Volume 26, No. 24

“All

Volume 26, No. 24

“All

By Dan Wacker dan.w@dairystar.com

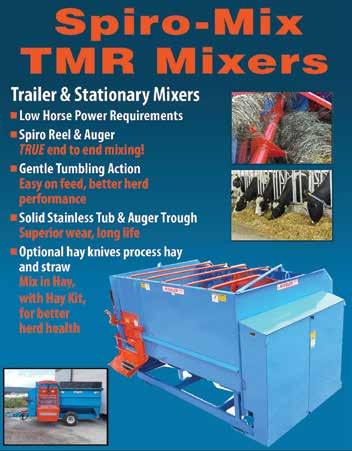

WAUKON, Iowa — July 27, 2024, started like every other morning at Ronan Family Dairy Farm near Waukon. Jim Ronan went to the barn to move cows around and get prepared for milking and the hoof trimmer, who was coming that day. While moving a cow to the barn, he was hit by the farm’s 3,000-pound bull.

Before he knew what happened, Jim was on the ground being pushed around by the bull, who had been on the farm for over 18 months without any signs of aggression.

“He hit me right in the back and I didn’t realize what was happening until he rolled me and I was looking right at him,” Jim said.

The bull continued to roll

Jim across the barnyard, rolling him directly into the side of a steel feed bunk. That is when Jim heard the crack of his ribs breaking. Out of the corner of his eye, he saw his dog, Miley.

“I yelled to Miley, ‘Get him,’ and she took off after him,” Jim said.

The Australian Shepherd pushed the bull back 20 feet, to the entrance of the barn. This gave Jim the time he needed to try to stand up. On a knee, with his hands ready to push himself back up, he saw the bull again.

“Miley had come over by me, but when I saw the bull again, he was on a full sprint,” Jim said. “I yelled to Miley to get him again, and she went right back after him. If it wasn’t for her, there’s no way I could have gotten out of there.”

a dream come true for Michigan brothers

By Danielle Nauman danielle.n@dairystar.com

GREEN BAY, Wis. — Dairy farming and the Green Bay Packers are synonymous with Wisconsin, an essence that is at the heart of the recently released independent lm “Green and Gold,” which chronicles a fourth-generation dairy farmer on the verge of losing the family farm.

The lm was created by brothers Anders and Davin Lindwall, who brought the story to life. Anders directed the lm and Davin produced it. “Our grandfather was a

dairy farmer in Stevenson, Michigan, near Menominee,” Anders Lindwall said. “The dairy closed after his death, but the land was still cropped

for a neighbor’s dairy farm. We grew up with cousins who were dairy farmers and involved in FFA.” The pair make their liv-

ing creating commercials for businesses, but the allure of lmmaking has always called them, so they returned to their Upper Peninsula roots to look

for inspiration.

“A general principle of lmmaking is to look close to home to create things that are meaningful to you,” Lindwall said. “We were surprised at how little the farming community is represented in lm, for how important and prominent it is in our lives.”

The project began to grow when one of their commercial clients inquired about what other projects they were working on. When they shared the premise of what was at that time called, “God Loves the Green Bay Packers,” their client was intrigued and backed the project, providing start-up capital for the Lindwalls.

www.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, SD, Nebraska) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Keya Sleister (Eastern IA, Southwest WI, IL) 563-608-5988 • keya.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

and

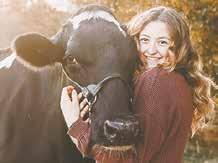

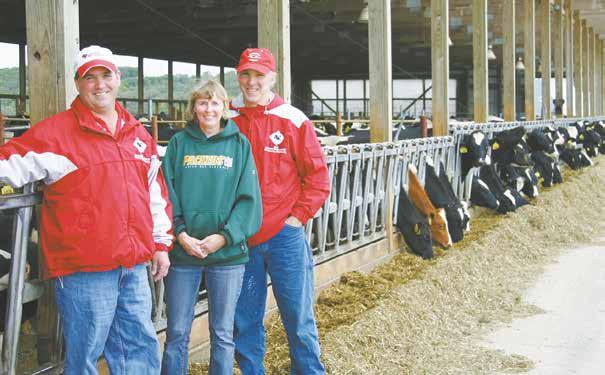

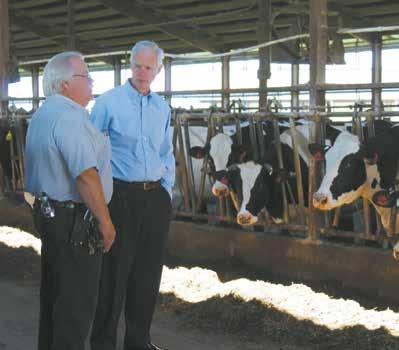

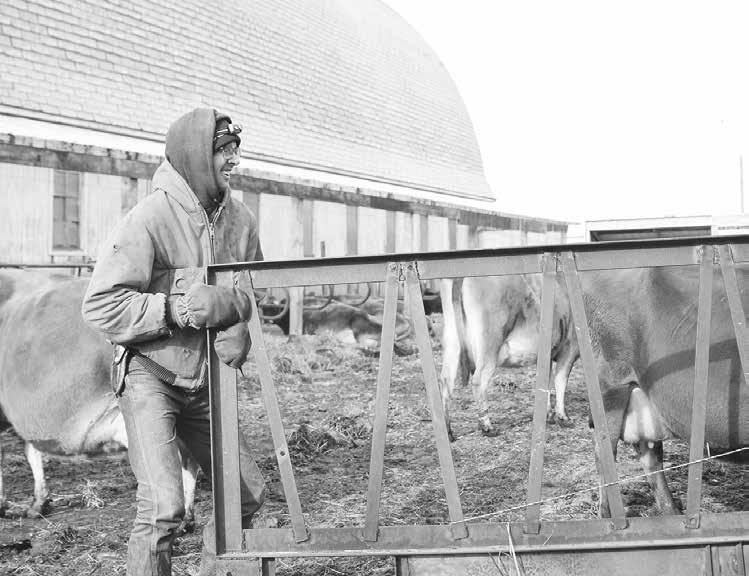

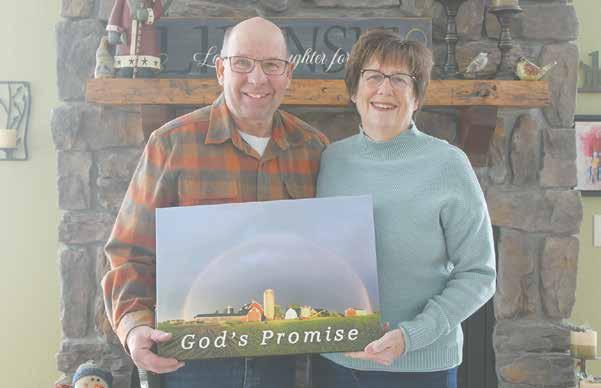

DAN WACKER/DAIRY STAR

Jim Ronan stands outside his shed Jan. 22 on his farm near Waukon, Iowa. Ronan Dairy Farm has had milking cows since 1855.

Jim rolled into the steel bunk and out of the pen to safety. He pushed open the gate and made his way up to the house where he found his wife, Sara.

Sara called emergency services and their son, Tyler Ronan, who works sideby-side with his dad on the farm and lives a few miles down the road.

“I could barely hear what she was saying,” Tyler said. “The one thing I did understand was ‘The bull got Dad’.”

Tyler found his dad sitting at the kitchen table, with an ambulance on

the way. His older brother, Brandon, a strength and conditioning coach at the University of Northern Iowa, happened to be visiting and helped Jim prepare for the arrival of the paramedics.

“The ambulance came, and the medics took one look at me and immediately called for the helicopter,” Jim said.

While Jim was in the ambulance, Miley stayed nearby. The dog sat next to the ambulance for as long as she could until Tyler needed to pull her away.

Jim was own to La Crosse, Wisconsin, where he underwent a CT scan and x-rays. It was discovered that he had eight broken ribs, six on his right side with multiple fractures in each rib, and two on his left. The muscles on his spine were pulled away from the bone, leaving a basketball-sized indent.

Back at the farm, Tyler was left to milk their 80 cows in the tiestall barn and get ready for the hoof trimmer.

“Once word got out, I couldn’t keep up with my phone with people who were reaching out,” Tyler said. “I had to put it away so I could get something done, and I didn’t have an update for them anyway.”

When Tyler nally did answer the phone, it was his mother calling from the hospital.

