DAIRY ST R June 8, 2024 Second Section Visit us online at www.dairystar.com “All dairy, all the time”™ TMR MIXERS Feed your herd. Feed your bottom line. Feed the potential. Gutter Cleaner Chain & Parts ALSO AVAILABLE Call Us 320-836-2697 After Hours: 320-267-8568 310 Industrial Dr. Freeport, MN Oldest & Most Experienced Dealer In Central MN! LIQUID MANURE EQUIPMENT FOR RENT NEW & USED EQUIPMENT LAGOON PUMPS & TANKS Proudly Serving Our Dairy Industry Since 1975! COMPLETE PRODUCT LINE... GEA Houle Patz Ritchie Waterers Animat Pasture Mat Cow Comfort J&D Manufacturing VES-Artex Barn Solutions Schaefer Barn Fans Barn Cleaner Chain Alley Scrapers Cen•Pe•Co Lubricants Pik Rite Hydra-Ram Manure Spreaders Calf-tel Calf Huts & Pens Feed Carts & Choppers Cloverdale Mixers & Bale Haulers JBS Spreaders Bazooka Farmstar Boats & Dragline Dietrich Incorporators (DSI) Curtains Mayo Mattresses Weigh Tronix Scales Bulk Feed Bins Tire Scrapers & Bedding Buckets Legend Rubber Stocking All Sizes & Parts Performance, Reliability and Durability • Pontoon • Vertical • Electric • Lagoon • Hydraulic TMRS, TANKS & PUMPS & SPREADERS IN STOCK & READY FOR DELIVERY! er s E Feed the WOLVERINE SERIES Custom t to your new or existing building Motorized or Manual Options Highest UV inhibitor and lock stitch style sewing for longer curtain life Get the full value of air quality control curtains at the touch of a button 109 Industrial Parkway S., Strawberry Point, Iowa 52076 14451 430TH ST. • BERTHA, MN 56437 218-924-4522 HARMS MFG., INC. Easy to use • Easy to Fold • Transports Easily OVER 2,000 LAND ROLLERS OPERATING IN THE MIDWEST! • 1/2” drum wall thickness • 12’, 14’, 15’, 16’, 24’, 30’, 32’, 36’, 40’, 42’, 45’, 50’, 60’, 62’ sizes • Wing steering for easy folding • Rollers flex in the field on uneven surfaces INTRODUCING THE NEW 30” DRUM DIAMETER HARMS LAND ROLLER Tandem Bale Racks Big Bale Dump Racks NEW Harms Hay Hauler • Heavy Duty • All Steel Construction • Guaranteed To Trail • 10’x30’ bed Heavy Duty! Heavy Duty! • Big Square And Big Round Bales • Heavy Duty • Double acting hydraulic lift • 10’x24’ Bed • 8 Bolt Hubs • 8’x24’ Available, 8 or 10 ton • Built Harms strong • More cost effective www.harmsmfg.com

Page 2 • Dairy Star • Second Section • Saturday, June 8, 2024 Visit us 24/7...www.arnoldsinc.com Kimball 320-398-3800 Willmar 320-235-4898 Glencoe 320-864-5531 320-548-3285 St. Cloud 320-251-2585 Mankato 507-387-5515 Alden 507-874-3400 S034401 2019 CIH LB334R, 3x3 $109,900 S028095 2013 CLAAS 3300RC, 3x4 $67,000 2011 CIH 600 Quad, 2745 hrs $310,000 A035292 2016 CIH 580 Quad, 1830 hrs $405,000 G029353 W032549 2001 CIH STX375, 7660 hrs $114,000 A035018 2012 JD 9560RT, 3440 hrs $250,000 S020412 2014 CIH 280 Magnum, 2900 hrs $235,000 M033194 2016 CIH 270 Optum, 2265 hrs $179,900 A028089 2013 CIH 235 Magnum, 2300 hrs $159,500 G033514 2014 CIH 400 RT, 2265 hrs $325,000 A031053 2004 CIH STX375, 5940 hrs $109,000 W028197 2019 CIH 310 Magnum, 1970 hrs $255,500 W034076 2008 CIH 130 Maxxum, 4620 hrs $65,000 W023652 2012 CIH 115 Maxxum, 1465 hrs $99,500 A037493 2008 CIH 165 Puma, 2220 hrs $114,500 A034302 2020 CIH RB465, 4x6 $54,900 K026052 2016 CIH RB565, 5x6 $34,900 W028197 2013 CIH 290 Magnum, 3020 hrs $175,000 A037616 2014 CIH 250 Magnum, 2185 hrs $199,000 A037493 2019 CIH 200 Magnum, 1520 hrs $185,000

Cedar Crest Ice Cream loved for avor, freshness, scoopability

By Stacey Smart stacey.s@dairystar.com

MANITOWOC, Wis. —

The enormous Guernsey cow that towers over the Cedar Crest Ice Cream plant and ice cream parlor makes the establishment nearly impossible to miss when driving through Manitowoc. The statue of Bernice has become a landmark in the community, welcoming visitors to the parlor that serves the creamy and avorful treat that often has people lining up even before it opens.

A town staple since 1989, the Cedar Crest ice cream parlor serves customers from March through October. During peak season, it serves about 40 3-gallon tubs of ice cream per day. The parlor also makes sundaes, malts, oats and shakes.

A parlor favorite

Cedar Crest is proud to make ice cream the old-fashioned way, churning it today as it has for nearly 50 years. Made from scratch in small batches, the process begins with slow, low-temperature pasteurization, which enhances avor.

Shannon Simon, marketing manager at Cedar Crest, said this is what sets the company apart from its competitors.

“Cedar Crest is one of the few ice cream companies that still slowly pasteurizes ice cream despite the fact there are hightemperature, fast-pasteurizing machines available to make this process quicker,” Simon said. “It takes a lot longer to make ice cream the way we do it, but we simply believe this method is what keeps a quality avor. It works — why change it?”

Ken Kohlwey established Cedar Crest Specialties in 1976. Dairy was in his family’s blood as Kohlwey’s parents owned a milk bottling company called Cedarburg Dairy. However, ice cream drove the next generation.

Turn to PEOPLE MOVING PRODUCT | Page 4

“We

- Peter Kimball Hidden Pond Farm, Baldwin,

WI

Equipment Baltic, SD •605-359-0228

701-321-0203

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 3 Feeding Flexibility & Durability in One Mixer 5 YR. OR 5,000 LOAD WARRANTY ON MIXING TUBS, AUGER, FLOOR AND FRAME. STAINLESS STEEL CONVEYORS 9 Different Sizes to choose from 175 cu. ft.1,300 cu. ft. Go to www.cloverdaletmr.com for more information. New & Used Equipment Available at your local Cloverdale Dealers! Isaacson Sales & Service, Inc. Lafayette, MN 507-228-8270 • 888-228-8270 Ross Equipment Co., Inc. Lonsdale, MN 507-744-2525 Brynsaas Sales & Service, Inc. Decorah, IA • 563-382-4484 www.brynsaas.com Hartung Sales & Service, Inc. Freeport, MN 320-836-2697 Contact your local dealer to learn more! Knight 3142 wagon - $24,500 Knight 3130 wagon - $19,900 Patz 350 - $16,900 Patz 620 - $27,000 Patz 615 - $21,500 Patz 950 -$34,000 Kuhn Knight VT180 - $30,000 Patz 140 Stationary - $11,500 Patz 200 Stationary - $16,900 RT Equipment 605-359-0228 RT Equipment 605-359-0228 Ross Equipment Co., Inc. 507-744-2525 Ross Equipment Co., Inc. 507-744-2525 Isaacson Sales & Service, Inc. 507-228-8270 • 888-228-8270 Isaacson Sales & Service, Inc. 507-228-8270 • 888-228-8270 Ross Equipment Co., Inc. 507-744-2525 Ross Equipment Co., Inc. 507-744-2525 Ross Equipment Co., Inc. 507-744-2525 2014 Patz V350 - $18,500 Cloverdale 550T - $63,500 2022 Patz 950XH - $70,000 2016 Supreme 600T - $22,500 Brynsaas Sales & Service, Inc. 563-382-4484 Farwest Equipment 701-260-4959 Brynsaas Sales & Service, Inc. 563-382-4484 Brynsaas Sales & Service, Inc. 563-382-4484 RT

Farwest Equipment Dunn Center, ND 701-260-4959 Hefty Equipment Ashley, ND •

built heavier.”

had another vertical mixer before but our Cloverdale is

PEOPLE MOVING PRODUCT

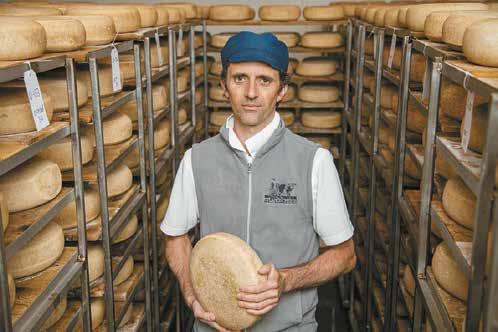

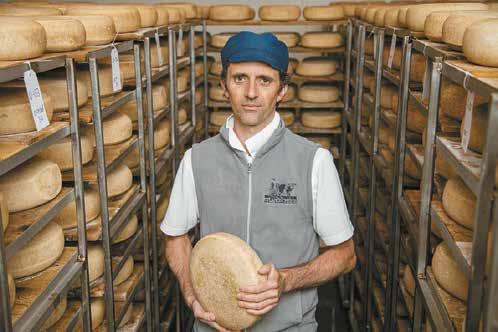

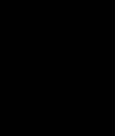

STACEY SMART/DAIRY STAR

Shannon Simon scoops ice cream May 30 at the Cedar Crest Ice Cream parlor in Manitowoc, Wisconsin. During peak season, the parlor serves about 40 3-gallon tubs of ice cream per day.

Starting out as a distributor for Oak Brand Ice Cream in Freeport, Illinois, Kohlwey ran two ice cream routes in Southwest Wisconsin. When that supplier left ice cream behind in 1977, the Kohlwey family purchased Smith Ice Cream Company in Oshkosh and began making their own ice cream. In 1979, they moved the corporate ofce from Milwaukee to Cedarburg. When the business outgrew its production facility, the family purchased Lake to Lake Manufacturing in Manitowoc in 1987.

“Bernice came with the property, and since then, we’ve been expanding, expanding, expanding,” Simon said.

Today, Kohlwey and his brothers, Bill, Tim and Robert, and Robert’s son, Luke, run Cedar Crest Ice Cream with help from 100-150 employees. Ice cream is made at the 45,000-square-foot manufacturing facility in Manitowoc. The milk used to make the ingredients in Cedar Crest’s ice cream base is sourced from local creameries. From cow to cone, Cedar Crest Ice Cream ensures quality at every step of the process.

Once it is packaged, ice cream is shipped to the Cedarburg location where it is stored in a freezer set at -20 degrees ensuring product freshness.

