March 8, 2025

Central Plains Dairy Expo brings trade show, entertainment, seminars

By Meghan Kropp meghan.k@dairystar.com

SIOUX FALLS, S.D.

More than two days lled with educational and networking opportunities will be coming to Sioux Falls again this year as the Central Plains Dairy Expo is set for the end of March.

“We’re very excited to be offering it again this year,” said Renee Brod, CPDE director of member services. “It is one of the area’s largest dairy-focused expos, bringing together dairy farmers, industry experts and key stakeholders. It’s a really exciting event that focuses exclusively on the dairy industry.”

The expo begins Tuesday, March 25, at the Denny Sanford Premier Center with the I-29 Moo University offering a dairy beef

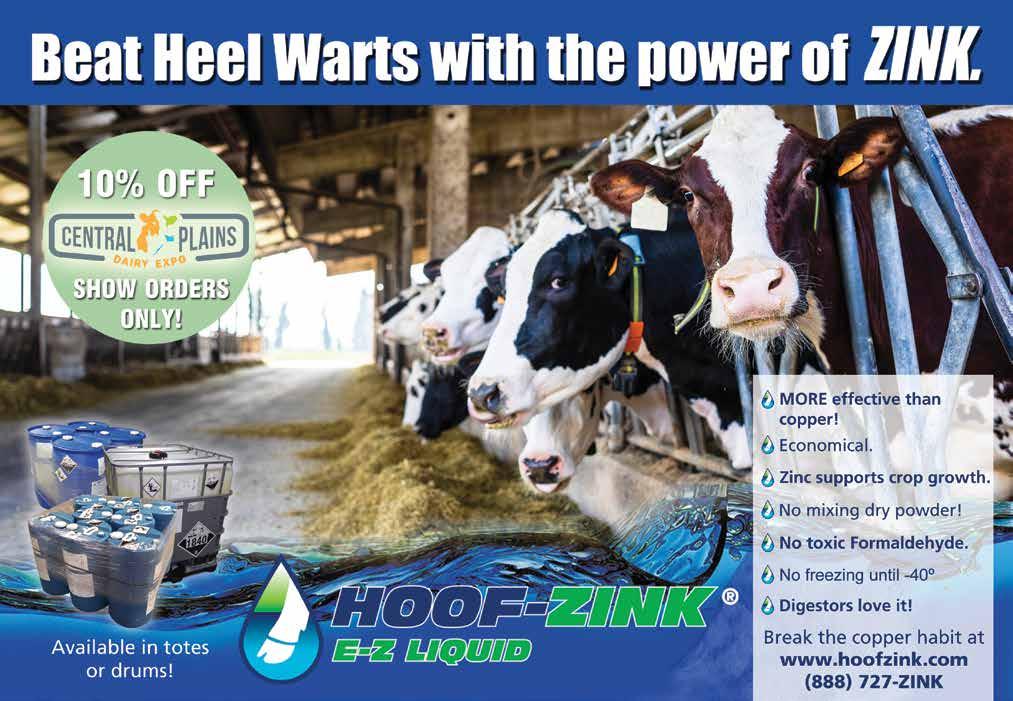

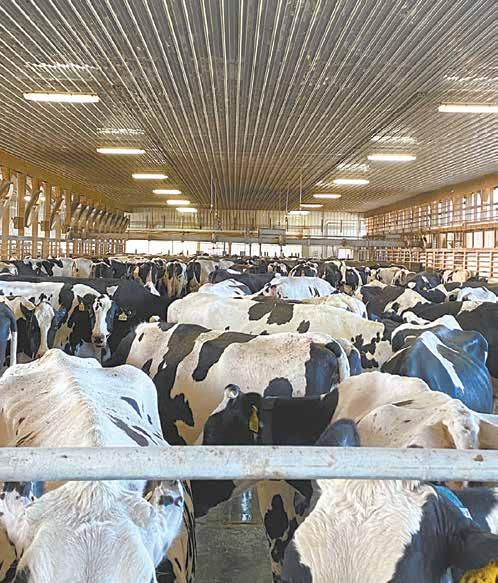

A endees walk through the trade show at Central Plains Dairy Expo in Sioux Falls, South Dakota. There will be almost 300 exhibitors at this year’s CPDE.

short course. Registration for this course is separate from registration for the expo, Brod said. To register for the course, attendees are

encouraged to visit the I-29 Moo University website. Doors open at 5 p.m. for the welcome reception on Tuesday, which will include

a conference hosted by Zoetis and happy hour hosted by Alltech in the Sheraton Hotel Fontenelle Room. Brod said multiple exhibi-

tors and sponsors will be hosting a hospitality suite in the Sheraton ballroom.

ISSN Print: 2834-619X • Online: 2834-6203

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell nancy.p@dairystar.com

Karen Knoblach karen.k@star-pub.com

Annika Gunderson annika@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101

danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

One

A�endees interact with exhibitors at the Central Plains Dairy Expo in Sioux Falls, South Dakota. In addi�on to the trade show, there will be 70 speaker sessions for a�endees, some of which will be offered in Spanish.

RaeLynn, a two-time Academy of Country Music new female vocalist nominee who is currently on tour with Jason Aldean, Nate Smith and Dee Jay Silver, will be this year’s performer. Brod recommended visiting the CPDE website to register ahead of time for a name badge. Name badge registration is free for producers. Expo doors open early on Wednesday, March 26. Attendees can nd their seats for the prayer breakfast at 6:30 a.m., with the program beginning at 7 a.m. The breakfast is free for attendees. All that is required is the name badge.

This year’s featured speaker is Rob Roozeboom, who founded RISE Ministries in 2001 and later launched RiseFest, an annual Christian music festival in northwest Iowa.

“He’s going to share his story to inspire people to nd hope and worth amidst brokenness,” Brod said. “He will be a fantastic speaker. We are looking forward to having him. I love that our prayer breakfast community nds people who are local, within our region, to come and provide these inspirational stories.”

The tradeshow oor will be open from 8:30 a.m. to 5:30 p.m. on Wednesday and will be open again from 8 a.m. until 3 p.m. on Thursday, March 27. Brod said there will be almost 300 exhibitors at this year’s expo with the newest exhibitors typically setting up in the arena.

topics this year range from managing milk prices to young stock monitoring to on-farm sustainability, all the way to practical things your employees can do for biosecurity. It’s really cool to have a lot of new topics that are going to be discussed this year.”

Attendees will be able to sit in on more than 70 speaker sessions over the two and half days at the expo. Eight of the sessions will be offered in Spanish.

Brod said one of the highlights this year is the Ed Shed, which will offer short presentations for attendees.

“Ed Shed sessions are quick hits on what you can do to help your farm immediately with some of the different topics that we have there,” she said.

“We have great companies representing all different aspects of the dairy industry,” she said. “Breakout session Turn to PREVIEW | Page 4

Subscriptions

56378-1246. ©

“One of the key elements of the expo is to provide educational programming, so offering this wide range of sessions and presentations on these topics — like sustainability, innovative dairy farming, herd management and product development — is really important for us. It’s one of the crucial things we do at the expo.”

Another highlight Brod said is the scholarships the Central Plains Dairy Foundation will be offering. This year, three new scholarships, along with the Tonneson Scholarship will be given.

“All funding for our foundation comes directly from the expo,” Brod said. “The foundation board this year decided that they wanted to help our students who are looking for scholarships in the dairy industry. We’re excited about this opportunity the CPDF is

able to provide, especially to students who want to be in the dairy industry.”

Brod said the foundation continues to invest in the CPDE area dairy industry by introducing new scholarships. The newest scholarships will offer $5,000 to three college or university students who have completed at least one semester of post-secondary education and are pursuing a degree in agriculture with an emphasis in the dairy industry. Scholarship applications can be found on the CPDE website.

“We’re looking forward to this year’s event and the incredible opportunities it’s going to provide for the dairy community,” she said. “It’s a fantastic chance to collaborate, learn and grow together as an industry.”

“Breakout session topics this year range from managing milk prices to young stock monitoring to onfarm sustainability, all the way to practical things your employees can do for biosecurity. It’s really cool to have a lot of new topics that are going to be discussed this year.”

RENEE BROD, CPDE DIRECTOR OF MEMBER SERVICES

Country music sensation RaeLynn will bring her signature charm and chart-topping hits to the Central Plains Dairy Expo on March 25, in Sioux Falls, South Dakota. A two-time Academy of Country Music New Female Vocalist nominee, RaeLynn has made waves in country music with her distinctive storytelling and vibrant personality.

