5 minute read

New Shining 3D AccuFab L4D 3D printer

By Terry Whitty

D printers are all the rage and the projected new norm will be for every dental lab and every dental surgery to have at least one. The uptake in dentistry in general has been reasonable so far, however, there is still a lot of confusion with many about what technology to invest in as many don’t want to get burnt and left with an expensive boat anchor. This is understandable, though most of the well-known brands marketed for dentistry are now reliable and spawn very good results. Even better, they are great value compared to machines of, say, 10 years ago where you would mortgage a much loved item to purchase one.as I certainly did!

Resin based vat polymerisation printers are really the “go to” printers for dentistry as they are relatively inexpensive and quite reliable. Many dentally-focussed companies are in their 2nd or 3rd generation of machines so lots of the bugs have been ironed out and all tend to produce good quality printers and materials. Invest in a good quality brand known in dentistry and you generally can’t go wrong.

Which brings us to the new Accufab L4D 3D Printer from Shining 3D (already well-known for it’s range of intraoral and benchtop laboratory scanners). The L is for LCD-based, the 4 is a 4K screen and the D is for Dental – now it’s easy to remember! This is an MSLA printer bursting with some really interesting features.

The printer uses Masked Stereo Lithography technology or MSLA and uses an LED array as a light source and an LCD panel that “masks” the light source that creates the patterns for each layer to be formed. Its advantages include fast printing times and that it’s relatively inexpensive to build compared to other resin printing technologies. For MSLA, there are extra consumable items such as the LCD screen which needs to be replaced periodically but considering the entry price, this is not a deal breaker and these sorts of printers - if constructed well - have a good long life span.

The Shining 3D Accufab L4D uses a 4K high resolution LCD screen and this is more than enough to cope with anything you want to print dental-wise. People seem to get caught up in the frenzy of 4K, 8K, 16K but don’t actually understand how this impacts the dimensional accuracy of 3D printers - suffice to say, a 4K screen is very good and for more information please see my article on 3D printer accuracy in eLABORATE Vol. 18 No 4.

The light source is self-calibrating

Featuring a large build volume of 192 x 120 x 160 mm and a fast print speed of up to 50mm/h, the L4D is no slouch, however, always remember that the build time of your part, be it a model, splint or surgical guide, will depend on a few factors. Namely, height of the object, layer thickness, material selection and the parameters needed for successful building of the part.

The printer has a clip-in build plate that is spring loaded and auto levelling so this makes any Z axis calibration of the Accufab L4D a breeze. Levelling and zeroing the Z axis is a common calibration needed for just about any resin printer as it gives the printer a “starting point” to start building layers. Having the plate level is important because each layer formed needs to be a certain even thickness. If not level, you will get all sorts of errors.

Having a self levelling mechanism is a great addition because some printers have very cumbersome way of zeroing and levelling the Z xis of their printers.

The resin tank fits easily in the machine and locates with 4 lugs and a clamping mechanism that is super easy to remove, so changing materials is very quick. Also, once you remove the resin tank, you can easily set it down on a flat surface without fear of damaging the film as the lugs will hold it away from the surface.

The tank also boasts a long life time of 100,000 layers. Let’s put that into perspective - Let’s say and an average 100 micron dental model is made up of 250 layers and you print one model per print then you would get at least 400 models. If you print 4 models per print, then you would assume 1600 models as they share layers as they are on the same build. Either way, you are getting a large yield resin tank with this printer.

What about materials I hear you ask? This is where it gets interesting. The Accufab L4D is open to third party resins. Sure, Shining 3D have a whole range of materials available under their own brand but they do allow 3rd party resins to be printed as well. Now some are verified and the parameters are already worked out for you but if you want to go and try your luck with your favourite resin you can try it out because you can tweak the settings yourself to help you succeed. Will it print any resin? This will require a bit of trial and error but suffice to say, if it will work on an MSLA printer, it will probably work on the Accufab L4D, just be prepared to experiment.

