THE GREAT

See pages 24 and 25 of this section for details!

See pages 24 and 25 of this section for details!

By Danielle Nauman danielle.n@dairystar.com

ATHENS, Wis. — Dairy farming in the 21st century can be complex, and understanding what it means to be sustainable, and how to achieve it, is paramount.

Farmers knowing their carbon footprint number and understanding carbon credits to capitalize on sustainability efforts were explained at the Professional Dairy Producers’ “Carbon, Crops and Cows” workshop Nov. 12 at Miltrim Farms Inc., near Athens.

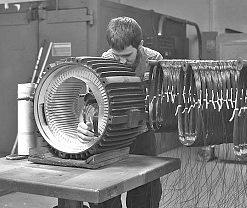

Carson Dugger

Lead Agronomist Eocene Environmental Group

“For years we have been hearing from our European counterparts about how sustainable they are because they have a carbon footprint number,” said Shelly Mayer, executive director of PDP. “The U.S. dairy farmer is leaps and bounds ahead — the most sustainable — but we need to know that number to be able to make that claim. If you can’t measure it, you can’t manage it.”

In response to the global drive towards sustainability, Mayer shared that PDP has developed Your Farm — Your Footprint, a farmer-led sustainability initiative aimed at empowering dairy producers to understand their environmental footprint and assist them in implementing solutions to help shape the future of their farm.

Lead agronomist Carson Dugger and technical services manager

By Sarah Middendorf sarah.m@star-pub.com

PENNOCK, Minn. — Caring for animals is a top priority at Carlson Dairy LLP. Doing so has led to their receipt of the 2024 National Dairy Farmers Assuring Responsible Management Program Excellence Award in Animal Care & Antibiotic Stewardship.

“It’s kind of nice to hear that somebody else is seeing that,” said Chad Carlson, a partner at Carlson Dairy. “We appreciate (that) other people have noticed. We are really proud of what we do.”

with help from clients and industry supporters to

By Stacey Smart stacey.s@dairystar.com

PLYMOUTH, Wis. — As the holiday season approaches, one veterinary clinic and its clients are giving back to their communities with milk in the spotlight. Through its “Gallons of Goodness” campaign, Dairy Doctors Veterinary Services has set a goal to donate 3,000 gallons of milk to lo-

ISSN

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Nadiia Griepentrog • nadiia@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One

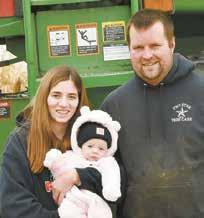

Carlson Dairy is owned by Carl and his brother, Chad, and their father, Curtney. The Carlsons milk 2,000 cows in an automated rotary parlor and farm around 1,400 acres of owned and rented land.

Chad oversees outside work, including the youngstock, while Carl watches over the cows inside the barn and handles herd health. Chad’s wife, Kindra, manages the business side of the dairy and Curtney helps with eldwork and anywhere else needed. Twenty-ve full- and part-time employees work alongside the family as well.

Nicole Frank, FARM program manager at First District Association, nominated the Carlsons for the award.

“I was very aware of the exemplary care that happens here on the farm to know that they would be a really good choice,” Frank said.

Frank met with the Carlsons a few years ago during their evaluation, which is conducted every three years to maintain certication with the FARM program. Frank also had the opportunity to visit the dairy during tours, which allowed her to develop a relationship with the family.

“The FARM program is the dairy industry’s way to show … customers and consumers that the dairy products they nd in their fridge or pantry are

Kindra Carlson holds the Na�onal Dairy Farmers Assuring Responsible Management Program Excellence Award in Animal Care & An�bio�c Stewardship Nov. 1 at Carlson Dairy near Pennock, Minnesota. The Carlsons received the award for their

orts in caring for their animals.

safe to consume and the people that care for them are doing the best they can to do that,” Frank said. Three letters of recommendation are required to nominate a farm for the award. The Carlsons’ recommen-

dations came from their nutritionist, veterinarian and a member at First District Association.

additional stories from our other zone, log on to www.dairystar.com

“We are doing everything in our power to make sure we are taking good care of our animals and bringing a good product to the market,” Kindra said.

When Frank goes to a farm to conduct an evaluation there are two parts to each visit — reviewing written procedures and a visual assessment of the dairy. She starts by observing their written protocols and ensuring each employee on the farm has a current record of training and a cow care agreement.

“(First District staff) guide us and provide resources,” Kindra said. “They’re not coming out here as police … looking for problems to try and get us into trouble.”

Frank then looks at the animals on the farm to conrm they are healthy and thriving in their environment.

The Carlsons said they make a point to train their employees and have consistent meetings. Chad holds quarterly calf meetings with all his employees, the nutritionists and calf consultants. There, they review protocols to ensure everyone is on the same page. They also play videos and explain different practices.

“That’s worked really well,” Chad said. “A lot of times the big thing is the why. ‘Why are we doing (this)?’ and ‘Why don’t we do other things?’”

The Carlsons lead by example.

“When they see how we handle the animals, they handle them the same way,” Carl said.

Each employee on the farm must sign a training and cow care agreement yearly. This is to conrm workers know the right protocol and procedures.

“There are a lot of things about the FARM program that have helped us (with) training,” Chad said. “They have resources. Otherwise, we would have to work hard to nd (them).”

Part of the FARM program is to put steps in place to prove to consumers that farms

are doing and tracking these proper protocols.

“It’s nice because within this program everything is researched and has the backing to say this is why we do it,” Frank said. “It’s in here because it is best for the animals.”

Chad and Carl said they knew from a young age the

cows come rst.

“Dad taught us that way back when we were kids, the cows are the most important, and you got to take care of the cows,” Chad said. “If you don’t take care of the cows, they won’t take care of you.”

Carlson Dairy’s employees are appreciated by the Carlson family for their help in creating a good product. Chad and Carl strive to show appreciation to their employees during daily tasks.

“Please and thank you go a long way,” Carl said.

On Carlson Dairy, each generation works alongside employees. Chad and Carl’s kids help on the dairy in different capacities, working full time or helping on evenings and weekends.

“It’s a family working with all of our employees,” Kindra said. “Our goal was to raise our kids in a way (that shows) how we expect animals to be treated.”

Carlson Dairy has made changes and improvements from the time when Curtney was milking 17 cows in the old barn to now the partnership milking 2000 cows.

“When we started this partnership and built this barn, I told them you will never get to the production that I have,” Curtney said. “They did. They passed me up. I am pretty proud of them. They have done well.”

“We’ve had a great response with more than 1,500 gallons donated in the rst week,” said Dr. Chris Booth, one of the owners of Dairy Doctors. “This campaign provides a simple way for our clients to share their goodwill with others in the community, and it’s neat how they’ve responded and kicked in donations.”

Dairy Doctors will donate the rst 100 gallons of milk. For every 10 gallons donated by clients and supporters, the Plymouth-based clinic will donate two additional gallons — up to a total of 400 extra gallons. Dairy Doctors hopes to donate 500 gallons, with clients and other supporters funding the remaining 2,500 gallons to meet their goal.

“Our clients are really excited that we organized this and that they have an opportunity to participate,” Booth said. “They’re dairy farmers and appreciate promoting dairy products and getting those products into the hands of families in need.”

Due to the perishable nature of milk, Dairy Doctors is not donating actual gallons, but rather, the dollar equivalent to match the cost of 3,000 gallons. Contributions will be used by local food pantries and food banks to purchase dairy products for distribution within their communities.

Mary Bender, Dairy Doctors ofce manager, said the goal is to provide as much milk as possible during the holiday season and beyond.

“We want to share the blessing of wholesome dairy products with others in our communities,” Bender said. “Milk is a unique thing to donate, but there is certainly a need. Our hope is the funds provided will extend weeks and months into the future for each organization to purchase milk and other dairy products.”

Booth and his team initiated a pilot campaign in 2018 that surpassed their 1,000-gallon goal by nearly 2,000 gallons. The donations were sent to two food pantries in Sheboygan County.

“It went over really well,” he said. “We haven’t done it the last few years, but our staff expressed interest in wanting to do some type of community service activity, which spurred us into action again this year.”

The campaign has expanded to reach four additional counties: Manitowoc, Calumet, Fond du Lac and Ozaukee. Donors can choose to give their donation to one or more of the recipient organizations in these counties.

“Our practice area expanded, and we wanted clients in those areas to be able to donate to their local food pantry,” Booth said. “Some have donated to multiple pantries. The campaign is very exible in allowing people to choose how to apply their dollars.”

