Optimizing Energy Load for an 80 m2 space in Uttarakhand

21/22 ART041 Climate, Comfort and Energy MSc Sustainable Mega-Buildings

By Deepak K Sadhwani February 2022

1

Table of Contents Declaration Form……………………………………………………….…………………………………....…1 Table of Contents…………………………………………………….…………………………………....…...2 List of Figures………………………………………………………….…………………………....................3 1. Introduction………………………………………………………….………………………………….…….4 1.1. Climate and Weather of the chose location………….…………………………………………………4 1.2. The Forrest Essentials Factory Packaging Area……………………………………………………….5 1.3. Thermal envelope specification…………………………………………………………………………..6 1.4. Occupants and space utilization………………………………………………………………………….6 2. Literature………………………………………………………………………………………………………6 3. Methodology…………………………………………………………………………………………………..7 3.1. Weather data………………………………………………………………………………………………..7 3.2. Selection of building and space……………………………………………………………………………7 3.3. Calculation of Energy demand of the base case ………………………………………………………..7 4. Discussion……………………………………………………………………………………………………11 4.1. Current practice & implications…………………………………………………………………………..11 4.2. Best practice……………………………………………………………………………………………….12 5. Conclusions and limitations………………………………………………………………………………...13 5.1. Conclusions………………………………………………………………………………………………..13 5.2. Limitations………………………………………………………………………………………………….13 References……………………………………………………………………………………………………...14 Appendix A. Thermal transmittance values elements of thermal envelope………………………………15 Appendix B. Ventilation & Infiltration rate calculation……………………………………………………….16 Appendix C: Table B.8 of EN 16798-1:2019…………………………………………………………………16 Appendix D. Grasshopper - Ladybug Solar Radiation Definition………………………………………….16 Appendix E: Internal Comfort Temperature calculation for average & extreme conditions…………….17 Appendix F: Heat transfer through conduction………………………………………………………………18 Appendix G: Heat transfer through ventilation………………………………………………………………19 Appendix H: Heat gains through solar radiation…………………………………………………………….19 Appendix I: Solar factor selection……………………………………………………………………………..19 Appendix J: Internal heat gain…………………………………………………………………………………20 Appendix K: Base Case Heat transfer table…………………………………………………………………20 Appendix L: Best Case Heat transfer table………………………………………………………………….20 Appendix M: Best case U values……………………………………………………………………………..21

2

List of Figures

Figure 1. (a) Site location. …….……………….……………………….…...............................................…4 Figure 2. Extreme Weather data ………………………………….…………………………………..............4 Figure 3. Exploded Axonometric view of the workshop space.……………….………………………….....5 Figure 4. Internal comfort temperature graph……………….………………………………………………..7 Figure 5. Heat transfer through conduction graphs.……….…………………………………….…………..8 Figure 6. Heat transfer through ventilation graph.……………………………………………………………9 Figure 7. Heat gain through solar radiation graph.………………………………………………………….10 Figure 8. Heat transfer across all months……………………………………………………………………11 Figure 9. Best case vs Base case heat transfer graph………………………………………………………12

List of Tables

Table 1. Dimensions of the workshop space…………………………………………………………………5 Table 2. Base Case Envelope specifications…………………………………………………………………5 Table 3. Best Case Envelope specifications…………………………………………………………………12

3

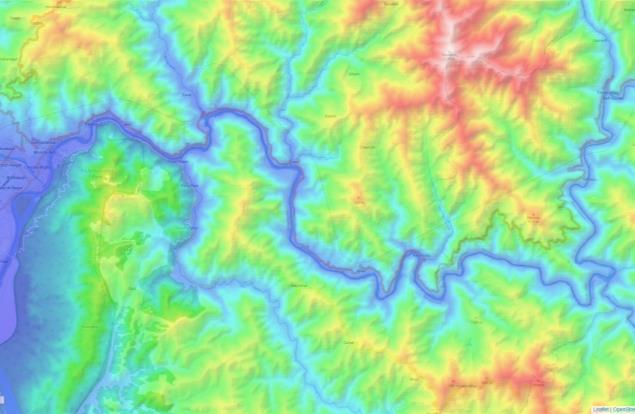

1. Introduction The aim of the paper is to investigate and optimize the Forrest Essentials factory’s workshop area in Uttarakhand in terms of fabric specifications and servicing. The space will be investigated based on heat loss and heat gains during an entire year for average and extreme temperatures. The results will be used to identify problems with fabric and servicing and suggest optimizations to reduce the annual energy demand. 1.1. Climate and Weather of the chose location The space is in Lodsi, Uttarakhand at 682m altitude (Figure 1). The site location falls under ‘Cwb’ region according to the Köppen-Gieger classification matrix (Kottek et al., 2006), depicting temperate climate with dry winters and warm summer.

