By Emily Breth emily.b@star-pub.com

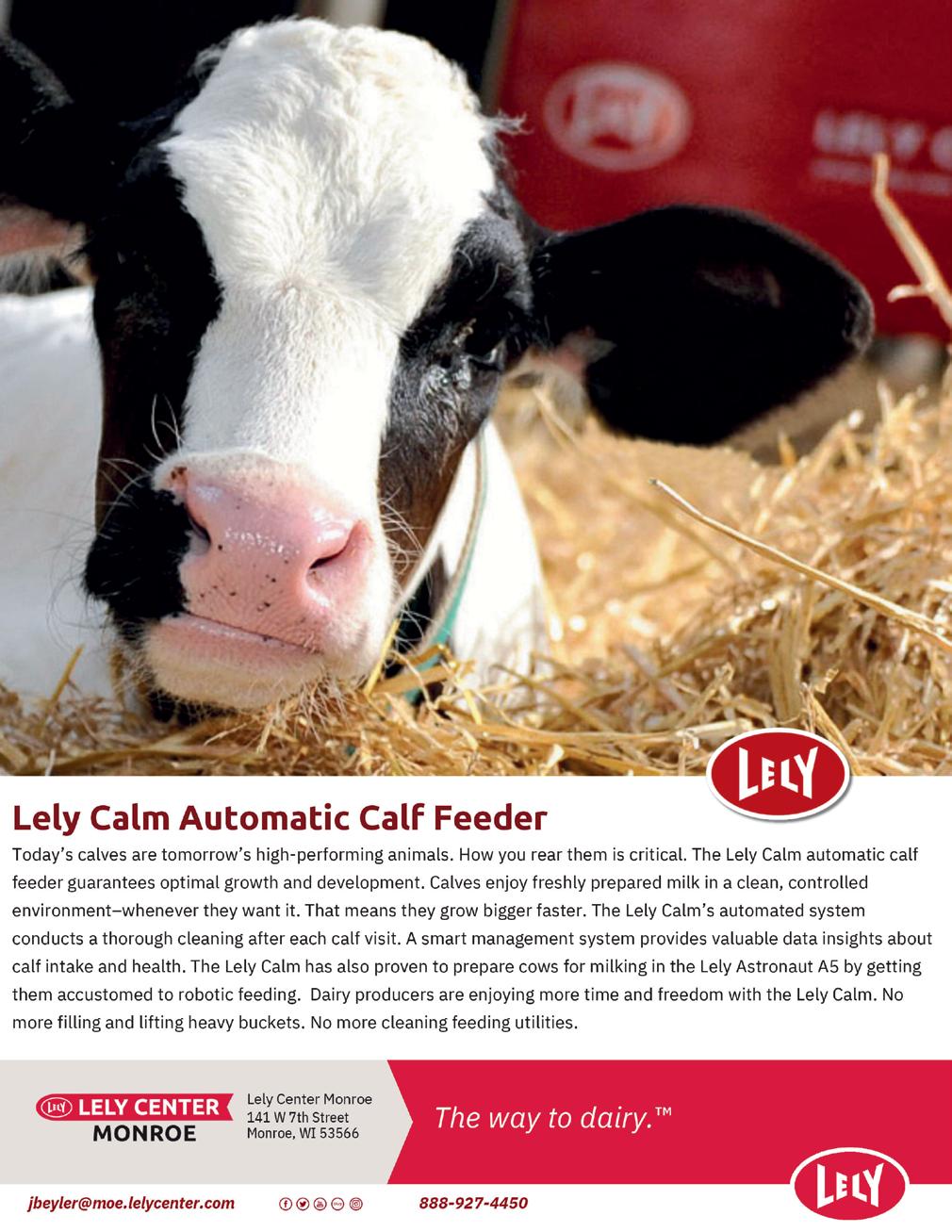

S.D. — When caring for newborn calves, the Moes family at MoDak Dairy Inc. takes the responsibility seriously.

MoDak Dairy is owned by Jim, Greg and Jacob Moes. Together with the help of other family and their team, the farm milks around 2,500 cows in a double-30 parlor. All the youngstock and steers are raised on the farm, as well.

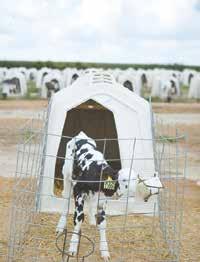

With the new calf barns in place, the mortality rate of the calves has dropped to well below 1/4%, Greg said. It is too low to calculate simply.

