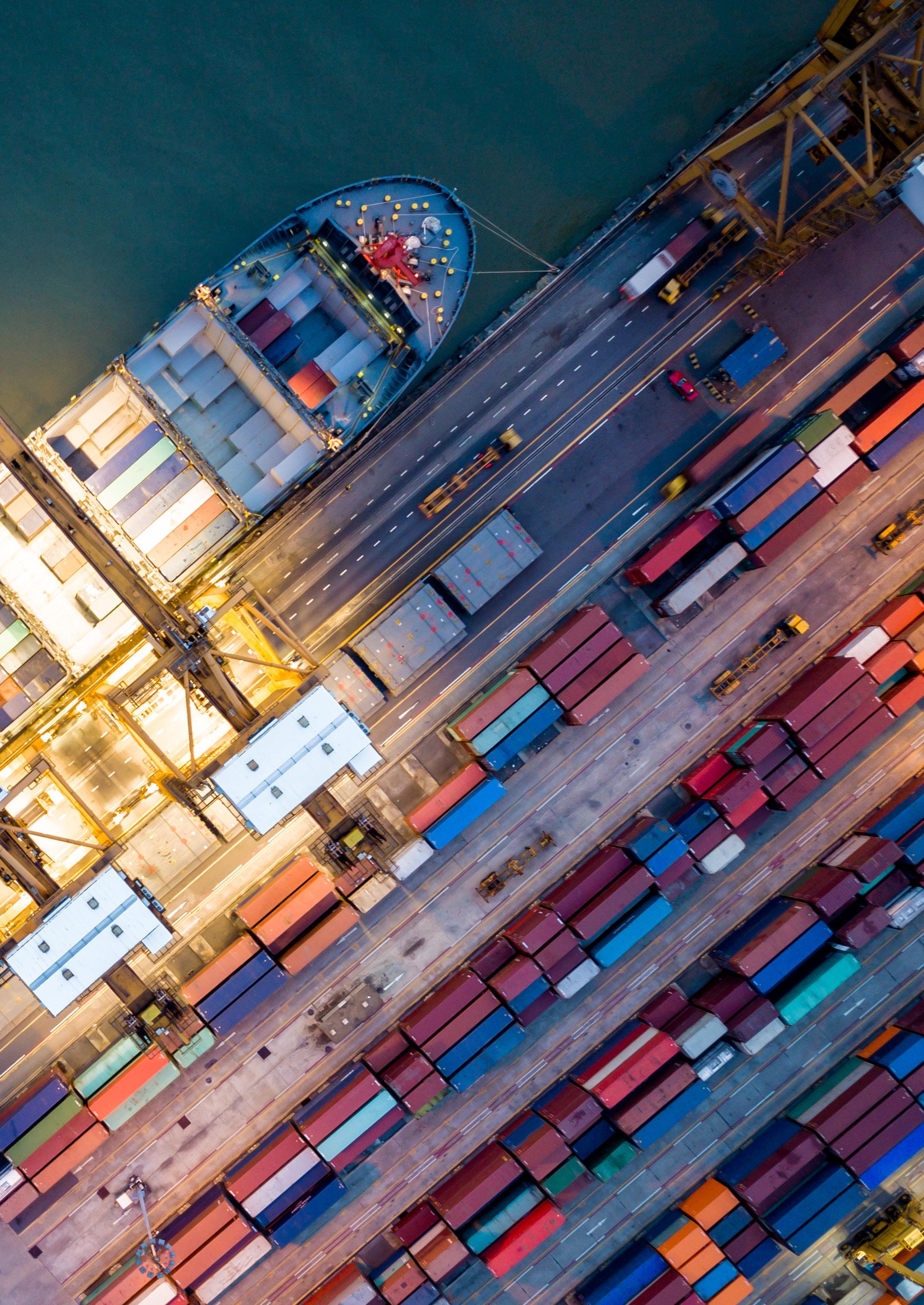

Tássia Pacini, Head of Procurement and Quality at ZAMP discusses the company’s journey of supply chain transformation and digital innovation

The Flagship Procurement Event to Benchmark Your Strategy with the World’s BIGGEST Companies SAVE 5% OFF ticket price using our code PCE5CHAIN 250+ 250+ 80+ 80+ 3 DAYS 3 DAYS 12+ 12+ H Y A T T R E G E N C Y B A R C E L O N A T O W E R , S P A I N 26 - 28 SEPTEMBER 2023 Visit: procureconeu.wbresearch.com Or simply scan the QR Code

Welcome to the August 2023 edition of CHAIN Magazine!

We are delighted to share five insightful interviews with you this month in CHAIN, the go-to digital magazine for the latest global supply chain, procurement and logistics news and stories.

Our cover interview is with Tássia Pacini, Head of Procurement and Quality at ZAMP, who shares insights into the company’s new chapter alongside the digital innovation and supply chain transformation behind its success. Learn more about their drive to conquer and connect with new markets, flavours and consumers on page 6.

I sit down with Tomasz Borowski, Chief Operations Officer at Tonik Bank, the first digital bank in the Philippines. We discuss scaling operations through digital transformation at Tonik, where the aim is to provide simple, accessible and competitive financial solutions to the underbanked and underserved people that make up 70 per cent of the country’s population (p24).

Hady Kfoury, Founder and CEO of NAYA, chats with me about the fast-casual company’s expansion, supply chain transformation and culinary innovation that never loses sight of cultural authenticity or striving towards sustainability (p50).