“She immediately started telling me that Dad was trying to make sure I was going to mix feed right and which cows I needed to have sorted for the trimmer,” Tyler said. “He was still giving me orders from the hospital, and it was then that I knew he was going to be alright.”

Tyler is the sixth generation at Ronan Family Dairy Farm. The family has been milking on the same farm since 1855 and earned a Heritage Farm Certicate from the Iowa Department of Agriculture and Land Stewardship.

Turn to RONAN | Page 5

by

“We began looking at a bottle washer to keep bottles cleaner and eliminate an extra job. After seeing the option to purchase the bottle washer and pasteurizer combination, we started to look at its benefits. Once we calculated what we would save by not buying bags of milk replacers, it was an easy decision to add the pasteurizer. Since installing the new system of the bottle washer and pasteurizer combination the calves drink better and are healthier.”

Following the incident, the bull was shipped two days later. Using a skid loader, Tyler moved the bull into the milking barn and set the gates to load him onto the trailer. Once the gate opened, the bull was not ready to depart.

“When I couldn’t get him out of the barn, I knew exactly who to call,” Tyler said.

Miley was called back into action and loaded the bull onto the trailer and off the farm.

Two years prior, Miley had her own health scare. A working dog, Miley had injured her hip working cattle. Initially, the dog worked through her injury and was back to working cattle how she was accustomed to, until one day she could not move her back legs. The Ronans took her to the vet and were informed Miley needed hip surgery. Now the Ronans realize that what started as a surgery to keep one of their top cattle dogs around, turned into a life-changing decision.

Jim passed all the tests, and three days after being own in, he was on his way back home.

“The people at the hospital were tremendous, but I just knew I couldn’t stay in there any longer than I had to,” Jim said.

Upon his return, Jim needed to use a walker to get around and had a hospital bed brought into the lower level of his home.

Tyler kept the farm going while Jim recovered, with help from his girlfriend, Karly Hemmersbach, and several nephews who helped on the weekend.

“I wouldn’t be here today if it wasn’t for Miley.”

“That stretch was tough during the week because the work for two of us fell completely on me,” Tyler said. “It made for some long days, but we had a lot of family and neighbors asking how they could help. We had great support. That’s just what we do around here. When someone needs help, we’re all willing to lend a hand.”

At the hospital in La Crosse, Jim was already trying to get back home.

He was told it would be at least a week before he would be released, and he had an array of physical tests he needed to pass. It started with a breathing capacity test, three unassisted walks around the hospital, and a test with the physical therapist requiring him to get in and out of a car without assistance.

Two and a half months after the attack, Jim was back in the tractor chopping corn.

“I wouldn’t be here today if it wasn’t for Miley,” Jim said. “I wouldn’t have time with my grandkids. It really makes you think about the little things. Maybe slow down, spend more time with family. It denitely makes me appreciate my dog a lot more.”

February 20, 2025 | 9:00AM - 3:30PM

Florian Gardens | 2340 Lorch Ave | Eau Claire, WI

In the lm, the main character is facing the foreclosure of his farm. He makes a deal with the banker: if the Packers can bring home the Lombardi Trophy, his loan will be extended.

“Movies are high-risk investments; nine out of 10 lose money,” Lindwall said. “We brought the Packers into the story to help expand the viability of the audience.”

The lm pays homage to Wisconsin’s nearly universal love of the Packers. Even the franchise itself has become involved.

“Once the Packers caught the vision, they went all in,” Lindwall said. “It was like an out-of-body experience.”

The Packers, along with their corporate partners, came to appreciate the project for its wholesome nature.

“‘Green and Gold’ portrays the story of Packers fans’ devotion to legacy and community,” said Justin Wolf, director of the Packers corporate sales and activations. “It’s a must-see; we are proud to be part of a story celebrating supporting one another and showcasing the critical role that family farms play across our great state of Wisconsin, and beyond.”

With multiple pieces of the puzzle beginning to fall in place, the Lindwalls

turned their thoughts towards preparing for production. Davin’s wife suggested that actor Craig T. Nelson was a perfect choice for the role of Buck, the main character in the story.

“Our casting directors kind of laughed us out of the room when we said we wanted Craig,” Lindwall said. “At that point, we were just shing for anything we could get. Craig literally called us the next day after he read the script and said he wanted to do this lm with us. He’s been the best, so gracious to us as rst-time lmmakers.”

The story appealed to Nelson on several levels.

“The story felt personal,” Nelson said in a press release. “I felt a real connection to it because the Nelson family farm has been a working farm in South Dakota since the Civil War; and my wife’s family were also farmers.”

Nelson’s character is a quintessential Wisconsin dairy farmer, a man who names his cows after legendary Packers players while facing a bevy of issues that are part of the everyday landscape for many in the state’s ever-changing dairy industry.

The cast and crew of the independent lm “Green and Gold” work to set up a scene among a herd of beef cows near Sturgeon Bay, Wisconsin. The movie was lmed primarily in Door County, with scenes shot in Appleton and at Lambeau Field in Green Bay.

“There’s some Hollywood fun, like plowing elds with horses and milking cows by hand —Buck’s friends nicknamed him ‘Horse and Buggy,’” Lindwall said. “It’s not a documentary on dairy farming, it’s just about the person Buck is, doing things as old-school as he can. There are a lot of authentic moments dairy farmers can relate to, especially the parts about family.”

The movie, lmed entirely in Wisconsin, touches on many of the complex and difcult social issues facing the dairy farm community in rural America, Lindwall said.

“I think that is a unique component, sharing that vulnerability,” Lindwall said. “A lot of people wouldn’t think the dairy industry, lled with people that are so salt of the earth, would have such an alarming rate of suicide.”

As the Lindwalls moved into the marketing and distribution phase of their project, the Culver’s restaurant franchise signed on to support the project.

“There aren’t a lot of brands that are more general population brands that have the farming attachment that Culver’s does with their Thank You Farmers Project,” Lindwall said. “We were thrilled when they signed on after telling us they loved the lm — that it

represented everything they believe in.”

Culver’s dedication to rural communities, supporting agricultural education by donating millions of dollars, impressed the Lindwalls so much that at the end of the movie, there is a QR code to make a donation to support the Thank You Farmers Project.

As the brothers prepared to release “Green and Gold,” their original goals were small: hoping the lm would appear in maybe 100 theaters throughout Wisconsin.

“Our distributor sent out a screener link, nationwide, nearly 1,000 theaters across the country signed up to take it and 100 theaters in Canada expressed interest,” Lindwall said. “My jaw dropped; I nearly fell out of my chair when they sent me the list.”

The experience of living out their dream and making a lm that hits close to home, has been one Lindwall said he and his brother will cherish forever.

“The farmers we grew up around and knew, they were an important part of our lives, and we wanted to share that story,” Lindwall said. “We’re so proud of this lm, even if it’s the only one we ever get to do — it has been bigger and has already had so much more impact than we ever could have imagined.”

By Dan Wacker dan.w@dairystar.com

RIVER FALLS, Wis.

The University of Wisconsin–River Falls recommitted itself to dairy food production education with the addition of the Wuethrich Family/Grassland Dairy Center of Excellence. A project 11 years in the making, the dairy pilot plant opened its doors in October 2023, revitalizing the efforts of UWRF to be a leader in the food science world.

Rueben Nilsson, the dairy pilot plant manager, and Mike Orth, the dean of the College of Agriculture, recognize how special it is to have this type of plant available for students interested in food science.

“It’s critical to have this on campus,” Orth said. “I think a differentiator between us and other schools is that we’re really student driven. The faculty do a lot of the teaching, and we want the students to get in there and get their hands dirty.”

With over 90% of the state’s milk going towards cheese production, the University saw the need to train students with hands-on experience to better prepare them for the workforce.

Nilsson works with UWRF faculty and others in the dairy industry to help train the workforce on the school’s new equipment.

“There’s only UW-Madison and us who can provide this kind of learning experience,” Nilsson said. “I get to work with some of our professors and help them craft what they want to do in the pilot plant.”

The plant helps provide a hands-on learning experience partnered with traditional classroom education. The experience that is offered students of working directly with food production can help illuminate career opportunities that were previously unknown.

“The plant helps provide more awareness of our food science degree,” Orth said. “Very few students come in

interested in these areas until they learn about it here. With a food science degree, and the work experience we can offer, there are plenty of job opportunities after graduation.”

