DAIRY ST R

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

BARRON, Wis. – Feeding calves has always been Sherry Arnold’s favorite chore. When her parents, Norman and Judy Busse, decided to sell their herd of 150 dairy cows in 1999, they, along with Arnold, wanted to nd a way to stay on the farm. They started custom raising heifers for a neighboring dairy and raised bull calves as well. Arnold and her parents, along with an employee, raised 600 calves that year. In 2022, that total was up to 14,000 calves.

Arnold said it has been a steady learning curve.

“I took that love of feeding calves and turned it into what it is today,” Arnold said. “I haven’t done it by myself either. I feel like we’re on this train that just keeps moving.”

Today, the farm is run by Arnold and her parents, business partner Micah Halvorson and a group of 35 employees. The team custom raises calves from 19 dairy farms. Over the years, a strategic system has been put in place.

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: (320) 352-6303

Fax: (320) 352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

320-352-6303 • maria.b@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer

320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) • 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, SD)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, SW WI)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (NE WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (SE MN and NE IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) • bob.l@star-pub.com

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication. Subscriptions

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Calves are picked up from farms weekly. One trailer is dedicated to newborn calves to help keep illnesses off the farm. When calves are brought to the farm, they are vaccinated, weighed and tagged with a radio frequency identication tag before leaving the trailer. They are then put into calf huts. Each calf gets its own hut.

Afternoon feeding begins at 1 p.m., with the newest arrivals getting fed rst.

From there, calves are kept on milk for 60 days. They are fed milk replacer twice a day and started on grain immediately. While most calves double their birth weight in those two months, Arnold said that is not the only goal.

“My goal in those 60 days is to develop a ruminating animal,” Arnold said. “In order to do that, I need to introduce feed early and monitor that really well.”

Calves typically gain 1.6-1.7 pounds per day in the winter and a little less than that in summer. Arnold said it is easier to grow calves in the winter because fat supplements can be added for extra energy.

Calf huts are washed and moved in between every calf. Once a year, all the calf huts are moved to new ground on the farm. The manure is cleaned up, and the ground is tilled and reseeded. Then, it is left vacant for a year.

“It takes a lot of ground to do that,” Arnold said. “But, I don’t have all the viruses that want to live in the soil to affect the next calf.”

Besides the convenience of being able to move them to new ground, calf huts also provide the best air quality, Arnold said. She also likes that she can

look at every individual calf that comes in, easier than in a group feeding system.

“I can assess her condition within 10 seconds of seeing her and treat accordingly,” Arnold said. “I know, when I get there and I feed her, if she gets up, if she drinks, who’s sick and who’s not sick.”

Weaned calves move to one of ve weaning barns. The barns are all enclosed and have center feeding. Tube ventilation has been used ever since the technology became available.

Calves spend the rst two weeks on the same starter grain they had in the huts. By the end of week two, a total mixed ration is introduced. By the end of the fourth week, the calves are fed exclusively TMR.

Once the calves are completely transitioned to TMR, around 100 days old, they are moved to the farm’s second site, which is called Halvorson Cattle and located in Chetek. The calves are kept there from 3.5 months to about 5.5 months old. The dairies that own the calves arrange trucking from that site back to their farms.

One thing that has worked well throughout the entire system is the record keeping software Arnold uses. HeiferPRO allows them to record everything that happens on the farm and then send the data straight to the calf’s home dairy. There, the data can be directly transferred into the dairy farm’s DairyComp program. It also allows Arnold to generate billing off the program.

One of the biggest challenges that the farm has faced is how to physically get milk fed to so many calves.

“A lot of the equipment that exists today didn’t exist in the year 2000,” Arnold said. “It’s just been an evolving process of learning how to get milk out there.” Turn

The farm currently uses utility vehicles with milk mixing tanks.

While nding dedicated employees can be a challenge, Arnold said she appreciates her calf manager, Ally Carlson, who is also a necropsy specialist.

“She can open up a calf and tell you what’s going on in there,” Arnold said. “Then, she can take samples, and we’re fortunate enough to have a lab right here in town. We can quickly get a diagnosis, work with the vet and gure it out. That’s made a big difference. If you can identify it early, then you’ve got a chance. She’s a marvel.”

