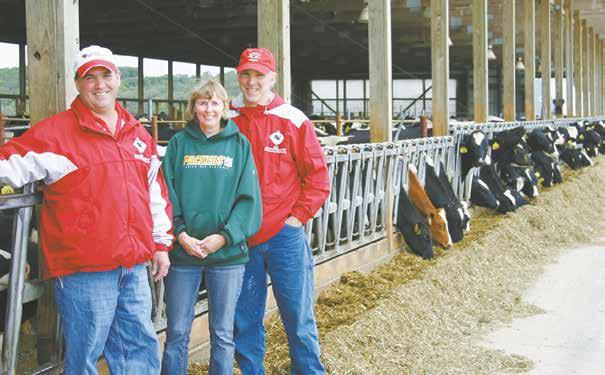

EDEN VALLEY, Minn. Tim and Megan Schrupp have accomplished being active both on their dairy farm and in the dairy industry on the local and national levels. Tim and Megan were named First District Association’s Young Cooperator of the Year. The Schrupps and Megan’s parents, Vern and Mary Kay Becker, own and operate NexGen Dairy LLC where they milk 1,000 cows near Eden Valley.

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, SD, Nebraska) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Keya Sleister (Eastern IA, Southwest WI, IL) 563-608-5988 • keya.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

and

Ronan stands outside his shed Jan. 22 on his farm near Waukon, Iowa. Ronan Dairy Farm has had milking cows since 1855.

“He hit me right in the back and I didn’t realize what was happening until he rolled me and I was looking right at him,” Jim said.

The bull continued to roll Jim across the barnyard, rolling him directly into the side of a steel feed bunk. That is when Jim heard the crack of his ribs breaking. Out of the corner of his eye, he saw his dog, Miley.

“I yelled to Miley, ‘Get him,’ and she took off after him,” Jim said.

The Australian Shepherd pushed

the bull back 20 feet, to the entrance of the barn. This gave Jim the time he needed to try to stand up. On a knee, with his hands ready to push himself back up, he saw the bull again.

“Miley had come over by me, but when I saw the bull again, he was on a full sprint,” Jim said. “I yelled to Miley to get him again, and she went right back after him. If it wasn’t for her, there’s no way I could have gotten out of there.”

Jim rolled into the steel bunk and

out of the pen to safety. He pushed open the gate and made his way up to the house where he found his wife, Sara. Sara called emergency services and their son, Tyler Ronan, who works sideby-side with his dad on the farm and lives a few miles down the road.

“I could barely hear what she was saying,” Tyler said. “The one thing I did understand was ‘The bull got Dad’.”

Tyler found his dad sitting at the kitchen table, with an ambulance on the way. His older brother, Brandon, a strength and conditioning coach at the University of Northern Iowa, happened to be visiting and helped Jim prepare for the arrival of the paramedics.

“The ambulance came, and the medics took one look at me and immediately called for the helicopter,” Jim said.

While Jim was in the ambulance, Miley stayed nearby. The dog sat next to the ambulance for as long as she could until Tyler needed to pull her away.

Jim was own to La Crosse, Wisconsin, where he underwent a CT scan and x-rays. It was discovered that he had eight broken ribs, six on his right side with multiple fractures in each rib, and two on his left. The muscles on his spine were pulled away from the bone, leaving a basketball-sized indent.

Turn to RONAN | Page 5

by

“We began looking at a bottle washer to keep bottles cleaner and eliminate an extra job. After seeing the option to purchase the bottle washer and pasteurizer combination, we started to look at its benefits. Once we calculated what we would save by not buying bags of milk replacers, it was an easy decision to add the pasteurizer. Since installing the new system of the bottle washer and pasteurizer combination the calves drink better and are healthier.”

Back at the farm, Tyler was left to milk their 80 cows in the tiestall barn and get ready for the hoof trimmer.

“Once word got out, I couldn’t keep up with my phone with people who were reaching out,” Tyler said. “I had to put it away so I could get something done, and I didn’t have an update for them anyway.”

When Tyler nally did answer the phone, it was his mother calling from the hospital.

“She immediately started telling me that Dad was trying to make sure I was going to mix feed right and which cows I needed to have sorted for the trimmer,” Tyler said. “He was still giving me orders from the hospital, and it was then that I knew he was going to be alright.”

Tyler is the sixth generation at Ronan Family Dairy Farm. The family has been milking on the same farm since 1855 and earned a Heritage Farm Certicate from the Iowa Department of Agriculture and Land Stewardship.

the Ronans realize that what started as a surgery to keep one of their top cattle dogs around, turned into a life-changing decision.

At the hospital in La Crosse, Jim was already trying to get back home.

He was told it would be at least a week before he would be released, and he had an array of physical tests he needed to pass. It started with a breathing capacity test, three unassisted walks around the hospital, and a test with the physical therapist requiring him to get in and out of a car without assistance.

Jim passed all the tests, and three days after being own in, he was on his way back home.

“I wouldn’t be here today if it wasn’t for Miley.”

JIM RONAN, DAIRY FARMER

Following the incident, the bull was shipped two days later. Using a skid loader, Tyler moved the bull into the milking barn and set the gates to load him onto the trailer. Once the gate opened, the bull was not ready to depart.

“When I couldn’t get him out of the barn, I knew exactly who to call,” Tyler said.

Miley was called back into action and loaded the bull onto the trailer and off the farm.

Two years prior, Miley had her own health scare. A working dog, Miley had injured her hip working cattle. Initially, the dog worked through her injury and was back to working cattle how she was accustomed to, until one day she could not move her back legs. The Ronans took her to the vet and were informed Miley needed hip surgery. Now

“The people at the hospital were tremendous, but I just knew I couldn’t stay in there any longer than I had to,” Jim said.

Upon his return, Jim needed to use a walker to get around and had a hospital bed brought into the lower level of his home.

Tyler kept the farm going while Jim recovered, with help from his girlfriend, Karly Hemmersbach, and several nephews who helped on the weekend.

“That stretch was tough during the week because the work for two of us fell completely on me,” Tyler said. “It made for some long days, but we had a lot of family and neighbors asking how they could help. We had great support. That’s just what we do around here. When someone needs help, we’re all willing to lend a hand.”

Two and a half months after the attack, Jim was back in the tractor chopping corn.

“I wouldn’t be here today if it wasn’t for Miley,” Jim said. “I wouldn’t have time with my grandkids. It really makes you think about the little things. Maybe slow down, spend more time with family. It denitely makes me appreciate my dog a lot more.”

“I never, in my wildest dreams imagined my dad would still be milking,” Tauer said. “At age 65-70 I was like, ‘OK, now Dad, you can start slowing down.’ … He actually sped up.”

At 75, she said he had a few health issues and had a pacemaker installed, so she braced herself for potential retirement.

“He just jumped right back up again with even more energy than he had before,” she said.

Tauer feels lucky she said. Working alongside her parents is a blessing.

Hillesheim said he is not interested in retirement.

“What am I going to do?” he said. “I have to have something to do or I’ll go nuts. It’s just not good. Retirement stinks.”

Family is part of what has kept her dad dairying Stacey said, along with his passion for farming. Besides herself and her children, other family members are involved in the dairy as well. Her brother, Mitch, helps with repairs. Her sister, Nikki Fischer, and her husband, Darrel, and their family, who live across the road, help during extra busy seasons such as haying time. Her niece, Sophie Kyllonen, helps as able as a college student.

Hillesheim and Rosie raised their ve children on the farm. He said family is the best part of dairy farming.

“A lot of people don’t see their kids all day long,” he said. “When they come home from school, you’re here. It’s just nice. That’s one thing you’d never give up.”

Rosie agreed.

“This is a family farm,” she said. “Gary and I and Stacey are in that barn every morning at 4:30.”

