Vice President of Supply Chain at Hooters on the partner ecosystem and supply chain strategy behind releasing an exciting new product line in US supermarkets

Stay ahead of the curve with the go to digital platform for senior supply chain executives.

Welcome to the July 2024 edition of CHAIN Magazine.

ummer’s here, the sun is shining and football fever is in full sway for the Euros here in the iThink Media office!

We’re delighted to share four exclusive interviews with you this month, along with the latest global supply chain news and features.

Kicking things off in our cover interview this month, I chat to Joel Pounds, Vice President of Supply Chain at Hooters about the partner ecosystem and supply chain strategies behind releasing some of the guest favourite menu items as an exciting new product line in US supermarkets (

Bogdan Iliescu, Vice President of IT Products at METRO.digital joins me to explore how the company is wielding new technologies and transforming its supply chain to disrupt the retail industry, driving growth and enhancing customer experiences along the way (

Our community consists of C, V and D level executives from a wide range of industries. A unique blend of thought leadership interviews and features that cover digital transformation, supply chain, procurement, logistics, technology, AI and sustainability. CHAIN is a specialist technology platform with over 211,300+ readers.

I sit down with Dennis Stelljes, Associate Director of Strategic Sourcing and Procurement at Bristol Myers Squibb (BMS) to discuss the company’s pioneering approach to procurement in the pharmaceutical supply chain of its European operations (

Maytham Al-Elg, Localization Strategy Director of Baker Hughes offers his expert insights into the technological innovations and localised approaches driving growth in the MENAT energy sector

Our features this month cover looking ahead to the future of the cold storage market ( identifying six strategies the construction industry could borrow from the retail sector to drive ), reshaping the manufacturing sector by integrating control tower systems ( weaving AI and robotics into retail supply chains to promote flawless order fulfilment ( striving to cement Abu Dhabi’s position as a global life sciences distribution hub (

We are thrilled to welcome Jens Fath, Operations and Transformation Partner at PwC Germany as the guest in our spotlight feature

Please enjoy our latest edition. As always, if you would like to be considered as an interviewee or you have a story for us to include, please do get in touch.

editorial@ithink.media connect with me on LinkedIn.

6

20

Delve into the supply chain strategy and partner collaboration behind Hooters’ new product line with Joel Pounds

Technavio’s latest report offers insights into the future of the cold storage market

30

38

Bogdan Iliescu divulges the supply chain approach and tech transformation behind METRO.digital’s growth and success

Six strategies the construction industry can lift from the retail sector to catalyse progress

48 Dennis Stelljes on wielding technological innovation within pharmaceutical procurement for BMS’ operations in Europe

62 Industry blueprint for integrating control tower systems to reshape the manufacturing sector

72 Energy sector insights from Maytham Al-Elg of Baker Hughes

84

96

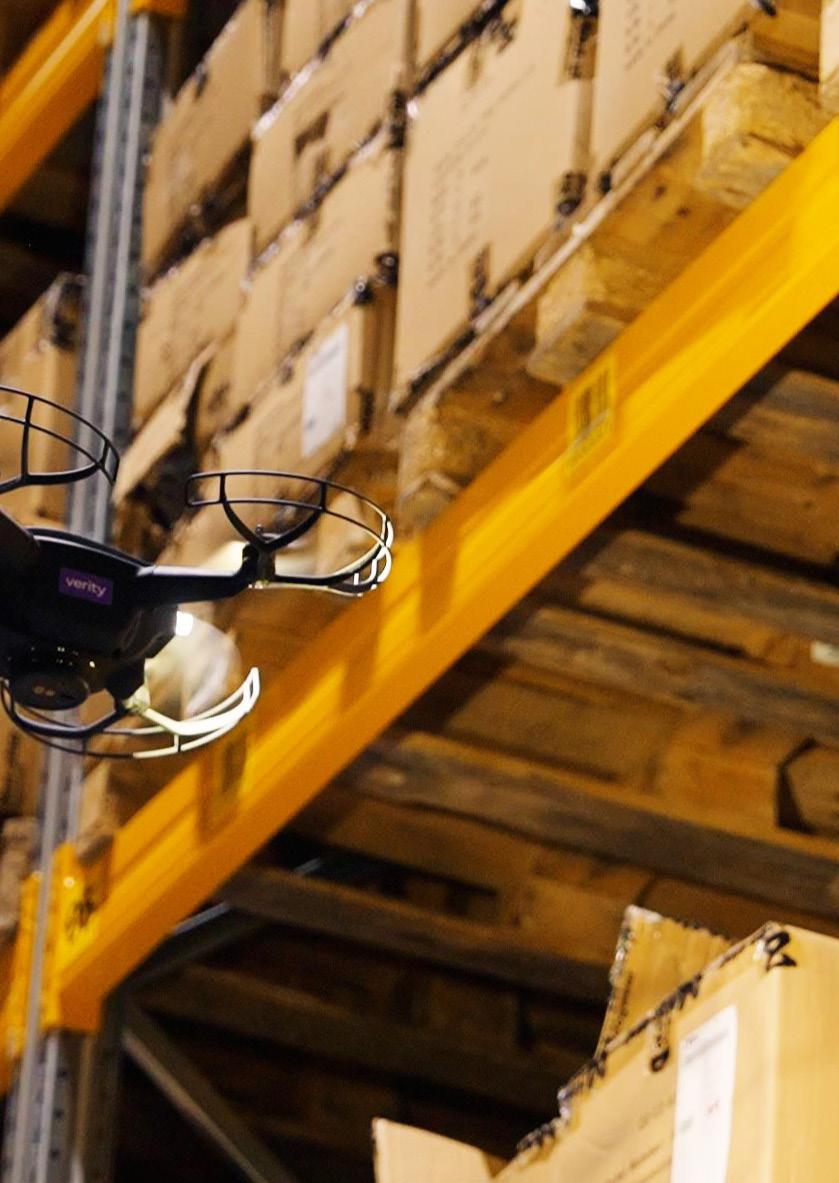

On and Verity partner to transform retail supply chain operations with AI and robotics

Industry leaders in Abu Dhabi set their sights on becoming a global life science distribution hub

108 In the company of… Jens Fath

Joel Pounds, Vice President of Supply Chain at Hooters on the partner ecosystem and supply chain strategy behind releasing an exciting new product line in US supermarkets.

is the franchisor and operator of more than 367 Hooters restaurants in 36 US states and 18 countries globally.

Known for its world-famous Hooters Style chicken wings, the first Hooters opened its doors in 1983 in Clearwater, Florida.

Expectations were so modest at the time that the simple fact the doors opened was deemed worthy of a toast. Since then, millions have been liberated from the ordinary at Hooters while enjoying great food, fun and one-of-akind hospitality that can only be served up by the Hooters Girls.

Last month, Hooters embarked on an exciting new journey – taking an array of its beloved menu items and offering them for sale in supermarkets across the US. Here to tell us more about the partnership and supply chain strategies at the company and behind the release of the new products is Joel Pounds, Vice President of Supply Chain at Hooters.

Joel has been in the Hooters system for 23 years, working across all the supply chain and distribution aspects of the company.

Setting the scene for the release of guests’ favourite menu items in US supermarkets, Joel rewinds to the challenging circumstances of the COVID-19 pandemic where the early inspiration for the project emerged.

“I think you have to look back to COVID-19, when people weren't able to get out of their homes, lacked the opportunity to have food delivered or couldn't go pick it up at Hooters,” explains Joel. “So we started brainstorming ideas for how we could share our great Hooters products, wings and appetisers with people who may not be able to go to our restaurants or receive them via delivery services.

“Through our brainstorming, we came up with the idea of exploring how we might offer some of our menu items in retailers. Keep in mind we've had certain products in retailers for years now – for example, some of our sauces and seasonings. But we wanted to offer a complete package.

“Nowadays, with the array of culinary options made possible by modern domestic kitchen appliances, you can have the same great products at home that you could in a restaurant. This realisation led the charge for our new product range.”