“The ice cream stays frozen solid until leaving our facility,” Simon said.

A large volume of dairy products travel through the doors of Cedar Crest Ice Cream. The company makes and sells 3 million gallons of ice cream, custard, sorbet, sherbet and frozen yogurt annually.

Cedar Crest Ice Cream can be found in ice cream parlors and retail outlets

throughout Wisconsin, Michigan, Minnesota, Iowa and Illinois. Ice cream parlors carrying the Cedar Crest brand sell it exclusively as their scooped product but may carry soft serve ice cream in addition.

“As we grow, ideally we would love to sell nationally,” Simon said. “We are capable to expand to that size. It’s an interesting future we can have.”

Cedar Crest claims that its ice cream was made for parlors because it scoops better, stays fresher longer and is consistently more avorful than other brands. Simon said scooping ease is a result of the ice cream containing 11% butterfat.

“That makes a signicant difference,” she said. “Sweet avors are even easier to scoop because of the sugars they contain, which make the ice cream super smooth and easy to scoop.”

Parlors can choose from 80 avors of Cedar Crest ice cream. The best-selling avors include Super Madness, blue raspberry, cherry and vanilla avored ice cream; Pirate’s Bounty, a caramel-avored ice cream with M&M’S and cookies; and Caramel Collision, a caramel ice cream with caramel swirls and chocolatecoated caramel mini cups.

More than 50 avors of Cedar Crest ice cream are available for retail sales. Included in this lineup are limited edition and seasonal avors like peppermint and pumpkin pie. Cedar Crest packages other avors to meet geographic demands.

Turn to PEOPLE MOVING PRODUCT | Page 5

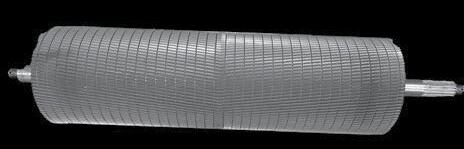

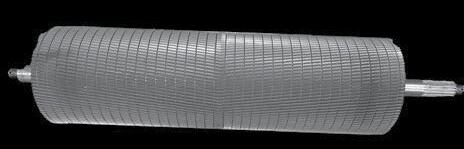

Page 4 • Dairy Star • Second Section • Saturday, June 8, 2024 FREE SAME DAY SHIPPING The World’s Best Attachments at the World’s Best Prices Our family-owned company has nearly two decades of experience, and we always prioritize quality when manufacturing our skid steer quick attachments. In Stock, get your world-class attachment now and make completing the job simple and efficient 6” tine spacing 84” wide bucket 910 lbs. Other bucket widths and tine spacing available 20 grinding teeth Also available in high flow 2” hex drive Various auger bits from 4” up to 48” diameter N6680 County Road Q • P.O. Box 38 • Knapp, WI 54749 715-665-2000 • Email: Contact@StoutBuckets.com • stoutbuckets.com 1000E MONTANA POST DRIVER STOUT SKID STEER 5470 XHD BRUSH GRAPPLE STOUT SKID STEER STUMP GRINDER LOWE SKID STEER 1650 CLASSIC AUGER Weight - 2000lbs. 8” tool diameter 400-800 Blows per Minute GPM 13-24, 2200PSI Minimum Other models available perience p to O STE BRU LOWESKID DRI 40 GPM family-ow 20 gr Also avai OU G STO STE O KERNEL PROCESSORS for New Holland 900, FP230, FP240 and CIH FHX300 pull-type choppers DARE TO COMPARE! ,, New 1-piece roll design! The most user friendly KP on the market. D uddertechinc.com Help Udder Tech give back to the community! SHOP ONLINE: Our goal for 2024 is to donate over 800 GALLONS of milk to local food pantries

Con nued from PEOPLE MOVING PRODUCT | Page 3

PHOTO SUBMITTED

Containers of Cedar Crest Ice Cream are stacked on a counter at Cedar Crest Ice Cream in Manitowoc, Wisconsin. The company makes and sells 3 million gallons of ice cream, custard, sorbet, sherbet and frozen yogurt annually.

STACEY SMART/DAIRY STAR

ice cream parlors and retail outlets throughout

and

Bernice, a giant Guernsey cow statue, stands May 30 outside the Cedar Crest Ice Cream plant and ice cream parlor in Manitowoc, Wisconsin. Ice cream is made at the 45,000-square-foot facility

and sold in

Wisconsin, Michigan, Minnesota, Iowa

Illinois.

“A avor might be more popular in Iowa than in Michigan, for example, so we have different avors for different areas,” Simon said.

Cedar Crest has formulated over 200 avor combinations. Each year, new feature avors are released as the creamery brings back old favorites while also curating new avors for parlors.

“We’re innovative and always try to come up with something new and fantastic,” Simon said. “We want to keep it refreshing and think about what we haven’t done yet, but we also have to ask if it’s possible to make. We need suppliers that can give us these ingredients while meeting our standards to ensure a premium and quality product.”

New exotic avors on the Cedar Crest menu include Southern Bourbon Pecan and Firecracker. The rst is a

It’s no secret that a Dairy Star classied ad can help you buy or sell your farm items!

Look for the classifieds in our third section!

bourbon-avored ice cream that has become popular among adults. Firecracker, a strawberry-avored ice cream infused with POP ROCKS candy, is the company’s featured avor for June.

“It provides a different ice cream-eating experience,” Simon said. “Pop rocks had their trend back in the day then faded away, and now they’re back again.”

Cedar Crest also enlists the help of Wisconsin 4-H clubs in coming up with new, fun avors in their annual 4-H Flavor Creation Contest. The grand prize for winning is $500.

“It gets the Wisconsin community involved and emphasizes how important agriculture and the dairy industry is to us as a state and to Cedar Crest’s future,” Simon said. “The kids come up with quirky names and ingredients and are really good at creating those unique

candy avors.”

New avors are tested in parlors before they are placed in retail outlets.

“We want to see how much of a rave they are before we invest in packaging,” Simon said. “We like to do our parlors a favor by offering avors that will draw people in. We have parlor-exclusive avors like bubble gum and licorice.”

Cedar Crest also began making ice cream sandwiches this year for retail sales. They are a novelty item for ice cream trucks and stands as well.

With a cow in their front yard, Cedar Crest’s connection to dairy is unmistakable.

“We’re very passionate about the dairy industry,” Simon said. “Without it, we wouldn’t be able to make our ice cream.”

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 5 the Smartbacteria & Nutrition CompanyTM 920-682-0264 priorityiac.com ©2024 Priority IAC, Inc. All rights reserved. Gold Spike ® Gold Spike is an oral, non-drug option, helping those who want to reduce the use of antibiotics. New Research shows better intestinal wall by decreased cell permeability, strengthened cell junction integrity, and regulated expression of both pro-inflammatory and anti-inflammatory cytokines leaving no residues in meat or milk. - No Meat or Milk Withholding - Immune Support - Reduced Inflammation Traction in all directions Reduce animal stress Aids in heat detection Cost effective & practical Prevent costly falls before they occur We offer grooving & scarifying! BEST FOOTING CONCRETE GROOVING Strum,

bestfootingconcretegrooving.com CLASSIFIED Doesn’t Always Mean Top Secret!

WI 715-579-0531

Con nued from PEOPLE MOVING PRODUCT | Page 4

Caprine Farming

Taking control of costs

McCauleys dial in feed variables with equipment, baled corn silage

By Abby Wiedmeyer abby.w@dairystar.com

LA VALLE, Wis. — When Chad and Robin McCauley embarked on their dairy goat career seven years ago, they were told over and over again that they could not feed corn silage.

“It’s not that goats can’t eat corn silage, it’s just that most of the people that have goats can’t keep corn silage fresh enough to feed it to them,” Chad McCauley said. “They can’t feed it fast enough.”

The McCauleys had always fed baled hay and a grain mix from the mill. But when they experienced inconsistencies in the grain mix and other feed costs continued to rise, they revisited the concept of feeding corn silage to their goats.

McCauley milks 175 goats near LaValle with his wife, Robin. Chad manages the daily re-

sponsibilities on the farm while Robin works full time off the farm. They have been renting their facilities and have always tried to be conscientious about operating costs.

McCauley was determined to try feeding corn silage. He began integrating corn silage into the diet by purchasing daily amounts from a neighboring farm. He fed baled hay on one end of the bunk and corn silage topped with protein mix on the other. The goats were fed cracked corn in the parlor. Eventually, the corn was top dressed on the corn silage as well.

The goats responded well to the corn silage, with production and components increasing. McCauley continued to increase the amount fed until the farm he was sourcing from said they could not sell corn silage anymore due to dry weather conditions.

McCauley went back to feeding hay and the protein mix until he discovered a farm in Hillsboro that was making baled corn silage. The corn silage is chopped and then dumped into a

Turn to MCCAULEY | Page 7

Page 6 • Dairy Star • Second Section • Saturday, June 8, 2024 44326 County 6 Blvd | PO Box 185 | Zumbrota, MN 55992 507.732.7860 | dpuppe@centrallivestock.com Available in Zumbrota, MN We will ship to Albany, MN area upon request. Charges apply. Check out our inventory Gates • Chutes • Feeders • Pens Stockman’s Supply has the Livestock Equipment You Need! At Stockman’s Supply in Zumbrota we have a large selection of Marweld Goat and Sheep products, ranging from Gates, Pens and Feeders to Treating Chutes and Spin Chutes. Stop by or call and speak with Dave in Zumbrota. We also ship to Albany, MN area. Charges apply. AilbliZbMN CURTISS 715-613-7308 EDGAR 715-352-2011 BOSCOBEL 715-937-5190 Edgar Curtiss Boscobel Meet the Endura-Flo! High Capacity silo unloader / distributor • 1/4” stainless steel blower band • Wider stainless steel cupped paddles • Improved auger flighting • All stainless steel blower (Opt.) • Stainless steel main frame (opt.) • Twin belts on gearbox & blower (Opt.) • Stainless steel wall wheel mounts d Opt.) ower mounts Dependability from top to bottom Blower The stainless steel sides, outer band, and impeller cups provide long life for the high performance blower. Arms can operate either fixed or swinging. Main drive The auger gearbox and the blower are each powered by twin belts for trouble-free starting. The tilt & slide motor mount is easy to adjust. Large drive ring with rigid splice Stainless steel shroud panels Swing-away power distributor High density plastic wheels on stainless steel axles Features Multiple ring drive choices 10” diameter auger with extra-thick flighting ends Standard arms for central distributors or high-lift arms for side-fill distributors