“Consistency is a big deal with animals,” Greg said. “(They do well when) they know when they are going to get fed, how much and that it’s not going to be too cold or hot (in the barn).”

Jacob (from le ), Greg and Jim Moes stand Oct. 15 in front of freshly chopped sorghum at their farm near

kota. MoDak Dairy Inc. is a 2,500-cow dairy.

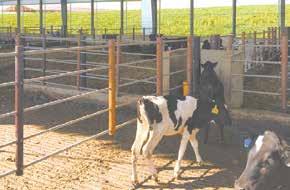

The barns are 100-by 150 feet with two separate rooms. Each room has 12 10- by 26-foot pens that hold nine calves each. The airow in each of the rooms is automatically controlled by tem-

perature. This feature helps the calves grow better in the winter, Greg said.

“They do gain better because they don’t take as much to keep warm,” he said.The series of vents in

the new barns are like those found in hog barns. Air is drawn in from the attic of the barn, circulated throughout the pens and then exits the barn through an exhaust chimney in the roof.

Greg also said he appreciates that the calves have access to clean food, water and bedding all day without someone having to make multiple trips a day. Turn to MOES | Page 2

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Nadiia Griepentrog • nadiia@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

The

One

Deadlines

Subscriptions

Letters

“We always make sure the calves are getting plenty of bedding,” Jacob said.

Though more bedding means the calf pens have to be cleaned more often, it is not a problem because the pens are easy to clean, Jacob said.

“We are able to put all the calves on one side and then go in with the skid loader and clean it in one go,” Jacob said. “Then we just have to bed it and repeat the process on the other side.”

Feeding the calves has also been easier since water and feed troughs are all located on one side of the pen and with the introduction of the Hateld system, which is a row of bottle slots with headlocks.

“(The calves) are pre-trained to go into the headlocks,” Greg said. “That is a side feature that you don’t think about.”

All the calves receive pasteurized milk until they are weaned. The milk is pasteurized in a separate building near the calf barns. Here there are wagons that hold 105 bottles.

The new system it allows the team to go down the row, drop the bottles and go. The barn being open also helps them catch if there is a calf acting abnormally.

In this setup, the dairy can utilize the all-in all-out method. A group of calves will remain together from when the last calf is added to the group until they are all weaned and combined with one or two other groups. After the barn is emptied, it is wash and sanitized before the next group of calves are moved in.

“With group housing, the calves are social,” Greg said.

Turn to MOES | Page 4

healthier.”

“One goes to eat and they all go to eat. We also do everything in groups like vaccinating, castrating and dehorning

since we have the headlocks there.”

Aside from the positives for calves, Jacob also said

“With group housing the calves are social. One goes to eat and they all go to eat. We also do everything in groups like vaccinating, castrating and dehorning since we have the headlocks there.”

GREG

EMILY

Calves stand in one of the new barns Oct. 15 at MoDak Dairy Inc. near Goodwin, South Dakota. The barns are 100-by-150 feet with two separate rooms with each room having 12 10- by 26-foot pens that hold nine calves.

A cart of bo les sits Oct. 15 at MoDak Dairy Inc.

are given pasteurized milk un l they are weaned.

there are multiple features about these barns that make it easier on the team. This is a big deal to the Moes family because they pride them-

selves on the longevity of their team and their welfare just as much as the calves.

“Welfare of the animals and the people, that is one

of the highlights of our mission,” Greg said. “Making sure everyone is taken care of is our rst priority.”

By Sarah Middendorf sarah.m@star-pub.com

Colostrum is important and can impact the calf’s overall health starting from day one. Providing cow care during the dry period can help maximize the immunoglobulins in colostrum for calves.

“There’s a huge nutritional component that comes in with colostrum,” Sandra Godden, DVM, said.

Godden is a professor for the Department of Veterinary Population Medicine at the University of Minnesota. She spoke during an I-29 Moo University dairy webinar series in August about colostrum management.

There can be many benets when achieving successful passive transfer. Some of these include reduced treatment and mortality rates, improved growth rates and feed efciency, decreased age at rst calving, and increased rst and second lactation milk.

