6 minute read

Jansen digital strategy shapes our future

Most recently, travel limitations have accelerated the deployment of wearable point-of-view cameras that allow off-site subject matter experts to support and guide on-site workers without the risk, cost, and inconvenience of physical travel.

The S3d and synchro tools help us input data and have a 3D model on our portal. The data loaded into the model ranges from physical data, schedule data, cost data, and operational data. Digital technology is everywhere.

It is estimated that there are now 4.6 billion Internet users globally, 5.1 billion mobile phone users, two billion online shoppers, and 3.7 billion social media users. every 60 seconds there are 200 million emails sent, 4.2 million Google searches made, and 60,000 Instagram images uploaded.

the data created by all this almost unimaginable – a staggering 44 zettabytes.

this is doing amazing things for businesses as they harness the power of technology. but a new system or piece of software alone will not guarantee success. that is why a team from Jansen have been busy preparing a digital strategy to shape the future of the business.

the team’s goal has been to put together a strategy that will help Jansen thrive in the future. but this isn’t just technology for technology’s sake. all digital initiatives will deliver measurable value through cost reduction, throughput, recovery, utilization, and then immeasurable value through improvements to Hse and workforce culture.

Breaking down geographic barriers

It starts with what the team calls integrated project delivery, which allows for a high level of collaboration even in a decentralized team.

the s3d and synchro tools help us input data and have a 3D model on our portal. the data loaded into the model ranges from physical data, schedule data, cost data, and operational data. enriching the engineering data, or shifting it from 3D to 4D to 5D and beyond, creates an almost infinite range of opportunities, including the ability to simulate construction.

See what we see. A better world unearthed with a di erent perspective.

Part of the benefit of a greenfield operation is that the team has the opportunity to really challenge the status quo and build their vision from scratch.

the project has adopted the philosophy that data is entered only once, controlled at the source, and then consumable for further enrichment. In other words, as soon as data is published, it becomes visible at other locations and available to anyone who needs it: anytime, anywhere, and on any device.

this has benefited our suppliers. We have been able to integrate the engineering details with contracts and procurement, and then share this detail with suppliers. this means they get the most accurate information. there’s no email, no misplaced documentation, no lag, the data is entered once and used many times.

Disrupting construction for the better

Construction comes next, and even though this may sound like a purely physical pursuit, a data-centric approach can significantly improve productivity.

typically, a complex construction project will have a number of pain points: document centricity, a lack of integration, as well as manually intensive, sequential, and hierarchal processes. the strategy aims to alleviate these by building an easily accessible library of quality documentation that is the single source of the truth for those involved in the project.

the Integrated Construction Centre is where a whole heap of interconnected data is brought together for people in the field, from engineering, cost and schedule information, check sheets, punch lists, permits, work package data, incident management, as well as training and induction packages. It can even be used to book a seat on the bus or a room in the camp.

“this is not an assembly of discrete applications, this is a complete and integrated system that removes the need for overheads and administration, gets people into the field faster, and makes them more productive once they are there,” said Mike elliott, project director for Jansen and former head of engineering & digital strategy for the project. “a lot of the value that is gained is through connectivity. Construction work pack updates are pushed to mobile devices, services can be ordered from in the field, permits are linked to personnel training records, check sheets are linked to progress, area access is linked to your training and orientation…. and I can go on and on.”

according to brian Grosskleg from the technology team, this sounds like a simple concept, but has traditionally been hard to implement.

“When we have the ability to effectively retrieve technical details on demand throughout our operations it

provides value to bHP’s staff and bottom line through efficient, informed, and risk-mitigated decision making. this is a top priority for any project, and even more important when you consider the size of Jansen,” he said.

Building on solid foundations

Part of the benefit of a greenfield operation is that the team has the opportunity to really challenge the status quo and build their vision from scratch.

so what does the future look like?

the team will look to learn from other bHP operations around the world in implementing integrated operations, digital asset management, and a digital value chain.

the team is busy maturing non-traditional technology, including virtual and augmented reality capabilities, machine learning, reality capture techniques, and remote worker options. Most recently, travel limitations have accelerated the deployment of wearable point-of-view cameras that allow off-site subject matter experts to support and guide on-site workers without the risk, cost, and inconvenience of physical travel.

automation is another theme. the team have a technology roadmap to fully automate borers with partner, sandvik.

the borer has the technology to become fully autonomous, including a guidance system and a ground-penetrating radar coupled with automated bolting. the value is in removing people from potential harm, whilst significantly increasing utilization as mining never really stops.

People come first

While technology is often seen as the key in the future, Mike elliott has a different message. “the technology available to us is amazing, but without the people to make it work, it is pointless. there has been a lot of hard work in building this strategy and a lot of training and dedication from our people to think differently and embrace a new mindset,” says elliott. “as this continues, I know we will deliver great outcomes across productivity, safety, and people engagement at Jansen. I look forward to seeing us bring this to life, together.”

Grosskleg agrees. “rome wasn’t built in a day, and it was not the chariots or the chisel that built it, but the people, using those tools,” he says. “this parallel can be made in digital technology, all the gadgets on earth can’t help you if the user base isn’t comfortable using them.” s

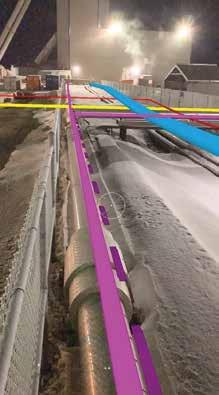

HDPE SOLUTION FOR DEWATERING AND TAILINGS

THE FASTEST WAY TO JOIN HDPE PIPE

INSTALLS UP TO 10x FASTER THAN FUSING

INSTALLS WITH SIMPLE TOOLS

victaulic.com/hdpesolutions

© 2021 VICTAULIC COMPANY. ALL RIGHTS RESERVED. MEETS OR EXCEEDS PRESSURE RATINGS OF HDPE PIPE

INSTALLATION IS WEATHER INDEPENDENT