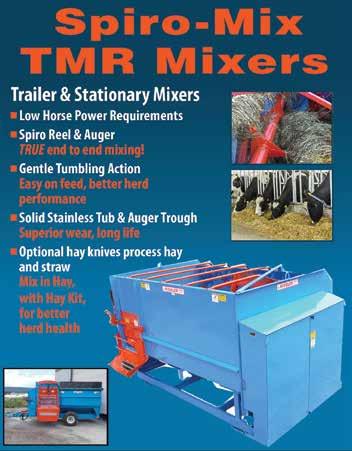

Each day Hillesheim starts his day by getting cows in for milking, followed by feeding and mixing total mixed ration. At 2:30 or 3 in the afternoon, he is back out to run off the TMR and mix the batch for the next day before joining Tauer in the parlor.

Riverside Dairy has 360 acres. Most of the acreage is devoted to growing alfalfa and corn for the cows, but about 80 acres are used for soybeans and 40 for sweet corn. Tauer said Hillesheim loves driving tractor and does 75% of the eldwork.

The dairy has changed since 1945, the year Hillesheim was born. In his

childhood, the barn was a 20-stall stanchion with additional stalls for the 14 horses that helped operate his dad’s threshing machine. Hillesheim remembers driving the horses just once. Other than threshing, they were used little since tractors were quickly becoming the only horsepower used on the dairy.

In 1959, they put in a bulk tank. Hillesheim’s younger brother by three years, Dean, hauled the milk from the barn to the milk house until he went to college. Then, the farm got a step saver.

In 1963, Hillesheim, alongside eight other young men from the area enlisted in the U.S. Army National Guard to avoid going overseas to Vietnam. He enlisted before he was 18 and a half because if he enlisted before this date the time commitment was 3.5 years versus six years.

Hillesheim was at basic training in South Carolina when John F. Kennedy was assassinated Nov. 22, 1963.

“That whole camp just stopped dead,” he said. “We didn’t know what was going to happen. I don’t think anybody did. That was awful.”

In 1964, Hillesheim was invited by a friendly sergeant to go on a tour to Germany.

“He said, ‘Gary, you going to go along with me?’” Hillesheim said. “I said, ‘I have to go home and farm.’”

The Hillesheims were milking about 30 cows when he returned home to dairy in 1964. In the early 1980s, the pipeline went in. In 1995, Hillesheim added to the barn and doubled the herd to 60 cows. In the 2000s they built the compost barn.

Hillesheim has seen changes in technology over the years. Having a gutter cleaner, silo unloader, TMR mixer and skid loader are among some of the pieces of technology he said have been most useful. Looking to the future he said he thinks robots will be more prominent as labor is hard to nd.

“It’s hard to tell what’s all coming,” he said. “Everything’s changing so fast. Equipment is getting so big. Big isn’t big enough anymore and it’s expensive too.”

Looking to the future, Hillesheim hopes he can continue to pass up retirement for a couple more years.

“It’s going to come sooner or later I’m sure, but not as long as I can keep moving,” he said.

Along with the award, the Schrupps were delegated to be a part of the National Young Cooperators Program. When the Schrupps attended the program, they decided to get more involved.

The Schrupps applied to be on the National YC Program’s advisory board, which is funded by National Milk Producers Federation, and were selected. Then, the Schrupps took their role a step further by applying to be the chair of the advisory board. After a vote by the board, the Schrupps were named this year’s chair for the National YC Program.

“We were very excited to get voted in,” Megan said. “This will be a good way to nish out our time on the YC board.”

Tim agreed.

“We thought it would be a great way to get involved and hear what is going on nationally,” he said. “We will get to network, listen and learn from other young farmers and leaders from across the country.”

The National YC Program puts on webinars and meetings throughout the year. It also hosts a dairy policy and legislative forum in Washington, D.C., and workshops at World Dairy Expo and the joint meeting of NMPF and the National Dairy Promotion & Research Board.

“Being in (Washington) D.C. is really cool because we get to go into the legislator’s ofces and lobby,” Megan said. “You get to see the whole process the legislators go through and how stuff gets done.”

There are eight young farmers on the National YC Advisory board from across the country. As chair, the

Schrupps will attend all in-person workshops, quarterly meetings, additional webinars put on by the YC Program and attend all the NMPF meetings.

“We will get to be a little further involved because we will represent the YC group to the board,” Megan said.

Tim and Megan have been active on the young cooperative board with First District Association since 2014. Over the past 10 years the couple has helped coordinate the annual bingo night, sum-

mer for 4-H,” Megan said. When Tim’s family quit milking their registered Guernsey herd, the Guernseys came to NexGen Dairy. NexGen Dairy was formed in 2016 and has now grown to milking 1,000 cows in a double-16 parallel parlor three times a day. The mixed herd is primarily Jersey but also includes Jerseycrosses along with about 30 registered Guernsey cows and Guernsey heifers. Megan said at NexGen Dairy everything is done on-site — including raising their own replacements, veterinary work and hauling manure — by Tim, Megan, Vern or one of their employees. Megan is a licensed veterinarian and is in charge of managing the cows. Tim works with their nutritionist to develop the rations and takes care of the equipment, crops and manure management. Megan’s sister, Ellen Stenger, helps with accounting for the farm. She also helps with the farm stand, NexGen Market, where she and Megan sell homegrown produce, maple syrup, honey, fresh cut owers, tallow soaps and balms.

mer picnic and winter conference that the board orchestrates each year.

“Gaining leadership skills is big part of why we do this,” Tim said. “Seeing how our local cooperative works is neat too.”

The couple is using those leadership skills by also being involved with the Minnesota Guernsey Breeders Association and by leasing their registered Guernsey cattle to local youth to show at the Meeker County Fair and at the Midwest Guernsey Show.

“We don’t have kids of our own but we lease Guernseys to 14 kids all sum-

“You can do the day to day on your farm, but you have to be willing to share your story,” Megan said. “If nobody goes out there and speaks up, we will be faced with a lot of unfair policies.”

The Schrupps have learned a lot by being involved with their local cooperative they said. Now they are bringing those skill sets to the national level to make a difference in the dairy industry.

“I think it’s great for personal and professional development,” Megan said. “Less and less people grow up on farms so it’s important to stay involved locally and nationally to stay abreast of what is going on. It’s nice to be involved to know both what is coming and how policies and decisions are being made.”

CLAAS builds custom cart for young wheelchair user to operate on family’s dairy

By Amy Kyllo amy.k@star-pub.com

Editor’s note: This story comes as an update to a story from Kellogg, Minnesota, which Dairy Star published on Oct. 26, 2024, entitled, Finding his own way to help: Franke assists with chopping using motorized wheelchair, coaster wagon.

OMAHA, Neb. — After reading about 9-year-old Memphis Franke helping Evers Dairy haul corn silage last fall with a Radio Flyer coaster wagon pulled by his motorized wheelchair, Tyler Roucka, the JAGUAR self-propelled forage harvesting marketing manager for CLAAS of America, wanted to do something.

Roucka said the photos of the coaster wagon, which had been loaded by a CLAAS self-propelled forage harvester, stood out because he thought CLAAS could upgrade Memphis’ wagon.

A bit of brainstorming with the product team and several months of work later, Memphis was presented with a custom CLAAS wagon Jan. 20 at the CLAAS showroom in Omaha.

When he rst received the gift, Memphis’ mom, Tracy Franke, said

20 outside the CLAAS manufacturing plant in Omaha, Nebraska. The Frankes traveled to Omaha for a meal, tour of the plant and to receive the wagon and gi s inside for Memphis.

Memphis did not realize it was for him.

“I said, ‘Memphis, this is all for you, they made this wagon for you,’” Tracy said. “He had tears in his eyes and obviously turned away. He didn’t want to be embarrassed because he was crying. He had so much joy that they made him a wagon.”

Memphis’ grandparents, Mark and Janet Evers, are part owners of the Evers Dairy farm near Kellogg, Minnesota. The dairy milks about 2,600 cows and includes about 20 family members plus employees.

