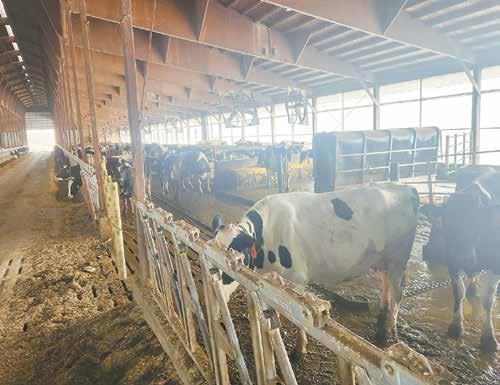

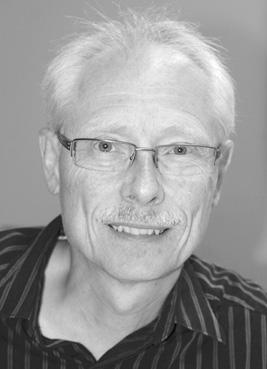

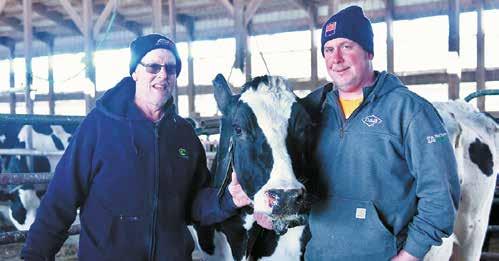

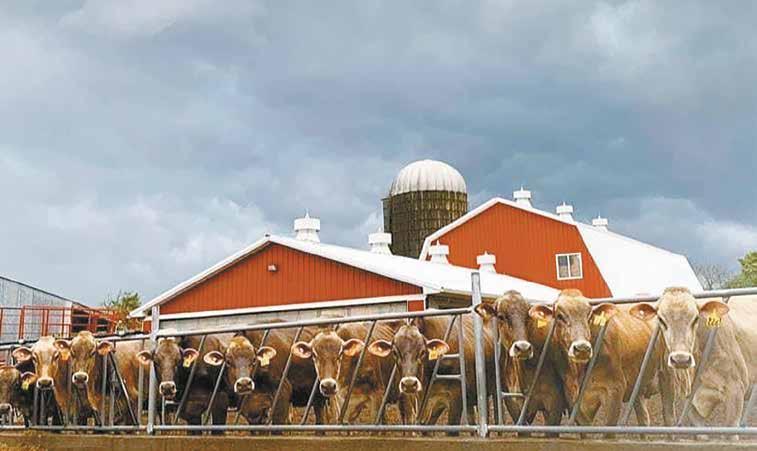

When John Hoeer’s dad upgraded from a stanchion barn to a double-4 parlor, freestall barn and Harvestore silo in 1964, he was ahead of his time.

“Everybody told him he was crazy and that he was going to go broke,” Hoeer said. “We were milking about 200 cows down there and running them through a double-4 parlor for years.”

The family eventually built a new freestall barn and double-12 parlor on the hill above the old facilities in 2012 and then installed a robotic milking system in 2023.

Those patterns of progress laid the foundation that would allow the dairy farm to continue to the third and fourth generations. Today, the family is nine months into their transition to robotic milking, with 230 cows utilizing four Lely A5 robots. Hoeer runs the farm with the

help of his two grown sons, Devyn and Austin.

Austin has been the main feeder since 2018. Devyn has overseen calves, youngstock, breeding and computer work since returning from college in 2021.

The Hoeers considered robots when they upgraded to a parlor but decided against them.

“We talked about robots and said we’re never going to do it; it’s a crazy idea,” Hoeer said. “If these guys (sons) weren’t farming, I never would have done it.”

The combination of his sons returning from college and the loss of a longtime employee led the Hoeers to reconsider robots. Additionally, their neighbors were in their 12th year with robots and had no regrets.

“That kind of pushed me over,” Hoeer said. “I learned to never say never.”

The family looked at a couple of new facilities and further discussed the ideas with their neighbors. With the help of the Lely dealer, who

is just 10 minutes away, they decided to put all the robots on one end of the barn. This allowed them to complete the

project with minimal construction since they used existing space for the robots and added on to the utility rooms.

Hoeer said the transition went better than he thought it would. The robots were in place for two weeks before milking was enabled, so the cows could walk through them to access feed.

While this helped to get the cows accustomed to walking through the robots, there was a slight regression when the milkers started operating.

The rst time walking through and getting milked was OK because the cows thought they were getting fed, Hoeer said. The next time was difcult because they knew they were getting milked, and by then, the brush was operating as well.

For the rst week of milking, there were people in the barns 24 hours a day to push cows through the robots. Gates were set up to make holding pens, and groups of cows were brought to the robots day and night to get milked. The second week, the gates were removed, and cows were given the option of going through on their own.

“They weren’t getting pushed anymore, so at rst, they didn’t think they had to come up,” Hoeer said. “Then, we were back pushing cows and letting them know they could come up any time, not just when we’re pushing them.”

All in all, the cows were pretty much trained in three weeks. The family did run into challenges with the extreme cold weather in early January. Because the facility is situated on a ridge, the barn is exposed to fresh air, which caused the robots to freeze.

They managed to thaw the robots with heaters and hung silage plastic over them to provide a temporary enclosure. They are working on plans for a more permanent option for next winter.

Milk production started to increase about six months after installation. Hoeer said it is still increasing, although the average has been impacted by a group of heifers that

recently calved. Cows are milked 3.1 times per day on average and give 81 pounds of milk.

The freestall barn is cleaned with automatic scrapers. Cows are periodically run through footbaths on each side of the barn to ensure foot health.

Hoeer said the biggest benet of installing robots is setting the next generation up for success. Devyn and Austin are starting to buy into the operation as Hoeer plans to retire within the next 5-10 years.

“They wouldn’t be able to start on their own,” Hoeer said. “I’m glad it’s staying in the same family as long as I’m around. When their time comes, that’s their business.”

5 years ago

Blizzard causes widespread destruction

Corey and Bridget Hoffman, of Chateld, Minnesota, made the hard decision to sell their 420-cow herd in 2019. Due to a blizzard that hit Feb. 2324, 2019, two sections of the freestall barn collapsed. The family knew right away that the cows needed a new home once the second section collapsed. At the time, Corey said the worst part of it was picking up steel, thinking nothing was under it, and then nding a cow that wasn’t able to get up. In total, the family lost 13 cows. The family didn’t want to chance someone getting hurt by pushing through the winter, with more snow projected and knowing that likely more sections of roof would come down. The Hoffmans rebuilt later that year and started once again.

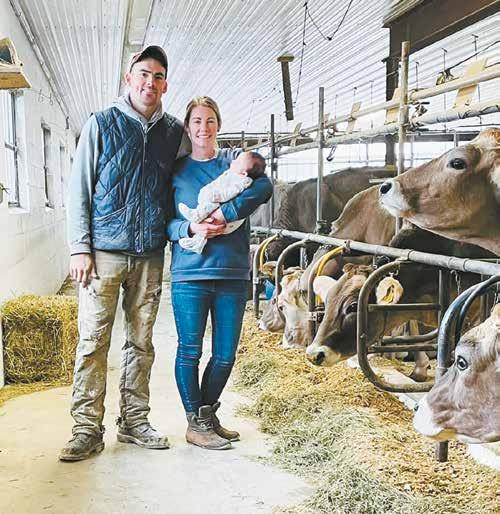

Near Mayer, Minnesota, Becca and Ryan Jopp could be found raising their son, Derek, on the family farm in 2019. Ryan, with the help of his parents, Rick and Colleen, milked 85 cows in a stanchion barn with eight milking units and farmed 160 acres. Becca worked full time as a large animal veterinarian, but she was in the barn whenever she was able and often brought Derek with

her to see Ryan after work. Becca said Derek’s favorite place to be was the barn. The couple is the fth generation to dairy farm on the land. It was Ryan’s great-great-great-grandfather who homesteaded the land in 1886. This grandfather milked cows in a log barn.

Jim Brandenburg, of Fort Atkinson, Wisconsin, alongside his wife, Peggy, and children, Olivia, Sawyer and Emerson, ran a 50-cow dairy while trying to stay aoat in the economy of 2019. The family milked the herd in a 32-stall stanchion barn with the hopes of being able to upgrade to a parlor as soon as the economy leveled out slightly and they would be able to nancially support it. At the time, the family managed their milk prices by increasing their components while keeping the quantity of milk up. The family successfully reached a butterfat of 4.5% and protein of 3.5%. They said they planned to focus on Jersey cows going forward. Already, they had bred many of their Holstein cows to Jersey bulls.

Heatherstone dispersal celebrates 35-year career

Mike and Valerie Holschbach, who owned Heatherstone Enterprises

Learnaboutavarietyofconservationpracticesrelatingto livestockmanagement.

Learnhowtomanagemanurewhenintegratingcovercropsand reducedtillageintoyourcroppingsystem. Sitbackandlistentoallthedifferentannualforagemixesthat couldworkonyouroperation.

