By

Tiffany Klaphake

tiff

any.k@dairystar.com

RAYMOND, Minn. — Aaron Zenner grew up on his parents’ dairy farm and often tinkered with wood to make toy farm machinery. Today, he has turned his hobby into a fulltime career.

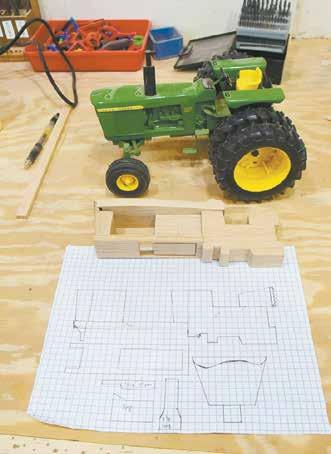

Zenner operates Wooden Wheels LLC out of his garage at his Raymond home, where he creates life-like 1/16-scale tractors, farm implements and semi-trucks, all from wood. To date, he has created 390 models that have been shipped to more than 30 states, Canada and several European countries.

“My customers are farmers and truckers; they are my kind of people,” Zenner said. “It’s really fun to see their reaction the rst time they see it. A lot of times it was their dad’s rst tractor or the truck that they drove for 30 years or something that means a lot to them.”

Zenner built his rst model nine years ago: a Peterbilt semi with a cattle trailer. That summer, he built another one. Then a friend asked Zenner to build a model of one of his trucks,

and he became Zenner’s rst customer. From there, Zenner got more orders, and in 2018, he created a Facebook page for his business.

“(The orders) just exploded since I created a Facebook page and I haven’t slowed down since then,” Zenner said. “I started out working for a farmer in the area and doing this on nights and weekends, then I got burnt out trying to do both.”

In 2022, Zenner stopped working at the farm to focus on his business. He still helps a local farmer out with spring planting and harvest each year.

“I spend about ve weeks a year traveling delivering my pieces,” Zenner said. “It is safer and easier to deliver them in person versus shipping them and I really enjoy seeing the country.”

About half of Zenner’s orders are for tractors and farm implements and the balance are semis. With the hundreds of models Zenner has created, he keeps a spreadsheet of what he has made, how long it took and where it went. On average, it takes him 32 hours to make a model. Some of the simpler, older model tractors take nine hours and combines take around 70 hours.

“I really enjoy the challenge of drawing up plans and guring out how to build a new

piece,” Zenner said. “My mind is always spinning, thinking of new ideas on how to do things. It can be frustrating at times but I really enjoy it because when each model is nished, it is all worth it.”

For the farm machinery pieces, Zenner purchases a toy model of the piece and uses that to get measurements. For some unique pieces, Zenner will take measurements in person and then scale them down.

“A couple of years ago, I drove down to Texas to measure a cotton harvester and took a lot of pictures, then came back here and drew it on graph paper,” Zenner said.

Once Zenner has the individual pieces drawn on paper, he selects the types of wood for each piece and starts cutting. Zenner primarily uses oak, maple and walnut for his models, but has 15 types of wood he purchases from all over the

world to bring his models to life. Each model has hundreds of individual pieces of wood. Some have over 1,000 individual pieces.

“I try not to stain any of the wood because I like to see the natural color show through,” Zenner said. “I can do purple, red, orange and yellow naturally. The only time I will dye

Turn to ZENNER | Page 4

something is if it is blue or green simply because wood does not come in those colors.”

Generally, Zenner’s models are xed and do not move, as some of the small pieces of wood can be fragile. However, the augers on his combines swing out, the spouts on his self-propelled choppers swing out and some parts on the semis extend.

“I have to balance out accuracy versus strength of the wood,” Zenner said. “There are times I can’t get it to do everything I want it to do, but I am getting better all the time, and it is neat to see my models get better each year.”

Zenner’s work is getting noticed by people from around the world. Every time he makes a Facebook post of a recent build, he receives more orders.

“The number of requests can get overwhelming,” Zenner said. “It’s so unique and every aspect is a challenge, but I enjoy it, so it is worth it. The hard-

est part is saying no to some requests. I would love to say yes to every order that comes in, but I am only one person.”

Zenner has even been contacted by CLAAS and other manufacturers and asked to make models for them to display. Over the years, Zenner has met farmers and truckers from all over and many of them have become repeat customers.

“I consider many of my customers as friends,” Zenner said. “I have gotten to know them so well during the process of building their model.”

When Zenner is not driving a tractor or building one, he serves as an emergency medical technician and a volunteer reghter.

“Like a lot of small towns, there’s not always many people who can respond to emergencies during the day,” Zenner said. “I feel fortunate to be able to drop what I’m doing and respond.”

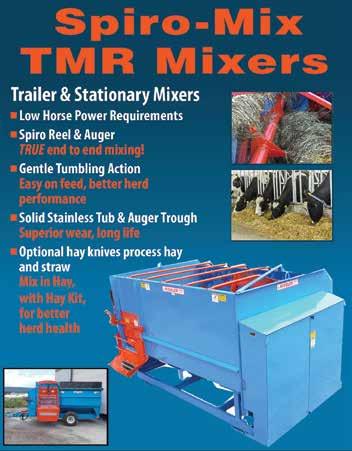

Keep your cattle happy & healthy with a great TMR mix. A Supreme vertical mixer is powerful, thorough & accurate, providing the best TMR mix on the market. Unlike other mixers, a Supreme is built to last, providing exceptionally accurate mixes throughout its entire life. With proper care & maintenance, a Supreme will offer the same great mix from the first cow to the last - Guaranteed.

TIFFANY KLAPHAKE/DAIRY STAR (Above) A model tractor and corn planter are showcased March 25 at Aaron Zenner’s home in Raymond, Minnesota. Each model has hundreds of individual pieces of wood, with the corn planter’s totaling about 1,200 to make it as realis c as possible.

(right) Hand-drawn pa ern pieces are laid out March 25 at Aaron Zenner’s home in Raymond, Minnesota. Zenner uses toy models to get measurements or measures the actual machine and scales it down.

A model Peterbilt and ca le trailer are displayed March 25 at Aaron Zenner’s home in Raymond, Minnesota. This is one of the rst pieces Zenner built.