Memphis received the gift with

18 family members, extended family members and Evers Dairy employees there as guests of CLAAS to cheer him on.

“Meeting Memphis and his family just really solidied that he’s in really good hands, and that they want him to be a part of the dairy operation and day-to-day farm activities,” Roucka said. “I just hope that the cart can do everything and anything that he wants it to do.”

Memphis has Duchenne’s muscular dystrophy, a rare form of muscular dystrophy which causes muscle degeneration over time. He was diagnosed at the age of 3, and, in 2021, he lost his ability to walk and started using a wheelchair.

“We have a lot of sad days dealing with this disease,” Tracy said. “These good days, these fun days give us strength to get through the bad days. You remember the joy felt during these incredible acts of kindness and generosity.”

Memphis’ mom, and his dad, Kevin, had been collaborating with CLAAS to keep the gift a surprise.

The gift was revealed using a CLAAS JAGUAR self-propelled forage harvester. After taking a family picture in the showroom, the family stepped back to give Memphis center stage. The 50th Anniversary JAGUAR in the showroom was started, and the spout, which was attached to a tarp covering the gift, was raised to reveal the wagon lled with CLAAS swag.

Turn to FRANKE | Page 12

House Agriculture Committee Chairman Glenn ‘”GT” Thompson did not give a timeline for the farm bill but said it would happen sooner rather than later. “The longer we wait into the fall, the more likely we’re going to have to come back next December and ask for more economic disaster relief,” Thompson said. “Producers don’t want that and we don’t want to do that; we won’t have to do that if we get this farm bill that has such a strong safety net component in it passed sooner rather than later.”

Consumer demand highlighted at International Dairy Foods Association meeting

Associated Milk Producers recognized for export excellence

Minnesota Governor Tim Walz presented Associated Milk Producers Inc. with the Governor’s International Trade Award. This award recognizes businesses that have shown exceptional progress and results in foreign markets. AMPI began a targeted export program in 2020. Today, more than 20% of the co-op’s packaged cheese production is sold overseas. Sliced American cheese, loaves and shreds of natural cheese are now distributed to 14 countries, primarily in Asia, the Middle East-North Africa, Central America and the Caribbean.

Speaking at the International Dairy Foods Association Dairy Forum, IDFA President and CEO Michael Dykes discussed everything from tariffs to ag labor, articial intelligence to sustainability. Consumer demand was also touted. “Per capita consumption’s increasing butter is at levels we haven’t seen since the 1950s,” Dykes said. “They (consumers) also voted with their wallets. (We) saw double-digit growth in categories like cheese, probiotic yogurts and specialized nutrition products. Ninety percent of consumers have no plans to reduce their dairy product purchasing behavior.”

Cattle supply shrinks again

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty.

Model VP CA: Belt Drive, 1 HP, 115/230 volt, 9.6/4.8 amps single phase one speed 587 rpm

By Don Wick Columnist Ag Insider

The U.S cattle supply is at its lowest point in 64 years. According to the U.S. Department of Agriculture’s annual cattle inventory report, the total number of cattle and calves is 86.7 million head. That’s down 0.6% from a year ago. Beef cow numbers are down a half-percentage point from the same time in 2024. Beef heifer replacements declined 1%. The dairy cow inventory is nearly unchanged from a year ago, while the number of dairy replacements dropped nearly 1%.

Slaughter cow prices remain strong

The price of cutter cows has risen for eight consecutive weeks. According to a report from Urner Barry, the price of these slaughter cows is $238 per hundredweight. That’s up from $185 at the beginning of the year. Year-over-year, these prices are up nearly 29%.

Minnesota Milk Producers Association calls for exibility in paid leave requirements

Minnesota’s Earned Sick and Safe Time law requires employers to provide paid leave to employees. Minnesota Milk Producers Association Executive Director Lucas Sjostrom testied before the state legislature on behalf of S.F. 310, which would amend the 2024 ESST law to exempt agricultural businesses with ve or fewer employees. “Over the past 12 months as farmers are dealing with this law farmers have talked about the cumbersome process and how this doesn’t work well for agriculture with seasonality and only hiring some workers for a season.” An exemption to the ESST law already exists and Sjostrom hopes it can be expanded to include broader operations. “There is already an exemption for sugar beet farmers if they hire someone for, I believe less than about 21 days, and I think the same thing should happen for dairy farmers.”

Dairy innovation

The latest issue of Food Business News highlighted new dairy ingredient innovations. Fit Butters LLC of Minneapolis was cited. The company produces nut butters formulated with whey protein isolate to create avors like Boston Cream Pie Cashew. A New York company, David, is selling the David Protein Bar. The high protein bar is made from milk protein isolate, collagen, whey protein concentrate and egg white. Dry dairy ingredients, like casein and whey, have a neutral color and avor prole, which is favored over plant proteins.

The American Farm Bureau Federation presented its highest honor to former House Agriculture Committee Chairman Collin Peterson, the Distinguished Service to Agriculture Award. During his comments, Peterson recognized two special guests sitting in the crowd: House Agriculture Committee Chairman Glenn “GT” Thompson and new Ranking Member Angie Craig Peterson said he worked with Craig for many years. “She has just done an outstanding job for us in Minnesota and also on the committee, she’s someone you can work with and she gets it, she understands agriculture.” Peterson said he represented a Republican district for 30 years and Craig is doing the same thing. “She’s representing some real solid red areas and she’s outperforming other Democrats by quite a bit and that’s why she is now the ranking member of the committee.”

Vilsack returns to Iowa

Former Agriculture Secretary Tom Vilsack will take over as the chief executive ofcer of the World Food Prize Foundation. Vilsack succeeds another former Iowa governor, Terry Branstad, in the role. Vilsack’s ofcial start date is March 1.

Minnesota FFA Hall of Fame class of 2025 named

Seven individuals will be inducted into the Minnesota FFA Hall of Fame this spring. The Class of 2025 includes A.J. Duerr, Lynn Ketelsen, Sarah Kuschel, Shawn Linder, Dr. Amy Smith, Al Stemp and Dr. Curtis Youngs. Duerr has championed legislation to help advance ag education. Ketelsen is an award-winning farm broadcaster and longtime FFA supporter. Kuschel is the regional Ag in the Classroom coordinator and supports the Sebeka FFA Alumni and Friends and Minnesota FFA. For 22 years, Linder has been an ag instructor at Grand Rapids. Smith is a program leader of agricultural education at the University of Minnesota. Former Foley FFA ag teacher and FFA advisor, Stemp helped start the successful chapter. Youngs is a former Minnesota state FFA ofcer and is now the endowed chair of international animal agriculture at Iowa State University.

Trivia challenge

Dairy cows can produce up to 125 pounds of saliva per day. That answers our last trivia question. For this week’s trivia, how many essential vitamins and nutrients are found in milk? We’ll have the answer in our next edition of the Dairy Star. Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

“The

In addition to production and SCC, we use the milk pregnancy test, MUN, Johne’s and Leukosis.

Which is your favorite and why? The production and SCC.

How do you use them within your dairy? We use the production and SCC reports for culling decisions and use the fat, protein, and MUN reports to evaluate feed ration changes.

How long have you been using the DHIA pregnancy test? We have been using the milk pregnancy test for about two years.

What do you like about the DHIA Pregnancy Tests? It’s nice to be able to do the pregnancy test without any extra time or labor.

How does testing with DHIA bene t your dairy operation? We use the information to improve production and ensure milk quality. The negative herd tests for Johne’s and Leukosis help with marketing show and breeding stock. The milk pregnancy test provides timely information for reproductive management between vet herd health checks.

Tell us about your farm. I farm with my wife, Barb, and two youngest sons Benjamin and Daniel. We milk 85 cows. The boys plan to take over the farm in the near future. We raise farm 560 acres and corn, oats, alfalfa and grass.

Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

USED TRACTORS

CIH 8910, 1955 hrs., 2WD, like new$105,000

CIH 7120, 2WD, 5800 hrs. ................$55,000

CIH 7110, 2WD, 4500 hrs..................$63,000

CIH 5250 2WD, 4,700 hrs. .............. $54,000

CIH MX120, 2WD, 3,800 hrs. ............$72,000

CIH MX120 w/loader ........................$75,000

IH 1456, cab ..................................... $22,000

IH 1466, 6800 one-owner hrs ............$21,000

IH 686 . ..............................................$14,000

‘98 JD 7610, 19 spd., PS, 5,500 hrs., 25 MPH, very sharp ....................... $75,000 McCormick MC120 FWA, 2,600 hrs ..$57,000

TILLAGE

CIH Tigermate II, 26’$28,000

CIH Tigermate II 26’ w/rolling basket $32,000

CIH Tigermate 200 w/basket, 34’ ..... $42,500

CIH Tigermate 200, 28’ w/rolling basket ...............................$40,000

CIH Tigermate 200 28’ w/basket ...... $37,000

Tigermate 200 28’ w/rolling basket ....$31,000

DMI Tigermate II, 26.5’, 3-bar mulcher ..................................$14,000

CIH RMX 340, 28’ w/mulcher ...........

(Right) Memphis Franke pulls his new custom CLAAS wagon as a CLAAS employee looks on Jan. 20 in the CLAAS showroom in Omaha, Nebraska. Franke pulled the wagon in the showroom for about an hour a er receiving it.

(Below) Mabel (front, from le ) and Memphis Franke along with the Franke family and extended Evers family and Evers Dairy farm employees stand Jan. 20 near the wagon CLAAS of America made for Memphis at the CLAAS showroom in Omaha, Nebraska. Memphis Franke has plans to use his new wagon for hauling wood, water for the swimming pool, shelled corn, and, of course, corn silage.

Tracy said she was emotional watching her son receive the gift.

“Even I had tears, … seeing the joy,” she said. “He was so happy with it. … Immediately we had to hook it up to him because he wanted to pull it around. … Then he took off with it. He was just whipping around in the

store.”

Roucka said Memphis pulled the wagon around the showroom for about an hour. Roucka had initially worried whether the wagon would be suitably navigable, but his fears were soon eliminated.

“He was a pro within about 30 seconds of it being hooked up,” he said.

The wagon bed, which latches to the frame in the front has a sloping back end. Once unlatched, it tips back to unload. The wagon can accommodate up to 400 pounds of weight. The

tires are big, suitable for traversing elds.

Roucka said CLAAS purchased the cart from an Amish company, Pinecraft. Then, they painted it CLAAS colors and had it wrapped by a local company in specially designed CLAAS wrap patterned after the wrap used on their European dump trailer, CARGOS.

Memphis already has plans of using the wagon to haul wood, water for the swimming pool, shelled corn, and, of course, corn silage.

“I want it to be something that he’ll enjoy,” Tyler said. “I hope that it provides everything that his grandparents and family members would love for him to utilize to be more part of (the farm).”

Along with the gift, the Franke

family and the group from Evers Dairy enjoyed a meal catered for them by CLAAS and members of the family took a tour of the facility.

Tracy said they wanted other family members and employees from Evers Dairy to join them because of all they have done for Memphis to allow him to be part of the dairy.

“The farm has done such an amazing job with Memphis,” she said.

Tracy said the trip to CLAAS came at an almost perfect time as the Franke family is approaching the anniversary in February of Memphis’ diagnoses.

“That smile just said it all,” Tracy said. “(That) warmed your heart up. … (We can) help him ght this battle.”

Bill

Demerath

(pictured with Jessi Fanta)

Demerath Farms Inc

Plainview, Nebraska

Antelope County 240 cows

What method do you use to recruit quality employees? Currently, it has been through word of mouth. I have a group of people that I call if I am looking for help and usually that will result in nding someone.

How many employees do you have, and what are their duties? I have three other employees whom I work alongside. I have a herd manager, Jessi Fanta, who runs the barn and dairy side of the farm. The other two guys mainly work on the dairy side, which consists of feeding calves and general barn work in the robot barn. They also help with other farm work if needed.

When you hire an employee, what is the onboarding process? We break down the daily responsibilities of each employee. This is so new employees have a clear understanding of their specic duties. This leads to the overall positive production of our cows.

How do you remain competitive in retaining employees? I have a good wage that I pay my employees. I also try to keep a good working environment and atmosphere around the farm, so they are happy where they are at.

How do keep your staff motivated? I am out in the barn with them, and we are pretty relaxed throughout the workday. We have fun while we work, and we all work together and help each other out. The big thing is that they see that I am out there doing all of the work with them and that I do not ask them to do anything I would not do myself.

What is a benet your employees receive? I have specic goals on the farm for which employees get a bonus if they are reached. For Fanta, this is based off production.

Tell us about your farm and family. Demerath Farms Inc. was started in 1976 by my dad, Jim, and grandfather, Edward. I returned to the farm in 2000. At that time, we upgraded our double-4 herringbone parlor to a double-8 parallel parlor and milked 150 cows. In 2017, we built a robot barn with four Lely robotic milkers and currently milk 240 cows. I have three employees including Fanta. We are a closed herd, so we raise all of our own youngstock. We farm around 900 acres and grow our own feed. I have a 12-year-old son, Quinn, who helps on the farm as well. My mom, Jane, lives at the dairy and is helpful with running errands.

Michael Kolb (pictured with Alayna (middle) and Nicole Kolb)

Paynesville, Minnesota

Stearns County

430 cows

What method do you use to recruit quality employees? We go with recommendations from current employees. We also get people stopping in sometimes looking for work and we have hired some of them.

How many employees do you have and what are their duties? We have ve employees. Their duties include milking and scraping and I have one designated for animal health who takes care of breeding and works with our veterinarian to ensure the animals stay healthy. We have one employee, who is bilingual, who helps us with recruiting and training.

When you hire an employee, what is your onboarding process? Employees are rst trained with owners and we go over protocols and procedures. Then they are trained by other employees. We also have industry folks who come in to do employee training. For example, Form-A-Feed has some bilingual people who can come out and explain things. We have some people from the National Dairy Farmers Assuring Responsible Management program come in and show some videos too.

How do you remain competitive in retaining employees? We provide onsite housing and bouses for milk quality.

How do you keep your staff motivated? We provide trainings and offer incentives to keep somatic cell count low. During training sessions, we bring food in. What is a benet your employees receive? We have quality bonuses when somatic cell counts are kept low and have holiday bonuses.

Tell us about your farm and family. Our farm was started in 1861. We are milking in a double-12 parlor. We raise all our own feed and replacements. We farm 2,000 acres of corn, soybeans, oats and alfalfa. Three of my brothers — David, Leon and Jason — work on the farm as well. David’s daughter, Alayna, works on the farm too and is the herdsperson and manages employees in the parlor. We all have our own responsibilities. I am in charge of feeding and parlor maintenance. David and Jason do the crop management. Leon does the transition cow management. David’s wife, Nicole, helps with the calves and wherever is needed. Jason does the maintenance and repairs in the shop.

Bryce Peters (pictured with his wife, Katie, and children, Macey and Archie) Chaseburg, Wisconsin Vernon County 300 cows

What method do you use to recruit quality employees?

I heavily rely on my current employees' thoughts and considerations when it comes to bringing on a new employee. They are the ones doing the work and typically have a good feel for who will work out well here.

How many employees do you have, and what are their duties? We have four full-time employees and eight part-time employees who do milking, scraping, eldwork and maintenance.

When you hire an employee, what is the onboarding process? Onboarding depends on the position. There is some paperwork, educational videos and a lot of hands-on training.

How do you remain competitive in retaining employees? We give them something they can't get at another job: exibility in hours; opportunity to put in a lot of hours; fun, enjoyable work; and being part of a good team.

How do keep your staff motivated? We share with them the success of the farm and treat them as a valued team member.