Project Site

Project Site

(a)

(b)

Figure 1. (a) Site location, (b) Altitude map: Uttarakhand. Source: SolarGIS, ArcGIS

In extreme summers the air temperature ranges from 12 °C to 44 °C. In extreme winters, the air temperature ranges from 1 °C to 33 °C. At its extremes, the location will receive 2350mm precipitation with its peak number of days in July (27 days) and August (26 days). Relative humidity (RH) greater than 90% has been recorded for all the months. The dominant wind direction is North-East (70% of hours) with highest ever recorded wind velocity of 12 meters per second in May (Figure 2).

Figure 2. Extreme Weather data (a) Annual wind wheel, (b) Rainfall data, (c) Daily temperature range. Source: Climate Consultant, Meteonorm

4

1.2. The Forrest Essentials Factory Packaging Area The area of the chosen workshop is 80 square meters with surface to volume ratio of approximately 1. The space is designed to be predominantly free running for its users to conduct light manual work. Workshop space faces North with a Window to wall ratio (WWR) of 70% (Table 1).

Figure 3. Exploded Axonometric view of the workshop space. © Author. Source: SketchUp Table 1. Dimensions of the workshop space. Length 8M

Breadth

Breadth

Surface

Height

Wall Area (sqm)

AreaArea (sqm) Glazing Doors (sqm)

olume

Height 4Mm to 5 M N-S slope External 10

10 M

8m

oof

8m

Length

Area

Volume

80all sqm

337 cum

East

West 4

10 m

Façade North

la ing

5m 4 to South

12

16

Floor

80 s40uare meters 14 -

7

olume

337 cubic meters

all Area

12

la ing Area

40

5

16 14

34

to 5 m

34

meters 80 s uare -

-

-

337 cubic meters

34

34

1.3. Thermal envelope specification Thermal transmittance values for the elements provided by the architecture firm were verified by recalculating each material’s thermal resistance (Appendix A). The U-values ae found to be 1.68 W/(m2K) as against 1.3 W/(m2K) for external walls, 0.27 W/(m 2K) as against 0.25 W/(m 2K) for roof. The U-value for floor (1.90 W/(m 2K)) has been calculated using the same equation. The ventilation flow rate has been calculated to be 2.56 air changes per hour @ 4Pa using Table B.8 of EN 16798-1:2019 (Appendix B). Refer table 2 for other specifications. Table 2. Base Case Envelope specifications. Base Case envelope Parameter

Value

Units

Source

External Wall

1.68

W/(m2K)

Govt. Scotland. 2020

Roof

0.27

W/(m2K)

NBC 2016

Floor

1.90

W/(m2K)

Govt. Scotland. 2020, Author

Glazing U Value

2.80

W/(m2K)

Saint-Gobain 2022

Glazing g Value

0.49

Saint-Gobain 2022

Window Wall Ratio North Elevation Infiltration rate

70%

Author 3

0.6

m /h/m

2

Passivhaus PHPPP

1.4. Occupants and space utilization The area is used as for packaging products with 8 workstations. The space is occupied from 9 am to 5 pm for 5 days per week. There is no active heating or mechanical ventilation system installed. Southern side is predominantly view windows towards the corridor with 2 doors on either side for access. The space is designed for 16 permanent women. The metabolic rate of the occupants associated with light benchwork is 2.1 met (Table 6.2 CIBSE Guide A). The thermal insulation values for garments associated with the location are 0.5 clo in summers and 0.9 clo in winters. There is no applicable equipment associated with the activity. LED Lighting profiles are suspended above the 8 workstations.

2. Literature CIBSE Guide A Environmental Design has been used to derive some base case specifications and occupant comfort ranges. Thermal envelope specifications have been calculated for each element using U values specified in government published sources such as National Building Code of India, 2016, and

overnment of Scotland’s document on table of U-values. Ventilation rates have been

calculated using BS EN 16798-1:2019 (Appendix C). Infiltration rates and glazing specifications have been suggested by Passivhaus standards.