UWRF had a dairy plant on campus starting in the 1980s, but with outdated equipment, the plant shut its

doors in 2018. Former director of dairy production, Michelle Farner, led the charge for funding the new facility. What started as a smallscale project gained traction from businesses within the dairy industry and led to a 6,000-square-foot, $9 million facility. Donations in-

cluded over $5 million from businesses, $1 million from the Wuethrich family and the state funding the balance.

The plant works in conjunction with Mann Valley Farm to bring in milk for use at the dairy plant. Along with the campus farm, the plant provides opportunities for departments across campus to learn in a real-world scenario.

“There’s the marketing side of it,” Orth said. “We could go to computer science and use some traceability software and reporting. There could be a student project that could use some of that data; the art department could create artwork for labels. It’s a really strong opportunity to work with other departments on campus.”

Orth said that kind of synergy is something UWRF can benet from.

“It’s critical that we work with other departments within our university,” Orth said. “The better you can integrate students and faculty from other colleges, the more benets you can see.”

The on-campus dairy plant provides Nilsson and his staff with a chance to learn new techniques and take chances to create something new. They can also partner with other departments on campus to potentially ll a need.

“We’ve talked with the athletic department about what kind of product we could produce that they nd benecial,” Nilsson said. “Could we produce something high in protein for a post-workout beverage or product? We’re continuing to nd these opportunities as we go and expanding what we can create.”

Most recently, Nilsson began developing a nacho cheese to use on campus in concession stands during events.

The dairy plant’s nacho cheese was projected to be unveiled at the UWRF Science Olympiad Border Battle Jan. 25. Other products Nilsson cooked up include a variety of avored cheese curds, including chipotle, gochujang and chili lime. The opportunity to create new products and be creative is what intrigued Nilsson.

“That was one of the big attractions to the job, the freedom to play with whatever I wanted to try making and providing experiential learning for our students,” Nilsson said.

Being a newer plant, not all cheese types have yet to be duplicated. A challenge the plant faces is storage space to provide more opportunities to expand its line of products.

“We’re limited on space as far as aged cheese,” Nilsson said. “But the avored younger cheeses are where we can really start to work.”

Nilsson’s background in cheese production helped the plant start production as soon as possible with the rst batch of cheddar produced in March 2024. Nilsson and his team will focus on ice cream production soon.

“I’m excited to start working with the ice creams,” Nilsson said. “We need to nail down our base rst, get that vanilla right, and then we can continue to add in more toppings.”

House Agriculture Committee Chairman Glenn ‘”GT” Thompson did not give a timeline for the farm bill but said it would happen sooner rather than later. “The longer we wait into the fall, the more likely we’re going to have to come back next December and ask for more economic disaster relief,” Thompson said. “Producers don’t want that and we don’t want to do that; we won’t have to do that if we get this farm bill that has such a strong safety net component in it passed sooner rather than later.”

Understanding needed for all farm bill titles

House Agriculture Committee

Pasteurization inactivates bird u virus

After evaluating H5N1 infections in dairy cattle, University of Wisconsin Center for Dairy Research Director John Lucey is convinced pasteurization inactivates the virus in milk. “It seems like this bird u virus, this inuenza virus, is pretty easy to inactivate by heat treatment,” Lucey said. “I’m pretty hopeful that all of these raw or heat-treated cheeses would be inactivated by the treatment when we’re using it.”

Ranking Member Angie Craig was part of a farm bill forum at the Farm Bureau convention with committee chair GT Thompson. Craig said it is important for her entire committee caucus to understand every title of the farm bill. “That’s our job on the committee, but that is also a role that each of you can play particularly with the Democratic members of Congress.” Most of the Democratic members on the House Agriculture Committee represent major metro areas and have focused on the nutrition title. However, Craig said she has new members who have a background in agriculture and farm policy. In front of the Farm Bureau audience, Craig said she is not afraid to stand up to members of her own party on important ag issues. “I have a history of calling the balls and strikes on whatever administration I’m in Congress under,” Craig said. “It pisses off Democrats when I complain about the Democratic administration and annoys some of my Republican colleagues when I complain that certain policies aren’t good for the country.”

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty. Model VP

By Don Wick Columnist Ag Insider

innovation

The latest issue of Food Business News highlighted new dairy ingredient innovations. Fit Butters LLC of Minneapolis was cited. The company produces nut butters formulated with whey protein isolate to create avors like Boston Cream Pie Cashew. A New York company, David, is selling the David Protein Bar. The high protein bar is made from milk protein isolate, collagen, whey protein concentrate and egg white. Dry dairy ingredients, like casein and whey, have a neutral color and avor prole, which is favored over plant proteins.

Dairy Business Association highlights legislative priorities

The Dairy Business Association has unveiled its legislative priorities for the year ahead. The list includes protection for Wisconsin’s dairy industry from disruptions that would hurt its growth and sustainability, regulatory fairness and support for clean water initiatives and lasting ag transportation infrastructure.

Final Milk Marketing Order rule is out

The U.S. Department of Agriculture has issued its nal rule on Federal Milk Marketing Orders. Most of the changes take effect June 1. National Milk Producers Federation President and CEO Gregg Doud said, “ this change will provide a rmer footing and fairer milk pricing.” For this region, there is an update for the make allowances for Class III milk. American Farm Bureau Federation President Zippy Duvall said these reforms will not be uniform for dairy farmers across the country. Duvall is calling for a mandatory audited survey of the milk processing costs used to help establish make allowances.

Consumer demand highlighted at International Dairy Foods Association meeting

Speaking at the International Dairy Foods Association Dairy Forum, IDFA President and CEO Michael Dykes discussed everything from tariffs to ag labor, articial intelligence to sustainability. Consumer demand was also touted. “Per capita consumption’s increasing butter is at levels we haven’t seen since the 1950s,” Dykes said. “They (consumers) also voted with their wallets. (We) saw doubledigit growth in categories like cheese, probiotic yogurts and specialized nutrition products. Ninety percent of consumers have no plans to reduce their dairy product purchasing behavior.”

Cattle supply shrinks again

The U.S cattle supply is at its lowest point in 64 years. According to USDA’s annual cattle inventory report, the total number of cattle and calves is 86.7 million head. That’s down 0.6% from a year ago. Beef cow numbers are down a half-percentage point from the same time in 2024. Beef heifer replacements declined 1%. The dairy cow inventory is nearly unchanged from a year ago, while the number of dairy replacements dropped nearly 1%.

Slaughter cow prices remain strong

The price of cutter cows has risen for eight consecutive weeks. According to a report from Urner Barry, the price of these slaughter cows is $238 per hundredweight. That’s up from $185 at the beginning of the year. Year-over-year, these prices are up nearly 29%.

At its annual meeting in Charlotte, North Carolina, members of the National Mastitis Council approved a name change. The group is now known as NMC: The Global Milk Quality Organization. National Dairy Quality Awards were presented to six dairy operations including two Wisconsin farms: Cottonwood Dairy of South Wayne and Country Aire Farms of Greenleaf.

Wisconsin family named Innovative Dairy Farmer of the Year

At the International Dairy Foods Association Dairy Forum, Grotegut Dairy was named the 2025 Innovative Dairy Farmer of Year. The Newton, Wisconsin, dairy farm is owned by Doug Grotegut and features a 3,500 head cow herd. IDFA cited Grotegut Dairy for its “commitment to technological innovation, building a sustainable future and giving back to their local community.”

Vilsack returns to Iowa

Former Agriculture Secretary Tom Vilsack will take over as the chief executive ofcer of the World Food Prize Foundation. Vilsack succeeds another former Iowa governor, Terry Branstad, in the role. Vilsack’s ofcial start date is March 1.

Hall of Fame honors for Traynor

Bob Traynor has been inducted into the Wisconsin Association of Fairs Hall of Fame. Traynor chairs the Pierce County Fair Committee and serves as the junior dairy superintendent.

Trivia challenge

Dairy cows can produce up to 125 pounds of saliva per day. That answers our last trivia question. For this week’s trivia, how many essential vitamins and nutrients are found in milk? We’ll have the answer in our next edition of the Dairy Star. Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

In addition to production and SCC, we use the milk pregnancy test, MUN, Johne’s and Leukosis.

Which is your favorite and why? The production and SCC.

How do you use them within your dairy? We use the production and SCC reports for culling decisions and use the fat, protein, and MUN reports to evaluate feed ration changes.

How long have you been using the DHIA pregnancy test? We have been using the milk pregnancy test for about two years.

What do you like about the DHIA Pregnancy Tests? It’s nice to be able to do the pregnancy test without any extra time or labor.