What is a benet your employees receive? Education, especially for younger employees. There is no better place to learn basic mechanical skills, teamwork, the importance of hard work and animal stewardship than on a farm.

Tell us about your farm and family. Peters Farms has been shipping organic milk since 1988. We also raise organic hogs and laying hens. The current owners of the farm include my uncle, Roger Peters, and cousin, Russell Peters.

John Rosenhammer

Sleepy Eye, Minnesota

Brown County 200 cows

What method do you use to recruit quality employees? The vast majority of our employees are high school kids. A few come back during college breaks and over the summer. I rarely have to look for employees; most of them are friends of present workers who are interested in working for us. Sometimes, I visit with employees during school or community events. The hours we require are from 4-6:30 in the afternoon. This time frame seems to t very well with the high school aged students.

How many employees do you have and what are their duties? We have a pool of about 10 employees available throughout the year, depending on school activities. We expect them to show up at 4:00 p.m. and be nished and heading home by 6:30 p.m. Their duties are to milk cows, move cows, scrape pens, bed stalls and clean up the milking parlor after.

When you hire an employee, what is your onboarding process? I work with the employees and go through the basics of what I expect. I prefer to milk beside them and to work with them as different situations arise and show them how to problem solve.

How do you remain competitive in retaining employees? I think the key to keeping employees happy is working with and beside them. I never expect them to do anything that I wouldn’t want to do myself. I never refer to milking as ‘work’ but rather, try to create an atmosphere of fun. Often, I ask what is going on in their lives and try to encourage them, thus building relationships. Also, I am very understanding when unexpected things come up in their lives, because I also had ve kids of my own.

How do you keep your staff motivated? Our help is paid per milking, rather than by the hour. I always preach efciency. I am amazed how their speed improves after they gain condence and experience. I always try to complement them for their work and thank them for coming.

What is a benet your employees receive? We provide bottled water, cookies and ice cream treats. Occasionally, they are lucky enough to have Patty’s Special K Bars. In the past, we have taken hay rides to graduation parties and participated in various parades. We’ve also had “end of summer” bonres in the evenings. A time or two during Christmas break, we have hosted an afternoon of card games at our house.

Tell us about your farm and family. Our dairy is a family-run partnership started by my parents and is now managed by my brother, Greg, and me. We milk two hundred cows in a double-12 parallel parlor. Family help has always been the driving force behind our dairy. Greg is in charge of the crops and mixes feed. Laura lls in if necessary and is responsible for vaccinations and repro checks. Mary milks most week-day mornings and helps with odds and ends to keep the farm looking neat. Becca tries to help with morning milking one day a week. Joe operates a custom-farming business and lls in when needed. Johnny has a year left in the military and is anxious to get home and join in somewhere. During harvest, we are fortunate to have uncles and cousins help with harvest, tillage and maintenance. Dairy farming is the best way to raise a family.

Brent Ziegler

Green Isle, Minnesota

Sibley County

355 cows

What method do you use to recruit quality employees? We currently use our team members to recruit additional people. We have a very good team right now and I trust their judgment. This is also helpful because they know who they will be compatible with. In the past, we used advertisements in the local newspaper. This was very effective but not as much anymore.

How many employees do you have, and what are their duties? We currently have six full-time and six part-time team members. All full-time employees take a milking shift and then do general farm work for the rest of the day, including hauling manure and eld work. Two of the part time people are my relief feeders and help me with eld work and more extensive repair projects. The other part-time people take milking shifts, mainly on the weekends.

When you hire an employee, what is the onboarding process? New employees work with existing team members for a period of time until they are procient in their assigned tasks. I will follow up with the new people at the end of their rst shift and a couple of days in to see how they are doing. I am always there for the

person’s rst day to show them where to park, where the bathroom is, how to do their timecard, and most importantly, when they are going to get paid.

How do you remain competitive in retaining employees? We stay competitive nancially with the local area. We don’t necessarily compete with other farms; we mainly compete with manufacturing for our labor force. Most importantly, we treat our team like human beings. I say “Good morning” or “Hello” to everyone at the beginning of their shift and “Goodbye” and “Thank you” at the end. I am also trying to learn Spanish so that I can communicate better with everyone. They seem to appreciate me trying to do this.

How do keep your staff motivated? Similar to the previous question. Also, allowing opportunities for growth is very important. People want to be able to grow their skill base and know that what they do matters. We are currently growing the business to accommodate this.

What is a benet your employees receive? We pay overtime over 40 hours per week and double time on eight holidays. We also pay out any unused earned sick and safe time at the end of the year to make sure that everyone is treated fairly. We used to provide health insurance but found out that people preferred more money instead because they were getting health care through their spouses.

Tell us about your farm and family. My wife, Sarah, and I have two boys. Matthew is a junior majoring in data science at the University of Minnesota. Tommy is a freshman majoring in mechanical engineering at the University of WisconsinStout. We farm about 600 acres. Sarah is involved with the nancial management and human resource side of our business. We are very fortunate to sell our milk to Bongards.

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk three times a day. Our current rolling herd average is 34,518 pounds of milk, with tests of 4.6% butterfat and 3.3% protein. We peaked last June at 35,420 pounds of milk, with 4.6% butterfat and 3.3% protein, and an energy-corrected rolling herd average of 41,611 pounds of milk.

Describe your housing and milking facility. Our primary barn is a 6-row, sand-bedded free stall with tunnel ventilation. The fresh cow barn is a single-row, 20-stall barn that’s also has sand-bedded free stalls. Both barns have longday lighting. Cows are milked in a double-12 parallel parlor.

Who is part of your farm team, and what are their roles? Tim oversees employees and helps his wife, Sandy, with bookwork and does the clearing of the heifer shed and waste management. He also works with the veterinarian for the herd. Mark does the record keeping of cattle vet work and mixes feed while managing the repro vet work and records. Sandy is the farm bookkeeper and handles calf care. Andrew, Tim and Sandy’s

Mark (from

Wisconsin. The Kellers currently milk 293 cows with a rolling herd average of 34,518 pounds of milk, with tests of 4.6% bu erfat and 3.3% protein.

son, also works as part of our crew. He helps with the day-today chores, feeding calves and other daily duties.

What is your herd health program? We use weekly pregnancy checks and utilize a double ovsync program for breeding. Fresh cows are vaccinated every 28 days with

Bova Shield and J-5. At dry off, cows get J-5 and SRP Salmonella vaccine. Calves and heifers get Bova Shield and Ultra Back-7 twice.

What does your dry cow and transition program consist of? Dry cows are housed in our old dairy barn set up with tunnel ventilation and sand-

bedded free stalls. Far-off dry cows are fed a dry cow diet with low-potassium grass hay, corn silage, hay silage, winter rye and a mineral mix. The prefresh group gets a milk cow ration along with some Reashure and X-Zelit for two weeks before calving. We have about a 50-day dry period. Cows calve in a large pack pen next to the

pre-fresh group. Heifers calve in a pack next to the pre-fresh group. After calving, both heifers and cows are moved to our post-fresh cow barn for 3-4 weeks. Post-fresh cows get fed the milk cow ration along with some Nutra Cal and Reashure and a top dress of some nice grass hay.

What is the composition of your ration, and how has that changed in recent years? The main cow diet is a total mixed ration of corn silage, hay silage, winter rye silage, cotton seed, dry distillers grain, high moisture corn and dry corn, both ground fairly ne, 5 pounds of alfalfa hay and some liquid molasses along with a protein mix with all the goodies in to balance the ration. Over the past several years, it seems we are going to more of a corn silage-based diet and less alfalfa hay silage. The ration is balanced by our nutritionist, Bob Hagenow, with Vita-Plus.