As the clinic supports their community, Booth said their efforts are being greeted with generosity that extends beyond their clientele.

“Some of our suppliers and pharmaceutical companies and random people from the community who follow us on Facebook have brought in donations,” Booth said. “A local FFA chapter donated 100 gallons.”

Booth said he was pleased with the number of shares the campaign received when it was announced on Facebook.

“It was mostly our clients sharing it with their families and friends, and it was great to see support for it right away,” he said. “Hopefully, this spurs activity for others around the state and country to set up something similar.”

Dairy Doctors is collecting donations until Nov. 30 and will turn the donations over to the beneting organizations in early December. Booth said each pantry handles the acquisition in different ways.

“We’re letting them utilize the funds to help expand the system they’ve already created,” he said.

During the holidays, the Gallons of Goodness campaign aims to help those less fortunate enjoy the nutritious benets of milk — a staple not easily accessible to everyone Bender said. All donations will make a positive impact, she said, as the need is great and continues year-round.

“We challenge people outside of the areas we serve to nd out what their local food pantry or food bank does to provide dairy products to those in need,” Bender said. “It’s important to understand that the need is everywhere.”

Courtney Titus of Eocene Environmental Group explained how dairy farmers understanding the science and learning their farm’s carbon footprint number can create opportunities for their dairy.

Both carbon and nitrogen cycles play a role in how greenhouse gases are emitted into the atmosphere. Understanding both can improve carbon management on the farm, Dugger said.

tion and processing for that product are not included in the farm’s carbon footprint.

Once a reduction from the baseline has been realized, the option exists for dairy farmers to enter the carbon market. There are two types of carbon markets in place — regulatory and voluntary.

“We’re looking at what we can control and manage to start to reduce those scores,” Titus said.

The three main greenhouse gases that typically result from dairy production are methane, nitrous oxide and carbon dioxide.

“The scope is what you’re trying to measure,” Titus said. “While the boundary is looking at where is this emission happening and what is its impact.”

Courtney Titus Technical Services Manager, Eocene Environmental Group

Dugger explained there are multiple ways to measure carbon impact on a farm. The farm’s carbon footprint can be calculated by determining the amount of greenhouse gas emissions released into the atmosphere through activities on the farm. Carbon intensity is measured by the amount of carbon created per unit of production.

“The carbon footprint reects more long-term change,” Dugger said. “Carbon intensity is easy to impact on-farm by increasing efciency, doing more with less. Ultimately, we’re looking at greenhouse gas emissions, and if we have less total GHG emissions per product, our carbon intensity score decreases.”

“Methane is one we hear a lot about, with enteric emissions that dairy and beef get a pretty bad rap for,” Dugger said. “Methane is considered short-lived in the atmosphere because over time it degrades down into carbon dioxide and eventually goes back into the soil.”

Conversely, Dugger said nitrous oxide is worse because it is longer lived in the atmosphere and has greater potential for global warming.

During the photosynthesis process, plants remove carbon dioxide from the air, turning it into plant material. The amount of carbon captured in the soil through carbon sequestration versus the amount released back into the air plays a role in determining the carbon footprint.

Soil organic carbon is the most stable form of carbon. It is benecial not only to the soil, but to the farm’s overall carbon footprint.

To determine a farm’s carbon footprint score, Titus said emissions are considered from “cradle to farm gate,” meaning that once the product leaves the farm, further transporta-

Emissions used to develop a carbon footprint score are categorized as Scope 1, which are direct emissions, and Scope 2 and 3, which are indirect emissions created by either upstream or downstream activities.

Scope 1 emissions include fuel usage and enteric methane emissions.

Determining a farm’s carbon footprint involves the collection and analysis of data, which is run through three models to determine a baseline number. Using that information, dairy producers can look within their farms to nd avenues to increase efciencies and decrease their footprint score.

“We want to get as detailed as possible so we can avoid overestimating,” Titus said. “When you get into Scope 3, it is very hard to gather data.”

Many farms are most interested in Scope 1 and 2 Titus said.

Eocene’s function is to visit the farm, collect information, and run it through their models, creating a baseline carbon number. A year later, the same data is collected again, allowing for comparisons to determine where carbon reduction has been recognized.

“Most of the carbon markets we’re participating today in the U.S. are voluntary markets,” Titus said. “With carbon credits and carbon markets, verication is required. They are looking for quantication of a baseline and they are looking for implementation — what did you do to improve?”

Entering the carbon marketplace can allow dairy farmers to create revenue from their efforts to reduce their carbon footprint. Titus cautions farmers to remember that once they sell a carbon credit, they can no longer claim that towards their farm’s overall carbon footprint score, as it will factor into the purchasing entity’s score.

Grasping the opportunity to create an individual path towards sustainability is something Mayer urges dairy farmers to pursue.

“As dairy farmers, nding your voice and knowing your business is more important today than it has ever been,” Mayer said. “If we’re going to have a market, we’re going to have to stand up proactively and continue to share our story. We can complain as much as we want about consumers and the retail chain, but we’re all connected.”

By Tiffany Klaphake tiffany.k@dairystar.com

CLARISSA, Minn. — At Twin Eagle Dairy, the Lunemanns and their team work together to keep the Clarissa farm thriving.

The Minnesota Milk Producers Association has recognized the Lunemann family as their 2024 Producer of the Year.

“(This award) is about recognizing our whole community,” Pat Lunemann said. “From our employees, to those who help us raise our heifers, to the custom chopping crew, agribusinesses that we work with, and the community around us that supports us.”

Lunemann and his wife, Jody, and their team milk 900 cows in a double-12 parallel parlor and farm 1,600 acres of corn and alfalfa. The farm employs 20 individuals, many of whom have been with the Lunemann family for more than 10 years.

“The goal here is to hire good people and empower

the ones we have to be the best that they can be,” Lunemann said.

One employee, Beth Ruegemer, has been with the Lunemanns for more than 30 years.

“It’s a good place to work,” Ruegemer said. “They are just an excellent family to work for, and the culture here is excellent.”

When Ruegemer rst started working for the Lunemanns, they were milking in a tiestall barn, and Ruegemer got to know all aspects of operating the farm. As the farm grew, so did Ruegemer’s knowledge and level of responsibility.

Today, Ruegemer is in charge of scheduling employees, DairyComp software, ordering supplies and general organization of the farm.

“It’s been a good place with exible hours as my own personal family grew,” Ruegemer said. “I can work remotely and log into DairyComp wherever I am and check on things.”

Cesar Garcia is the herdsman and has been with Twin

Eagle Dairy for more than 20 years.

“I like the cows and the people here,” Cesar said. “When I rst started, I didn’t

(understand) the cows well, but now, I know when and what is wrong with each of the cows.”

Another longtime em-

ployee, Javier Garcia, is in charge of calf care until calves are 400 pounds. At that point, employee Dale Reining takes over until heifers are pregnant. Then the animals are sent to a local heifer grower, where they stay until one month before calving.

“Because we are successful at calf raising, we are able to sell quality animals beyond what we need to other dairies while still maintaining a good herd,” Lunemann said.

Industry advances have made it easier for the crew to care for the herd at Twin Eagle Dairy.

“Managing the cows has become so much easier because of technology,” Lunemann said. “We use activity monitors, and those have made things much simpler for Cesar and our A.I. technician.”

Ruegemer agreed.

“Communication is key,” she said. “Cell phones have enabled us to call and text back and forth much easier.”

Lunemann said it is because of dependable employees like Ruegemer and Cesar that he can participate and take on leadership roles at the local and state level.

“It is so much

ture organizations,” Lunemann said. “The conversations and ideas you gain are just fun. You come back to the farm with a different perspective.”

Lunemann has served on the board of AgriGrowth for 20 years, chairing it for three years. He sat on the board of the Minnesota Milk Producers Association board for 18 years, nine years of which he was president. He is also serving on the state’s Governor’s Advisory Council on Climate Change.

“Getting off the farm and rubbing shoulders with other people in the dairy and agriculture industry has meant a great deal to me,” Lunemann said. “I bring so much knowledge back home when I work with other people in leadership positions.”

The son of a German immigrant, Lunemann uses his voice to advocate for dairy farmers.

“This coming May will be the 100-year anniversary of when (my grandparents and dad) got off the ship in Ellis Island in New York,” Lunemann said. “They found their way to Browerville, Minnesota, and we are still farming here.”