Lastly,taketheopportunitytotalktoanareaengineerashe answersyourquestionsaboutmanurestoragefacilities.

near Baraboo, Wisconsin, were named Distinguished Breeders in 2019 at the Wisconsin Holstein Association’s annual convention in Manitowoc. Mike and Valerie raised their three children, Brienne, Chelsea and Chase, on the farm and shared their passion for dairy with them. Together, the family milked 130 cows in a tiestall barn, with about 230 head total. The farm’s herd dispersal was set for April 13, 2019. Mike and Valerie had deep roots in the dairy world and said they would miss breeding and watching the generations of cattle and anticipating what they would turn into.

Steve and Kristine Ruther, of Perham, Minnesota, had what Steve called a good family moment Jan. 21, 2014, when he had to deliver his own daughter. Kristine started having contractions Jan. 20 around 2:30 a.m. At around 6 a.m., they called their midwife, Rebekah Knapp. Throughout the day, the contractions started to slow down, so they told Rebekah she could leave. When the contractions seemed that Kristine was close to birth, they called Knapp again, who was in Itasca delivering another baby. The couple had another child who was born at home, so they had a general idea what to do. Around 3:32 a.m., Steve had his new daughter, Hannah, in his arms.

Steve and Kathy Tschida, of Grey Eagle, Minnesota, made the decision to switch from their tiestall barn to a parlor in 2012. After looking at their options, they settled on a double-8 parabone parlor that they built themselves. Kathy’s brother, Mike Berscheit, was a full-time welder and helped every day after work to build the parlor. Prior to building the parlor, the Tschidas milked

60 cows in a 30-stall barn. Milking took Steve three hours. With their new parlor, the couple got milking done together in 1 hour. When the couple knew they needed to x up their barn and upgrade their system, they rst designed a robotic barn, only changing their mind when they realized there wasn’t wiggle room in cattle numbers in order to cash ow the robot.

20 years ago

In November 2003, John Merdan, of Avon, Minnesota, built a tarpcovered 3-row freestall barn. Merdan farmed with his two sons, Eric and Joe. The new barn measured 65 feet by 150 feet with 12 foot by 12 inch poles buried 8 feet deep to create the base structure. Before they moved the cattle to the barn, the family’s biggest worry was losing cattle. However, after about ve days, their worries disappeared when they saw how the cattle adjusted. Merdan said that they experienced better breeding results and dry matter intake. The tarp allowed for more natural light instead of the timed lights they had installed.

A modern milk maid

Sarah Lynn, of Verdi, Minnesota, was only 19 when she started taking on a business role on her parents’, Steve and Paula’s, 80-cow dairy farm. Sarah handled all of the articial insemination, did all of the record keeping and kept track of herd health. Steve said he and his dad farmed together for many years and faced struggles together. He was glad that he got the opportunity to do exactly that with his daughter. Paula said she saw great potential in her daughter. She said it was like Sarah had a sixth sense about the animal’s health, since she would always seem to know something was wrong before anyone else.

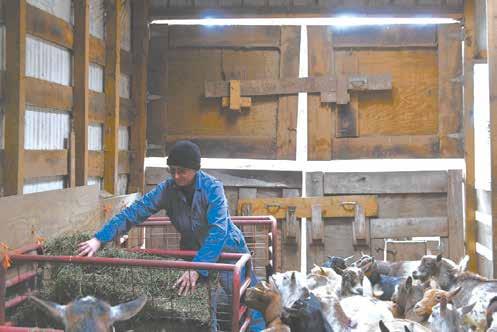

SPRING GROVE, Minn.

— A crowd of amiable Nigerian goats is ready to come and say hello in Tatiana Deters’ barn at Russian Ridge Farm.

“Everybody (is) overly friendly here,” Deters said.

With a loud bark emitting from a massive body, the goats are guarded by a Karakachan livestock protection dog.

Deters’ herd, which is located near Spring Grove, is noncommercial. She will be milking about 30 does in May when she is done with kidding. She is expecting around 80 kids, some of which are already born.

“What’s not to love?” Deters said. “You get hooked. (They’re a) labor of love. ... It’s not much money, and hay and feed are expensive and medi-

cation and vet bills and all of it, but ... I just love those animals. They’re amazing.”

Deters moved to the 6-acre farm in 2001. Deters said it took a while to convince her late husband that she could get goats. In 2014, she bought her rst Nigerians. In 2016, after being introduced to registered Nigerians by local goat farmers Marge Kitchen and Karyl Dronen, Deters bought her rst registered goats.

Deters sells most of her kids each year, keeping nine or 10 back. Deters also sells does after they freshen.

“Every year, it’s harder and harder to choose them because you’ve produced better goats, and it’s hard to decide who will stay and who will go,” Deters said.

Deters attends four to ve shows each year. She said the shows are an opportunity to prove her herd, which makes her kids more valuable.

“Being on the farm, ... most of the time, you can’t go out,” Deters said. “You have to milk in the morning, and you have to milk at night. You have feeding babies in between and other chores. ... When you go talk to other goat people, ...

you get inspired.”

Deters grew up in a city in the Central Volga region of Russia but spent summers with her grandma in the country.

didn’t know how to make a shot,” Deters said. “You learn how to draw blood and pull babies and all that stuff.”

Ta ana Deters pets her goats March 4 at Russian Ridge Farm near Spring Grove, Minnesota. Deters has a noncommercial milking herd of about 30 Nigerian goats. Turn to

“When I just started, I

The farm she lives on is across the road from where her late husband grew up.

Her farm name, Russian Ridge, is a nod to her heritage.

and feeds kids three mes a day.

During kidding season, all of the milk goes back to the kids which are raised on bottles. Deters pasteurizes the milk and heat treats colostrum that she feeds. She said that feeding the kids on bottles has been important for her farm and helps with disease prevention.

Deters’ herd is linear appraised. Her top doe scored Excellent 92. This doe won best in show last year at the Bluff Country Dairy Goat show in Caledonia. This year, she hopes to take that doe to the American Dairy Goat Association National Show if she freshens without problems and is healthy.

Deters said appraisal has been an important management practice on the farm, helping her to choose what genetics she will use.

“You can see what traits you have to work on,” Deters said. “Set your goals, (see) what you need to improve.”

Deters has brought in bucks from Florida, Pennsylvania and California.

“You always try to breed for excellence,” Deters said. “There’s no perfect goats, but you always try to do the best.”

Right now, Deters is on what she calls a “learning curve” as she works to learn how to successfully articially inseminate the does. She said her goal is to incorporate more advanced reproductive options.

Deters said the most difcult part of her job is when she loses a doe, which is more apt to happen at kidding time.

“It’s really hard to lose animals, with so much work, so much love and

then so much hope,” Deters said.

Deters keeps the herd in an old, stone-bottomed barn. On one side are her does, and in a separate area are small pens for groups of kids. To the side of the kids is a room for equipment, including a shower to wash and store equipment and an area to pasteurize the milk.

Deters milks twice a day. She uses a Surge bucket milker, which her husband, who passed in December 2023, xed so she could milk two does at a time. Milking takes about two hours.

Deters starts her day at 4 a.m. and feeds the kids in the basement of the house. By 5:30 a.m., she is outside milking, feeding the kids in the barn, feeding the goats and doing any extra chores. The morning process takes around three to four hours.

At noon, she feeds the kids again. Evening chores begin at 5:30 p.m.

When she is not feeding kids milk, Deters uses the milk to make cheese: farmstead cheddar, blue cheese and chevre. The milk and the products go to family and friends. Sometimes, Deters also trades milk for vegetables, grain or help with chores.

In 2021, Deters’ farmstead cheddar won rst place and best in show at the ADGA annual convention in Tuscon, Arizona. Her blue cheese won second.

An amateur cheesemaker, Deters said she enjoys making cheeses.

“I try different kinds of cheeses,” Deters said. “I have a big stash of cultures in my freezer.”

Complete Herd Dispersal of 60 Registered Holstein Dairy Cows and 4 Holstein Springing Heifers (6 Of Them Are Dry)

• Average SCC 89,000

• Production 27,630# M

• % Fat 4.4

• Fat 1,210# F

• % Protein 3.3.

• Protein 932# P

• All AI breeding and AI sired with low SCC bull producers

• Closed herd since 1977

• Regular hoof trims

• Vaccinations up to date

If you’re looking for some really nice cows that are registered also, be sure to attend the sale.

For more information, please call Brad at 320-266-0724 or the barn at 320-732-2255

STEVENS POINT, Wis. — Sun Prairie might have Jimmy the Groundhog to herald the arrival of spring, but in Stevens Point, opening day at Belts’ Soft Serve has been considered the ofcial beginning of spring since 1981.

The long-standing community tradition of launching spring on the rst Friday in March, when the shop opens its sliding windows for the rst time, fell March 1 this year. Anticipation runs deep as faithful customers line up hours before the 11 a.m. opening. Some will pitch tents the evening before to be the rst customer served.

Cole Racine is the third generation of his family to operate the popular Portage County ice cream spot. It was established by his grandparents, Don and Joyce Belts, as an extension of their Barley Brew coffee shop, which they ran at the same location during the 1970s.