Halvorson has also been instrumental in the cooperation from its early

The new MTX 4.0 featuring Smart Mix, Smart ID & the Calf Guide System will ramp your calves up to wean them off of milk just like an auto feeder, no matter who is feeding the calf! The Smart Mix knows how much milk, milk replacer, or combination, that you need to mix for the next feeding. No guess work.

days, Arnold said. He began working for her parents at the age of 16 when they were still milking cows. He was made a partner in the business a long time ago. When they added the second farm site in 2021 for weaned calves, the site was named after him.

“We’ve kind of worked it out between the two of us, and we’re still guring it out,” Arnold said. “Micah’s son, Cole, is 21, and he’s part of the farm. … So, we’ve got this multigenerational thing going on. My dad has always wanted the farm to continue, so I’m helping him with his dream, and my dream is to pass it on and keep going.”

“Since

· Patented folding pattern eliminates the need for adhesives, allows quick and easy application

· 2 mil oxygen barrier and 6 mil black and white silage film in a single roll excludes more oxygen and resists punctures and tears

· Reflects sunlight, guaranteed UV stable for 18 months

· Both layers are completely recyclable

It might be argued that feeding calves is one of the most delicate and detail-oriented tasks on a dairy farm, but how much do farmers really know about what they are feeding their calves? Understanding the differences between whole milk and milk replacer can be a building block in the foundation upon which a successful calf program is built.

Those differences were discussed by Dr. Liz Cox, animal care program manager for the California Department of Food and Agriculture, during the March 2 edition of The Dairy Signal series, “Understanding Milk Replacer.” The series is an online resource developed by Professional Dairy Producers for dairy farmers and industry leaders.

“It is important to be able to make informed decisions when you’re evaluating a milk replacer for your calf raising operation,” Cox said.

The rst step to making those decisions, Cox said, is to understand what combination of components comprise both whole milk and milk replacer.

“The components of both milk and milk replacer are water, fat, protein, sugar as an energy source, and vitamins, minerals

and ash,” Cox said.

Cox said the key is to carefully consider what exactly those different components consist of in each.

Water is the primary component of both whole milk and milk replacer.

On average, Cox said, whole milk is around 12% total solids and 88% water. The percentage of water in the milk replacer solution can vary more than the percentage of water in whole milk due to mixing directions and human error.

“The water in whole milk is cow ltered,” Cox said.

This is not the same as water from an on-farm source, such as a well, used in mixing milk replacer, she said.

“What we want from a water quality standpoint for a baby calf is potentially very different than an adult cow,” Cox said. “A baby calf is a monogastric on a 100% liquid diet.”

Cox said sodium levels in water need to be taken into consideration, noting that the osmolality of whole milk is 300 mOsmol/kg, which she explained is the same osmolality of blood. The osmolality of milk replacer is dependent on the water used to mix it, but it is always going to be higher than whole milk.

“Milk replacer is already salty, and we need to make sure that we are not just continuing to add more salt to her diet with the water we are using to mix the milk replacer,” Cox said.

Cox said water testing, specic to calf suitability, is available from Dairyland Laboratories Inc.

“If you operate a water softener, you don’t want to be using soft water for mixing milk replacer,” Cox said. “It will increase the salt and the osmolality.”

Offering clean, free-choice water from day one will help offset the higher osmolality of milk replacer.

“I often get asked how much water they need, especially in the summer,” Cox said. “The answer is as much as they will drink. It is so important for health and for driving starter intake.”

The differences between whole milk and milk replacer are not limited to water quality. Since milk replacer is made from the byproducts of human food production, the sources of both the fat and protein in milk replacer vary from whole milk. The fat source in whole milk is butterfat, while milk replacer is made of blends from a variety of other fat sources such as lard, tallow, coconut and other plant-based oils.

The protein in whole milk is primarily casein with smaller amounts of whey present. Milk replacer typically uses whey protein with smaller amounts of animal plasma, soy and casein possibly present.

Both whole milk and milk replacer have lactose as their sugar for an energy source. However, milk replacer has a higher volume of ash than whole milk, due to the processing, drying and mixing processes.

“Just to remind you, the vitamins will not survive pasteurization, which is why we need to fortify pasteurized milk,” Cox

said. “You need to think about that if you are feeding pasteurized whole milk to calves.”