Joel describes the array of Hooters menu items now available to customers in their weekly grocery shop: “So along with being able to get our iconic wings, great burgers, delicious seafood and amazing appetisers, in our restaurants or ordered online delivered to your door – now we present customers the opportunity to enjoy some of our most popular menu items at home, by purchasing them in supermarkets.

“We partnered with Golden West Food Group out of California to make the products and they're using all Hootersspec items. They have products shipped from all of our vendors. It's exactly what you would get in our restaurants. We launched them in June at Publix Super Markets, which has almost 1,400 locations in the south-east US. From here, we will be going after other grocery chains as well in the near future.”

With the rollout of the new products underway, Joel emphasises the benefits of having an established, prominent brand behind the project.

“So the good thing about Hooters is it's an iconic brand,” says Joel. “Wherever you go in the world, everybody knows us. We’re famous for great wings, allaccess sports, a terrific hospitality

“In terms of a highly partner, we have a terrific Ferraro Foods who we north-eastern region

experience and of course the Hooters Girls. If you head into a supermarket, wander into the frozen food section and clock that unmistakable orange, the products will leap out at you. That brand awareness and the guests’ association with what we stand for are crucial to these new products.”

Both supply chain optimisation and a robust partnership ecosystem have been crucial to planning, developing and executing Hooters’ new supermarket product line. Joel explains how both these dynamics go hand in hand at the company.

“In my 23 years at Hooters, we've been able to build incredible partnerships

regarded distributor terrific relationship with we work with in the region of the US”

with all of our suppliers and distributors, to the point where they've gone beyond being partners – they’ve become friends and family,” says Joel. “Building strong relationships with all our partners has enabled us to go out and source the best products, ensuring that we maintain the highest specs in our restaurants and now on supermarket shelves.”

Here, quality assurance is of fundamental importance to Hooters.

“We have labs where we consistently test all of our products,” explains Joel. “We conduct regular inspections at all these labs. We also inspect all our vendor partners – arranging third-party

audits to make sure they're up to our standards. And by doing so, we've been able to secure all these top-ofthe-range products and share them globally with all of our franchisees, retail partners, other partners such as government food groups, and now out into the supermarkets as well.”

Emphasising the importance of these lab-based procedures, Joel adds that a crucial component within these internal and external quality assurance checks is ensuring products meet sustainability standards too.

“As far as being sustainable goes, our products are always meeting top-level specifications and we're never cutting any corners,” insists Joel. “Sustainability is of paramount importance to us – we see it as an obligation to be responsible as a company. For instance, right now we're looking at our suppliers of chicken wings for 2025. Who will we get them from? What volumes are we going to allow? Because it shifts every year based on bird size. We strive towards sustainability by working closely with our partners and treating them as friends and family, rather than just business associates.”

According to Joel, Hooters’ robust partnership ecosystem is essential to the company’s supply chain and entire operational success.

“During the COVID-19 pandemic, many restaurant companies out there were closing because they were unable to serve all of their products,” recalls Joel. “Because of our terrific partnership

Unmatched Excellence: Top-Tier Logistics Solutions

Extensive Coverage

Serving a wide geographic area to meet diverse customer needs.

Temperature-Controlled Units

Ensuring product freshness and quality during transit.

Experienced Drivers

Skilled professionals dedicated to timely and safe deliveries.

Real-Time Tracking

Advanced GPS systems for accurate delivery status updates.

Customisable Solutions

Tailored transport services to fit specific customer requirements.

125

Straight refrigerated trucks

141 Tractors

174

Refrigerated Trailers

With almost 1 million square feet of warehouse space across our eight locations on the East Coast and Indiana, Ferraro Foods offers expansive storage capacity to accommodate a diverse range of products. Our strategically located facilities are positioned to efficiently serve a broad customer base, utilising advanced inventory management systems for optimal stock control. Temperature-controlled environments ensure product quality, while rapid distribution capabilities facilitate quick and efficient order fulfillment. Our scalable operations are designed to meet the growing demands of our customers, with top-tier security measures in place to protect inventory. Managed by skilled professionals, our warehouses embody excellence in logistics.

ecosystem, Hooters never ran out of any products. We stayed consistent. Our close partner relationships and the innovation embedded at the core of our systems, allowed us to track inventory, keep up with our partners and distributors, see what they have –anticipating and adapting if they were going to run short.”

Broadly speaking, Joel divides the Hooters partnership ecosystem into two main categories.

“Here at Hooters, there are two main types of partners: suppliers and distributors,” summarises Joel. “One example of a valued supplier partner is Pacific Coral. They're our largest seafood supplier. They sort our shrimp, fish sandwiches and our fish and chips. They consistently come to us with new menu innovations, making sure the specifications are 100% where we want them to be, or suggesting new specs if it makes sense. If prices escalate,

they bring us alternative options. They always have ideas for us to reinvigorate and innovate our menu and they are absolutely solid when it comes to consistently delivering the products that we order. In my 23 years at Hooters, we've never been short of seafood from Pacific Coral – they always take care of us.

“In terms of a highly regarded distributor partner, we have a terrific relationship with Ferraro Foods who we work with in the north-eastern region of the US. Even when we've had bad weather up there, Ferraro Foods has always delivered to our restaurants: ensuring driver safety and partner safety first and foremost, of course. But they consistently deliver everything we need, when we need it. If there's ever a time when they feel they might run short, they call us, let us know and present us their recovery plan to make sure we receive our orders before the day is out.”

“In my 23 years at Hooters, we've never been short of seafood from Pacific Coral –they always take care of us”

But Joel describes how Hooters’ partnerships extend beyond supply and distribution into the realm of innovating the company’s products and menus.

“We always try to involve our partners in collaborative menu development,” says Joel. “We have what's called a Product Development Committee (PDC), where we invite our partners’ chefs to come in and ideate on Hooters-specific items that fit our wheelhouse. We welcome them to our kitchen here in the Restaurant Support Centre or we can go to a Hooters location and meet them. Pacific Coral, for instance, came up with a shrimp and spinach salad limited time offer for us over the past few years. They also created a hoagie for us, what’s called a po-boy.

“We offer three main desserts that we've had on our menu close to 40 years now. But we just launched another one, which is funnel fries. These are based on carnival funnel cakes, but with a fries twist, to create a shareable dessert. We offered them

as a limited time offer but they took off so well that we added them to our current menu.

“We consistently turn to our partners for menu innovation, through their chefs and fresh ideation, to help us grow our offering to guests.”

So what does the future hold at Hooters for the rest of 2024 and beyond?

According to Joel, expansion is key.

“We are always eager to expand our presence, and we recently opened a restaurant in Corpus Christi, Texas,” shares Joel. “We're consistently looking at new places to open restaurants, while also growing our franchise partners in fresh locations. Whether it's globally or domestically, we are always looking for great new partners for franchises and ideal locations to open new venues.”

Wrapping up our conversation and reflecting on his 23 years at Hooters, Joel celebrates the culture and community contribution at the core of the company.

“As our CEO Sal Melilli puts it, Hooters is in the people business,” says Joel. “You can go to other restaurants, have dinner and break bread – but our philosophy goes far beyond this. Approaching our enterprise as a people business starts not only with taking care of our guests, but also looking after all our people: front and back of house in the restaurants, but also behind the scenes supporting the whole organisation.”

Joel explains how serving the community is closely connected to the concept of being in the people business at Hooters.

“We feel it's our duty to give back to our communities,” says Joel. “In the

first four months of 2024, we donated over 40,000lbs of food which has been translated into 33,000 meals distributed at local food banks.

“Hooters, with the generous support of its restaurant staff teams and guests during the annual ‘Give a Hoot’ fundraising campaign in October, successfully raised $786,000 in 2023 in support of National Breast Cancer Awareness Month, bringing the grand total raised by the campaign to an impressive $9.4m. The efforts culminated in a presentation of funds to the V Foundation for Cancer Research during the 2023 Men’s Jimmy V Basketball Classic at Madison Square Garden in New York City on December 5, 2023.