Tell us about the forages you plant and detail your harvest strategies. Alfalfa has been harvested for extra seed for about 13 years and we try to run a 5-cut system on 28 day

“We’ve used Udder Comfort™ over 10 years: Blue spray on fresh animals and lotion with massage for any flareups. We tried others but always came back to this product because it works,” says Staci Sexton. In 2013, she started Schoene Kuh Dairy, today milking 60 registered Holsteins and Jerseys with a genetic focus on production, health traits, and components. Along with the Irish Ridge herd of her parents and brother, where she helps with herd work, 125 cows are milked at the Millville, Minnesota dairy farm that has been in the family over 160 years.

Schoene Kuh is German for ‘beautiful cow.’ Staci loves working with cows and genetics, earning progressive breeder and milk quality awards. Her 9th AI bull in 10 years is a homozygous polled, high cheese merit bull named King Kong.

“It’s exciting to breed, flush, and wait nine months hoping to get something great,” she says, and when it comes to first calvers “we use Udder Comfort to reduce swelling. Fresh heifers are comfortable with better, faster milkout. It’s easy to use and helps keep our SCC low.”

The farmsite

cut. For corn silage, we plant conventional corn that is tall with high grain yields. We believe this gives us high starch feed and higher tons per acre.

What is your average somatic cell count and how does that affect your production? Our somatic cell count generally is around 120,000. Our goal is to produce very clean, high-quality milk.

What change has created the biggest improvement in your herd average? Our single-row fresh cow barn added a couple thousand pounds to the RHA 14 years ago. In the spring of 2021, we updated the ventilation system in our main barn to a tunnel ventilation system and that added another 3,000 pounds to the RHA.

What technology do you use to monitor your herd? We have the DelPro Activity system from DeLaval to help monitor cows, both high and

low activity. With the DelPro system we also have daily milk weights. With both activity and milk, we can follow if cows are in heat, sick or humming along just ne. We have Dairy Herd Improvement approved meters, so each time we test cows the 7-day running average is what DHI uses for a cow’s milk weights. This makes for a very accurate and reliable test.

What is your breeding program, and what role does genetics play in your production level? Our breeding program is simple: use good bulls. We have had this philosophy for 50 years now. We mainly use high Type Production Index bulls that are 1,2001,500 pounds plus for milk, plus for fat and protein, and 1-2 points for type with sound feet and legs and good udders. We like pretty cows, but they must work. We also look at Net Merit and have an understanding of where it comes from. We are looking more at

Cow Conception Rate. We are a very genetic base herd. We like our high production, putting bulls in bull studs but also enjoy making a nice show cow or heifer for showing.

List three management strategies that have helped you attain your production and component level. Our top strategy is to use good bulls that have a high genetic base that will set you up for the long haul. Cow comfort is our second strategy. We love our sand bedding. As Bob Hagenow of Vita Plus says, “Clean, dry and comfortable.” We say, “We take care of our cows so they can take care of us.” Our third strategy is using high-quality forages. You need good forages to make optimal and economical milk.

Tell us about your farm and your plans for the dairy in the next year. Kellercrest is a genetic-based herd. We believe in longevity and old cows.

We just had our 21st cow go over 300,000 pounds of milk lifetime. We work as a leader trying to protect our local watershed from waste runoff. We have planted cover crops for almost 20 years now, and contour farmed for 50 years. We take care of our cows and land so they can take care of us. As for plans for this year, we just want to continue to try to make high-quality, economical milk. At some point, we would like to upgrade our dry cow facilities.

JD 1780 2001, #587172 .................................................................

JD 1790 2003, 24,000 Est. Acres, #579847

JD 1790 2014, 8000 Est. Acres, #584396

JD 1790 2009, 20,000 Est. Acres, #591065

JD 1790 2014, #583560 .................................................................

JD 1795 2023, 700 Est. Acres, #573347

IH 2150 2021, 4500 Est. Acres, #569307

3500

Contact one of the following dealers to

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA

712-476-9290

United Dairy Systems, Inc.

West Union, IA

563-422-5355

Monticello, IA

319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI

715-772-3201

Bob’s Dairy Supply Dorchester, WI

715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI

608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH DAKOTA

Farm Systems

Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN 320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

By Dan Wacker dan.w@dairystar.com

RIVER FALLS, Wis. —

The University of Wisconsin–River Falls recommitted itself to dairy food production education with the addition of the Wuethrich Family/Grassland Dairy Center of Excellence. A project 11 years in the making, the dairy pilot plant opened its doors in October 2023, revitalizing the efforts of UWRF to be a leader in the food science world.

Rueben Nilsson, the dairy pilot plant manager, and Mike Orth, the dean of the College of Agriculture, recognize how special it is to have this type of plant available for students interested in food science.

“It’s critical to have this on campus,” Orth said. “I think a differentiator between us and other schools is that we’re really student driven. The faculty do a lot of the teaching, and we want the students to get in there and get their hands dirty.”

With over 90% of the state’s milk going towards

cheese production, the University saw the need to train students with hands-on experience to better prepare them for the workforce.

Nilsson works with UWRF faculty and others in the dairy industry to help train the workforce on the school’s new equipment.

“There’s only UW-Madison and us who can provide this kind of learning experience,” Nilsson said. “I get to work with some of our professors and help them craft what they want to do in the pilot plant.”

The plant helps provide a hands-on learning experience partnered with traditional classroom education. The experience that is offered students of working directly with food production can help illuminate career opportunities that were previously unknown.

“The plant helps provide more awareness of our food science degree,” Orth said. “Very few students come in interested in these areas until they learn about it here. With a food science degree, and the work experience we can of-

fer, there are plenty of job opportunities after graduation.”

UWRF had a dairy plant on campus starting in the 1980s, but with outdated equipment, the plant shut its doors in 2018. Former director of dairy production, Michelle Farner, led the charge for funding the new facility.

What started as a smallscale project gained traction from businesses within the dairy industry and led to a 6,000-square-foot, $9 million facility. Donations included over $5 million from businesses, $1 million from the Wuethrich family and the state funding the balance.

The plant works in conjunction with Mann Valley Farm to bring in milk for use at the dairy plant. Along with the campus farm, the plant provides opportunities for departments across campus to learn in a real-world scenario.

“There’s the marketing side of it,” Orth said. “We could go to computer science and use some traceability software and reporting. There could be a student project that could use some of that data, the art department could create artwork for labels. It’s a really strong opportunity to work with other departments on campus.”

Orth said that kind of synergy is something UWRF can benet from.

“It’s critical that we work with other departments within our university,” Orth said. “The better you can integrate students and faculty from other colleges, the more benets you can see.”

The on-campus dairy plant provides Nilsson and his staff with a chance to learn new techniques and take chances to create something new. They can also partner with other departments on campus to potentially ll a need.

“We’ve talked with the athletic department about what kind of product we could produce that they nd benecial,” Nilsson said. “Could we produce something high in protein for a post-workout beverage or product? We’re continuing to nd these opportunities as we go and expanding what we can create.”

Most recently, Nilsson began developing a nacho cheese to use on campus in concession stands during events.

The dairy plant’s nacho cheese was projected to be unveiled at the UWRF Science Olympiad Border Battle Jan. 25. Other products Nils-

son cooked up include a variety of avored cheese curds, including chipotle, gochujang and chili lime. The opportunity to create new products and be creative is what intrigued Nilsson.

“That was one of the big attractions to the job, the freedom to play with whatever I wanted to try making and providing experiential learning for our students,” Nilsson said.

Being a newer plant, not all cheese types have yet to be duplicated. A challenge the plant faces is storage space to provide more opportunities to expand its line of products.

“We’re limited on space as far as aged cheese,” Nilsson said. “But the avored younger cheeses are where we can really start to work.”

Nilsson’s background in cheese production helped the plant start production as soon as possible with the rst batch of cheddar produced in March 2024. Nilsson and his team will focus on ice cream production soon.

“I’m excited to start working with the ice creams,” Nilsson said. “We need to nail down our base rst, get that vanilla right, and then we can continue to add in more toppings.”