How does testing with DHIA bene t your dairy operation? We use the information to improve production and ensure milk quality. The negative herd tests for Johne’s and Leukosis help with marketing show and breeding stock. The milk pregnancy test provides timely information for reproductive management between vet herd health checks.

Tell us about your farm. I farm with my wife, Barb, and two youngest sons Benjamin and Daniel. We milk 85 cows. The boys plan to take over the farm in the near future. We raise farm 560 acres and corn, oats, alfalfa and grass.

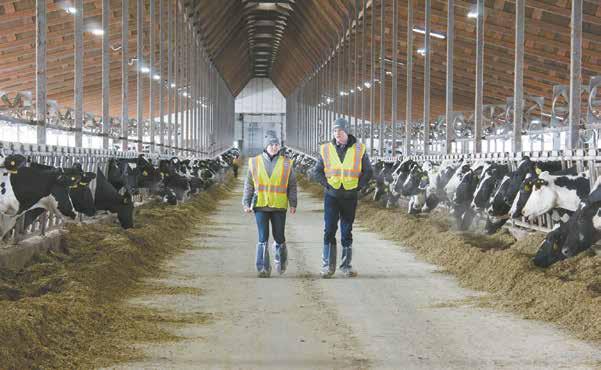

URUS Dairy Consulting Experience gives students real-world skills

By Stacey Smart stacey.s@dairystar.com

MADISON, Wis. — Nineteen college students from across the U.S. and Canada came together for a week-long, hands-on learning opportunity with one common goal — to help dairy farmers succeed. Shaping the next generation of dairy professionals is the backbone of the URUS Dairy Consulting Experience which took place Jan. 6-10 in Madison.

The program provides students with an opportunity to gain a compet-

itive edge in herd consulting as they work with experts on dairy record analysis, reproduction, genetics, calf care and conditions impacting herd performance. Students networked with industry leaders from URUS companies, including Alta Genetics Inc., GENEX Cooperative, VAS, PEAK, Trans Ova Genetics and SCCL.

Through a mix of classroom and on-farm learning, students collaborated as teams to evaluate and analyze dairies and learn how to understand and apply theories to real- world challenges. This year’s program included visits to Statz Bros. Farm near Marshall and Maier Farms near Waunakee.

USED TRACTORS

www.mndhia.org

CIH 8910, 1955 hrs., 2WD, like new$105,000

CIH 7120, 2WD, 5800 hrs. ................$55,000

CIH 7110, 2WD, 4500 hrs..................$63,000

CIH 5250 2WD, 4,700 hrs. .............. $54,000

CIH MX120, 2WD, 3,800 hrs. ............$72,000

CIH MX120 w/loader ........................$75,000

IH 1456, cab ..................................... $22,000

IH 1466, 6800 one-owner hrs ............$21,000

IH 686 . ..............................................$14,000

‘98 JD 7610, 19 spd., PS, 5,500 hrs., 25 MPH, very sharp ....................... $75,000 McCormick MC120 FWA, 2,600 hrs ..$57,000

TILLAGE

CIH Tigermate II, 26’$28,000

CIH Tigermate II 26’ w/rolling basket $32,000

CIH Tigermate 200 w/basket, 34’ ..... $42,500

CIH Tigermate 200, 28’ w/rolling basket ...............................$40,000

CIH Tigermate 200 28’ w/basket ...... $37,000

Tigermate 200 28’ w/rolling basket ....$31,000

DMI Tigermate II, 26.5’, 3-bar mulcher ..................................$14,000

CIH RMX 340, 28’ w/mulcher ...........

“The URUS Dairy Consulting Experience is a worldclass program for the most elite undergraduate dairy students,” said Eva Doornink, marketing and communications coordinator at PEAK.

“Through DCE, students learn what it means to be a successful consultant on the world’s most progressive dairies.”

Throughout the week, students participated in case studies and presented their ndings to URUS’ panels of experts. Analyzing each farm’s DairyComp data was a big piece of the program, Doornink said. The students searched for opportunities for improvement and gave nal presentations at the end of the week.

Students competed for a chance to win a $1,000 scholarship, which was awarded to Carmen White of Alberta, Canada. White is a senior at the University of Guelph in Ontario, where she is studying food and ag resource economics.

“The DCE program is a fun-lled experience for anyone who wants to learn more about being helpful to farmers in the areas of genetics, reproduction and full-on data analysis,” White said. “The sessions were amazing, and this is a really good way to get hands-on experience.”

Joselyn Hurlburt, talent acquisition coordinator at

February 8, 2025

Students par cipa ng in the URUS Dairy Consul ng Experience share ideas Jan. 7 during a farm walk-through at Statz Bros. Farm near Marshall, Wisconsin. During DCE, students collaborated as teams to evaluate and analyze dairies as they learned to apply theories to real-world challenges.

URUS, said the most important thing they look for in a candidate is a passion for the industry.

“We want someone who has that drive for wanting to learn,” Hurlburt said. “We’re looking for that person who is super excited to soak up the opportunities and knowledge presented to them here.”

Helping to educate and give back to upcoming youth in the industry is the reason the program was started,

Hurlburt said.

“We’re big on training and development at URUS,” she said. “We want to give students the tools they need to grow in their career. DCE provides a networking opportunity and chance to see our different companies and organizations along with possible career paths. It’s a totally different outlook compared to a school setting.”

Applicants selected for

the program received a oneweek, all-expenses paid trip to Madison. Most students come from dairy farms or have an agricultural background. All have agricultural majors, such as animal science or dairy science.

“We’re always trying to expand the program,” Doornink said. “This year, we had ve students from Canada, which emphasizes the global aspect of DCE, which is in its

fth year.”

Anna Poull, a senior at South Dakota State University studying communication and media studies served as the marketing and communications intern for this year’s DCE.

“I don’t think there’s another opportunity anywhere else to connect with this many employers and network with this many companies,” Poull said. “It’s such a supportive learning environment.”

Grady Taylor, a senior from Temecula, California, studying dairy science at California Polytechnic State University, said he has always wanted to be a consultant.

“I enjoy consulting and really wanted to get out here and see Wisconsin and learn what it is to be a consultant,” Taylor said. “The DCE program is a great place to network and a great place to learn. I like to be hands-on, and that is what I got every day here.”

The classroom portion also included sessions on consultative selling and relationship building.

“I learned so much about people’s personalities and how we can all interact,” Taylor said. “I think that’s a great takeaway for conducting business on a dairy farm.” Turn to URUS | Page 13

The college students selected to par�cipate in the 2025 URUS Dairy Consul�ng Experience gather Jan. 6 at the URUS office in Madison, Wisconsin. The students came from across the U.S. and Canada for a week-long, hands-on learning opportunity.

Emory Bewley, a senior at The Pennsylvania State University studying animal science with a dairy science focus, comes from a dairy farm in northeast Pennsylvania where her family milks 50 cows.

In addition to expanding her horizons on the reproduction side of a dairy, Bewley said meeting other likeminded college students motivated her to apply to the DCE program.

“DCE truly is a networking opportunity and a chance to learn more about the dairy industry while working with the URUS community,” Bewley said. “We learn from those professionals in the industry who have experience and can offer advice to help us in our future endeavors. We are also able to rene those classroom skills we learned in a more practical, real-world setting.”

Bewley said her family’s farm is mainly focused on high-type show cows, and DCE has shown her the more commercial side of the industry.

Kylie Konyn from San Diego, California, is a senior at the University of Wisconsin-Madison studying dairy science with certicates in ag business and science communications. Her family’s 900-cow dairy is the last remaining dairy farm in San Diego County.

After graduation, Konyn plans to pursue a master’s degree in nutritional physiology with special emphasis in transition cow health and metabolism at Cornell University. Following that, she hopes to return to the dairy industry as a nutritionist in management consulting.

“Regardless if you’re in repro, genetics, or nutrition consulting, it’s all about creating a uniform team on the farm and creating that whole, rounded relationship,” Konyn said. “Even if I as a nutritionist may not have a direct input into what bulls they are using, I learned the effects I can have on-farm and gained an understanding of where other consultants on the farm may be coming from.”

Konyn said she enjoyed learning about different technologies and innovations within the industry and what is coming in the future.

As the students prepare for the next phase in their agricultural journey, they went home with a depth of knowledge to benet the future of the dairy industry.

“DCE is a great way to step out of your comfort zone and test your abilities in a bunch of different areas,” White said. “I’m excited to take the things I learned this week and apply them not only on my farm, but in the rest of my career and personal life.”