“I started helping out and working here at the shop when I was a kid,” Racine said. “It’s been a part of my whole life.”

Racine’s father, Dan, purchased the business from Don and Joyce in 1991. Racine came back to work in the business full time in 2005 and became a partner with his father. Now his daughter, Sadie, is working alongside him, marking four generations to serve ice cream with a smile.

Each opening day is like a homecoming, Racine said. He estimates they serve over 1,000 people, giving shirts to the rst 25 customers and commemorative glasses to the rst 125.

“We have regulars who’ve been coming here for longer than I can remember,” Racine said. “That’s what makes Belts’ special — relationships built with our customers over the past 40 years.”

Michelle Cuestas and her grandson, Brayden Banks, pitched a tent in front of the service window at 7 a.m. Feb. 29 to guarantee they would be the rst customers for 2024. They said the earliest they have ever pitched their tent was on Wednesday prior to the opening.

“It’s a family tradition we do to create memories,” Cuestas said. “I started doing it with my kids maybe in 1995.”

Banks became the third generation of campers at the age of 6 in 2009.

“Last night wasn’t too bad for camping,” Banks said. “We’ve been here when it has been negative temperatures.”

Cuestas agreed the weather this year was ideal compared to other years.

“One year there was so much snow, we almost dug an igloo,” Cuestas said. Melissa Ostrowski, of La Crosse, and Sean Moderson, of Appleton, arrived at 11:30 p.m. Thursday and were disappointed to nd they would be placing the second order.

“I really thought we’d be rst in line,” Moderson said. “This is my rst time coming to Belts’. I’ve heard so much about it that it became a bucket list item.”

Ostrowski, a native of Stevens Point and a past customer, had never camped out in preparation for opening day.

“We just like doing wild and crazy things,” Ostrowksi said. “We talked about it for a while, and then all of a sudden, we just decided to make it happen. It’s been a lot of fun.”

Belts’ Soft Serve focuses exclusively on ice cream-based dessert items, with their claim to fame being the large cone, which far exceeds expectations of its name.

“It’s well over 2 pounds of ice cream,” Racine said. “We put it on a cone, but because of simple physics, we put the cone into a dish right away. It lls up our largest 32-ounce cup. Not everyone can make it, balancing all that ice cream on a cone. It denitely takes a special talent.”

Racine said that on opening day alone, his business will dispense over 150 gallons of soft serve mix to create its nal products. They have sourced from Classic Mix Partners in Neenah since the business opened.

“We are proud to be serving the exact same product heading into our 44th season that Grandma and Grandpa started with,” Racine said. “It’s what people have come to love and expect from us.”

Starting with a creamy vanilla base, Racine’s family has created and concocted a variety of avors and treats.

“My grandparents started with the basics and created what they called a Zebra cone: chocolate and

vanilla twisted together,” Racine said. “They enjoyed being creative with naming their avors.”

Besides the standard ice cream cone, Racine said Belts’ Soft Serve is well known for a variety of other ice cream treats such as urries, shakes, malts, smoothies, sundaes and oats.

“We’re best known for our urries, and they are our biggest sellers,” Racine said. “We have about 30 different avors on our menu board, but we can make just about any avor combination you can dream up. The combinations are limitless. We bake all our own baked goods as ingredients. We bake brownies and cakes fresh daily.”

Racine said their brownie sundaes and turtle sundaes are among customer favorites.

Belts’ Soft Serve is well-known for the local ingredients they source to make their ice cream novelties.

“My dad was decades ahead of the whole local farm-to-table concept,” Racine said. “When he took over the store, he started working with local farms to source fresh strawberries, raspberries and other fruits in season.”

Racine gives credit to his staff for being the foundation of success. He said each season, he employs a staff of 20-25 workers to manage the shop seven days a week from 11 a.m. until 10 p.m.

“We have a great staff, and I’m proud of the work they do,” Racine said. “They truly enjoy what they are doing, serving ice cream and making others happy. And, they do it with a smile.”

After spending his life serving up smiles and happiness in the form of ice cream, Racine said his best memories are of the customers who have become friends.

“There are people who started coming here as kids, and now they are bringing their kids and grandkids,” Racine said. “We’ve watched their family grow, and they’ve watched our family grow. Those relationships are truly special.”

Customers await their turn for the rst Belts’ So Serve of the 2024 season March 1 in Stevens Point, Wisconsin. Owner Cole Racine esmated over 1,000 customers would be served that day.

Fort Atkinson Hay

Ft. Atkinson, Iowa • 563-534-7513

Feb 28, 47 loads

Small Squares

2nd crop $130/ton 1 load

Grass $155/ton 1 load

Large Squares

1st crop $165/ton 2 loads

2nd crop $200/ton 1 load

3rd crop $165-180/ton 2 loads

Grass $155/ton 1 load

Rounds

1st crop $135-180/ton

2nd crop $95-175/ton

3rd crop $135-185/ton

4th crop $140/ton

Grass $85-180/ton

Rye hay $75/ton

Oats hay $90/ton

Corn stalks $40-45/ton

loads

loads

loads

load

loads

load

load

loads

Rock Valley Hay Auction Co.

Rock Valley, Iowa • 712-476-5541 Feb. 29, 77 loads

Small Squares

Grass $165/ton

Large Squares

1st crop $120-210/ton

2nd crop $130/ton

3rd crop $177.50-205/ton

4th crop $165/ton

Grass $117.50/ton

Mixed $145/ton

Straw $125/ton

Large Rounds

1st crop $122.50-162.50/ton

2nd crop $130-160/ton

3rd crop $130-175/ton

4th crop $160/ton

Grass $95-237.50/ton

Mixed $135-147.50/ton

Straw $135/ton

Corn stalks $40-50/ton

The nation’s benchmark milk price reversed two months of decline in February but still has a way to go to return protability to most U.S. farms. The federal order Class III price was announced at $16.08 per hundredweight, up 91 cents from January but still $1.70 below February 2023.

Late Friday morning futures portend a March price at $16.77. April was at $16.74; May, $17.19; June, $17.74; July, $18.05; August, $18.49; September, $18.71; October, $18.78; November, $18.65; and December, $18.10.

The plunge in whey prices this week and butter’s descent is pressuring the futures markets. The Class III breakeven price varies widely and is dependent on a number of factors but currently ranges from $18$22 cwt.

The February Class IV price is $19.85, up 46 cents from January and 99 cents above a year ago.

After a bullish December 2023 cold storage report showing a large drawdown on butter, the U.S. Department of Agriculture’s January data told a different story.

Butter holdings jumped to 249.1 million pounds, up 49.5 million pounds, or 24.8%, from December, which had no revision. But, stocks were 15.2 million pounds, or 5.8%, below those a year ago.

American-type cheese slipped to 836.4 million pounds, down 1.3 million pounds, or 0.2%, from December but were up 13 million, or 1.6%, from a year ago.

The “other” cheese holdings climbed to 596.2 million pounds, up 12.5 million pounds, or 2.1%, from December but down 3.6 million, or 0.6%, from a year ago.

The Jan. 31 cheese inventory totaled 1.454 billion pounds, up 11.8 million pounds, or 0.8%, from December, largest since October 2023, and was up 7.7 million pounds, or 0.5%, from a year ago.

Back on the farm, a drop in the U.S. all-milk price

was not offset by lower corn, soybean and hay prices in January; thus, the milk feed price ratio was pulled lower for the second consecutive month. The USDA’s latest ag prices report shows the January ratio at 1.98, down from 2.00 in December and the lowest since September 2023, but it compares to 1.73 in January 2023.

The index is based on the current milk price in relationship to feed prices for a ration consisting of 51% corn, 8% soybeans and 41% alfalfa hay. One pound of milk would purchase 1.98 pounds of dairy feed of that blend.

The all-milk price averaged $20.10 per cwt with a 4.35% butterfat test, down 50 cents from December and $3 below January 2023, which had a 4.23% test.

California’s average at $20 per cwt was down 90 cents from December and $3.90 below a year ago. Wisconsin’s, at $18, was down $1 from December and $4 below a year ago.

The national corn price averaged $4.74 per bushel, down 6 cents from November, after gaining 14 cents the previous month, and $1.89 below a year ago.

Soybeans averaged $12.80 per bushel, down 30 cents from December, after gaining a dime the month before, and was $1.70 per bushel below a year ago.

Alfalfa hay slipped to $202 per ton, down $3 from December and $61 below a year ago.

Looking at the cow side of the ledger, the January cull price for beef and dairy combined crept up to average $103 per cwt, up $2 from December, $21.30 above January 2023, and $31.40 above the 2011 base average.

January quarterly replacements averaged $1,890 per head, up $40 from October and $170 above January 2023. Cows averaged $1,750 per head in California, down $50 from October, and $70 below a year ago. Wisconsin’s average, at $2,060 per head, was up $70 from October and $250 above January 2023.

Milk production margins dropped below $10 per cwt for the rst time since September 2023, according to dairy economist Bill Brooks of Stoneheart Consulting in Dearborn, Missouri, and were 34 cents per cwt below December.