“If it takes 5, 10 (or) 15 minutes to do a decent job delivering that rst colostrum feeding to the calf to

achieve success, it is 10 or 15 minutes that is well spent,” Godden said. “You are going to be paid back many times over.”

Passive absorption of Immunoglobulin G protects the calf in the rst weeks and months.

“We measure IgG, immunoglobulin G, as our primary marker of whether we’ve achieved this successful transfer of passive immunity,” Godden said.

Colostrum has about 24% or more total solids in it, Godden said. This gives the calf an extra level of fat and protein and certain vitamins and minerals.

“Colostrum just isn’t about those hundreds of antibodies,” Godden said. “There are hundreds of bioactive compounds, non-specic immune factors (and) growth factors, all of which work to drive development, immune regulation, gene regulation and so forth.”

Godden talked about the ve Qs of colostrum management. They are: quantifying passive transfer; quality and yield; quantity; quickness; and squeaky clean.

When quantifying, or monitoring, passive transfer, the level of IgGs can be measured indirectly on the farm. Godden said blood samples should be taken from 12 or more clinically normal calves that are 1-7 days old.

Turn to GODDEN | Page 7

There’s only one opportunity for successful transfer of passive immunity. First Day Formula® is simple, safe, and scientifically proven when used as a replacement for, or supplement to, low-quality maternal colostrum. Contact your Select Sires representative today to BUILDCALF A BETTER ®

From there, the serum will need to be separated and can be measured on a serum total protein refractometer. The goal is to have a 90% pass rate with a reading above 5.2 grams per deciliter. It can also be measured using a brix refractometer with a goal of 90% pass rate and a cut point of 8.4%.

“We have made dramatic improvements (in colostrum) across the industry,” Godden said.

The STP refractometer or the brix refractometer can also test the colostrum. The results can be used to monitor the herd level or calf level feeding. When monitoring the calf level feeding it can be used to decide whether it is fed to a heifer or bull, rst or second feeding, or enriched with colostrum supplement.

“If you want to be very accurate or concise you would test the composite sample from the whole bucket,” Godden said.

The goals set for maternal colostrum may be different than colostrum replacement.

“If you are measuring serum total proteins to monitor transfer passive immunity … the cut points that apply when we feed maternal colostrum don’t necessarily apply when you’re feeding a colostrum replacement product,” Godden said.

When colostrum is manufactured it is different than the maternal colostrum, so producers may need to have a different cut point than with maternal colostrum, Godden said. Producers can send samples to a lab to get IgGs measured directly.

Attention to cow care during pregnancy, and more specically, during the dry period, impacts colostrum quality and yield, Godden said. These include having a dry cow vaccination protocol, feeding dry cows a balanced diet, providing heat abatement, providing an appropriate dry period of 60-65 days and milking cows as soon as possible after they calve.

It is important to feed nutrient-rich colostrum to a newborn as soon as possible. This is when the calf can absorb IgGs the best. As the calf gets hours older, it starts a process called gut closure, a progressive loss of ability to absorb IgGs. Godden said it is believed to be done by 24 hours of age, meaning the ability to absorb IgG after 24 hours is low.

“What is important is that you get volume into the calf,” Godden said.

The goal is for the calf to get fed in less than 6-8 hours if unsupervised and 1-2 hours if supervised, Godden said.

“The truth is, it’s not a volume goal, it’s a dose goal,” Godden said. “How many grams of IgGs do we want to deliver to that baby.”

The minimum dose recommended by Godden is 150-200 grams of IgGs in the rst feeding. This can be administered by a bottle or an esophageal tube.

There are also many critical control points such as the cow’s udder and equipment used. There can be a correlation with feeding pathogens to calves, especially when they have an open gut. Being able to keep the cow and the equipment clean and free of pathogens can be important during this process.

“There is a signicant negative relationship, so the higher coliform counts in the colostrum, the less IgG is absorbed,” Godden said

Taking time to feed colostrum can benet and impact calf health, not just at birth but for weeks or months later.

“Colostrum is a cornerstone for successful calf rearing,” Godden said. “Decide if you are where you want to be. If you are, great. Go nd another bottleneck to x. If you’re not,we want to go back to the list of ‘Qs’ and determine where there are opportunities to make improvements.”

MELROSE, Minn. — When Ken Kerfeld’s son, Eric, joined the family farm, they decided to increase their herd and improve their facilities.