John Rosenhammer

Sleepy Eye, Minnesota

Brown County 200 cows

What method do you use to recruit quality employees?

The vast majority of our employees are high school kids. A few come back during college breaks and over the summer. I rarely have to look for employees; most of them are friends of present workers who are interested in working for us. Sometimes, I visit with employees during school or community events. The hours we require are from 4-6:30 in the afternoon. This time frame seems to t very well with the high school aged students.

How many employees do you have and what are their duties? We have a pool of about 10 employees available throughout the year, depending on school activities. We expect them to show up at 4:00 p.m. and be nished and heading home by 6:30 p.m. Their duties are to milk cows, move cows, scrape pens, bed stalls and clean up the milking parlor after.

When you hire an employee, what is your onboarding process? I work with the employees and go through the basics of what I expect. I prefer to milk beside them and to work with them as different situations arise and show them how to problem solve.

How do you remain competitive in retaining employees? I think the key to keeping employees happy is working with and beside them. I never expect them to do anything that I wouldn’t want to do myself. I never refer to milking as ‘work’ but rather, try to create an atmosphere of fun. Often, I ask what is going on in their lives and try to encourage them, thus building relationships. Also, I am very understanding when unexpected things come up in their lives, because I also had ve kids of my own.

How do you keep your staff motivated? Our help is paid per milking, rather than by the hour. I always preach efciency. I am amazed how their speed improves after they gain condence and experience. I always try to complement them for their work and thank them for coming.

What is a benet your employees receive? We provide bottled water, cookies and ice cream treats. Occasionally, they are lucky enough to have Patty’s Special K Bars. In the past, we have taken hay rides to graduation parties and participated in various parades. We’ve also had “end of summer” bonres in the evenings. A time or two during Christmas break, we have hosted an afternoon of card games at our house.

Tell us about your farm and family. Our dairy is a family-run partnership started by my parents and is now managed by my brother, Greg, and me. We milk two hundred cows in a double-12 parallel parlor. Family help has always been the driving force behind our dairy. Greg is in charge of the crops

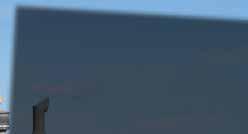

Bryce Peters (pictured with his wife, Katie and children Macey and Archie)

Chaseburg, Wisconsin Vernon County 300 cows

What method do you use to recruit quality employees? I heavily rely on my current employees' thoughts and considerations when it comes to bringing on a new employee. They are the ones doing the work and typically have a good feel for who will work out well here.

How many employees do you have, and what are their duties? We have four full-time employees and eight part-time employees who do milking, scraping, eldwork and maintenance.

When you hire an employee, what is the onboarding process? Onboarding depends on the position. There is some paperwork, educational videos and a lot of hands-on training.

How do you remain competitive in retaining employees? We give them something they can't get at another job: exibility in hours; opportunity to put in a lot of hours; fun, enjoyable work; and being part of a good team.

How do keep your staff motivated? We share with them the success of the farm and treat them as a valued team member.

What is a benet your employees receive? Education, especially for younger employees. There is no better place to learn basic mechanical skills, teamwork, the importance of hard work and animal stewardship than on a farm.

Tell us about your farm and family. Peters Farms has been shipping organic milk since 1988. We also raise organic hogs and laying hens. The current owners of the farm include my uncle, Roger Peters, and cousin, Russell Peters.

and mixes feed. Laura lls in if necessary and is responsible for vaccinations and repro checks. Mary milks most week-day mornings and helps with odds and ends to keep the farm looking neat. Becca tries to help with morning milking one day a week. Joe operates a custom-farming business and lls in when needed. Johnny has a year left in the military and is anxious to get home and join in somewhere. During harvest, we are fortunate to have uncles and cousins help with harvest, tillage and maintenance. Dairy farming is the best way to raise a family.

Kyle Abel (pictured with his wife, Brittany, and son, Derry)

Loyal, Wisconsin Clark County 400 cows

What method do you use to recruit quality employees? My best luck has been with current employees recruiting. Employees like to bring in people they know. I do use different online sources; I like to post on my personal and farm Facebook pages when we have openings, especially part time, and I like to post on Indeed and Craigslist for full-time positions. I nd different positions need to be advertised differently for best results.

How many employees do you have, and what are their duties? We have about 20 employees at any given time. Because of our short shifts (3-4 hours), it is a good place for people wanting part-time or supplemental income. Only about a third of our staff at any given time are averaging more than 40 hours a week. I would break it down as one nancial manager, two overall general managers, one feed/crop/maintenance lead, one robotic lead, two parlor and youngstock leads, and the rest are milkers and general laborers.

When you hire an employee, what is the onboarding process? There is usually about a one-hour walk-around interview to explain duties and facilities. There is an extensive packet including tax and employee info, safety protocols, animal welfare agreements, employee conduct agreements, and more that they need to read, review, sign, and return. Lastly, there is a training shift, where they will work side by side with a manager until we feel they have grasped the task at hand. Then we monitor them to see if further retraining is required in the future. We try to always be teaching and expanding roles, it is the quickest way to increase an employee's compensation.

Katie Grinstead

Vir-Clar Farms LLC

Fond du Lac, Wisconsin

Fond du Lac County

3,300 cows on two sites

What method do you use to recruit quality employees? We rst try to recruit from within. I feel this is a great way to keep our employees engaged and growing. For example, if we need a new calf team member, we offer it to current employees rst. If we are looking for an entry-level position, we have an incentive bonus for our employees as well as the new employee we hire. We give a bonus to both employees at 30 days and 90 days. We feel that if we create the right environment for our employees, they will want their family and friends to work at the dairy.

How many employees do you have, and what are their duties? Between our two dairies, we have 57 full-time employees, and we hire seasonal employees to help with crops. We do everything we can at the dairy except that our heifers are custom raised in Nebraska from 5 ½ months until 60 days before calving. Because of our size, our employees have their areas of focus, such as milkers, calf team, maternity area, hospital team, shop and cropping crew. This allows for consistency in the job getting done by the same people every day.

When you hire an employee, what is the onboarding process? Typically, new hires start out as a milker. We have managers who started at the farm milking. I think when employees see there is opportunity for growth, this keeps them motivated to keep learning and do a good job. When a new employee starts, they are given a tour and our herdsman, Joaquin, spends time talking about the dairy and getting to know the new employee. They are given a mentor in the parlor who works side by side with them for at least three days. We want the new employee to understand the milking protocol and feel comfortable. We also have learned over the years that some people are happy in the parlor and that’s where they want to stay. We have an employee who has been milking cows for 27 years.

How do you remain competitive in retaining employees? I try to pay competitively in comparison to the farms in our area. I will never compete with the big corporations like Land O’Lakes and Grassland, but when I post a new opening, I check the farm ads in our area and try to be on the top end of what I nd. I expect a lot from our staff and try to pay accordingly. Over time, I try to use technology and protocol efciencies to increase the amount of milk shipped per employee hour so I can pay competitively.

How do you keep your staff motivated? My dad is the driver behind motivating our staff on a regular basis. He breaks down weeks and days into projects that people can rally around: “Be prepared for next week, there’s 18 due to calve” or “We’re going to need everybody’s best next week because we’re going to haul manure.” By giving everyone time to prepare, we can ensure their best.

What is a benet your employees receive? We try to offer exible scheduling for our staff. I think a person should be able to go to the doctor, dentist, court, kid’s spelling bee, eld trip, etc., without fearing losing their job. We also offer quarterly bonuses based on attendance and punctuality. We pay $1 per hour worked in said quarter if an employee has managed to be punctual and not miss any shifts unscheduled. Mistakes happen and we work with people but things like a “no call, no show” are unacceptable, except in cases of emergencies.

Tell us about your farm and family. My wife, Brittany, and I bought our family farm from my father in 2023. We have a four-year-old son, Derry. My father, Perry, is still very involved in the day-to-day management. He and my son are best friends. My sister-in-law, Cassandra, is our robotics lead and her kids, Todd and Tawnee, help out on the farm as much as they can. We currently milk about 200 cows robotically with four DeLaval VMS robotic milkers installed in 2016 and milk 200 cows in a double-6 Universal step-up parlor built in 1996. We raise all of our own replacements and sell roughly 50-60 dairy replacements every year as springers or lactating cows. We crop just shy of 800 acres and are currently working on doing more eldwork ourselves and hiring less done. Our primary forage is corn silage and we purchase a large amount of our concentrated feeds (dry corn and protein).