The CPDE concert starts at approximately 7 p.m. Prior to the concert, CPDE will host its welcome reception, which starts at 5 p.m., in the Denny Sanford Premier Center. The free welcome reception features hearty appetizers, 800 pounds of cheese served charcuterie style and, of course, ice cream – offered in numerous avors.

These events are free to dairy producers, but registration is required. CPDE organizers encourage dairy producers to register before the event to avoid long lines and signicant wait

times.

RaeLynn has captivated fans with her emotional ballad, “Funny Girl,” which dropped in March 2024. This single marks a signicant milestone in her musical journey, highlighting her evolution as an independent artist dedicated to authenticity.

Over the past decade, RaeLynn has built a diverse career, from publishing a children’s book, “Raisin’ Me A Country Girl,” to becoming the rst country artist to partner with global beauty brand Too Faced Cosmetics and making her acting debut in Hallmark Channel’s “A Nashville Christmas Carol.”

With more than 2.8 million followers across her social media platforms, RaeLynn boasts both Gold — “Love Triangle” and “Lonely Call” — and Platinum — “God Made Girls” — singles, while amassing more than 1 billion career streams.

Tues., March 25, 2025 • 9:00 am – 3:15 pm

Denny Sanford Premier Center • Sioux Falls, SD

9:00 am Registration - Taylor Leach Hildebrandt Assistant Editor with Dairy Herd Management will MC

9:30 am Update on Implants - Zachary Smith, SDSU

10:15 am Vaccination management - Jennifer Spencer, Texas A&M

11:00 am Calf management research “preparing ‘em for the feedlot” - Gail Carpenter, ISU

11:45 am Q&A Session - Taylor Leach Hildebrandt, moderating Noon Lunch

12:45 pm What the Dairy Crossbreed Research Is Telling Us About The Feedlot - Garland Dalke, ISU

1:30 pm Economics of BXD In The Feedlot - Melanie Pimentel-Concepcion, MSU

2:15 pm Hoof related Lameness in Feedlot Cattle - Sarah Erickson, TELUS Agriculture

3:00 pm Q&A Session - Taylor Leach Hildebrandt, moderating 3:15 pm Adjourn

• Students $20 Register online at: https://go.iastate.edu/DBSC25

“The

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

•Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

•Modular design for easy installation

By Michele Ackerman Contributing writer

Cows agree. When it comes to bedding, sand is the gold standard. Nothing beats it for comfort and cleanliness, udder health and traction on concrete said Renee Schrift, director of global sales for agriculture systems at McLanahan Corporation.

But, sand can get expensive. For farmers who have invested in a reclamation system — or are considering one — it behooves them to learn how to recover as much sand as they can for bedding, so they have less to spread on the elds. For dairy farmers considering an anaerobic digester, they must keep in mind that some types of sand must be virtually eliminated from manure.

Sand will be the focus of Schrift’s presentation at Central Plains Dairy Expo in Sioux Falls, South Dakota, March 26 at 11:30 a.m. and March 27 at 8:30 a.m. She will draw from her 24 years of experience with sand separation systems to offer tips for producers who want to improve their reclamation setups or prepare for a potential manure digester.

From the cow standpoint, the cows themselves will tell farmers what kind of sand is best, Schrift said.

“Cows will lay down in stalls where the sand is loose and soft and conforms to their bodies,” Schrift said. “When it is too ne, traps moisture and gets packed and hard, cows are going to tell you that is not a very comfortable stall.”

From a sand recovery perspective, settling characteristics — how easily the sand and manure separate — are paramount Schrift said. In the best-performing systems, at least 90% of sand can be reclaimed, and settling plays a major role in this success.

“We don’t want too many nes, and we don’t want too many coarse particles,” Schrift said. “We

don’t want sand that is so powdery ne that once wet or in the soil, it compacts like concrete. We also don’t want pea-sized sand that could be detrimental to hoof health.”

There are standards for sand gradations that yield high reclamation rates, but they are not the be-all and end-all Schrift said. She said she gives guidelines because farmers have to start somewhere.

“Our view is there is no ‘best’ sand,” she said. “You must consider what works well for your cows and your manure management goals. If you nd sand that moves loosely in the stall and works with the cow and not against her, you will have sand that is pretty good on the separation side as well.”

Producers often have limited control over sand quality, including particle size, because they purchase what is available locally to save on the cost of hauling. This does not mean there are no options for lessthan-desirable sand.

Schrift said there has been a lot of evolution of sand separation systems. How these systems work with sand and how they reclaim it are getting better all the time she said.

“We see dairies bed with really ne sand as well as coarser sands,” Schrift said. “We just need to put in equipment to customize to those situations. We can get high reclamation rates even with these systems.”

Because no two management systems are the same, Schrift said sand reclamation systems cannot be cookie-cutter.

“Manure is what you feed your cows and how much water is entering the system,” Schrift said. “That varies from site to site and from dairy to dairy and is even different regionally. Some dairies want to use more water because they irrigate. Others use hardly any at all.”

An effective sand reclamation system also considers a producer’s goals, which may include a manure digester.

If there is a digester in future plans, Schrift said the sand reclamation system needs to do a better job of getting out the sand that could potentially settle in the digester.

“There are some sands and silts that will probably stay suspended and head to the digester with the manure and cause no issues,” she said. “But there are some that will settle. That is what we want to capture and get that out before it enters the digester.”

She said the industry has not dove into the types of sand and gradations that settle in digesters. This will be a focus of part of her presentation.

Whether planning to install a digester or not, the effort to reclaim cleaner sand improves milk quality and cow health, reduces the budget for virgin sand and minimizes the need to haul sand to the elds.

“The goal should always be to get as much sand out, make a quality product and get a good return on investment,” Schrift said. “All of those things determine what the system is going to look like at the end of the day.”

High Sand Reclamation: What Types of Sand Work Best?

March 26 at 11:30 a.m. in MR 8 and March 27 at 8:30 a.m. in MR 3

3x4 Bales • 1st, 2nd & 3rd Cutting Hay WE

By Sarah Middendorf sarah.m@star-pub.com

Dry matter intake can have a positive and a negative impact on a cow’s productivity, health and overall performance said Ron Van Beek, CEO and founder of Van Beek Natural Science.

Van Beek will be presenting “From Data to Impact: Maximizing Dry Matter Intake for Optimal Performance” March 26 at 3:30 p.m. and March 27 at 9 a.m. at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

During his presentation, Van Beek will talk about the topics of palatability, dry matter intake, and mold and wild yeast growth in dairy cattle feed, among others.

may eat fresh food more often than dayold food or week-old food.

“If we have a fresh baked loaf of bread in front of us, we will probably eat two slices,” Van Beek said. “If we have a slice of bread that’s been lying on the counter for six hours, we will probably only eat one slice. If we have a slice of bread … that smells like mold we will probably eat a half or less.”

This analogy connects back to the benets of having freshly mixed feed that has not been in the bunk for an extended period of time Van Beek said. Fresh feed appeals to animals just as it does to people. Van Beek said if he were to ask someone who already had dinner, “Are you hungry?” they would say, “No.”

“If somebody walked in the room behind you with a freshly baked plate of cinnamon rolls within a minute you would start smacking your lips and salivating,” Van Beek said. “(In) another minute you wouldn’t care what I’m saying. You’d be looking around (at) which is the largest piece (saying) ‘That’s the one I want.’”

“Anytime you can increase dry matter intake, you’re naturally going to have more milk,” Van Beek said. “Anytime you can preserve your feed, you are naturally going to have better health in the cows.”

Van Beek will also provide tips for getting animals to consume the maximum amount of energy possible to drive production. Van Beek said during a 24-hour period, a cow’s energy is divided between digestion, body maintenance, immunity and production.

Being able to offer freshly mixed feed that is maintained in the same state to prevent mold growth is important Van Beek said.

Even though the cinnamon rolls were not seen at rst, the airborne phenols they release stimulated the want for a cinnamon roll Van Beek said. Animals also have this when they smell the feed they want. Their desire to eat more is stimulated.

“That’s the same thing we are going to try to do to livestock,” Van Beek said.

Van Beek has been working on different models to enhance dry matter intake.

March 26 at 3:30 p.m. in room MR 6/7 and March 27 at 9 a.m. in room MR 6/7

“If you don’t do something to prohibit that (mold or yeast) growth, it kills palatability,” Van Beek said. “Plus, the growth itself is utilizing energy that’s not left for the cow. The cow has to deal with the mold, which is hard on the microbiome within the rumen. It’s also hard on the liver and it can cause abortions.”