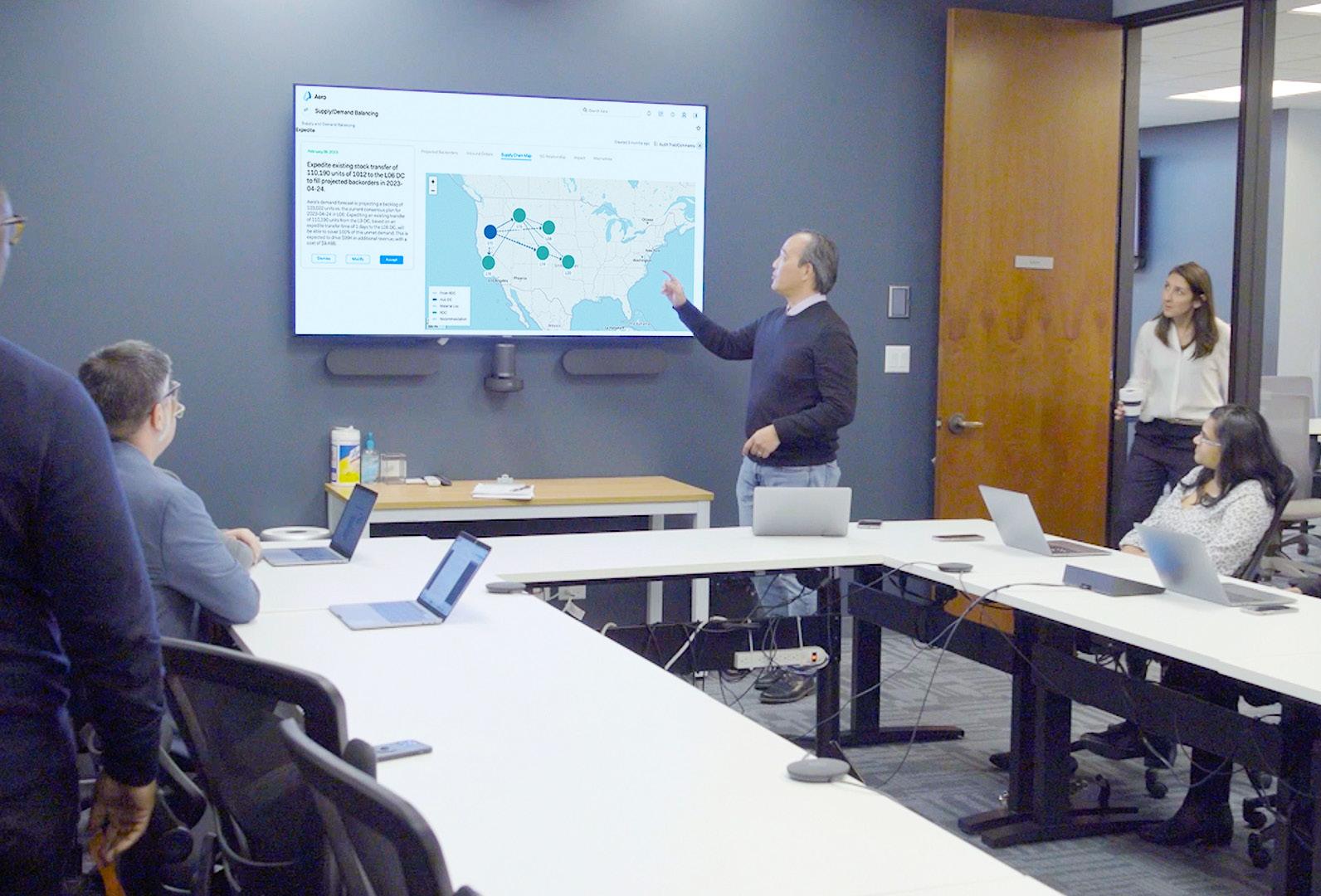

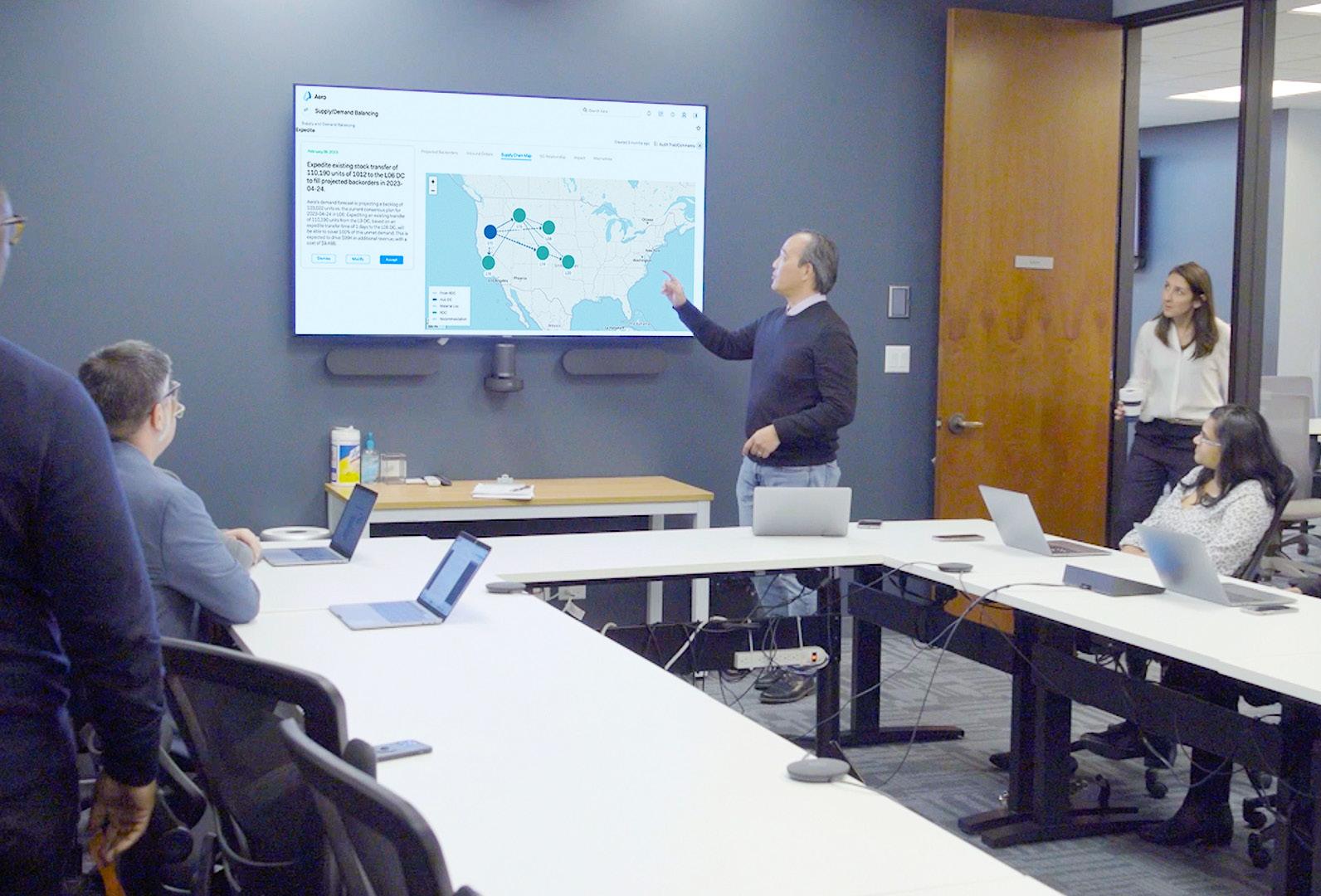

I speak to Michael Späth, Regional VP, DACH at Aera Technology about the company’s mission to revolutionise decision-making with innovative technology solutions to help businesses transform their enterprises (p80).

Nadine Hessel, Global Director for Supply Chain & Infrastructure at FläktGroup tells me all about the company’s innovative technology and supply chain strategies as a global leader in the indoor air quality industry (p100).

Our features this month include the latest fascinating industry insights from the Deloitte Global Chief Procurement Officer Survey 2023 (p38) and exciting news of Tower Cold Chain’s expansion into the Americas region with its opening of a new headquarters in Philadelphia, US (p68).

Wrapping things up, we are thrilled to welcome Gregor Stühler of Scoutbee as the second guest in our new recurring feature In the company of… (p114).

We hope you enjoy our latest edition. As always, if you would like to be considered as an interviewee or if you have a story for us to include, please do get in touch.

3

+44 (0) 203 890 1189 enquiries@ithink.media d.harris@ithink.media t.barnes@ithink.media editorial@ithink.media Editor Ben Craske Director Danielle Harris Director Tom Barnes design@ithink.media Senior Digital Designer Daniel May All rights reserved. Every effort is made to ensure the accuracy of material published in CHAIN Magazine. However, the company cannot accept responsibility for the claims made by advertisers or contributors, or inaccurate material supplied by advertisers. CHAIN magazine is a product of iThink Media Ltd. Company Registration Number: 10933897. Company Registered in England and Wales

FROM THE EDITOR AUGUST 2023

6 We speak to Tássia Pacini, Head of Procurement and Quality at ZAMP – formerly Burger King Brazil

24 Tomasz Borowski on revolutionising how money works in Southeast Asia at Tonik Bank

38 Explore key takeaways from the Deloitte Global Chief Procurement Officer Survey 2023

50 Hady Kfoury, Founder and CEO of NAYA discusses culinary innovation, supply chain transformation and sustainability strategies

68 Cold chain company expands into the Americas with new regional HQ

80 We sit down with Michael Späth, Regional VP, DACH at Aera Technology

100 Nadine Hessel on innovation and transformation in the supply chain strategy at FläktGroup

114 In the company of… Gregor Stühler of Scoutbee

4 AUGUST 2023

5

68 6

Michael Späth

38 24

Tássia Pacini

114

Tomasz Borowski

80

Gregor Stühler

100 50

Nadine Hessel

Hady Kfoury

An appetite for AND

Tássia Pacini, Head of Procurement and Quality at ZAMP – formerly Burger King Brazil – discusses the company’s transformational journey in the past year while driving innovation and supply chain transformation across such a vast country.

6

COVER STORY

n August 2022, after 10 years as Burger King Brazil, the company adopted the name ZAMP. The change came with the objective of presenting the company's new chapter, focusing on new experiences for the consumer and the advancement of digital transformations for employees and consumers. Here to talk more about the ZAMP’s journey to conquer and connect with new markets, flavours and consumers is Tássia Pacini, Head of Procurement and Quality at the company.

A journey of transformation

Tássia begins by highlighting how ZAMP is responsible for two major brands, Burger King and Popeye’s, with 1,000 restaurants across Brazil. But one of the biggest sources of pride for ZAMP is they operate 80 per cent of these restaurants, selling 15 million hamburgers per month.

“We are the biggest operator of brands in Brazil and we impact a lot of people here,” says Tássia. “I came here to be part of this big new moment for the company, to give more

8

ZAMP Brazil is a renowned restaurant operator with a broad portfolio of authentic brands that deliver food diversity and customerfocused service provision.

9

agency to the procurement and supply chain dynamics of ZAMP.

“We are very market focused, but in the past two years ZAMP placed more emphasis on developing and empowering a supply chain focus in our operations. My role here is to

oversee all aspects of our supply chain, procurement – direct and indirect – and quality control, research and development.”

Speaking to ZAMP’s transformational journey in the past 12 months, Tássia highlights the fundamental importance of

10

digital transformation within its supply chain and operations.

“We are going very deep into digital transformation not only with technology but in innovation,” explains Tássia. “So as part of this journey, the company is accelerating at a

pace we’ve never seen before. And I can say that our digital transformation is not only from the inside out, but also from the outside in.

“We are very focused on having close contact with our clients but making our engagement even

11

deeper and more meaningful. We are investing heavily in digital restaurants and ‘totems’ – digital displays that show rich information to our consumers, allowing them to have a better, more personalised experience in our restaurants, thereby improving our relationships with the guests.

“Alongside this, we are investing in systems like our loyalty club that we started two years ago. We were one of the pioneer companies in Brazil to have

this kind of service and now we have more than 12 million users in our loyalty club. Our huge membership base generates a terrific volume of information and we only want to increase that as part of our digital transformation.

“We also have to consider our entire environment, the ecosystem of information or touchpoints with our customers. Here our total network is 17 million users, including the twelve million people in our loyalty club.

12

“As we have been embarking on our digital transformation journey, it has become even more important due to the implications of challenging economic conditions in recent years. But we were very confident we would recover and it heightened our focus on technology and digitalisation. We accelerated our digital transformation because we knew it would benefit our consumers but also benefit us as a company in terms of efficiency, cybersecurity and supply chain benefits.

“In particular we have seen fantastic progress within our logistics efficiency. In a country as large as Brazil, with so many restaurants spread out over such a huge area, it’s crucial to be efficient with our deliveries.

“We are also investing in automation to enhance our processes, increasing the speed and agility of our internal work but also how we engage with our customers.”

So how will ZAMP build on this momentum and what are its growth plans for 2023 and beyond?

Tássia answers that ZAMP will continue to focus on its digital transformation and dive even deeper into digitalisation. But the company also has ambitious plans to embed new technology into its stores and open more of them.