“We did some research, talked with Arnzen Construction Inc. and toured a couple of other barns in the area to determine what would be best for us,” Kerfeld said.

The Kerfelds currently milk 130 cows with two milking robots near

Melrose. They raise all their own replacements in a calf barn that was built in 2015 that is attached to the freestall barn.

The calf barn, which is a 32- by 64-foot facility, has tunnel ventilation, three exhaust fans on the south wall to aid in the winter, and a 4-foot fan on the east wall to help in the summertime. In the summer they also open the overhead doors on the north and west sides of the barn to allow for better airow, Kerfeld said.

“The biggest thing we have noticed is overall healthier calves,” Kerfeld said. “As cows they produce more than before too.”

Another feature that sets Kerfeld’s barn apart from most is the 14foot ceiling.

“The reason we have 14-foot ceilings is to match the freestall barn that it is connected to,” Kerfeld said. “Most wouldn’t recommend that, but I love it because I can get the skid loader in and out and clean the pens so easily. It also gets the dead air away from the calves.”

The calves have unlimited access to water and are fed a calf starter in addition to milk replacer from the automated calf feeder in the barn.

“(Calves) get fed more often this way,” Kerfeld said. With the automated calf feeder, Kerfeld said, the calves on average come up to drink six times a day consuming about a quart of milk replacer at a time.

“(When we rst looked into them) I thought it was a nice way to go,” Kerfeld said. “The biggest trick was getting the water the right temperature.”

Once a calf is born, it will spend a week in individual pens and then be moved to the rst section of the calf barn. After seven weeks, the calves are then moved to the second section of the calf barn, where they will remain until they are 4 months old. Each side of the calf barn can house 15-18 calves before it starts to get overcrowded.

“We keep (the baby

calves) separate for the rst week so they don’t suck on each other,” Kerfeld said.

“By then their immune system is up and running too. They also take to the calf feeder right away.”

To optimize calf health, the automated calf feeder gets cleaned twice a day and the nipple on the calf feeder every day. The Kerfelds clean out the calf barn once a

week, putting a large square bale of chopped wheat straw on each of the two sides, each week. The whole calf barn gets pressure washed three times a year and is allowed to fully dry out before calves are returned.

(Below) Calves lounge in their pens Oct.

By Elrosa Lumber Company

The DairyFeed J C400+, V600+ and V640+ calf feeders are professionally designed to support calf rearing at your agricultural operation. The automated feeders are computerized, giving you targeted control over all relevant data and enabling you to optimize daily nutrition for your calves from the day they are born.

BENEFITS:

• Using the calf feeders reduces your workload

• Calves grow healthily

• Suitable for any herd size: one to four drinking boxes with teats designed for calves

• Variable portion sizes as either powder or all-milk blends

• Quick and easy: Link the calf feeders using DairyPlan 21 software

Calf vaccines, antibiotics, milk replacers, colostrums, electrolytes, vitamins, ID tags, calf jackets, bottles and nipples & much more – all from popular brands you know.

Fight Bac for calf navels: Fight Bac’s antibacterial formula with chlorhexidine has been proven to be just as effective as 7% tincture of iodine, plus it’s more available and costs a lot less at only $0.08 per navel compared to $1.10 or more for navel dip. Fight Bac also is more convenient and less messy than using iodine in a dip cup (or paper cup). No gloves are needed, and there is no chance to spread infection. Dairy producers have benefited for decades from using Fight Bac on teats post milking. Now they also can benefit from using it on calf navels, cuts, wounds, injection sites, udder rot and to cleanse a teat prior to intramammary infusion. Put a can in every corner of your dairy.

smart way to disinfect teats and so much more.

A calf stands Oct. 30 in its pen at Ken Kerfeld’s dairy farm near Melrose, Minnesota. Calves are in this pen range from one to seven weeks old.

Kerfeld said they only lose 1-2 calves a year since building their calf barn. He has also noticed that since the calves are healthier, they can be bred sooner and can go into production around 23 months instead of 25-27 months.

Eric is the primary calf caretaker and has been in partnership with his dad since 2019. His daily routine includes checking the computer to see if any of the calves are under normal water intake, feeding calf starter and then heading to town for his off-farm job.

The Kerfelds rst started looking into upgrading their facilities in 2013, when Eric expressed interest in coming back to the home farm. In 2015, a freestall barn and the calf barn were built. The herd expanded from 65 cows to 130 cows, but they were still milked in the 65-cow tiestall barn until 2023 when two milking robots were installed.

