4 minute read

Thriving and striving for the future

Brother’s Specialized Coating Systems Ltd.: Thriving and striving for the future

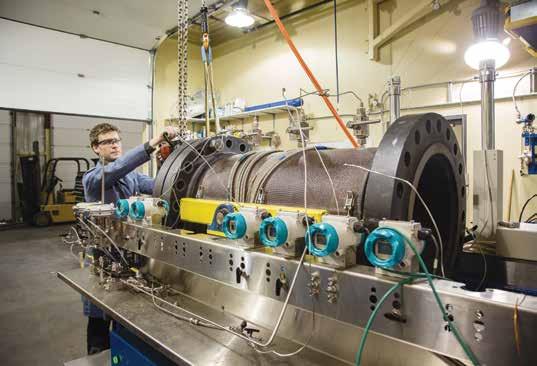

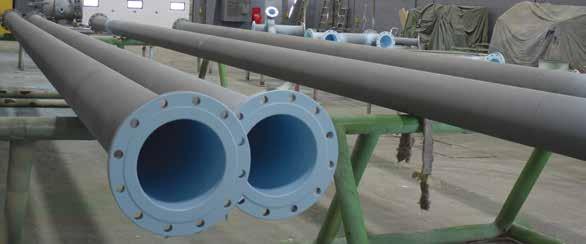

Brother’s Specialized Coating Systems Ltd. has been serving the oil and gas, water and wastewater treatment industries for the past 34 years. Located in Edmonton, Alta., Brother’s has garnered a solid reputation from Industry for being one of Western Canada’s most trusted provider of high-quality protective coating solutions, to ensure their investment remains protected from corrosion, erosion and harsh environmental conditions.

Brother’s has been providing, in shop, specialized internal and external applications for equipment such as fabricated pipe spools, pipelines, pressure vessels and tanks. They also do below grade pipeline coatings as per CSA Z245.30 specification.

Just as in any other industry during this past year and with COVID-19 protocols in place, Brother’s has had to adjust to the new norms of how business is being conducted.

“It has been a challenging year to say the least. We have been highly focused on making sure our staff and all visitors to our plant are following mandated protocols and safety to protect themselves and others,” says Brian Payne, general manager of Brother’s.

Brother’s has still managed to maintain a positive reputation throughout the industry for their high level of service, communication and quality. These values are still driven throughout the company with welltrained, long-term employees who provide consistent output each time, allowing the quality to stay the same with each job completed.

“The staff at Brother’s take their jobs seriously; they take a lot of pride in the work they do and they genuinely care about the products we deliver to our customers. The end results matter and it shows. If you have had work done by Brother’s in the past 15 to 20 years, those same craftsmen are doing that same level of quality here today,” says Payne.

Brother’s follows industry standard protocols set out by two main organizations: NACE and SSPC. These two organizations have recently merged to become one entity called AMPP. This streamlines the industry processes and standards that have been relied on by industry from these two organizations.

Having their own in-house quality program, NACE Level 3 Inspectors and SSPC Train the Trainer, enables Brother’s to maintain a higher level of quality that customers have come to expect from them over the years. Being a smaller shop allows Brother’s to have their eyes and hands on each and every job that comes through.

Brother’s is dedicated to safety by maintaining COR status through the Alberta Construction Safety Association. They are also registered with vendor management systems such as ComplyWorks, ISNetworld and Avetta.

“As a company that has strong values with safety, Brother’s makes it a priority to get all of their staff and clients home safe to their families each and every day,” says Payne.

Brother’s applies a complete range of internal and external liquid spray on coatings. When putting together a coating specification, each coating has a chemical, temperature, pressure and abrasion resistance that must be considered for the specified service.

Brother’s is approved by all the major coating suppliers as an approved applicator for their materials. This allows them access to a number of qualified technical individuals and laboratories that can assist in making the best recommendations for the requested service environment no matter how challenging.

Brother’s works with an array of industry partners, ranging from engineers to fabricators to end-users and owners. Their quality does not discriminate and they provide the same level of quality and service to all of their clients.

Payne says, “We take pride in telling our customers what they need to know and not what they want to hear. This isn’t always an easy conversation; however, we are not doing our job if we don’t have that conversation. What is important is that they have all the correct information and the best recommendation in order to make an informed buying decision when putting together a job scope.”

The experienced staff at Brother’s can assist in design applications by providing input for lengths, configuration, pre-blast issues and access points to various pieces of equipment.

Brother’s has some new advancements in the works coming in 2021, starting with a new field division. They started out as both a shop and field company back in 1987 and that continued into the 2000s.

“We previously specialized in vessel and small tank linings in the field,” says Payne.

Fast forward to 2021. With an everchanging market, the demand and inquiries to Brother’s for field crews has been bigger with each passing year.

“We have owners and industry partners who have really pushed us into getting back to the field. We are making the commitment and investment to get back out there and perform the same quality and service that we have always been known for. We look forward to working with our industry partners and owners in providing field applied solutions to help protect their investments.”

Providing the best possible solutions to your inquiry, discussing the design parameters or keeping you updated along the way on the delivery schedule, Brother’s maintains that these are all important aspects of a successful job being completed to reach the desired outcome. v

Carnduff, SK S0C 0S0 p: (306) 482-3244 e. info@fasttruckingservice.com www.fasttruckingservice.com