13

“We accelerated our digital transformation because we knew it would benefit our consumers but also benefit us as a company in terms of efficiency”

“Our plan is to close 2023 with 100 restaurants transformed into entirely digital stores – which constitutes 10 per cent of our operations in Brazil,” says Tássia. “We also want to universalise the presence of self-service ‘totems’ in every single one of our restaurants. Another valuable investment we are making in technology focuses on better understanding the behaviour of our customers. We want to become even more innovative with what we can offer to our clients.

Finally, by the end of 2023, we aim to open 80 more restaurants to join the 1,000 we already operate.”

Societal role

Tássia thrives on the energy and innovation at ZAMP but she also celebrates how the company takes a threepillar approach to its environmental, societal and corporate governance (ESG) responsibilities.

14

15

“Our plan is to close 2023 with 100 restaurants transformed into entirely digital stores – which constitutes 10 per cent of our operations in Brazil”

“We really believe in doing the right thing because at ZAMP we see it as our role in society because we impact the lives of many, many people”

Tássia Pacini, Head of Procurement and Quality at ZAMP

ZAMP’s three pillars all promote progressive approaches to ESG with core strategies related to people, food and the company’s ‘pegada’ – which translates to ‘footprint’ in English, but here means ZAMP’s way of doing things.

People

When it comes to people, Tássia explains how ZAMP champions equality and inclusivity.

“We are a very open-minded company and about half of our leadership team are females,” emphasises Tássia. “For Brazil, these are very strong numbers that reflect our diversity and commitment to equality. But even more than this, ZAMP is committed to promoting female empowerment and eliminating any form of restrictions in our selection or promotion processes. We are open to all kinds of diversity,

18

without prejudice towards anyone regardless of their race, gender or socio-economic circumstances. We also host and promote awareness meetings for different groups of employees within the company, training and educating our people on issues ranging from maternity leave and communication strategies to empowerment.

“ZAMP is a wonderful place to work. The culture here means I feel like

I can be myself and I also feel totally supported and equal with my colleagues.”

Food

For the second pillar, food, ZAMP relishes its goal to offer its customers the most pleasurable experience possible.

But Tássia emphasises how the company extends its sense of

19

accountability beyond enjoyable cuisine and promotes transparency, responsibility and inclusivity around its food.

For instance ZAMP includes certification of origins on its packaging and recycles 100 per cent of the oil used by its restaurants.

But Tássia is particularly proud of how ZAMP was the first fast food

“By 2025, we want to remove artificial ingredients from 100 per cent of our menus.”

The final piece of the puzzle for ensuring their food provides a pleasurable experience is ZAMP’s focus on reaching new consumers and markets by diversifying their offerings.

Here Tássia stresses the importance of business

“PlantPlus Foods were the first company we worked with to help us provide food for everyone and diversify our menu. We worked together to offer more vegetarian options and plant-based foods, culminating in the release of our first plant-based hamburger”

company in Brazil to pioneer a clean labelling programme.

“We started the clean labelling programme almost three years ago and since then we have eliminated 90 per cent of artificial ingredients from all our menus,” lauds Tássia. “It was a huge undertaking to find the right suppliers, develop ingredients, attract investment and execute extensive research programmes for the benefit of our customers.

partnerships and ZAMP’s work with PlantPlus Foods.

“PlantPlus Foods were the first company we worked with to help us provide food for everyone and diversify our menu,” says Tássia. “We worked together to offer more vegetarian options and plant-based foods, culminating in the release of our first plant-based hamburger.

“We weren’t used to making these kinds of products because in

21

Brazil, compared to other countries, vegetarian or vegan diets aren’t as prevalent.

“But more and more people come to our restaurants with diverse dietary needs or preferences and we decided to develop our menu, production, marketing and innovation efforts to serve these customers and connect them to new flavours. We want everyone to feel welcome in our restaurants and part of that involved transforming what choice we can offer them.”

Pegada

ZAMP’s ‘pegada,’ or ‘way of doing things’ is the term used for the third pillar of the company’s approach to ESG.

Elaborating on the term, Tássia explains “In Brazil, ‘pegada’ is like our ‘footprint.’ This third pillar can cover things like having better energy efficiency in

our restaurants and using renewable sources of energy wherever possible. “Today we have about 80-90 percent of our energy from renewable sources because we have a partnership with five green power plants that generate electricity through solar or wind power.

“A lot of companies approach ESG with costsavings at the front of mind ahead of sustainability. But at ZAMP, we are proud to flip this on its head with our three pillars because our ESG endeavours put progress and sustainability before cost reductions or considerations.

“We really believe in doing the right thing because at ZAMP we see it as our role in society because we impact the lives of many, many people.”

For more information about ZAMP, visit their website zamp.com.br.

22

Added Value

Cultural curiosity

Tássia embraces open-minded curiosity in her personal life and professional career, where she actively explores the experiences of different people and cultures to learn from them.

“I love to understand what motivates people and engages them. I find it fascinating to learn about different cultures, different countries, different ways of working and different ways of thinking. As I built my career I have lived and worked in several countries: France, Japan, USA and Sweden for instance. Every time I visit a new country I take notes so I can learn from my experience there.

“People make the world go around and it is important to me that I continually expand my horizons because it deeply interests me.

“One of my favourite books that grapples with our shared experience as humans is Sapiens: A Brief History of Humankind by Yuval Noah Harari.”

Events

Tássia is looking ahead to November with excitement, when she will be attending Brazil Supply Chain, Logistics and Procurement Summit 2023.

23

Serving the underserved: Operational growth and transformation at Tonik Bank

BUSINESS INTERVIEW

digital Bank

Tomasz Borowski, Chief Operations Officer discusses Tonik Bank’s mission to provide financial solutions for the 70 per cent unbanked population of the Philippines.

underserved:

Based in the Philippines, Tonik aims to revolutionise how money works in Southeast Asia by providing a transformative digital banking service.

nderpinning the business is a belief that unbanked Filipinos deserve a better choice of simple, accessible and competitive financial services.

Tonik puts its customers first with its products which include retail financial products, including deposits, loans, savings accounts, payments, and cards on a highly secure digital banking platform.

Tomasz Borowski, Chief Operations Officer at Tonik joins us to shed light on the digital transformation and mindset behind the bank’s operational growth.

Tomasz’s role is to prepare Tonik for rapid growth and oversee the upscaling of its services. He begins by explaining how in the past few years, Tonik has built everything from the ground up as the first digital bank in the Philippines.

“In the last few years we’ve been building everything from scratch – from developing our applications to attracting clients for our deposit products,” recounts Tomasz. “We moved on to building additional products and developing our loan services. Now we’ve finished the

26

27

28

building phase, so it's time for scaling. This is the most exciting time in operations – when you get to scale a business.”

As Tonik turns its attention to scaling, Tomasz explains the vital importance of digital transformation in the bank’s journey so far.

banking, meaning the branches, or they have been underserved by those traditional banks if they can reach them.”

Digital transformation hinges on innovation, but Tomasz highlights how it is the mindset behind the innovation that sets Tonik apart from its competitors.

“The Tonik journey started because we saw and felt the need to offer a more user-friendly approach to banking and help to address financial inclusion issues,” says Tomasz. “This is particularly relevant in the Philippines, where a significant portion of the population, 70 per cent, are still unbanked and that's why we are here as a digital bank. Digital banks, such as Tonik, provide access to financial services for people who traditionally may not have easy access to physical

“Of course, you need to invest money into new technologies, automate processes and explore new platforms. But where we need to start is with our mindsets. Here is where Tonik differs from the mindset in traditional banking. We are not digitalising traditional processes, we create digital processes in the first place. For instance, we were in discussions with a potential partner and exploring the services they were supposed to provide us in the future. They proposed to send

29

“We can always strive to provide a better customer experience whether that’s related to products that they use or how we understand our clients to better serve them”

Tomasz Borowski, Chief Operations Officer

us an email every day with the register of the services that people used. That might have worked at a traditional bank but at Tonik we ask questions and approach suppliers differently. If you want to be our partner, you need to think about how to create a digital process first instead of suggesting a typical, manual process that we must digitalise in the future.

“The majority of people still think

there are makers and checkers in operations. I think personally that the era of the makers is finished. With all the algorithms and all available technology at our disposal in operations, including AI, human makers are already less reliable. Digital banks need only the checkers, humans who are making sure that digital processes are executed properly by machines. The mindset is where it all starts.”

30

Further, Tomasz stresses that operational growth at Tonik also banks on the belief that operations can always be better.

“What I find exciting about operations is that it’s a neverending story,” says Tomasz. “We never stop improving. In other industries, the product improvement cycle takes years, if you look at cars as an example – in retail banking operations,

you constantly challenge existing processes, improvements are implemented every month and that's what I really love about the job.

“There is always space for standardisation or automation of processes. And this applies to all areas that operations are involved in, starting with customer service. We can always strive to provide a better customer experience whether

31

that’s related to products that they use or how we understand our clients to better serve them. Then there’s security. We can always try to improve the security of our transactions, enhance our data privacy or minimise potential issues that might arise. Let’s not forget external collaborations as well because they are an important part of Tonik’s existence. We are very demanding in terms of choosing our business partners to make sure our cooperation is based on the same level of professionalism and understanding of our customer needs and Tonik’s highest standards.”