“For over nine years (this October will be the tenth year), the annual Give A Hoot campaign has directly benefitted the V Foundation for Cancer Research, one of the nation’s leading cancer research funding organisations, as well as other local beneficiaries through the Kelly Jo Dowd Breast Cancer Research Fund. Part of the Hooters Community Endowment Fund (HOO.C.E.F.), the Kelly Jo Dowd Breast Cancer Research Fund was established in honour of the late Kelly Jo Dowd, an original Hooters Girl and the 1995 Hooters Calendar Cover Girl.

“In addition, we coordinate a golf tournament every year where all the money is donated to the V Foundation. At a grassroots level, we do a lot of local events supporting charities and militaries. We have also shipped care

packages overseas to the US military, sending them our iconic Hooters sauces and merchandise since, unfortunately, shipping out our iconic wings isn’t feasible!”

But Joel emphasises how Hooters matches serving external communities with efforts to support its internal community as well. Joel explains this incorporates a comprehensive programme from facilitating training and professional development for staff to sharing valuable resources for holistic wellbeing.

“For example, something we started this year is distributing a book called Training for a Healthy Life companywide,” says Joel. “It helps readers with their goals related to diet, exercise and wellness. As a company, we do all we can to ensure that our colleagues are staying healthy and living the best life they can.

“I bleed orange. I love this brand. I love this company and the people directing us at the helm. Being a leader at Hooters is a privilege and gives me the opportunity to help people grow. I like to think of it as servant leadership. I will do whatever I need to do to make my team successful and add value to the business. As a company, Hooters and the entire leadership team do whatever we need to do to make sure we're successful at all levels of the organisation.”

To learn more, visit hooters.com.

Turn over for Added Value with Joel.

“Every year, some of the members of my team and I go to the Market Vision conferences,” says Joel. “It’s a terrific event series for getting the low down on what’s going on in the supply chain within the field of food service. Here we can spend time with our peers and exchange ideas, providing inspiration to bring back with us to benefit Hooters.”

“I train GRACIE® Jiu Jitsu at American Black Belt Academy in Athens, Georgia two to three nights a week,” says Joel. “I train under retired Special Forces Master Sergeant Sensei Randy McElwee and his son Sensei Ryan McElwee. I have been doing that for about eight years now. It gives me a sense of humbleness, awareness and respect for not only myself – but everyone around me too.”

“Here at Hooters, every year we host the Miss Hooters International Pageant,” says Joel. “The event started back in 1997, and we bring in Hooters Girls from around the world to compete for the title of Miss Hooters International. This event provides these women with scholarships and avenues to pursue other goals in their life, whether it be acting, journalism, medicine, government or whatever their aspirations may be. We've had several of our Hooters Girls go on to great things after competing in the pageant. One of the former Hooters Girls I'm particularly fond of is my wife, Jessicah Pounds, who has entered the Hooters Girls Hall of Fame after her service to the company in a variety of roles. She is now the Vice President, Training and Leadership Development at GoTo Foods. Hooters gave Jessicah an opportunity to grow, and there are countless other women for whom Hooters paved the way to be a success across industries.”

When asked what his favourite Hooters meal combo would be, Joel doesn’t miss a beat before answering:

“I would pick the Daytona Beach® style chicken wings because it's a sauce that you can't get anywhere else, along with our hot seasoned curly fries, a side of classic ranch dressing and an icecold Mountain Dew.”

Connect with Joel Book of Five Rings by Miyamoto

“There is nothing outside of yourself that can ever enable you to get better, stronger, richer, quicker, or smarter. Everything is within”

Musashi.

Explore emerging growth opportunities and key challenges in the cold storage market.

he market is also estimated to grow at a compound annual growth rate (CAGR) of 13.83% during this forecast period.

As the cold storage market experiences significant growth, companies in multiple industries are investing in advanced technologies such as automated temperature control and remote monitoring systems to keep pace with the sector’s upward trajectory.

Several factors are contributing to the growth of this market, including the rise of e-commerce and online food delivery services. These trends have boosted the need for efficient cold storage logistics and facilities, as has the increasing demand for perishable goods or temperature-sensitive product preservation to avoid waste.

However, despite experts predicting that the cold

storage market will continue its upward trajectory, there are some crucial considerations for both companies and vendors regarding the emerging technologies in the sector.

The cold storage market experiences seasonal fluctuations due to the higher demand for refrigerated products in the summer. In order to mitigate these demand risks, vendors must adjust

offerings and balance seasonality through global operations.

There is also the challenge of implementing and operating cold storage facilities. They require high energy consumption to maintain low temperatures, are costly to construct and maintain, and have to be close to production and distribution centres to minimise transportation costs.

“ THE COLD STORAGE MARKET EXPERIENCES SEASONAL FLUCTUATIONS DUE TO THE HIGHER DEMAND FOR REFRIGERATED PRODUCTS IN THE SUMMER”

While these challenges can mean companies need to take further considerations before deploying new cold storage technologies, these solutions can save companies costs in the long term, make the transportation of products more efficient and prolong the shelf life of products.

A notable area of progress has been the use of fuel cell technology, which powers optimally-performing forklifts in low temperatures. These forklifts, using hydrogen in an electrochemical reaction, generate combustion-free energy and save valuable warehouse space.

Compared to batterypowered forklifts, which can only function for 3-6 hours or less in cold temperatures, fuel cell-based forklifts can operate efficiently even in temperatures as low as -30 degrees celsius. Additionally, refuelling a hydrogen-powered forklift takes only five minutes, saving over 120 hours in lost productivity per forklift. This efficiency translates to significant growth in the global cold storage market.

Overall, cold storage facilities are essential in

“ TAKING ALL THIS INTO CONSIDERATION, THE FUTURE

OF TECHNOLOGY AND INNOVATION ACROSS THE COLD STORAGE MARKET WILL BE EXCITING TO WITNESS ”

various industries such as food and beverage, pharmaceuticals and chemical manufacturing.

The market is driven by factors like increasing demand for temperaturesensitive products, advancements in technology leading to energyefficient solutions, and stringent regulations for food safety. The use of automation and IoT technologies

in cold storage systems is also gaining traction, offering benefits like improved efficiency and reduced energy consumption.

Taking all this into consideration, the future developments of technology and innovation across the cold storage market will be exciting to witness.

Source: Technavio

Bogdan Iliescu, Vice President of Product - Supply Chain at METRO.digital on the company’s strategies for supply chain and technological innovation, driving growth and enhancing customer experiences.

In 1964, METRO opened as a cash-and-carry store in Germany. Sixty years later, METRO the leading wholesaler and partner for around 15 million customers in the hotels, restaurants and catering (HoReCa) industries, as well independent traders across Europe and

ETRO.digital is the tech product-led company of METRO which develops customised IT services and products worldwide for all METRO countries.

Speaking to us today about how the company is wielding new technologies and transforming its supply chain to disrupt the retail industry is Bogdan Iliescu, Vice President of ProductSupply Chain at METRO.digital.

To begin, he explains the METRO ambition – the company’s goal to reach €40bn in sales by 2030 – and the strategy behind that objective.

“The METRO ambition is driven by three main pillars: the wholesale stores, food service distribution (FSD) and the digital marketplace,” says Bogdan.

serve the traditional business while functioning as efficiently as possible for our FSD customers.

“In each and every pillar we are applying the latest technologies to drive success, and the same goes for every component of our supply chain. To improve forecast accuracy, for example, we’ve been using machine learning and AI models for the past three years. With this technology, we managed to improve the accuracy of our forecasts by more than 20% in the last year alone. This solution allows us to improve the stock availability to a level of around 97%.”

“When we talk about wholesalers, we’re talking big volumes,” says Bogdan. “We need to be efficient and to make the journey of the goods optimised in a way that both we and the customers can benefit from. To achieve this we are transforming our entire cash-and-carry METRO is around restaurants well as Asia.