Cows are able to smell danger before humans are, Van Beek said. To put it in perspective of how humans determine what food they will eat, he said humans

“(We worked) to create a stronger appetite by using plant phenols and by preserving feed from molds and yeast,” Van Beek said. “That’s giving the cow the ability to milk closer to (their) genetic potential.”

Keeping dry matter intake in mind when feeding animals can lead to better health, productivity and overall performance as an animal.

“If (farmers) spend the money they do preparing the feeds … to feed the cows, why wouldn’t (they) want to get the maximum return?” Van Beek said. “If (farmers) spend money on genetics for having the best herd, why wouldn’t (they) want (cows) to perform to their maximum potential?”

By Sherry Newell Staff Writer

There are many things that come together to make a farm run smoothly. And though it is important to control insects, the effort to get rid of ies in the milking parlor is not always high on the list of things to do.

That is the dilemma explained by Anna Hansen, a technical services support specialist for McLaughlin Gormley King Company. She will present a session March 26 at 11 a.m. and March 27 at 1 p.m. called “The Power of Multiple Modes of Action for Pest Control” at the Ed Shed at Central Plains Dairy Expo in Sioux Falls, South Dakota.

Paul@adaent.net •

Anna Hansen McLaughlin Gormley King Company

“It’s so easy to push (pest control) down on the rung of priorities,” Hansen said. “But the reality is that insects cause a lot of damage. There are economic losses that come with uncontrolled populations.”

Hansen said she chose the topic because knowledge about how insecticides work is not at the forefront of all dairy farmers’ brains. Her presentation will include background on how insecticides work and how the insect ghts the effort to be controlled.

“It’s a little biology and a little of how on earth you choose (an insecticide), given the huge variety of products on the market,” she said.

Hansen’s session will focus primarily on y control, where she said the most important component is sanitation. She cited calf hutches as an example, calling the area around them “maggot heaven.” The spilled feed and moisture make an ideal environment for ies.

She said farm cleanup can make a big difference in y control before considering various insecticides.

Many of the products for pest control have overlapping active ingredients, but the formulation lends itself to various controls she said. Using the same active ingredient over the years may help pests develop immunity.

“That’s when you bring in another ingredient— target a different site on the insect body,” she said. “Flies do overwinter and there is constantly an inux. So you know they can build up resistance and you have to battle harder.”

Hansen’s session will provide concrete steps for building a y control protocol on a dairy farm. A recommend protocol starts with a walk around the farm, an inspection, and then an understanding of which type of y is present and at what level of population.

Identifying which species of y is impacting the dairy is important, she said. Her session will focus on four of the many species of the insect.

“From a distance (ies) look similar to one another,” she said. “But look at where they are going on a cow’s body.”

For example, stable ies are attracted to cows’ legs, while face ies are around the noses and mouths, and horn ies crowd on their backs. House ies are more of a general nuisance, Hansen said. Identication matters because it can allow producers to focus their sanitation efforts. Immature ies found around the calf hutches and other soiled media are often house ies and stable ies, while face ies and horn ies lay eggs in fresh manure.

“It’s not realistic to say there will never be ies on my farm, but once you’ve identied the main problems, you can establish an action threshold,” Hansen said.

A good monitoring program, according to Hansen, will tell a dairy farmer when to take action.

“It’s easier to deal with them when activity is picking up rather than later,” she said.

The nal steps in a farm’s protocol are guring out how long to wait before evaluating the effort and knowing what to look for when doing that.

In the meantime, she points out the variety of resources available to help dairy farmers manage their pest management efforts, citing extension as well as livestock specialists who understand pest control.

Heat treated, mechanically extracted soybean meal

Excellent protein and energy source for lactating cows

High in intestinallydigestible, rumen undegradable (bypass) protein

Higher metabolizable energy than solvent extracted soybean meal products

Palatable to cows - all plant protein, no animal protein component

All natural, chemical-free process

To improve reproduction and reduce stress

To assist immune function and reduce inflammation

Privately held company with excellent customer service

TUESDAY, MARCH 25

5:00 PM Welcome Reception, Doors Open 9:00 PM Sheraton Hospitality Room

WEDNESDAY, MARCH 26

6:30 AM Doors Open

7:00 AM Ag Prayer Breakfast Program Begins

8:30 AM Trade Show Floors Open

8:30 AM-5:30 PM Free Donuts, Free Grilled Cheese, Free Ice Cream Treats 11:00 AM-4:30 PM Beer Garden Open

8:30-9:30 AM BREAKOUT SESSIONS

Dry Off: A New Beginning or End of the Line?

- Chris Rock (Sponsired by AHV USA) MR 8

Optimizing Calf Health: Strategies for Management, Nutrition and Immunity - Minnie Ward (Sponsored by Feedworks) MR 12

U.S. Genetic Progress – Where Did We Gain and Where Did We Fall Short!? - David Erf (Sponsored by Zoetis) MR 3

9:00-9:30 AM ED SHED SESSION: Shedding Light on Stray Voltage: Understanding and Solving a Hidden Dairy Challenge - James Neawedde Jr.(Sponsored by Zero Tolerance/Current Defense) Ed Shed

9:00-10:00 AM BREAKOUT SESSIONS

Setting Up Calves for Success Before Birth Through Dam Nutrition - Billy Brown (Sponsored by Balchem) MR 9/10

Credit for Good: Producer Pathways to Profit for Sustainable Practices - Kevin Dhuyvetter & Sara Kvidera (Sponsored by Elanco) MR 13

9:30-10:30 AM BREAKOUT SESSIONS

Commodity Price Risk Management – Protect Your Bottom Line - Mark Newman (Sponsored by CIH) MR 6/7

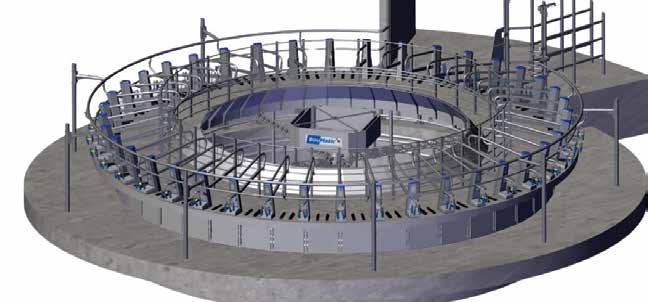

Advantages of Rotary Milking - Jeff Hahn (Sponsored by DeLaval) MR 14

Elevate Your Dairy Operation with New Innovations from VAS - Dylan Ash & Meagan Young (Sponsored by VAS)

10:00-11:00 AM BREAKOUT SESSIONS

Calf Scours Continues to be a Prevailing Problem in Calves... A New Treatment Strategy Proves Successful!

MR 1/2

- Dr. Michael Nagorske (Sponsored by TechMix, LLC) MR 8

Goldilocks: How Much Gut Health Technologies is ‘Just Right’? - Jill Soderstrom (Sponsored by Land O’Lakes) MR 12

10:00-10:30 AM ED SHED SESSION: Cool Cows, Thriving Herds: Advanced Heat Mitigation Techniques - Bill Stone (Sponsored by Diamond V) Ed Shed

10:30-11:30 AM BREAKOUT SESSIONS

Growing Again: A Look at the Dairy Markets in 2025

11:30 AM-12:30 PM BREAKOUT SESSIONS

The Future of Calf Care - Andrew Beckel & Dagmar Beckel Machyckova (Sponsored by Golden Calf) MR 13 High Sand Reclamation: What Types of Sand Work Best? - Renee Schrift (Sponsored by McLanahan Corporation) MR 8

12:00-1:00 PM BREAKOUT SESSIONS

Managing Milk Prices in 2025 - Katie Burgess (Sponsored by Ever.Ag) MR 12

SPANISH SESSION: Milk Quality, Mastitis and Parlor Interactions - Jorge Luna (Sponsored by Zoetis) MR 9/10

12:00-12:30 PM ED SHED SESSION: Turning Waste into Wealth: Transforming Farm Manure into a Low-cost Fertigation Asset for In-season application with Drip Irrigation - Kurt Grimm (Sponsored by NutraDrip Irrigation Systems) Ed Shed

12:30-1:30 PM BREAKOUT SESSIONS

It Starts with the Bugs: Optimizing Rumen Development in Dairy Calves - Craig Louder (Sponsored by Axiota Animal Health) MR 14

Youngstock Monitoring: Insights Gained and Future Opportunities - Sarah Anderson (Sponsored by Merck Animal Health) MR 1/2

Navigating Uncertainty: Guiding Producers Through Transition with Confidence - Rena Striegel (Sponsored by CPDE Future Connections) Denny Sanford Premier Center