“Income over feed costs in January were above the $8 per cwt level needed for steady-to-higher milk production for the fth month in a row,” Brooks said. “Input prices were lower, but all three input commodities remained in the top six for January all time.

“Feed costs were the fth highest ever for the month of January and the 70th highest of all time. The ratio was below the ve-year average for the 20th month running, as the average ratio for January is 2.07.

“Milk income over feed costs for 2023 came in at $8.14 per cwt and were near the level needed to maintain or grow milk production. Protability was

down $3.77 per cwt from 2022 and $1.58 lower than the 2018-22 average.

“Looking at 2024, milk income over feed costs (using Feb. 29 CME settling futures prices for milk, corn and soybeans plus the Stoneheart forecast for alfalfa hay) are expected to be $13.25 per cwt, a gain of $5.11 per cwt versus 2023. Income over feed in 2024 is $1.19 per cwt higher than last month and would be above the level needed to maintain or grow milk production.”

The week ending Feb. 17 saw 59,300 dairy cows go to slaughter, down 2,400 from the previous week, and 8,600, or 12.7%, below a year ago. Year-to-date, 396,700 head have been culled, down 77,200, or 16.3%, from a year ago.

Meanwhile, dairy farmers are encouraged to sign up for the Dairy Margin Coverage program. Enrollment runs through April 29.

“The DMC is improved from the previous farm bill, thanks to the permanent incorporation of updated production histories in the program, and recent low producer margins underscore just how critical DMC is for dairy farms of all sizes,” the National Milk Producers Federation said.

“Dairy producers are also struggling across the pond,” said Sarina Sharp, in the Daily Dairy Report’s Feb. 23 Milk Producers Council newsletter. “Milk output in Europe and the United Kingdom fell 0.7% year-over-year in December. Poland was the only country in the bloc’s seven largest dairy nations with greater milk output in December 2023 than in the nal month of 2022.

“Tractors have blocked trafc in cities around Europe as the farm sector protests the red tape in the bloc’s Green Deal. Farmers are also angry about rising fuel costs and competition from imports that are not subject to similarly onerous regulations. In a sign of agriculture’s growing political power, the EU Commission simplied or reduced some of the requirements in the bloc’s Common Agricultural Policy, gave farmers some exibility from government mandates to fallow farmland and withdrew a plan that would have halved pesticide use by 2030.”

CME block cheddar closed March 1 at $1.55 per pound, unchanged on the week but 11.75 cents below its Feb. 1 post and 40 cents below a year ago.

The barrels got to $1.67 Monday, highest since Nov. 15, 2023, but nished Friday at $1.65, up 3.50 cents on the week, 11 cents above their Feb. 1 post, 7.50 cents above a year ago and 10 cents above the blocks.

Sales totaled 12 loads for the week and 62 for the month of February, down from 81 in January. There were 16 sales of barrel on the week and 45 for February, down from 113 in January.

Mid-week spot milk prices ranged from 25 cents to $2.50-over Class this week, according to Dairy Market News. Last year, they ranged $10-$2.50-under Class. Some cheesemakers say they are using internally sourced milk, but handlers’ offers have been mum. That’s expected to change as Class I demand slows and milk production increases seasonally, reports DMN. Cheese demand remains lackluster, according to a number of Midwest cheesemakers, though some, particularly barrel makers, say demand is better.

Cheese demand in the West is mixed. Some manufacturers and distributors say retail demand is stronger while others say it’s at. Food service is varied, and international buying is stronger. Class III milk is tighter in some parts of the region but enough to accommodate strong to steady production, DMN said.

Butter headed south this week, falling to a Friday nish at $2.7575 per pound, down 9.25 cents on the week, lowest since Feb. 16 but still 41.25 cents above a year ago. Thirty-one cars sold on the week and 80 for the month, up from 63 in January.

Butter makers had expectations in late January that cream would be full through the second month of the year, and DMN said their expectations materialized. Cream multiples have held from at market to around 1.20. Demand is slowly starting to tick higher for milkfat and not specically from just butter makers. There are expectations that churning, which has been very busy this year, will take a step back in coming weeks. Butter demand is holding somewhat steady at a seasonally light pace, according to DMN.

Cream is plentiful throughout most of the West, and churns continue to run at-or-near capacity to ensure supplies for later quarter demand and during planned summer downtime. Domestic demand is strong to steady while export interest is steady to lighter, DMN said.

Grade A nonfat dry milk closed the week at $1.1975 per pound, 0.25 cents lower but 2 cents above a year ago. Sixteen loads sold on the week and 61 for February, down from 63 in January.

CME dry whey tumbled this week, falling to 42.50 cents per pound Friday, down 9.75 cents on the week, lowest since Jan. 18, and 2 cents below a year ago. Sales totaled seven loads on the week and 13 for February, down from 19 in January.

The Feb. 29 Daily Dairy Report said, “The strong dollar has made European whey increasingly competitive. Since the turn of the year, the U.S. dollar has advanced 2.4% against the euro, effectively trimming European whey by a further 2.4% relative to U.S. product.”

StoneX reported that Chinese data suggests China continues to liquidate its cow herd and “could be a medium term headwind for whey demand.”

In January, the herd was at 40.67 million head, 3 million head less than a year prior, and a 1.8% decrease from December, StoneX said.

Tuesday’s GDT Pulse saw 4.28 million pounds of product sold, down from 4.35 million Feb. 13, with 97.1% of the total offered sold. Prices were sharply lower with whole milk powder down 2.6% from the event last week while skim milk powder was down 2.7%. The March 2 GDT is expected to lose more ground.

Demand was sharply lower for most buying regions, reports StoneX.

“It is no guarantee that we will see this again, but volume available is less than it was at this time last year,” StoneX said. “Typically, the GDT auction sees a seasonal decline in volume from January through the end of the season.

“While some of this weakness is probably driven by weaker demand, the supply outlook for New Zealand has also been shifting higher. Weather conditions, as measured by the pasture growth index, climbed back above year-ago levels in late January and have remained supportive through the rst half of February with the South Island looking better than the North Island.”

Dairy exports continue via the farmer subsidized Cooperatives Working Together program. Member

cooperatives accepted ve offers of export assistance this week that helped them capture sales of 1.1 million pounds of American-type cheese and 112,000 pounds of anhydrous milkfat.

The product is going to customers in Asia, Central America, the Caribbean and Middle East-North Africa. Product will be delivered through June and brings year-to-date CWT sales to 20.1 million pounds of American-type cheeses, 112,000 pounds of anhydrous milkfat, 7.1 million pounds of whole milk powder and 1.3 million pounds of cream cheese. The products are going to 18 countries and are the equivalent of 251.4 million pounds of milk on a milkfat basis.

Our hearts and prayers went out to Texas this week as the second largest wildre in Texas’ history was raging in the Panhandle, in Hutchinson, Hemphill, and Roberts counties, north and west of Amarillo and into Oklahoma.

HighGround Dairy economist Betty Berning reported in the March 4 Dairy Radio Now broadcast that at least 1.1 million acres have been impacted, affecting more beef operations than dairy. Texas dairy cow numbers are depressed from the devastating barn re last spring in Dimmitt, but Berning said that beef operations in Texas were more at risk than dairy operations.

It comes at a bad time, according to Berning, as the beef cow herd Jan. 1 was at its lowest level in 63 years. Dairy cow inventories are also low, she said, so prices have risen and that is why we saw high slaughter rates last year in dairy. She warned that, depending on how this re impacts the beef herd, “Dairy producers might be led to continue to breed to beef or, if prices get high enough, to send some of their stock to the packing plant to get a nice paycheck.”

Consigned for March 25 includes a 60-cow herd, along with 10 bred heifers, from Don Swenson of Glenwood, Minnesota. This fourth-generation farm that started in 1930 is stepping out of dairy. The herd consists of mostly black and white Holsteins, with a couple red and white Holsteins mixed in. The cows currently have a 58-pound tank average with 4.0 butterfat and 3.2 protein and the SCC is under 200,000. This is an extremely young herd of cows; half being first lactation animals that are currently housed in a tie stall and bedding pack barns. The Swenson family has been using AI breeding for many years, starting with Minnesota Valley, and they currently use young, proven sires from Select Sires. An Angus bull is used for clean-up. The herd is fed with a TMR, is on DHIA, and has been for 45 years with the most current records available on sale day. The Swensons have a closed herd and their vaccination program includes Vira-Shield and J-Vac at dry off and Bovi-Shield prior to breeding. If you are looking for some young replacements for your herd, these are the cattle to buy.

Coming from Don Bitzer of Warroad, Minnesota

Also consigned is a 110-cow herd from Don Bitzer of Warroad, Minnesota. This herd has a 60-pound tank average with 3.5, protein, 4.36 butterfat and 140 SCC. The herd is currently housed in a free-stall barn bedded with sand and milked in a parlor. They are fed TMR. They have been AI breeding for over 40 years and use Genex bulls emphasizing feet, legs and production. Twenty-seven cows are fresh to 75 days in milk. The majority of animals are first or second lactation. The cows vaccination program includes Bovi-Shield Gold after calving and Vision 7 at dry off. The cows are hoof trimmed twice a year and milked twice a day. The Bitzers have been dairying near Warroad for over 40 year. “We really enjoyed our time milking cows.