“Our growth is driven primarily by the FSD sales, which are set to more than triple by 2030, leveraging our widespread network of more than 600 locations. That means the supply chain transformation is essential, especially around the stores’ transformation into multi-channel fulfilment centres. What we’re working on now is leveraging our assets to still

At METRO.digital, the purpose of putting this technology in place is to create an autonomous supply chain, streamlining operations.

operations and digital solutions to be autonomous and task-driven.”

For Bogdan, working on this process of transformation is a source of tremendous pride.

“We’re facilitating convenience in our customers’ lives,” he says. “Using the scan and go technology we’re embedding into our mobile apps is simple and saves time for our customers. They can shop, scan, go and locate the item and that’s it. It makes the process a nice experience for the customer, as well as making things easier for our employees. Everything has become more efficient by injecting technology into the equation.”

“Our IT strategy is built on the principle of ‘best of breed,’” says Bogdan. “Yes, we are a technology company. Yes, we are following best practice. Yes, we are continuously innovating our processes with datadriven strategies. But in the end, we know we cannot do everything alone, particularly in the area of workforce planning.”

One such boost for the company’s efficiency has been its work with intelligent software solution provider SISQUAL.

“People are at the core of our operations, so we wanted to make sure we were working with a professional partner to implement

“There are also a lot of legal regulations we must comply with, which SISQUAL has been great at working with. They’re open to new ideas, and we have collaborated in a terrific way”

a strong workforce planning solution. So, we decided to work with SISQUAL, who are expertly implementing these processes in accordance with our specific needs. It’s amazing what they can do.

“It’s not easy to be a worker in a store moving huge quantities of goods, so we want to ensure shifts are properly planned to serve not only the business, but also our people’s needs. There are also a lot of legal regulations we must comply with, which SISQUAL has been great at working with. They’re open to new ideas, and we have collaborated in a terrific way.”

For Bogdan, transforming the supply chain at METRO.digital has been another keystone to catalysing change for the business.

“Everything we’re doing, we do for our customers and their needs,” says Bogdan. “And this stems from the heart of the company, the supply chain. In an era of speed and labour force challenges – particularly in the HoReCa industry – you need a strong partner to supply you with the right assortment, the right quality

and the right quantity at the right time. And that’s what we’re doing at METRO. Our core proposition is to be a trusted partner of independent businesses, and that’s where the inspiration for innovation within the supply chain is coming from.”

However, this process of technological innovation is not done blindly.

“People take technology for granted,” says Bogdan. “It’s easy to do. There are so many ideas and so many things to do. But while we’re investing in new technologies, there’s one element that makes a difference. What METRO is doing is identifying the right opportunities and tackling them in a prioritised way using clear objectives and performance indicators. We’re always staying focused on doing what makes an impact for us instead of just delivering new features day by day.”

This philosophy towards innovation has helped the company grow at scale and will continue to drive growth in the years to come, Bogdan believes.

“When I look to the future from a METRO.digital perspective, it’s a matter of being consistent on the road to building extraordinary products,” says Bogdan. “Technology is evolving, as are the opportunities that come with it. We are continuing to leverage technology to create

game-changing solutions for our customers. At the end of the day, it’s a marathon that we need to run together to deliver quality to our customers – not a sprint.

“In supply chain, we’re focusing on doing what creates excellence for the business and the customers. That way, the innovation will continue finding ways to make even more use of the technology to reduce both the physical and cognitive load on our workers.”

These workers, Bogdan concludes, are crucial to company growth and the development of a flourishing culture at METRO.

“When I talk about METRO. digital, first I like to look at the passionate people on our team,” says Bogdan. “It’s a multicultural business, with a lot of nationalities across our locations in Germany, Romania and Vietnam. There’s a wide spectrum of knowledge and culture, but what’s consistent is the value of respect and the drive to grow and learn. I’ve climbed the ladder at METRO step by step and each day I’ve felt supported and felt that I learned something new. I’ve been in the company for 12 years, and I’m enjoying it now as much as I did on my first day.”

For further information on METRO.digital, visit metro.digital.

“I think we are responsible for our own growth, and the growth of others,” says Bogdan. “I’m always considering how I’m supporting my people’s growth and development while providing them with new opportunities. To help this development, I always encourage people to read Empowered by Marty Cagan, which delves into innovative approaches to delivering technology to transform businesses. But mental development is equally important. I found that reading When the Body Says No by Gabor Mate made me very aware of a lot of things working deeply inside the body. I enjoy reading and learning about psychology in this way, as it helps me know myself and my journey better.”

“I used to be a football referee, which was an amazing learning opportunity,” says Bogdan. “Doing this taught me what it means to be fair and taking responsibility. That experience of guiding and supporting has shaped me to this day.”

Explore these innovative, cross-sector strategies that can help the construction industry adapt quicker to new challenges.

y taking inspiration from the retail industry, where new strategies are constantly being implemented to meet consumer demands, the construction industry can add flexibility to projects of all sizes.

Construction logistics expert Wincanton has identified six strategies that the construction industry can take from retail and incorporate to push the industry forward.

A key factor for construction falling behind other industries is the failure to understand and adopt new technologies. Retail has added artificial intelligence (AI), Internet of Things (IoT) and advanced data analytics to streamline monotonous operations such as optimising delivery routes and managing stock.

Similar investment into these technologies could significantly impact the construction sector. Many processes within the sector are still done through paper processes, which can be arduous and slow projects down. However adding emerging tech can help centralise project management into a single curated platform, increasing progress visibility and reducing deadline delays.

Within retail logistics, the biggest concern is ensuring that consumers' buying experience is seamless. Customers receive real-time updates on the delivery status from the moment of purchase. This is something that infrastructure projects can take inspiration from with data-driven insights.

These insights can provide a much more efficient solution to supply chains, from the very beginning with procurement to managing the inventory available and minimising delays from shortages of materials. A more proactive approach – like breaking down the data gathered about processes within construction companies – can ensure that projects are executed with attention to scheduling, much like retail orders.

Businesses in retail rely on understanding and responding to customers and their changing needs, which is done through extensive feedback and review systems from on-site options to third-party sites like Yelp or Google Reviews. This is something that construction could adapt to reap the benefits through transparent communication with clients and making sure they’re involved in decision-making.

Placing clients at the heart of construction’s mission can help to develop long-term relationships and establish loyalty within these transactions. This is a huge factor in consumer behaviour that leads them to repeat purchases from chosen retailers, and the construction industry could gain a lot of fantastic business from it.

Both site managers and consumers can easily track their orders and deliveries to know exactly when to expect their products and materials. Having this added transparency and live updates can help increase communication on all levels of the project.

Internally, this could mean workers on the project are alerted to any issues that might arise with delayed delivery of materials, machine breakdowns or anything that might cause a workday to slow down. This extends externally, as clients can make more informed decisions on the project through improved visibility. It also contributes to loyalty and trust being built between the business and the client.

The retail industry must constantly plan and forecast for major calendar events, adjusting product stocks and inventory based on previous sales data and statistics. Construction has various industry elements that could benefit from greater forecasting for large-scale projects using data gathered from jobs of similar sizes.

This will also allow for better preparation when it comes to holidays and seasons, where more work takes place. For example, if you’re expecting to see more projects commissioned in the summertime when the weather is better (with less downtime from rain and adverse conditions), businesses in the industry can order materials well in advance, preparing them to get straight to work.

While change is necessary for industries to continue advancing, maintaining the level of improvement while also delivering exactly what construction projects require is crucial. This is something that retail has shown to be capable of, constantly incorporating and exploring new technologies, training schemes, quality control methods, and many other elements to keep delivering consumers seamless shopping experiences.