1:00-2:00 PM BREAKOUT SESSIONS

To 7 Pounds and Beyond – Maximizing Milk Components for Profitability - Michael Hutjens (Sponsored by Quality Liquid Feeds, Inc.) MR 3

Ultraplus Sex Sorted Semen: Huge Technology Packed in a Tiny Straw - Eric Zwiefelhofer (Sponsored by Stgenetics) MR 8

Learnings and Implementation of On-farm Sustainability

Reporting - Lucas Sjostrom, Michael Crinion, Jamie Fisher (Sponsored by Edge Dairy Farmer Cooperative) MR 13 1:00-1:30 PM ED SHED SESSION: Forage 360: Producing Forage Year Round - Jeff Jackson (Sponsored by Land O’Lakes) Ed Shed 1:30-2:30 PM BREAKOUT SESSIONS

Practical Insights for Managing Transition Cow Inflammation - Tim Doherty (Sponsored by Form-A-Feed) MR 6/7

SPANISH SESSION: The Importance of Your Role as a Dairy Worker in the Sustainability of the Dairy Industry - Jorge Delgado (Sponsored by Alltech) MR 9/10 2:00

2:00-3:00 PM The Power of the Female - Chelsea Abbott (Sponsored by Trans Ova Genetics) MR 1/2 Avian Influenza: Protecting Farms and Industry in the Face of HPAI Threats - Dr. Matt Hille (Sponsored by CPDE) Denny Sanford Premier Center 2:00-2:30

- Sarina Sharp (Sponsored by Farm Credit) Denny Sanford Premier Center Unleashing the Power of Alfalfa in Your Cropping System – A Fireside Discussion - Erika Rodbell (Sponsored by Forage Genetics International)

MR 3

SPANISH SESSION: Enhancing Biosecurity on Dairy Farms: Practical Tips for Dairy Workers - Maristela Rovai & Noelia Silva del Rio ( Sponsored by SDSU) MR 9/10

11:00 AM-12:00 PM BREAKOUT SESSIONS

Prevention and Treatment of Subclinical Hypocalcemia to Optimize Health and Reproduction in Dairy Cattle

- Claira Seely (Sponsored by Phibro Animal Health) MR 14

Maximizing the Profit Centers Within your Feed Management System - Keith Sather (Sponsored by Supervisor Systems) MR 6/7

Do High Oleic Soybeans Fit Your Farm? Research and Producer Panel Discussion - Kevin Harvatine, Nathan Brandt, Tim Hood (Sponsored by Vita Plus Corp.) MR 1/2

11:00-11:30 AM ED SHED SESSION: The Power of Multiple Modes of Action for Effective Pest Control

- Anna Hansen (Sponsored by MGK) Ed Shed 11:00

SCHEDULE OF EVENTS SUBJECT TO CHANGE

The Evolving Dairy Landscape: Addressing Cow Health, Environmental Impacts and Economic Pressures - Luke Miller (Sponsored by Alltech) MR 3 The Sweet Spot: How Molasses Complements Adult Cow Rations - Gail Carpenter (Sponsored by Westway Feed Products) MR 8

3:00-4:00 PM SPANISH SESSION: The 7 Pillars for Raising a Healthy Calf - Tiago Tomazi (Sponsored by Merck Animal Health) MR 9/10

3:30-4:30

Optimizing Herd Productivity and Health: Advanced Transition Cow Management and Nutrition Strategies - Ruby Wu (Sponsored by Arm & Hammer Animal Nutrition) MR 1/2 From Data to Impact: Maximizing Dry Matter Intake for Optimal Performance - Ron Van Beek (Sponsored by Van Beek Natural Science) MR 6/7 4:30 PM Wine & Cheese Social on the Trade Show Floors

5:30-10:00 PM Dairy Checkoff and State Trade Association Networking Reception (Sponsored by Midwest Dairy) MR 12/13/14 5:30 PM Trade Show Floors Close

THURSDAY, MARCH 27

8:00 AM Trade Show Floors Open

8:00-10:00 AM FREE Pancake Breakfast

8:00-9:00 AM BREAKOUT SESSIONS

It Starts with the Bugs: Optimizing Rumen Development in Dairy Calves - Craig Louder (Sponsored by Axiota Animal Health) MR 1/2

The Dairyman’s Perspective of the Feed Market Outlook and Dairy Margins - Jenny Wackershauser (Sponsored by Ever.Ag) MR 9/10

The Power of the Female - Chelsea Abbott (Sponsored by Trans Ova Genetics) MR 12

8:30-9:30 AM BREAKOUT SESSIONS

Optimizing Herd Productivity and Health: Advanced Transition Cow Management and Nutrition Strategies - Ruby Wu (Sponsored by Arm & Hammer Animal Nutrition) MR 13

High Sand Reclamation: What Types of Sand Work Best?

- Renee Schrift (Sponsored by McLanahan Corporation) MR 3

The Sweet Spot: How Molasses Complements Adult Cow Rations - Gail Carpenter (Sponsored by Westway Feed Products) MR 8

9:00-10:00 AM From Data to Impact: Maximizing Dry Matter Intake for Optimal Performance - Ron Van Beek (Sponsored by Van Beek Natural Science) MR 6/7

9:00-9:30 AM ED SHED SESSION: Forage 360: Producing Forage Year Round - Jeff Jackson (Sponsored by Land O’Lakes) Ed Shed

9:30-10:30 AM BREAKOUT SESSIONS

Advantages of Rotary Milking - Jeff Hahn (Sponsored by DeLaval) MR 12 Do High Oleic Soybeans Fit Your Farm? Research and Producer Panel Discussion

- Kevin Harvatine, Nathan Brandt, Tim Hood (Sponsored by Vita Plus Corp.) MR 1/2

SPANISH SESSION: The 7 Pillars for Raising a Healthy Calf - Tiago Tomazi (Sponsored by Merck Animal Health) MR 9/10

10:00-11:00 AM BREAKOUT SESSIONS

The Evolving Dairy Landscape: Addressing Cow Health, Environmental Impacts and Economic Pressures

- Luke Miller (Sponsored by Alltech) MR 8 Practical Insights for Managing Transition Cow Inflammation - Tim Doherty (Sponsored by Form-A-Feed) MR 3

U.S. Genetic Progress – Where Did We Gain and Where Did We Fall Short!? - David Erf (Sponsored by Zoetis) MR 13

10:00-10:30 AM ED SHED SESSION: SRP Technology and an Experimental Salmonella Dublin Vaccine - Dr. Jason Anderson (Sponsored by Vaxxinova) Ed Shed

11:00AM-3:00 PM Beer Garden Open

11:00 AM-1:00 PM Free Grilled Cheese Sandwiches

11:00 AM-12:00 PM BREAKOUT SESSIONS

Setting Up Calves for Success Before Birth Through Dam Nutrition - Billy Brown (Sponsored by Balchem) MR 6/7

Youngstock Monitoring: Insights Gained and Future Opportunities - Sarah Anderson (Sponsored by Merck Animal Health) MR 1/2

Calf Scours Continues to be a Prevailing Problem in Calves... A New Treatment Strategy Proves Successful!

- Dr. Michael Nagorske (Sponsored by TechMix, LLC) MR 12

SPANISH SESSION: The Importance of Your Role as a Dairy Worker in the Sustainability of the Dairy Industry

- Jorge Delgado (Sponsored by Alltech) MR 9/10

11:00-11:30 AM ED SHED SESSION: Shedding Light on Stray Voltage: Understanding and Solving a Hidden Dairy Challenge - James Neawedde Jr. (Sponsored by Zero Tolerance/Current Defense) Ed Shed

11:30 AM-12:30 PM BREAKOUT SESSIONS

To 7 Pounds and Beyond – Maximizing Milk Components for Profitability - Michael Hutjens (Sponsored by Quality Liquid Feeds, Inc.) MR 3

Ultraplus Sex Sorted Semen: Huge Technology Packed in a Tiny Straw - Eric Zwiefelhofer (Sponsored by Stgenetics) MR 8 Learnings and Implementation of On-farm Sustainability

Reporting - Lucas Sjostrom, Michael Crinion, Jamie Fisher (Sponsored by Edge Dairy Farmer Cooperative) MR 13

12:00-12:30 AM ED SHED SESSION: Cool Cows, Thriving Herds: Advanced Heat Mitigation Techniques - Bill Stone (Sponsored by Diamond V) Ed Shed

12:30-1:30 PM BREAKOUT SESSIONS

Maximizing the Profit Centers Within your Feed Management System - Keith Sather (Sponsored by Supervisor Systems) MR 6/7