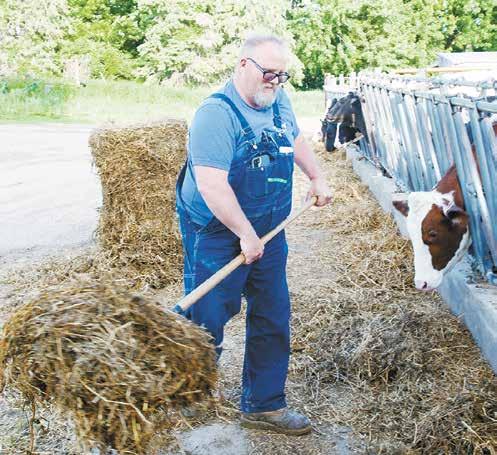

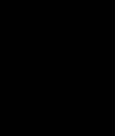

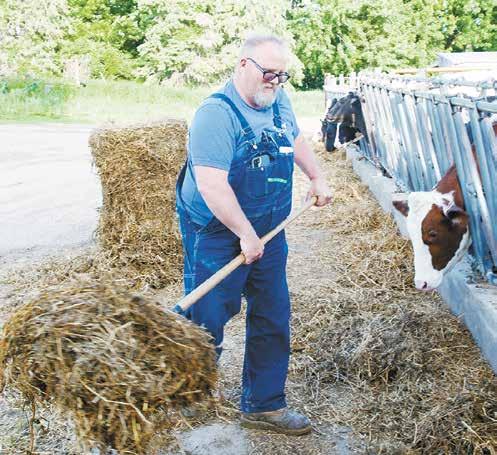

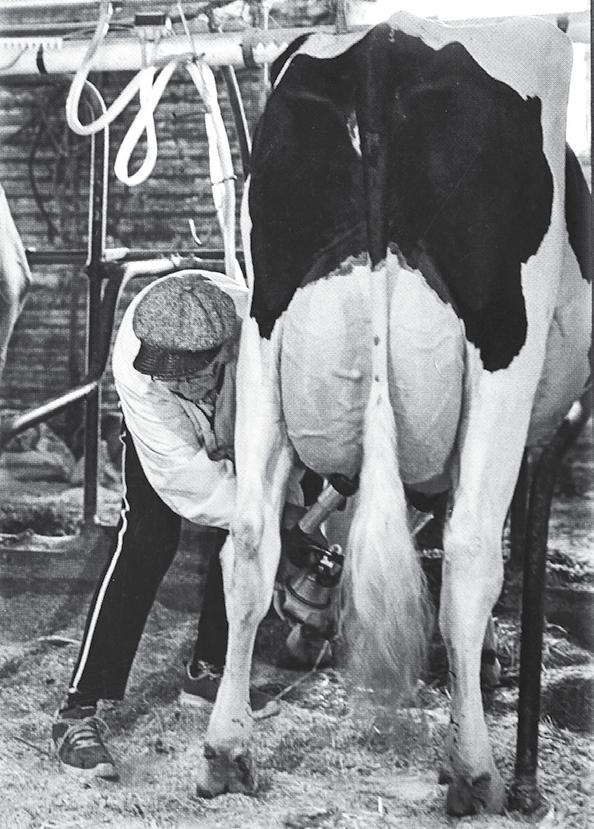

ABBY WIEDMEYER/DAIRY STAR

Chad McCauley pushes up feed May 20 at his rented farm near La Valle, Wisconsin. McCauley and his wife, Robin, milk 150 goats in Sauk County.

compactor. It is wrapped in plastic to cure and then bale wrapped for more durable protection. It is about the size of a large round bale of hay.

McCauley purchases 10 bales of corn silage at a time, which lasts about a month. This solution resolves the freshness issue.

“This (the open top of the bale) is my face to keep fresh,” McCauley said. “Whereas with a silo, I’d have to feed a foot a day out of it.”

With a reliable source of silage available to him, McCauley’s next move was to get a more consistent product. He began by looking at total mixed ration mixers. He considered a pull-type TMR but was already making hay all summer with one tractor and did not want another implement to hook and unhook. A friend suggested feeding with a feed cart, but he did not like not being able to weigh the ingredients to create a consistent product.

Then McCauley discovered the selfpropelled TMR. It has a capacity of almost 800 pounds and ts in the haymow of his barn. It combined the two concepts of pull-type TMR and feed cart in one. He worked with a local dealership to order a machine and has been using the new equipment for about three months.

Working with his nutritionist and the new equipment, McCauley was able to get his total feed costs down from $6,000 per month to $2,000 per month. This was due in part to experimenting with different supplement options in the parlor. He settled on a corn gluten pellet that was

about a third of the cost of the original supplement he was feeding.

McCauley said the feed cost savings have allowed him to continue farming.

“In 2022 everything was going up and 2023 wasn’t any better,” McCauley said. “I said we can’t continue like this because we’re not making enough money. If we hadn’t switched to TMR, I probably would have had to sell out because everything was just going up in price.”

McCauley mixes feed in the haymow and unloads the TMR through a hole in the oor to the bunks below. Now that warmer weather is upon him, he is remodeling his outdoor feed bunks so he can drive by with his new TMR to feed.

Though ingredients are added by hand, McCauley can incorporate everything except the pellets into the mixer. He can mix and feed in about 1 1/2 hours.

The new system also saves on hay and bedding. The goats used to grab mouthfuls of long hay and drag it into their pens to eat. This contributed to a layer of hay on top of the sawdust bedding pack, which prevented the sawdust from doing its job.

With lower feed costs and a longerlasting bedded pack, McCauley is glad he made the equipment upgrade and feed changes.

“Every time that I mix, it comes out the same,” McCauley said. “I’m feeding a more consistent feed and I’m not leaving my nancial situation in somebody (else’s) hands.”

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 7 Looking E more family farms ORGANIC VALLEY PROVIDES: • Stable Organic Pay Price • Veterinary & Agronomic Support • Organic Transition Premium • Feed & Forage Sourcing Contact our Farmer Hotline to learn more. 888-809-9297 | www.farmers.coop Tues LongPrairie Livestock Auction Company SALES START EVERY TUESDAY AT 1 PM Market Phone 1-320-732-2255 Fax: 1-320-732-2676 Starting with hogs, goats and sheep, followed by baby calves, slaughter, replacement and feeder cattle. Home of the longest running dairy sale in the Midwest! 43 Riverside Drive Long Prairie, MN 56347 For an on the farm estimate or current market info, call 320-732-2255 WE APPRECIATE YOUR BUSINESS! DAIRY SALES are held EVERY FRIDAY. Dairy cattle sell at noon EVERY FIRST SATURDAY is the EVERYTHING SALE starting at 9 a.m. EVERY THURSDAY we are in Belgrade - Misc. at 10am and cattle at 1:30 p.m. Tues., June 11 Feeder & Slaughter Cattle Sale with hay/straw, baby calves, feeder cattle, replacement cattle, goats, sheep, hogs, fat and slaughter cattle Fri., June 14 Dairy Sale - Noon Tues., June 18 Feeder & Slaughter Cattle Sale with hay/straw, baby calves, feeder cattle, replacement cattle, goats, sheep, hogs, fat and slaughter cattle SALE DATES: Please consign your cattle as early as Thankpossible! You!!! D I R T B U C K E T COMMITMENT • QUALITY • DURABILITY • RESULTS Visit www.silverstarmetals.net for details and options on attachments Dealer Inquiries Welcome OUR BUCKETS WILL GET YOUR PROJECTS DONE!! SILVER STAR METALS LLC N15435 Frenchtown Ave., Withee, WI 715-229-4879 • 1/4” steel • T1 wear plates • Bolt on reversible edge available • 20” high x 36” deep • 3/4”x 6 cut edge Width Options: 72” • 78” • 84” • 90” 96”(available on order) THESE QUALITY ATTACHMENTS ALSO AVAILABLE: • Concrete Chuter • Brush Cutter • Roto-Tiller • Pallet Fork • Driveway Grader • Brush Grapple • Wood Splitter • Rock Buckets • Bale Bedders • Mini Attachments • Trailer Mover Con nued from MCCAULEY | Page 6

ABBY WIEDMEYER/DAIRY STAR

Chad and Robin McCauley’s goat herd relaxes May 20 at their rented farm near La Valle, Wisconsin. The McCauleys milk 150 goats and recently started feeding total mixed ra on which has kept their bedding pack cleaner.

ABBY WIEDMEYER/DAIRY STAR

Chad McCauley mixes feed May 20 at his rented farm near La Valle, Wisconsin. McCauley started feeding a TMR to his dairy goats in January this year to incorporate corn silage and achieve a more consistent feed.

The “Mielke” Market Weekly

Butter inventory rises

U.S. butter stocks jumped in April. The U.S. Department of Agriculture’s latest cold storage report shows April 30 inventory at 361.3 million pounds, up 44.1 million pounds or 13.9% from the March count. This was revised up 624,000 pounds and was 29.8 million pounds, or 9.0%, above April 2023.

Churns have been running well ahead of a year ago the past four months, and April likely followed that. Cheese vats weren’t quite as busy. HighGround Dairy reported that the March to April butter climb was “the most signicant build for the month since 2020 which was an outlier due to the start of the COVID-19 pandemic. Eliminating that year results in the largest March to April increase since 2016.” HGD added that the cheese data was “neutral.”

American type cheese stocks climbed to 839.2 million pounds, up 10.6 million or 1.3% from the March level, which was revised up 3.1 million pounds but down 2.7 million pounds, or 0.3%, from a year ago.

The “other” cheese category holdings slipped to 598.4 million pounds, down 5.3 million or 0.9% from March’s count, which was revised 7.2 million pounds lower. Stocks were down 6.7 million pounds or 1.1% from a year ago.

The total April 30 cheese inventory stood at 1.46 billion pounds, up 5.6 million pounds, or 0.4%, from the March count, which was revised 5.1 million pounds lower at 8.8 million pounds, or 0.6%, below a year ago.

Chicago Mercantile Exchange butter headed south the rst day of trading following the Memorial Day holiday as a result of the cold storage data, plunging 12 cents, the rst time it was below $3 per pound since May 14. But butter wasn’t down for the count. It rallied Thursday, regaining 5.50 cents, and added 6 cents Friday to close at $3.09, still 3.25 cents lower on the week but 64.50 cents above a year ago. There were nine loads that traded hands on the shortened week.

Speaking in the June 3 “Dairy Radio Now” broadcast, StoneX broker Dave Kurzawski addressed the message on butter he interpreted from the cold storage report. “We may not have a supply problem on butter so much as we have a problem on the supply of available futures contracts,” Kurzawski said.

This rally really began at the end of January, he said, and has been driven primarily by the futures market.

“Understandably, end users want coverage,” Kurzawski said. “South of $3 per pound would be ideal, but the spot market has been the follower.”

“When we have a legitimate bull market on a product, typically the spot market will lead the rally,” he said. “The market is saying we have a supply demand imbalance. We can argue about what that imbalance is. It exists. We’re going to put the spot price, the actual product price, the highest price on the board and the futures will be at a discount to disincentivize anybody who makes that product from putting it away. Make the product today; then bring it to the market today. That’s the absolute best price you can get. That didn’t happen the past three months.”

Kurzawski said he expects more downside on butter but sees the report as relatively neutral on cheese. As to nonfat dry milk, he said, “The old habit of looking at world prices and global demand and saying it’s been bearish the past 8-12 months and will continue that way, those old habits die hard.”