The so-called “Liberation Day” came and went this week, a name given by President Trump to the implementation of reciprocal tariffs that apply to all trading nations, adding to recent tariffs on aluminum, steel and cars, plus all goods from China.

Lucas Fuess, Rabobank senior dairy analyst, speaking in the April 7 Dairy Radio Now broadcast, said Trump announced a 10% baseline tariff on all imports to the U.S. and would be in addition to previous tariffs. Custom, higher tariffs were also announced for the worst offenders, according to Fuess, which include about 60 countries, and they are designed to offset tariffs those countries levy on U.S. imports. They are in addition to actions already taken on countries like China, Canada and Mexico, he said, but we do not know how the countries will respond.

China announced that it would reciprocate with a 34% tariff on U.S. products and banned some American companies from doing business there. Trump’s tariffs have largely been delayed on goods that are compliant under the U.S., Mexico, Canada Free Trade Agreement.

As of Friday morning, Mexico had not announced any retaliatory action, but Fuess said the markets are watching this closely. Retaliatory action from countries like Southeast Asia, where we send a signicant amount of dairy exports, could have a big impact on the U.S. dairy industry. Exports are critical, he said, as 2024 saw the second-highest dairy export level ever on a value basis.

“Tariffs can be a useful tool for negotiating fairer terms of trade. To that end, we are glad to see the administration focusing on long-time barriers to trade that the European Union and India have imposed on our exports. The administration has rightly noted both countries’ penchants for restricting sales of American products,” said Gregg Doud, National Milk Producers Federation president and CEO, on behalf of the NMPF and the U.S. Dairy Export Council. “In fact, 20% reciprocal tariffs are a bargain for the EU considering the highly restrictive tariff and nontariff barriers the EU imposes on our dairy exporters. If Europe retaliates against the U.S., we encourage the administration to respond strongly by raising tariffs on European cheeses and butter. We also appreciate the president’s recognition of the sizable barriers facing U.S. exports into the Canadian market.”

“Through productive negotiations, this administration can help achieve a level playing eld for U.S. dairy producers by tackling the numerous tariff and nontariff trade barriers that bog down our exports,” Doud said. Speaking of exports, U.S. dairy exports were down in February, even when adjusted for leap year. However, HighGround Dairy reminds us that last February held the monthly record, and February 2025 ranks second.

On a 30-day adjusted basis, the month-to-month change was a plus 11.8%. “An increase is typical from January to February,” HGD said. “The 5-year average build between these months is 14%, meaning 2025 was close to the mean.”

Cheese exports surged to 99 million pounds, up 7.3% from a year ago, thanks to U.S. competitive pricing. Domestic cheese prices have trended below global benchmarks since late October, HGD said. Sales to Mexico fell 6% but were offset by increases to South Korea and Australia. Cheese imports were up 1.7%.

Butter exports, at 11.5 million pounds, were up

134.2%, while butter imports, at 12.7 million pounds, were down 2.1%.

Nonfat and skim milk powder exports remain subdued, amounting to 106.9 million pounds, down 25.7%, and dry whey hit 34.6 million pounds, up 3.2%.

The March Federal Order Class III milk price was announced at $18.62 per hundredweight, down $1.56 from February, $2.28 above March 2024 and matching the December 2024 price. The 3-month average stands at $19.71, up from $15.86 a year ago, and compares to $18.44 in 2023. Late Friday morning futures portend April at $17.02 and May at $16.87 with an $18.30 peak in October.

The March Class IV price is $18.21, down $1.69 from February, $1.88 below a year ago and the lowest Class IV since December 2024. Its 3-month average is at $19.61, down from $19.78 a year ago, and compares to $19.08 in 2023.

Chicago Mercantile Exchange cheddar block cheese climbed to $1.6650 per pound Wednesday, highest since March 14, but closed the rst Friday of April at $1.64, up a half-cent on the week and 12.50 cents above a year ago, as traders awaited the afternoon’s February dairy products report. The barrels hit $1.6975 Wednesday, highest since March 13, but nished Friday at $1.66, 2.50 cents higher and 13 cents above a year ago. There were 47 sales of block on the week and 16 of barrel.

Midwest cheesemakers said buying activity remains quiet, according to Dairy Market News, while others said ordering during the past two weeks underwent a bullish change, particularly compared to the rst two months of the year. Inventories continue to build. Milk availability grew noticeably this week, with mid-week prices as low as $4.50-under class. Cheese markets have found stability in the $1.60s, DMN said, but that concerns cheesemakers who are paying for relatively pricey milk and experiencing quieted cheese demand.

Seasonally strengthening milk output in the West is providing plenty for cheese manufacturers, and output is seasonally stronger. Availability of varietal cheese is mixed, with certain varieties heavily allocated to meet contractual obligations through the second quarter. Retail demand is steady to stronger. Food service is weaker, and export demand is mixed, though domestic prices are competitive with international levels, DMN said.

Cash butter closed Friday at $2.2950 per pound, down 5.50 cents and 64.50 cents below a year ago, on 28 sales on the week.

Central butter manufacturers said demand is still somewhat stable, even as holiday needs have generally been met. The focus now is on fall holiday demand. Cream availability is still ample, according to DMN.

Western cream also remains readily available; however, certain parts of the region report it has become a little less available, and “loads too inexpensive to pass up are no longer around,” DMN said. For the most part, churns continue to run at or near full capacity. Retail butter demand is steady to strong. Food service is weaker. Exports are steady to strong, thanks to competitive U.S. prices.

Grade A nonfat dry milk saw its Friday close at $1.1575 per pound, down a nickel on the week, but still 2.50 cents above a year ago on 12 sales for the week.

Dry whey closed the week at 49 cents per pound, down a penny on the week but a dime above a year ago, with six Chicago Mercantile Exchange sales put on the board for the week.

U.S. farmers say they will plant 95.3 million acres of corn this spring, according to the U.S. Department of Agriculture’s annual prospective plantings report. That would be an increase of 4.7 million acres or 5% from 2024 if they do. Planted acreage is expected to be up or unchanged in 40 of the 48 estimating states, according to the report.

Soybean plantings were at 83.5 million acres, down 4%. Planted acreage is down or unchanged in 23 of the 29 states. Wheat acreage would be down 2% and cotton acreage down 12%. Weather, politics, tariffs, input costs and crop prices could change farmers’ intentions before seed is put in the ground.