Cox said typically ingredients and information on a milk replacer tag are listed as dry matter, while milk test data is typically provided based on the liquid form, making conversions necessary to accurately compare the information, dividing the liquid percentages by the total solids percentages. For example, milk that is 3.3% protein and 3.8% fat with 12% total solids would be considered 28% protein and 32% fat.

“Think of it as a pie chart,” Cox said. “If we only have 20% protein and 20% fat, the rest is going to be taken up by the lactose. A 20-20 milk replacer is going to have a very high percentage of lactose.”

Cox said she has been asked the question about feeding larger quantities of cheaper, lower-quality milk replacer, which she said is something she advises against.

“My answer is always no, period,” Cox said. “We have to be careful about feeding large amounts of lactose in one feed-

ing. Lactose is a good sugar and it is there naturally in cows’ milk, but it is highly digestible, and if we feed a large amount at once, it is going to lead to challenges like osmotic scours, abomasal bloat and clostridial disease.”

As protein and fat percentages are increased, the percentage of lactose decreases, reducing the incidence of problems associated with higher lactose levels.

“There is a lot of science and research that goes into that fat-protein balance,” Cox said. “Yes, we want to get calories in, but we want to make sure we have that balance.”

Once the best milk replacer has been determined, Cox said it is imperative to follow the manufacturer’s directions as far as the ratio of replacer powder to water when mixing, and she recommends weighing ingredients rather than measuring by volume. High-speed agitation is also necessary to ensure complete dissolution. Following directions for water temperature for mixing, as well as being aware of feeding temperatures, is also paramount, she said.

NORWOOD YOUNG AMERICA, Minn. – Calves are vital to the future of every farm, and shedding light on what can impact their growth and prosperity was a topic Jeremy Schefers, DVM, thought imperative for producers to hear.

Schefers presented “Environmental Impacts on Calves” Feb. 20 at the Carver County Dairy and Beef Expo in Norwood Young America.

“We live in an area that has a lot of moisture or weather uctuation between the seasons,” Schefers said. “Calves need to be constantly readjusted to accommodate their energy needs during those times.”

brought in for necropsy. He observed that not once while looking through those calves did he think overheating was a cause of death.

Heat abatement, though important Schefers said, may not be as large a concern for producers as managing the calf’s body temperature during extreme cold or wet times of the year.

“I think with things like air conditioning and heat in our houses, we lose perception of what real hot and real cold is,” Schefers said. “It’s important to watch for signs of cold stress; a dead giveaway to a cold calf is visible shivering.”

The thermoneutral zone for preweaned calves is between 50 and 77 degrees. As the temperature drops, calves’ needs for digestible energy increases.

Calf environment temperature can be a challenging task for farmers to perfect. Schefers spent time in a diagnostics lab looking at calves that had been

There are many signs of cold stress in calves. Calves which are slow, dull and non-responsive are likely cold, especially when their environment outside is cold. Schefers said it is important to not assume a calf showing those symptoms is sick and needs antibiotics. Oftentimes, a calf is cold and needs additional energy, bedding and a jacket.

One way to help diagnose calves is by taking their temperature.

“If their rectal temperature is under 101.5, that’s too low,” Schefers said. “At that point, we need to work on getting that body temperature back where it needs to be.”

Calves that become too cold exhaust their sugar levels. Schefers said calves’ brains do not like low sugar levels, and sometimes that will cause a calf to have inebriated-like behaviors.

Frost bitten limbs are an indication that a calf was too cold for too long. As a survival instinct, animals will channel their blood ow to their core so their heart and brain stay warm.

A telltale sign Schefers noticed while in labs during necropsies was calves that were too cold for too long had little to no brown fat around their heart and liver, or their bladders were expanded.

“The shivering burns glucose at a rate four times faster than normal,” Schefers said. “When they start shivering, their breathing becomes short and shallow because the air is cold.”

When the calf starts to breathe short and shallow, this is when Schefers said the calf will likely develop pneumonia. Producers should also be aware of pneumonia developing because of an increase in humidity.

Schefers advised producers at the panel to invest in calf jackets.

“When the weather hits 45 degrees or less, put the jackets on,” Schefers said. “It’s also important to increase their feed or energy needs.”