“The market’s been pretty sideways,” he said. “Globally, it’s been sideways to a little bit rmer as we’re starting to see that on prices in the GlobalDairy Trade, but the reality is you will have more buyers, unfortunately at $1.25 in the U.S., or $1.28, than you do at $1.18 because there’s a fear of missing out like we saw in cheese in April.”

Dairy Market News reported that butter plants were running normally despite the holiday weekend. Cream was and is available. Multiples were steadily moving in the mid- to upper-1.10s, which mirrored previous months. Butter makers and cream handlers do not expect cream availability, and therefore churning, to last much further into the waning spring weeks. Components have started to tighten at the farm milk level. Butter makers are not overly concerned about the falling price, said DMN, and are comfortable with their stocks and current demand.

Butter production is strong in the West as manufacturers work to build stocks to cover planned downtime for churn maintenance during the next month. Cream demand is strengthening, and cream volumes are generally available throughout the region. Retail and food service butter demand is strong domestically while demand from international buyers is moderate, said DMN.

Block Cheddar lost 6 cents on the week, the third week of decline, closing Friday at $1.81 per pound,

lowest since May 3 but still 38 cents above a year ago.

Barrels nished at $1.94, down 4 cents on the week, 42.75 cents above a year ago, and 13 cents above the blocks. There were 14 sales of block on the week and eight sales of barrel.

Recent production hurdles have been reported by a number of cheesemakers, according to DMN. Multiple plants were on both holiday and unexpected downtime the week before Memorial Day and over the weekend. Some took an extra half-day off, while others were down for multiple days. Demand tones were consistent with the past few weeks to the past month and are “healthy.”

Retail and food service cheddar/Italian cheesemakers say demand from regional and eastern customers is hearty. Milk remains ample and spot prices mid-week were holding in a similar range to the previous week. Market tones have turned bearish, said DMN, but longer-term outlooks are “steadier to even bullish.”

Most cheese manufacturers in the West noted strong production. Some parts of the region are seeing stronger milk components compared to a year ago, and that is helping keep production strong and balancing milk supplies. Milk output is weakening in some parts, but upcoming summer school breaks are expected to ease bottling demand and increase milk availability for Class III manufacturers. Domestic cheese demand is steady while exports are steady to weaker.

CME nonfat dry milk fell to a Friday nish at $1.1675 per pound, 0.75 cents lower on the week and a quarter-cent below a year ago, on nine sales.

Whey slipped to 39.50 cents per pound Wednesday but closed Friday at 41.50 cents, up 1.50 cents on the week and 15.75 cents above a year ago, on 11 sales.

Dairy cow slaughter for the week ending May 18 totaled 47,000 head, down 1,000 from the previous week and 7,900 or 14.4% below a year ago. Year to date, 1,112,700 have been culled, down 169,300, or 13.2%, from 2023.

HGD said, “A weekly total of under 50,000 head is notable as it typically only occurs during holiday weeks. Further, this was the lowest value for the week in over 15 years. 2008 was the last time this gure was smaller. Milk prices have dramatically improved in second quarter, which has likely caused farmers to change their culling practices.”

The latest Crop Progress report shows 83% of U.S. corn was in the ground as of the week ending May 26, up from 70% the previous week, 3% ahead of a year ago, and 1% ahead of the ve-year average. Fifty-eight percent emerged, 8% behind a year ago.

Page 8 • Dairy Star • Second Section • Saturday, June 8, 2024

By Lee Mielke

| Page 9

Turn to MIELKE

Farm Material Handling Specialist “Service After The Sale” ROD FLUEGGE “the boss” 2040 Mahogany St., Mora, MN • 320-679-2981 LEASING AVAILABLE Looking for good, used trades! 1960-2024 Celebrating 64 years! FLUEGGE’S AG HAY EQUIPMENT ON THE LOT AND READY TO GO! STOP IN AND TALK TO ROD, THE BOSS! ROERS WHITEWASHING & STEAM CLEANING We’ll whitewash with the cows in the barn! FLY CONTROL Pipeline, Windows and Light Bulbs cleaned at the end of job. Call now to get on our summer and fall schedule! 41 Years of Experience “The friendly people” CALL FOR FREE ESTIMATES Cliff: 320-815-8488 or Tim: 320-815-5103 Serving MN, WI, SD & IA LIC#: 20122719

Sixty-eight percent of the soybeans were planted, 10% behind a year ago, but 5% ahead of the ve-year average. Thirty-nine percent emerged, 11% behind a year ago.

In its May 29 Early Morning Update, StoneX reported, “The harsh storms and severe weather patterns we’ve seen this year are brought on by the changing seasons combined with a stronger-than-normal jet stream above the northern hemisphere, bringing not only tornados and severe thunderstorms but also signicant rainfall in the corn belt. As El-Nino begins to fade, the question of if — and if so, when — LaNina will develop becomes the focus.”

The Global Dairy Trade Pulse auction Tuesday saw 3.6 million pounds of product sold, down from 3.75 million May 14. Of the total offered, 94.4% sold. There were 888,454 fewer pounds of instant whole milk powder and 771,610 pounds more regular WMP sold versus the last Pulse. There was 8,818 pounds more skim milk powder sold.

Much of global trade is inuenced by China, whose dairy purchases continue to lag. Part of the explanation may be in an article by the Daily Dairy Report’s Sarina Sharp in the May 24 Milk Producers Council newsletter.

Sharp wrote, “USDA’s on-theground analysts in Beijing raised their estimates of Chinese milk output. They now show roughly 7% growth in Chinese milk production every year from 2020 through 2023 and project Chinese milk output to grow another 1.3% in 2024.”

The May 28 Daily Dairy Report added, “China’s dairy herd has grown faster than anticipated, up 3% year over year in 2023, as producers keep lowproducing cows in the herd and large herds expand. A recent report from the USDA Global Agricultural Information Network said, “Growth in raw milk production continues to outpace consumption, creating an oversupply in the Chinese market.” The DDR added that “China’s increased milk production this year will be pulled into manufacturing, and that will weigh on dairy product imports.”

In politics at home, the U.S. House Agriculture Committee approved its version of the 2024 Farm Bill, one that comes with a $1.5 trillion price tag over the next decade. The National Milk Producers Federation praised Chairman Glenn Thompson and committee members from both parties for approving a bill that “includes critical dairy priorities that will help support and grow this industry,” according to Gregg Doud, NMPF president and CEO.

“Provisions beneting dairy urged by NMPF include extending the Dairy Margin Coverage program through 2029; update production history for participating dairies to be based on the highest production year of 2021, 2022, or 2023; and extend the ability for producers to receive a 25% premium discount for locking ve years of coverage.”

The bill would restore the “higher of” Class I mover to, as NMPF said, “Reinstate orderly milk marketing and require plant cost studies every two years to provide better data to inform future make allowance conversations. It also supports the bipartisan, Housepassed Whole Milk for Healthy Kids Act to reverse the under consumption of nutritious milk in our schools, and boosts funding for dairy trade promotion programs and protect the use of common food names worldwide.”

The bill supports voluntary, producer-led conservation programs, such as the Environmental Quality Incen-

tives Program, with dedicated funds for livestock operations and language encouraging states to prioritize methane-reducing practices and improves the certication of Third-Party Service Providers with technical expertise related to conservation planning to better assist producers participating in National Resources Conservation Service programs.

Meanwhile, on the Senate side, the May 24 “Daily Dairy Report” said, “Democrats on the Senate Ag Committee expressed concern about any cuts to Supplemental Nutrition Assistance Program (SNAP) benets. The bill does not call for outright cuts to food stamp benets. Rather, it authorizes a return to the pre-2021 SNAP formula, which adjusted for ination but did not account for gaps between the overall rate of ination and the rising cost of a healthy diet.”

Michael Dykes, D.V.M., president and CEO of the International Dairy Foods Association, said, “IDFA was pleased to see the House Agriculture Committee’s Farm Bill expand the SNAP Healthy Fluid Milk Incentive (HFMI) to include the full suite of nutritious milk options.”

He said, “Congress created the SNAP HFMI pilot program in the 2018 Farm Bill to test the most effective ways of incentivizing SNAP participants’ purchases of healthy uid milk. Since then, HFMI pilots operating under the name ‘Add Milk!’ have been running in more than 700 retail outlets in 19 states, including locations in rural communities, counties with persistently high poverty rates, Opportunity Zones, low-income and low access census tracts, and Tribal Nations and surrounding tribal communities.”

“The program has been very effective in doubling the purchasing power of SNAP participants through the use of electronic incentives,” Dykes said. “The House Farm Bill recognizes this success by expanding the program to incentivize nutritious milk options like 2% and whole milk, and by providing more certain funding to ensure increased access and continued success of the program.”

The bill also makes the Dairy Forward Pricing Program permanent, which IDFA said “would eliminate the gap in forward pricing programs for proprietary plants and their producers that occurs if farm bills are delayed.”

The measure also allows schools to serve whole milk and reduced fat milk to students, pursuant to the Chairman’s Whole Milk for Healthy Kids Act, which IDFA supported. It also mandates biennial cost surveys to ensure make allowances accurately reect the cost of manufacturing dairy products, a consensus priority across the industry.

“Unfortunately,” concluded the IDFA, “The bill also includes a provision that circumvents USDA’s mandate to complete the ongoing Federal Milk Marketing Order (FMMO) hearing process, by restoring the ‘higher-of’ formula for the calculation of the price of Class I (uid) milk. The USDA process to make changes to the FMMO through a Federal Order Hearing has been underway for well over one year, and USDA will soon announce its proposal.”

“IDFA believes Congress should not intervene on one select issue, especially one that is included in the current USDA FMMO Hearing process and one that has signicant impacts across all policies in the FMMO and like many of the hearing proposals, affects many parts of the dairy supply chain,” IDFA said.

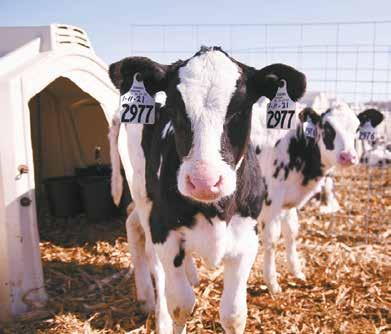

years, top sires used through Alta Genetics. Some sires include Morrison, Abba, Pinetta, Orinoco, Stafford, Flashback, Acer, Jurgen and more. Nelson bred for good legs, feet, udders and components. Dry cows treated with Tomorrow. 75% of this herd tested A2A2. Owner is transitioning to goats. ***Cows are PENDING the HPAI/H5N1 Avian In uenza test*** Coming from Nelson Miller, Argyle WI

COMPLETE HERD DISPERSAL #2

35 Holstein Dairy Cows. Tie stall milked, outside everyday, bunk fed. 70# 4.2F 3.1P 150SCC, not pushed. AI breeding for over 50 years, currently using Holstein bulls. Vaccination program. Regular herd health. Coming from Pepin County

COMPLETE HERD DISPERSAL #3

60 Holstein Dairy Cows, tie stall milked, outside everyday, bunk fed, more information coming soon! SPRINGING HEIFERS

9 Holstein Springing Heifers, freestall adapted, over 30 year AI breeding though Select Sires. Owners previously sold their herd at Premier and now selling heifers as they get close. Reputation consignor. Coming from Jim & Karol Creaser, Menomonie, WI ***Herd For Sale Private Treaty – See website for more information! ***

Expecting our usual run of dairy cows, dairy bulls, springing heifers, short bred, and open heifers.