A sharp rise in corn, a higher soybean price and a lower all-milk price pulled the February milk feed price lower. The USDA’s latest ag prices report shows the ratio at 2.68, down from 2.82 in January, and it compares to 2.13 in February 2024.

The all-milk price averaged $23.60 per hundredweight with a 4.43% butterfat test, down 50 cents from January, which had a 4.46% test, and compares to $20.60 in February 2024, with a 4.30% test.

The national corn price averaged $4.58 per bushel, up 29 cents from January and 22 cents above a year ago. Soybeans averaged $10.20 per bushel, up 20 cents from January but $1.70 below a year ago. Alfalfa hay averaged $159 per ton, down $2 from January and $42 below a year ago.

The February average cull price for beef and dairy combined was at $135 per cwt., up $9 from January, $26 above February 2023 and $63.40 above the 2011 base average.

“Milk production margins moved lower for the second time in the past three months but remained at historically high levels and 75 cents per cwt. below January,” said dairy economist Bill Brooks of Stoneheart Consulting in Dearborn, Missouri. “Income over feed costs in February was above the $8 per cwt. level needed for steady to higher milk production for the 16th month in a row. Input prices were mostly higher with two of the three input commodities inside of the top 10 for February all-time. Feed costs were the ninth highest ever for the month of February and increased 25 cents from January.”

“Milk income over feed costs for 2025, using March 31 CME settling futures prices for milk, corn and soybeans, plus the Stoneheart forecast for alfalfa hay, are expected to be $13.24 per cwt., a loss of 21 cents per cwt. versus 2024. It would also be above the level needed to maintain or grow milk production and unchanged from last month’s estimate,” Brooks said.

The latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC said, “Dairy margins improved slightly over the last half of March as milk futures held steady while the feed markets continued to sell off.”

The MW detailed the latest milk production data and said that the report “showed expanding milk output in February, driven largely by an increasing dairy cow herd. Increasing component levels also added to production. February cream production increased by 12.7 million pounds or 4% above last year while milk protein production increased by 3.1% during the month and nonfat solids were 2.3% higher than February 2024.”

The USDA’s weekly slaughter report shows 52,500 dairy cows were sent to slaughter the week ending March 22, down 5,100 or 8.9% from a year ago. Year to date, 644,000 head had been culled, down 47,100 or 6.8% from a year ago.

Western United Dairies reports that, as of March 26, 274 California dairy herds were still under quarantine for bird u, according to Dr. Michael Payne of the University of California-Davis School of Veterinary Medicine.

“A larger number, 493 dairies, have been released,” Payne said. “No human cases have been reported since January, and our poultry farms are increasingly repopulating their ocks. Using FEMA’s (Federal Emergency Management Agency) terminology, we are starting to move past responding to the emergency to recovering from it.”

Skim milk powder led the April 1 Global Dairy Trade auction higher. The weighted average was up 1.1% after holding steady March 18. Volume fell to 38.9 million pounds, down from 43.1 million March 18 and the lowest since June 18, 2024. The average metric ton price, at $4,250 U.S., was up from $4,245.

Skim milk powder was up 5.9% after slipping 0.4% March 18. Whole milk powder, however, inched 0.1% lower after gaining 0.2% March 18. Buttermilk powder was down 5.6%, and lactose was down 2.6%. anhydrous milkfat was up 2.3% after dropping 1.8%, while butter was down 1.2%, following a 1.1% gain. Cheddar was up 1.7% after a 1.0% rise, while mozzarella dropped 4.0%, following a 5.1% gain last time.

StoneX says the GDT 80% butterfat butter price equates to $3.3643 per pound U.S., down 2.9 cents after rising 4 cents last time, and compares to CME butter, which closed Friday at a cheap $2.2950. GDT cheddar equated to $2.2763, up 1.9 cents, and compared to Friday’s CME block cheddar at a bargain $1.64. GDT skim milk powder averaged $1.3044 per pound, compared to $1.2379 last time. Whole milk powder averaged $1.8424 per pound, up from $1.8380 CME Grade A nonfat dry milk, closed Friday at $1.1575 per pound.

HighGround Dairy said that “Trump’s Liberation Day” was “adding to already turbulent trade discussions between the U.S. and other nations. Ongoing concerns around global trade disruptions, paired with generally tight milk supplies from the EU, have continued to support GDT commodity values. Meanwhile, the stronger milk ows previously seen out of New Zealand have eased signicantly, and current supplies are likely struggling to keep up with committed demand.”

In politics, the International Dairy Foods Association said, “A new dairy incentive program aimed at encouraging healthy behavior among people participating in the Supplemental Nutrition Assistance Program, or SNAP, is gaining bipartisan support in the U.S. House and Senate.”

“The Dairy Nutrition Incentive Program Act of 2025 seeks to address that 90% of Americans do not

consume enough milk and other nutritious dairy products, according to federal dietary guidelines,” the IDFA said. The legislation would provide SNAP participants with a dollar-for-dollar match for the purchase of milk, cheese, yogurt and cultured dairy products.

And, in a hearing Tuesday before the U.S. Senate Agriculture Committee, lawmakers, nutrition experts and school ofcials emphasized the need to restore whole and reduced-fat milk to federal school meal programs, according to the IDFA. The focus of the hearing was the Whole Milk for Healthy Kids Act, a bipartisan bill that would allow schools to offer these milk options. For more than a decade, federal regulations have restricted schools to offering only fat-free and low-fat milk, despite widespread under-consumption of dairy among children.

“Between 68% and 94% of school-age boys and girls are failing to meet the recommended levels of dairy intake, depriving them of essential nutrients during key developmental years,” the IDFA said.

Meanwhile, the U.S. Dairy Export Council, National Milk Producers Federation and Consortium for Common Food Names praised this week’s reintroduction of the Safeguarding American Food and Export Trade Yields Act. The legislation would direct USDA to partner with the U.S. Trade Representative to prioritize the protection of common names like “parmesan” and “bologna” in international trade negotiations.

Slow, gummy kernel processing for high-moisture corn is maddening. Leave those troubles behind with the amazing Horning shredder mill. Ridiculously fast. Consistently fine.

Holstein Dry Cow, due 5/27/25 to Slash. She’s All Things Red x White Out. Fancy young cow!