The easiest way to increase a calf’s energy intake is through increasing the amount of feed they are given. Schefers said calves cannot consume four times the amount they were originally giv-

en to account for the shivering or cold swing, but increasing solids in the milk with a fortier can be a good way to increase energy. Feeding calf starter is a good way to provide a source of energy for calves as well, he said.

Weather is a constant battle for producers. Schefers showed information on the weather and how it impacted the number of pneumonia cases in calves. The charts showed that March is the toughest month for calves due to cold and wet conditions that can cause pneumonia.

“Humidity is tough to manage,” Schefers said. “Ideally, humidity stays below 80% in your calf barns or hutches. Anything over 80% is considered wet. Fog is a bad sign in your barns.”

Creating a dry and warm environment for calves is essential to youngstock vitality, Schefers said, and creating a good environment for calves starts from day No. 1.

“Ideally, for the rst 3 days of their life, that calf should be in a thermoneutral environment, like a calf warmer, or I’ve seen people put heat lamps over an individual pen,” he said. “After three days, they should get that jacket and be put somewhere with wind block and deep, dry bedding.”

Bedded packs, despite being a great source of heat, cause humidity. Schefers referred to a bedded pack like 500 wet, soggy diapers. He said calves are better off being in a clean, dry bedded environment without a bedded pack because there are additional ways producers can keep a calf warm.

“My trifecta is a calf jacket, dry, bedded environment, and adequate energy from feed,” Schefers said. “Those three are a great place to focus on.”

Calf Blankets: Machine wash

An

LVES: Up to 1 year 1 mL/per 100 lbs. bodyweight

CATTLE A : From 1-2 years 1 mL/per 150 lbs. bodyweight

CATTL A E: Over 2 years .. 1 mL/per 200 lbs. bodyweight yg

CAUTION:

PRECAUTION:

Selenium and copper are toxic if administered in excess. UO

Always follow recommended label dose. Do not overdose.

It is recommended that accurate body weight is determined prior to treatment.

Do not use concurrently with other injectable selenium and copper products. oouou

Do not use concurrently with selenium or copper boluses.

Do not use in emaciated cattle with a BCS of 1 in dairy or 1-3 in beef. oot

Consult your veterinarian

Slight local reaction may occur for about 30 seconds after injection. A slight swelling may be observed at injection site for a few days after administration. Use standard aseptic procedures during administration of injections to reduce the risk of injection site abscesses or lesions.

WITHDRAWAL PERIOD:

Meat 14 days. Milk zero withdrawal.

DIRECTIONS:

This product is only for use in cattle. MULTIMIN® 90 s to be given subcutaneously (under the skin) ONLY. It is recommended to administer the product in accordance with Beef Quality Assurance (BQA) guidelines. Minimum distance between injection sites for the MULTIMIN® 90 product and other injection sites should be at least 4 inches. Inject under the loose skin of the middle of the side of the neck. Max volume per injection site is 7 ml

times per year

4 weeks before breeding

4 weeks before calving

4 weeks before calving

4 weeks before insemination at dry-off at birth at 3 months and/or weaning every 3 months –especially 4 weeks before breeding

(program gives planned dates that can be varied to suit management programs)

By Amy Kyllo amy.m@star-pub.com

By Amy Kyllo amy.m@star-pub.com

PRESTON, Minn. – A smell of sawdust wafts through the air and heifers mill around in Todd Hendrickson’s freestall barn. Hendrickson has converted 19 years of dairy farming experience into a custom heifer raising operation.

Hendrickson raises 150 heifers for two dairy farms on the building site of his former dairy farm near Preston. He raises the heifers from 10 to 11 months of age to seven months pregnant.

Having dairy farmed from 1989 to 2018, Hendrickson has been using that experience to raise heifers commercially for almost a year.

“I’ve always taken an interest in how good a heifer is,” Hendrickson said. “Obviously, the heifers are in the future of your farm or your herd. … I like to think that we did a really good job of taking care of them.”

Now, Hendrickson is working to raise good heifers for others. He said he believes farmers should ip their narrative when they consider the nancial aspects of heifer raising.

“Don’t think of your heifers as an expense,” Hendrickson

said. “Think of them as an investment in the future for your farm.”