How do you remain competitive in retaining employees? It is something we work on every day. We consider our employees to be our work family. I think it is important to be competitive in pay, and I also feel it is important that employees feel like they are part of a team. We also try to celebrate the great things (reaching a certain somatic cell count or milk production goals, harvest nally being done). I really think it’s important to listen to your employees and the ideas they have. In our reviews, someone suggested English classes at the farm. We found a great person who came to the dairy and taught English to employees who signed up for the class. It was very successful, and we are currently planning the next class.

How do you keep your staff motivated? By doing a lot of the things listed above. Hiring the right people and getting them in the right seat on your bus is key. We work hard to keep the farm tour-ready at all times. I think people enjoy working in a nice, clean environment. We celebrate birthdays, and I post them on our Facebook page. I know a lot of our employees follow our page and are proud that we acknowledge them.

What is a benet your employees receive? We have an SCC bonus as well as a bonus for a dead-on-arrival rate of less than 4%. I will make lunch when we celebrate someone or when we have meetings. We feed the cropping crew when they are working late. We pay vacation based on years of service. We also celebrate 10 and 20 years of service with a special bonus.

Tell us about your farm and family. Vir-Clar Farms is a fourth-generation dairy farm. We are currently milking 2,400 cows in Fond du Lac, Wisconsin, and 900 cows in Ridott, Illinois. All the cows calve in Wisconsin, and the Illinois site is just for milking. We farm 3,500 acres in Wisconsin and have approximately 350 acres in Illinois. The farm in Fond du Lac is owned by my parents, Gary and Rose Boyke; me and my husband, Grant Grinstead; and my brother, JR Boyke, and his wife, Samantha. Vir-Clar Farms in Fond du Lac has a double-30 parallel parlor where we milk three times a day and ship our milk to Grande Cheese, which produces Italian cheese. At Vir-Clar Meadows in Illinois, we milk three times a day in a double-12 parallel parlor and ship milk to Supremo, which produces Mexican cheese.

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk three times a day. Our current rolling herd average is 34,518 pounds of milk, with tests of 4.6% butterfat and 3.3% protein. We peaked last June at 35,420 pounds of milk, with 4.6% butterfat and 3.3% protein, and an energy-corrected rolling herd average of 41,611 pounds of milk.

Describe your housing and milking facility. Our primary barn is a 6-row, sand-bedded free stall with tunnel ventilation. The fresh cow barn is a single-row, 20-stall barn that’s also has sand-bedded free stalls. Both barns have longday lighting. Cows are milked in a double-12 parallel parlor.

Who is part of your farm team, and what are their roles? Tim oversees employees and helps his wife, Sandy, with bookwork and does the clearing of the heifer shed and waste management. He also works with the veterinarian for the herd. Mark does the record keeping of cattle vet work and mixes feed while managing the repro vet work and records. Sandy is the farm bookkeeper and handles calf care. Andrew, Tim and Sandy’s

Mark (from

Wisconsin. The Kellers currently milk 293 cows with a rolling herd average of 34,518 pounds of milk, with tests of 4.6% bu erfat and 3.3% protein.

son, also works as part of our crew. He helps with the day-today chores, feeding calves and other daily duties.

What is your herd health program? We use weekly pregnancy checks and utilize a double ovsync program for breeding. Fresh cows are vaccinated every 28 days with

Bova Shield and J-5. At dry off, cows get J-5 and SRP Salmonella vaccine. Calves and heifers get Bova Shield and Ultra Back-7 twice.

What does your dry cow and transition program consist of? Dry cows are housed in our old dairy barn set up with tunnel ventilation and sand-

bedded free stalls. Far-off dry cows are fed a dry cow diet with low-potassium grass hay, corn silage, hay silage, winter rye and a mineral mix. The prefresh group gets a milk cow ration along with some Reashure and X-Zelit for two weeks before calving. We have about a 50-day dry period. Cows calve in a large pack pen next to the

pre-fresh group. Heifers calve in a pack next to the pre-fresh group. After calving, both heifers and cows are moved to our post-fresh cow barn for 3-4 weeks. Post-fresh cows get fed the milk cow ration along with some Nutra Cal and Reashure and a top dress of some nice grass hay.

What is the composition of your ration, and how has that changed in recent years? The main cow diet is a total mixed ration of corn silage, hay silage, winter rye silage, cotton seed, dry distillers grain, high moisture corn and dry corn, both ground fairly ne, 5 pounds of alfalfa hay and some liquid molasses along with a protein mix with all the goodies in to balance the ration. Over the past several years, it seems we are going to more of a corn silage-based diet and less alfalfa hay silage. The ration is balanced by our nutritionist, Bob Hagenow, with Vita-Plus.

Tell us about the forages you plant and detail your harvest strategies. Alfalfa has been harvested for extra seed for about 13 years and we try to run a 5-cut system on 28 day

“We’ve used Udder Comfort™ over 10 years: Blue spray on fresh animals and lotion with massage for any flareups. We tried others but always came back to this product because it works,” says Staci Sexton. In 2013, she started Schoene Kuh Dairy, today milking 60 registered Holsteins and Jerseys with a genetic focus on production, health traits, and components. Along with the Irish Ridge herd of her parents and brother, where she helps with herd work, 125 cows are milked at the Millville, Minnesota dairy farm that has been in the family over 160 years.

Schoene Kuh is German for ‘beautiful cow.’ Staci loves working with cows and genetics, earning progressive breeder and milk quality awards. Her 9th AI bull in 10 years is a homozygous polled, high cheese merit bull named King Kong.

“It’s exciting to breed, flush, and wait nine months hoping to get something great,” she says, and when it comes to first calvers “we use Udder Comfort to reduce swelling. Fresh heifers are comfortable with better, faster milkout. It’s easy to use and helps keep our SCC low.”

The farmsite

cut. For corn silage, we plant conventional corn that is tall with high grain yields. We believe this gives us high starch feed and higher tons per acre.

What is your average somatic cell count and how does that affect your production? Our somatic cell count generally is around 120,000. Our goal is to produce very clean, high-quality milk.

What change has created the biggest improvement in your herd average? Our single-row fresh cow barn added a couple thousand pounds to the RHA 14 years ago. In the spring of 2021, we updated the ventilation system in our main barn to a tunnel ventilation system and that added another 3,000 pounds to the RHA.

What technology do you use to monitor your herd? We have the DelPro Activity system from DeLaval to help monitor cows, both high and

low activity. With the DelPro system we also have daily milk weights. With both activity and milk, we can follow if cows are in heat, sick or humming along just ne. We have Dairy Herd Improvement approved meters, so each time we test cows the 7-day running average is what DHI uses for a cow’s milk weights. This makes for a very accurate and reliable test.

What is your breeding program, and what role does genetics play in your production level? Our breeding program is simple: use good bulls. We have had this philosophy for 50 years now. We mainly use high Type Production Index bulls that are 1,2001,500 pounds plus for milk, plus for fat and protein, and 1-2 points for type with sound feet and legs and good udders. We like pretty cows, but they must work. We also look at Net Merit and have an understanding of where it comes from. We are looking more at

Cow Conception Rate. We are a very genetic base herd. We like our high production, putting bulls in bull studs but also enjoy making a nice show cow or heifer for showing.

List three management strategies that have helped you attain your production and component level. Our top strategy is to use good bulls that have a high genetic base that will set you up for the long haul. Cow comfort is our second strategy. We love our sand bedding. As Bob Hagenow of Vita Plus says, “Clean, dry and comfortable.” We say, “We take care of our cows so they can take care of us.” Our third strategy is using high-quality forages. You need good forages to make optimal and economical milk.

Tell us about your farm and your plans for the dairy in the next year. Kellercrest is a genetic-based herd. We believe in longevity and old cows.

We just had our 21st cow go over 300,000 pounds of milk lifetime. We work as a leader trying to protect our local watershed from waste runoff. We have planted cover crops for almost 20 years now, and contour farmed for 50 years. We take care of our cows and land so they can take care of us. As for plans for this year, we just want to continue to try to make high-quality, economical milk. At some point, we would like to upgrade our dry cow facilities.

JD 1780 2001, #587172 .................................................................

JD 1790 2003, 24,000 Est. Acres, #579847

JD 1790 2014, 8000 Est. Acres, #584396

JD 1790 2009, 20,000 Est. Acres, #591065

JD 1790 2014, #583560 .................................................................