OSHKOSH, Wis. — Feeding a family at an agricultural event should not cost an arm and a leg. Such is the belief of Jim Memier, coordinator for the Winnebago County Holstein Breeders Association food stand at the Wisconsin Public Service Farm Show. The show will take place March 26-28 on the grounds of the Experimental Aircraft Association in Oshkosh where the food will be ready.

All proceeds from the food stand will fund the Winnebago County Holstein Association and benet juniors of Winnebago County. The money allows kids to receive scholarships and calf grants, attend camps and the junior Holstein convention, earn awards from the state Holstein association and provide entry fees for anyone who wants to participate

in district shows.

“It’s a big fundraiser,” Memier said. “You’ve got to keep the dairy community going, and we try to give back what we (dairy farmers) are producing.”

The food stand is in the main food tent with about ve other vendors. There is a public seating area with picnic tables in the middle of the tent. The Winnebago County Holstein Association stand uses a lot of dairy products. Menu items include grilled ham and cheese sandwiches, ice cream sundaes, brownie sundaes, cream puffs, white and chocolate milk, and coffee and donuts in the mornings.

Donations from sponsors leading up to the event allow the organization to keep their

| Page 14

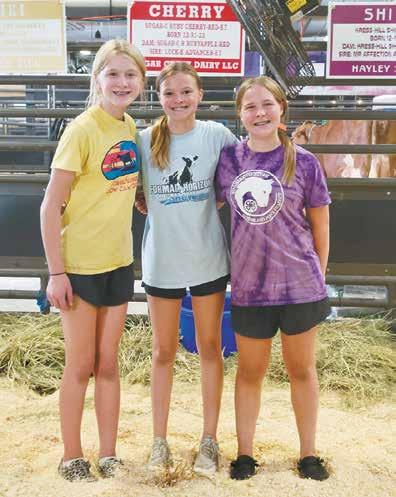

a break at the 2023 Midwest Spring Show in Madison, Wisconsin. The

Con nued from FOOD STAND | Page 13

prices low. For example, a grilled ham and cheese sandwich costs $3.

“It makes a good breakfast sandwich too,” Memier said. “A family can come there and not over-exceed versus a state fair where you’ve got to spend umpteen hundred dollars to feed a family of four or ve. This way, you can get by and ll everybody up on a pretty decent budget.”

The stand is staffed by Holstein association member volunteers, junior Holstein members and FFA chapter members. Volunteers can reach upward of 25 kids per day. Some people take orders while others are busy grilling sandwiches, scooping ice cream, putting toppings on sundaes, pouring coffee, preparing cream puffs and running the food to the counter.

They are equipped with six griddles for making sandwiches so they can make 2550 at a time, allowing people to be served with virtually no waiting.

“We have enough help that we’re ahead,” Memier said. “We can keep the product fresh.

A lot of times, it comes off the grill and goes right out to the person.”

The sundaes are made with Cedar Crest ice cream and scooped to order. A regular sundae includes three toppings

of choice, and the brownie sundae is bigger than other sundaes, Memier said. The biggest brownie sundae they sell is $5, which is the highestpriced item on the menu. The sundae includes large scoops of ice cream, two brownies and a topping choice of straw-

school was in session and the week before spring break, so some kids took off a day of school,” Memier said. “This year, it’ll be nice for them all to be able to be there.”

The affordable prices and opportunities for the kids are all possible because of spon-

“It’s a big fundraiser,” Memier said. “You’ve got to keep the dairy community going, and we try to give back what we (dairy farmers) are producing.”

JIM MEMIER, COORDINATOR FOR THE WINNEBAGO COUNTY HOLSTEIN BREEDERS ASSOCIATION

berry, chocolate or caramel.

Last year, the stand served 2,200 grilled ham and cheese sandwiches, 300 cream puffs and close to 1,500 sundaes. This equated to 53 3-gallon tubs of ice cream.

Memier said sundaes are always a popular menu item.

“It doesn’t matter if it’s cold or warm, everybody wants a sundae,” Memier said.

Memier said it is helpful that the show is in the club’s county so kids can attend and manage the stand. This year will be even better since the show falls during the school’s spring break.

“Last year, it was while

sors, Memier said. With six new sponsors this year, they have a total of 22 sponsors. Memier anticipates almost all costs for supplies and ingredients will be donated this year. Additionally, sponsor vendors hand out food tickets that are redeemable only at their food stand. Eleven sponsors participate in the ticket feature.

“We can’t do this without the sponsors,” Memier said. “We’d like to thank all the sponsors that support this event. It’s really appreciated. We look forward to seeing everyone at the WPS Farm Show and hope they stop by to say hi.”

Members of the Winnebago County Junior Holstein Associaon Addee Zick (from le ), Hayley Sleik and Alison Bu ke take a break at the 2023 Wisconsin Holstein State Show in Madison, Wisconsin. The kids raise funds every year at the WPS Farm Show by working at the Winnebago County Holstein Breeders Associa on food stand.

What three things are you looking forward to doing or seeing this year at the WPS Farm Show? March

•

•

How long have you been attending the WPS Farm Show? I have been attending the show for probably 40 years. What three things are you looking forward to doing or seeing this year at the WPS Farm Show? The latest technology, new dealers and parlor op-

tions. We are in the early stages of getting ideas about an expansion for our dairy. Our parlor is 25 years old and cannot be expanded. We are exploring different options, from potentially utilizing our existing facilities along with building a new parlor or going with a green-site dairy. With that being said, we are always looking for new technology.

How does attending the WPS Farm Show benet you and your dairy? Potentially nding new ideas to improve efciency is a benet to our farm. It could be some form of better efciency on the dairy side or in the eld, which we’ve done with variable rate planting, variable rate fertilizer, grid sampling and cover crops.

What is one thing you implemented on your farm from the WPS Farm Show? About 35 years ago, we were one of the rst to purchase Agri-Speed hitches. Back in the early 1980s, when we chopped hay with a pull-type chopper, we happened to go to the farm show and came across these speed hitches that allowed you to attach your forage harvester and wagons without having to get on and off the tractor to hook up the wagons. They were a great idea and a labor saver. We used them for about 30 years until we went to a self-propelled chopper with trucks.

What does the WPS Farm Show offer that is different from other agricultural shows you attend? They offer more of a broad spectrum of agricultur-

al products and ideas, which are offered at a good time of year before you are in the eld.

Tell us about your farm and your plans for the dairy this year. We are a sixth-generation family farm and in the process of a transitional phase of three members of the limited liability company to buy out brothers, Dennis and Dave. We milk three times a day in a double-5 auto-ow parlor and thrive on high quality and high components at our dairy. Our milk is shipped to Grande Cheese Company in Brownsville, Wisconsin, which is less than 2 miles from the farm. Oechsner Farms run a total of 2,200 acres of owned and rented land. Members of the dairy include Dennis and Jeni Oechsner, Dave and Cheryl Oechsner, Alan and Tabbitha Oechsner, Travis and Susie Hahn, Tony and Gabby Gallitz, and a great team of employees who complete the puzzle. This year on the farm, we will be planting Plenish soybeans and will be investing in an on-farm roaster, which will allow us to feed our own beans without having to purchase the bypass soybean meal.

March 26–28, 2024 Oshkosh, WI

What three things are you looking forward to doing or seeing this year at the WPS Farm Show?

Jim Potratz Oshkosh, WisconsinWinnebago County

160 cows

How long have you been attending the WPS Farm Show? I have been attending for about 35 or 40 years, going back to when it was in Green Bay, Wisconsin.

What three things are you looking forward to doing or seeing this year at the WPS Farm Show? We are looking at adding a robotic feed pusher in our freestall barn, so we will likely be looking at those while at the show. We like to see what’s new in equipment. If there is something we bought, we may want to touch base to see improvements. We may also look at something for the future. My son, Matt, put in an ear tag ID system this year for monitoring sickness and heat in the cows and may be looking to touch base with those people as well. Every year, we like to see the same farmers and vendors. It’s a social time. We walk through and spend time chatting with everyone we know. At my age, that’s probably the bigger draw. My grandkids want to go to every booth that gives away candy. It’s almost like Halloween for them.

How does attending the WPS Farm Show benet you and your dairy?

We usually target something specic for improving the farm. It is an educational event, and a lot of times, you get discounts if you buy something at the show. You can get signicant savings on things you buy there.

2013, waterbeds were something we looked at during the farm show and decided to go with over sand. The company that sold them always exhibited there. We added vapor lime bedding on top, which has been a nice t from Alternative Animal Bedding, which always has a booth at the show also. With the wear and tear sand brings to everything, we were happy to have avoided that. We have been happy with our choice.