At Hendrickson’s operation, he separates the heifers into three pens. The rst pen has a bedded pack and usually houses around 20 heifers. Heifers enter this pen rst and stay there for two months. They are then moved to the breeding pen where they remain until they have been conrmed pregnant, at which time the heifers move to the third and nal pregnant pen.

Hendrickson raises all the feed for the heifers on his cropland. He does the nutrition work himself, focusing on a total mixed ration balanced for healthy maturing.

“I’m a big believer in pushing ber on heifers because you get one chance to develop a rumen and one chance to develop the rib on a heifer,” Hendrickson said. “If you don’t have that, you have nothing to work with when they’re cows.”

He said that a challenge in heifer raising is balancing the nutrition needs of heifers coming in with varying conditions.

All pens receive the same ration except the breeding pen, which receives a richer diet. Hendrickson is centered on making sure heifers have proper body condition at his facility.

“The problem when you start having fat heifers or fat cows in general is, sure, you can see the fat on the outside of the heifer or the animal, but you don’t see the fat that’s on the inside,” Hendrickson said. “That’s

the fat that causes the problems down the road.”

For his heat detection program, Hendrickson takes a hands-on approach. Every heifer has tail paint sprayed on each day in the breeding pen. He has three colors of tail paint that correlate to three stages of life. Orange is for heifers that have never been bred. Pink is for heifers that have been bred at least once. Green is for conrmed pregnancies before they move to the pregnant pen.

Hendrickson utilizes his feed lockups for most of the tail painting, but for the rest, he just walks up to the heifers and sprays them. Part of the reason he utilizes the headlocks is so the heifers learn to feel comfortable with being contained, which makes them easier to manage.

Between tail painting and cleaning the free stalls in the breeding pen, Hendrickson is in with the breeding heifers two or three times a day. He said this

human component is a piece missing in some heifer-raising strategies.

“You’re commingling with the heifers, and they get to know you,” Hendrickson said. “They just get to be so much easier, more pleasant to be around. The more you’re around them, they get used to humans. I think that’s pretty important.”

Hendrickson breeds the heifers based on matings. All heifers are bred at least once to sexed semen. After that, the breeding protocol depends on which farm the heifer is from. Hendrickson uses a technician for his articial insemination work.

Heifers that have not come into an observed heat by 15 months are given a blind prostaglandin injection followed in seven days by a CIDR. Hendrickson said getting heifers bred to calve in a timely manner is a key management area he focuses on.

Two types of bedding are used in Hendrickson’s operation. The rst pen has a bedded pack to keep the heifers more relaxed, which Hendrickson said is optimal because they are experiencing transition. The other two groups are in deep-bedded sawdust free stalls.

The freestall barn is scraped every day, and one of the four rows of free stalls is bedded with locally sourced sawdust.

This means all bedding is switched every four days. Hendrickson also spreads sawdust in the alley. He does this to provide increased traction for heifers that may be aggressive because of heat or other factors. Hendrickson also does this to keep heifers who do not sleep in the free stalls clean. He said that even with nice free stalls, some heifers choose to lie elsewhere.

Hendrickson does all the work of raising the heifers himself.

“I’m pretty much a one-man show,” Hendrickson said. “I probably have just enough to keep me out of trouble.”

While still being able to utilize the facility he already had, Hendrickson said he has gained exibility in his lifestyle and fewer time constraints. He plans on raising heifers until he retires and said he appreciates the life balance that heifer raising has brought to him.

many

companies and nutritionists including Purina, Hubbard, Agri-King, Form-A-Feed, Vita Plus along with independent nutritionist to get your animals

The Dairy Calf & Heifer Association is excited to announce that the 2023 Annual Conference and Trade Show will be held April 11-13 in Prior Lake, Minnesota. With the theme “Commitment to Excellence,” the DCHA Conference and Trade Show offers an opportunity to build on past accomplishments, learn from worldwide calf and heifer experts, and lead calf and heifer growers toward a sustainable future.

This year’s conference will be held in person and also have a virtual option for those unable to attend. The conference committee has focused on three areas of calf raising when creating the program and optional tours, allowing more variety of sessions to attract a broader range of calf raisers. The tracks include: wet calf/weaning, post-weaned/reproduction and beef-x-dairy.