6

3. Methodology 3.1. Weather data The typical year weather file for the nearest major city of Dehradun for 2014 is available on Indian Society of Heating, Refrigerating and Air Conditioning Engineers (ISHRAE). The data has been interpolated on Meteonorm from present, future (2100 at RCP 8.5) periods and highest ever recorded values to calculate extreme conditions. The epw file has been recreated by converting the weather file of Dehradun to CSV and updating it with the extreme data of Lodsi from Metonorm.

3.2. Selection of building and space The space to be analyzed is an existing project by Morphogenesis, New Delhi. The project has been categorized as a naturally ventilated zero energy factory off-grid with high quality construction details. Photovoltaic panels have been utilized to supply the total energy demand. The aim of the paper is to assess whether the energy demand of the building could have been reduced without using renewables.

3.3. Calculation of Energy demand of the base case All the calculations are performed at steady state. Internal comfortable temperatures have been calculated for both, average and extreme conditions using adaptive equation for thermal comfort in free-running buildings (Nicol and Humphreys, 2010). 𝑇ei = 11.9+0.534 𝑇𝑜. Refer Appendix E for calculation. where Tei is interior comfort temperature (°C) To is monthly mean/extreme outdoor temperature (°C)

Figure 4. Internal comfort temperature graph. (a) Average temperature range, (b) Extreme temperature range.

Using Figure 3, we observe that Internal comfort temperatures are higher than outdoor temperatures for the summer months of May, June, and July, for both average and extreme conditions. This suggests high gains through the envelope and relatively higher solar gains compared to the other months. Heat transfer through fabric is calculated using the following equation, Qf = ΣUA(To-Tei) where: Qf = heat transfer across the envelope due to conduction; kWh U = thermal transmittance (U-value) of the element; W/(m 2K) A = Surface area of the element; m 2 7

Figure 5. Heat transfer through conduction graphs. (a) Annual Heat Transfer for average and extreme conditions, (b) monthly break-up (c) Break-up of elements for average condition, (b) Break-up of elements for extreme condition.

In average conditions, annual energy demand accounts to ~11,000 kWh (Appendix E). Extreme conditions result in additional 2000 kWh of energy demand. Extreme conditions will therefore be analyzed for heat transfer calculation. Heat transfer through fabric suggests heat loss during the months of September to April. Summer months of May, June and July suggest heat gains. Heat transfer through external wall, floor is higher in average conditions in winter months, whereas extreme conditions state higher energy demand in summer months. Heat transfer through floor accounts for maximum heat transfer across all months. Roof and door have negligible impact on the energy demand. A lower U value for floor, glazing and external wall elements may result in drastic decrease in energy demand.

Heat transfer through ventilation is calculated using the following equation, Qv = nV/3(To-Tei) where: Qv = heat transfer across the envelope due to ventilation and infiltration; kWh n = ventilation flow rate + infiltration rate; ac/h @ 50 Pa V = Volume of the space; m 3 Heat transfer has been calculated for both, occupied and unoccupied hours. Occupied hours are assumed to be naturally ventilated for 9 hours a day and 5 days a week. Unoccupied hours are calculated for the rest of the time when the windows are shut and only infiltration losses take place.

8

Figure 6. Heat transfer through ventilation graph.

The annual heat transfer through ventilation is 1850 kWh (Appendix G). Unoccupied hours amount to 6% of the total energy demand. Summer months of May, June, and July result in heat gains, whereas the remaining months result in heat losses. Heat gains account to 7% of the total energy demand. Heat transfer through solar radiation is calculated using the following equation, Qs = (I x tg x A) where: Qs = heat transfer across the envelope due to solar transmission; kWh tg = g value of glass. A = Area of the space; m 2 I = Irradiance on the surface; kWh/m 2 The building is open to sun from the North. The solar radiation simulations are caried out in Ladybug plugin of Grasshopper using the definition specified in Appendix C targeting the north façade only. The space is assumed to be exposed to capture maximum radiation on façade. Windows are assumed to be double glazed units, air filled with 12mm gap between panes, The solar factor (g-value) has been referenced from manufacturer’s data (Appendix I).

9

Figure 7. Heat gain through solar radiation graph.