Elevate Your Dairy Operation with New Innovations from VAS - Dylan Ash & Meagan Young (Sponsored by VAS) MR 1/2

Goldilocks: How Much Gut Health Technologies is ‘Just Right’? - Jill Soderstrom (Sponsored by Land O’Lakes) MR 12

SPANISH SESSION: Enhancing Biosecurity on Dairy Farms: Practical Tips for Dairy Workers - Maristela Rovai & Noelia Silva del Rio (Sponsored by SDSU) MR 9/10

1:00-2:00 PM BREAKOUT SESSIONS

Credit for Good: Producer Pathways to Profit for Sustainable Practices - Kevin Dhuyvetter & Sara Kvidera (Sponsored by Elanco) MR 8 Prevention and Treatment of Subclinical Hypocalcemia to Optimize Health and Reproduction in Dairy Cattle - Claira Seely (Sponsored by Phibro Animal Health) MR 13

Unleashing the Power of Alfalfa in Your Cropping System – A Fireside Discussion - Erika Rodbell (Sponsored by Forage Genetics International)MR 3

1:00-1:30 PM ED SHED SESSION: The Power of Multiple Modes of Action for Effective Pest Control - Anna Hansen (Sponsored by MGK) Ed Shed

1:00 PM Free Ice Cream

2:00-3:00 PM BREAKOUT SESSIONS

Dry Off: A New Beginning or End of the Line? - Chris Rock (Sponsored by AHV USA) MR 6/7

Optimizing Calf Health: Strategies for Management, Nutrition and Immunity - Minnie Ward (Sponsored by Feedworks) MR 1/2 The Future of Calf Care - Andrew Beckel & Dagmar Beckel Machyckova (Sponsored by Golden Calf) MR 12

SPANISH SESSION: Milk Quality, Mastitis and Parlor Interactions - Jorge Luna (Sponsored by Zoetis) MR 9/10

SCHEDULE OF EVENTS SUBJECT TO CHANGE

2:00-2:30 PM

ED SHED SESSION: Turning Waste into Wealth: Transforming Farm Manure into a Low-cost Fertigation Asset for In-season application with Drip Irrigation - Kurt Grimm (Sponsored by NutraDrip Irrigation Systems) Ed Shed

3:00 PM Trade Show Floors Close

Sponsored by Alltech

Sponsored by AMPI, at the Valley Queen Cheese Dairy Bar, located in the Arena’s northeast concession stand

On Wednesday and Thursday in the Arena

On Thursday, March 27, in the Arena at 8:00 a.m.

On Wednesday, March 26, at the Valley Queen Cheese Dairy Bar at 4:30 p.m.

at the Valley Queen Cheese Dairy Bar

By Dan Wacker dan.w@dairystar.com

Growing and harvesting alfalfa is a Midwest summertime tradition synonymous with baseball and sunshine. At Central Plains Dairy Expo, Dr. Erika Rodbell will host a reside chat to discuss how alfalfa has become the “Queen of Forages” and how it can be used to improve dairy operations. Rodbell, a forage research agronomist at Forage Genetics International, will host two of these reside chats at CPDE in Sioux Falls, South Dakota.

Rodbell, a rst-time presenter at CPDE, will discuss the benets of alfalfa, not just for hay producers, but for dairy farmers and dairy nutritionists, explaining how it can benet dairy operations beyond being a source of feed. Those interested in attending can do so March 26 at 10:30 a.m. or March 27 at 1 p.m. in Room MR3.

“I want people to come to this conversation with questions about alfalfa, with concerns about alfalfa on

their operations and what the agronomic benets are,” Rodbell said. Rodbell’s discussion will delve into three benets of alfalfa: sustainability, pest management and feed.

“When you think about crop rotation, farmers aren’t likely to have a longer-term rotation than the typical two, so what’s a farmer to do,” Rodbell said. “Others suggest a longer, more diverse rotation if you want to outcompete the pest species, and alfalfa allows you to do that.”

Dr. Erika Rodbell Forage Genetics International

Alfalfa is vital to sustainability by stopping nitrate runoff and managing weeds as a perennial crop. Alfalfa’s green matter alive in and on top of the soil during different seasons provides several sustainability benets, including making weed seeds germinate later, shading weeds and limiting weeds before they go to seed or even ower.

Rodbell’s studies in pest management also showed how alfalfa can break pest cycles. She focused on corn rootworm traditionally managed by Bacillus thuringiensis. In August 2024, a lead agronomist released a publication citing that corn rootworm has developed a resistance to the pore-forming crystal, aka Cry, proteins generated from Bt corn.

To manage these pests, Rodbell and her team developed a 4-year crop rotation theory.

Dealing with a pest that has developed a Bt resistance reduces what farmers can use to eradicate them, making management strategies a challenge. Alfalfa has become an economically viable solution to this problem.

Rodbell will also discuss the HarvXtra Alfalfa varieties.

“HarvXtra has a multitude of benets,” Rodbell said. “There’s nutritional exibility, it provides higher protein for wet and dry cows. If you want to be nancially viable, you need to have high protein content.”

HarvXtra also allows for exibility in the harvest window. That is an important detail as dairy operations continue to grow larger, needing more alfalfa and trying to keep production in-house. It provides a unique nutritional package, with high digestibility in its reduced lignin.

With a later harvesting window, the plant can grow longer.

The reduced lignin levels are also a key component to the exibility in the harvest window because of added digestibility.

“Digestibility is something you need to balance when harvesting conventional alfalfa,” Rodbell said. “HarvXtra reduces lignin content for added digestibility.”

Rodbell hopes attendees of her reside chat can walk away with answers to their questions, or resources to learn more about how alfalfa can benet their operation.

Unleashing the Power of Alfalfa in Your Cropping System – A Fireside Discussion

March 26 at 10:30 a.m. and March 27 at 1 p.m. in room MR 3.

“With conventional alfalfa, the harvest window is nite,” Rodbell said. “There are specic windows to get the ideal nutrition. What HarXtra allows you to do is have increased yield potential, without quality loss by waiting to take that hay off.”

By Tiffany Klaphake tiffany.k@dairystar.com

Many things that happen on and off the dairy farm impact the dairy industry.

Luke Miller, dairy technical support specialist with Alltech, will address some of these issues during his breakout session “The Evolving Dairy Landscape: Addressing Cow Health, Environmental Impacts and Economic Pressures” held March 26 at 2:30 p.m. and March 27 at 10 a.m. at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

“It is meant to be a discussion of emerging cow health issues and en-

vironmental concerns,” Miller said. “I don’t put any products into my talks so there is no pressure or sway in my information.”

In Miller’s presentation, he will cover cow health issues, such as Highly Pathogenic Avian Inuenza. He will also cover environmental concerns; economic pressures, such as government subsidies; and markets for methane greenhouse gas emissions.

One of the biggest topics in the dairy industry for the past year has been H5N1. Miller will discuss where the disease has been discovered in the last 30 days, and where it has been over the past year. Because the bird u is mutating, he said it will continue to

be a major concern for farmers.

“It all comes down to, it is not just affecting birds anymore, it is not just affecting cows anymore,” Miller said. “It is affecting humans, so it is a major concern. We are starting to see some of the things that happen to birds happen to humans, and that is not good.”

While vaccines are available, Miller will discuss why some farms choose to vaccinate and some do not.

“I will talk about why we do eradication versus vaccination, what countries do vaccinate, what countries don’t vaccinate, and the pros and cons of each,” Miller said.

The environmental impacts and economic pressures in the dairy industry go hand in hand as they deal with government policies. With recent changes in leadership at the federal level, that means there will be changes to federal policies. In the meantime, there are a lot of questions while the transition settles.

“We are getting questions like, ‘Will my project get funded, will my funding continue, and what subsidies are going to go on?’” Miller said. “What does the (U.S. Department of Agriculture) funding look like and what does the private sector look like? Will that be a strong option in the future?”

Miller said some private companies are still seeking carbon credit opportunities.

“We are selling (carbon credits) credit by credit and brokerages are going out and nding homes for all these credit on a case-by-case basis,” Miller

said. “As this year goes on, we will see who will still be in the market for these types of options.”

Tariff rates and their effect on exports is another factor that has come with the change in leadership, Miller said. A lot more will be determined in the coming months as new staff members are appointed and committees are formed.

One local concern farmers can take control of on their farms is the use of technology. Miller will go over a Top 10 questions to ask technology dealers to determine if a piece of technology is right for their farm. Miller said to ask questions about where these companies are getting their numbers from and their data integrity practices.

These are some of the national and global factors affecting the dairy industry and Miller said he can address other concerns guests may have.