Registered Holstein Heifers Polled Max from 6 generations VG or EX Dams DOB September 2024 Unix x Doorman 2 yr old x 2nd gen. EX 96 Hazel cow family DOB August 2024 Red Altitude from 91pt Absolute Red x 92 pt Redliner and 4 more VG and EX high component dams. These are consigned by Ferdi Seewus, Sheldon Heifers

600 lb Lineback heifer Organic Cattle

15-month-old Holstein Bull Rex son, Polled , Proven, aAa 2641, out of a 8 lactation cow.

(2) 18 month old heifers.

Bulls (Expecting our usual run of 20 to 30 Bulls) Holstein DOB 10/8/23 Hancock x Dragonhart x Socrates, Proven and A2A2. 4th lactation records of 37037M 3.6F x 2.9P. Grand dam has 6 lactations of records of 24000 to 30000M. Marlin Horst, Curtiss. R&W Polled Holstein Bull, Proven, DOB 8/14/23 aAa 3125. Michael Martin, Loyal 16- month- old Ison P son, Proven breeder, fully vaccinated! David Lamar Ringler.

18 month old Red Lineback, Proven breeder. No papers. John Fisher, Darlington 1300 lb Holstein crossbred. Proven Breeder, Cary Schneider 800 lb Angus Semen sells at 11AM Sharp.

Lots of famous old bulls. If buying online please download and print this PDF and make your notations. Be prepared as bidding is fast paced. Register to bid at Cattle USA (6) Gold Chip 2431; (6) Atwood 3241; (9) Advent 3241; (11) Airlift (Sexed) 243; (4) Alligator (Stanton); (5) Boss Iron 315; (3) Blackstar 3451; (7)

By Stacey Smart stacey.s@dairystar.com

BLACK WOLF, Wis.

In 1922, a barn unlike any other in the area was built near the shores of Lake Winnebago. Located in the small town of Black Wolf near Oshkosh, the barn stood on a 400-acre property owned by the Fahrney family. An architectural masterpiece, the brick barn was part of Fahrnwald Farm, also known as Fahrney’s Woods or the E.C. Fahrney Farm.

The building featured a tile brick façade and four cupolas on its roof with matching twin silos erected on one end. The architect of the barn was Auler and Jensen, and the barn’s architectural style was considered Astylistic Utilitarian Building.

In 1918, two brothers from Chicago, E.C. and E.H. Fahrney, purchased the property where the barn now sits. E.C. Fahrney constructed a 30-room summer home on the estate. The Fahrneys made their fortune from the family’s production of Alpen Krauter, an old country doctor’s remedy said to cure a wide assortment of ailments. In 1930, Fahrney’s nephew — John Vette — inherited the property.

Turn to FAHRNWALD | Page 12

The iconic barn at Fahrnwald Farm stands beneath a cloudy sky April 1 near Black Wolf, Wisconsin. Built in 1922 near the shores of Lake Winnebago, the barn was once the home of Fahrnwald Farms Dairy, which bo led milk from their herd of 150 Guernsey cows for the Oshkosh area.

The barn was once the home of Fahrnwald Farms Dairy. The dairy bottled milk for the Oshkosh area and provided employment for 30 families. The dairy delivered milk directly to homes, stores, restaurants and hotels in glass bottles or cartons. At the time, the farm was home to a herd of 150 Guernsey cows.

A 1956 video explains how Fahrnwald Farms Dairy was on the cutting edge of producing and bottling milk. Staff were devoted to maintaining the highest quality standards and providing the best in animal care within a clean facility.

During this period, a young man named Paul Fowler was learning the ropes of dairy farming within the barn at Fahrnwald Farm. He was not from the area. Fowler, a New Jersey native, visited his grandfather’s farm every summer, which

The barn at Fahrnwald Farm was built in 1922 on a 400-acre property owned by the Fahrney family.

was down the road from the dairy.

“He loved helping his grandfather on the farm,” said Fowler’s daughter, Diane (Fowler) Scott. “My dad also worked at the Fahrnwald Dairy, and I think that’s where he learned a lot of his dairy science and how to care for animals.”

After graduating from Cornell University in 1959 with an agricultural engineering degree, Fowler worked at Merrill Lynch on Wall Street’s trade oor but soon realized it was not the life for him. In his heart, he wanted to be a dairy farmer, like his grandfather.

Fowler took over his grandfather’s farm and with his father, Titus, expanded the business to include two other farms down the road.

“My dad ran a Grade A dairy farm and was into registered cattle and

The architect of the barn was Auler and Jensen, and the barn’s architectural style was considered Astylistic Utilitarian Building.

doing record keeping and milk testing,” Scott said.

“He was doing cuttingedge stuff in the 60s.”

Fowler leased Fahrnwald Farm from John Vette from 1968 to approximately 1987.

“I was there all the time when I was a kid,” Scott said.

Scott rode her bike or motorcycle to the farm and sat on the fence and drew the cattle markings for registration.

“Fahrnwald Farm is a fascinating place with a rich history,” Scott said.

“When my family took over, the dairy business at Fahrnwald had been shuttered. We referred to it as ‘Farm Three.’ As kids, we thought it was a lot of fun. It was a fun place to explore with all the bottles and bottle caps and crates. It was cool stuff.”

to FAHRNWALD | Page 13

In 1930, E.C. Fahrney’s nephew — John Vette — inherited the property. Paul Fowler leased Fahrnwald Farm from John Vette from 1968 to approximately 1987.

Scott said the front of the barn contained ofces, the lab, and the bottling and shipping/receiving areas.

“I remember crawling around by all the equipment when we found these big tubes of bottle caps,” Scott said. “My dad let us keep them, and we were so excited. We later donated them to a local school to use as counters for math classes. It was like a treasure hunt if we found an old bottle, etc. There was a lot of equipment that we as kids had no idea what it was.”

Fowler hired a farm manager to run the farm, and that manager lived in the house located next to the barn. The herdsman and other farmhands lived in an apartment building be-tween the barn and house.

“The barn was phenomenal, especially for the time it was built,” Scott said. “It was beautiful.”

Scott went from exploring the barn

as a kid to working in it as an adult when she and her husband managed the farm from 1981-1984.

“Farming was tough, but it was incredible to work in a barn of that splendor,” Scott said. “You walked in and could see its beauty and the craftsmanship.”