Annual heat gains due to solar radiation amount to 123 kWh (Appendix H). Facing north, the space receives sparse heat gains. The maximum being 19.1 kWh in July. A better performing glass with lower solar factor can reduce these gains substantially, if required. Internal heat gains comprise of occupant (Qo) and Lighting (Ql). There are 16 women workers in the space. Therefore, using Table 6.3 CIBSE Guide A, the occupant heat gains (both sensible and latent) amounts to 200 W per women per hour. A factor of 85% has been applied due to the occupants being women. This contributes to 633 kWh per month for 22 working days of 9 hours each. Lighting Heat gains have been calculated using Table 6.2 CIBSE Guide A. The sensible heat gain from lighting has been assumed to be 12W per square meter. Assuming the lighting is switched on during all working hours, heat gains contribute to 211 kWh heat gain per month (Appendix J).

Heat balance is calculated using the following equation. Qf + Qv + Qs + Qo +Ql + Qh + Qc = 0, where: Qh = heat transfer from heating equipment; kWh Qc = heat transfer from cooling equipment; kWh As the space is naturally ventilated, Qh and Qc are assumed to be zero. The heat balance equation is used to calculate the heating and cooling demands of the space specific to each month. (Appendix K)

10

Figure 8. Heat transfer across all months.

Based on the graph of base case heat transfer for the space (Figure 7), an optimization can pe recalculated with better envelope specifications to reduce the energy demand of the space. U value of the floor, external wall and glazing can be enhanced with the aim to balance the heat transfer.

4. Discussion 4.1. Current practice & implications April to September experience net heat gains primarily due internal and thermal envelope specifications. The space will require cooling during these months. The remaining six months experience net heat loss primarily due to thermal envelope and will require heating. The annual energy demand of the building is 15714 kWh annually. Heat transfer due to thermal envelope is maximum. Flooring, glazing, and external walls contribute to most of the demands. Existing external brick wall with stone cladding (U value:1.68 W/(m2K)) can be replaced with better performing elements. Existing roofing can be enhanced by adding cavity and an insulation layer. Flooring RCC Slab with U value of 1.81 W/(m 2K) can be replaced with a better performing alternative. Double Glazing can be replaced with Triple Glazing with low e argon filled to reduce heat transfer. Blinds can be utilized to reduce heat gains during summer months. The envelope performs well against convective heat transfers, so no further optimizations have been suggested. However, a higher surface to volume ratio will result in reduced energy demands. Heat gain through solar is negligible. Changing the orientation will result in increased energy demand. Sun shading is not required for the purpose of energy demand but can be added to protect the space from rain. Glazing area can be further increased for better views. Slightly better performing lighting fixtures can be utilized with heat gain of 10W per square meter. Further limiting the use of artificial lighting and relying on natural light during morning and afternoon will reduce the energy demand. 11

4.2. Best practice Table 3 highlights the optimizations in thermal envelope. To optimize heat transfer through conduction, external wall has been replaced with 200mm AAC blocks, 200mm mud brick wall, mineral wool insulation and a 10mm cavity. Cladding and plastering stays the same as base case. For roof, internal liner has been replaced with timber, and stone wool insulation is replaced with mineral wool. Flooring has been changed from 150mm RCC to 200mm Cellular concrete with specific heat capacity of 1.05 kJ/kgK. The inner glass of the existing glazing unit has been replaced with a triple glazed insulated unit. The pane is replaced by PPC insulated metal top panel and timber frame to provide structural support. Outer glass stays the same. Refer Appendix N for revised envelope calculations. Table 3. Best Case Envelope specifications. Best practice envelope Parameter

Value

Units

Source

External Wall

0.25

W/(m2K)

NBC2016, Author

Roof

0.16

W/(m2K)

NBC2016, Author

Floor

0.81

W/(m2K)

NBC2016, Author

Glazing U Value

0.58

W/(m2K)

Saint-Gobain 2022

Glazing g Value

0.52

Saint-Gobain 2022

WWR North Elevation

95%

Author

The annual energy demand reduces to 4853 kWh, which is an improvement of 70% from the base case scenario (Appendix M). Figure 8 shows the improvement of the space after applying the abovementioned replacements. January and November are observed to be in a state of heat balance. Negligible heating losses are observed for February and December. Heating is required during these months. Heat gains are observed from March to October contributing to 4000kWh cooling energy demand.