JD 1795 2023, 700 Est. Acres, #573347

IH 2150 2021, 4500 Est. Acres, #569307

3500

Contact one of the following dealers to

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA

712-476-9290

United Dairy Systems, Inc.

West Union, IA

563-422-5355

Monticello, IA

319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI

715-772-3201

Bob’s Dairy Supply Dorchester, WI

715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI

608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH DAKOTA

Farm Systems

Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN 320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

By Danielle Nauman danielle.n@dairystar.com

WASHINGTON — On Jan. 22, U.S. Sen. Ron Johnson of Wisconsin reintroduced the Codifying Useful Regulatory Denitions Act to the U.S. Senate — legislation he champions as being vital to Wisconsin’s cheesemakers and dairy farmers, alike.

The bipartisan bill, co-sponsored by fellow Wisconsin Sen. Tammy Baldwin, along with Sens. Ron Wyden of Oregon, James Risch and Mike Crapo, both of Idaho, and Bernie Sanders of Vermont, will create a statutory denition of natural cheeses in comparison to processed cheese products, a move Johnson says is imperative to protect Wisconsin’s cheesemaking industry in today’s everchanging world.

“There have been efforts to dene what natural food is, which gets pretty thorny with the way we process food,” Johnson said. “What is natural, versus what is really processed is going to become an even greater issue as we enter the age of ‘Make America Healthy Again.’”

Johnson said recent testimony about the legislation pointed

to how European countries approve food ingredients in a much different fashion than the U.S.

“Europe has approved something on the order of 400 ingredients, while in America we use a system called ‘Generally Recognized As Safe,’ with 10,000 or so ingredients listed — that’s a huge difference,” Johnson said. “You can imagine if suddenly somebody tries to start dening what is natural versus processed or ultra-processed. It could really impact our cheese industry.”

The bill will solidify the denitions for both natural and processed cheeses the industry has been adhering to for years, according to Rebekah Sweeney, the senior director of programs and policy for the Wisconsin Cheese Makers Association.

“The dairy processing industry has used the term ‘natural cheese’ for decades to help differentiate cheese made with fresh milk and dairy ingredients from pasteurized processed cheese,” Sweeney said. “We thank Sen. Johnson and the bipartisan group of lawmakers working to codify the denition of this commonly-used term in the CURD Act, and demonstrating their support of the dairy industry and transparency in the marketplace.”

This Congressional term is not the rst time the bill has

Sen. Ron

Lee

Wisconsin’s dairy industry in 2017 at a dairy farm in Ozaukee County, Wisconsin. Johnson recently reintroduced the Codifying Useful Regulatory Deni�ons Act to the U.S. Senate in an effort to set statutory deni�ons of natural and processed cheeses.

made the rounds through the U.S Capitol. The CURD Act was previously passed in the Senate but did not get approval in the House of Representatives, to Johnson’s frustration.

“This is one of those rare, completely bipartisan bills,” Johnson said. “People on both sides of the issue completely agree — natural cheese producers and processed cheese pro-

ducers — that we should have a denition of each. It’s just something that we ought to pass with no problem.”

The stumbling blocks the bill has run into in the past have had more to do with philosophical differences than with the intent of the bill, Johnson said.

“I have empathy for individuals who have a real problem

with federal government dictating these things,” Johnson said. “That is the primary opposition.”

Previously the bill had been presented as a stand-alone piece of legislation. Johnson said that is somewhat unusual for a bill like the CURD Act, and cited that as a reason it may have gotten held up in the House. A strategy is being developed to attach it to other must-pass legislation, such as the farm bill, he said, adding he has already had discussions with the chair of the ag committee.

“There will be hurdles to overcome,” Johnson said. “But, I have overcome them before and I believe I will again. We should be able to pass it through the House as well, but it is going to take an effort.”

At this time, Johnson said he is unsure who will sponsor the bill in the House, or when it will be introduced to that chamber.

Johnson believes the legislation is worth ghting for, for the benet of Wisconsin’s dairy industry.

“I’m from the private sector, and speaking from a business standpoint, stability is very important to doing business,” Johnson said. “The worst thing for business is volatility — rules that change can impact things. Dening these terms brings certainty to the market. That is good for dairy farmers and cheesemakers, alike.”

“Do

Reduce cost, intake, over-conditioning with high-ber diet

By Stacey Smart stacey.s@dairystar.com

MARSHFIELD, Wis.

Forage-based diets containing large amounts of corn silage or other high-quality forages often exceed the energy needs of growing dairy heifers. When consuming such diets, heifers usually eat more than they need, leading to undesirable weight gain and over-conditioning.

Research has shown that increasing ber in the pregnant heifer diet reduces unnecessary intake. Diets focused on ber typically reduce feed intake in pregnant heifers by 10%.

Matt Akins is a dairy scientist and research leader in the Environmentally Integrated Dairy Management Unit with the U.S. Department of Agriculture-Agricultural Research Service’s U.S. Dairy Forage Research Center.

Sorghum-sudangrass is cut Sept. 22, 2017, at the University of Wisconsin-Marsheld Agricultural

eld, Wisconsin. Research studies have shown sorghum-sudangrass to work well as a high-ber forage in

to control feed intake.

Having more body fat can cause hard calvings and problems into early lactation.”

“We don’t want excessive condition going into lactation,” Akins said “An ideal body condition score for heifers is 3.25-3.5. We don’t want heifers coming in at 4-plus.

Akins and his colleagues have conducted studies using higher ber forages in the diets of animals that have been bred or conrmed pregnant. Over the last several years, their studies have focused on forages capable of increasing ber and diluting energy in rations.

“Feeding a higher ber diet with lower energy was the goal, and we found that heifers fed this diet have more optimal weight gain,” Akins said. “They eat less and gain a more appropriate weight, compared to

feeding a higher energy diet based on corn silage and alfalfa.”

Akins’ work is based on the fact that dairy heifers generally eat about 1% of their body weight in ber each day.

“The rumen can only t so much ber in it,” Akins said. “We can use that to our advantage by feeding higher ber diets to control feed intake.”

Nutrition targets for the pregnant heifer diet are 50%55% neutral detergent ber, 55%-60% total digestible nutrients and 13%-14% crude protein.

“That puts us pretty close to where we need to be for energy,” Akins said.

When feeding a high-ber diet, Akins has found that

feed intake is often reduced by 5%-15%, depending on forage type and ber levels, with a 10% decrease being typical.

Akins said a gain of 1.82.2 pounds per day is ideal growth for a Holstein heifer, and heifers on these higher ber forage diets are reaching this level of growth. On the other hand, heifers consuming diets of corn silage and alfalfa containing 45% NDF and 65% TDN were gaining 2.5-3 pounds per day in Akins’ studies.

“If we go above 2.2 pounds, heifers start to get overweight and have too much condition,” he said. “They put less growth into muscle and more into fat, especially as they get closer to

maturity.”

Akins said this is particularly problematic in connement situations where heifers get less exercise. In ultrasounds on pregnant heifers consuming a high-ber forage diet, researchers saw less fat growth on heifers’ backs and less internal body fat, particularly on the kidneys.

Furthermore, frame development on heifers is as good or better on these diets as it is on a higher starch corn silage diet.

Through their testing of various forage options, Akins and other researchers have discovered that any higher ber forage can accomplish these weight goals.

He said sorghum-sudangrass works fairly well as do other types of straw. Wheat straw, corn stover, and Eastern gamagrass are some of the forages Akins and colleagues have conducted studies on at the University of Wisconsin-Marsheld Agricultural Research Station.

“Any of these three works well, especially gamagrass in a chopped corn silage,” Akins said. “Corn stover tends to have problems with sorting if it’s not chopped down ne enough. It’s necessary to process wheat straw and corn stover more aggressively to ensure heifers eat it.”

A distant relative of corn, Eastern gamagrass is a perennial warm-season grass that can survive winter conditions. It thrives on a one-cut harvest system, with yields maximized during mid-to-late September and concentrations of neutral detergent ber ranging from 75%-80%. During feeding trials, heifers did not exhibit sorting behaviors with Eastern gamagrass.

Akins plans to do additional testing on other forages in the next few years.

“There are a lot of options people are working with,” he said. “It depends on the agronomic system on your farm and soil conditions.”

Akins said one example that can potentially work well in heifer or dry cow rations is long-day corn silage. It never fully develops an ear and therefore yields a lot of forage tonnage without grain.