Lunemann and his wife took over the farm in 1983. At the time, the farm consisted of 55 cows milked in a 51-stall tiestall barn. In 1996, the Lunemanns built the freestall barn and milking parlor and expanded to 400 cows. Over the next 15 years, they expanded the operation to its current size.

The Lunemanns have six grown children, seven grandchildren, and

are looking to retire and transition the dairy farm. Their youngest son, Alex, works on the farm and prefers the cropping and equipment maintenance part of the business. Since the other Lunemann children hold jobs off the farm, the Lunemanns are working with the Minnesota Department of Agriculture’s FarmLink program to

nd a young person or family interested in taking over their dairy farm.

“We worked hard to achieve a lot of things,” Lunemann said. “There are a lot of dairies in our area that haven’t made it, but we are still here. There are a million small decisions that have gone right in order for us to make it work.”

Through it all, the Lunemanns have remained each other’s biggest supporters.

“Every time I come up with a crazy idea, Jody says, ‘OK, I support you,’” Lunemann said. “We wouldn’t be where we are without Jody and I being a true team. It is also by the grace of God that we are still here.”

The U.S. Department of Agriculture has issued a nal decision in its proposal to amend the uniform pricing formulas in all 11 Federal Milk Marketing Orders. The nal decision puts forth a package of amendments to update formulas and makes limited changes based on public comments. USDA Agricultural Marketing Service Deputy Administrator Dana Coale said the next steps are the most important. “This is where the dairy farmers get an opportunity to vote on each Federal Order as it has been amended through this nal decision. As soon as the nal decision is published in the federal register, we will begin the referendum process.”

Every eligible dairy farmer or dairy cooperative will receive a ballot for each order where they have no pool. Ballots must be returned by Dec. 31. AMS will be hosting three webinars this month.

Long list for potential ag secretary pick

• Willmar, MN 320-235-3672 • 877-484-3211 810 Mayhew Lake Rd. NE • St. Cloud, MN 320-240-2085 • 844-262-2281 19612 US-71 • Long Prairie, MN 320-732-3715 • 866-514-0982

year. With an extension, it might be harder for us to get some of the resources that we want.” In addition to the farm bill, the 45Z tax credit guidance, yearround E15, and ex-fuel vehicles are on the to-do list. When an immigration bill is heard, Klobuchar also emphasized the need to address ag labor issues.

By Don Wick Columnist Ag Insider

Veteran Washington analyst Jim Wiesemeyer is describing Donald Trump’s win as the greatest political comeback in history. Trump won all of the battleground states and expanded his broad support in rural areas. The speculation now begins over who will get the nod for Trump’s new cabinet. Numerous names are part of that guesswork for the agriculture secretary including former ambassador to the U.N. Agencies for Food and Agriculture, Kip Tom. Tom is an Indiana farmer and co-chaired the “Farmers and Ranchers for Trump 47 Committee.” Other potential choices include Texas Agriculture Secretary Sid Miller, American Farm Bureau Federation President Zippy Duvall, former House Agriculture Committee Chairman Mike Conaway, former USDA Undersecretary Ted McKinney and former USDA Chief of Staff Ray Starling.

Divided government will change Minnesota legislative dynamics

The control of the Minnesota House remains uncertain, but it could end up being a 67-67 tie. Rather than the current DFL trifecta, political analyst Blois Olson expects a different scenario for the next session. “I think the biggest issue is how you get a budget done with a tied House,” Olson said. “Governor (Tim) Walz is going to come back. I think his attitude, his experience on the national stage and how he chooses to work with the legislature is going to be one of the key components. He has not been as engaged with the legislature as other governors. He’s only got one veto in six years. As a former legislator, he thinks that the legislature should do their job and he should work with them. He’s probably going to have to dive in earlier with the split House.”

Petersen optimistic about 2025 session

With the election behind us, the Minnesota Department of Agriculture is preparing for the 2025 legislative session. Agriculture Commissioner Thom Petersen is evaluating budget and policy priorities. “Some of the policies that we’ve looked at would really focus around animal disease.” High-path avian inuenza and African swine fever are two animal health threats mentioned. There will be different dynamics at play for the upcoming legislative session. “With the tie in the (Minnesota) House, that’s not the end of the world for agriculture. Agriculture works together a lot of times in the legislature so I’m optimistic that we’re one of the bills that can get done.”

Klobuchar wants farm bill before end of year

Minnesota Senator Amy Klobuchar will serve as the Ranking Member of the Senate Agriculture Committee in the next session of Congress. During a stop at the Minnesota Ag and Food Summit, Klobuchar said she’d prefer to complete the farm bill before the beginning of the new year. “I just think we’re going to be better off when we’re doing all the disaster relief for the southern states and we’re doing that with good reason. There’s going to be funding that’s spent on that if the farm bill gets jettisoned as kind of an orphan at the end of next

Economic relief likely, farm bill not University of Missouri Food and Agricultural Policy Research Institute Director Pat Westhoff is not optimistic that a new farm bill will be nished before the end of the year. “The fact that we haven’t been able to reach a compromise yet on the bill makes it difcult to imagine how we get the entire thing done during a short lame-duck session.” Westhoff believes there is more support for economic relief. “I do think the chance of some sort of economic assistance package is probably a bit higher,” Westhoff told Red River Farm Network. “Separate from a farm bill, a shorter-term bill that might actually provide some additional support to farmers might still be possible.”

Farm bill uncertainty

With the election over, Minnesota Farmers Union President Gary Wertish wants the focus to return to the farm bill. “The top thing on everybody’s mind is the importance of getting a farm bill done, hopefully within this lame-duck session. I did talk to (Minnesota Senator) Amy Klobuchar this (Wednesday) morning and she’s very committed to doing it.” Wertish admits there’s no guarantee the legislation will be addressed before the end of the year. “There’s uncertainty with that, too, whether we’ll go forward, or they’ll decide they want to hold off and put it into the next session, which starts the whole process all over again.”

Farm bill may be punted to ’25 Congress has a big to-do list during the lameduck session. What does that mean for agriculture? “Honestly, I think the real question for people in agriculture is not whether or not we’ll do a farm bill in lame duck, but really whether we even do one in 2025,” said Jay Truitt, president/CEO, Policy Solutions LLC. “It may take a while; I can imagine a lot of stuff changing on the nutrition side of the equation now.” Truitt expects Congress to address disasters, like the drought and hurricanes, before the end of this term. Regarding President-Elect Trump’s cabinet, Truitt believes there will be a role for North Dakota Governor Doug Burgum. “I’d be surprised if he doesn’t have something to do with the energy or commerce departments; he’s earned his place just from a policy knowledge standpoint.”

The latest data from Minnesota farm country

An agricultural impact study will be released later this month, but AgriGrowth members got a preview during the Ag and Food Summit. Land O’Lakes Vice President of Government and Industry Relations Matt Wohlman said agriculture accounts for 8.5% of Minnesota’s economy and is responsible for 330,000 jobs. “Another key nding from the report is the economic contribution of crop production has overtaken livestock production in Minnesota and while both crop and livestock production are up, crop production is growing at nearly twice the rate over the last ve years,” Wohlman said. “When it comes to job creation, more than 18,000 jobs were created by crop production in the last ve years, that’s a 21% increase. For livestock, we’ve seen a loss of jobs, about 6,700 jobs, a decrease of about 5%.” The research found the average Minnesota farm has 390 acres. That’s only slightly larger than the 350-acre average 25 years ago. During that same time, the average market value of that farm has increased nearly 500%.

Don’t move the goal posts

Wells Fargo Chief Agricultural

Economist Michael Swanson compared Minnesota with other Midwestern states during his AgriGrowth presentation. Swanson said Minnesota would benet if it leaned into specic segments of animal agriculture, especially the poultry and swine industries. To grow the livestock and poultry sectors, Swanson advocates for a consistent environmental regulatory framework. “Companies achieve a standard that was deemed acceptable ve years ago and they’re told it’s no longer acceptable and they’re not really given a cost-benet rationale for that, so I would say once goalposts are set, you’ve got to have a good reason to move the goalposts.”

Centers for Disease Control and Prevention calls for more testing Farm workers who have been exposed to avian inuenza should be tested for the virus even if they don’t show symptoms. The Centers for Disease Control and Prevention is making that recommendation as USDA steps up its testing of milk for H5N1. This virus has been found in 450 dairy farms across 15 states.