Optional tours for the conference include:

NexGen Dairy: NexGen Dairy is a third-generation dairy farm milking 1,000 Jersey and Jersey cross cows. Calf health along with cow health and longevity are priorities at NexGen. The dairy hosts a state-of-the-art transition facility which includes a wet calf room, separate fresh cow parlor and calf milk processing room. Heifers are all raised on-site from birth through breeding. Calves at NexGen are being group raised but individually fed in a new calf facility which is powered with a 40kW solar energy system.

University of Minnesota Huntington Bank Stadium & Andrew Boss Laboratory of Meat Science: Huntington Bank Stadium is the home of the Minnesota Golden Gophers football team. This is the rst new football stadium in the Big Ten conference since 1960 and the rst LEED (Leader-ship in Energy and Environmental Design) certied college football stadium in America. The spaces toured include the president’s suite, club rooms, hall of fame, the eld and a peek into the foot-ball-shaped home Golden Gopher Locker Room. (Tour space subject to change.) At the University of Minnesota Andrew Boss Laboratory of Meat Science, tourists will learn about differences between dairy and beef steer carcasses and the harvest process. There will also be a dairy rib and beef rib, which will be cut up for discussion on the differences between the two. If time permits, further processing (jerky, sausage) will be discussed.

Register at www.calfandheifer.org. Any questions can be directed to DCHA staff at info@calfandheifer.org or 1-855-400-DCHA.

Healthy calves create a more profitable herd. Make First Arrival® with Encrypt® a core part of your digestive and immune health support program for your calves during the critical early growth period.

“We installed our posts and 5 wire fencing in spring for our cattle receiving/training pen. Post and fencing were easy and quick to install & fiberglass is long lasting. We want to keep our farm natural looking so this product works well for us and the cattle.”

Morris and Debra Weyers, Bethany, MO

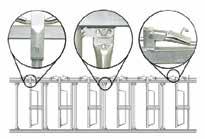

“These gates are very simple to take apart, like calf huts, only bigger. We put 1-3 calves in a pen, which gets them accustomed to group housing. Ventilation is better for the calves having an open pen.We are very happy with our investment in the gates.”

Top Deck Holsteins-Westgate, IA, Jason, Derek, Justin Decker

“We decided to install freestalls from TJ’s Fencing after a friend recommended them. They were easy to install and the cows really like them. We only have about half of the stalls converted right now, but are eager to get the rest of our stalls converted to freestalls from TJ’s Fencing.“

- Bernard County Dairy, Richard Decker Installed in February 2020

“I have free stalls from TJ’s and love them!

With my old steel stalls I was constantly repairing from the cows bending them. TJ’s stalls are very flexible and reasonably priced. I have saved a lot of time and money on repairs with TJ’s free stalls.”

Will Gerdes Caledonia, MN

Will Gerdes Caledonia, MN

“We have been supplying Glasfiber boxes for 10 years. Every customer is satisfied with this product and will definitely choose the glass fiber freestall again in the future. It is also a good fit for renovation projects. In addition, we also offer glass fiber fencing. The glass fiber is an excellent alternative to the iron barn equipment.”

Bertha Swaving, Holland, Netherlands

“We built our new ABS Global Calf Facility in the summer of 2016. This was the first time we utilized anything except steel at one of our facilities and it was a hard sell to the staff. However, after meeting with Travis at TJ’s Fencing in Harpers Ferry, and having him bring a gate home to show the staff, we were sold. We utilize more than 200 different sizes of gates, all purchased from TJ’s Fencing and installed by Cliff’s Incorporated from Friesland, Wis. The gating is holding up very well. We intend to expand our calf facility this summer and will definitely continue utilizing TJ’s Fencing for the gating.”

- Jim Meronek, Health Assurance, Production and Supply Chain Director ABS Global, Inc., DeForest, WI

“I have purchased fences from TJ’s twice. My original fences were purchased 20 years ago and they have held up well. I enjoy not having to paint them. Recently, I purchased fences with rounded corners. These have been very sturdy and the ends cannot pop out of place. Both types of fences are very flexible and safe for my horses.”

- John Bengfort, Bluff Country Equine, Winona, MN

- John Bengfort, Bluff Country Equine, Winona, MN