Akins and his team continue to investigate new types of forages and plan to do feeding trials with long-day

Pregnant heifers eat a high-ber ra on at the University of Wisconsin-Marsheld Agricultural Research Sta on near Marsheld, Wisconsin. The diet contains Eastern gamagrass as the high-ber forage source, in addi on to corn silage and alfalfa silage as the forage base.

corn silage in a couple of years. They are also looking at pearl millet as a future option.

“Depending on how you manage it, pearl millet would be a fairly good candidate for this type of diet,” Akins said. “We did some test plots on it last summer and are going to do more in the upcoming year.”

Large-scale eld studies and feeding studies on pearl millet are in the works for 2026. He said they rst need to tweak agronomically how to plant the crop and get a better stand.

From 2021-2022, Akins was part of a study done on the perennial intermediate wheatgrass crop, Kernza. After harvesting the grain, the stem and

leaf material is harvested like wheat straw. During a feeding trial, the team found that Kernza worked well in a heifer diet and could be a good replacement for wheat straw.

Lower feed costs is another benet of a ber-based diet. Most high-ber forages cost less to produce than corn silage or haylage. Akins said farmers can also purchase these forages on the market fairly economically.

“Sorghum-sudangrass bears a pretty signicant cost reduction at a savings of 20-25 cents per animal per day,” he said. “A single-cut system is ideal for getting the highest ber value.”

A single harvest for these highber forages at bloom stage produces 1.5-2 times more biomass than a 2-cut system, Akins said.

Dan Olson, owner of Forage Innovations, said crops that can be grown in between other grain crops lower the cost per pound of dry matter and help spread out land cost.

“Finding crops that t in between years of corn, such as sorghum-sudan, can really help,” Olson said.

At Forage Innovations, Olson and his team unite agronomy and nutrition to optimize forage systems. Olson works with about 300 dairy farms in 27 states and also milks cows on his farm in northeast Wisconsin.

Olson said pregnant heifers do well on a single-cut product like sorghum-sudan or a forage sorghum.

Turn to CLOSER LOOK | Page 27

Eastern gamagrass, a perennial warm-season grass that can survive winter condi ons, is pictured in a eld in Springeld, Tennessee. Eastern gamagrass is a high-ber forage that thrives on a one-cut harvest system.

“When you combine a warm season annual like sorghum-sudan with a winter small grain like triticale or cereal rye to maximize the cool portion of the year, you can regularly get 10 tons of dry matter in the Upper Midwest,” Olson said.

One of Olson’s clients in South Dakota is producing cereal rye and sorghum-sudan with out-of-pile costs at 4.5 cents per pound of dry matter.

“That’s 3 cents a pound less than wheat straw, and it’s a better product,” Olson said. “He has the ability to save 70-80 cents a head per day on ration costs.”

This strategy also helps promote soil health while providing more crops per acre.

“My favorite crop is a (brown midrib) photoperiod sensitive sorghum-sudan,” Olson said. “It has a lot of ber and stays vegetative and growing until mid-September. It’s cheap to grow, which helps lower feed costs.”

Dairy farms have options when it comes to supplementing high-ber forages into pregnant heifer diets. Akins said working these forages into the ration should be done in tandem with advice from a nutritionist.

“Work with your nutritionist in getting feed tested properly for nutrient values and in balancing diets properly for ber, energy, protein, minerals and vitamins,” Akins said. “That’s critical.”

By Dan Wacker dan.w@dairystar.com

WAUKON, Iowa — Jeremy Peake has taken boosting cow comfort into his own hands. Peake transitioned from milking cows in a stanchion barn to a swing parlor, pouring concrete and using his stick welder to build the facility himself with the help of friends and family.

Peake operates a grass-fed organic dairy near Waukon. Peake’s herd of 40 Jerseys and Jersey crossbreds are pastured on 80 acres. His transition project started in May 2022 and was operational by March 2023.

“I had thought about making the switch for a long time,” Peake said. “When our buyer decided to stop purchasing from cows housed in stanchion barns, we knew we had to make a change.”

The transition presented two options: remodel the barn to tie stalls or build a parlor.

“I thought the parlor would make more sense,” Peake said. “I thought it would work well right outside the milkhouse. We didn’t have to change much with the pipeline either, and that’s partly why it worked so well.”

Everything in the milkhouse stayed the same including the milking units. For now, Peake continues to take units back to the milk house for washing.

Peake milks with six units, so his setup is like a double swing, with units moved twice on each side to get all the cows milked.

The parlor has the potential to be 10 units. If Peake upgrades, there are plans to add a wash in place for the units and automatic takeoffs.

“I wanted it simple to start out,” Peake said. “There’s a blueprint in place to milk cows faster as the herd grows.”

Peake, in conjunction with Larry

Jeremy Peake stands Jan. 7 in the parlor he built on his farm near Waukon, Iowa. Peake used scrap steel from the farm and gathered other materials from a local scrapyard.

Tranel, an extension specialist with Iowa State University, came up with the plan for the parlor. Peake toured several parlors, taking ideas from each to congure his model.

“I knew what I wanted to make,” Peake said. “Knowing that from the beginning was important.”

Peake gathered the materials he needed and went to work to bring a new milking style to the farm he had been working on for the past 24 years. He used scrap steel he had on the farm already and made trips to the local scrapyard and TJ’s Fencing Company Inc. in Harpers Ferry to gather the rest of the materials.

Using a stick welder, Peake went to work to make his parlor a reality. He also needed to pour concrete, so he recruited friends to help him.

“I did most of the forming myself, with help from our summer intern, Shaundra, and my kids,” Peake said. “My dad helped me with some of it too. I helped other people pour concrete before, so I had a good

background in it. It’s not perfect, but I’m happy with it and we learned more along the way.”

Lang’s Dairy Equipment in Decorah assisted with the pipeline transformation.

With the change in the milking barn, came a change in cow housing. Peake used Tranel’s Cow Tell design to create an open-air free stall area outside the milking barn, with a sand-pack bedding and straw cover during the winter.

This was not Peake’s rst time taking on a renovation. He has a background in home remodeling from helping his dad at his dad’s oor covering and decorating business in Decorah.

“I helped Dad with somewhere around 10 different house projects, anything from light cosmetic changes to gutting and renovating the majority of the house,” Peake said. “Helping with these projects as a kid really gave me an eye for seeing what is possible in a space.”

As a child, Peake made trips to his grandpa’s farm to help with the dairy and orchard there. Peake Orchards is now owned by Peake’s father.

Working with his grandpa on the farm ultimately led Peake to a life in dairy and bringing cows back to the farm.

By Danielle Nauman danielle.n@dairystar.com

MERRILL, Wis. — A true acionado of ice cream might not need a reason to enjoy a scoop or two of the creamy frozen delight for breakfast. But for the rest of the world, National Ice Cream for Breakfast Day rolls around each year, celebrated on the rst Saturday of February.

For the fth time, Shelby Dzwonkowski, owner of The Grand Stand ice cream shop in Merrill, hosted an event to commemorate the day, which took place Feb. 1 at Cosmo Hall in Merrill.

“I feel like someone who didn’t live in Wisconsin came up with that idea,” Dzwonkowski said. “We do a full breakfast to gain more interest because ice cream isn’t necessarily in the front of everyone’s mind when it’s 30 below outside but it is denitely our focus, once they’re here.”

While the holiday was not born in Wisconsin, pop culture lore places the origin of the event in Rochester, New York, home of Florence Rappaport in the 1960s, who started it in an effort to entertain her housebound children on a cold and snowy winter day.

Dzwonkowski had never planned to open an ice cream shop, although her family owned and operated Merrill’s movie theater. Then, one day she ordered Chocolate Shoppe Ice Cream at a restaurant and an idea was planted.

Shelby Dzwonkowski and Em-Moo-Lee the Cow welcome guests to The Grand Stand’s Na onal Ice Cream for Breakfast Day celebra on Feb. 1 at Cosmo Hall in Merrill, Wisconsin. This marked the h me Dzwonkowski has hosted the event.

“I’m an ice cream snob, and it was so good,” Dzwonkowski said. “I kept the napkin, because I said that someday, somewhere I was going to sell this brand of ice cream. We never intended to have an ice cream shop, but here we are.”

Ten years ago, Dzwonkowski opened The Grand Stand, selling Chocolate Shoppe Ice cream, a premium, high milk fat product made in Madison.

“I was a stay-at-home mom, and when my kids went to school, it turned out I didn’t have a job anymore,” Dzwonkowski said. “We started an ice cream shop. Our rst location was a yearround, sit-down shop.”