SPECIAL SPRING SHEEP & GOAT AUCTION

Thursday, June 13, 2024

Accepting Sheep & Goats Wednesday evening 5-8:30pm.

Overnight sheep & goats selling rst. Have all sheep & goats in by 9:00am Thursday morning.

MACHINERY AUCTION

Friday, June 14, 2024

Now accepting your farm machinery and construction equipment. The Machinery deadline is Friday, June 7th. See other ad for machinery listings! Nationwide buyers, proven results!

ADVANCE NOTICE! Wednesday June 19, 2024 at 11:00 Ayrshire Herd Dispersal! See our website for details!

SPECIAL MONTHLY DAIRY HEIFER AUCTION

Tuesday June 25, 2024 at 11:00am

Expecting 500-600 dairy heifers. Call with your consignments. Always a great selection of dairy heifers at Premier Livestock and Auctions!

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 9

Con nued from MIELKE | Page 8 W5487 Eddy Rd., Owen, WI 54460 • PH: 715-721-5361 • Fax: 715-721-3620 Specializing in John Deere Pull-Type Choppers From General Repairs to Complete Rebuild Affordable Quality • We have the Parts in Stock Large selection of used parts We Ship daily UPS and Truck Freight DION F41 $29,500 w/hayhead, KP, new knives & shears bar field ready Call for partsFREEcatalog Nice, solid machine ONLINE BIDDERS AND BUYERS REGISTER AT CATTLEUSA.COM Premier Livestock & Auctions LLC Office: 715-229-2500 Ken Stauffer 715-559-8232 Rocky Olsen 715-721-0079 Travis Parr 715-828-2454 N13438 STATE HWY 73 WITHEE, WI 54498 SELLING MARKET CATTLE AND CALVES 4 DAYS A WEEK, MON.-THURS! SELLING 3000-3750 HEAD EACH WEEK, AND OVER 1000 CALVES! COME CHECK OUR STATE OF THE ART FACILITIES! WWW.PREMIERLIVESTOCKANDAUCTIONS.COM HAY & STRAW AUCTIONS Wednesdays at 9:30! Hay & Straw sold by the bale! All special auctions are on CattleUSA. Weekly Highlights at Premier Over 2,850 head sold this week. Tuesday 450 dairy heifers sold Most opens $200-300 per # up to 3.80. Top shortbreds $1,950-2,550. Springers up to $3,000. Wednesday we sold 220 dairy cattle with two Tiestall herds. Market was very strong with one herd averaging $2,469. Top dairy cows $2,400-3.100. Many other cows $1,900-2,375. About 125 head were tested negative for HPAI/HN1Avian In uenza (bird u), a requirement for selling milking cows to out of state buyers. Springing cows and heifers require no test. Top springing heifers $2,200-3,150. Top fed Hol strs 178 #. Top feed beef strs $199.50 #. Top market cows $145155 #. Top market bulls $155-161. Top Organic cows $180-198 #. Few over $200 #. Top Newborn beef calves $ 875-980 ph. Top Hol bull calves $650-740. Thanks for your business. Note! NOW selling COLORED FED CATTLE, EVERY Tuesday! Fed cattle auction will be online! SPECIAL FEEDER CATTLE AND BRED BEEF COW AUCTION! FEATURING BEEF BREEDING BULLS! Tuesday, June 11, 2024 at 10 am Expecting 600-800 head! • Demand is excellent! Scan the code for a direct link to our website! CALL WITH YOUR CONSIGNMENTS - Always a great selection of dairy cattle at Premier Livestock and Auctions! DRIVE-INS ARE ALWAYS WELCOME! PLEASE HAVE IN BY 9:30 AM TO BE INCLUDED IN THE DAIRY CATALOG DAIRY CATTLE AUCTION Wednesday, June 12, 2024 at 11:00 am See our website for updates! www.premierlivesockandauctions.com COMPLETE HERD DISPERSAL 46 High Quality Holstein Dairy Cows, RHA 24314#, averaging 75#. Cows will sell on of cial test. Many top cows 90-120# 4.2F 3.3P 129SCC. AI over 35

All forages are not created equally for ensiling

By Wayne Coblentz U.S. Dairy Forage Research Center (retired)

This article is reprinted with permission from the Midwest Forage Association.

As the last vestiges of winter drift into memory, forage farmers increasingly turn their attention to looming eldwork, which includes production of late-spring and early-summer silages. With that in mind, it is important to remember all forages are not created equally with respect to silage fermentation. Two key forage characteristics that can greatly affect silage fermentation are concentrations of plant sugars or watersoluble carbohydrates (WSC) and buffering capacity (BC).

Concentrations of WSC are a critically important component of silage fermentation because they serve as the substrate for production of various fermentation acids that reduce silage pH, thereby imparting a measure of stability to the silage. The two primary fermentation acids produced are acetic and lactic, of which lactic acid is generally considered most desirable because it is the strongest fermentation acid and most effective at depressing silage pH. In simplest terms, BC can be dened as the forage’s inherent or natural resistance to pH change; normally, it is measured in the laboratory as the milliequivalents of acid required to reduce forage pH from 6.0 to 4.0. Much of the difference in BC between forages is related to naturally occurring organic acids, their salts, and to a lesser degree, plant proteins. To some extent, these two forage characteristics work against each other with respect to a desirable fermentation that includes strong acidication of the silage. Adequate WSC are required for production of fermentation acids, but highly buffered crops are more resistant to the desired pH change.

Water-soluble carbohydrates. Many factors contribute to the wide variability

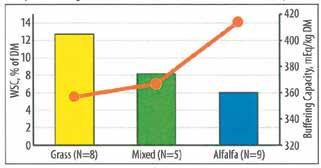

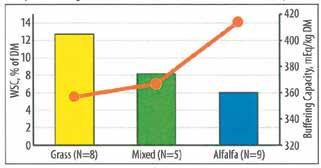

in concentrations of WSC within silage crops, which can vary from about 5-20%. Forage species is a major factor, and a general ranking of crops common to the north-central U.S. in order from highest to lowest would be corn, forage sorghums, cool-season grasses (annual or perennial), alfalfa or other legumes. Although not typically grown in the north-central U.S., most warm-season perennials (e.g., bermudagrass) are not notoriously low in WSC, making them difcult to ensile because of inadequate substrate for fermentation. Unfortunately, this problem also occurs to a lesser degree with alfalfa, which typically exhibits concentrations of WSC between 5-7%. To visualize the effects of plant species on availability of substrate for fermentation, consider Figure 1, summarizing the average WSC concentrations measured from: i) cool-season-grass monocultures (N=8); ii) mixed cool-season grass/alfalfa forages (N=5); and iii) alfalfa monocultures (N=9). These averages were obtained from University of Wisconsin Marsheld Agricultural Research Station silage studies over the last 20 years. The mixed-species forages ranged from 48-82% alfalfa, with an overall average of around 64%. Two points should be immediately obvious from this gure: i) average concentrations of WSC in cool-season grasses were more than twice those of alfalfa (12.7 versus 6.0%); and ii) WSC in the mixed-species forages were intermediate (8.2%) between the monocultures but were consistent with greater proportions of alfalfa within the mixtures. On this basis alone, it should be clear that cool-season grasses have clear advantages over alfalfa with respect to adequacy of substrate for fermentation. Other factors also affect concentrations of WSC in forages. Some of these include stage of growth, time of day, climate, frost events, nitrogen fertilization, rainfall and poor or extended wilting conditions. Of these, the most problematic for spring

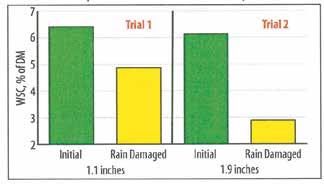

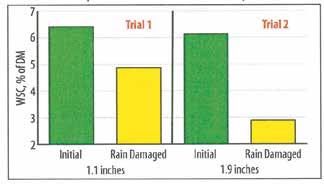

or early-summer silage harvests are the unfortunate effects of rain damage to mowed forages wilting in the eld. When this occurs, WSC are lost through direct leaching of sugars and by prolonged or extended respiration before these damaged forages can be wilted suitably for harvest. Rain damage is typically more severe as forages become drier and lose their cell functions. Rain damage effects to mowed/conditioned alfalfa forages wilting in the eld are presented in Figure 2 from two trials conducted at Marsheld, Wisconsin. In Trial 1, 1.1 inches of natural rainfall reduced WSC concentration from 6.4 to 4.9%. For Trial 2, 1.9 inches of natural rainfall that fell over an extended eight-day period reduced WSC available for fermentation from 6.1 to 2.9%. It is important to emphasize initial concentrations of WSC in alfalfa are marginal (at best) for supporting silage fermentation, and these rain-damaged forages were severely compromised by the noted losses.

GRAPH PROVIDED

Figure 1.Average concentra ons of WSC (bars) and BC (red line and markers) for monocultures and mixtures of cool-season grasses and alfalfa. Data were summarized from published silage studies conducted at Marsheld, WI, over the last 20 years.

served for cool-season grasses. Typically, BC is reduced as plants mature, and this has been documented for both cool-season grasses and alfalfa. For alfalfa, BC is much greater in the leaf compared to stem tissue, which contributes directly to the greater BC found in less mature forages.

Buffering capacity. A low BC is desirable for silage fermentation because it allows for an easier reduction of silage pH. A ranking of BC for commonly ensiled silage crops harvested throughout the north-central U.S. in order from highest to lowest would be alfalfa and other legumes, cool-season grasses, corn, where evaluations for legumes can exceed 500 mEq/ kg Dm, while corn can be less than 200 mEq/kg Dm. It should be clear that corn combines dual attributes of high WSC and low BC, making it the easiest crop to ensile and ferment properly. Conversely, the dual liabilities (marginal WSC, high BC) for alfalfa forages can be visualized by returning to Figure 1, where the average BC for alfalfa forages was 414 mEq/kg DM, which was considerably greater than ob-

GRAPH PROVIDED

Figure 2. Field losses of WSC from alfalfa a er two natutally occuring rainfall events at Marsheld, WI. [adapted from Coblentz and Muck (2012); J. Dairy Sci. 95:6635-6653].