Scott and her husband lived in the farmhouse and were employees of her dad.

“When you worked for one of my dad’s farms, you also got a house,” she said. “It was a great house, but it needed a lot of work, so I painted and wallpapered.”

The Fowler family milked 50–60 cows at Fahrnwald Farm. It was a stanchion barn containing 52 stalls. Bulls and heifers were housed across the street in the farm’s outbuildings.

“We had a mixture of registered and grade Holsteins, and I kept all the cattle records for the three farms,” Scott said. “My dad had a few Guernseys early on.”

Diane (Fowler) Scott and her husband managed the farm from 1981-1984, milking 50–60 Holsteins.

The barn was once the home of Fahrnwald Farms Dairy, which bottled milk for the Oshkosh area and provided employment for 30 families. The dairy delivered milk directly to homes, stores, restaurants and hotels in glass bottles or cartons and was home to a herd of 150 Guernsey cows.

Fowler ran a total of four farms, including a beef farm. Scott said her father was farming about 1,000 acres in the town of Black Wolf at his highest point, and Fahrnwald Farm was part of that acreage.

“After my husband and I left, I don’t remember if my dad lled that position or moved all the cattle to one of the other farms,” Scott said. “I’m guessing my dad would have loved to buy Fahrnwald Farm, but he couldn’t afford it.”

Down the road from the barn on 20 acres of the original Fahrney property, the grand home of E.C. Fahrney became the Jesuit Retreat House in 1961. Today, the barn at Fahrnwald Farm, although still a magnicent structure, appears to be empty. But if walls could talk, this historic barn would probably have much to say.

For the last year and a half, Wesley Martin had been building his farm from the ground up. He constructed a 101-stall freestall barn, a double-8 parallel parlor and an enclosed calf barn. The Martins began milking in their new facilities in January 2019. Previously, Martin worked with his father, Ernest Martin, at his dairy farm, holding partial ownership until 2018. At that time, Martin and his wife, Maria, were able to purchase 40 acres to build a home for the cows Martin owned but had housed at his dad’s place. After months of planning and building, the Martins had a farm to call their own.

When Charlie Sachs heard that the Plainview Milk Products Cooperative was left with 250,000 milk cartons due to school closings from the coronavirus pandemic, he had an idea. Sachs, a dairy farmer from Eyota, Minnesota, and a member of the Olmsted County American Dairy Association, helped team up the cooperative and association to donate the milk to Channel One Regional Food Bank in Rochester. The Plainview cooperative also donated milk to three additional food banks in the Twin Cities area.

Doug and Mary Behnke were in the process of transitioning their family farm to their daughter and son-in-law, Kellie and Ryan Zahn. The family milked 310 cows and farmed 1,000 acres near Clintonville, Wisconsin. Over the past four years, the Zahns had been earning equity in the cattle and gradually taking on more responsibility. Doug said Ryan and Kellie had earned over 100 head of cattle and he wanted them to own half the herd when he retired. The Behnkes and Zahns had met with lawyers and participated in farm transition workshops to nd a transition plan. Ryan also came from a dairy farm background, and he and Kellie had always intended to take over the farm.

Producers dump milk due to COVID-19

Dairy farmers across the country were being asked to dump milk due to the coronavirus pandemic. Farmers in Wisconsin were not exempt from this. Lisa Condon and her husband, Bob, started dumping milk April 1 at their 500-cow dairy near Horicon, Wisconsin. Condon said they were selected to dump milk because of their size and because they have a manure pit and direct ship with their own trucks.

years ago

Cows take a fresh drink

John Holtz knew his herd of 250 dairy cows and 200 beef cows were not producing as they should at his farm near Little Falls, Minnesota. He checked for stray voltage twice and upgraded his stalls but neither produced any results. Finally, Holtz checked his water quality and found the iron levels and manganese levels were higher than they should be. After installing a water treatment system, his cows started eating and producing better.

Gov. Mark Dayton had proposed a bill that required a 50-foot buffer zone on each side of a waterway, including rivers, streams and ditches, to reduce soil erosion, improve water quality and create wildlife habitat. Dairy farmer, Ken Schefers, who milks 75 cows near Paynesville, Minnesota, was concerned about this proposal. Schefers already had buffer strips in several areas on his farm, which totaled about eight acres of grassland. Increasing the buffer strip would have a major impact on Schefers’ farm. The bill had passed the House environmental committee, but had failed to get a hearing in the Senate agriculture committee.

Sellnow breathes life into Bertha, Minnesota, dairy

Bill Sellnow grew up on his parents’ hog and beef farm, but he preferred to go to his uncle’s dairy farm nearby to help out. After high school, Sellnow got a job in town for several years to save up money. Shortly after his parents sold their farm, Sellnow looked for a farm and found one with a double-6 parlor, 120-cow freestall barn and 340 acres for sale near Bertha, Minnesota. The farm had been sitting empty for the past four years and needed a lot of cleaning and xing. In March 2005, Sellnow was able milk cows at his farm.

David and Heidi Michels of Stacyville, Iowa, said March 30 started out like any other day until 2 p.m., when a storm came in. The winds picked up, and clouds started swirling, so they decided to grab their child and head to the basement in the house. However, shortly after entering the house, they heard the characteristic sound of a freight train and knew it was a tornado. As soon as it passed, neighbors started calling and showing up to help get cattle back in. A 36- by 70-foot shed used to house dry cows and heifers about a mile north of the house was destroyed along with a nearby 8- by 10-foot feed shed. The Michels said they would rebuild. None of the animals were harmed by the tornado or debris.

By Stacey Smart stacey.s@dairystar.com

LAKE GENEVA, Wis. — When Seth Loudenbeck and his dad, Steve, needed a better place to house the youngest members of their growing herd, they decided to build a nursery. Housing all their female kids under one roof since March 2024, the new nursery is giving these future does the best possible start.

“We kept milking more goats, and it got to be too much for the two of us,” Seth said. “We had more kids to take care of and needed a better, more efcient facility.”

Equipped with good ventilation and automatic feeding, the nursery has improved kid health and overall efciency at Loudenbeck Farms Dairy Goats LLC. Kids have unlimited access to milk replacer through an automatic feeder, helping the young goats to grow bigger, faster.