Dairy Farmers of American announces plant closure

Dairy Farmers of America plans to idle its milk condensing plant in Goshen, Indiana, Jan. 2, 2025. In a statement, DFA said this decision was part of the company’s strategy to optimize its farmer/owners’ milk value and deliver returns on their investment.

Trivia challenge

President Franklin D. Roosevelt signed a resolution into law in 1941 making Thanksgiving an ofcial holiday. That answers our last trivia question. For this week’s trivia, what is the rst compartment of a cow’s stomach called? We’ll have the answer in our next edition of the Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

In a story published Nov. 9, Dairy Star incorrectly identied Mark Lamborn as the fth generation on his dairy farm. Lamborn is the sixth generation. The article also listed Tim Phipps as Lamborn’s business partner. Phipps is an employee for Lamborn. Dairy Star sincerely apologizes for the errors.

By Emily Breth emily.b@star-pub.com

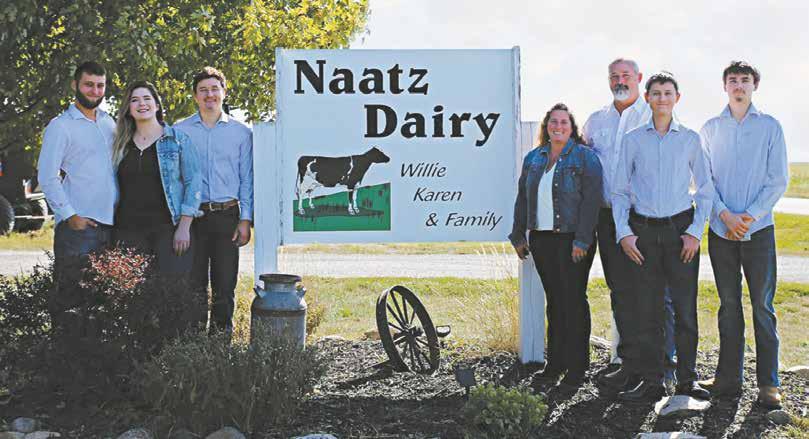

Minn. — Willie and Karen Naatz have been active in their community and have now been recognized as the 2024 Dodge County Farm Family of the Year.

“We have a very strong passion for ag and want to advocate for it — especially animal-related ag — as much as we can,” Karen Naatz said. “It is important people know how animals are treated and raised.”

Naatz was raised on a dairy farm where Willie started working when he was in middle school. The couple started to dairy farm with 25 cows when they were 18 and 19 years old.

In 2003, they bought their current farm and grew the herd to 250 cows. They milk in a double-10 herringbone parlor with the help of their four sons — Tristin, Trace, Brodee and Wyatt — and a few high school students.

Running a dairy farm is the best thing they have done, Naatz said. She and Willie have worked with their kids every day and continue to be blessed as hands-on parents. Their four sons continue to help on the farm.

Tristin works full time on the farm, owns a custom bal-

ing business and is a certied diesel mechanic. His wife, River, enjoys being on the farm and works at the Mayo Clinic. Trace received his undergraduate degree in health sciences in spring 2023 and currently serves as a licensed emergency medical technician on the Dodge Center Ambulance Service and helps on the farm. Brodee graduated from high school in 2023. He works full time on the dairy farm and helps with his brother’s baling business when needed. Wyatt attends high school online and helps on the farm.

The Naatz family said they were honored to receive two National Dairy Quality

Awards from the National Mastitis Council. In 2023, the family received the platinum level award.

“To be in dairy farming you have to really love what you do,” Naatz said. “My mom and dad always told me ‘If you don’t work hard for it, you won’t appreciate it.’”

The family owns 40 acres of land and rents an additional 28. They buy most of their feed and make local purchases as often as possible.

The family has been active in 4-H and FFA for numerous years and lease animals to young people who are not from farms.

“4-H is so good for kids,”

Naatz said. “It gives the kids such a strong background.”

Any youth involved with FFA or 4-H will blossom, Naatz said.

The Naatz children were involved in dairy judging and were members of a team that competed at the state level. The family is still active in both organizations.

“I think it is very important for kids to be in these organizations,” Naatz said. “The amount of leadership, values, support and integrity the kids get is beyond amazing.”

Naatz has served on the American Dairy Association boards for both Goodhue

and Dodge counties. Willie has been involved with the Dodge County Dairy Herd Improvement Association board. The whole family is active at their county fair.

“I want to share what we do with others,” Naatz said. “We might not get much sleep, but we feel like it was well worth it. Watching my kids grow and be part of the community has been really rewarding.”

The family also donates money and dairy products to their local food shelf to promote the dairy industry and support the community.

“We need to get out there and promote our product,” Naatz said. “We need to get that to our local people and show our support.”

Naatz also said it is important to help those who do not have a direct connection to a farm become better informed.

“If we don’t have a voice out there and bring (farming) to them, are they ever going to be around it or know fact from ction?” Naatz said.

www.franzensales.com

This calendar year, what are you thankful for?

Karen Kasper (pictured with grandson, Waylon Keck)

Owatonna, Minnesota Steele County 400 cows

This calendar year, what are you thankful for? This year, I am most thankful for our home, which is where much of our family works and gathers together to celebrate various events: baptisms, birthdays, holidays, Mother’s Day and Father’s Day, and pizza parties. We have adequate space for the grandkids to run, play and explore. It isn't always easy for all of us to leave the farm, so hosting special events here allows everyone to be together.

Family aside, what are you most grateful for?

I am most grateful for living in a free country with so many resources. In September, my husband, Pete, had a stroke and because we have such great medical facilities, they were able to quickly administer tissue plasminogen activator to prevent major debilitating problems.

On a daily basis, what ways do you show appreciation? I personally enjoy showing my appreciation by baking goodies, cooking meals or giving small gifts to others. Working with my grandkids allows for so many teaching opportunities and life lessons. It is so rewarding to have their help with chores and they are quite happy to receive a small allowance or gift.

What is your favorite tradition related to Thanksgiving? Our Thanksgiving tradition is having our three kids and their families and great-grandparents over for a potluck dinner. Each family brings their specialty dish to share with our group of 20.

What three essentials can you nd on your Thanksgiving plate? The three essentials on our Thanksgiving plate would be ham, mashed potatoes and gravy and Great-grandmother's sweet cranberry salad. However, there are so many other dishes that there are plenty of leftovers to share with everyone.

Tell us about your family and farm. Our 400-cow dairy farm is located in Steele County, just three miles south of Owatonna. We grow corn and hay and raise our own replacement heifers, Holstein and beef calves. We operate the farm with our son and his family. Our cows are housed in bedded-pack and freestall barns and are milked in a double-8 parlor. We have shipped our milk to Associated Milk Producers Inc. for over 50 years.

Branden and Kylee Sauer with their daughter, Kinley Pierz, Minnesota Morrison County

100 cows

This calendar year, what are you thankful for? In August, we welcomed our rstborn daughter, Kinley. We are thankful for this beautiful blessing and for the family and friends who have supported us in this new journey.

Family aside, what are you most grateful for? We are grateful for our farm and the lifestyle it provides. Although an everyday commitment, farming has provided numerous life lessons and opportunities for both of us. We would not be where we are today without it and are excited to share these experiences with Kinley.

On a daily basis, what ways do you show appreciation? Daily appreciation on the farm is never verbalized as much as it should be. One of our favorite things about working together on the farm is that we have different strengths and weaknesses that allow us to work as a team without even really talking about who needs to do what. We show our appreciation by upholding those responsibilities and communicating if there is a change.

What is your favorite tradition related to Thanksgiving? Setting aside some time to spend with family and relax on Thanksgiving is always a favorite tradition. We look forward to sharing the upcoming holidays with Kinley as well as starting some new traditions as a family of three.

What three essentials can you nd on your Thanksgiving plate? It is not Thanksgiving without stufng, mashed potatoes and ham.

Tell us about your family and farm. Branden farms full time while Kylee is employed as a registered nurse and helps with evening and weekend chores. We have been creative in nding ways to involve Kinley in our work on the farm as well. Our cows are milked in a double-9 parlor and the milk is shipped to First District Association by Sunrise Ag Cooperative. We farm 800 acres of corn and soybeans with Branden's dad, Dale, and buy all our hay.

Vicki Schultz Freeman, South Dakota Hutchinson County 2,000 cows

This calendar year, what are you thankful for. For this year, I am most thankful for faith, health, and, of course, family. I have two sons and a daughter and a total of eight grandchildren, ve of whom I get to see daily.