Consequences. A primary concern when ensiling these damaged or disadvantaged forage crops occurs when they are ensiled at high moisture. Clostridia love high-moisture forage, and their secondary activity is highly undesirable, producing primary end products of butyric acid, ammonia and amines. A silage fermentation exhibiting a rapid and extensive pH decline inhibits clostridial activity. Baled silages may be more at risk because their fermentations are inherently restricted relative to precision-chopped silages due to their long-stem nature and often lower silage densities. Inoculants improving production of lactic acid may be helpful in preserving compromised or disadvantaged forage crops. Alternatively, clostridia do not ourish in dry silages and wilting to lower moisture concentrations in an effective technique for avoiding their undesirable secondary activity, but overall preservation then relies more heavily on oxygen exclusion.

Page 10 • Dairy Star • Second Section • Saturday, June 8, 2024

2015 Vermeer 504 Pro Baler $29,000 2020 Vermeer TE1710 Tedder $9,900 HAMMELL EQUIPMENT HAMMELL EQUIPMENT, INC. Thank you “DAIRY” much to all dairy producers! JUNE DAIRY MONTH: NEW H&S 3210 Rake Call for Price NEW H&S LW1100 Bale Wrapper Call for Price MINNESOTA HOLSTEIN ASSOCIATION Schedule: 12:00 PM - Arrival 12:30 PM - Welcome 1:00 PM - Judging Contest 1:45 PM - Lunch 2:30 PM - Youth Fitting Demonstration 3:00 PM - Speakers: Jenna Davis, and Sarah Schmidt 3:45 PM - Dessert & Raffle Hosted by: Tony & Katherine Kohls (612) 226-4180 Address: 40917 296th St, Arlington, MN, 55307 All are welcome to join this free event! Field Day Field Day Saturday, June 22nd, 2024 event!

Area Hay Auction Results

Small

Large Squares

$70-152.50/ton Mixed

$190-215/ton

$140-190/ton

$137.50/ton Straw

1st crop

2nd crop

3rd crop

4th crop

Grass

$117.50/ton

Large Rounds

$50-122.50/ton

$140/ton

$127.50-145/ton

$165/ton

$77.50-175/ton

$40-47.50/ton

BREAKFAST ON THE FARM

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 11

Fort Atkinson Hay Ft. Atkinson,

•

Squares 1st crop $145/ton 1 load 3rd crop $105/ton 1 load New seeding $110/ton 1 load Straw $140/ton 1 load

Iowa

563-534-7513 May 29, 18 loads Small

Grass

1 load Rounds

crop

Large Squares

$200/ton

1st

3 loads 2nd crop

7 loads 3rd crop

2 loads Grass $175/ton 1 load Rock Valley Hay Auction Co.

Valley, Iowa • 712-476-5541 May 30,

loads

$165-235/ton

Rock

58

Grass

Squares

$205/ton

2nd crop

$80-150/ton 3rd crop

Mixed $100/ton Corn stalks

@NDEcoTMR www.NDEco.com|888.336.3127 Builtto dairy better. BIGGERAUGERS. BIGGERPERFORMANCE.

NEXT DAIRY SALE Pipestone Livestock Auction Market, Inc. PIPESTONE, MN For more information phone: Office 507-825-3306 www.pipestonelivestock.com CLIP AND SAVE THURSDAY, JUNE 20, 2024 DAIRY SALE RESULTS FROM May 16, 2024 Top Springing Heifer - $2,950 OUR COMMISSION IS ONLY 2.5%! EVERY TUESDAY: 9 a.m. Slaughter Hogs • 11 a.m. Hay - Straw 12 noon Slaughter Cattle 1ST & 3RD WEDNESDAYS: 1 p.m. all classes sheep & goats 2ND & 4TH THURSDAYS: 11 a.m. Stock cows Baby & Started calves • Feeder Cattle 3RD THURSDAY: 9 a.m. Dairy Sale • Springers, Bred & Open Heifers • Breeding Bulls • Herd Dispersals SALE SCHEDULE The Northeast Iowa Dairy & Agriculture Foundation proudly supports dairy farmers. Celebrate National Dairy month and enjoy a wholesome breakfast with delicious dairy products. Discover Iowa’s Dairy Center with guided tram tours of the farm, inflatables, corn pools, educational booths and more! You won’t want to miss the fun! � iowadairycenter.com � nicc.edu/agscienceFollow Us. @iowadairycenter

Ourcontinuous ightingsystempicksup morefeed,providesthebestliftactionand maintainsasteady,uniformreintroduction offeedbackintothemix. ExperiencetheNDEcodi erence.

June 22 8 am - Noon Iowa’s Dairy Center 1527 Hwy. 150 S., Calmar BRING YOUR FAMILY TO THE ANNUAL Drum Up Some Business - ADVERTISE! CALL THE DAIRY STAR AT 320-352-6303 FOR MORE INFORMATION

Spotlighting Wisconsin cheese

“Top Chef” cooking show features state’s signature culinary ingredient

By Abby Wiedmeyer abby.w@dairystar.com

MADISON, Wis. — The “Top Chef” television show has gained popularity in the 20 seasons it has aired and now attracts more than 7 million viewers per episode. The competition-style cooking show is lmed in a new location for each episode. The 21st season, which is airing now, was lmed in Wisconsin, putting Wisconsin cheese in the spotlight of those millions of viewers.

Rachel Kerr is the senior director of experiential and brand marketing at Dairy Farmers of Wisconsin.

impact which is incredible.” Kerr had a close hand in bringing the show to Wisconsin. “Top Chef” sends their scouts to potential locations each year. The Wisconsin Department of Tourism brought Dairy Farmers of Wisconsin along with other agricultural groups, cheese makers and dairy farmers to meet with the show producers. They shared their stories and provided samples of their products to the producers before the producers solidied their decision to lm in Wisconsin.

“We are obviously trying to promote Wisconsin dairy products and Wisconsin cheese, and getting it in front of that foodie audience is hugely important to us,” Kerr said. “Every time “Top Chef” goes to a new location, they see a signicant increase in tourism interest, in people interested in the culinary products of that state. So it does have a huge

“Cheese and dairy are synonymous with Wisconsin,” Kerr said. “That’s no new news. But they were shocked to meet master cheese makers and understand the kind of innovation that is happening in the state. I think that helped not only show them that Wisconsin is a great culinary destination but kind of helped inspire them to create creative challenges around Wisconsin cheese and Wisconsin dairy.”

During the show, 15 aspiring chefs compete to win the

A endees of the Dairy Farmers of Wisconsin watch party gather April 4 for

cheese episode at The Sylvee in Madison, Wisconsin. The event included

makers, media and other industry professionals who came together to

and celebrate their featured products.

title of “Top Chef America”. The third episode this season featured a cheese challenge, where contestants were assigned a task to create a dish using Wisconsin cheese within a limited amount of time. Part of the challenge was to cook the dish for 100 people. The cheese makers whose products were featured were able to attend the lming along with a few members of the staff at Dairy Farmers of Wisconsin. Some of the cheeses featured in the show included Pleasant Ridge Reserve by Uplands Cheese; Merlot Bel-

McHale Balers

laVitano by Pam Hodgson of Sartori; Sancho Cruz, a Mexican-style Manchego by Door Artisan Cheese Company; Widmer Brick by Widmer’s Cheese Cellars; a 15-year aged Cheddar by Hook’s Cheese

Turn to TOP

Anderson Wrappers

Mega

Page 12 • Dairy Star • Second Section • Saturday, June 8, 2024 Call Us At (715) 223-3361 Or visit us on-line at www.cloverdaleequip.com N13835 County Rd. E - Curtiss, WI 54422 HOME OF THE CLOVERDALE MIXER

range

round balers

known throughout the world

durability, reliability, innovation

value for money.

Built to last and developed on some of the world’s most rugged terrain, the McHale

of

are

for

and

Heavy-duty

diameter Pick-up wet

hay Loading arm adj.

Walking tandem axle

tires

Cloverdale

Round Bale Carrier Self-Loading & Unloading

10 or 14 Bales Round bales up to 6’6”

or dry

for 4’ or 5’ bales

with flotation

need to

change

inline

Get Ready for Haying Season New & Used Available Equipment LLC Over 85 employees to serve you 24/7/365 and to keep your herd comfortable and pro table. We pride ourselves in great, respectful service every time we step onto your farm. We also

brands

milking

A DAIRY FARMER Dorchester, WI 715-654-5252 Spring Valley, WI 715-772-3201 West Salem, WI 608-633-6690 Mondovi, WI 715-926-5777 Mora, MN 320-703-9752 Pierz, MN 320-468-2494 St Charles, MN 507-932-4288 Wadena, MN 218-632-5416 Main: (715) 772-3201 advanceddairy@wwt.net Business Hours, all locations: Mon - Fri 8:00 am - 4:30 pm, Sat & Sun Closed Call For An Appointment - 24/7 Emergency Service Available from all locations

The multi-purpose Anderson’s wrappers are designed for round or square bales. No

get out of the cab anymore to select or

the wrapping configuration. Models include single bale wrappers or

wrappers for multiple bales.

service all

of

equipment. We’re here to help, just give a holler! THANK YOU FOR BEING

PHOTO PROVIDED BY DAIRY FARMERS OF WISCONSIN

the “Top Chef”

dairy farmers, cheese

watch the show

CHEF

Page

|

13

Rachel Kerr

his

Company Inc; and Marieke Gouda. Other cheeses featured during the rest of the season include Canela by Roth Cheese; Cheddar curds by Decatur Dairy; Dunbarton Blue Cheese by Roelli Cheese Haus; Glacier Gorgonzola by Carr Valley Cheese; Limburger by Chalet Cheese Coop; Mount Raclette by Alpinage Cheese; Oaxaca by Crave Brothers Farmstead Cheese LLC and Triple Creme Brie by Schroeder Kase.

Andy Hatch of Uplands Cheese said he has already seen an impact of being featured through increased sales.

“Our phone and website started blowing up right away,” Hatch said. “I really appreciated Top Chef’s focus on artisan producers because we are the companies (that are) too small to have our own marketing budget to buy that kind of attention.”

Hatch creates an artisan style cheese with milk from his own small herd of cows. The cheese is only produced during the spring, summer and fall while the cows are on fresh pasture. The cheese is then aged with a natural rind, which requires constant care and attention throughout the 9- 12-month process.

It is difcult to do on a large scale, Hatch said. He said what has been gained in the industry for the sake of efciency and scale sometimes sacrices or dilutes character. He said they are trying to make sure their cheese has as much of their farm’s character as possible.

near Dodgeville, Wis-

Dairy Farmers of Wisconsin gave Wisconsin cheesemakers the opportunity to submit their product to be featured in the show’s studio kitchen throughout the entire season of lming. Kerr said the top judge, Tom Colicchio, had great reviews.

“Although the cheese episode was certainly the pinnacle moment of the show, I had the chance to talk with Tom, who said they loved having the cheese on set and were always taking samples,” Kerr said. “It was really great to see people of that (prominence) talking about the products from Wisconsin.”

Dairy Farmers of Wisconsin hosted a watch party of the cheese episode at The Sylvee in Madison, where dairy farmers, cheese makers, media and other industry professionals gathered to watch the show and celebrate their featured products. Two contestants of the show were also in attendance — Michelle Wallace, who won the cheese challenge, and Dan Jacobs, who is a Milwaukee native. Pam Hodgson and Sam Crave attended the watch party to represent cheese making and participated in a round table conversation with the contestants.