The Loudenbecks milk about 450 goats near Lake Geneva with plans to milk 700 by fall. Goats are milked twice a day in a double-14 parlor with 28 units. The Loudenbecks have a full-time employee who milks six days a week and one parttime employee who milks on Sunday afternoons.

“My dad and I milk Sunday morn-

ings,” Seth said. “That’s our opportunity to get our eyes on the goats a little more, and it is when we do a lot of our breeding protocols and dry offs.”

Seth’s uncle, Matt, also helps on the farm, which has been in the Loudenbeck family since 1950. The Loudenbecks milked cows until 2003 and began milking goats in 2013. The farm’s commercial herd is primarily Saanens and Alpines.

The Loudenbecks also have a small show herd of registered Nubians and registered Alpines.

Prior to building the nursery, kids were housed in various buildings, including the milking parlor. Growth of the herd and a desire to improve kid health were major motivators for building a nursery.

The nursery has also enabled the Loudenbecks to incorporate an automatic feed-er, which Seth said was a huge benet.

Previously, they fed a couple of hundred kids on nipple buckets. Now, kids start on bottles and are usually on the auto feeder before reaching 4 days old. The feeder can accommodate up to eight nipples — one for each pen. Seth said the 100% free-choice feeding system allows kids to drink as much as they want 24 hours per day.

“Each goat probably eats 6-10 times per day,” he said. “They’re eating 6-8 ounces multiple times daily now versus

At Stockman’s Supply in Zumbrota we have a large selection of Marweld Goat and Sheep products, ranging from Gates, Pens and Feeders to Treating Chutes and Spin Chutes. Stop by or call and speak with Dave in Zumbrota. We also ship to Albany, MN area. Charges apply.

20-25 ounces twice a day on a bucket. Five-week-old goats are drinking upwards of 150 ounces per day. They grow a lot faster on the auto feeder, and we get away with weaning them earlier than we did in the past.”

Goats are weaned around 7 weeks old. They are fed a starter pellet until 5 weeks of age before transitioning to a grower

An automa c feeder distributes milk replacer to kids in the

April

at Loudenbeck Farms Dairy Goats LLC near Lake Geneva,

The

was completed in March 2024 and can house up to 160 kids in eight pens.

textured grain mix.

The nursery also features in–oor heat, and Seth said they no longer need to use heat lamps because the kids are always warm.

Maintaining a stable temperature in the barn is important to the Loudenbecks. Two large ceiling fans run continuously for air circulation while exhaust fans on timers run 4-6 times per hour to pull in fresh air. If the temperature is above 53 degrees, the exhaust fans remain on. In the summer, the doors on each end are opened to achieve good airow.

“Ventilation is a key factor for kid health and an area we focused on when building this nursery,” Seth said.

Seth also attributes continuous access to milk as an important health contributor.

“The kids are much healthier,” he said. “They’re also quiet. I like that because it means they’re happy.”

A reduction in labor is another benet of the automatic feeder.

STACEY SMART/DAIRY STAR

Saanen goats spend me in their new barn April 3 at Loudenbeck Farms

Dairy Goats LLC near Lake Geneva, Wisconsin. The farm’s commercial herd contains primarily Saanens and Alpines.

“A couple hours spent managing and feeding kids is better than 4-6 hours feeding kids,” Seth said. “It’s a huge time saver, but it’s still a lot of work. I clean the auto feeder every morning, taking it apart to clean the hoses and nozzles. I’m also always on the lookout, making sure everyone looks like they are healthy and eating. Every morning, I start in the nursery where I spend a minimum of 1.5 hours.”

A well-lit space is another feature Seth said makes it easier to care for the kids.

“I wanted to make sure I could look at any pen and see what’s going on,” he said.

Built to accommodate future growth, the nursery is 26- by 64-feet long. Each pen can hold 15-20 kids. The Loudenbecks strive to keep numbers below the barn’s 160-kid capacity. Currently, the nursery has 70 kids. Pens are bedded with straw and pressure washed and sanitized between groups.

With the transition to the nursery, the Loudenbecks have shifted from a seasonal breeding schedule to a more spread-out kidding interval. Their goal is to breed and freshen 40-60 does per month.

“There will be no more big slam of kids, which will help keep the nursery at a lower capacity,” Seth said. “Kids do better when they’re not crowded. With this breeding schedule, we have a more consistent ow, and

things are easier to manage. This keeps the parlor consistent too in how we manage goats through it and results in consistent milk and a consistent milk check.”

Previously, when drying off half their herd in the fall, Seth said it was hard to justify a full-time milking employee.

“Consistency is the name of the game — in the nursery, the parlor and the dry pen,” he said. “We’re going to do as many extended lactations as possible. I like those.”

Simultaneous to building the nursery, the Loudenbecks built a new barn to house more milking does. The barn is home to 145 yearlings due to kid in May and June.

“That will be the last big bunch to freshen,” Seth said.

The Loudenbecks improved animal ow to and from the parlor with the building of the second barn, which measures 70 feet by 100 feet and has two 80-foot pens. The barn has capacity for 250 goats.

The move into the nursery coincided with the Loudenbecks installing DairyComp and moving to electronic ear tags.

“We try to make everything as efcient as we can, and DairyComp helped us improve our recordkeeping,” he said. “Now that we have our numbers where we want them, we are focusing on genetics and improving our herd.”

I farm with my dad, Kyle, my uncle, Kim, and my sister, Ali. I am the fourth-generation on this farm. We milk 120 cows with two robots. We farm 1,000 acres of land and raise corn, soybeans and alfalfa. This year we will have 500 acres of corn, 300 acres of alfalfa and 200 acres of soybeans. We planted 80-100 acres of new seeding last year, so we don’t plan to do any this year. We have a clay loam soil. We had 6-8 inches of snow and 0.5 inch of rain from the storm last week. We still have snow standing. We are probably two weeks out from getting in the field.

I farm here with my parents, Roger and Bonnie, my sister, Kayla Asmus, and my brother, Justin. We milk 250 cows with four robots and farm 2,600 acres. This year we plan to plant 1,200 acres of corn, 1,000 acres of soybeans, 100 acres of oats and we have 300 acres of alfalfa. We got 8 inches of snow from the storm last week which is going away. The fields were tracking pretty good before that. We have sandy soil and some heavier clay, so our soil is all over the place. One section to the next is different. One-third of our ground is irrigated.