Kerfeld said the farm has changed a lot since he started farming in 1995. But now it is set up well to bring in future generations. Even though the calf barn is nearly 10 years old, other farmers and groups stop in to view it.

“It seems like it does a great job,” Kerfeld said. “I wouldn’t go without it. Even the person I bought this farm from thought this barn was pretty neat.”

Calf raising can be fun times and also frustrating times and is one of the most important parts of a successful dairy operation. Those heifer calves are YOUR FUTURE!!! And those bull calves are someone else’s future. So protect them with RECAL CALF POWDER!!!

RECAL CALF POWDER is a probiotic focused toward putting huge numbers of good bacteria into the digestive tract of that calf to overwhelm the bad bacteria. To produce high levels of vitamin B-12 naturally in the calf which in return boosts appetite, immune system, aids in reducing stress levels and boosts energy levels for a more energetic, healthier calf that wants to eat and perform. This leads to more fun times raising calves with less drug costs. Now RECAL Calf Powder is no magic powder – good management and protocols still have to be in place.

Advantages to feeding

RECAL Calf Powder to Calves:

•More aggressive calves

•Calves that want to eat

•Less scours and use of drugs

•Healthier calves

•Calves go to eating grain and drinking water sooner

•Earlier weaning

•Calves transition better at weaning

•Better growth

By Danielle Nauman danielle.n@dairystar.com

ABBOTSFORD, Wis. — With the return to standard time in the rear-view mirror, the upper Midwest is preparing to descend into the long, cold winter months. During those colder days, dairy farmers must remain mindful of meeting the needs of the youngest residents of their farms.

Cold stress can impact the health, growth and overall performance of calves, who are the future of the dairy farm. Kim Ruescher, Ph.D., an assistant professor of animal science at Tennessee State University, shared some strategies for mitigating cold stress in a University of Wisconsin Extension program Oct. 31 in Abbotsford. She highlighted a novel approach that was the foundation of her graduate work with Dr. Jennifer Van Os at the University of Wisconsin-Madison.

“Cold stress affects most of us as farmers at some point,” Ruescher said. “There’s really no state in the U.S., that doesn’t have at least part of the state where a calf could experience cold stress for at least some portion of the winter, besides maybe

A map of the United States shows the average minimum temperatures across the

have an

age.

Florida and Louisiana.”

The impacts of cold stress on calves can be felt by dairies for years to come, in terms of decreased growth and increased morbidity, Ruescher said.

“Calves facing cold stress have increased maintenance requirements,” Ruescher said. “They have to eat a lot more to stay growing the same way as they would during temperature neutral times. They may have to even

double their intakes — that doesn’t mean they’re growing twice as fast, it means they’re using twice as much energy to keep warm.”

Calves suffering from cold stress have decreased average daily gains from their warm-weather peers. They also have decreased rectal temperatures, a reection of a decrease in core temperature. These factors lead to a decreased immune response in those calves.

Winter-time morbidity can increase to as many as half the calves suffering the effects of illness, compared to a much smaller number in warm months. Ruescher said mortality can increase to as many as a quarter of calves in really bad cases, because the increased demands on their systems can leave them depleted.

Ruescher explained that calves have a relatively small window of thermal neutrality, when their core body temperature remains stable. Within that range is an even smaller range of thermal comfort, where the animal is not responding behaviorally or physiologically to the environmental temperature.

“Once you get outside that thermal comfort zone, thermal neutrality is affected,” Ruescher said. “You can get into some dangerous areas for the calf if it’s not addressed.”

The lower end of the thermal neutral zone is what Ruescher called the lower critical temperature, where

the calf is going to have to begin expending extra energy to produce the body heat required to maintain her body temperature, allowing her less energy to put towards growing and developing.

For calves under three months of age, Ruescher said the LCT is between 46-50 degrees.

“That’s relatively warm, considering our adult cattle have a lower threshold,” Ruescher said. “This is because our calves don’t have a functional rumen, so they aren’t producing that rumenal body heat to keep themselves warm.”

Traditional methods of battling cold stress in calves include increasing nutrient intake through additional feedings or increased amounts at each feeding; providing deep straw bedding for nesting; and using calf jackets. Keeping calves dry and out of the wind plays a huge role in battling cold stress as well, Ruescher said.