“This was such a huge moment not just for Wisconsin but for the dairy industry,” Kerr said. “Putting Wisconsin cheese in front of millions of viewers nationwide and having it represented in a way that we always wanted it to be is truly an honor.”

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 13 45240 County Road 80 E • PERHAM MN 56573 218-346-3415 PerhamStockyards.com • CattleUSA.com Mitch Barthel Owner/Auctioneer 218-639-5228 Open Sundays Noon-8pm to Receive Stock • Complimentary Hay & Water Pens Provided SPECIAL ORGANIC CATTLE SALE & SPECIAL DAIRY SALE the LAST Monday of Every Month Copies of Organic Certificates must be provided at drop off. Organic Cows will sell before Conventional Cows • Professional Marketing • Catalog Cows for Breeding & Production Records • Mailing List to over 6,000 potential buyers • Website, Dairy Star, Radio Advertisements • Live Online thru CattleUSA Professional Auctioneers & Ringmen Many Years of Experience Selling Dairy Cattle FULL MARKET REPORT AVAILABLE AT WWW.PERHAMSTOCKYARDS.COM ORGANIC SLAUGHTER COWS EVANSVILLE MN 1 Hol Slaughter Cow 1420 183.00 C EVANSVILLE MN 1 BWF Slaughter Cow 1110 183.00 C EVANSVILLE MN 1 BWF Slaughter Cow 1330 183.00 C EVANSVILLE MN 1 BWF Slaughter Cow 1100 180.00 C EVANSVILLE MN 1 Hol Slaughter Cow 1200 180.00 C EVANSVILLE MN 1 Xbrd Slaughter Cow 1200 179.00 C EVANSVILLE MN 1 Xbrd Slaughter Cow 1100 178.00 C NEW YORK MILLS MN 1 Hol Slaughter Cow 1880 175.00 C NEW YORK MILLS MN 1 Hol Slaughter Cow 2000 172.00 C EVANSVILLE MN 1 BWF Slaughter Cow 1235 172.00 C NEW YORK MILLS MN 1 Hol Slaughter Cow 1530 171.00 C NEW YORK MILLS MN 1 Hol Slaughter Cow 1985 170.00 C NEW YORK MILLS MN 1 Slaughter Cow 1275 170.00 C MENAHGA MN 1 Hol Slaughter Cow 1130 170.00 C EVANSVILLE MN 1 Blk Slaughter Cow 990 169.00 C NEW YORK MILLS MN 1 Hol Slaughter Cow 1895 169.00 C SLAUGHTER COWS BATTLE LAKE MN 1 Blk Slaughter Cows 1025 167.50 C BATTLE LAKE MN 1 Blk Slaughter Cows 1065 167.50 C BATTLE LAKE MN 1 BWF Slaughter Cows 1050 162.00 C BATTLE LAKE MN 1 Blk Slaughter Cows 1105 157.50 C BATTLE LAKE MN 1 BWF Slaughter Cows 1150 153.00 C SWANVILLE MN 1 Blk Slaughter Cows 1060 150.00 C SEBEKA MN 34 Blk Slaughter Cows 1563 148.35 C BATTLE LAKE MN 1 BWF Slaughter Cows 1200 148.00 C BATTLE LAKE MN 1 BWF Slaughter Cows 1315 147.00 C BATTLE LAKE MN 1 Blk Slaughter Cows 1100 147.00 C SEBEKA MN 34 Blk Slaughter Cows 1499 146.75 C LAKE PARK MN 1 BWF Slaughter Cows 1570 145.00 C BATTLE LAKE MN 1 Blk Slaughter Cows 1245 145.00 C SEBEKA MN 1 Red Slaughter Cows 1215 145.00 C MARKET REPORT FOR MONDAY, MAY 27TH SALE DAIRY COWS MENAHGA MN 1 Hol Cow 1720 4,400.00 H MENAHGA MN 1 Hol Cow 1340 4,350.00 H MENAHGA MN 1 Hol Cow 1475 4,275.00 H MENAHGA MN 1 Hol Cow 1570 4,125.00 H MENAHGA MN 1 Hol Cow 1480 3,650.00 H MENAHGA MN 1 Hol Cow 1430 3,600.00 H MENAHGA MN 1 Hol Cow 1490 3,550.00 H MENAHGA MN 1 Hol Cow 1680 3,550.00 H MENAHGA MN 1 Hol Cow 1315 3,525.00 H MENAHGA MN 1 Hol Cow 1370 3,500.00 H MENAHGA MN 1 Hol Cow 1575 3,500.00 H MENAHGA MN 1 Hol Cow 1600 3,500.00 H CLITHERALL MN 1 Hol Cow 1255 3,500.00 H MENAHGA MN 1 Hol Cow 1345 3,400.00 H CLITHERALL MN 1 Hol Cow 1480 3,375.00 H MENAHGA MN 1 Hol Cow 1200 3,300.00 H MENAHGA MN 1 Hol Cow 1395 3,300.00 H MENAHGA MN 1 Hol Cow 1280 3,200.00 H MENAHGA MN 1 Hol Cow 1365 3,200.00 H MENAHGA MN 1 Hol Cow 1300 3,150.00 H MENAHGA MN 1 Hol Cow 1250 3,000.00 H MENAHGA MN 1 Hol Cow 1265 3,000.00 H MENAHGA MN 1 Hol Cow 1525 3,000.00 H CLITHERALL MN 1 RW Cow 1385 3,000.00 H MENAHGA MN 1 Hol Cow 1235 2,950.00 H MENAHGA MN 1 Hol Cow 1260 2,950.00 H MENAHGA MN 1 Hol Cow 1350 2,925.00 H MENAHGA MN 1 Hol Cow 1425 2,900.00 H CLITHERALL MN 1 RW Cow 1040 2,900.00 H MENAHGA MN 1 Hol Cow 1445 2,850.00 H MENAHGA MN 1 Hol Cow 1440 2,800.00 H MENAHGA MN 1 Hol Cow 1290 2,800.00 H Proud to be your Hometown Lumber Company since 1971! For all your Agricultural, Residential & Light Commercial needs: Planning/Drafting | New Construction | Updating | Portable Buildings Traditional Values. Continuing Excellence. Paynesville, MN | 320-243-7815 | BorkLumber.com 75 1945 AND COUNTING 2024 YEARS Friedrich’s Tire & Oil – Sauk Centre, MN • (320) 316-3701 Rule Tire & Auto – Willmar, MN • (320) 403-2783

Con nued from TOP CHEF | Page 12

PHOTO SUBMITTED

Hydrostatic & Hydraulic Repair Skidsteer Attachments For Sale 320-634-4360 www.stoens.com 16084 State Hwy. 29 • Glenwood, MN 56334 • Repair & Sales • Troubleshooting • Hose Assemblies • Design • Service Calls Toll Free 866-634-4360 How to make your cows disappear... Sell it in the classieds! 320-352-6303

Andy Hatch holds a wheel of cheese in

curing room

consin. Hatch is the cheesemaker behind Uplands Cheese, which was featured in the “Top Chef” cooking show this year.

Page 14 • Dairy Star • Second Section • Saturday, June 8, 2024 ‘11 H&S 5126 1 3/8 1000 PTO, 2600 Gals, 347 Cu Ft. $8,900 NEW H&S Bale Wrappers In Stock ‘21 Gehl V330 JS Ctrls, 72HP Dsl, 3300 Lift Cap, C/H/A, 2 Spd,1,224 hrs $53,900 Kuhn Knight SLC141 1 3/4 1000 PTO, 28L-26 Tires, 4100 Gals. $47,000 ‘19 Manitou MLT625-75H ELITE 75HP Dsl, 5500 Lift Cap, C/H/A, 2 Spd, 2,540 hrs $75,500 ‘17 Kuhn Primor 4270M 540 PTO, 6’ Bales $24,500 ‘21 Manitou 2700V NXT:2 H-Ctrls, 74HP Dsl, 3000 Lift Cap, C/H/A, 2 Spd,1,850 hrs. $47,700 ‘23 Kuhn Knight PS280 Accuspread Spinner Beater (Litter), Athne Scales- ISObus, Auto Chain Oiler $116,000 ‘18 Mustang 1650RT H/Ft Ctrls, 68HP Dsl, 2350 Lift Cap, C/H/A, 2 Spd, 975 hrs. $50,900 ‘22 H&S GM9117 135 Bu, 21” Mill w/ 66 Hammers, 8 Section Belt, Self Contained Hyds, Magnets, Variable Speed Intake Auger, 1 Screen (TBD), Digi Star 2500 Scale, Hyd Swing, 6’ Folding Unload Auger Ext - $55,500 ‘13 H&S 430 11L X 22.5 Truck Tires, Upper Beater, Endgate, T-67 Chain, 1000 And 540 PTO Options - $12,700 ‘13 Kuhn GMD600GII 540 PTO, 7’ 10” Cut $10,250 northlandfarmsystems.com The LW1100 In-LineBale Wrapper features a new EFI engine for fuel savings, and an updated hydraulic system for faster wrapping! HARVEST FASTER>>> Harvesting high-quality hay and forage is the focus of KUHN’s hay tool innovation. Our commitment is to help you gain a maximum return on investment by providing products known for performance, reliability, and longevity. Mowers Mergers Rotary Rakes Tedders Wheel Rakes tfn Les Kuehl Repair Service 30+ Years Experience No Emergency Charges--Ever! • Sealed silo parts & service • Best chains on the market • Used and rebuilt unloaders • Stainless steel roofs • Stainless steel conveyor chains 320-760-2909 Eve. 320-762-1827 YOUR CENTRAL MINNESOTA GOLIATH REPAIR SERVICE! • All parts needed to service your Goliath Unloaders Not af liated with the Harvestore brand Call for early maintenance specials WHO WILL YOU FIND IN OUR Business Directory? TO BE INCLUDED IN THE DAIRY STAR BUSINESS DIRECTORY CALL 320-352-6303 LOG ON TO: www.dairystarbusinessdirectory.com BULK OR BAG Wood Shavings S&S Wood Products 35335 Green Street | Independence, WI 54747 800-234-5893 | 715-985-3122

MARK KLAPHAKE/DAIRY

STAR

Greg Meyer rakes rst crop alfalfa together May 30 near Grove City, Minnesota. The Meyers have 17 acres of alfalfa.

Family tries to beat the rain

By Mark Klaphake mark.k@dairystar.com

GROVE CITY, Minn.—

When Patti, Greg and Nathan Meyer woke up May 30, they had one main goal in mind: Put up their rst-crop hay before it rained.

Nathan, who came back to the farm full time four years ago, and his parents milk 60 cows and farm around 120 acres near Grove City, Minnesota.

The Meyers were hoping to start baling May 28, but the hay wasn’t quite dry. That put a strong emphasis on securing it Thursday afternoon before the predicted rain rolled through later in the day.