Family aside, what are you most grateful for. I am grateful for the safety of family, friends and employees. I am also thankful for the bountiful crop with a crazy year of spring oods and a dry summer.

On a daily basis, what ways do you show appreciation? I rarely say no to anyone who asks for assistance, whether it is family or employees. My day ends in prayer in thankfulness for all we have been blessed with.

What is your favorite tradition related to Thanksgiving? My favorite Thanksgiving tradition is getting to see my whole family along with getting to celebrate Thanksgiving and eat a meal together.

What three essentials can you nd on your Thanksgiving plate? Turkey, mashed potatoes, sweet potatoes, stufng and cranberries will be on my plate. I will also have all the grandkids’ favorites.

Tell us about your family and farm. Our sons and their wives, John and Becca and Jeff and Yolanda, own Schultz Bros. Dairy. We have 2,000 milking cows, milk in a double-24 parlor and raise all of our beef/dairy calves and replacements. We have 30 employees between the dairy and crop production. My husband, Mike, is in charge of the feeder cattle and crops and we raise most of our feed. I do the bookwork, chase after grandchildren, and do a lot of farm errands. We have ve grandchildren on the farm — Axle, Olivia, Ava, Penny, and Harrison — and three — Meredith, Evelyn, and Nora — in Sioux Falls where our daughter and son-in-law, Jenny and Matt, live. We sell the milk to Associated Milk Producers Inc. in Freeman.

Julianne Myhre

Minneota, Minnesota

Lyon County

60 cows

This calendar year, what are you thankful for? I am thankful for those moments of peace in your life that sneak up on you, etch themselves in your memory and leave a mark on your heart forever. I was given a yearling colt in 2000. My girlhood dream horse, if you will, wasn't feeling well this past July so I spent the night walking around in the dark, just being with him. It was one of those rare clear nights where it was still, but the mosquitos were curiously absent. It was one of those kinds of nights when you linger after checking on a heifer in labor just because it's so still and peaceful. We wandered everywhere, playing follow the leader. I lasted until 3:30 a.m. before I sat down and fell asleep. By then he seemed to be content to graze in the front yard without wanting to lie down. It wasn't colic but equine protozoal myeloencephalitis that ultimately quietly took my Prince two days later. That last night, us walking, was a gift, just like all the people that having him brought into my life.

Tessie

Felling

Belgrade, Minnesota

Stearns County

700 cows

This calendar year, what are you thankful for? I am thankful for our new beautiful red-headed baby girl, Jeannette, who was born in April, our other children, Brentley, Evan and Petranella, and my husband, Brandon.

Family aside, what are you most grateful for? I am most grateful for where life has taken me because I get the opportunity to farm and take care of animals every day.

Family aside, what are you most grateful for? The rural community is what I am most grateful for: our fellow dairy farmers, neighbors, friends or even strangers who wave when we meet each other on the highway and the neighbors and friends you bump into when you run errands in town on a rainy afternoon. It is always nice to catch up and hear the latest news. It's just different in the country, wonderfully different.

On a daily basis, what ways do you show appreciation? As a former city girl I try to show my appreciation for my husband by dressing up a bit so he doesn't only see me in chore clothes and muck boots.

What is your favorite tradition related to Thanksgiving? Our Thanksgiving tradition is usually trying to sneak in an afternoon nap. We generally eat with family on the Saturday after Thanksgiving, so there are no sales calls or visitors on Thursday, and that makes for the best naps.

What three essentials can you nd on your Thanksgiving plate? Three essentials are jellied cranberry, dressing and a juicy slice of ham.

Tell us about your family and farm. Mike (my husband) and I do all our daily chores ourselves. We bring our cows into a stanchion barn to be milked and then out to a sawdust pack barn and large dry lot to relax. We raise all our own replacement heifers. We raise corn for grinding and making silage and alfalfa hay, which we wrap for balage. It denitely keeps us busy.

On a daily basis, what ways do you show appreciation? I show appreciation to others by helping them out. When it gets busy on the farm, I like to help where there is a need. During the harvest, I make meals and deliver meals to the workers. Also, at times I help out with eldwork.

What is your favorite tradition related to Thanksgiving? My favorite tradition is making stufng and pies from scratch. Some of my favorite pies to make are caramel apple pie and pumpkin pie.

What three essentials can you nd on your Thanksgiving plate? Mashed potatoes and gravy, turkey and stufng, and you also cannot forget the pumpkin pie.

Tell us about your family and farm. My husband, Brandon, and I farm on his family farm with his parents, Bruce and Kelly, and his brother, Kyle. We ship our milk to First District Association. We milk in a double-16 herringbone parlor and we raise all our youngstock.

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk twice a day and our current herd average is 26,329 pounds milk, 1,132 pounds fat (4.4%) and 887 pounds protein (3.4%).

Describe your housing and milking facility. Our cows are housed in a freestall barn that was built in 1972. We added on to the building around 20 years ago. Most of the stalls, 57, have waterbeds; the rest are bedded with sand. We milk our cows in a double-4 herringbone parlor. We also have a sprinkler system that kicks in when the temperature is 68-70 degrees. We don’t see a decline in milk production when it gets hot.

Who is part of your farm team, and what are their roles? I, Kevin, am the herdsman on the farm and Pete is in charge of the crops and machinery. We have one full-time person along with three parttime helpers. They take care of most of the milkings.

What is your herd health program? We do a herd check monthly and the cows get vac-

Kevin (le ) and Pete Ackerman stand near their close-up pen Nov. 13

Rapids, Minnesota. The Ackermans milk 118 cows and

fat, and 887 protein.

cinated twice a year with Triangle 10. The calves get Nasalgen 3-PMH at birth and four

weeks later. The older heifers get Bovi-Shield 10-way.

What does your dry cow and transition program consist of? The cows are dried off at

60 days and moved to a calving pen three weeks before calving. Their ration consists of corn silage, grass hay and minerals. They receive a pre-fresh protein mix in the calving pen. They are housed in a 3-sided shed that is bedded with corn stalks.

What is the composition of your ration, and how has that changed in recent years? Our ration consists of alfalfa haylage, corn silage, highmoisture corn, dry hay and a protein mix. We really haven’t changed much in the last several years.

Tell us about the forages you plant and detail your harvest strategies. We raise alfalfa and corn silage and try to harvest them at the highest quality. We usually harvest our alfalfa at the bud stage and try for four crops. The intervals are usually 28-33 days. We shoot for 65% moisture on our corn silage. Our forages are stored in bags or silos. We ll four 10-by-200 bags and two stave silos. One is 20-by-60 and the other is 18by-55.

“If you don’t have cow comfort, nothing else seems to matter. We minimize stresses at calving on her feet and legs, making sure she has feed and water and a good place to rest, she’s clean and she’s dry.

“That leaves the udder as the next thing to take care of, and with Udder ComfortTM they transition a lot more smoothly,”

Maynard, Iowa, milking 750 95 pounds of 4.2 fat milk.

“For 10 years we used Udder Comfort periodically. At the 2022 World Dairy Expo, they talked me into trying the Udder Comfort Battery-Operated Backpack Sprayer. I didn’t think it insisted, and they were right!

SCC fell from 165 to 137,000.

“We also notice any clinicals that do show up, clear faster, and don’t

“Now, we continue to use it 3x/day on all fresh cows for a week after calving. If we have a mastitis cow or high SCC, or anything not perfectly normal, we spray it on

“With fresh cows, we see a lot more udder texture at 2 weeks in milk as edema is pulled out. You can They’re up moving around more. They eat. They drink. They make more milk and higher quality milk.

“The Udder Comfort Backpack Sprayer made us more compliant on our udder health. It’s more user-friendly

MARK KLAPHAKE/DAIRY

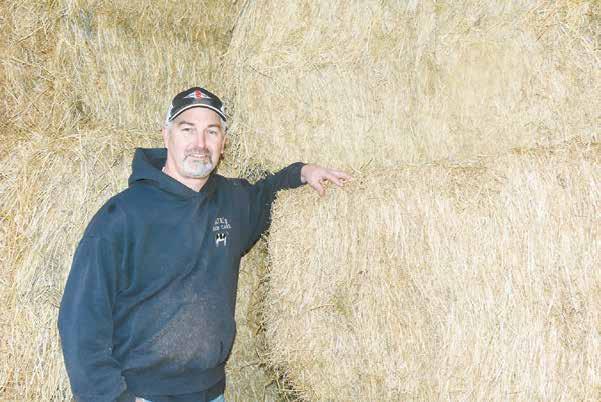

Kevin Ackerman stands near big square bales of alfalfa Nov. 13 on the farm he operates with his brother, Pete, near Sauk Rapids, Minnesota. The Ackermans focus on pu ng up high quality feed on their third genera on farm.