A discussion with a dairy farmer about the benets of paired housing led Ruescher to become interested in the concept as another tool to mitigate cold stress. He noticed his paired calves did better during winter than those raised individually.

Research has shown the benets of paired housing in

terms of social, behavioral and cognitive development in calves.

“Calves are highly motivated to access a companion,” Ruescher said. “The social buffering helps them navigate new, stressful situations

“If calves could share body heat, that is less on each individual calf to stay warm,” Ruescher said. “That would leave a little more energy for them to put towards growth. The farmer also noticed the social facilitation. When one

“Calves facing cold stress have increased maintenance requirements. They have to eat a lot more to stay growing the same way as they would during temperature neutral times. They may have to even double their intakes — that doesn’t mean they’re growing twice as fast, it means they’re using twice as much energy to keep warm.”

KIM RUESCHER, PH.D., TENNESSEE STATE UNIVERSITY

like dehorning and weaning. Sharing space with another calf teaches them to interact in different situations and reduces neophobia. They learn and pick up on things faster.”

Based on her on-farm conversation, Ruescher set out to determine if social housing could help calves deal with cold stress.

calf would get up to eat, the other would, too.”

For the trial, Ruescher looked at 16 calves housed individually and 16 pairs of calves housed socially. Individual calves were raised in a standard hutch and fence setup, while the paired calves had two adjacent hutches and a shared outdoor fenced area.

The hutches provided 7.5 square feet of interior room.

During the trial, calves underwent a restriction process during weeks four, six and nine, coinciding with increases in milk and the weaning process. Twice daily, for two consecutive days, calves were closed into the hutches with a mesh gate for an hour at a time, to simulate if the calf had chosen to be in that hutch at that time. The pairs went into both hutches, one day as a pair and one as an individual to monitor changes in hutch temperature.

During week four, the increase in hutch temperature for paired calves was negligible, only increasing by a half-degree. However, by week six, the hutch with two calves increased by 5.5 degrees, compared to an increase in hutch temperature of 4.1 degrees for the individual calf.

“The individual is still warming that hutch but having that pair can really make an impact when thinking about thermal comfort,” Ruescher said. “Thermal neutrality is a very small space where calves are stable, grow the best and will be the most productive. Once we venture outside that zone, we’re going to have problems.”

By Stacey Smart stacey.s@dairystar.com

OSHKOSH, Neb. —

When a group of Wisconsin dairy farmers were looking for a place to send their heifers, they decided to pool resources and start their own custom facility. The rst heifer was unloaded at Oshkosh Heifer Development Oct. 14, 2014. Today, the farm houses nearly 22,000 head.

“Our core value is to do what’s right for the heifer no matter what,” said founding and managing partner, Marc Braun. “A lot of feed yards were trying to bring heifers out here, but they fed them too much. We, as dairymen, need to control this.”

Braun and his wife, Karen, and several partners milk 1,800 Jerseys at Evergreen Dairy near Antigo. Braun founded OHD with Jeff Betley of Betley Family Farms in Pulaski, Kurt and Anna Duxbury of Quantum Dairy in Weyauwega, Allen and Aaron Kutz of Kutz Dairy

in Jefferson, and nutritionist Bill Matzke of Matzke Dairy Consulting LLC in Oshkosh, Wisconsin.

“If we worked together in a cooperative spirit, we could try to get the scale of a larger operation to drive down the cost,” Braun said. “It’s hard for any individual to do. OHD had to stand on its own nancially while also being competitive.”

In the high desert of Nebraska near Oshkosh is where Braun and his business partners found the ideal location for their heifer enterprise. It was a place with plentiful crops and a temperate climate.

“We get all the snowmelt coming out of the Rocky Mountains and the Wyoming range, which feeds this valley with the water it needs for raising crops,” he said. “It’s the perfect environment for raising cattle.”

The Wisconsin-born heifers at OHD are thriving on open ground, open sand and an open manure pack, Braun said.

“Matzke is from Nebraska, and his deep relationships helped pave the way for OHD to land here,” Braun said.

Braun and his partners purchased the farm from the Jessen family.

New Vienna, IA

“We

Roll-O-Matic curtains last because we have them on other buildings, so it was an easy decision to choose them again for our calf barn. We like having the motors on the curtains for raising/lowering because it has made it easy to keep the barn at the correct temperature and keep out the

“Their patriarch passed away, and he had built a cattle empire out here,” Braun said.