As such Tomasz believes that operational transformation emerges from many small victories. At Tonik, this has included significantly upscaling the operations department without needing to add any new full-time employees, the way the bank processes customer feedback, improving their deployment of AI chatbots and building a robust AIbased quality control system and AI analytics module among dozens of other projects.

Securing these victories that help Tonik build and scale as a

32

company relies on productive strategic partnerships. In banking, Tomasz divides partners into two groups.

“First, there are partners that you can fully outsource a process that is not from the bank’s core business, not really adding the value to our clients or building the value of the bank,” says Tomasz. “The second group of partners, on the contrary, are those who have the expertise in one particular area, who were focused on a specific topic for years and mastered the solution, be it a system or module covering a particular process.”

On the topic of software partnerships, Tomasz focuses on the importance of onboarding clients and Know Your Customer (KYC) procedure. Strict compliance rules and the difficulty of client verification in the digital space elevates this process to one of the most critical processes in digital bank operations.

“As a digital bank, we never see the clients in person,” explains Tomasz. “That is why

33

we need to rely on professional software during the client onboarding process that can identify the relevant documents, decrypt the data from different types of documents, authenticate these documents, recognise a client’s selfie and match it with

the photo in ID and then verify collected data with other sources and perform the necessary x-checks in real-time. With partners like Daon, Tonik is able to rapidly increase the number of clients attracted by our offer and services level.”

Seamless KYC or secure CIAM?

Most digital identity providers only offer one or the other

With Daon you don’t have to choose

• Instant digital trust with any customer, anywhere – in minutes, not hours

• Identity Continuity, Daon’s seamless integration between KYC, CIAM and account recovery

• Patented, NIST certified AI/ML powered biometric algorithms

• Cross-channel solutions for however customers access your services: mobile, web, contact centre or in-person

Tonik Bank chose Daon to create frictionless, futureproof digital experiences for their banking customers.

Choices matter. Choose Daon.

LEARN MORE

“With partners like Daon, Tonik is able to rapidly increase the number of clients attracted by our offer and services level”

35

So what does the future hold for Tonik?

Tomasz emphasises how Tonik is in an exciting scaling phase of its journey and the business is looking ahead with growth in mind.

“We are always preparing for the next phase. Currently, that means scaling our loan products. We already have a wide range of products, starting from buy now pay later loans, via unsecured, small ticket size cash loans and unsecured

Tomasz likes learning and embraces it as a way of life. Ten years ago, his curiosity led him to artificial intelligence, and he recalls the excitement he felt for its potential to revolutionise technology and operations.

He draws attention to the current hype surrounding ChatGPT and the concerns about potential risks it might pose. Tomasz is less concerned with things like chat functionality and instead relishes the technology's potential deployments elsewhere.

36

Lifelong learning and embracing AI

personal loans addressed to clients with a bit bigger loan amount needs, up to a secured, home equity product, up to 5 million Philippine pesos for entrepreneurs. We finished building the current product range last December, we tested

them and finally, we are ready to scale them now. The plan for the next 12 months is to double the number of clients we have currently.”

To learn more about Tonik Bank, visit their website tonikbank.com.

Connect with Tomasz

“I've been involved in and aware of AI for 10 years. Back then I started thinking how it would be fantastic if we could use the technology for automation and analytics.

“I recognised that if you had much more power to analyse all the data that we are producing in operations every day, then you could improve your processes in a more complex way, much more efficiently. The best examples are quality control, training and customer interactions. For us in operations 10 or 15 years ago, all these processes were handled manually.

“But with voice-to-text technology and AI analytics you can automate 100 per cent of quality control function by verifying all interactions with clients, evaluating those interactions and automating the creation of training materials, agent's evaluation and their profile matching with our clients to ensure the highest service level.

“Coming from a world ruled by manual processes, the potential of AI is an exciting, empowering phenomenon and I look forward to seeing how our implementations will improve our operational processes even further.”

37

Latest findings from Deloitte Global CPO survey

Delve into procurement industry insights from Deloitte

RESEARCH

REVEALED

For more than a decade, the Deloitte Global Chief Procurement Officer (CPO) Survey has served as an industry benchmark, revealing insights into the forces shaping procurement, supply chain strategies and performance.

ollowing the COVID-19 pandemic and the unprecedented levels of supply chain disruption there has been a growing need for procurement to enable growth, mitigate inflation and drive significant levels of value.

The 2023 survey delves into what makes top-performing CPOs or “Orchestrators of Value” — leaders who get everyone working together to play off the same “score” — and collaboratively build enterprises capable of orchestration.

Here, we break down some of the crucial insights from the 2023 Deloitte Global Chief Procurement Officer (CPO) Survey.

Key takeaways

• In 2023, the role of the chief procurement officer (CPO) continues to face intense complexity as leaders navigate unprecedented levels of supply chain disruption coupled with procurement's increasing value proposition at the heart of the enterprise.

• High-achieving CPOs see this volatility as an opportunity to invest in talent, transform their operating models and accelerate their digital transformation efforts to successfully deliver on business priorities.

• Allocation of time matters. Top-performing CPOs are leveraging digital advancements and outsourced talent models to remove themselves from

tactical, transactional and operational work to focus more on strategic activities like business engagement or supplier collaboration.

Shifting priorities

This year's study revealed that procurement is engaging across a broader set of priorities than ever before, with environmental, social and governance (ESG) and corporate social

“This year's study revealed that procurement is engaging across a broader set of priorities than ever before”

responsibility (CSR) becoming increasingly important. Digital transformation remained a top priority as well as a key strategy found among Orchestrators of Value. Other insights include:

• Enhancing ESG and CSR jumped to the No. 2 priority spot (72 per cent), up from No. 7 in the last report.

• Driving operational efficiency (74 per cent) remained the No. 1 priority.

Digital transformation (72 per cent) tied for priority No. 2 (up from its previous No. 3 spot), while improving margins via cost reduction (71 per cent) came in at No. 3 (down from No. 2 in 2021).

• The 2023 study found that Orchestrators of Value are three times more likely than their peers to be involved in digital transformation, the third most cited procurement priority.

KEY QUOTES

“Following the COVID-19 pandemic's unprecedented supply chain disruptions and the rising expectations for procurement to enable growth, CPOs are currently being challenged to do more, and better, with less. As we navigate this pivotal moment for the industry, investment and development of talent and operating models will likely differentiate the CPOs who win from everyone else.”

Ryan Flynn, Principal, Deloitte Consulting LLP

Ryan Flynn, Principal, Deloitte Consulting LLP

QUOTES

"The enablement of digital capabilities to aid decision-making and execution is allowing CPOs to build agile and digitally enabled procurement operations. Coupled with developments in AI and the speed at which it's advancing means that procurement is in a state of constant change. From basic process streamlining to driverless organisation enablement, AI is poised to help us make better, more data-driven decisions — and smart CPOs are paying close attention."

Jennifer Brown, Principal and supply chain procurement offering leader, Deloitte Consulting LLP

“To achieve successful digital transformation, CPOs must accurately define the value proposition that technology is intended to solve”

Orchestrators of Value versus Followers

To help transform value chains, enhance third-party management and maximise enterprise value beyond basic supplier cost reduction and risk mitigation, the CPO must take a leadership role in collaboratively building an enterprise capability of “orchestration.”

When comparing orchestration capability against value delivered, the 2023 survey found that the top quartile of CPOs has a 25 per cent performance advantage over their peers. These top quartile respondents were designated as Orchestrators of Value versus their peers, who were classified as Followers.

This year's study found that Orchestrators of Value focus on three main areas:

procurement has seen a continued trend toward increased centralisation of key capabilities. CPOs can optimise operational models by standardising processes and policies, creating purposeful teams and using outside intelligence to inform their highest priority opportunities.

2. Talent strategy — By sourcing capabilities more widely and investing in sophisticated talent development strategies, CPOs can not only close capability gaps but also optimise for demand fluctuations, quality and cost.

1. Operating model design — Organisationally,

3. Digitisation maturity — To achieve successful digital transformation, CPOs must accurately define the value proposition that technology is intended to solve and the capacity for the broader procurement team to engage digitisation programmes in meaningful ways.

Looking forward: Top strategies to deliver value

What are CPOs focused on to deliver value amid an uncertain and complex global business environment?

The answer focuses heavily on suppliers. Both supplier

collaboration (No. 1) and supplier renegotiation (No. 4) require strong category management, good data transparency and trust. These two top strategies also benefit greatly from advanced analytics and are enabled, in part, by the No. 2 strategy of digital transformation.

“CPOs can play an active role in proactively managing the procurement industry's current inflexion point”

Arguably the greatest impact CPOs can have on cost and risk is in defining demand, alongside internal stakeholders and even external customers. By helping to shape the specifications, volume commitments and timing of purchases, CPOs can play an active role in proactively

managing the procurement industry's current inflexion point.

For additional results from Deloitte's Global CPO Survey, read the full report here.

Source: Deloitte Consulting LLP

CHAMPIONING AUTHENTICITY AMID CULINARY INNOVATION, SUPPLY CHAIN TRANSFORMATION AND BUSINESS EXPANSION

Hady Kfoury, Founder and CEO of NAYA tells us about the strategies behind the fast-casual chain’s success.