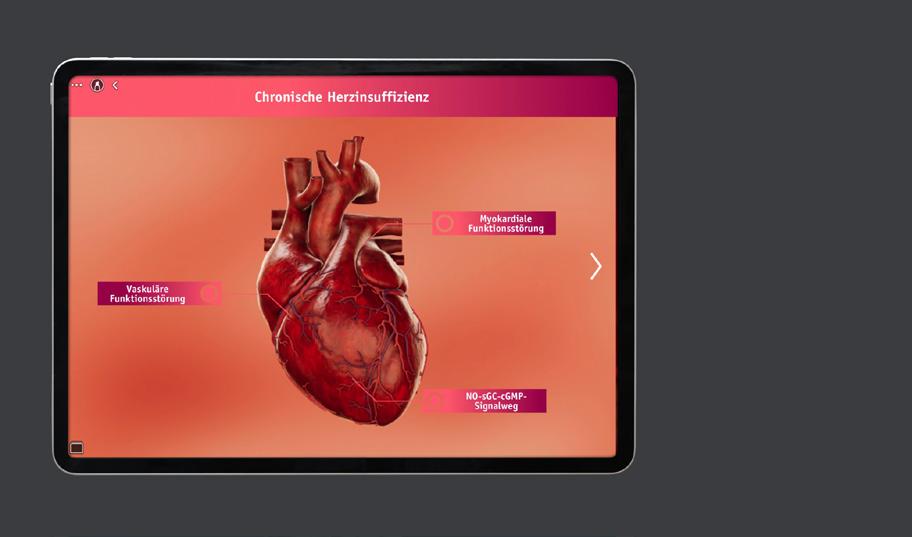

Dennis Stelljes, Associate Director of Strategic Sourcing and Procurement at Bristol Myers Squibb (BMS) responsible for the CHAT region, located in Steinhausen, Switzerland, on the company’s use of technological innovation to transform procurement in the pharmaceutical supply chain.

uelled by research in Oncology, Hematology, Immunology and Cardiovascular diseases, Bristol Myers Squibb (BMS) in Europe is a biopharmaceutical company with one of the most diverse and promising pipelines in the industry.

Here to tell us about how the company’s procurement strategy is a driver for growth is Dennis Stelljes, Associate Director of Strategic Sourcing and Procurement at BMS in Europe. To begin, he credits BMS for looking at procurement in a new light.

“At BMS procurement is seen not as a transactional function but as a strategic enabler,” says Dennis. “This means that the procurement goals are aligned with the overall business objectives, which helps us emphasise a long-term partnership with suppliers.

“We take this approach because we’re focusing on value-driven procurement, and we’re seeking supply partners who share that commitment to innovation and sustainability. We’re not interested in a cheap solution – we’re looking for

who can bring the greatest value to the business.

“In essence, we leverage our procurement strategy as a catalyst for growth. By strategically sourcing materials, services, and technologies, BMS ensures cost efficiency, supply chain resilience and quality assurance.”

To ensure the procurement team creates value for the company, Dennis explains how their strategic approach embraces collaboration to foster innovation and the

adoption of new approaches at BMS in Europe.

“In order to deliver innovation, we need strong partners,” says Dennis. “We collaborate closely with suppliers involving commercial projects, product development and process improvement. It’s impressive to see

what the supplier base is able to deliver in regard to innovation, and it demonstrates how important those partnerships are – we cannot do everything alone.

“Because we work so closely with these partners, we’re able to get ideas from them and explore new

“Our procurement teams worldwide are collaborating and regularly sharing information. We foster a culture of collaboration because we don’t want to reinvent the wheel”

“RMH Media is a fantastic partner for us to work with, The company has been transformational and inspiring in helping us revolutionise our marketing tactics”

ways of working. Personally, I believe that this strong collaboration and innovation exchange is what separates us from other companies.”

According to Dennis, BMS champions this spirit of collaboration internally as well as externally.

“This is what our new Chief Procurement Officer (CPO)

Paula Glickenhaus refers to as ‘crowdsourcing,’” says Dennis. “Our procurement teams worldwide are collaborating and regularly sharing information. We foster a culture of collaboration because we don’t want to reinvent the wheel.”

“So, we join forces with our business partners and teams across the region and across the market. One way we champion this is through our internal hackathons, where we discuss new and innovative ideas.

“We are also working with external partners, organisations and suppliers to deliver new ideas, but we rely on

internal collaboration to deliver them and add value in the process. Personally, I would say this showcases BMS’ role as a pioneer in healthcare and innovation – setting new standards for healthcare professionals (HCPs), patient outcomes and education.”

This focus on nurturing collaboration among its internal teams has paid off, explains Dennis.

“We have been awarded as a Great Place to Work in different countries across Europe, which we’re incredibly grateful for,” shares Dennis. “Our employees are anonymously interviewed about their experiences in the company, which we use to deliver results, prioritising inclusion, diversity and employee education.

“I recently hosted an internal learning session on artificial intelligence across the region on how AI can transform the way we work. It’s important for our teams to have a strong foundational knowledge of these new technologies because changes are happening so quickly. With AI, the evolution we’ve seen from just a year ago to today is extremely impressive, and it won’t stop there.”

While this technological innovation is a key component of BMS ongoing transformation, Dennis reiterates the importance of being mindful when deploying new technologies.

“We’re not using every new technology just because it’s there,” explains

Dennis. “It’s very easy to get caught up in new innovations, but we’re specifically choosing the emerging technologies that deliver benefits and promote the company’s values.

“If you look at the adoption curve, you can see that it starts with innovators, the people eager to embrace new solutions and new software. Then there are the early adopters. These people are quick to adopt new technologies –not as immediately as the innovators, but they’re pretty fast to adapt to new changes after observing the innovators and seeing that the technology is working. This is where we situate ourselves. It’s important for us to explore these new technologies before they’re picked up by the majority.

“One solution we’re using is robotic process automation (RPA) where, using automation, the RPA mimics

human workers. We’re using that most notably in invoice processing, where the RPA books invoices into the system.

“We’re continuously looking at how we can innovate across the company, from medical to commercial operations. However, whenever we look into a project or solution, we need to see tangible results. It’s not always easy to find them because the technology is so new, but if we feel that a technology will be a good implementation, we need to know if it will save costs, if it will be faster and if it will deliver results.”

Diving into an example of the technological innovation at BMS, Dennis describes recent transformations in the company’s marketing strategy, where the company collaborates closely with RMH Media.

requires

perspectives and a truly awesome team.

Sebastian Richter COO // RMH MEDIA GmbH

In today’s competitive market, key questions for marketeers persist: How can you boost customer retention? How to speed up time to market? How to create a streamlined and cost-efficient content pipeline?

At RMH MEDIA, we leverage real-world scenarios and proven strategies to provide actionable insights. Our role as interpreters for all stakeholders ensures that complex digital topics become accessible and understandable. Our experienced team speaks your language, whether in IT, brand management, or collaboration with creative agencies. We provide solutions that enable swift and decisive action, and help you implement them within your digital ecosystem.

Our solution range is specifically designed to meet the needs of the life science industry. SHOWCASE streamlines your content production pipeline, reducing costs and accelerating time to market for multichannel assets.

ONE MESSAGE connects your field force with healthcare professionals via popular instant messaging platforms, fostering unparalleled customer relationships. Additionally, enhance your customer experience by integrating 3D, AR, or VR into your customer journey, delivering a truly outstanding and immersive experience.

We help you maximise the potential of your digital ecosystem, driving success through innovation and efficiency.

We believe that good communication between pharmaceutical companies and healthcare professionals leads to better patient care. Since 1997, this has been our motivation to develop innovative digital marketing and outstanding software solutions for the pharmaceutical and healthcare industry worldwide. www.rmh-media.com

In the rapidly evolving pharmaceutical industry, effective and engaging digital content is vital for the success of field forces. RMH MEDIA recently partnered with a pharmaceutical client facing significant challenges with their eDetailers and their customer engagement.

The Challenge: Reports showed that the client’s field force was not using the eDetailers provided by the CLM team. Interviews showed that presentations were not engaging and difficult to use. Additionally, there were significant delays in content publication, often resulting in outdated information. These issues severely impacted the field force’s willingness to adopt the provided materials and the overall productivity and performance.

Analysing the Problem: To address these challenges, RMH MEDIA began with a comprehensive analysis of the customer journey. We identified key pain points and opportunities to optimise and enhance the existing digital ecosystem for better support and faster content production.