The patriarch’s son, Terry Jessen, stayed on and put in capital to become a partner at OHD.

“Terry and his sister-inlaw, Gwen, helped us from day one to get started in the area,” Braun said. “The Jessens own a lot of land, and we worked together to get this going.”

As the business grew, OHD brought in additional partners. Dairy farmers Steve Abel of Abel Dairy Farms in Eden, Mike Theunis of Tinedale Farms in

Wrightstown, and Tom and Mike Gerrits of Country Aire Farms in Greenleaf joined the operation.

“We took it to the next level at that point and began a full expansion of new pens and a new feed yard,” Braun said.

Turn to OSHKOSH | Page 18

Andreas Heer and his sons of Norswiss Farms in Rice Lake came in as a nal partner following the expansion. Every owner sends their heifers to OHD.

“Heifers are a cost center, and we wanted to leave our resources in Wisconsin to grow our cow herds,” Braun said.

Heifers arrive between 4.5-5 months of age and leave when they are 7.5-8 months pregnant. Each week, anywhere from 10-17 semiloads of cattle enter or exit the farm.

Troy’s Transport has done 95% of the farm’s transportation from day one.

“Troy has been a vital partner in handling our logistics,” Braun said.

Heifers from the same farm are housed together for several weeks until it is certain they have landed on their feet and are healthy. Animals are then sorted regardless of owner into a tight day range into pens of 120 heifers that begin owing into the growing portion of the operation. OHD raises Holsteins and Jerseys, and heifers are also sorted by breed.

“By sorting them early with their cohorts, that whole pen is ready to start on synchronization for reproduction at the same time,” Braun said.

In addition to the partners’ heifers, the owners work closely with eight Wisconsin family dairies who are customers of OHD.

“Our customers are treated identically to us as owners and billed exactly like we are,” Braun said.

Once sorted by age, a heifer’s feed bill is calculated according to the average dry matter intake of the pen she is in.

“Instead of a at fee, we have a moving index of what the heifer is actually eating and where she’s at in terms of dry matter consumption,” Braun said.

Four inseminators breed in the yard and once conrmed pregnant, the back half of the yard is sorted into days-carried calf to help manage vaccines. Braun said 85% of heifers leave bred to sexed semen, while 4%-5% are bred to clean up Angus bulls. Braun and his partners manage a clean-up pen as an option for dairies, which Braun said everyone has opted into to save costs.

“We have a beef-on-dairy program as well, offering genetics from the bulls at our Angus ranch,” Braun said. “Through our partnership with Zoetis, we’re helping grow the beef-on-dairy industry.”

OHD is also home to about 4,000 head of Black Angus/Holstein-cross steers.

Another service OHD provides is the collective management of cull heifers. Heifers that were unable to conceive or aborted a calf are fed and marketed as a group for maximum value in the dairy beef chain.

OHD includes a new feed mill with two large stationary mixers, an ofce, a shop and a processing barn featuring long runs and hydraulic chutes for measuring, weighing and sorting cattle. Heifers are brought through that barn three times during their stay — upon receiving, at pre-breeding checkpoint and before heading home.

Two large, three-sided barns are used as receiving barns, providing protection from the elements for new arrivals. Once leaving this barn, heifers remain outside on open lots. They are fed a total mixed ration with roughage as the focus.

“Another one of our beliefs is to not limit feed,” Braun said. “We want these cattle to be at about a 1.9-pound gain per day. The key is to have them grown out without being fat.”

The total mixed ration consists of corn silage, triticale silage, millet silage, sorghum silage and a small amount of alfalfa haylage. Heifers are also fed wet distillers, wet beet pulp from a large sugar plant from September to March, and dry distillers to supplement the wet.

OHD puts up high-moisture corn and feeds dry corn. Braun said they add cornstalks or wheat straw to keep heifers full. In addition, the ration includes a small assortment of local byproducts that can be utilized in heifer diets. OHD grows about one-third of its forage and purchases the rest. Dry manure is hauled back to crop ground as well as composted.

The partners farm about 9,500 acres in Nebraska and have approximately 34 employees between OHD and the cropping side. Braun splits his time between Nebraska and Wisconsin — managing OHD as well as his dairy back home. Matzke is the farm’s nutritionist and is also on site periodically.