Figure 9. Best case vs Base case heat transfer graph.

12

5. Conclusions and limitations 5.1. Conclusions Base case scenario showed higher energy demands (>1000 kWh) for 8 months. Best practices brough this down to all months utilizing less than 1000kWh with 2 months observed to be in a state of heat balance. This optimized cooling demand may be eliminated by utilizing natural ventilation solely. The user can control the cooling needed for the space. Thus, making the space net zero on energy demand. The key factor of the optimizations was the thermal envelope of the space. Changes in U values eliminated maximum energy demands. Other criteria such as infiltration losses would have had major implications on the calculations if the space was not assumed to be airtight.

5.2. Limitations The calculations were performed in steady state conditions and thus, conclude with a broader idea on the assumed space. A detailed dynamic state condition is more suitable for an existing space. Effects of thermal mass can also be considered to understand the space better.

13

References [1] BS EN 16798-1:2019 - Energy performance of buildings - Ventilation for buildings. 2019: BSI Standards [2] CIBSE Guide A - Environmental Design (7th Edition). 2015: CIBSE.

[3]Database.passivehouse.com.

2022. List

of

windows.

Available

at:

https://database.passivehouse.com/en/components/list/window?lat=51.4567&lon=-3.3434&cz=4.

[4] Nicol, F. and Humphreys, M., 2010. Derivation of the adaptive equations for thermal comfort in freerunning buildings in European standard EN15251. Building and Environment, 45(1), pp.11-17.

[5] Gov.scot. 2022. U Values: guidance. [online] Available at: https://www.gov.scot/publications/tablesof-u-values-and-thermal-conductivity/.

[6] Kottek, M., Grieser, J., Beck, C., Rudolf, B. and Rubel, F., 2006. World Map of the Köppen-Geiger climate classification updated. Meteorologische Zeitschrift, 15(3), pp.259-263.

[7] National building code of India 2016. 2nd ed.

[8[ Natural Stone Institute. 2022. What Natural Stone is best for heated surfaces. [online] Available at: https://www.naturalstoneinstitute.org/stoneprofessionals/technical-bulletins/rvalue/.

[9] Saint-gobain-facade-glass.com. 2022. Product Performance Tables | Saint-Gobain Façade. [online] Available

at:

https://www.saint-gobain-facade-glass.com/specification-tools/product-performance-

tables.

[10] Weather.whiteboxtechnologies.com. 2022. Select ISHRAE Weather Files. [online] Available at: http://weather.whiteboxtechnologies.com/ISHRAE.

[11] Zeng, T., Jiang, H. and Hao, F., 2022. Study on the effect of aluminium foil on packaging thermal insulation performance in cold chain logistics. Packaging Technology and Science.

14

Appendix A. Thermal transmittance values elements of thermal envelope. External wall Element

Thickness [m]

External surface resistance Limestone cladding

0.15

Brickwork Mud Plaster

0.23 0.015

K-value [W/(mk)]

Resistance [m2K/W]

Source

1.33

0.04 0.11

WSA, Energy & Heat Natural Stone Institute

0.84 0.4

0.27 0.04

WSA, Energy & Heat NBC 2016

0.13 0.59 1.68

WSA, Energy & Heat

Internal surface resistance Total thermal resistance U Value

W/(m2K)

Roof Element

Thickness [m]

K-value [W/(mk)]

External surface resistance

Resistance [m2K/W]

Source

0.04

WSA, Energy & Heat

External Aluminium Sheet

0.0009

247

0.00

NBC 2016

Stone wool Aluminium Foil Internal Liner Sheet

0.1

0.04

0.0006

247

2.50 1.00 0.00

NBC 2016 Zeng et. al NBC 2016

0.10 3.64 0.27

WSA, Energy & Heat

Internal surface resistance Total thermal resistance U Value

W/(m2K)

Floor Element Internal surface resistance RCC slab Screed Total thermal resistance

Thickness [m] 0.15 0.1

K-value [W/(mk)] 1.35 0.41

U Value Floor Element

Thickness [m]

K-value [W/(mk)]

Resistance [m2K/W]

Source

0.17 0.11 0.24 0.53

WSA, Energy & Heat Govt. Scotland. 2020 Govt. Scotland. 2020

1.90

W/(m2K)

Resistance [m2K/W]