“Do

Reduce cost, intake, over-conditioning with high-ber diet

By Stacey Smart stacey.s@dairystar.com

MARSHFIELD, Wis.

Forage-based diets containing large amounts of corn silage or other high-quality forages often exceed the energy needs of growing dairy heifers. When consuming such diets, heifers usually eat more than they need, leading to undesirable weight gain and over-conditioning.

Research has shown that increasing ber in the pregnant heifer diet reduces unnecessary intake. Diets focused on ber typically reduce feed intake in pregnant heifers by 10%.

Matt Akins is a dairy scientist and research leader in the Environmentally Integrated Dairy Management Unit with the U.S. Department of Agriculture-Agricultural Research Service’s U.S. Dairy Forage Research Center.

Sorghum-sudangrass is cut Sept. 22, 2017, at the University of Wisconsin-Marsheld Agricultural

eld, Wisconsin. Research studies have shown sorghum-sudangrass to work well as a high-ber forage in

to control feed intake.

Having more body fat can cause hard calvings and problems into early lactation.”

“We don’t want excessive condition going into lactation,” Akins said “An ideal body condition score for heifers is 3.25-3.5. We don’t want heifers coming in at 4-plus.

Akins and his colleagues have conducted studies using higher ber forages in the diets of animals that have been bred or conrmed pregnant. Over the last several years, their studies have focused on forages capable of increasing ber and diluting energy in rations.

“Feeding a higher ber diet with lower energy was the goal, and we found that heifers fed this diet have more optimal weight gain,” Akins said. “They eat less and gain a more appropriate weight, compared to

feeding a higher energy diet based on corn silage and alfalfa.”

Akins’ work is based on the fact that dairy heifers generally eat about 1% of their body weight in ber each day.

“The rumen can only t so much ber in it,” Akins said. “We can use that to our advantage by feeding higher ber diets to control feed intake.”

Nutrition targets for the pregnant heifer diet are 50%55% neutral detergent ber, 55%-60% total digestible nutrients and 13%-14% crude protein.

“That puts us pretty close to where we need to be for energy,” Akins said.

When feeding a high-ber diet, Akins has found that

feed intake is often reduced by 5%-15%, depending on forage type and ber levels, with a 10% decrease being typical.

Akins said a gain of 1.82.2 pounds per day is ideal growth for a Holstein heifer, and heifers on these higher ber forage diets are reaching this level of growth. On the other hand, heifers consuming diets of corn silage and alfalfa containing 45% NDF and 65% TDN were gaining 2.5-3 pounds per day in Akins’ studies.

“If we go above 2.2 pounds, heifers start to get overweight and have too much condition,” he said. “They put less growth into muscle and more into fat, especially as they get closer to

maturity.”

Akins said this is particularly problematic in connement situations where heifers get less exercise. In ultrasounds on pregnant heifers consuming a high-ber forage diet, researchers saw less fat growth on heifers’ backs and less internal body fat, particularly on the kidneys.

Furthermore, frame development on heifers is as good or better on these diets as it is on a higher starch corn silage diet.

Through their testing of various forage options, Akins and other researchers have discovered that any higher ber forage can accomplish these weight goals.

He said sorghum-sudangrass works fairly well as do other types of straw. Wheat straw, corn stover, and Eastern gamagrass are some of the forages Akins and colleagues have conducted studies on at the University of Wisconsin-Marsheld Agricultural Research Station.

“Any of these three works well, especially gamagrass in a chopped corn silage,” Akins said. “Corn stover tends to have problems with sorting if it’s not chopped down ne enough. It’s necessary to process wheat straw and corn stover more aggressively to ensure heifers eat it.”

A distant relative of corn, Eastern gamagrass is a perennial warm-season grass that can survive winter conditions. It thrives on a one-cut harvest system, with yields maximized during mid-to-late September and concentrations of neutral detergent ber ranging from 75%-80%. During feeding trials, heifers did not exhibit sorting behaviors with Eastern gamagrass.

Akins plans to do additional testing on other forages in the next few years.

“There are a lot of options people are working with,” he said. “It depends on the agronomic system on your farm and soil conditions.”

Akins said one example that can potentially work well in heifer or dry cow rations is long-day corn silage. It never fully develops an ear and therefore yields a lot of forage tonnage without grain.

Akins and his team continue to investigate new types of forages and plan to do feeding trials with long-day

Pregnant heifers eat a high-ber ra on at the University of Wisconsin-Marsheld Agricultural Research Sta on near Marsheld, Wisconsin. The diet contains Eastern gamagrass as the high-ber forage source, in addi on to corn silage and alfalfa silage as the forage base.

corn silage in a couple of years. They are also looking at pearl millet as a future option.

“Depending on how you manage it, pearl millet would be a fairly good candidate for this type of diet,” Akins said. “We did some test plots on it last summer and are going to do more in the upcoming year.”

Large-scale eld studies and feeding studies on pearl millet are in the works for 2026. He said they rst need to tweak agronomically how to plant the crop and get a better stand.

From 2021-2022, Akins was part of a study done on the perennial intermediate wheatgrass crop, Kernza. After harvesting the grain, the stem and

leaf material is harvested like wheat straw. During a feeding trial, the team found that Kernza worked well in a heifer diet and could be a good replacement for wheat straw.

Lower feed costs is another benet of a ber-based diet. Most high-ber forages cost less to produce than corn silage or haylage. Akins said farmers can also purchase these forages on the market fairly economically.

“Sorghum-sudangrass bears a pretty signicant cost reduction at a savings of 20-25 cents per animal per day,” he said. “A single-cut system is ideal for getting the highest ber value.”

A single harvest for these highber forages at bloom stage produces 1.5-2 times more biomass than a 2-cut system, Akins said.

Dan Olson, owner of Forage Innovations, said crops that can be grown in between other grain crops lower the cost per pound of dry matter and help spread out land cost.

“Finding crops that t in between years of corn, such as sorghum-sudan, can really help,” Olson said.

At Forage Innovations, Olson and his team unite agronomy and nutrition to optimize forage systems. Olson works with about 300 dairy farms in 27 states and also milks cows on his farm in northeast Wisconsin.

Olson said pregnant heifers do well on a single-cut product like sorghum-sudan or a forage sorghum.

Turn to CLOSER LOOK | Page 27

Eastern gamagrass, a perennial warm-season grass that can survive winter condi ons, is pictured in a eld in Springeld, Tennessee. Eastern gamagrass is a high-ber forage that thrives on a one-cut harvest system.

“When you combine a warm season annual like sorghum-sudan with a winter small grain like triticale or cereal rye to maximize the cool portion of the year, you can regularly get 10 tons of dry matter in the Upper Midwest,” Olson said.

One of Olson’s clients in South Dakota is producing cereal rye and sorghum-sudan with out-of-pile costs at 4.5 cents per pound of dry matter.

“That’s 3 cents a pound less than wheat straw, and it’s a better product,” Olson said. “He has the ability to save 70-80 cents a head per day on ration costs.”

This strategy also helps promote soil health while providing more crops per acre.

“My favorite crop is a (brown midrib) photoperiod sensitive sorghum-sudan,” Olson said. “It has a lot of ber and stays vegetative and growing until mid-September. It’s cheap to grow, which helps lower feed costs.”

Dairy farms have options when it comes to supplementing high-ber forages into pregnant heifer diets. Akins said working these forages into the ration should be done in tandem with advice from a nutritionist.

“Work with your nutritionist in getting feed tested properly for nutrient values and in balancing diets properly for ber, energy, protein, minerals and vitamins,” Akins said. “That’s critical.”

Tell us about your family and farm. We are a fourth-generation family farm. My parents, three brothers and I help on the farm.

What is a typical day like for you on the dairy? I help milk and feed calves in the mornings and nights and work from home during the day.

What decision have you made in the last year that has beneted your farm? This year, we started selling our excess colostrum, creating additional revenue for the farm.