What does the WPS Farm Show offer that is different from other agricultural shows you attend? Farmers are itching to get out by that time, and

What is one thing you implemented on your farm from the WPS Farm Show? When we did an expansion in Turn to POTRATZ Q&A |

Con nued from POTRATZ Q&A | Page 20

it’s a nice way to get the spring season rolling. It’s always a fun time and one of the rst things we look forward to in spring when we’re getting sick of a long winter. The show is also in the perfect location for us as it is only 3 miles from our farm, which automatically makes it easier to attend. It’s really nice having it so close. Matt sometimes goes a couple different days. He may take the kids one day and then go another day to talk with vendors. I don’t go to a lot of other shows. Wisconsin Farm Technology Days moves all over the state. If it’s in the area, it’s nice. But a lot of times, it’s too far away for me to go.

Tell us about your farm and your plans for the dairy this year. My wife,

Paula, and I farm with our son, Matt, who is the third generation on our farm, which has been in our family since 1947. We milk 160 cows in a swing-10 parlor and ship our milk to BelGioioso Cheese Inc. Cows are housed in a 4-row freestall barn, and we farm 300 acres. We recently built a freestall heifer barn to house heifers from 10 months old to breeding age, and the heifers have taken to that well. The barn has room for up to about 50 head. We have the doors and end walls left to complete, which we will do this year. We like to do eld tiling whenever possible, but it doesn’t look like this will be the year for that with nances where they are. In a low milk price time, we’re looking to keep things maintained and running.

55

Kaukana, WI 54130

Phone: 920-766-0603

www.llsalesandserviceinc.com • www.cowcomfortzone.com

What three things are you looking forward to doing or seeing this year at the WPS Farm Show?

How long have you been attending the WPS Farm Show? I have been going since 1992 when it was in Green Bay, Wisconsin. That year, I was thinking about putting up another silo. The company I was thinking of going with was going to be at the show. I looked through the material for the project that year and chose them to build our silo. That’s how it all got started. Now, I attend more for crop inputs and to see the latest ideas.

farming more efcient and ideas of how to make my cows happier. Going to the show gives us a day away from the farm. My wife, Lenore, and I get to escape the hustle and bustle of the farm that day. We enjoy meeting people that we know and gathering ideas. Lenore likes to buy house decor at the show too. It has something for everyone.

How does attending the WPS Farm Show benet you and your dairy? As you walk down the aisles, you kind of memorize stuff. Then, if I run into problems during the year, I can contact the company with the product that could solve that problem. Cows throw you a curve ball, so it’s good to have those resources. The vendors at the show are attentive to your needs, and I commend them on that.

What three things are you looking forward to doing or seeing this year at the WPS Farm Show? Crop inputs, some of the latest machinery to make Turn to PETERSON Q&A | Page 24

Con nued from PETERSON Q&A | Page 23

What is one thing you implemented on your farm from the WPS Farm Show? We have purchased a lot of things from ideas that we’ve gotten at the show, such as aftermarket equipment for our Haybine years ago. Seeing equipment side by side helps you make a comparison, and you might decide one piece of equipment seems to work better than what you were originally looking at. Not everyone advertises in the local paper, so there are things we didn’t know about or had ever seen before until we got to the show. It’s eyeopening.

What does the WPS Farm Show offer that is different from other agricultural shows you attend? The show is held inside, making it immune to the weather. It is also a very well-run show. It’s a tough market out there, and farm-

ers are very cost-conscious. We are a tough sell. I like being face to face with the vendors as they are very knowledgeable about their product.

Tell us about your farm and your plans for the dairy this year. We milk twice a day in a tiestall barn using 10 AIC stall barn detachers. We ship our milk to Mullins Cheese. Cows are housed in the tiestall barn and in a freestall barn. We farm 400 acres of corn and alfalfa along with small grains. My daughter, Melissa, does the milking with help from hired hands. Her husband helps when he can, too, and my grandkids help feed the calves. Lenore works off the farm at Central Wisconsin Electric Cooperative. We bought this farm in 1984, and in the future, we would like to transfer the farm to Melissa.

Wet or dry hay. Part-time, full-time or custom operations. Vermeer has the round baler you need to put up dense, high-quality bales you can be proud of. 920.269.4307

1201 Church Street, Lomira, WI 53048 schraufnagel.com

What three things are you looking forward to doing or seeing this year at the

Shirlee (from left), Mitchel and Ron Kohlbeck

Kellnersville, Wisconsin Manitowoc County

100 cows

How long have you been attending the WPS Farm Show? We have been attending this show for 24 years.

What three things are you looking forward to doing or seeing this year at the WPS Farm Show? We don’t get out very much, and this is a nice way to spend time with each other in a less stressful environment. It’s a relaxing situation with your spouse. We like spending the day together just the two of us. It’s also nice conversing with vendors, and we enjoy hearing about what’s new. We also like to see other farmers we know and talk with them. We are interested in looking at autonomous tractors this year. This is an automated tractor that does not require a driver to be present. The show provides an opportunity to talk with people in the know and nd out about things you wouldn’t normally hear of. We make acquaintances there and interact with people with different life experiences.

How does attending the WPS Farm Show benet you and your dairy? Even though we might not implement some of these things, it keeps you current on what’s going on and gives us knowledge of the industry, which is important. While at the show, we have also learned about different ways to build a house. We have been looking for ideas because we might build a house one day that would be more convenient for our disabled son, Mitchel.

What is one thing you implemented on your farm from the WPS Farm Show? A couple years back, we were having a lot of trouble with calves. We started on a milk replacer that we learned about at the show, and it was a night and day difference. When we switched to that, it was the end of our problems.

What does the WPS Farm Show offer that is different from other agricultural shows you attend? Wisconsin Farm Technology Days is the only other show we attend, but the timing of the WPS Farm Show is good as we are not in the eld yet, so it’s easier to get away. It’s a nice setup with everything being close together instead of spread out. Parking works out well too. It’s a nice show, and they do a good job.

Tell us about your farm and your plans for the dairy this year. We milk about 100 cows in a tiestall barn and farm 670 acres with the help of one full-time employee, Kendall Grimm. We ship our milk to Agropur. Ron grew up here, and we bought the farm in 2000. We pride ourselves on treating every calf and cow as an individual and caring for them as such.

STRATFORD, Wis. — The year 2021 went out with a crash, bang and boom, quite literally, for Megan Steines of Stratford, when a crash during her early morning commute to her part-time job milking cows left her standing on the side of the road looking at her damaged vehicle.

“It was quite the way to ring in the New Year,” Steines said.

Steines was on her way to milk cows at Briggs Family Farm, a 55-cow dairy near Stratford, owned by Jim and Jenny Briggs, on New Year’s Eve morning.

Since that April, Steines had been working part time for the couple, helping with morning and afternoon milkings along with a full-time job.

“It was about 5:15 in the morning, and I had just turned off of Highway 97 onto County Road P,” Steines said. “From out of the eld, a deer ran up onto the road. It was kind of misty and a little rainy, and even though I was driving slowly, there was no way I was going to stop. I hit the deer, and it spun my car around several times. It was pretty scary.”

If the initial impact of hitting the deer was not enough on its own, Steines said almost immediately, her car quit running in the middle of the road, about 10 minutes from the farm.

“I couldn’t even put my ashers on,” Steines said. “It was dark, and there is usually a fair bit of trafc on that road. I got out of my car and discovered the impact had just decimated the front end of the car.”

Luckily for Steines, she had enough cell phone service to call Jim Briggs, asking him to come help her get her car off the road.

“I was standing on the side of the road, in the cold, damp dark,” she said. “The deer wasn’t dead, but I had no way to put him out of his misery.”

As she began to pray that it could not get any worse, it did. About a half mile up the road, headlights crested a knoll.

“I used the ashlight on my phone to try and signal from the side of the road, but I doubted the driver could see it,” Steines said. “As it got a little closer, I realized it was a semi and knew it was bad. Then I realized it was a tanker of milk, and I knew there was no way he was going to stop.”

With a milk truck on a collision course with her disabled vehicle, Steines took off running in the ditch,

trying to put enough distance between herself and her vehicle to survive the imminent crash.

“There was nothing I could do,” Steines said. “I wasn’t sure how that impact might send my car ying.”

The milk tanker sent Steines’ car careening toward the ditch, but fortunately, she was far enough away to avoid the danger of the impact.

“I just stopped and watched as the milk truck hit my car and ung it into the ditch,” Steines said. “I was about 50 yards away from where it hit the car.”

After the impact, Steines said the tanker began to shtail, and she feared it would ip onto its side, adding a new level of havoc to an already less-than-ideal December morning.

“I called Jim and told him he didn’t need to come and move my car off the road,” Steines said.

Meanwhile, the milk truck driver was trying to wrap his head around what had happened to him as she explained why her disabled car had been sitting in the middle of the road, in the dark, Steines said.

“The milk truck driver had called the cops to report the accident,” Steines said. “When the cop got there, he was as confused at rst about what had happened as we all had been. Then, he told me he had called a tow company to come pick up my car. He said it was Killdeer Autobody out of Athens. I thought that was rather ironic, given that the situation all started with a deer.”

While she waited in the back of the cop car, Steines said she experienced another episode she would rather not repeat. She called her mom to ask for a ride back to her house, to get ready to head to her full-time job in Marsheld.