I farm with my dad, Mike, and grandfather, Julian. We have two full-time and one part-time employees that help on the farm. We milk 240 cows in a double-eight herringbone parlor. The cows are on a bedded pack and sawdust covered mattresses in the freestall barn. We have 330 acres of owned and rented ground that we farm. This year we plan to plant 165 acres of corn for silage, 30 acres of soybeans to roast, and 135 acres of annual forage cocktail mix that includes BMR pearl millet, dwarf sorghum sedan, clover and brassica. The fields are drying up from the 3 inches of rain we had last week. I expect we will see some small grain planted in the next two weeks.

I farm here with my wife, Kim, daughter, Samantha, grandson, Tyler, and great nephew, Jeric. We milk 90 cows in a tie-stall barn. I grew up on this farm. We started buying mom out in 1991 and in 2004 we bought the farm. We farm 750 acres and we plan to plant 160 acres of corn, 70 acres of oats underseeded with alfalfa, and 10 acres of soybeans. We currently have 300 acres of pre-existing alfalfa and the rest is grass. We have a couple inches of snow on the ground and should be in the field by the end of the month.

I am the fifth generation on my family’s farm. I have been farming fulltime alongside my family for three years. We farm about 1,400 acres, 550 of which goes to our milking herd. We are growing corn, soybeans, alfalfa, peas, sweetcorn and oats. Myself, my brother, Tim, and my dad, Ed, crop farm alongside my uncle, Bill. My brother, my dad and I milk 300 cows with four DeLaval robotic milking units. Our cows are housed in sand-bedded free stalls.

I farm here with my brother, Brian, and we milk 550 cows in a double-12 parlor. This is the home farm and is a century farm that was established in 1901. We farm about 745 acres — 545 acres of corn and 200 acres of fifthyear alfalfa. We have a combination of a lot of different soils. We have hills, sandy spots, and black soil. We don’t have rocks. We pumped the pit March 27 and have been hauling solids on the cold mornings and covering it as we can. We have had 2 inches of moisture since March 29.

We own two separate dairies in Atkins, Iowa. Our main farm is Schanbacher Acres where we milk 180 cows. Our other dairy is the Atkins Raw Milk Dairy, located just down the road. There we milk five cows for our farm to table store. My wife Barb, along with my parents, Allan and Joyce are as involved as they can be and we have four full-time employees. We have 900 acres total, but 800 are tillable. Our intention is to plant 315 acres of corn, 330 acres of soybeans and the remaining 140 acres will be alfalfa. We have a sandy loam soil profile. By the end of this week, I’m hoping to have our preplanting spring herbicide application finished, weather permitting.

We milk around farm about 800 acres of land, owned and rented. Our soil is primarily silt loam. We are planning on planting about 600 acres of corn. Everything we use is either Roundup Ready or triple-stack. We farm about 150 acres of alfalfa and 50 acres of grass hay. We plan to seed down about 50 acres this year. We are not planning on trying anything new with our cropping this year. Everything is in pretty good shape right now, and, if the weather cooperates, we are hoping to start hauling manure in two weeks.

We crop about 500 acres, 450 owned and 50 rented. We plant about 220 acres of corn for grain and silage, 80 acres of soybeans, and usually about 25 acres of oats, peas and alfalfa new seeding. We farm mostly heavy soils with our best soils being silt loam. We have some sandy loam ridges and some poorly drained lower ground, which we are working to improve with tile. We are probably on the dry side compared to what we usually have this time of year, but not extremely dry. We still have plenty of cold weather in the forecast, so we are in no hurry to get in the fields for anything other than manure hauling.

I farm with my parents Larry and Sherry Nelson and my brother, Andrew, where we milk 240 cows. We have about 1,700 acres that we’ll plant, roughly 850 of that will be corn, 350-400 will be soybeans and the remainder will be alfalfa. We have about 20 acres of winter wheat that we’ll be harvesting before we plant the rest. Most of our soil is lighter, but not complete sand with some rented ridge ground that is heavier clay. Our hope is to plant soybeans next week, but that’s weather dependent. April 25th is kind of our target date to start planting corn, depending on temperatures and conditions. We started seeding alfalfa this past week.

Silo Lake Lillian, MN 320-664-4171

Hartung Sales & Service Freeport, MN 320-836-2697

Melrose Imp. Melrose, MN 320-256-4253 Anibas Silo & Eq. Arkansaw, WI 715-285-5317

Brubacker Ag Equipment LLC Curtiss, WI Edgar, WI Bagley, WI 715-613-7308

I farm with my wife, Dawn; our son, Alex, and his wife, Mattie; and granddaughters, Ruth and Lucy. My parents, Tim and Sue, are retired but involved in some decision-making. We farm about 3,500 acres with about 1,500 acres of corn and 2,000 acres of alfalfa this year. Our soil is 50% sandy loam and 50% clay with silt loam on the lower ground. Our land is mostly flat. It has been quite wet in our area. We have been incorporating manure and are hoping to do alfalfa seeding around April 20. We usually plant corn around May 1. I think there is going to be plenty of moisture in the ground when planting. Even if it dries out, all the ponds and creeks are full.

I farm with my wife, Rachel, my parents, Joe and Lisa, and my brother, Kevin. We farm 2,100 acres — 850 acres of corn, 800 acres of soybeans, 400 acres of wheat and 50 acres of alfalfa. We try to run a 3-year rotation with wheat and do corn on corn to space out the soybean year. Our goal is to run soybean acres once every 3 years. We have everything from sandy loams to dense clay with small field sizes and rolling lands. We’ll plant new seeding anywhere from April 1-20, soybeans from April 20 to May 1 and corn around May 1. At the end of March, we did first-pass fertilization on wheat. We do a two-pass nitrogen application on wheat acres and do some spring pot ash.

www.mndhia.org

The Minnesota DHIA rolling herd average production yields in 2024 reached a new all-time high of 25,895 milk, 1,123 fat, and 853 protein pounds. Especially noteworthy is the record solids percentages, which were 4.34% for butterfat and 3.29% for protein. The SCC ended the year at an average of 195,000. The dollar value is weighted by the pay prices for these four components and was also a new record of $5,653. For 2024, the dollar value formula saw a major increase in the value of butterfat relative to protein.