Tell us about your most memorable experience working on the farm. When my family transitioned from milking in a tiestall barn to a parlor and freestall barn.

What have you enjoyed most about dairy farming or your tie to the dairy industry? It teaches accountability and good work ethic. It also keeps you connected with nature and the simple way of life.

What is your biggest accomplishment in your dairy career? In college, I was a part of North Dakota State University’s Dairy Club, where we did a lot of advocacy for the dairy industry. One of the events we hosted was the annual Midwest Regional American Dairy Science Association - Undergraduate Student Divi-

Taylor Witt Little Falls, Minnesota Morrison County 200 cows

sion. My senior year, our club was in charge of setting up the event and hosting schools from the Midwest. The event had a quiz bowl competition, industry speakers and various presentations.

What are things you do to promote your farm or the dairy industry? I work for the Minnesota Dairy Initiative. This allows me to work side by side with farmers, helping them make the best decisions for their business.

What advice would you give another woman in the dairy industry? Everyone’s job is just as important as another’s, and everyone contributes to the dairy industry in different ways.

What is a challenge in the dairy industry you have faced and how did you overcome it? Coming out of college wanting to work in the dairy industry, there was low job availability for careers supporting the dairy industry. Trying to nd a job that allowed me to still contribute to the farm was hard to nd. Luckily, my job now with the Minnesota Dairy Initiative allows me to do both.

When you get a spare moment, what do you do? In the winter, I am a head coach for the Little Falls High School Dance team. In the summer, my husband and I enjoy taking our paddle boat out on the lake.

When was the last time you did something or took time just for yourself? How did you feel during and afterwards? Was it relaxing, challenging or still stressful? Hobbies are a great way to relieve stress. Sometimes the hobby itself can be mentally or physically draining but in the end will ll your cup. Purposely setting aside “me time” is one of the most important and benecial things you can do for yourself mentally, physically, emotionally, spiritually, and sometimes even nancially if your hobby turns into a money-making side gig.

read every night before bed because it usually slows my brain down and puts me to sleep. Maybe you like to go for a walk or ride a bicycle around the neighborhood consistently. A little exercise and fresh air, and you can choose to do some thinking or try to shut your brain off and just enjoy your surroundings.

By Brenda Miller University of Minnesota

Everyone has something they like to do outside of farming. A few different types of hobbies are good to have for variety as some hobbies are more seasonal, whereas others can be worked on throughout the year. Hobbies do not have to be expensive. Although some can be more intense than others, and supplies or repairs add up in a hurry. Whatever it is you like to do, schedule the time and do it. It can be as simple as sitting down and reading a book for a half hour each day or a few times a week. I like to

I know of a group of farmers and their friends who go snowmobiling on local trails once a week in the winter when there is good snow for it. They will have a destination point (restaurant) where they sit down for appetizers or supper and then continue on their ride. It sure looks like a ton of fun and a great way to decompress from farming while catching up with friends.

Recently, I met up with my aunt and a few of my cousins for a weekend girl’s retreat. It was at a resort and we could all bring whatever we wanted along to work on. My aunt was switching between working on a cross-stitching project and doing puzzles. Two of my cousins were doing various scrapbooking projects and the others brought needlework, books to

read, and a few random things to do. I brought my sewing machine to patch a boxful of pants that I had not found time to work on before the retreat. However, in my opinion, the very best thing about the weekend was the conversation, laughs and fellowship. It was a great time to catch up with all of them, do some brainstorming/ troubleshooting, and just enjoy each other’s company. It was short in duration but lled my cup in so many ways.

A friend of mine is a full-time dairy farmer and her main hobby is woodworking. She makes beautiful creations, oftentimes for gifts, but she sells some too. She was even asked to make awards for a local dairy cattle show. They turned out amazing. The skills, creativity and hidden talents that people have are often mind blowing. Fishing is a big hobby of many of my friends and family. Sometimes there are even mini contests for the person who catches the rst sh, biggest, smallest, most, least, etc. It can get competitive at times but there is always more laughing and ribbing going on and that is what really counts.

Gardening is a fabulous hobby.

Dana Adams adam1744@umn.edu 320-204-2968

Luciano Caixeta lcaixeta@umn.edu 612-625-3130

Gerard Cramer gcramer@umn.edu 612-625-8184

Marcia Endres miendres@umn.edu 612-624-5391

Brad Heins hein0106@umn.edu 320-589-1711

Nathan Hulinsky huli0013@umn.edu 320-203-6104

Karen Johnson ande9495@umn.edu 320-484-4334

Emily Krekelberg krek0033@umn.edu 507-280-2863

Claire LaCanne lacanne@umn.edu 507-332-6109

Brenda Miller nels4220@umn.edu 320-732-4435

Whether it be one tomato plant in a 5-gallon pail, a ower bed by the barn, or a big vegetable garden, anyone can do it, and it always makes a person happy to see pretty owers or harvest fresh produce for lunch that they grew from their garden. I have always had a vegetable garden but started planting a few owers with the veggies for some color. Last year, I planted dahlia bulbs for the rst time, just for something different. When they started blooming my daughter picked them and put them in a canning jar on the counter. I never realized how even just one bloom can turn a person’s day around, from being crabby and stressed to enjoying what nature gave you with a little elbow grease. Hobbies are vital to a person’s well-being. Be intentional. Set aside time for yourself. Whether it is truly by yourself, like reading a book or spending time in the company of peers, or doing something you enjoy, like snowmobiling. Your mind and body will thank you. Sometimes it is the simple things in life. Take the time to stop and smell the roses. Better yet, grow some yourself.

Isaac Salfer ijsalfer@umn.edu 320-296-1357

Jim Salfer salfe001@umn.edu 320-203-6093

Mike Schutz mschutz@umn.edu 612-624-1205

Melissa Wilson mlw@umn.edu 612-625-4276

Isaac Haagen hagge041@umn.edu 612-624-7455

Michael Boland boland@umn.edu 612-625-3013

Sabrina Florentino slpore@umn.edu 507-441-1765

Scott Wells wells023@umn.edu 612-625-8166

Erin Cortus ecortus@umn.edu 612-625-8288

Melissa Runck mkrunck@umn.edu 507-836-1143

DEALERS: Hanson Silo Lake Lillian, MN 320-664-4171 Hartung Sales & Service Freeport, MN 320-836-2697

Melrose Imp. Melrose, MN

Finding a way to fairly compare milk, fat, and, more recently, protein production records made by cows of different ages, calving in different seasons, and even from herds in different parts of the country has been a long-time goal of the dairy industry. Fair comparison or the use of standardized records allows the assessment of milk, fat and protein yield records of cows to determine a cow’s economic value or sale price, to make decisions about cows for management purposes, and perhaps most importantly, to allow accurate calculation of cow and bull Predicted Transmitting Abilities for genetic selection.

riority of their offspring across their actual lactations. However, they continue to report production records on the 305-2X-ME basis.

By Mike Schutz University of Minnesota

For many decades, sets of adjustment factors were used to multiply 305-day milk production records of cows to determine how much the record would have been for a mature cow of the same breed milked twice per day and calving in an average month. This was termed a 305-2XME record. The adjustment factors were separate for breed, age at calving, month of calving and region of the country.

The U.S. Department of Agriculture developed one such set of factors in 1974. Twenty years later, in 1994, I was hired by the National Association of Animal Breeders to update those adjustment factors. Additionally, the new adjustments also considered the effect of the number of days open in the previous lactation. Two changes were readily apparent in comparing records from 1974 to 1994. First, seasonal differences were less and less pronounced over time as farms began to address heat stress and fewer cows were housed on pasture. Second, cows appeared to reach mature production levels at an earlier age. At that time, the decision was made by the industry to continue standardization to mature age (calving age of maximum yield), which ranged from 61-86 months, depending on breed. After all, the practice of adjusting to mature age had been followed since 1935, but clearly, there were more older cows around at that time. The U.S. remained one of only three countries that continued to standardize records to a mature age.