“Of course, an early morning call is unusual; people know something is wrong, and trying to explain you hit a deer and then a milk truck hit you, it gets people — including my mom — a little ustered,” Steines said.

Not surprisingly, Steines’ vehicle was deemed to be a total loss.

“I really loved that car,” she said. “I had only had it for about six months at the time of the accident. The insurance company was great to work with. I got the full value for the car. Unfortunately, that was in a time when it was hard to nd good, used cars, so it was difcult to replace.”

Steines did not grow up on a dairy farm but found her enjoyment of dairy farming when she joined an FFA chapter at a school in Marsheld. Her advisers told her of a dairy farm looking for help, and she became hooked. She decided to attend Northcentral Technical College, where she joined the dairy science program.

She enjoyed milking cows for the Briggses so much that she left her full-time job March 30, 2023, to begin working full time for the Briggs family.

“As a kid, I never would have guessed I’d grow up to loving cows and dairy farming, but I did,” Steines said.

N15518 State Road 73, Thorp, WI

Tuesday, April 2nd • 9:30 a.m.

Auction will be held live in heated shed. Also online at Equipment facts and Hi Bid

Tractors & Combines

MXM 190 tractor. MFWD, CAH, A/C, Front 3 point, 540/1000 PTO, 3930 hours. PTO runs good but will shut off at random. Park brake not working; Magnum 180 tractor. 2009 model, 4WD, CAH, 3 PTO’s, 9198 hours, LED lights, 420/80R46 & 380/80R30 tires, duals with inside tires brand new. Been through shop and good condition!!; John Deere 4455 tractor. 1990 model, 16k hours, 3 remotes, CAH, 20.8 x 38 & 16.9 x 25 tires. One owner tractor!; 1660 Case IH combine. 4WD, 5500 hours, Major overhaul at 4600 hours, lots of new parts in last 2 years. Professionally inspected by Harvtec LLC; Skid Loaders

ASV RCV skid loader. 4450 hours. CAH, Brand New tracks, Fully rebuilt under carriage & drive motors. Hydraulic quik-tach. Nice machine, ready to go!!; Planters & Grain Drills

Great Plains Solid Stand bean drill. 30 ft. 15 inch rows, very good condition!; John Deere 7200 corn planter. 6 row 30” with liquid fertilizer; John Deere 450 grain drill. Grass seed, packer hitch; John Deere 1770 corn planter. 12 row with dry fertilizer. Good working condition!;

Wagons

H&S Super 7+4 forage wagon; 9×18 flat wagon on tandem gear. New oak bed; 9×16 kicker wagon with new oak floor; 8-1/2 x 18 flat wagon with new oak floor, 12 ton tandem gear; 7 x 14 flat wagon; Kill bros gravity box on gear; Hay & Forage Equipment

Vermeer TE 1710 tedder. Excellent condition!!; Kosch bale mover. Good working cond. Quarter turn on lift; H&S 860 blower. Working cond; Little Giant hay & grain elevator; Hay fluffer; NH 355 grinder mixer. Needs work; Tillage Equipment

JD 960 cultivator, with spike tooth drag, Nice!; JD 960 cultivator with spring tooth leveler; John Deere 724 cultivator. Converted to 960, spring tooth leveler; Brillion 3 point 3 shank ripper; Trailers

2021 Haul-About cargo trailer, 16ft with ramp; 2000 Southern Classic cattle trailer. 8×30, aluminum, good condition; 1985 Mallard bumper hitch camper trailer. Good working condition, winterized, 25 ft, has title; Featherlite 16 ft cattle trailer. Bumper hitch; Diamond C 20 foot flat bed trailer. Bumper hitch, Ex cond; Manure Handling / Fertilizer

Dry Hill DA 52-8 manure pump. 540 PTO; Houle SP-1-17 manure pump. 3 point, 17 ft.; 33 ft hydraulic manure pump; NH 185 manure spreader. Good working cond.; Fertilizer spreader. Hay & corn tires. Working cond.;

Attachments

(2) 48” pallet forks. New!!; (2) 3 prong bale spears. New!!; Tomahawk 96” bucket. New!!; Skid steer bucket; Rhino 3 point bush mower; 3 point 6 ft brush mower;

Vehicles

Tel Elect 1500CR crane truck. 540 PTO, 15 ft beam, 9.5 ft extension;

Cattle Handling

Tuff Built head chute. Brand new!!;

Misc Farm Items

Rissler 620 mixer cart. 60 cu. ft. Newer web chain & auger. Working cond.; 550 Gallon water tank. (4) wagon tires with rims.; (2) 218/4-26 tires with rims; (6) barn fans; (3) 11 ft drag sections off JD disc; Agro-Power alternator. 25KW, good cond.; 500 Gallon fuel tank with electric pump;

In the Feb. 24 Dairy Star, Minnesota DHIA highlighted top lifetime production cows.

Within the list were these ve cows that are all older than 12 years old and within their respective dairy herds.

14 years old 10th lactation

Where is this cow housed, and does she receive any special attention? She is housed in the freestall barn with the others and does not receive any special attention.

Owners: Loren & Keith Schumacher of Schumacher Dairy Inc. Comfrey, Minnesota

Tell us about the lifetime production of the cow. She is at 254,180 pounds of milk with a fat of 10,534 and protein of 8,271. What has been the key to the longevity of her in your herd? Just keeping her healthy and treating her if she ever got sick.

Tell us more about this cow family. She has healthy offspring; we are not sure on the production of the offspring in the herd.

What are your future plans with this cow? To keep her in the herd as long as she remains healthy and comfortable.

Tell us about the oldest cow you have ever had. This is the oldest cow we have had on the farm.

Tell us about your farm. We milk 140 cows in a double-8 parlor with three parttime employees. Our milk is shipped to First District Association. We have 550 tillable acres planted between corn, soybeans and alfalfa.

Where is this cow housed, and does she receive any special attention? She is housed in a sand-bedded free stall and on pasture in the summer.

13 years old Ninth lactation Owners: Jeremy Holst of Holst Family Farms Lake City, Minnesota

Tell us about the lifetime production of the cow. She has produced 228,940 pounds of milk.

What has been the key to the longevity of her in your herd? She is a solid cow, gentle and friendly. She is also a Red & White, which is fun.

Tell us more about this cow family. She currently has two milking daughters, Kaycee and Orange Crush, and another heifer calf, Christmas, who is 14 months. Overall, she has three daughters, ve granddaughters and two greatgranddaughters.

What are your future plans with this cow? She will retire in the pasture when not milking.

Tell us about the oldest cow you have ever had. No. 65 Carmel was one of our oldest cows. We have had a handful of 15-year-old cows over the years.

Tell us about your farm. I farm with my mom, Maren. My wife, Jessi, and I have two kids, Adalida and Lane. We milk 120 cows and grow corn and alfalfa. We pasture our cows outside of winter.

No. 10128

13 years old 11th lactation

Owners: Matt and Tony Berktold Lake City, Minnesota

Where is this cow housed, and does she receive any special attention? She stays in the free stalls with the rest of the herd.

Tell us about the lifetime production of the cow. She is at about 358,000 pounds of milk in her lifetime with 11,918 fat and 9,866 protein. What has been the key to the longevity of her in your herd? She continues to breed back and remains fairly healthy.

Tell us more about this cow family. She has two daughters, a granddaughter and two great-granddaughters that are in the herd. What are your future plans with this cow? We will keep her as long as she’s healthy and productive.

Tell us about the oldest cow you have ever had. This is the oldest cow we have had on the farm.

Tell us about your farm. My father and I milk 150 cows. We grow alfalfa, corn and soybeans.

Where is this cow housed, and does she receive any special attention? She doesn’t receive any special attention. She is in with the rest of the cows in the pregnant pen in the sand-bedded freestall barn. We try to care for all of them in the best manner we can. We have our own sand pit on our other farm, 1.5 mile away. We have dump trucks that we haul our own sand with, so we use an abundance of sand. That really helps our cows. She will need a little TLC when she calves in, a little extra calcium bolus to get her going and keep her going. That is going to be her tough time. Her last calving was a tougher comeback.

No. 128 12 years, 5 months 10th lactation

Owners: Marvin and Mary Kuhn of Kuhn Dairy Farms Mabel, Minnesota

Tell us about the lifetime production of the cow. She has 309,120 pounds of milk, 10,555 pounds of fat and 9,326 pounds of protein. At her last test, she was giving 82 pounds of milk.

What has been the key to the longevity of her in your herd? She has good feet and legs. We are very faithful on hoof trimming on all of our cows and making sure their health is as good as it can be. She walks like a Rockstar, and she’s not a runner. She’s a little slow, but she’s good on her feet. Her udder is very strong and tucked up for her age. Maybe part of the reason she has lasted is that she is slower. Tell us more about this cow family. She has two daughters in the herd. One is probably approximately 6 years old, and the other is probably approximately 4 years old. We do not know if she has granddaughters in the herd or not.

What are your future plans with this cow? Hopefully she calves in, has her little heifer calf and does well. She’ll stay here as long as she is capable. More than likely, we will breed her again. If she is looking good, we will start her up again. Tell us about the oldest cow you have ever had. I think she is the oldest one we have ever had.