Enhancing eDetailing: RMH MEDIA’s consulting team redesigned the eDetailers to incorporate best practices for digital engagement. We developed a performancefocused eDetailing playbook tailored to the customer, ensuring future content would be both engaging and user-friendly.

Content Production:

SHOWCASE was introduced to speed up the content creation process and reduce previously separate processes into one unified production pipeline. SHOWCASE enabled faster, more structured, and cost-effective production, significantly reducing turnaround times and enhancing content quality.

Improving Communication with ONE MESSAGE: Further analysis revealed that healthcare professionals were overwhelmed by excessive email communication. To address this, we implemented ONE MESSAGE, a compliant instant messaging solution and customised it for the medical liaison unit. This tool provided concise, highly personalised information and immediate responses to queries via major instant messaging apps like WhatsApp and LINE.

Results: The implementation of these solutions led to significant improvements:

Increased Engagement:

The revamped eDetailers were highly engaging, leading to better adoption by the field force.

Cost Efficiency:

SHOWCASE streamlined content production, reducing costs and time to market.

Enhanced Customer Experience:

ONE MESSAGE improved the quality of interactions with HCPs, reducing email fatigue and delivering timely, relevant information.

Conclusion: This case study demonstrates how RMH MEDIA’s innovative solutions can transform digital marketing strategies in the pharmaceutical industry and bring them to life. By leveraging expertise in content production and tailored digital solutions, RMH MEDIA helped this client achieve significant improvements in engagement, efficiency, and cost reduction. Now, let’s sit down together and delve into your customer journey. Contact us today to start enhancing your customer experience and driving your business forward.

Noel Wack

“RMH Media is a fantastic partner for us to work with,” celebrates Dennis. “The company has been transformational and inspiring in helping us revolutionise our marketing tactics. In the past, we used the more traditional approach of face-to-face interactions with healthcare professionals (HCPs). This can be a very effective approach, but it has limitations in terms of scalability, personalisation and timely communication. Our email campaigns also used to be one size fits all, so everyone received the same message, and we were missing the nuances of individual preferences.

“Today, we’ve revolutionised our marketing with the omnichannel approach, and RMH Media has played a key role in the execution. Omnichannel marketing is not just about using multiple channels, but about creating a seamless, intuitive integrated experience for HCPs across all touchpoints.

“RMH Media have been pivotal in helping us shift towards this more holistic approach, particularly in our use of their SHOWCASE solution, which allows us to create, manage and publish curated content efficiently. Now,

we’re able to send out personalised emails created with this tool in a fraction of the time, making us more agile and simplifying the way we work.”

In particular, Dennis credits RMH Media’s ability to collaborate with companies in highly regulated industries.

“As a pharmaceutical company, there are a lot of rules and regulations we need to comply with,” says Dennis. “All of our outside communication must be run through medical, legal and regulatory (MLR) approval to ensure the

content is correct and adheres to brand guidelines. The tools RMH offer integrate seamlessly with our systems, simplifying content distribution significantly.

“There are several tools we use from RMH, including its website creation tool for several of our websites, and its interactive residual advertisements, which are often used by sales to customise presentations to suit specific HCPs.

“By helping us revolutionise these processes, RMH is helping us create value. They’re highly adaptable and quick at implementation when we need adjustments. Looking to the future, we want to continue to prioritise patient centricity with omnichannel marketing and other innovations, and we’re very excited to achieve this with RMH Media.”

When speaking about the company’s future, Dennis reveals that the priority lies in sustained growth.

“We have a diverse portfolio, and digital transformation is so crucial in building that,” says Dennis. “Our priority is investing in digital capabilities to enhance customer experience and operational efficiencies. As Peter Drucker wisely advised, ‘The best way to predict the future is to create it.’ We envision a future where innovation and collaboration are key drivers of growth, and that’s what we’re aiming to build.”

Learn more about BMS Europe here.

Turn over for Added Value with Dennis.

Dennis mentions three quotes that particularly resonate with the way he approaches procurement strategy:

“Price is what you pay, value is what you get.” – Warren Buffett.

“The technology you use impresses no one. The experience you create with it is everything.” – Sean Gerety.

“The best way to predict the future is to create it.” – Peter Drucker.

“You need to be in the right frame of mind to challenge your own ideas,” says Dennis. “You can’t allow yourself to become close minded and rely on the status quo. I’m always looking to challenge my own thoughts, and I do that by reading, watching Ted Talks and consuming a variety of thought leadership content.”

The Code of the Extraordinary Mind: 10 Unconventional Laws to Redefine Your Life and Succeed on Your Own Terms by Vishen Lakhiani

“I loved this book,” says Dennis. “It can teach you to transform your life and become a better person.”

Never Split the Difference: Negotiating as if Your Life Depended on It by Chris Voss and Tahl Raz

“I highly recommend this book to anyone working in procurement,” says Dennis. “Chris Voss is an ex-FBI hostage negotiator, and in this book, he explains how he would get results in high-pressure situations. A lot of the strategies he explores can be very easily applied to the procurement industry.”

Start With Why: How Great Leaders Inspire Everyone to Take Action by Simon Sinek

“This is a great book to refer to when leading a team,” says Dennis. “A key takeaway from this book is that we need to go forward with purpose. For BMS in Europe, that purpose is delivering medicines to patients. My grandfather died of cancer, and if we had had better help available at the time, maybe we could’ve expanded his life expectancy. To me, things like this are the core purposes of my role.”

A deep dive into Info-Tech Research Group’s latest industry blueprint and how control tower systems can reshape the manufacturing sector.

anufacturers face challenges in timely product delivery, supplier reliability and customer satisfaction while striving to enhance operational efficiency in a cost-sensitive environment. Addressing these complexities is the concept of control tower integration.

Global IT research and advisory firm Info-Tech Research Group (Info-Tech) has released a new resource, providing insights into how the integration of control tower systems could address these complexities and reshape the manufacturing industry.

The industry blueprint, Harmonizing Complexity: Control Tower Integration, provides manufacturing IT leaders with guidance on harnessing exponential technologies such as artificial intelligence (AI), machine learning (ML) and the Internet of Things (IoT). By leveraging emerging technologies, organisations can access timely data, crucial for driving operational excellence and ensuring customer and employee satisfaction.

The research suggests that manufacturers can face

Control Centre

Orchestration | Visualisation | Collaboration

Communication Services

Collaboration | Sensing | Analysis Planning | Response

Digital Twin Visualisation

Decision Management Services

Demand | Inventory | Supply

Integration Services

Protocols

Sensing

Data

Advanced Intelligence

significant challenges in integrating control towers, primarily due to ineffective collaboration between IT and operational technology (OT). Many of these organisations operate in silos, leading to poor communication and hampering integration efforts. The industry also struggles with the complexities of legacy systems and intricate supply chain operations that involve multiple suppliers, manufacturers and distribution networks. Furthermore, a shortage of skilled specialists capable of effectively managing and operating a modern control tower exacerbates these challenges.

Info-Tech’s blueprint also highlights several control tower integration service capabilities designed to tackle the key challenges facing the manufacturing industry. These capabilities can facilitate realtime information sharing among customers and businesses to enable more efficient operations and better decision-making, and include:

• Control centre: Streamlines operations through orchestration, visualisation and collaboration.

• Communication Services: Enables real-time information sharing via collaboration, sensing, analysis, planning and response.

• Decision Management Services: Optimises demand, inventory and supply management decision-making.

• Integration Services: Facilitates seamless data exchange through protocols, sensing and integration.

• Advanced Intelligence: Leverages AI, ML and deep learning for actionable insights. Implementing a supply chain control tower is not just a strategic advantage but a fundamental necessity for sustainable growth.

“THE TECHNOLOGY ECOSYSTEMS THAT MANUFACTURING BUSINESSES CAN ADOPT ARE DRASTICALLY CHANGING, AND THE NEW SOLUTIONS THAT THEY ARE ADOPTING CALL FOR SIGNIFICANTLY DIFFERENT SKILL SETS”

Kevin Tucker, Advisory Practice Lead at Info-Tech

Info-Tech concludes that by providing real-time insights and enabling proactive decision-making, control towers can help businesses adapt swiftly to market changes, optimise operations and maintain high levels of customer satisfaction.