“If something new comes up I can adapt to cover any relevant topic that attendees want to learn more about,” Miller said.

The

March 26 at 2:30 p.m. in room MR 3 and March 27 at 10 a.m. in room MR 8

• Specifically-selected bacteria that work together

• Added enzymes specifically formulated to boost feed efficiency

• Proprietary technology that lasts longer— our bacteria is grown and processed in order to remain stable over longer periods of time.

• Contains potassium sorbate, which starts to work immediately and does not have to compete with epiphytic microbes, and does not depend on acetic acid like Lactobacillus buchneri, a common ingredient in other silage inoculants.

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Central Ag Supply Juneau, WI; Baraboo, WI

Central Ag Supply Juneau, WI; Baraboo, WI

Eastern Iowa Dairy Systems Epworth, IA

Eastern Iowa Dairy Systems Epworth, IA

Ederer Dairy Supply Plain, WI

Ederer Dairy Supply Plain, WI

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Gorter’s Clay & Dairy Equipment Pipestone, MN

Gorter’s Clay & Dairy Equipment

J. Gile Dairy Equipment, Inc.

Pipestone, MN

Cuba City, WI

Leedstone

J. Gile Dairy Equipment, Inc.

Cuba City, WI

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI; Sparta, WI

Leedstone

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Lely Center Monroe Monroe, WI

Lely Center Monroe Monroe, WI

Midwest Livestock Systems

Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

Midwest Livestock Systems

Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

Monroe Westfalia Surge Monroe, WI

Monroe Westfalia Surge Monroe, WI

Professional Dairy Services Arlington, WI

Professional Dairy Services Arlington, WI

Redeker Dairy Equipment Brandon, WI

Redeker Dairy Equipment Brandon, WI

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Stanley Schmitz Inc. Chilton, WI

Stanley Schmitz Inc. Chilton, WI

Total Dairy Service Kewaunee, WI

Total Dairy Service Kewaunee, WI

Tri-County Dairy Supply Janesville, WI

Tri-County Dairy Supply Janesville, WI

United Dairy Systems West Union, IA; Monticello, IA

United Dairy Systems West Union, IA; Monticello, IA

4-D AG World/4-D AG Fashion .......................................C810

360 Ag Supply, LLC.....................................................Outside

A1 Development Solutions ..............................................H109

A1 Mist Sprayers .............................................................A513

ABS Global ......................................................................C306

ADA Enterprise Inc. .........................................................A512

Adisseo ............................................................................C328

Archer Daniels Midland Company ...................................C632

Advanced Ag Products ....................................................C804

Afimilk ..............................................................................A306

Ag Processing, Inc. .........................................................C628

Ag Property Solutions ......................................................C706

Ag Tech Business..........................................................AF109

South Dakota Dairy Producers ............................................BB

Agri Feed International, LLC............................................C407

Agri-King, Inc. ..................................................................C404

Agri-Placement Services, Inc. .........................................A103

Agri-Plastics/Agri-Comfort ...............................................C724

AgriSteel USA..................................................................C301

AgroChem USA, LLC ......................................................C703

Agromatic, Inc..................................................................C704

Agropur, Inc. ....................................................................C122

AHV USA .........................................................................C112

Albers Dairy Equipment, Inc. ...........................................C507

Alltech ..............................................................................C415

Amelicor...........................................................................H113

American AGCO Trading Co. ..........................................C629

American Dairymen/Twin Rivers Media ..........................C128

AMPI ................................................................................A400

Anez Consulting, Inc........................................................C633

Animal Health International .............................................C530

Animat Inc......................................................................A1011

Arm & Hammer Animal Nutrition .....................................H102

Armor Animal Health .......................................................C228

Arnolds of Kimball, Inc. ....................................................C433

Artex Manufacturing ........................................................A406

Aurora Pharmaceutical ..................................................A1109

Axiota Animal Health, Inc. ...............................................H111

Balchem Corporation .......................................................C527

Beck’s ..............................................................................A413

BECO Dairy Equipment ...................................................H110

Bio-Vet Inc. ......................................................................H123

Boehringer Ingelheim ......................................................C310

BouMatic..........................................................................C232

Bovine Hoof Adhesives/Glue-U Inc. ................................A219

BoviSync........................................................................A1107

Butler Machinery Company .............................................A803

Byron Seeds, LLC ...........................................................H132

Calf Care & Quality Assurance, National Dairy FARM Program .......................................................................A1210

Calf Star.........................................................................A1113 CalfStart LLC ...................................................................H122

Calf-Tel ...........................................................................C400

Cambridge Technologies.................................................C309

Central Confinement Service LLC ...................................A108

Central Life Sciences............................................................M

Central Valley Dairy Supply Inc. ......................................A402 Novonesis (formerly Chr. Hansen) ..................................C114 CIH/Commodity & Ingredient Hedging, LLC ....................C113

Cloverdale Equipment LLC..............................................A800

Comfort Hoof Care ........................................................A1214

Conewango Products Corp. ..................................................U

Control Solutions Inc. ....................................................A1013

Corteva Agriscience MCS, LLC - Dairyland Seed ..........A600 Countryside Dairy Solutions ............................................C304

CowManager ...................................................................A211

CRV USA.......................................................................A1112

Crystal Creek Natural ......................................................A209

Cumberland Valley Analytical Services ...........................H127

Zero Tolerance/Current Defense .....................................C930

Dairy Farmers of America..............................................AF102

Dairy Star.........................................................................C220

Dairyland Laboratories ....................................................C604

DairyVisor, Inc. ................................................................C307

Dakota Fluid Power .......................................................A1215

Dakota Iron Equipment ................................................Outside

Datamars Livestock .........................................................A116

Dave’s Repair ..................................................................C818

DBC Ag Products & LIRA GOLD Supplements .............A1103

DeHaan, Grabs & Associates, LLC .................................C835

Dellait - Animal Nutrition & Health ............................C100 & B

Deluxe Animal Health ...............................................C610 & C

Development Resources of Iowa, Inc. .............................C700

DLF ..................................................................................C324

Diamond V .......................................................................C402

DM Concrete Grooving ..........................................................Z

Diesel Machinery Inc. ......................................................C828

Doda USA......................................................................A1003

Dordt University .....................................................................L

EASYFIX Livestock Comfort............................................C731

EBJ Livestock Market Inc. ...............................................A214

Edge Dairy Farmer Cooperative ......................................C330

Elanco Animal Health ......................................................C427

Elite Plastic Products, A Division of AmeriLux International.................................................A1104

ENDOVAC Animal Health ...............................................C200 Equipment Blades ...........................................................A315

Essential Water Solutions, Inc. ........................................A405

Ever.ag ............................................................................C300

Everlast Industries ...........................................................C808

Evolution Spray Foam .....................................................A309

Excel Machine & Mfg .......................................................C901

Extrutech Plastics ............................................................A106

Faber’s Farm Equipment .................................................C121

FAMO Feeds, Inc. ...........................................................C702 Farm Inc. .........................................................................C609 Farm Systems .................................................................C313 FarmFirst Dairy Cooperative ...........................................C734 Feedworks USA, Ltd........................................................C511 FERA Diagnostics and Biologicals Corp. ........................C327 Forage Genetics International .........................................C607 Form-A-Feed, Inc. ...........................................................C134 Frontier Mills Inc. .............................................................H125

GEA Farm Technologies Inc. ..........................................C618 GENEX ............................................................................C101 Gingerich Structures, LLC .............................................A1213

Golden Calf Company .....................................................C430

Gorter’s Clay & Dairy Equipment of MN, Inc. ..................C521 Central Plains Lely Centers: Gorter’s Clay & Dairy Equipment; Leedstone; Automated Dairy Specialists NE ..................C318 Hanson Silo Company .....................................................C518

Hatfield Mfg. Inc...............................................................C902

Hawke & Company Ag ....................................................C824

Heart of America DHIA ....................................................H126

Heartland Builders Co. ....................................................C609

Hoard’s Dairyman ..................................................................G

Hoof-Zink .......................................................................A1207

Hoppe Roofing Inc. ................................................................E

Hover Chute ....................................................................C509

Hubbard Feeds Inc. .........................................................C115

Hundertmark Cleaning Systems, Inc. ..............................A511

I-29 Moo University Collaboration ...................................A203

Iowa Area Development Group .......................................C605

J & D Manufacturing ........................................................C905

J. B. Hunt Ag Services...........................................................X

JDJ Solutions...................................................................A115