BUSINESS INTERVIEW

TRANSFORMATION

52

NAYA has come a long way since it opened its first full-service restaurant in New York in 2008. The company pivoted to a fast-casual model and has seen incredible growth in the past 15 years.

ere to tell us more about the culinary innovation, supply chain transformation and sustainability strategies behind their success is Founder and CEO, Hady Kfoury.

Origins

Hady moved to the USA in 2004 and after working with celebrity chefs Daniel Boulud and Francois Payard for three years, he realised Lebanese cuisine was underrepresented in the New York food scene.

“I thought there was such a great opportunity to elevate the

53

cuisine and bring it to where it deserves to be,” recounts Hady. “That's where the idea arose for NAYA in 2007. I raised money from my family and started working on my first restaurant. The process took me a while between finding real estate and starting the new venture. At the time, the market used to be called the landlord’s market. There were very few vacancies compared to today.

“To get a prime location in New York, you had to go to a landlord and present your business plan. The first question was always ‘How many restaurants do you own?’ and unless you already had an establishment, they turned you down. So it took me about a year to find a very basic location, nothing crazy or particularly fancy, and it wasn’t the prime location where I wanted to be.”

Hady’s plan was to open a fastcasual restaurant in an area with a dense population of offices, much like NAYA is today. But his first restaurant which opened in 2008 was in a more residential area, so it had to be full-service to match the expectations of local customers.

The ups and downs of this first establishment provided Hady

54

with several valuable lessons but one of the key challenges was opening without any working capital.

“We opened in 2008 in November without any working capital because I had a certain budget to build the place and actually it cost one and a half times more than I anticipated. Unfortunately, I had to open the doors with no working capital and 70 per cent of restaurants fail in New York City in the first year due to a lack of working capital. We were fortunate to find generous suppliers who gave us 15 or 30 days of credit. Usually, nowadays, they'll start with COD (cash on delivery) until you're up and running for a few months and then they'll start giving you credit.

55

“Hady’s plan was to open a fast-casual restaurant in an area with a dense population of offices, much like NAYA is today”

Fortunately, we were able to get credit from day one.

“Back then there was no social media – in the restaurant industry, you looked to the New York Times Wednesday paper because they had a whole dining section. It used to be the Bible of restaurants. We were lucky to feature in there a month after we opened since New York had never had a Lebanese restaurant. The next day we were inundated with customers and in a way that article saved us because we then didn’t have to worry about cashflow.”

From 2008 to 2010, the restaurant thrived. After the global economic crash in 2008 and the downturn in real estate prices, by 2010 Hady realised there was a valuable opportunity to expand his business enterprise at a reasonable price.

“In 2010, I decided to venture with an offshoot of NAYA called NAYA Express. It evolved into the model that I'm currently running, which is a fast-casual version of the original NAYA restaurant. We rebranded in 2017 and we dropped the word ‘Express’ from our name.”

The first four years after the first fast-casual store opened in 2010 were challenging. Hady recalls how difficult it was to build brand awareness in Midtown, Manhattan and survive when you only open five days per week because the vast majority of trade came from office workers. But despite these early challenges, NAYA rode out the rocky first years, started breaking even and then Hady began expanding –slowly but surely.

Fast forward to 2019, NAYA had seven locations and Hady brought in partners for the first time.

“We were the talk of Midtown,” beams Hady. “We could have continued with self-funded organic growth but with our partner TriSpan onboard we could accelerate our growth far quicker. TriSpan is a London and New York-based private equity firm with a dedicated fund for restaurants. The company is great at spotting emerging brands that have a promising future based on a proven concept. Since NAYA partnered with TriSpan we’ve been able to upscale our growth plans to add 10-15 locations per year.”

Hady opened back in 2008 has just been converted to a fully digital fast-casual restaurant in 2022.

Culinary Innovation

Throughout NAYA’s journey of growth since 2008, Hady stresses how culinary innovation has allowed the company’s menu, services and operations to develop alongside the evolving brand.

At NAYA, culinary innovation began with Hady’s family.

Here, Hady lauds his mother’s contributions to the first NAYA restaurant, where she helped bring authentic, quality Lebanese cooking to the business. The only issue? She was trying to apply the principles of home cooking in a restaurant setting. When a staple menu item like hummus took 72 hours to produce, Hady admits the business needed to adjust its culinary approach – although he stresses it was the love and passion for authentic Lebanese cuisine that put them on the map in the 2008 New York Times article.

Bringing the NAYA story full circle, the first full-service restaurant that

“Lebanese cuisine, in general, is very labour intensive,” explains Hady. “Once we moved to the fastcasual model we had to evolve in how we prepare ingredients and manage the kitchen. We kept our cooking authentic. But we started

57

to use automation more and more. You see in Lebanon labour is very cheap. So at restaurants in Lebanon you could find 20 cooks in the kitchen, with one person just chopping parsley all day and another cutting onion all day. This model is not possible or practical here in the US. So you have to be smart with how you engineer your menu and how you cross-train the team to be able to do it all.

58

“After we had four or five locations we opened our commissary, which supported 50 or 60 per cent of our menu”

“So as we started evolving the way we prep with a reasonable amount of kitchen staff, then we brought in the right equipment to speed up our preparation process even further. We did extensive R&D and accepted we’d encounter a lot of trial and error during this time. But we always asked the question: how can we keep up production while maintaining the authenticity aspect of the menu?

“After we had four or five locations we opened our commissary, which supported 50 or 60 per cent of our menu. It offered a bigger space where we could produce all our dips and sauces, cut and marinade our meats and then ship the items to the stores every day. Produce was still cut on-site every day at every location to ensure ingredient freshness.”

59

Today, roughly 50 per cent of NAYA’s menu items are produced in its commissary but Hady indicates they will be removing it from their operations in the near future by looking for the right copackers.

“Moving away from the commissary to copackers has been a very big challenge so far,” admits Hady. “But the goal is always authenticity and to keep our unique flavour profiles. It’s a work in progress but we're almost there, working day and night on the project because we outgrew our commissary. Once we have the right co-partnerships in place, we will be able to grow tremendously.

“First, we won’t be dependent on the geographic location of our commissary, so we could expand anywhere in the US. Second, we won’t be beholden to products with a shelf life of two or three weeks and can start implementing HPP (high pressure pasteurisation), for example, which will extend the shelf life for 60 to 90 days without any

preservatives. This is where we are focusing our culinary innovation, putting a lot of work and effort into our products so we can keep on growing – while still putting the customer first and championing authentic Lebanese cooking.”

One of the key early co-partners NAYA has started working with is Fadaro Foods.

“Fadaro Foods has been a great partner to NAYA in terms of securing our produce. We get our produce from them daily across all our locations, covering the New York tri-state area. We've been very happy with Fadaro’s service and their products. For instance, with tomatoes, we have certain size and firmness specifications to be able to chop them easily. Fadaro Foods meet these needs very well, but they also deliver flexibly based on our needs – day or night. As such, they've been great partners in terms of freshness, due to their local sourcing, and they offer great quality and prices. They've

61

“Fadaro Foods has been a great partner to NAYA in terms of securing our produce. We get our produce from them daily across all our locations, covering the New York tri-state area”

been very supportive and very accommodating, especially now we have 21 restaurants, and we buy a lot of produce.”

Sustainability

Alongside their culinary innovation, NAYA strives for sustainability in its operations on several fronts and within their supply chain.

“We support local businesses and source our produce locally as much as possible,” says Hady. “Also our containers are made from fibre and we’re investing more and more into electric equipment to move away from gas appliances. Our newer NAYA stores are 100 per cent electric.

“We are also introducing a reusable bowl for our customers. Guests grab their meal in the bowl and then they can bring it back and we’ll either give them a newer version, recycle it, or rewash and reuse it. The advantage is customers using the

62

“When it comes to new locations, we are focusing this year on the sustainability aspect of our construction”

63

recyclable bowl will receive a 10 per cent discount on their order, motivating them to bring it back.

“When it comes to new locations, we are focusing this year on the sustainability aspect of our construction. We're trying to use natural and recyclable materials as much as possible. Across all our locations, established or

under construction, we use smart thermostats and all our lights are sensor-based so they turn off by themselves too. We also use smart sensors with our taps, soap dispensers and dryers to limit our environmental footprint. As many of our cleaning products as possible are organic and we try to use limited plastic, opting for glass instead. They’re baby steps

64

but they all contribute towards our greater emphasis on ESG and sustainability.”

NAYA works with multiple suppliers but Hady explains how the company tries to consolidate its supply chain to further improve its sustainability.

“Say we have four suppliers making

four deliveries in four trucks –the environmental impact soon starts to add up. So we try to consolidate our suppliers as much as possible and reduce the total number of orders we place. As we move away from the commissary and towards co-partners, maintaining our emphasis on local products wherever possible, we are trying to keep making

65

progress with our company’s impact on the world around us.”

So what does the future hold for NAYA?

Today NAYA has 21 restaurants: 14 in New York with establishments in three other states – Connecticut, Pennsylvania and New Jersey.

Hady shares how the goal is to open 25 restaurants in New York with expansion radiating outwards on the east coast north to Boston and south towards Washington DC.

“We are trying to grow as much as possible,” says Hady. “We’re not looking to the west coast because we would like to maintain our local approach to sourcing from our New York City base of operations and avoid using aeroplanes. We’ve proven our concept in urban areas so next we would like to break into suburban areas because here the potential for growth is limitless. One of our major goals at this point is to open 50 stores by 2025 and if things go as planned, hopefully, we will become a public company at some point.”

