European Topping Magazine

A world of ham and pepperoni

A world of ham and pepperoni

The toppings of Tulip Professional go on millions of pizzas every year. We supply large international chains and industry customers, as well as small individual stores through our distributors. We are specialists in the production of pepperoni and ham products.

Innovation and product development are important to us. We always pay close attention to the consumer’s needs and trends in the market, and transform these into products and concepts that meet and excel the market requirements. The combination of high quality ingredients, ongoing development and our many years of experience ensure consistent good products every time.

Tulip Professional as part of Danish Crown is Europe’s largest pepperoni supplier. Our factories in Thorning and Svenstrup are experts in the production of pepperoni, and have a focus on foodservice and industrial customers. This enables them to produce large quantities in an effective manner, without compromising the quality and uniformity of the pepperoni.

All our pepperoni products start with a mince of raw materials. Our unique, high-quality recipes are constantly being monitored and analyzed in close cooperation with our customer to meet their demands.

The mince is then filled in casings and transferred to the fermentation room, which has a constant temperature of 24 degrees. Depending on the recipe, the pepperoni sticks will spend 2-3 days fermenting until they are ready for the drying process, which takes 2-5 weeks depending on the costumers wishes and the size of the sticks.

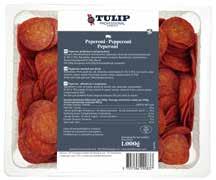

Finally, the pepperoni is peeled from the casings and ready to be packed as sticks or as sliced pepperoni in a frozen or cooled format.

Despite the large quantities, pepperoni production is still a craft to us. Therefore, every pepperoni stick is monitored in all processes by employees that are assisted by state-of-the-art technology.

Our pepperoni products are subject to strict quality controls before they are approved for sale, just as only world class food safety is good enough for us.

A world famous favorite and the biggest pizza topping in both USA and UK. Working well on all types of pizzas – ranging from deep pans to traditional pizzas – as the tasty protein topping.

A favorite for customers preferring a less spicy taste experience than with the classic pepperoni. Known especially from the German market.

Our halal pepperoni is made from beef and chicken and produced as a classic pepperoni. It carries the halal certficicate and is already sliced and packed, which makes it easy to handle and use.

In Dinklage, Germany, and Aalborg, Denmark, we produce our topping products with a focus on ham. The production is specialized on foodservice and industrial customers. We therefore are able to produce large quantities in a cost-effective way while focusing on the importance of consistent quality, uniformity, and world-class supply chain reliability.

From ham muscle to ham topping

Our production is fully automated and built for producing large batches in an effective manner. Every customer is different, and to us every type of ham topping is different as well. We take pride in the craft of delivering a product, that both we and our customer can be proud of.

Our raw materials primarily come from our own abattoirs in Danish Crown. From start to finish, our ham toppings are subject to strict quality controls as

we focus on delivering the highestquality food.

The raw material is cured with a brine mixture before it is filled into casings. Here, the product needs to rest for 24 hours before the ham is boiled and cooled down again.

Afterwards, the ham needs to rest a couple of days for the texture and taste to develop, before it is ready to be diced and packed either chilled or frozen.

The topping production is part of Danish Crown’s ambitious sustainability strategy, with the vision to becoming the world’s most sustainable meat producer by 2030 and achieving climate-neutral meat production by 2050.

We also have a strong commitment to CSR, as reflected in our compliance with 10 of the principles of the UN Global compact. These efforts ensure that we deliver safe, responsible and respectable products – both now and in the future.