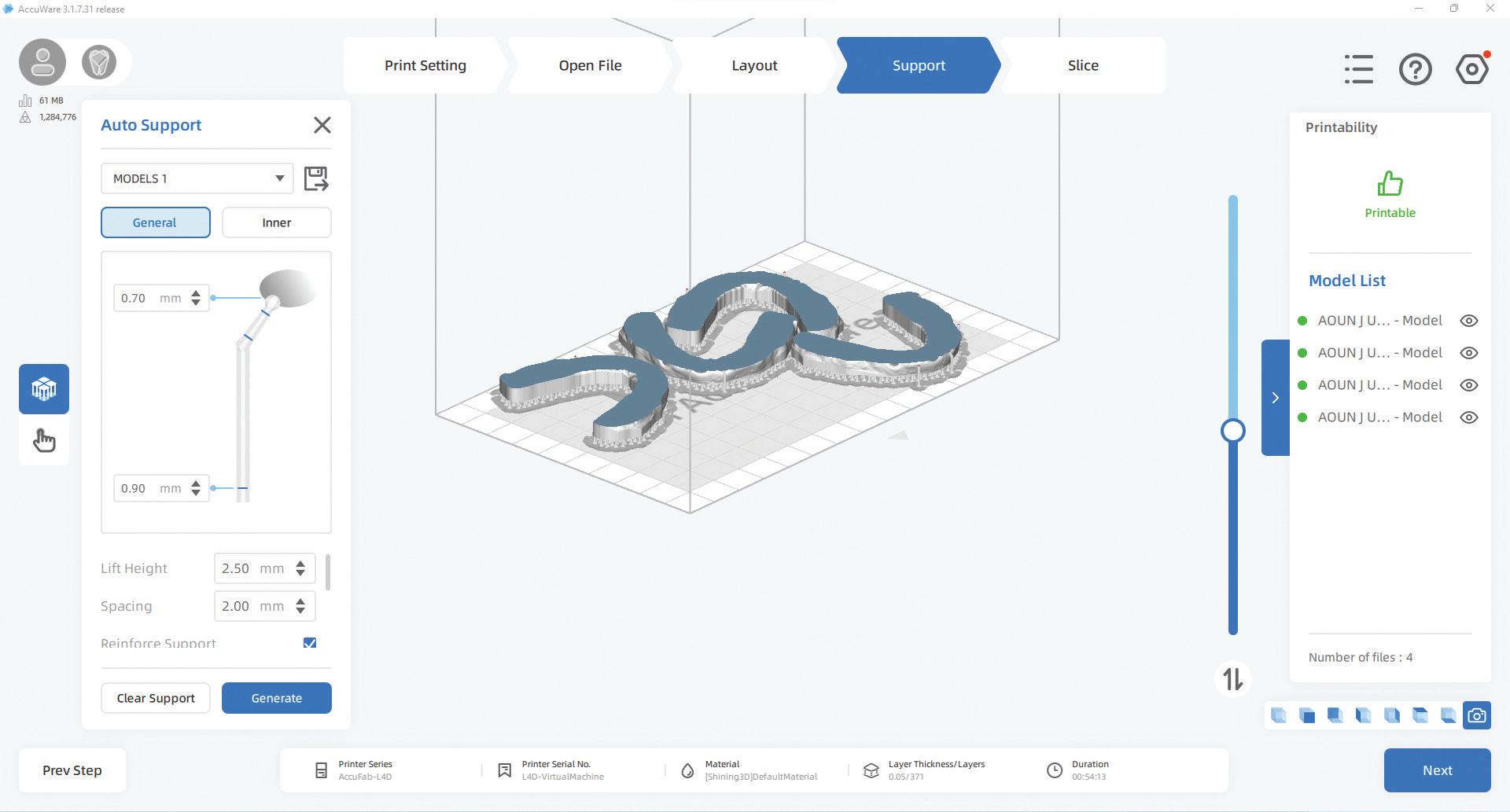

The software supplied with the Accufab L4D is comprehensive and has some really neat additions.

I’ve used many 3D printing softwares and after you’ve used a few different ones, generally you will start to see similarities; the work flow is similar. Add a part to print, position it, add supports if needed, slice, send to the printer. This is the basic workflow and Shining’s software does a good job of this.

It has a wizard-like interface making the software user friendly. It has automatic part placement and it will create drain holes for those who want to print hollow models. Support generation is also good so all the basic functions stack up well.

An addition of note is the material calibration tool, where you can really work on getting the best dimensional accuracy from your materials. It will allow you to print the in-built calibration shapes for each type of material, then physically measure the results and adjust the parameters in the software accordingly by entering the measurements to get optimum dimensional accuracy. This is a really handy feature as a lot of companies do not add this sort of inbuilt material calibration feature.

Also just released is the Shining 3D Fabcure light curing unit and expect a washing station in the near future as well.

Summary

There you have it - a smartly priced quality 4K.MSLA printer. It’s easy to calibrate the machine and there are plenty of materials, z huge build platform, great software, it’s open to 3rd party resins and backed by a well-known customer focussed company.

What will it print? All types of dental models, trays, surgical guides, splints, IDB trays, denture teeth and bases, try ins, long term temporaries and probably anything else you throw at it! It’s hard to fault this printer and it would be great chairside or in a laboratory. Check one out today!

About the author

Terence Whitty is a well-known dental technology key opinion leader and lectures nationally and internationally on a variety of dental technology and material science subjects. He is the founder and owner of Fabdent, a busy dental laboratory in Sydney specialising in high tech manufacturing. Using the latest advances in intra- and extra-oral scanning, CAD/ CAM, milling, grinding and 3D printing, most specialties are covered including ortho, fixed and removable prosthetics, computerised implant planning and guidance, TMD, sleep appliances and paediatrics.