Jefo Nutrition USA Inc. ....................................................H135

Johnson Concrete Livestock Waterers ............................C904

Johnson Engineering Group, LLC .................................A1108

Jones-Hamilton Co. .......................................................A1014

K2S Engineering Inc. .......................................................C800

Kemin Animal Nutrition & Health .....................................C209 Kooima

Kuhn

Marsh McLennan Agency ................................................C411

MB Nutritional Sciences, LLC ..........................................H100

McFinn Technologies ....................................................A1012

McLanahan ......................................................................C111

MEDA/Chemstar & Milk-Rite USA .................................AF100

Medgene..........................................................................A109

Mensch Mfg .....................................................................C613

Merck Animal Health .......................................................C206

MGK Insect Control Solutions .........................................C602

Micro Technologies and MWI Animal Health ...................C832

CHS .................................................................................C308

Midwest Dairy .................................................................C204

Midwest Dairy Solutions ..................................................C230

Midwest Livestock Systems, LLC ....................................C624

Midwest Sidewalls ...........................................................A415

milc Group .......................................................................C630

Minnesota Department of Agriculture ..............................C303

MN DHIA (MN Dairy Herd Improvement Assoc.) ..........AF104

MTech Dairy Solutions ....................................................C326

Munters............................................................................C935

NDEco / New Direction Equipment Co. ...........................A603

Nebraska State Dairy Association .........................................N

Neogen ..................................................................................H

Norbco .............................................................................C830

North Central Steel Co. ...................................................A307

Northland Farm Systems ...............................................A1003

Northern Plains Forage Association ......................................Q

NovaMeal by Novita Nutrition ..........................................C331

Novus International..........................................................C603

NuAge Builders................................................................H133

Nuhn Industries Ltd. ........................................................A619

NutraDrip Irrigation ..........................................................C510

Nutrient Advisors ...................................................................Y

Osakis Silo Repair DBA: WW Erection ............................C728

OZOLEA RETE AGRICOLA ..................................................T

Parnell Living Science .....................................................A602

PEAK Forage Solutions Inc. ............................................C730 Dairy Coach, LLC. DBA PeopleCor .................................A107

Phibro Animal Health .......................................................C221

Pifer’s Auction & Realty .................................................A1008

Pioneer Seeds .................................................................H101 POET ...............................................................................A412

Polytank Inc. ....................................................................A213

Herd-Boss/Post Equipment Company .............................C826

Post Equipment Company/Herd-Boss .............................C424

PowerLift Doors by Rick’s Welding..................................A414

Poseidon, LLC. ..............................................................A1111

Prairie Farms Dairy..........................................................A305

Prairie Land Ag Supply, Inc. ............................................C235

ProfitPro Ag .....................................................................A206

Progressive Dairy ............................................................H115 Promat .............................................................................A310

PSI Power Washer ................................................................P

Puck Enterprises ...........................................................A1203

QualiTech, LLC................................................................C520

QualiTru Sampling Systems ..........................................A1010

Quality Liquid Feeds, Inc. ................................................C213

Ralco ...............................................................................C409

RDO Equipment Co. ........................................................A806

Real-Tuff, Inc. ..................................................................C302

ReproScan.......................................................................A105

Ridgewater College ...............................................................A

Rippleview Hoof Care, Ltd. ..............................................A204

RMH Jones Equipment..................................................A1110

Safe-Trac Grooving .........................................................C908

Scherer Inc. .....................................................................C502

Schwartz Manufacturing ................................................A1106

Select Sires Member Cooperative .........................C119/H114

Sharp Industries ..............................................................C809

Silostop Agri ..........................................................................I

SIDUMP’R Trailer/The BatchBox ....................................A104

Sioux Dairy Equipment ....................................................C615

Sioux Nation Ag Center .........................................................F

smaXtec Inc. ....................................................................C932

SDSU, College of Ag, Food & Environmental Science ..........K

South Dakota, Governor’s Office of Economic Development...............................................A1206

Soy Best ..........................................................................C226

Specialty Sales, LLC .......................................................A111 Steelwerx, LLC ................................................................C806

Steuart’s Natural Health ..................................................C600 STgenetics.......................................................................C224

Syngenta Enogen ............................................................A110

TechMix, LLC ..................................................................C109

TerraKat LLC ...................................................................A208

The Coburn Company Inc. ..............................................A113 TLAY Dairy Video Sales ..................................................C124

Topcon Agriculture ..........................................................A410

Wisconsin:

Abts Equipment LLC

New Franken (920) 866-2485

Gillett (920) 866-2485

Argall Dairy Systems, Inc.

Belleville (608) 424-6110

Platteville (608) 348-3385

Fuller’s Milker Center LLC

Lancaster (608) 723-4634

Richland Center (608) 723-4634

Gehring Sales & Service, Inc.

Rubicon (262) 673-4920

Joe’s Refrigeration, Inc.

Withee (715) 229-2321

Leedstone, Inc.

Menomonie (866) 467-4717

Midwest Livestock Systems

Menomonie (715) 235-5144

Redeker Dairy Equipment

Brandon (920) 960-9260

The Scharine Group Inc.

Whitewater (608) 883-2880

Tri-County Dairy Supply Inc.

Janesville (608) 757-2697 Iowa:

Decorah (563) 382-8722

Minnesota:

Gorter’s Clay & Dairy Equipment, Inc.

Pipestone (507) 825-3271

Leedstone, Inc.

Melrose (888) 267-2697

Glencoe (877) 864-5575

Plainview (800) 548-5240

Midwest Livestock Systems

Zumbrota (507) 732-4673

South Dakota:

Midwest Livestock Systems

Renner (605) 274-3656

music, Roozeboom shares the gospel message with thousands of people in Iowa, South Dakota and Minnesota.

Roozeboom also serves as the Christian Festival Association chairman, hosts the podcast “Enjoying the Journey” and produces annual Christmas and Easter TV programs and “Stories of Strength,” a video series with real-life stories of overcoming adversity through Jesus.

Be prepared to walk away inspired from this year’s Central Plains Dairy Expo Prayer Breakfast as Rob Roozeboom — a Jesus-follower, husband, dad, evangelist, speaker, podcaster and author — shares his “Broken – still chosen” journey. Roozeboom strives to inspire people to nd hope and worth amidst brokenness. The breakfast will be held March 26 at the Denny Sanford Premier Center in Sioux Falls, South Dakota.

As a young child, Roozeboom dreamt of becoming an athlete and farmer. A muscular dystrophy diagnosis at age 5 crushed those dreams. Feeling painfully different and forgotten, Roozeboom questioned his very existence and wrestled with God about his future. God had bigger dreams for Roozeboom.

In 2001, Roozeboom founded RISE Ministries and in 2005 he launched RiseFest, an annual Christian music festival in northwest Iowa that features some of the nation’s top Christian artists and speakers.

Living with muscular dystrophy has given Roozeboom a unique and relatable perspective on walking through adversity while holding onto faith. His authenticity connects with and encourages people from all walks of life. He is a sought-after speaker who shares his story and delivers Jesus’ message of hope to communities, businesses and prominent events nationwide. He has shared the stage with Phil Wickham, For King + Country, TobyMac, Skillet, Lecrae, Anne Wilson, Jep Robertson, Megan Fate Marshman and Darryl Strawberry.

In 2022, Roozeboom and the RISE team created RISE with Rob and Friends to bring singer-songwriters together for storytelling and music. Inspired by Nashville Writers’ Rounds, artists perform their original songs and share how they were inspired. Through this night of hope through storytelling and

Recently, Roozeboom wrote his rst book, “Broken Still Chosen.” It weaves Roozeboom’s inspiring story with biblical teaching, offering hope to those who feel broken, unloved, unseen or forgotten.

The CPDE Prayer Breakfast is free to dairy producers, but registration is required.

Start your day on Wednesday, March 26, at the Central Plains Dairy Expo Trade Show with the Ag Prayer Breakfast. The breakfast buffet in the Sanford Premier Center will open at 6:30 a.m.

Real-time alerts ensure each calf gets the attention it needs, leading to timely interventions, lower treatment intensity, reduced reliance on antibiotics, and improved labor efficiency. Powered by Artificial Intelligence and continuously evolving algorithms, the system adapts to your specific farm and the unique behavior of each calf.

With CowManager's Lifetime Monitoring system, you can support the full lifecycle of your herd - from calf to cow - ensuring optimal health, growth and performance at every stage.

Implement the technology designed to optimize calf rearing and maximize future herd health and productivity. Youngstock Monitor uses lightweight ear sensors to track crucial development stages, helping you improve calf health and welfare now for a strong, productive herd later.

By Stacey Smart stacey.s@dairystar.com

Feed costs loom large on many dairies. Therefore, when targeting areas for potential savings, feed is often a top consideration. Carefully managing the purchase of this high-price tag item and buying at opportune times can help control feed costs.