What is your average somatic cell count and how does that affect your production? Our somatic cell count is 91,000. We have been in the top 100 for SCC in Minnesota for several years.

What change has created the biggest improvement in your herd average? Genetics. I do some embryo work on the better animals. We are not afraid to spend money on good bulls. I focus on production, components, good feet and legs and udders, 1.5 or better. I usually select higher genomic sires.

What technology do you use to monitor your herd? We test through Minnesota Dairy Herd Improvement Association and we are 95% registered through Holstein Association USA. We genomic test all our heifers in the rst three months.

What is your breeding program, and what role does genetics play in your production level? All our females are on a mating program from Select Sires. Genetics are very important to us. We spend the money on better bulls. My ag instructor once told me you only get 20 crops of females if you milk for 40 years.

List three management strategies that have helped you attain your production and component level. Genetics, making high-quality feed and putting a rubber mat over the slatted oors in the free-stall barn, which has added more comfort for the cows.

Tell us about your farm and your plans for the dairy in the next year. We are a third-generation farm that was started in 1944 by our grandpa, Bart. My dad, Adrian, took over in 1965 and Pete and I took over the farm in 1994. We farm 500 acres.

• Hoof Health Products

• Boluses

• Pharmaceuticals

• Injectables

balling guns, magnets and many other animal health items.

• Intramammary Infusions

• Dewormers

• Scours, Diarrhea Products

• Nutritional Products

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA 712-476-9290

United Dairy Systems, Inc.

West Union, IA 563-422-5355 Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI

715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN

320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN

507-932-4288

Wadena, MN

218-632-5416

There is a fairy tale that comes to life in Louisville, Kentucky, the rst Sunday of November each year. The lights over Freedom Hall dim, and then, that year’s class of the National Jersey Jug Futurity steps onto the green shavings, each cow spotlighted as her name is announced.

The National Jersey Jug Futurity, held with the All American Jersey Show, is the oldest and richest continuous dairy cattle class in the world, and the pageantry and prestige of Jug Day live up to its history. The class is lled with suspense. After the dramatic entry, the rst pull of cows is made in numerical order, and cows stay in numerical order until each is placed. Eventually, the six top cows remain. Their placings are announced over the microphone until two remain. The winner is draped with a purple banner by the judges and a collar of roses is placed around her neck.

Jug and was in awe of the tradition.

Our Jug dreams began in 2009 when Austin purchased Tierneys Barbaro Lucine, a heifer entered in the Jug. In 2010, Austin and my dad spent the trip back home from Louisville making plans for taking Lucine back for her Jug appearance the next year.

My dad did not make it to the 2011 Jug as he passed away Dec. 26, 2010. Lucine did not make it to her Jug Day either as she did not settle in time to calve and be ready.

By Danielle Nauman Staff Writer

Making it to the spotlight on Jug Day is no easy feat. Calves are entered, and nomination fees must be paid by various deadlines. Heifers need to calve in with the exceptional quality of udder that can potentially propel them to the top. Cows need to breed back, ensuring they are at their prime come November. So many things can keep a cow from making it to the Jug.

Growing up a Holstein girl, my dad was passionate about the art of breeding and I was raised with the understanding that a good cow, was a good cow, regardless of her color. My dad was always intrigued by the mystique surrounding the Jug, and he admired those who could capture that moment.

I watched my rst Jug on my rst trip to Louisville in 1994, just a few months after purchasing my rst Jersey. The desire to breed a Jug winner began to sprout within me.

When my son, Austin, made his rst trip to the All American in 2008, he saw his rst

In 2015, we came close. Lucine’s daughter, Smokin Hot Rendition Letitia, nished fth. The exhilaration of watching her parade among the nal six is a feeling I will never forget.

This year’s Jug dreams began July 16, 2021, when Smokin Hot Texas Tornado was born. A young milking yearling calved with a heifer calf sired by Guimo Joel-ET, nearly a week overdue. We were excited about the yearling’s future, but it was her calf that caught my attention.

Some calves are born special, and Texas Tornado was one of them. I swear she may have actually told me she was as her mother licked her off. Thoughts of roses and November Sundays ickered through my head.

We consign many of our calves to sales. When the sale managers came looking for consignments that winter, TT was passed on because of her birth date. That was ne with me, I was committed for the long haul.

The next year as the sale managers came looking, Michael Heath took an interest in the chubby, young, bred heifer, about 60 days from her due date. He told me to be sure to have Austin let him know when she calved in good.

Just a few days before the farm accident that ultimately took his life in mid-March, Michael inquired about the “good young Joel.” TT went a week over, calving the morn-

ing of March 22, 2023, just a couple of hours before I got word that Michael’s family had decided to take him off life support.

TT calved with a lovely little udder, and every day brought improvement, growth and change. We showed her successfully as a twoyear-old, got her bred back and put our focus on Nov. 10, 2024 — the day of the National Jersey Jug Futurity.

Just a few days before TT calved, the bird u struck America’s dairy industry, and concerns about the movement of livestock being restricted began to cloud my thoughts. We kept TT home throughout the year for fear of potential quarantines in the event of exposure to a positive cow, keeping our focus on the Jug.

Early the morning of Nov. 4, I put TT on a trailer, headed for her date with destiny in Louisville. I stayed home, with plans to watch the live feed from Freedom Hall.

Anxiously I watched, perched on the

edge of a ve-gallon bucket directly in front of the television. I watched as TT made the rst pull, as she was sent to the group of 11, and as that narrowed down to the group of six. The sixth-place cow was announced...fth... fourth...third.

My heart raced. Two cows were left standing.

I felt a quick icker of disappointment when the purple banner did not waft down over her shoulders. But this was followed with awe. Texas Tornado had nearly accomplished the unimaginable as she was named the Reserve Winner of the National Jersey Jug Futurity.

The kaleidoscopic emotions running through my mind were intense — were we victorious, or did we fall short? Depending on the moment, I am still not certain of the answer. And then I walk out to the calf hutches and start dreaming of roses on a Sunday in November, three years away, all over again.

Grand Prize Drawing Will Be Held Wednesday, December 11, 2024 THE WINNERS WILL BE POSTED ON WWW.DAIRYSTAR.COM, MILK BREAK NEWSLETTER AND ON FACEBOOK. “Grand” Prize Heifer Calf: OLMAR ROCKET SURPRISE

PLUS: 11 DAYS OF GIVEAWAYS FOR ADULTS LEADING UP TO GRAND PRIZE DRAWING S

Sire: Terra-Linda Rocket-ET Dam: Olmar Helix Sansi Look for the red box at participating locations to enter!

Pictured is Olmar Rocket Surprise, the heifer that will be given away in the Great Christmas Giveaway drawing. GrandPrize CalfownedbyBrian comesandJillNelson FarmsfromOlmar Eye,inSleepy Minn.

Born: September 25, 2024

• Equity Livestock, Waukon Waukon • 563-568-4501

• Farmers Union Coop

Postville • 563-864-7234

DELAWARE COUNTY

• Del-Clay Farm Equipment

Edgewood • 563-928-6445

• Edgewood Feed Mill

Edgewood • 563-928-6405

• Helle Implement Dyersville • 563-875-7154

• Farmers Union Coop Manchester • 563-927-6050

DUBUQUE COUNTY

• Eastern Iowa Dairy

Epworth • 563-876-3087

• New Vienna Ag Automation New Vienna • 563-921-2896

• Rexco Equipment Farley • 563-744-3393

• Roeder Implement Dubuque • 563-557-1184

• Scherrmann’s Implement Dyersville • 563-875-2426

• Skip Breitbach Feeds Sherrill • 563-552-2393

• Ungs Shopping Center (IAS) Luxemburg • 563-853-2455

CLAYTON COUNTY

• Windridge Implement Elkader • 563-245-2636

FAYETTE COUNTY

• Baumler Implements Inc.