Learn more about NAYA by visiting their website eatnaya.com.

66

Connect with Hady

Added Value

Mentor appreciation

Hady expresses deep gratitude to his first culinary mentor, celebrity chef Daniel Boulud.

“Daniel is a legend in New York and the US in general,” says Hady. “He’s had a tremendous impact on me and mentored many successful chefs and restaurant operators. His impact on cuisine in the US has been profound.”

Formative education

Alongside his appreciation for his time spent with Chef Daniel, Hady celebrates his formative years spent attending the École hôtelière de Lausanne, the worldrenowned Swiss hospitality school.

Events

Hady recently returned from the National Restaurant Association Show in Chicago and he is looking forward to the next event in Chicago, May 18-21, 2024.

Every year Hady attends the North American Association of Food Equipment Manufacturers (NAFEM) show and insists it’s a must for anyone involved in the food service industry.

LEADING COLD CHAIN SPECIALIST SETS SIGHTS ON THE AMERICAS WITH NEW US HEADQUARTERS

Tower Cold Chain expands its global presence with the opening of its American Centre of Excellence

COLD CHAIN

69

PHARMACEUTICAL THERMAL PROTECTION

SPECIALIST TOWER COLD CHAIN HAS OPENED ITS NEW HEADQUARTERS IN THE AMERICAS REGION.

ocated in Philadelphia, just 1.6 miles from PHL International Airport, the 26,000 sq. ft building strengthens Tower’s container conditioning and storage capabilities, marking a significant milestone in the company’s

commitment to pharmaceutical, airline and 3PL customers in North, Central and South America.

Following the success of its Centre of Excellence in the United Kingdom, Tower Cold

Chain has replicated this proven model, with its latest facility offering design, laboratory and testing capabilities in the development of its temperature-controlled solutions.

The newly established Americas headquarters also includes office space accessible to customers, offering beneficial opportunities for meetings, demonstrations, as well as new product

72

“THIS MARKS A SIGNIFICANT STEP IN TOWER’S GROWTH TRAJECTORY”

Niall Balfour, Tower’s

Chief Executive

73

development in partnership with customers.

By establishing a dedicated Centre of Excellence in the Americas, Tower Cold Chain aims to strengthen its collaborative partnerships with pharmaceutical manufacturers, airlines and 3PL providers in the region. The facility will serve as a hub of innovation and expertise, fostering partnerships, knowledge

exchange and the development of customer-focused solutions to address the evolving challenges in the cold chain logistics industry.

“We are thrilled to inaugurate our Centre of Excellence in Philadelphia, which demonstrates our unwavering commitment to the Americas market,” says Niall Balfour, Chief Executive Officer of Tower Cold Chain.

74

“This marks a significant step in Tower’s growth trajectory. As demand for robust, reliable, reusable pharmaceutical logistics continues to surge, our investment in strategic

locations enables us to provide essential support for the seamless transportation of temperaturesensitive pharmaceutical and lifescience products.”

75

“TOWER’S DECISION TO ESTABLISH THE AMERICAN CENTRE OF EXCELLENCE IN PHILADELPHIA, PENNSYLVANIA IS A TESTAMENT TO THE REGION’S FAVOURABLE PHARMACEUTICAL BUSINESS CLIMATE”

76

Tower’s decision to establish the American Centre of Excellence in Philadelphia, Pennsylvania is a testament to the region’s favourable pharmaceutical business climate, proximity to customers and its robust logistics infrastructure. The company plans to leverage these advantages to build strong partnerships, whilst supporting its network of hubs throughout the region, including Los Angeles, San Francisco, Chicago and Puerto Rico.

An official Open Day will be held on September 12, 2023, in which Tower invites customers, partners and industry stakeholders to visit the Centre of Excellence and witness firsthand its cutting-edge facilities and expertise.

Contact the Tower Cold Chain Americas team by visiting the company’s global contact centres website.

Source: Tower Cold Chain

77

78

79

by NEVER MISS AN ISSUE SIGN UP FOR FREE!

Produced

SUBSCRIBE

Michael Späth, Regional VP, DACH at Aera Technology, champions the transformative power of Decision Intelligence.

80

BUSINESS INTERVIEW

82

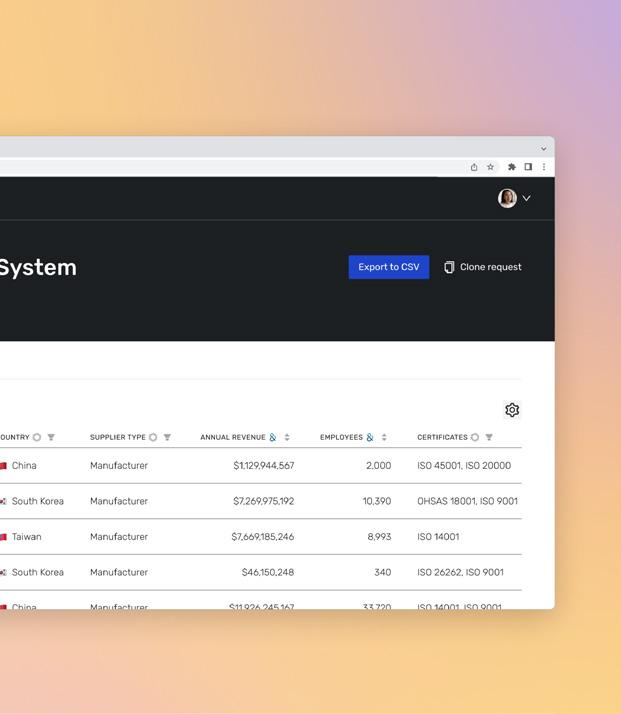

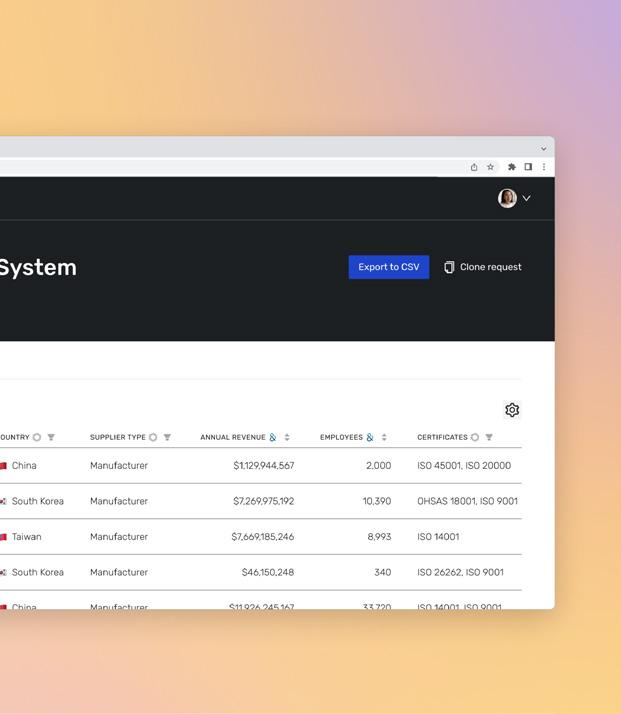

Aera Technology President and CEO Fred Laluyaux (left) and the company's founder and Chief Technology Officer Shariq Mansoor (right)

When they launched the company in 2017, the founders of Aera Technology had a clear vision: they wanted to revolutionise decisionmaking using innovative tech solutions and help businesses transform their enterprises.

rawing on many years of experience in enterprise software, specifically within the space of performance improvements and business intelligence, the founders always felt something was missing.

Aera Technology is on a mission to address this gap in the market and make companies

wildly successful by helping to make their operations more sustainable, intelligent and efficient. Delivering an AI and machine learning-powered platform that enables Decision Intelligence, Aera Technology helps businesses streamline and autonomously orchestrate their operations.

83

Here to discuss the company’s Decision Intelligence platform and how they can help businesses adapt to pressing supply chain demands is Michael Späth, Regional VP, DACH at Aera Technology.

Michael begins by explaining how the pace of market changes and volatile environments companies are operating in, combined with the complexity and scale of globalisation, means that businesses are

84

“After building the foundation, on top of that you need to have what we call the intelligence pillar, which is then the set of capabilities that you use to codify and model decision-making”

Michael Späth, Regional VP, DACH

struggling to make sense of all the data before them.

“The idea here is that if we can build assistance, at scale, that provides recommendations on decisions which liberate a lot of time people would spend on very complex, or very menial, tasks,” says Michael. “In doing so, we remove the pressure to deal with easy problems, allowing people to focus on the more valueadding tasks and the tougher problems that companies have to deal with.

“The fundamental idea is that human factors will always be paramount to any company: the human intellect and the human intelligence. But unfortunately today, in many cases, human intelligence is being used for things that machines can do a lot better and a lot more precisely. We're not even relying on people for what is truly uniquely human. And that's where we are as a company –we seek to support people with our platform by enabling companies to do what they do best.”

Michael breaks data-driven, digitised decisions into four pillars.

First, companies need a foundation to build upon. “You need to have the data harmonisation and the data wrangling capability at scale,” explains Michael.

“This includes connecting to enterprise systems of any shape or form, but also connecting into data sources from the outside world and bringing it all together into a single data model. That’s the foundation.”