Source

Internal surface resistance RCC slab

0.3

1.3

0.17 0.23

WSA, Energy & Heat NBC 2016

Steel

0.05

50

0.001

NBC 2016

0.40 2.49

W/(m2K)

Total thermal resistance U Value Glazing Element Double glazed Steel Sections with

Thickness [m]

K-value [W/(mk)]

Source Govt. Scotland. 2020

0.1

U Value g Value Door Element

Resistance [m2K/W]

2.80 0.49 Thickness [m]

K-value [W/(mk)]

Solid Timber U Value

Resistance [m2K/W]

3.00

15

Saint Gobain

Source Govt. Scotland. 2020 W/(m2K)

Appendix B. Ventilation & Infiltration rate calculation No. of occupants Volume Airflow per person Airflow total

Flow rate Infiltration rate Infiltration rate Ventilation+ Infiltration rate

16 337 10 240 0.24 864 2.56 0.60 0.06 2.62

l l/s/ person l/s m3/s m3 ac/h @5 Pa ac/h @50 Pa

Appendix C: Table B.8 of EN 16798-1:2019

Appendix D. Grasshopper - Ladybug Solar Radiation Definition

16

Appendix E: Internal Comfort Temperature calculation for average & extreme conditions Table 1. Average conditions Month

External Temperature (°C)

Adaptive Equation

Thermal

Comfort

Internal Temperature (°C)

ᐃT (°C)

Jan

15

𝑇𝑐=11.9+0.534 𝑇𝑜

19.9

4.9

Feb

14

𝑇𝑐=11.9+0.534 𝑇𝑜

19.4

5.4

Mar

18

𝑇𝑐=11.9+0.534 𝑇𝑜

21.5

3.5

Apr

24

𝑇𝑐=11.9+0.534 𝑇𝑜

24.7

0.7

May

27

𝑇𝑐=11.9+0.534 𝑇𝑜

26.3

-0.7

Jun

28

𝑇𝑐=11.9+0.534 𝑇𝑜

26.9

-1.1

Jul

26

𝑇𝑐=11.9+0.534 𝑇𝑜

25.8

-0.2

Aug

25

𝑇𝑐=11.9+0.534 𝑇𝑜

25.3

0.3

Sep

25

𝑇𝑐=11.9+0.534 𝑇𝑜

25.3

0.3

Oct

20

𝑇𝑐=11.9+0.534 𝑇𝑜

22.6

2.6

Nov

16

𝑇𝑐=11.9+0.534 𝑇𝑜

20.4

4.4

Dec

13

𝑇𝑐=11.9+0.534 𝑇𝑜

18.8

5.8

Table 2. Extreme conditions Month

External Temperature

Adaptive Equation

Thermal

Jan

11.9

𝑇𝑐=11.9+0.534 𝑇𝑜

18.3

6.4

Feb

15.1

𝑇𝑐=11.9+0.534 𝑇𝑜

20.0

4.9

Mar

20

𝑇𝑐=11.9+0.534 𝑇𝑜

22.6

2.6

Apr

25.2

𝑇𝑐=11.9+0.534 𝑇𝑜

25.4

0.2

May

28.1

𝑇𝑐=11.9+0.534 𝑇𝑜

26.9

-1.2

Jun

28.4

𝑇𝑐=11.9+0.534 𝑇𝑜

27.1

-1.3

Jul

26.7

𝑇𝑐=11.9+0.534 𝑇𝑜

26.2

-0.5

Aug

26.1

𝑇𝑐=11.9+0.534 𝑇𝑜

25.8

-0.3

Sep

25.3

𝑇𝑐=11.9+0.534 𝑇𝑜

25.4

0.1

Oct

22.1

𝑇𝑐=11.9+0.534 𝑇𝑜

23.7

1.6

Nov

17.3

𝑇𝑐=11.9+0.534 𝑇𝑜

21.1

3.8

Dec

13.2

𝑇𝑐=11.9+0.534 𝑇𝑜

18.9

5.7

17

Comfort

Internal Temperature

ᐃT

18

4.9

2.6

0.2

-1.2

-1.3

-0.5

-0.3

0.1

1.6

3.8

5.7

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

U Value W/(sqm. K)