Tell us about your farm. We both work full time on the farm. We milk 329 cows three times a day. We have three full-time employees and one part-time employee. Our son, Mitchell, is a lineman, and when he gets done with work, he comes to help us. Our son, Ryan, is a plumber, and if we need help, he comes. They are lifesavers. We have a heated shop. That has been crucial. On a cold day, the equipment is inside where it is warm. The shop has been a major problem solver. We do the majority of our repairs. We have 520 acres where we raise corn and alfalfa. We raise 95% of our feed on the farm. We try to be aggressive on the cropping side, because we need every acre to count. We sell our milk to Foremost Farms Inc.

Where is this cow housed, and does she receive any special attention? She is housed in one of our pole sheds with our other aged cows. Most cows in that group are 7 to 9 years old. She was shown at the county fair for ve years.

Tell us about the lifetime production of the cow. She has produced 117,000 pounds of milk in her life.

12 years old Ninth lactation Owners: Josh Wright of Wright Farms Lake City, Minnesota

What has been the key to the longevity of her in your herd? She has never had any major health problems. We always keep feed in front of our animals and get the hoof trimmer out on a regular basis. We feed all of our cows calcium pills when they calve.

Tell us more about this cow family. She did have three daughters in milk on the farm, but now, we are down to one daughter and two granddaughters in the barn. No. 1025 was shown for ve years, and her two granddaughters were shown at the county fair as well. The two granddaughters had bull calves, so showing that family has stopped for now.

What are your future plans with this cow? To keep her as long as possible. She just calved in January, so it is too soon to breed her back. We plan to when the time comes. She is a solid cow and is in good health.

Tell us about the oldest cow you have ever had. The oldest cow we ever had was No. 612, and she was 16 years old. Her last calf would have been her 12th lactation, but she didn’t keep the calf that time.

Tell us about your farm. We are milking 200 cows in a double-4 step-up parlor. My cousin, Devon, and I milk the cows. My dad, Jim, mixes all the feed and feeds the cows and heifers. My grandparents, Lyle and Rose, feed the calves. I am the fourth generation on our farm. Together, we farm 900 acres to grow our own feed.

The Minnesota DHIA rolling herd average produc�on reached an all-�me high of 25,668 milk, 1,088 fat and 837 protein pounds with a soma�c cell count of 179,000. The dollar value is weighted by the pay prices for these four components and was also a new record of $5,219.

Below are the highest-ranking herds within each county affiliate, alphabe�cally by county and herd owner. Congratula�ons to all!

RINGOES, N.J. — Jared Weeks was not born into the dairy industry but found it to be his calling. He grew up near a dairy farm and was involved in the 4-H dairy project by leasing calves, leading him down the path that would become his life’s work.

“It seemed like a nice lifestyle, and I enjoyed working with the cows,” Weeks said. “Granted, I wasn’t there for the bad days with down cows or broken barn cleaners. Being involved in 4-H, I caught the bug, and it just kind of escalated from there.”

That escalation brought Weeks to where he is today.

He milks 50 cows with his wife, Treacy, and is on the verge of launching an on-farm processing plant on their Hun-Val Dairy Farm in Hunterdon County in the central New Jersey town of Ringoes.

Weeks’ rst-generation dairy farm dream was born when he graduated from high school. He spent two years milking in a rented barn before building his current tiestall barn in 2008.

“I didn’t have anything to start with,” Weeks said. “I just started piecing it together from the ground up. In some ways, that’s kind of nice, and other times, you wish that you had three or four other people who had been there, done that.”

While Weeks said Brown Swiss cattle have always been his preferred breed, he built a herd that is primarily Holsteins.

“The milk market where I’m located was paying no premiums for butterfat or protein,” Weeks said. “It was just paying for volume.”

Weeks began investigating onfarm processing, but the project received a push when Weeks’ milk marketing situation became dire.

“The small processor I was shipping to shut down, and everyone got pushed to (Dairy Farmers of America),” Weeks said. “With my plans to develop the on-farm processing, they told me if I wasn’t sending them all my milk, they didn’t want anything. So, I’ve been a feather in the wind for over a year and a half now.”

Weeks propelled, laying the groundwork for his creamery.

“I’m a jump-in-with-two-feet type of person, so the research process wasn’t nearly as long as it probably would be for most people,” Weeks said. “In New Jersey, we are short on farms but not on people, and we’re close to everything pretty much, with lots of nearby urban areas.”

Without a steady milk market, Weeks worked with small cheese plants in Lancaster, Pennsylvania. They purchased some of his milk and allowed him to start bottling milk under his own label and make ice cream to establish a customer base.

“That turned out to be a great opportunity for me,” Weeks said. “We have learned that people around here are very supportive of local farms.”

Weeks said he has faced challenges throughout the project to establish an on-farm creamery.

“We started working on the creamery before COVID,” Weeks said. “That whole situation really complicated the whole process. Things were back ordered, and then construction prices skyrocketed. Budgets were a novel thought, but they went out the window quickly.”

Now that the creamery is reality, Weeks is looking toward the future.

Weeks will market his milk through his retail location, selling cream-line, pasteurized milk in glass bottles along with ice cream. He plans

past.

to add cheese to the repertoire as well. He has wholesale accounts lined up for bottled milk.

“The glass-bottled milk has really generated a lot of interest from higher-end grocery stores,” Weeks said. “Ice cream is a draw to bring people to the retail location. There isn’t anyone around us doing that.”

The shift to on-farm processing gave Weeks the opening to milk a herd of Brown Swiss cows.

“Swiss are a great t for what we

want to do,” Weeks said. “You can’t beat the combination of components and longevity. It’s kind of a no-brainer once you’re taking your milk from start to nish.”

Weeks was presented with an opportunity when the R-Hart Brown Swiss herd, owned by Alan and Randi Rinehart from western Ohio, went up for auction.

Turn

“The timing wasn’t great, as I wasn’t looking to make that switch until we were a little bit closer to processing on-site,” Weeks said. “But, the Rineharts had the cows for sale, and it was just one of those things you had jump on, something you would kick yourself if you passed it up. I’m glad I made the decision to pursue that group.”

Weeks pared down his Holstein herd to make room for the Brown Swiss cows.

“Some people thought I was crazy, taking a herd of Swiss cows used to a parlor, freestall and pack barn setting into a tiestall barn, but the cows transitioned beautifully,” Weeks said. “They are the quietest and easiest group of cows to work with. In less than two weeks, they were all trained to the new environment.”

With that storied herd of cows came what Weeks said is an obligation to the Rinehart family to continue their tradition of breeding high-quality Brown Swiss.

“The Rineharts have a phenomenal amount of passion and time that they have put into the breed,” Weeks said. “I feel a pretty big responsibility to Alan and his family to keep that going. They have developed a lot of

good cows throughout their family’s history with the breed.”

As Weeks is preparing for the rst batch of milk to head through the processing plant, he has been reecting on what he has learned through the journey.

“Direct marketing is a great opportunity to educate our consumers,” Weeks said. “As a whole, people are very detached from agriculture. We all need to be mindful of creating that connection and telling the real story of the dairy industry.”

Milk and cookies are a classic combination. This past holiday season, Midwest Dairy capitalized on the quintessential pairing through a signage collaboration promoting the sale of milk with the Dollar General Corporation.

Martha Kemper is the vice president of dairy experience-demand with Midwest Dairy.

“It really is a win-win,” Kemper said. “The retailer wins because that generates extra dollars. Our farmers win because they’re selling more pounds of milk off their farms. And, at the end of the day, that’s what we’re really charged to do.”

The collaboration featured dual signage in the dairy and the cookie aisles at Dollar General from Nov. 13, 2023, to Jan. 14. The signage encouraged consumers to remember to buy milk, emphasizing the affordable

nutrition dairy offers and reminding them of how well milk pairs with cookies.

“We are looking for opportunity to drive that messaging and trust, which eventually will drive sales,” Kemper said. “Fluid milk has a very large household penetration. ... We just need to remind people.”

Signage messages included, “Don’t forget the milk! (Your cookies will thank you): Cookies love real milk,” “Cheers to your health: Pick up real milk today,” “Milk and cookies: A true slam dunk. Don’t forget the milk,” and “Milk: Good value for what you value: Pick up real milk today.”

The signs also included the Undeniably Dairy logo with the tagline, “Real Dairy. Real Nutrition.”

The signage was featured in 9,500 Dollar General stores, including 2,400 in the Midwest. Dollar General has 19,000 stores nationwide. Seventy percent of Americans live within 5 miles of a Dollar General. Dollar General is the No. 2 grocery destination in the U.S. behind Walmart.

Collaboration between Midwest Dairy and Dollar General is something the dairy farmer-led board suggested.

“We listen to our farmers,” Kemper said. “We’re trying to spend their money like it was our own. ... We put our money here, and it was a big win.”

Cole Hoyer, a dairy farmer milking 120 cows near Estelline, South Dakota, is a member of the Midwest Dairy board. He said part of the importance of the project is dairy farmers could see their checkoff dollars working.