“After building the foundation, on top of that you need to have what we call the intelligence pillar, which is then the set of capabilities that you use to codify and model decision-making,” says Michael. “You start with simple rule-based decisions, but then you can start mixing in advanced AI-optimised algorithms with simulation.”

The third component is what Aera Technology calls the ‘engagement layer.’

So, what does Aera Technology’s Decision Intelligence platform offer in terms of technology, capabilities, applications and results?

“We understand that when people are not accustomed to working with these advanced

85

86

algorithms, the fundamental problem to crack is trust,” says Michael. “How do you deliver a recommendation to a user? How do you explain that recommendation so that users understand how the platform arrived at this course of action? Are users able to modify these recommendations when needed before moving to execution?

“And how do you create a user experience that is gratifying so that people enjoy engaging with the software, and capture the feedback users give? This step is vital because leaders need to understand how users are interacting with the platform and its recommendations.”

87

“Our platform is robust and it's more a question of where you deploy it, and this really depends on the level of maturity of a company”

The final pillar is around acting and learning, enabling decision automation.

“We understand that when people take decisions, there's still a lot of work that happens after the decision,” says Michael. “There's the work of actually making sure it gets implemented and executed, often by manually updating transactional systems or even spreadsheets, before people can start to track whether the decision is delivering on the expected outcome.

“The whole capability to automate and to learn from decisions is the final pillar of the platform,” he summarises.

How Decision Intelligence can transform enterprises

What are some of the sectors where Aera Technology deploys its solutions?

“We've been building use cases with Decision Intelligence across various business domains,” responds Michael. “We have a heritage in supply chain and operations management. We’ve also explored a few use cases across procurements, both

operational procurements and strategic procurements. More recently, we're getting heavily into the space of revenue management – which covers things such as dynamic pricing, but also more importantly how companies measure and manage marketing spend.

“When large companies run campaigns on social media to promote particular products, we help those companies ensure that they have enough product available to meet the generated demand.

“We’ve also done quite a bit of work around optimising service levels. Here, our platform drives additional top-line revenue. We have several customers telling us that we've actually delivered up to 3 per cent additional top-line revenue through the increased service levels we can offer them.

“We have other customers focusing more on networking capital optimisation, which might be in terms of reducing inventories, or reducing accounts receivables and accounts payables. Doing so has freed up significant working capital for these companies totalling hundreds of millions of dollars.

88

“Many of our customers are speaking about the cost of unmade decisions. We like to focus on that area because there’s a massive opportunity that companies are not tapping into today”

“Lastly we have several customers, for instance in procurement, that have been looking to optimise spend, and our recommendations have accomplished this to the tune of tens of millions of dollars.”

Counting the cost of decisions left unmade

“But the real beauty of Decision Intelligence is that it's not so much about optimising the decisions that are being taken today,” explains

89

Michael. “It's actually about taking the decisions that are not being taken today.

“Because of the velocity of business today, there are so many demands being placed upon decision-makers, planners or procurement operators that they simply don't have the time or bandwidth to address all the issues they would need to deal with on a daily basis. Many of our customers are speaking about the cost of unmade decisions. We like to focus on that area because there’s a massive opportunity that

companies are not tapping into today.”

Focusing on the supply chain in particular, Michael highlights several pressing demands facing the industry where Aera Technology’s platform enables and empowers businesses to thrive.

Michael addresses the elephant in the room: the massive disruptions caused by the COVID pandemic. But he emphasises that the implications of the pandemic and national lockdowns are actually a spike in a broader trend of

90

increasingly shorter cycles of globally disruptive events.

“The rate of massive disruptions to supply chains has been increasing when you contemplate events on a longer horizon,” says Michael. “They used to happen every three years. Now, we're down to 14- or 12-month cycles where things really get mixed up. The old way of working, where you have an inflexible process model on an underlying ERP or planning system, is just not agile enough because there are so many new situations that people have to deal with.

“Today companies try to work around the corners with data, spreadsheets or visuals and try to make the best decisions they can. But at the scale of a global, multinational company, it's just impossible to take that level of decisive action on every single issue.

“We help companies to better sense and anticipate demand challenges, not just around forecasting but also around responding in real time to things occurring in the market.

“Our platform harmonises data across the ecosystem, then applies AI and ML to model scenarios and predict the best solution options – which could consist of inventory deployments, sizing order allocation or a host of other challenges. We also seek to help customers shape their demand by coupling marketing spending to supply.

“Then we also seek to work towards the upstream supply chain, which is really around the procurement side. For example, if the platform identifies that a customer is still buying materials that they’re not going to be able to sell, then it notifies them with a recommendation to stop buying materials.

“We focus a lot of effort on wastage avoidance, which is a growing concern and a very visible issue for

91

“To help businesses get from A to B and deploy Decision Intelligence, Aera Technology relishes the chance to work with valued technology and data partners in areas of growth and operations”

consumers as well as investors. Customers that are working with us seek to synchronise their endto-end value chain so that they reduce obsolescence and avoid destroying materials, which in turn has obvious benefits for the environment.”

From decisions which avoid waste to those which free up working capital, the ability to take more decisions, more quickly and accurately, is transformative.

A true digital transformation of supply chains

Beyond helping businesses to lean into challenges facing their supply chains, Michael emphasises that Decision Intelligence enables companies to instigate, and achieve, true digital transformation of supply-chain decisionmaking.

“The traditional view of supply chain has always been, ‘Let's get our basics and our executional processes in order, then let’s deploy a next-generation planning system on top of that to make sure that we do good planning,’” explains Michael. “However, if you plan, let's say on the weekly cycle

or a monthly cycle, in reality, the minute after you publish the plan, it is out of sync with reality. That disconnect is immediate because your operations won’t consistently deliver on the plan, and also because for many companies there's actually a great deal of volatility in their operations. This can be on the customer side, but it's often also on the supply side of operations.

“This is where we can change the game with Decision Intelligence,” emphasises Michael. “We not only have state-of-the-art technology powered by AI and machine learning, we also bring the expertise and deep knowledge of industries to truly improve decision-making processes in supply chain and across different functions.”

To help businesses deploy Decision Intelligence, Aera Technology relishes the chance to work with valued technology and data partners in areas of growth and operations to continue serving their customers and elevate their success. But in particular, Michael highlights the importance of Aera Technology’s work with consulting partners.

92

“Our goal is to help businesses with building a decision-making ecosystem and leveraging our partners to help deliver value quicker and focus on that scaling component because the foundational work by Aera Technology has already been laid”

The value of partnership

“The journey with Decision Intelligence is foundationally a transformation to the way of working,” says Michael. “It's going from people doing the

work supported by machines, to machines doing the work guided by people.

“In this new paradigm, companies are going to be relying on knowledgeable people who

93

will engineer the system and enable the enterprise to run in a smoother, more agile manner.

“That's a big change, and this is where consultants and partners like EY are paramount because it's fundamentally a transformation of how companies run their

to fully realise the benefits of Decision Intelligence on their own.

“Companies like EY have a massive footprint. Of course, they do consulting – but they often lead the way with other crucial considerations like tax

businesses. There's a lot of design work, change management and onboarding enablement training, and there's also a lot of delivery work that must be done.

“By working with partners like EY, we always strive to enable our customers and our shared customers to be self-sufficient. We'd love to see our customers establishing centres of excellence where they build their own Decision Intelligence capabilities. Our consulting partners are truly paving the way to get there by helping our customers accelerate in the early days, run massive programmes and build the set of capabilities that companies need

work, handling transactions and much more. So they have a unique value that they can bring into companies for them to run decisions at scale.

“If you think about why consultants are being contracted today, it's because they have a set of specialised knowledge that companies don't retain themselves in-house around a very particular problem, needing a set of specialised knowledge to solve. Now if you could codify that knowledge, which consulting companies like EY are actually doing, they could provide that knowledge as a software service into the operating system of

94

“By working with partners like EY, we always strive to enable our customers and our shared customers to be self-sufficient”

What intelligence will we need to create a smart future? Learn how Decision Intelligence can help organizations make better, more informed decisions and increase success through applying advanced decision-making. Download our whitepaper or get in touch with our professionals: Heiko Kahrels Partner, Ernst & Young GmbH Wirtschaftsprüfungsgesellschaft heiko.kahrels@de.ey.com Alexei Koifman Partner, Ernst & Young AG alexei.koifman@ch.ey.com #decisionintelligence © 2023 EYGM Limited. All Rights Reserved. ED None. EYG no. 005711-23Gbl

the business, to allow them to scale and have that knowledge embedded into the way they take their daily decisions. This is really where the most exciting and innovative collaboration potential comes into play.”

So, what does the future look like for Aera Technology in the coming years?

“We're proud to work with some of the largest, most renowned companies in the world, particularly in consumer products, pharma, life sciences and chemicals,” says Michael.

“We want to become touchless in the sense that companies can go on their own journey, they can make use of all the content that we deliver – but they can take it from there to solve their own unique problems. Because what really constitutes the competitive advantage of a company is the unique set of knowledge and experience that belongs to the people who are running the business from day to day. Ultimately, to make the business succeed, they need to learn to codify their unique knowledge into a system that can help at scale.

96

“Our goal is to enable Decision Intelligence for business users, to provide them a platform that will empower them to automate decision making at scale.”