4.9

5.4

3.5

0.7

-0.7

-1.1

-0.2

0.3

0.3

2.6

4.4

5.8

Jan

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

ᐃT

Feb

Month

80

80

80

80

80

80

80

80

80

80

80

80

346

92

60

26

2

-4

-9

-21

-19

2

41

73

102

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

1.68

96

96

96

96

96

96

96

96

96

96

96

96

3048

702

517

310

30

29

-26

-134

-82

83

422

605

590

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

80

80

80

80

80

80

80

80

80

80

80

80

407

94

69

41

4

4

-3

-18

-11

11

56

81

79

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

4.25

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

0.27

5446

1454

940

405

28

-64

-137

-327

-302

38

653

1151

1607

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

U Value W/(sqm. K)

54

54

54

54

54

54

54

54

54

54

54

54

2422

647

418

180

12

-29

-61

-145

-134

17

290

512

715

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

Glazing Area Heat Transfer U Value sqm kWh W/(sqm. K)

7

7

7

7

7

7

7

7

7

7

7

7

336

90

58

25

80

80

80

80

80

80

80

80

80

80

80

80

6412

1478

1088

653

63

61

-55

-281

-173

175

888

1272

1242

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

54

54

54

54

54

54

54

54

54

54

54

54

2852

657

484

290

28

27

-24

-125

-77

78

395

566

552

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

3.00

7

7

7

7

7

7

7

7

7

7

7

7

2

-4

-8

-20

-19

2

40

71

99

Doors Area Heat Transfer sqm kWh

2974

1922

829

57

-131

-281

-668

-618

79

1335

2354

3288

3022

13115

2225

1335

129

125

-112

-575

-353

358

1817

2602

2540

396

Total Fabric Heat Transfer (kWh)

11138

Total Fabric Heat Transfer (kWh)

91

67

40

4

4

-3

-17

-11

11

55

79

77

Doors Glazing Floor Area Heat Transfer Area Heat TransferU Value Area Heat Transfer U Value kWh kWh W/(sqm. K) sqm sqm kWh W/(sqm. K) sqm

80

80

80

80

80

80

80

80

80

80

80

80

Floor Area Heat Transfer sqm kWh

0.27

2588

691

447

193

13

-31

-65

-155

-144

18

310

547

764

Roof Area Heat Transfer U Value sqm kWh W/(sqm. K)

Roof Area Heat TransferU Value kWh W/(sqm. K) sqm

96

96

96

96

96

96

96

96

96

96

96

96

External Wall Area Heat Transfer U Value sqm kWh W/(sqm. K)

External Wall Area Heat TransferU Value U Value kWh W/(sqm. K) sqm W/(sqm. K)

Table 1. Average conditions

6.4

Jan

ᐃT

Feb

Month

Table 1. Average conditions

APPENDIX F: Heat transfer through conduction

Appendix G: Heat transfer through ventilation Table 1. Annual heat transfer through ventilation Month

ᐃT

Occupied hours

Ventilation heat transfer Unoccupied hours kWh

Total

Jan

4.9

287

17

304

Feb

5.4

314

19

333

Mar

3.5

205

12

217

Apr

0.7

42

3

44

May

-0.7

-40

-2

-42

Jun

-1.1

-67

-4

-71

Jul

-0.2

-13

-1

-13

Aug

0.3

15

1

15

Sep

0.3

15

1

15

Oct

2.6

151

9

160

Nov

4.4

259

16

275

Dec

5.8

341

21

361

1599

Appendix H: Heat gains through solar radiation Table 1. Annual heat gains through solar radiation

Solar Irradiance kWh/m2

Month

Area m2

g value kWh

Jan

0.3

40.0

0.5

6.1

Feb

0.3

40.0

0.5

6.7

Mar

0.5

40.0

0.5

9.3

Apr

0.5

40.0

0.5

9.8

May

0.7

40.0

0.5

12.7

Jun

0.9

40.0

0.5

16.7

Jul

1.0

40.0

0.5

19.1

Aug

0.8

40.0

0.5

15.7

Sep

0.5

40.0

0.5

9.8

Oct

0.3

40.0

0.5

6.4

Nov

0.3

40.0

0.5

5.4

Dec

0.3

40.0

0.5

4.9

Appendix I: Solar factor selection Table 1. Selection of solar factor of gla ing using Saint

obain’s product performance table.

19

Appendix J: Internal heat gain Table 1. Annual internal heat gains.