“The manufacturing industry faces a formidable challenge in meeting customer demands characterised

by increased technology adoption, shorter lead times, greater transparency requirements and decreased tolerance,” says Kevin Tucker, Advisory Practice Lead at InfoTech. “The technology ecosystems that manufacturing businesses can adopt are drastically changing, and the new solutions that they are adopting call for significantly different skillsets.”

Source: InfoTech

Explore industry insights from the energy sector in this exclusive interview with Maytham Al-Elg, Localization Strategy Director at Baker Hughes in the Middle East (ME).

Maytham Al-Elg is a senior leader in the Middle East (ME) at Baker Hughes, a leading energy technology company, and has worked in the sector for two decades.

ver the years, his specialisms have spanned oil and gas, energy, petrochemicals, refinery and utilities –primarily in the MENAT (Middle East, North Africa and Turkey) region.

Today, Maytham joins us to reflect on his career growth, working in the MENAT region and the technological innovations driving growth in the energy sector.

Maytham Al-Elg

Maytham began his career as a field engineer in upstream operations after graduating with a mechanical engineering degree. From here, Maytham developed his knowledge further by performing a range of roles, including handling customer interface for sales and operation developing key accounts, before moving to the midstream and downstream sector, dealing with projects and operations execution for rotating equipment. He credits these positions for helping him build his knowledge in order to move to a more strategic role developing processes, operational excellence, improved efficiency and team building for customer and organisation success.

This professional progression has led Maytham to the position of Localization Strategy Director at Baker Hughes ME, a role that involves localisation strategies alignment and ecosystem development across product lines to meet customer needs and regional requirements.

Maytham believes his career journey has taught him the importance of self-discipline and challenging yourself to drive both personal and organisational growth, as well as the value of teamwork, commitment and taking accountability for your actions.

Launching our conversation, Maytham explores how embracing localisation for Baker Hughes works on a strategic level.

“The process starts with aligning all requirements from customers,

regulatory bodies and Baker Hughes itself – framing the need to reach a common ground for development,” explains Maytham. “When you work across several countries, there is a diverse range of needs that must be met in a specific way to support customers and serve the company’s vision. I view localisation needs as a driver for faster and more efficient results – positioning the end user and companies in a stronger place. From a strategic viewpoint, solutions developed closer to customer operations will be more tailored to their needs.”

“We are successful when multiple individuals and organisations work together”

Upstream - Midstream Downstream

From sourcing unique materials to developing innovative formulations and blends, our experts can create customer-centric solutions for specific applications

Using engineering expertise, complex modeling, and first-class laboratory testing, we custom design high-performance polymer products and components to perform in the most extreme environments.

Our vertically-integrated manufacturing means our advanced manufacturing facilities offer over 30 processes and integrate cutting-edge technologies for greater efficiency, insight, and quality.

A6R, OL, P, FS, S, & T Seals

Piston Rings

Downhole Packers

Rider Rings / Wear Bands

Packing & Packing Cases

SigmaSeal®

Sintermesh®

OptiSeal®, OptiPak®, OptiVee® Tuff Breed® Well Service Packing

HPHT Seals

Bonded Seals

Valve Stem Seals & Seats

Tubing/Casing Hanger Seals

Pump Wear Rings & Bushings

Graphite Pressure Seals

“The Middle East region is no different from other developed regions when it comes to innovations, and it has become one of the leading regions in implementing new ideas and concepts”

For Maytham, it is a particularly exciting time to work in the MENAT region, as businesses from the area are driving key innovations transforming the energy sector.

“The Middle East region is no different from other developed regions when it comes to innovations, and it has become one of the leading regions in implementing new ideas and concepts,” says Maytham.

“Currently, there is a significant focus on implementing new technologies to lead the energy transition. Some of the key implementations include Carbon Capture technology, hydrogens, non-metallics, solar energy, digital transformation and many more. Adopting these new technologies is promoting innovation within the region, and these new ideas are expected to foster the energy transition globally.”

According to Maytham, localisation is also playing an instrumental role in driving sustainable energy within the Middle East.

“Localisation helps us secure a reliable source of energy in times of uncertainty – to both the region and on a global scale,” says Maytham.

“Having a robust supply chain ecosystem and strong localised support builds the foundation

for meeting energy needs during geopolitical conflicts and disruptions such as the COVID-19 pandemic, simultaneously helping to lower emissions by reducing the needs of international logistics and transportation.”

Technology is also playing a significant role in driving innovation and localisation within the Middle East, explains Maytham.

“As the Middle East region – and more specifically the Gulf states – count for a significant portion of global energy needs, the future of energy in this region is looking bright”

“When it comes to localisation, the focus on enhancing the supply chain ecosystem in the region through development is igniting research and development,” says Maytham. “Specific ideas tailored to the harsh environment are forming, resulting in new technological innovations. This is crucial to the energy sector within the MENAT region, as we are seeing a steady need in growing and maintaining the large needs for different energy resources.”

However, while emerging technologies are crucial for transforming energy production, Maytham stresses that the development of new processes would not be possible without collaboration.

“We are successful when multiple individuals and organisations work together,” says Maytham. “In regards to success in localisation and meeting targets, one of the most critical elements is developing the supply chain ecosystem. This means partnering with a variety of local and international partners to enhance it. To begin, we start by identifying critical gaps along the supply chain to implement developments for products and services alongside our partners.

“In some cases, this development requires us to work with reliable global suppliers. When a need to enhance the development of high-performance polymers for the ecosystem in Saudi Arabia emerged, international suppliers were identified to start the journey in localising operations within the country. CDI Products is an incredibly successful example of partnering together to develop the supply chain ecosystem within a local market.”

So, what does the future look like for energy in the Gulf states? Maytham believes it’s all about utilising consistent innovation as a transformative power.

“As the Middle East region – and more specifically the Gulf states –count for a significant portion of global energy needs, the future of energy in this region is looking bright,” says Maytham. “We’re driving new technologies forward to support the energy mix, and this is expected to have steady growth, as seen with ongoing projects in the pipeline. And as this development grows, our processes become steadily more innovative.”

Learn more about Baker Hughes at bakerhughes.com.

Maytham is always looking to further his knowledge of the field.

“With the current developments in the industry, I am becoming more focused on the new energy needs by reading and learning about the new technologies in the fields of energy transition, digital transformation, artificial intelligence, machine learning and more,” says Maytham. “I make sure to dedicate some of my time to reading and looking into the latest developments in those areas, through conferences, books, webinars, new research papers and more.”

Maytham is looking forward to attending:

• The Future of Energy on the 15th-16th October in Riyadh Front, Saudi Arabia

• Abu Dhabi International Petroleum Exhibition & Conference (ADIPEC) 2024 on the 4th-7th November

Connect with Maytham

Disclaimer: Views expressed in this article reflect Maytham Al-Elg’s personal experiences and perspectives.

The collaboration between On and Verity operations for retail and e-commerce

Verity is set to transform supply chain e-commerce with AI and robotics.

ON, A LEADING GLOBAL SPORTSWEAR BRAND, AND VERITY, A PIONEERING AI AND ROBOTICS COMPANY, HAVE ANNOUNCED A STRATEGIC COLLABORATION TO TRANSFORM WAREHOUSE OPERATIONS AND OPTIMISE INVENTORY MANAGEMENT, ULTIMATELY ENHANCING SUPPLY CHAIN EFFICIENCY AND PRECISION.

On and Verity join forces, leveraging fleets of fully autonomous drones in warehouses to enable full operational visibility through smart, real-time inventory tracking – minimising stockouts, misplacements and shrinkage across the supply chain. This ensures flawless order fulfilment for retail and e-commerce.