“It’s stressful,” Greg said. “You have a nice crop out there, and you don’t want it to get rained on and then have it sit for two more days. That stuff bothers me. When we cut it, I didn’t think it was going to rain until Friday, and then the weather forecast changed.”

Having quality hay is a major goal for Greg.

“I don’t like feeding poor feed,” he said.

The Meyers’ focus was to do their lone eld of alfalfa,

A day in the life of the Meyers A in the life of the Meyers

a 17-acre eld rented from a neighbor.

Their other elds they plowed up last fall because they had over 200 bales of baleage to carry them over. They said they like baleage because it has helped raise their herd butterfat.

The day started out with each doing their daily morning chores. Nathan and Greg headed to the barn before 5:30 a.m., and by 6 a.m., Nathan was milking and Greg started feeding calves. They milk 60 cows in a 4-row tunnel ventilated sand-bedded tiestall barn.

They added two rows to the east of the current barn in 2016. They also have calf pens at the end of the oldest part of the barn.

A short time later, Patti helped with the calves. After milking, Greg and Nathan fed the cows and the 200 steers they raise. Some are housed in a hoop barn they built four years ago, and the others are housed at another site.

By 11:30 a.m., Greg drove his John Deere 70 to the eld to start raking rows together. Just 15 minutes later, Nathan was on his way to start round baling as rain clouds started to gather in the west.

“I was looking at my radar every 15 minutes, but (the rain) seemed to stay on the other side of Willmar all day,” Greg said.

By 2:30 p.m., Greg was done raking, and an hour later, Nathan had made the last round bale.

They promptly switched over to picking up the bales, hauling them a quarter mile home and getting them wrapped.

Patti and a neighbor helped Greg pick up 68 round bales

and transport them home, and Nathan went home and wrapped. They were done by 5 p.m.

“I was happy, just elated that it worked out,” Greg said.

“If we wouldn’t have gotten them moved, we could have picked them up Friday, but then we would have been tracking up the elds. It couldn’t have

worked out any better. It was a good crop.”

The urgency of getting the hay wrapped pushed chores back almost an hour, but for the Meyers, the delay was worth it. By 7:30 p.m., it started drizzling, and shortly after 8 p.m., it started to downpour.

Turn to MEYERS

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 15 CALL FOR A QUOTE TODAY 605.368.5221 OR VISIT US AT equipmentblades.com Loader Edges Grader Blades Snow Plow Blades Custom Edges Skid Steer Blades Box Scraper Dozer Blades Wear Steel

MARK KLAPHAKE/DAIRY STAR

Pa (from le ), Nathan and Greg Meyer stand in front of their hoop barn May 29 on their dairy near Grove City, Minnesota. The Meyers milk 60 cows and raise 200 steers.

| Page 16 LARGE SELECTION OF USED MOTORS ON HAND FROM 1-10 HP 105 County Rd. 10 • Albany, MN 320-845-4690 WWW.AMPSRS.COM New Winco 50 KW PTO unit ..................Call Winpower 25/15 PT2 w/trailer, powershaft, load cable ...........$1,600 GENERATORS We Sell and Service Generators! Each WINCO PTO generator is designed using the highest quality components and the best workmanship available. Baldor 5 HP .........................................................$450 Century 5 HP .......................................................$450 Leroy-Somer 3 HP ...............................................$350 (2) GE 7-1/2 HP ...................................................$550 DeLaval 7-1/2 HP ................................................$550 GE 1-1/2 Stirator motor .......................................$175 WE STOCK FRACTIONAL TO 10 HP SINGLE AND 3-PHASE MOTORS! • quick • dependable • nearly 40 years experience WE ALSO DO MOTOR REPAIR O New Winco 100 KW pto unit - Call

| Page 15

“I was smiling from ear to ear,” Greg said. “It doesn’t get any better than that. It was the perfect day.”

Greg’s introduction to the dairy industry came from his grandpa.

“I spent summers with him, and then when he sold his cows, I helped neighbors all the time,” Greg said.

After high school, he studied dairy management at Iowa Lakes Community College.

The Meyers rented a farm near Watkins for ve years before buying their current farm.

“I started with a pickup and tools and nothing else,” Greg said. “I like being here. I lived everywhere growing up.”

They have been living and

milking at their current location for 30 years.

“I enjoy milking cows,” Greg said. “I just wish it was more consistent with pay. It’s stressful.”

Turn to MEYERS | Page 16

Page 16 • Dairy Star • Second Section • Saturday, June 8, 2024 THANK YOU DAIRY FARMERS! Since 1958. WWW.CALEDONIAHAULERS.COM (507)725-9000 KP Rolls For JD & Dion pull-type chopper KP rolls & 5000 series self-propelled Call JnD Harvestor Shop 715-721-5361 For New Holland pull-type chopper KP rolls Call The Chopper Shop 715-223-8060 Free shipping when you purchase a set of rolls & bearings* Free shipping when you purchase a set of rolls & bearings* *Within the 48 states

MARK KLAPHAKE/DAIRY STAR

Nathan Meyer does maintenance on a bale wrapper May 29 near Grove City, Minnesota. The Meyers wrapped 68 bales a day later.

MARK KLAPHAKE/DAIRY STAR

Nathan Meyer ejects a round bale May 30 near the Meyers’ farm near Grove City, Minnesota. Nathan has been helping his parents full- me on the farm for four years.

EMILY BRETH/DAIRY STAR

Greg Meyer feeds calves in the morning May 30 at his farm near Grove City, Minnesota. Meyer and his son, Nathan, head to the barn before 5:30 a.m. to start chores.

MARK KLAPHAKE/DAIRY STAR

Con nued from MEYERS

Greg Meyer visits with his milk hauler, Brian Schwandt, May 29 near Grove City, Minnesota. The Meyers have been milking at their current loca on for nearly 30 years.

Feed Bin FINANCING PROGRAM

Greg and Patti’s other children all have ties to agriculture as well. Ben is a carpenter and helps construct ag buildings, Matt works for a crop farmer and a cabinet maker, and Maggie does quality assurance for Cady Cheese. A couple years back, she was a Princess Kay of the Milky Way nalist.

“All of my kids are in agriculture, which I am proud of,” Greg said.

Nathan worked off the farm for many years but still found time to do the morning and night milking.

“I really enjoy milking, and the eldwork is fun,” Nathan said. “There

is never a dull moment. It seems like you are always doing something different.”

Nathan’s future goals are to continue to work with his parents and someday take over.

“It’s good that we have someone who wants to take on the family business,” Patti said.

To do that, Nathan will have to weather the ups and downs that farming brings.

“It was a good day,” Greg said. “They are not all like that. You have to take the bad with the good.”

Dairy Star • Second Section • Saturday, June 8, 2024 • Page 17 Stand out from the herd. DAIRY ST R R 522 Sinclair Lewis Avenue, Sauk Centre, MN | 320-352-6303 | www.dairystar.com Professional Print, Website & Sign Solutions for Farms & Small Businesses Contact your area sales representative listed in First Section, page 2 to learn how our customized services can help your farm or business!

*At the end of the 12 months, interest rate converts to 4.00% for the next 12 months, and then standard variable rate until maturity BENSON · CLONTARF · DEGRAFF · MILAN · MURDOCK · SUNBURG SU INTEREST RATE FOR 12 MONTHS* 0% PROGRAM PURPOSE Provide customers with access to safer and more efficient storage solutions as costs of bags and delivery continue to rise. PROGRAM OVERVIEW Take advantage of low interest rates on feed storage bins and associated equipment while purchasing feed from GPC. Take advantage of interest free financing today! • GPC will provide a customized feed storage bin solution for your operation at a competitive cost. • All bins will be equipped with a monitoring system to help ensure that your animals never run out of feed. www.GlacialPlains.com • 320-843-3999 CAApril6-1B-MS * Offer subject to credit approval and program requirements EMILY BRETH/DAIRY STAR

Greg Meyer feeds hay to the steers housed off-sight in the morning May 30 near his farm by Grove City, Minnesota. The Meyers’ raise 200 steers.

EMILY BRETH/DAIRY STAR

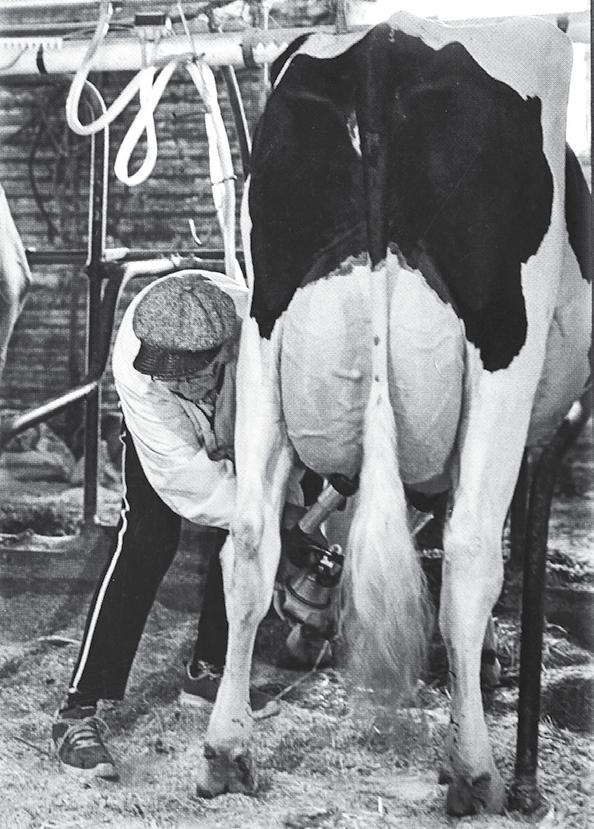

Nathan Meyer hooks up a milking unit May 30 at his parent’s farm near Grove City, Minnesota. Meyer returned to the farm four years ago.

Con�nued from MEYERS | Page 16

Big FFA win for New Vienna youth

Background in dairy inuences Hageman’s agriscience research

By Sherry Newell Contributing writer

NEW VIENNA, Iowa — The cows may be gone from the daily life of Libby Hageman, but her interest in dairy lives on through agriscience research as a Dyersville Beckman Catholic FFA member.

Hageman’s dairy-related work earned her rst place in Iowa FFA this year in the integrated systems division of agriscience research, and a nalist for star in agriscience.

The awards were presented at the Iowa State FFA Convention April 14-16 in Ames.

Hageman, of New Vienna, comes from a farm where her parents, Bob and Amy, milked 70 cows until two years ago. She continues to milk cows at the neighboring McAllister dairy.

But before the Hageman cows were sold, the soon-tobe high school senior began a research project addressing

a challenge on the family’s farm.

“I looked at scours in dairy calves and how bacteria on the bottles can affect the spread,” Hageman said. “We were struggling with that personally on our farm.”

Hageman’s research compared three cleaning methods for calf bottles: using a dishwasher, soaking in bleach and using hot water. She said the results surprised her.