Braun said their goal for the future is to continue doing the best job possible for the heifer.

“We haven’t taken on new customers for a while because we’ve been full,” he said.

In the next ve years, Braun plans to remodel older pens and do a small addition to gain efciencies and handle growth from current customers.

“We want to grow with our owners to make sure we have space for their heifers,” he said. “We’re getting close to having the right amount of animals for this site’s footprint.”

• AG VENTURE FEED & SEED Watkins, MN • 320-764-9910

• HWY FEEDS Platteville, WI • 608-744-2444

• GALEN FLICK Boyden, IA • 712-439-1359

• SHELDON POWER & EQUIP. Sheldon, IA • 712-324-4455

• INWOOD HATCHERY Inwood, IA • 712-753-4736

• ROBERT FAUST Strawberry Point, IA • 563-933-6561

• DAIRYLAND SUPPLY Sauk Centre MN • 320-352-3987

• LINDELL SALES & SERVICE Cannon Falls, MN • 651-258-4311

• LEEDSTONE Melrose, MN • 800-996-3303

• SIOUX NATION VET SUPPLY Marshall, MN • 507-532-3716

• PIERZ CO-OP Pierz, MN • 320-468-6655

• RON MILLER Waconia, MN • 952-442-4808

• FLOODWOOD FARM & FEED Floodwood, MN • 218-476-2233

• BJERGA FEED Motley, MN • 218-352-6383

• FEDERATED CO-OPS Princeton, MN • 763-389-1567

• GORTER’S CLAY & DAIRY EQUIPMENT, INC. Pipestone, MN • 507-825-3271

• ADKINS EQUIPMENT Detroit Lakes, MN • 218-847-2079

• FARMER’S CO-OP Lafayette, MN • 507-228-8224

• NEW ULM FEED STORE New Ulm, MN •507-359-7500

• AGRI-TECH Watertown, SD • 605-882-7015 Brookings, SD • 605-692-0955

• GERTKEN’S SALES Richmond, MN • 320-597-2207

• GILMAN CO-OP CREAMERY Gilman, MN • 320-387-2770

Fiberglass freestalls offer a heightened level of comfort which can lead to an increase in milk production!

New additive in our paint now prevents & protects against the growth of mold & mildew.

• All Solid Rail Fencing that has a 20 year UV coating to prevent slivers, colors available

• Show Fencing & Pasture fencing

• Cattle Panels & Continuous Fencing

• 1" & 1-1/4" Electric Fence Post UV Protected

•13% Chrome Post for Head Locks & Feed Rail

• Guard Rail and Fiberglass posts.

• Lifetime warranty on our fiberglass products from rusting and rotting

“ We installed freestalls and gates from TJ Fencing after seeing how reasonably priced they are compared to other options. I will never install a steel post again either after using their posts which will never rust. I really like the products I have from TJ Fencing and plan to put more of their freestalls in my next barn.”

- KG4 Farms, Ridgeway IA

“If you are looking for satisfaction guaranteed call TJ’s Fencing. They are a great company to work with and have top notch customer service. We like how our new free stalls are hardy and sturdy but are also flexible”

- Adam and Drew Martins, Luana, IA

“These gates are very simple to take apart, like calf huts, only bigger. We put 1-3 calves in a pen, which gets them accustomed to group housing. Ventilation is better for the calves having an open pen.We are very happy with our investment in the gates.”

Top Deck Holsteins-Westgate, IA, Jason, Derek, Justin Decker

“Very easy to install, the fencing should last a lifetime and is very high quality. I would recommend it. My dad has had fencing from TJ’s in for over 16 years and it is still holding up like the day we installed it.”

- Jeff Novak, Highland, WI

“I have free stalls from TJ’s and love them! With my old steel stalls I was constantly repairing from the cows bending them. TJ’s stalls are very flexible and reasonably priced. I have saved a lot of time and money on repairs with TJ’s free stalls.”

Will Gerdes Caledonia, MN

“We have been supplying Glasfiber boxes for 10 years. Every customer is satisfied with this product and will definitely choose the glass fiber freestall again in the future. It is also a good fit for renovation projects. In addition, we also offer glass fiber fencing. The glass fiber is an excellent alternative to the iron barn equipment.”

Bertha Swaving, Holland, Netherlands