Occupant

Lighting

Month

W

Nos

kWh

W

sqm

kWh

Jan

200

16

633

12.0

80.0

211

Feb

200

16

633

12.0

80.0

211

Mar

200

16

633

12.0

80.0

211

Apr

200

16

633

12.0

80.0

211

May

200

16

633

12.0

80.0

211

Jun

200

16

633

12.0

80.0

211

Jul

200

16

633

12.0

80.0

211

Aug

200

16

633

12.0

80.0

211

Sep

200

16

633

12.0

80.0

211

Oct

200

16

633

12.0

80.0

211

Nov

200

16

633

12.0

80.0

211

Dec

200

16

633

12.0

80.0

211

Appendix K: Base Case Heat transfer table Total Fabric

Ventilation heat transfer kWh

Month

kWh

Solar Occupant Lighting Heat Gain Heat Gain Heat Gain kWh kWh kWh

Jan

2540

304

6.1

633

211

Feb

2602

333

6.7

633

211

Mar

1817

217

9.3

633

211

Apr

358

44

9.8

633

211

May

-353

-42

12.7

633

211

Jun

-575

-71

16.7

633

211

Jul

-112

-13

19.1

633

211

Aug

125

15

15.7

633

211

Sep

129

15

9.8

633

211

Oct

1335

160

6.4

633

211

Nov

2225

275

5.4

633

211

Dec

3022

361

4.9

633

211

Net Result kWh 1994 2084 1181 -451 -1252 -1506 -988 -719 -709 644 1651 2535 15714

Description Heat Loss Heat Loss Heat Loss Heat Gain Heat Gain Heat Gain Heat Gain Heat Gain Heat Gain Heat Loss Heat Loss Heat Loss

Inference Heating required Heating required Heating required Cooling required Cooling required Cooling required Cooling required Cooling required Cooling required Heating required Heating required Heating required

Appendix L: Best Case Heat transfer table Total Fabric

Ventilation heat transfer kWh

Month

kWh

Solar Occupant Lighting Heat Gain Heat Gain Heat Gain kWh kWh kWh

Jan

462

304

3.3

633

48

Feb

477

333

3.3

633

48

Mar

330

217

3.3

633

48

Apr

65

44

3.3

633

48

May

-64

-42

3.3

633

48

Jun

-105

-71

3.3

633

48

Jul

-20

-13

3.3

633

48

Aug

23

15

3.3

633

48

Sep

24

15

3.3

633

48

Oct

243

160

3.3

633

48

Nov

406

275

3.3

633

48

Dec

549

361

3.3

633

48

20

Net Result kWh 82 126 -136 -574 -790 -860 -717 -645 -645 -281 -2 227

Description Heat Balance Heat Loss Heat Gain Heat Gain Heat Gain Heat Gain Heat Gain Heat Gain Heat Gain Heat Gain Heat Balance Heat Loss

Inference No energy demands Heating required Cooling required Cooling required Cooling required Cooling required Cooling required Cooling required Cooling required Cooling required No energy demands Heating required

APPENDIX M: Best case U values External wall Element

Thickness [m]

K-value [W/(mk)]

Resistance [m2K/W]

External surface resistance Limestone cladding AAC

0.04 0.15

1.33

0.11

0.2

0.089

2.25

Cavity

0.01

Mineral Wool

0.03

0.03

1.00

0.2

0.75

0.27

0.015

0.4

0.04

Mud brick Mud Plaster

0.15

Internal surface resistance

0.13

Total thermal resistance

3.98

U Value

0.25 Roof Element

Thickness [m]

K-value [W/(mk)]

Resistance [m2K/W]

External surface resistance

0.04

GI Sheet

0.1

0.5

0.20

Mineral wool

0.1

0.03

3.33

Aluminium Foil Internal Timber

1.00 0.1

0.072

1.39

Internal surface resistance

0.10

Total thermal resistance

6.06

U Value

0.16 Floor Element

Thickness [m]

K-value [W/(mk)]

Resistance [m2K/W]

Internal surface resistance Cellular concrete

0.17 0.2

0.188

1.06

Total thermal resistance

1.23

U Value

0.81 Glazing Element

Thickness [m]

K-value [W/(mk)]

Resistance

Double glazed Steel Sections with

0.1

U Value

0.58 W/(m2K)

g value

0.52 Door Element

Thickness [m]

K-value [W/(mk)]

Resistance [m2K/W]

Solid Timber U Value

1.23

21