The 2024 Dollar Value formula is: (0.0150 x milk pounds) + (3.38 x fat pounds) + (1.68 x protein pounds) + [(350SCC/1000) x 0.00090 x (milk pounds/100)]

Below are the highest-ranking herds within each county afliate, alphabetically by county and herd owner. Congratulations to all!

Loretta Franke Layfayette, MN 507-920-9535 2

Everyone claims to be Irish on St. Patrick’s Day, so why can’t we claim any day to be an Irish Meal Day? Works for me, but I’m an Irish girl through and through, so every day is a day to celebrate being Irish. It may seem strange to start with the dessert recipe rst, but it will take a bit longer to make to serve with your meal. You can sip on the Irish Cream while you work on the main dish. Enjoy!

Grasshopper bars

Filling:

1/2 cup milk

3 cups mini marshmallows

2 tablespoons butter, cut into small pieces

2 tablespoons heavy cream

2 teaspoons peppermint extract

1 teaspoon vanilla extract

6-8 drops green food coloring

1 cup heavy cream

In a medium saucepan, heat milk on medium until hot. Add marshmallows and butter and stir to melt. Remove from heat; stir in 2 tablespoons heavy cream, extracts and food coloring; let cool to room temperature, about one hour.

Once marshmallow mixture is cool, using an electric mixer, beat remaining 1 cup cream until stiff peaks form. Fold spoonfuls of cream into marshmallow mixture to loosen, then fold in remaining cream and spread on top of chilled crust. Refrigerate until set, at least 30 minutes.

Food columnist, Natalie Schmitt

Crust:

34 chocolate wafer cookies

6 tablespoons butter, melted

While lling cools, line 9-inch square baking pan with parchment paper, leaving a 2-inch overhang on two sides. In a food processor, pulse cookies to form ne crumbs. Add butter and pulse to combine. Press evenly into bottom of prepared pan and refrigerate.

Topping: 3/4 cup heavy cream

6 ounces bittersweet chocolate, nely chopped

In a small pot, heat cream on medium heat until hot but not boiling. Remove from heat and add chocolate; let sit one minute, then stir until melted and smooth. Spread evenly over lling and refrigerate until set, at least 30 minutes or up to a day. When ready to serve, use overhangs to transfer to a cutting board and cut into pieces.

Irish cream

1 14-ounce can sweetened condensed milk

1 cup heavy cream

1 cup Irish whiskey (or 1 cup milk for non-alcoholic version)

2 tablespoons chocolate syrup

1 1/2 teaspoons instant coffee or espresso granules

1 teaspoon vanilla extract

1/2 teaspoon almond extract

Blend ingredients together. Store in mason jar or other bottle. Add to a splash of coffee. Pour over ice cream. Sip straight on the rocks.

Cottage pie

1 pound Yukon potatoes, peeled and cut into 2-inch pieces.

Kosher salt pepper

2 tablespoons butter, room temperature

2 tablespoons olive oil

1 large onion, chopped

2 carrots, peeled, cut into ¼-inch pieces

1 1/4 pounds hamburger

3 tablespoons tomato paste

1/4 teaspoon cinnamon

1/2 cup beef (lager or stout)

1/2 teaspoon beef bouillon 1/2 cup water

1/2 cup at parsley, chopped fresh thyme for topping

Put potatoes in medium saucepan. Cover with cold water. Bring to boil; add 2 teaspoons salt and reduce heat and simmer until tender (12-15 minutes). Reserve ½ cup cooking liquid. Drain potatoes and return to pot. Mash with butter, adding reserved cooking liquid (2 tablespoons at a time) to reach smooth mash texture.

While potatoes are cooking, add oil and onion to a 9-10-inch cast iron skillet (or other heat-tolerant pan). Cook, uncovered on medium heat three minutes. Add carrots and cook, covered, stirring occasionally, until veggies are just tender (5-6 minutes). Add beef and cook, breaking into small pieces, until it is no longer pink (3-5 minutes). Stir in tomato paste, cinnamon, ½ teaspoon salt and ½ teaspoon pepper. Cook one minute. Stir in beef, ½ cup water and then bouillon. Simmer until mixture is slightly thickened (about three minutes). Fold in parsley.

Preheat broiler. Spread mashed potatoes over beef and top with thyme if desired. Broil until golden brown (2-4 minutes).

As their four children pursue dairy careers off the family farm, Natalie and Mark Schmitt started an adventure of milking registered Holsteins just because they like good cows on their farm north of Rice, Minnesota.

Biscuit dough of your choice

1 8-ounce package cream cheese

3/4 cup salad dressing

1 pint sour cream

1 package Hidden Valley Ranch Dressing mix

Bake a thin layer of biscuit dough in a pizza pan or on a cookie sheet.

Let cool. Mix cream cheese, salad dressing, sour cream and Ranch mix.

Spread over biscuit crust. Top with vegetables of your choice: lettuce, cauliower, green pepper, onion, tomatoes, celery and shredded cheese.

3/4 cup butter

1 1/2 cups sugar

2 eggs

cake from the kitchen of Sarah Petersheim

1 cup mashed bananas

2 cups our, sifted

1 teaspoon baking soda

1/2 teaspoon salt

1/2 cup buttermilk

1 teaspoon vanilla 1/2 cup pecans

1 cup shredded coconut

Cream butter and sugar until uffy. Add eggs; beat together. Add bananas. Add our, soda and salt, alternating with buttermilk and vanilla. Beat well. Stir in nuts. Grease a 9- by 13-inch pan. Sprinkle batter with coconut. Bake at 350 degrees for 25-30 minutes.

1/2 cup butter

Topping:

1 1/2 cups sugar

1 egg

2 cups diced rhubarb

1 teaspoon salt

1 teaspoon baking soda

1 cup milk

3 cups our

1/2 cup brown sugar

2 tablespoons nuts

1 teaspoon vanilla

1/2 teaspoon cinnamon (optional)

Put dough in a mufn pan and then sprinkle with topping. Bake at 350 degrees until done.

Secure your tires and Secure Covers with us too!

“The Hanson Silo Bunker empowers us to control shrink loss. With our piles, we used to see lots of spoilage. But now we see very little, if any at all.”

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

• Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

• Modular design for easy installation