West Union • 563-422-3835

• Nexus Cooperative Elgin • 563-426-5566

• United Dairy Systems West Union • 563-422-5355

HOWARD COUNTY

• Farmers Win Co-op

Cresco West • 563-547-3660

• Windridge Implement Cresco • 563-547-3688

JACKSON COUNTY

Equity Livestock, Maquoketa Maquoketa • 563-652-8080

SIOUX COUNTY

• Sioux Dairy Equipment, Inc. Rock Valley • 712-476-5608

WINNESHIEK COUNTY

• Brynsaas Sales & Service

Decorah • 563-382-4484

• Farmers Union Coop Fort Atkinson • 563-534-7216 Ossian • 563-532-9381

• Farmers Win Coop

Ridgeway • 563-737-2244

• Franzen Sales & Service Fort Atkinson • 563-534-2724

• Lang’s Dairy Service

Decorah • 563-382-8722

• Windridge Implement Decorah • 563-382-3614

BECKER COUNTY

• Adkins Equipment Inc.

Detroit Lakes • 218-847-3131

BENTON COUNTY

• Farm-Rite Equipment

St. Cloud • 844-262-2281

• First National Bank of MilacaGilman Of ce • 320-387-2233

• Gilman Co-op Creamery Gilman • 320-387-2770

• Midwest Machinery

Sauk Rapids • 320-259-6222

• Pine Country Bank

Royalton • 320-584-5522

Rice • 320-393-4200

BROWN COUNTY

• New Ulm Regional Vet Clinic New Ulm • 507-233-2500

CARVER COUNTY

• Lano Equipment of Norwood Norwood/Young America

952-467-2181

DAKOTA COUNTY

• Werner Implement

Vermillion • 651-437-4435

DOUGLAS COUNTY

• Midwest Machinery

Alexandria • 320-763-4220

• Osakis Creamery Assn.

320-859-2146

• Pro Ag Farmers Co-op

Gar eld • 320-834-2271

FILLMORE COUNTY

• Farmers Win Co-op

Rushford • 507-864-2161

• First Southeast Bank

Harmony • 507-886-6922

• Hammell Equipment

Harmony • 507-886-2255

Rushford • 507-864-2845

• Minnwest Bank Spring Valley • 507-346-9899

GOODHUE COUNTY

• Ag Partners

Cannon Falls • 507-263-4651

Goodhue • 651-923-4496

Pine Island • 507-356-8313

• Central Livestock

Zumbrota • 507-732-7305

• Finnesgard Trucking

Goodhue • 651-923-4861

• Midwest Livestock Systems, LLC

Zumbrota • 507-732-4673

• Midwest Machinery

Cannon Falls • 507-263-4238

Wanamingo • 507-824-2256

• Stockman’s Supply

Zumbrota • 507-732-7860

HOUSTON COUNTY

• Farmers Win Co-op

Caledonia • 507-725-3306

Houston • 507-896-3147

• Hammell Equipment

Eitzen • 507-495-3326

• Midwest Machinery

Caledonia • 507-725-7000

KANDIYOHI COUNTY

• D&D Ag Supply & Construction Pennock • 320-599-4466

• Farm-Rite Equipment Willmar • 877-484-3211

MCLEOD COUNTY

• Ag Partners Belle Plaine • 952-873-4244

• Leedstone Glencoe • 877-864-5575

• Midwest Machinery Glencoe • 320-864-5571

MEEKER COUNTY

• Farm-Rite Equipment Dassel • 888-679-4857

• Schlauderaff Implement Co. Litch eld • 320-693-7277

MILLE LACS COUNTY

• First National Bank of Milaca Milaca • 320-968-3101

• Foreston Farmer’s Co-op Creamery Foreston • 320-294-5711

MORRISON COUNTY

• Elmdale Creamery Association & Locker Bowlus • 320-573-2608

• Litke’s Veterinary Service Pierz • 320-468-6666

• Magni Financial

Little Falls • 888-330-8482

• Midwest Machinery

Little Falls • 320-632-5469

• Modern Farm Equipment Pierz • 320-468-2161

• Pierz Co-op Pierz • 320-468-6655

• Pine Country Bank Little Falls • 320-632-9740

• Sunrise Ag Cooperative Buckman • 320-468-6433 Lastrup • 320-468-6433 Little Rock • 320-584-5147

MOWER COUNTY

• Midwest Machinery Grand Meadow • 507-754-1100

• Nexus Cooperative LeRoy • 507-324-5242

OLMSTED COUNTY

• Ag Partners Stewartville • 507-533-4222

• Hammell Equipment Chat eld • 507-867-4910

OTTER TAIL COUNTY

• Bongards’ Perham • 218-347-4142

• Farmers Elevator of Fergus Falls & Henning 218-736-3301

• PCCA-Country Store Perham • 218-346-7075

• Perham Stockyards Perham • 218-346-3415

• Pro Ag Farmers Co-op in Henning 218-583-2947

• Pro Ag Farmers Co-op in Urbank 218-267-2401

PIPESTONE COUNTY

• Gorter’s Clay & Dairy Equipment Pipestone • 507-825-3271

POPE COUNTY

• Midwest Machinery Glenwood • 320-634-5151

RICE COUNTY

• Ag Partners Le Center • 507-357-6868

• Midwest Machinery North eld • 507-645-4886

STEARNS COUNTY

• A&C Farm Service

Paynesville • 320-243-3736

• Arnold’s of Kimball Kimball • 320-398-3800

• Arnold’s of St. Martin St. Martin • 320-548-3285

• Arnzen Construction/St. Rosa Lumber Freeport, In St. Rosa 320-836-2284 or 1-888-276-1751

• Centre Dairy Equipment & Supply Inc. Sauk Centre • 320-352-5762 or 1-800-342-2697

• Dairyland Supply Sauk Centre 320-352-3987 or 1-800-338-6455

• Ecker Feed Service, LLC New Munich • 320-837-5800

• Elrosa Grain & Feed Elrosa • 320-697-5515

• Elrosa Lumber Elrosa • 320-697-5591

• Farm Systems

Melrose

1-800-636-5581 • 1-800-247-0012

• Freeport State Bank

Freeport • 320-836-2126

Greenwald • 320-987-2265

Melrose • 320-256-7208

• Hartung Sales & Service, Inc. Freeport • 320-836-2697

• Lake Henry Implement Paynesville • 320-243-7411

• Leedstone

Melrose • 800-996-3303

• Magni Financial

Albany • 888-330-8482

Avon • 888-330-8482

Belgrade • 888-330-8482

Cold Spring • 888-330-8482

Freeport • 888-330-8482

Melrose • 888-330-8482

Paynesville • 888-330-8482

Sauk Centre • 888-330-8482

• Melrose Implement Inc.

Melrose • 320-256-4253

• Midwest Machinery

Paynesville • 320-243-7474

Sauk Centre • 320-352-6511

• Modern Farm Equipment Sauk Centre • 320-352-6543

• Nutrien Ag Solutions

320-352-6564

STEELE COUNTY

• Northland Farm Systems Owatonna • 507-451-3131

TODD COUNTY

• Magni Financial Grey Eagle • 888-330-8482 Long Prairie • 888-330-8482

• Farm-Rite Long Prairie • 866-514-0982

• Olson’s Custom Farm Service Staples • 218-894-2474

• Pro-Ag Farmers Co-op in Browerville Browerville • 320-594-2711

• Pro-Ag Farmers Co-op in Clarissa Clarissa • 218-756-2112

• Pro-Ag Farmers Co-op in Eagle Bend Eagle Bend • 218-738-2552

WABASHA COUNTY

• Ag Partners Plainview • 507-534-2531 Lake City • 651-345-3328

• Beck Implement Elgin • 507-876-2122

• Leedstone Plainview • 800-548-2540

• Midwest Machinery Plainview • 507-534-3116

• Wingert Sales & Service Plainview • 507-534-2285

WADENA COUNTY

• Dairyland Equipment of Menahga Menahga • 218-564-4958

• Midwest Machinery Wadena • 218-631-2311

• Olson’s Custom Farm Service Verndale • 218-445-5500 Sebeka • 218-837-5749

WINONA COUNTY

• Ag Partners Lewiston • 507-523-2188

• Elba Co-op Creamery Elba • 507-796-6571

• Kalmes Implement Altura • 507-796-6741

• Lang’s Dairy Equipment Lewiston • 507-452-5532

• Lewiston Sales Lewiston • 507-523-2112

• Midwest Machinery St. Charles • 507-932-4030

• Minnwest Bank Lewiston • 507-523-2161

WRIGHT COUNTY

• Hobert Sales Inc. Cokato • 320-286-6284, 1-800-820-6455

• Midwest Machinery Howard Lake • 320-543-2170

BROOKINGS COUNTY

• W.W. Tire Service Brookings • 605-628-2501

CODINGTON COUNTY

• Glacial Lakes Livestock Watertown • 605-886-5052

MINNEHAHA COUNTY

• Central Valley Dairy Supply Garretson • 605-467-0812

• Midwest Livestock Systems Renner • 605-274-3656

ROBERTS COUNTY

• Valley Dairy Supply Corona • 605-432-5224

SPINK COUNTY

• Kasemeister Creamery Frankfort • 605-475-2020

Halli Poppler

Waverly, Minnesota

Ridgewater College

Major: ag business (associate of applied science) and ag marketing and communications (certicate)

Why did you want to obtain your American FFA Degree?