Wrapping up our conversation, Michael reiterates that five years ago when he joined Aera Technology he spent the majority of his working week preaching the importance of Decision Intelligence because it was a new idea. He welcomes the fact that today, more and more companies spanning multiple sectors and industries are embracing Decision Intelligence in their strategies and discussing its enabling potential.

“It’s amazing to see how our vision has become part of the shared understanding of practitioners in global markets,” says Michael. “With Decision intelligence, we can move beyond incremental progress and thrive with exponential improvements which will be foundational to achieving what we need to do as a world: to become more sustainable, intelligent, and efficient across every industry, and to continue to innovate towards progress.”

To learn more about Aera Technology, visit their website www.aeratechnology.com.

97

ALSO IN THIS ISSUE

Produced by NEVER MISS AN ISSUE of our sister publication SUBSCRIBE SIGN UP FOR FREE!

IMPROVING AIR QUALITY AND FOR PEOPLE AROUND THE WORLD

Nadine Hessel, Global Director for Supply Chain & Infrastructure at FläktGroup discusses the company’s innovative technology and supply chain strategies as a leader in the indoor air quality industry.

BUSINESS INTERVIEW

AND SAFETY WORLD

WITH A HERITAGE STRETCHING BACK MORE THAN A CENTURY, FLÄKTGROUP IS A MARKETLEADING COMPANY SPECIALISING

IN INDOOR AIR QUALITY AND CRITICAL VENTILATION SOLUTIONS.

he name stems from ‘Fläkt’ – the Swedish word for ventilation, an integral part of the company since its original inception in 1909.

FläktGroup was formed in 2016 when Fläkt Woods joined forces with DencoHappel (formerly part of the GEA Group) to become a market leader for energy-efficient Indoor Air Comfort and Critical Air solutions serving a global market.

We sat down with Nadine Hessel, Global Director for Supply Chain & Infrastructure to discuss

the supply chain strategy and innovation at FläktGroup.

Nadine begins by explaining how the company takes a holistic approach to their operations since they cover all stages from design and manufacturing products to delivery, after-sales and servicing provision.

“You can find our products everywhere – in commercial buildings, residential buildings, industrial buildings, and critical applications like data centres,” says Nadine. “We

102

103

have 13 production sites, 3,500 employees and we sell in 65 countries around the world. I’m responsible for the supply chain and infrastructure in our business area Services. My main focus is the global availability and storage of spare parts within our service supply chain. This is a bit different from the manufacturing supply chain as the sourcing is not only build and buy, but you can also repair a unit or secure replacement parts.”

So what does the supply chain strategy look like at FläktGroup?

Nadine describes how the approach to the service supply

chain today looks different to the provision offered in the past.

“For us, we need to focus on all components of the supply chain,” explains Nadine. “All aspects provide room for improvement. So if we start with planning it has always been important, but it has shifted from planning for just-intime delivery or just-in-case delivery for service, to now even getting components at all. So it's quite different from the way it used to be. We try to have inventory buffers on the one hand, and on the other hand, we seek to find alternatives for missing components. But if there are some components with a lead

104

time of two years, the customer can't wait that long.

“So instead of replacing them one by one like we used to do, we try to find an alternative part if it's available. Consequently, one of the core components of our strategy is multi-sourcing. So, of course, we have our main suppliers and it's vital to keep our relationships strong with them. But I'm always open to getting in contact with new suppliers. So I have a lot of suppliers that reach out to me on LinkedIn for example. Usually I meet with them and listen to their propositions. Maybe they will have some components I can use. So that has changed.

“The important thing to note with FläktGroup is that we are a group of international companies put together through acquisitions. So growing together is a challenge for us. Therefore it's quite important within the supply chain strategy to take a global view. To find a component for an urgent service visit, for instance, I can check the stock in our factories around the world. I can ask them ‘What is your production stock like?’ and ‘Can I have that part?’ When you have high commodity availability, you can look at individual entities. But in today's situation, I think a global view is critical. So this has brought

us closer together within FläktGroup. We have cross-departmental support and always set a global strategy, even for small parts. I can always just look at all the stocks we have and find parts somewhere.

“What is special about the service supply chain is that the demand is not predictable. But it's a good thing because if it was predictable, it would represent bad news for product failures. There are some components that you can exchange and maintain on a service visit, but most of the demand levels for parts are unpredictable. But nonetheless, for me, it's important to have an overview of what we have sold to do some kind of forecasting when possible. So planning is still super important.”

At FläktGroup the company’s supply chain strategy hinges on embracing innovation and transformation to keep their operations and service

105

“My main focus is the global availability and storage of spare parts within our service supply chain”

Nadine Hessel, Global Director for Supply Chain & Infrastructure

CONTROL THE GAME,

CHOOSE US AS YOUR IT PARTNER

www.wuerth-phoenix.com

info@wuerth-phoenix.com

Marketing Automation | Sales Management | After Sales Field Service Management | Power Apps

Passionate about Dynamics 365, we believe in CRM projects as business accelerators for all companies. Dynamics 365 is a powerful cloud-based platform that offers a wide range of applications to help companies streamline their operations and improve customer relationship management. It already offers a number of specific solutions for sales and customer management. However, we aim to go one step further by introducing Sales+, a value-added feature that caters to the diverse needs of the sales force. Sales+ aims to optimise the daily operations of the sales force by enhancing functions such as offer and order management, article searches, price information, warehouse stock monitoring and automation of approval flows. By leveraging Sales+, users can significantly reduce processing times, minimise manual operation and boost their operational effectiveness.

106

Constant quality of IT services to support company business.

provision for customers at the leading edge of the air technology industry.

“Especially in a changing business environment, it's important to be flexible and open for innovation,” says Nadine. “I'm not only responsible for the supply chain, but for the infrastructure at FläktGroup as well. We combine those two things, which for me is fantastic because I love IT and bringing them both together. It's

with the benefits and then decide whether it's the right tool at the right time. Not all innovation is good innovation.

“But at the moment, digitalisation is super important for us and we aim to have user-friendly and efficient tools. Here, we have been working with Würth Phoenix for several years to introduce Microsoft Dynamics 365. I started to work with them on a sales project some years ago, and now

a strong combination because if I see there are some processes or systems we need to adjust, I'm then responsible for those changes as well.

“As a company we are always looking for innovation be it in technological terms or digitalisation. But on the other hand, you cannot follow every trend and we won't explore them just because they're hip. Instead, we will compare our experience

in my new role it’s a pleasure to work with them again on behalf of our service technicians. By working with Würth Phoenix, our service technicians can do most of their administrative tasks with a smartphone, say to record their hours or fill out service reports. Of course, many technicians within the group were able to do this before but as we are different companies put together, we used to have different systems. Now we would like to harmonise

107

“By working with Würth Phoenix, our service technicians can do most of their administrative tasks with a smartphone, say to record their hours or fill out service reports”

that into one global system for everyone.

“Another exciting technological innovation for our service technicians could be smart glasses they wear out in the field. That is one thing we are testing right now. Say the technician requires some support from the back office, their colleagues might need to see the unit as well to help them –especially with such technologically complex products. With smart

glasses, the technician can share exactly what they are seeing with their colleagues – crucially leaving both hands free to continue their work on the ground. In turn, back office staff can then share images, instructions or files with the technician from their end as well and the technician will see them clearly within the device on a small monitor.

“Another important aspect of innovation and transformation for

108

“We put QR codes on our unit and customers can scan it and find all details regarding their orders like manuals, spare parts lists – everything they need for the order”

FläktGroup is to make life easier for customers as well. So we have started working with QR codes. For example, we put QR codes on our unit and customers can scan it and find all details regarding their orders like manuals, spare parts lists – everything they need for the order. Additionally, we put QR codes on components, so our customers can find a list of contacts and know where to order a new part easily and quickly.

“Besides these QR codes, our customers can also make spare parts requests directly on our website. What’s more, we also have some units that offer remote access and we will be expanding this feature to benefit our customers and enhance the assistance we offer them. As I'm responsible for the whole service supply chain, this includes digital service provision and site visits. Remote access has been a gamechanger because it saves time and

109

costs for both parties, which is a fantastic innovation for us.”

Underlying the innovation and transformation at the company, Nadine highlights the importance of partnerships for FläktGroup’s supply chain strategy.

“So for us, strong and reliable partnerships are fundamentally important to our operations,” explains Nadine. “We are dependent on primary materials or components and our partners help us meet our requirements and support us in difficult situations. So even if there are lengthy lead times we can talk to our suppliers. If we don't have materials, we cannot produce units or parts. Without partners, there is no growth or success so partnerships are super important to our supply chain strategy and it all starts with the initial supplier. In turn we not only rely on the partnership with our suppliers, but we have to consider the relationships they have with their suppliers as well. Even if our suppliers have a high vertical integration, they rely on others at some point in their supply chain. As a result, it's crucial to share information. So if our supplier knows there are some parts that are at risk, but we know about that in advance, it's less of a problem because we can adapt

110

accordingly. So if you have partners, you have to share information and be open to each other. Sharing information is important but I also think it's a huge advantage to have partners who know your requirements. For instance with Würth Phoenix, we've been working with them for years. They know our processes, they know our businesses and they know our IT landscape – so they know what we need. Long-term partnerships are essential for our business.”

At FläktGroup innovation, transformation and robust partnerships built on transparent communications are the core components for achieving success with its supply chain strategy. But what are some of the major challenges facing supply chain professionals today that these approaches help offset?