Jenny Wackershauser, a senior dairy analyst and a Feed Foundations program advisor at Ever.Ag, has extensive experience in dairy risk management and feed and grain risk management. During her session at Central Plains Dairy Expo, “The Dairyman’s Perspective of the Feed Market Outlook and Dairy Margins,” Wackershauser will help dairy producers learn how to manage price risks related to the grain market. The session will be held March 26 at noon in room MR 12 and March 27 at 8 a.m. in room MR 9/10.

Wackershauser will share a look back on feed and grain markets over the last years to explain how recent historically high prices came about. She will discuss the tools available for managing these higher prices, such as cash markets and futures contract options. In addition, she will provide an outlook on

the grain market for the year.

“This session will be like a tutorial on all the things available to dairymen to manage their price risks,” Wackershauser said.

Rather than looking at grain markets from the perspective of a grain sell, Wackershauser encourages dairy farmers to approach markets with the mindset of a grain elevator.

help farmers manage positions during the year. This strategy can help maintain a position that is not at the mercy of the markets.

sell the product,” Wackershauser said. “We strive to be the neutral voice to help dairies make educated decisions.”

“Through the years, elevators have traditionally been successful because they buy at the low time during harvest and are able to store grain during the year and utilize ‘carry’ in the market,” she said. “This means the elevator can take advantage of markets during the year and buy at the cheapest time when every grain farmer is trying to sell grain.”

The company has grown their Feed Foundations program over the last four years. The program aids dairymen through the procurement process by helping manage each element of the buying process individually.

Wackershauser said there are currently a lot of soybeans in the global market while the corn supply has gotten tight despite a large U.S. crop.

“We haven’t had a tight-corn, heavy-soybean market for a while,” she said.

However, it is too early to pinpoint prices for the year.

Wackershauser said corn silage can sometimes have less exibility in pricing. For example, in the fall of 2023, corn silage priced during early September harvest was priced at $5 per bushel corn, versus a softer price as the year progressed.

“Dairymen were essentially buying corn silage during the most expensive time of year she said. “Using option strategies and strategies within the Chicago Board of Trade can help recoup some of this loss. This is the same strategy an elevator would use if buying corn today as a way to offset their risk on the CME.”

Ever.Ag looks at seasonality, opportunities for cash markets during harvest and CME Group Inc. tools that can

“We leverage exchange traded options alongside the physical purchases and help farmers understand futures and basis independently, as they often have an inverse relationship to each other,”

Wackershauser said. “The local basis for various products can be difcult to track and manage, but Ever.Ag has built a strong historical database of basis values to help guide dairymen.”

Wackershauser said this is a tactic few dairy producers are utilizing.

“There is a large percentage of smart, progressive dairymen who have no idea what a basis is or what ‘carry’ is in the market,” she said. “They’ve managed it over time just by keeping good records and buying things when they think it’s a good price.”

Often, one of the only sources of market insight for dairy farmers comes from those who are trying to sell them a product. Ever.Ag seeks to be an independent voice working on behalf of the dairy.

“Our greatest motivation is in helping purchase feed when opportunities are present, to whomever is willing to

“There is lot of data to come in regarding both the U.S. and South American corn crops in the coming months,” she said.

When taking a sneak peek at 2025 milk margins, Wackershauser said strong exports are needed to keep the U.S. cleaned up on cheese markets.

“It’s going to be one of those years where we have strength early,” she said. “There are a lot of variables no one can control, like the bird u and trade wars which could have us teetering either way out of the spot we’re at. Hopefully, there is still a strong milk over feed position for Midwest dairymen.”

The Dairyman’s Perspective of the Feed Market Outlook and Dairy Margins

March 26 at noon in room MR 12 and March 27 at 8 a.m. in room MR 9/10

• AG VENTURE FEED & SEED

Watkins, MN • 320-764-9910

•HWY FEEDS

Platteville, WI • 608-744-2444

• SHELDON POWER & EQUIP. Sheldon, IA • 712-324-4455

•INWOOD HATCHERY Inwood, IA • 712-753-4736

• DAIRYLAND SUPPLY Sauk Centre MN • 320-352-3987

• LINDELL SALES & SERVICE Cannon Falls, MN • 651-258-4311

• LEEDSTONE Melrose, MN • 800-996-3303

•SIOUX NATION VET SUPPLY Marshall, MN • 507-532-3716

•PIERZ CO-OP Pierz, MN • 320-468-6655

•RON MILLER Waconia, MN • 952-442-4808

•FLOODWOOD FARM & FEED Floodwood, MN • 218-476-2233

• BJERGA FEED Motley, MN • 218-352-6383

• FEDERATED CO-OPS Princeton, MN • 763-389-1567

• GORTER’S CLAY & DAIRY EQUIPMENT, INC. Pipestone, MN • 507-825-3271

• ADKINS EQUIPMENT

Detroit Lakes, MN • 218-847-2079

•GERTKEN’S SALES Richmond, MN • 320-597-2207

• FARMER’S CO-OP Lafayette, MN • 507-228-8224

• AGRI-TECH Watertown, SD • 605-882-7015 Brookings, SD • 605-692-0955

• GILMAN CO-OP CREAMERY Gilman, MN • 320-387-2770

Advanced Ag Products

Ag Processing, Inc.

Agri Feed International, LLC.

Agri-King, Inc.

Albers Dairy Equipment, Inc.

American AGCO Trading Co.

AMPI

4-D

A1

ABS Global

Ag

Agri-Plastics/Agri-Comfort

AgriSteel USA

Agromatic, Inc.

Agropur, Inc.

Amelicor

Anez Consulting, Inc.

Archer Daniels Midland Company

Arnolds of Kimball, Inc.

BECO Dairy Equipment

Bio-Vet Inc.

Bovine Hoof Adhesives/Glue-U Inc.

Butler Machinery Company

Technologies

Valley Dairy Supply Inc.

Cloverdale Equipment LLC.

Corteva Agriscience MCS, LLC

- Dairyland Seed

Dairy Farmers of America

Calf-Tel

Dairyland Laboratories

DairyVisor, Inc.

DBC

FERA Diagnostics and Biologicals Corp.

Heartland Builders Co.

Lawley’s

MGK Insect Control Solutions

Micro Technologies and MWI

Animal Health

CHS - Animal Nutrition

Post Equipment Company/ Herd-Boss

TLAY Dairy Video Sales

Valley Dairy Farm Automation Inc.

Jones-Hamilton Co.

Kooima Ag

Lange Ag Systems, Inc.

Legend Rubber Inc.

Maas Energy Works

MB Nutritional Sciences, LLC.

MEDA/Chemstar & Milk-Rite USA

milc Group

Minnesota Department of Agriculture

MTech Dairy Solutions

Norbco

NovaMeal by Novita Nutrition

Novus International

NuAge Builders

Nuhn Industries Ltd.

Parnell Living Science

PEAK Forage Solutions Inc.

Pioneer Seeds

QualiTech, LLC.

Real-Tuff, Inc.

Safe-Trac Grooving

smaXtec Inc.

Steuart Labs

TranSource Truck & Equipment Inc.

Udder Comfort Inc.

Udder Health Systems

Udder Tech Inc.

Valley Queen Cheese

VES-Artex

Vetagro Inc.

Zero Tolerance/Current Defense

March 25 - 27, 2025

Sioux Falls, South Dakota

By Tiffany Klaphake tiffany.k@dairystar.com

RUTHTON, Minn. — For the DeRuyter family, the Wednesday of the last week in March is known as the day they get to attend Central Plains Dairy Expo.

Rich and Stephanie DeRuyter and their family milk 85 cows at their farm near Ruthton.

“We always go (to Central Plains Dairy Expo),” Stephanie said. “Our boys were just little when we started going and now our oldest is in his 30s. I don’t think we have missed a year since we started going. It’s kind of a big deal for us.”

Rich and Stephanie have seven children — Levi,

Dylan, Isaiah, Sierra, Clay, Sadie and Kai. Three are still at home and help around the farm. The oldest four are grown and work at jobs off the farm. Twenty-year-old Clay is farming full time, milking the cows twice a day and taking care of calf chores.

Stephanie helps milk in the evenings and Rich does all the feeding and cleaning. The two youngest children help as needed outside of school.

No matter what is happening on the farm, the last week in March the family sets aside one day to make the drive to Sioux Falls, South Dakota.

“We always take the kids,” Stephanie said. “The kids just love the trade (show) and walk around. It is such a safe environment for them; I never have to worry about them.”