Poppler: FFA has been a major inuence in my life, and earning the American FFA Degree was the perfect way to showcase all that I have accomplished in the organization. FFA has provided countless opportunities for me to grow not only in my leadership abilities but also as a person and professional. This degree represents my commitment to those experiences and the skills I have gained.

Schefers: I already have my Minnesota FFA Degree, which I needed before earning my American FFA Degree. I’m proud of my accomplishments and contribution to FFA. The American FFA Degree is the highest degree that an FFA member can receive, and not many members have it. I’m the rst in my family to re-

Jesse Schefers Foley, Minnesota University of Wisconsin-River Falls

Major: agriculture education and a dairy science minor

ceive it.

Sellner: I wanted to receive my American FFA Degree because not many FFA members get this honor. Only 1% of FFA members get it and I want to be in the 1%. Also, no one in my family has their American FFA Degree and I wanted to be the rst to get one.

Thorson: Along my journey in FFA, I realized that it was an opportunity to close one door that leads to another. Obtaining my American FFA Degree was closing the door of being in the blue corduroy jacket. Yet, the experience and leadership that I gained from my high school and college efforts opened a new door to pursuing my supervised agricultural experience on a professional level.

Wright: Being in the 1% of members to achieve their American FFA Degree and receiving it

Sleepy Eye, Minnesota

South Dakota State University

Major: agricultural education with a minor in animal science

Oct. 26 means the world to me. My dream of receiving this degree started when I learned about all of the achievements you can strive for in FFA in my ag classes. It quickly became a goal of mine to receive the American FFA Degree. Two years ago, I watched my sister, Allison, receive hers, and seeing this made my dream of earning it matter even more. Completing my goal was the best way I could have ended my FFA career, and I know I made my past self proud. Although my life in the blue jacket is complete, my life of advocating for agriculture is not. I plan to have a career as an agriculture teacher to help other students complete their goals in FFA.

What was your reaction when you found out you received it, and who did you tell rst? Pop-

Waverly, Minnesota

South Dakota State University

Major: Dairy production with minors in leadership and agribusiness

pler: I was thrilled. Receiving such a prestigious recognition that less than 1% of members achieve was an incredible honor. I immediately told my advisors and family, as they have been by my side, encouraging and supporting me throughout my entire FFA journey.

Schefers: I was happy to receive my American FFA Degree and proud of all my accomplishments to receive it. The rst people I told were my family and friends who also received their American Degrees. I couldn’t have done it without their help.

Sellner: When I found out I received my American FFA Degree I remember feeling shocked and really proud of myself. I remember bursting into tears because I just remember little me wanted this so badly, and honestly it was the best feeling getting the news

South

because I showed myself that if I dream it, I can do it. The rst person I told about receiving my degree was my parents because without them I wouldn’t be the person I am today. My parents have taught me everything I know and they also have pushed me to succeed. I don’t know what I’d do without them. Thorson: Ecstatic. The joy, relief and excitement of walking across the stage and accomplishing my goal was an incredible feeling. Right after I found out, I called my parents, specically my mom, because they have been my biggest supporters while also pushing me to achieve the goals I never thought I was capable of.

Turn to FFA DEGREES | Page 27

techniques to stir up and suspend the solids prior to and during the pumping process.

use state-of-the art agitation boats which provide vertical agitation throughout the lagoon. It can easily stir up and maintain the solids in suspension. In addition, Lagoon Pumping uses traditional stick agitators to wash down the banks and to maintain a horizontal movement to the lagoon to assure suspension of the solids throughout the pumping process.

Wright: Finding out I was on the list of recipients for the American FFA Degree was an incredible moment. It was Friday morning at our county fair, and the list was posted just as I nished getting my livestock in place. My mom was the one who pointed out that the list was up, so we looked at it together. I was trying to stay calm, worried that I might not see my name, but when I glanced at the list from Minnesota and saw not only my name but also all of my friends’ names, I couldn’t stop smiling. As the rest of my family trickled into the fair after completing chores at home, I shared the good news with them. My FFA advisors and the advisor from the Glencoe FFA Chapter were also in the barn for the FFA children’s barnyard, so I told them the great news, too. Having my family and ag teachers be the rst to know and celebrate with me meant so much as I couldn’t have received my American FFA Degree without their support and positive impact in my life.

What was your Supervised Agricultural Experience? Poppler: My SAE focused on vegetable production. I worked in our FFA chapter’s Community Supported Agriculture garden, managing it for two years. We served over 35 community members each summer and fall with a variety of fresh produce. Additionally, I worked at a local greenhouse, where I gained hands-on experience in wholesale and retail, helping customers choose plants and making recommendations.

Schefers: I worked at Fleet Farm in the yard department for my job in college during my freshman and sophomore years. My responsibilities included organizing and moving various supplies, assisting customers with loading their purchases, ensuring the yard remained clean and accessible and doing yearly inventory. One of the key skills I developed was operating a forklift, which I used to move larger items such as pallets of feed, fencing materials and other heavy products. This job required attention to safety, effective communication with my coworkers and customers and the ability to work efciently under pressure, especially during busy periods.

Sellner: My SAE was working on my family’s robotic dairy farm for dairy production placement.

Thorson: My SAE was dairy production placement. Essentially, I worked on my family’s dairy farm while showing records of personal improvements while I was there. These improvements ranged from personal growth, like how to effectively work with employees to obtain different strengths, and to gain practical skills, like how to properly care for an animal that is sick using protocol that follows the industry and consumers’ expectations.

Wright: My SAE was in diversied livestock production with all of the different species we have on our farm. These species included our breeding beef, dairy cows, rabbits, turkeys, show pigs and meat ducks. I tracked things such as the care I gave them, how many hours I spent with them, nances, etc. Having this SAE helped me grow in many skills such as record keeping, responsibility, nances and time management.

What are your future plans? Poppler: I am excited to pursue a career in agricultural marketing and communications. Through various internships, I’ve enjoyed developing a wide range of skills, from social media management and advertising to design, website development and company branding. This eld lets me blend creativity with my passion for agriculture. Schefers: I plan to graduate college with an agriculture education major and dairy science minor. I would like to get a teaching job as an agriculture teacher and FFA advisor and teach agriculture and shop classes. Someday, I would like to get more involved with the family dairy farm and implement new ideas and advancements that I learned with my dairy science

minor and what I learned from working with dairy at my current job at Mann Valley Farm at the University of WisconsinRiver Falls.

Sellner: My passion is educating others on the importance of agriculture, which has led me to major in agriculture education with a minor in animal science. Upon college graduation, I want to be an ag teacher where I can teach youth of all ages that our community has a place for everyone. Whether you grew up on a farm or in town, everyone has a place in agriculture.

Thorson: After I graduate college, my career goal is to return to my family’s sixthgeneration dairy farm to own and operate it with my parents. My personal goal is to be a reliable source of information for people to reference so I can make an overall positive impact on the dairy industry.

Wright: After graduating, I hope to become a high school agriculture teacher. This has been a longtime dream of mine as it allows me to connect with students through agriculture. In this role, I aim to expand students’ knowledge in agriculture, serve as an FFA advisor and help foster youth’s connection to agriculture. As a strong advocate for hands-on learning, I plan to own a small farming operation with various livestock species, crops and machinery for youth in the community to gain hands-on agricultural experience. I hope this will help them discover a passion for agriculture or, at the very least, learn where their food comes from.

Tell us about your farm. Poppler: I grew up on Poppler Dairy, our family dairy farm in Waverly, Minnesota, where we milk around 650 cows. Helping out on the farm from a young age sparked my passion for agriculture.