On is one of the fastestgrowing sportswear brands in history and seeks every technical advantage in its supply chain execution to support this growth, while Verity is renowned for its expertise in AI and robotics with in-depth technical expertise and a proven, intelligent and efficient system. Verity’s solution is used to perform

millions of fully autonomous inventory checks each month in over 80 warehouses operated by different clients worldwide.

This partnership delivers tangible business value by improving immediate product availability across On customer touchpoints – both physical stores and online –and maximising successful order fulfilment by improving on-time and accurate deliveries. Verity clients see their operational issue rates reduced from 5-12% to less than 1%, significantly increasing their warehouses’ labour efficiency. By further digitising On's supply chain, Verity has strengthened its data accuracy and improved the quality and speed of decision-making.

Already live at a US facility, Verity’s fleet of fully autonomous drones is

“VERITY

IS A PIONEERING BRAND IN THE FIELD OF AI AND ROBOTICS, AND A PERFECT FIT WITH ON'S VALUES OF HARNESSING INNOVATION FOR THE BENEFIT OF THE CUSTOMER EXPERIENCE”

Caspar Coppetti,

Co-Founder and Executive Co-Chairman

at On

scanning On products on a daily basis, ensuring full availability of stock for customer fulfilment.

The solution is not only improving key performance indicators (KPIs) but also supporting On's sustainability objectives, as Verity clients observe an average reduction of 1,000 tonnes of CO2 emissions per warehouse each year.

The collaboration’s goal is to explore new technology solutions to drive operational excellence and enhance inventory visibility, with On bringing Verity onboard with its 3PL partners.

“We are excited to partner with Verity to transform our supply chain operations,” says Caspar Coppetti, Co-Founder and Executive Co-Chairman at On.

“Verity is a pioneering brand in the field of AI and robotics, and a perfect fit with On's values of harnessing innovation for the benefit of the customer experience. By leveraging innovative technological solutions, we aim to improve our operations' efficiency further, become a more sustainable brand and take customer

“WE SHARE THE SAME GOALS WITH ON, IN PARTICULAR THAT OF DELIVERING AN EXCEPTIONAL CUSTOMER EXPERIENCE. THIS SYNERGY IS FURTHER AMPLIFIED BY OUR HIGHLY ROBUST SYSTEMS, BOASTING BETTER THAN 99.99% RELIABILITY RATES”

Raffaello D’Andrea, Co-Founder and CEO at Verity

satisfaction to new heights. The collaboration of two pioneering Swiss brands can only mean an explosion of innovation!”

“At Verity, we are dedicated to pushing the boundaries of AI and robotics to drive operational excellence,” says Raffaello D’Andrea, Co-Founder and CEO at Verity.

“Partnering with On, the most

exciting sportswear brand in the market today, is a great opportunity to apply our shared commitment to leveraging technology to meet customer expectations. We share the same goals with On, in particular that of delivering an exceptional customer experience. This synergy is further amplified by our highly robust systems, boasting better than 99.99% reliability rates.”

Source: On and Verity

Stay up-to-date on the global tech sector's latest news, features and exclusive interviews.

"The team were professional and diligent throughout"

Leigh Feaviour, CTIO for BT’s Supply Chain

"Absolute pleasure working with the Digital Innovation team"

Mun Valiji, Chief Information Security Officer at Sainsbury’s

"A highly professional approach"

Andy Brierley, Vice President, Cloud Application Modernisation at IBM

"Digital innovation Magazine is a very flexible and professional team"

Kim Larsen CTIO, T-Mobile Netherlands

Abu Dhabi’s industry leaders forge strategic partnership to transform the global pharmaceutical landscape.

The Department of Health – Abu Dhabi, the Abu Dhabi Investment Office (ADIO), Etihad Airways and AD Ports Group have signed a landmark Memorandum of Understanding (MoU), with the intent to strengthen Abu Dhabi’s position as a global pharmaceutical and life sciences distribution hub, leveraging its strategic location, lucrative investment opportunities and advanced logistics capabilities.

his MoU is a pivotal step in the city’s ongoing efforts to become a leading healthcare destination on a global scale, in line with the Abu Dhabi Economic Vision 2030. The strategic

partnership hopes to create attractive value propositions for pharmaceutical, biotechnology and medical technology companies to establish their operations in Abu Dhabi.

“Leveraging to the Middle pleased to partner

Dr. Asma Ibrahim at the Abu Dhabi Department

“Leveraging Abu Dhabi's

the

Middle East and North Africa (MENA) region, we are partner with world-class leaders”

Al Mannaei, Executive Director of the Research and Innovation Centre Department of Health

By capitalising on the Department of Health’s worldclass regulatory framework alongside ADIO’s attractive investment platform, Etihad Cargo’s expertise in air freight and AD Port’s robust logistics infrastructure, the collaboration looks to position Abu Dhabi as a leader in this industry.

“Leveraging Abu Dhabi's strategic location at the gateway to the Middle East and North Africa (MENA) region, we are pleased to partner with worldclass leaders in investment and logistics, offering advanced infrastructure with easy access to regional and global markets,” says Dr. Asma Ibrahim Al Mannaei, Executive Director of the Research and Innovation Centre at the Abu Dhabi Department of Health. “Our

vision is to create a healthcare environment where patients have access to the latest treatments and medical technologies. By establishing a robust healthcare and life-science distribution hub, we are poised to enhance healthcare outcomes and improve lives across the region. The establishment of this distribution hub will not only solidify Abu Dhabi's position as a critical player in the global pharmaceutical

industry, but also drive economic growth and job creation for Emirati citizens in the healthcare and logistics sectors.”

As part of the agreement, the entities will work together to ensure timely access to innovative healthcare products for patients across the region, enhancing Abu Dhabi's role in global pharmaceutical supply chains.

“Abu Dhabi has made supporting the healthcare and life sciences industry a strategic priority, benefiting our nation and the world”

Badr Al-Olama, Director General of ADIO

Aligned with the Emirate's economic aspirations, the collaboration is expected to attract significant investment in healthcare and logistics, promoting sustainable economic growth and diversification within the healthcare and life sciences sectors. The MoU also includes plans to support local manufacturing and packaging of pharmaceutical and biotechnology products, in addition to local capability enhancement.

“Abu Dhabi has made supporting the healthcare and life sciences industry a strategic priority, benefiting our nation and the world,” says Badr AlOlama, Director General of ADIO. “Today, Abu Dhabi stands as a leading hub in this field, with advanced infrastructure and supportive regulations enabling a vibrant community of health-tech companies.”

Source: Department of Health Abu Dhabi

Stay ahead of the curve with the go to digital platform for senior supply chain executives.

CHAIN is a specialist technology platform with over 211,300+ readers.

Our community consists of C, V and D level executives from a wide range of industries. A unique blend of thought leadership interviews and features that cover digital transformation, supply chain, procurement, logistics, technology, AI and sustainability.

Team up with CHAIN and build media programs that deliver.

Find out more

Welcome to our spotlight profile feature where we chat with the leaders and innovators in the supply chain, procurement and logistics industries.

For this month’s In the company of… we sit down with Jens Fath, Operations and Transformation Partner at PwC Germany.

A brief summary of your role and what your company does

PwC is among the world's leading professional services networks. Our community of solvers is committed to building trust in society and delivering effective organisational transformation. To be future-ready, enterprises need an end-to-end approach. From discussing ideas and roadmaps to implementation, we ensure the success of our customers' transformation.

I'm part of our Operations Transformation leadership team. Our domain is competence, strategic view, IT expertise and a clear focus on the market play a central role. I lead our Smart Manufacturing team, develop our team members and shape our portfolio.

How did you start working in manufacturing?

My career in consulting started in 2002, primarily in ERP transformations. A lucky punch came during a communication concerning a merger and acquisition and a manufacturing execution system. A board member asked, “We need a young and energised guy who can support the integration process from a people and content perspective. Who are the volunteers?” I raised my hand, which was the starting point for getting deeper and deeper into topics ranging from the top floor to the shop floor.

Optimising existing factories and building new ones has been an incredible journey. After 20 years, it is still exciting to see the impact we can have on our customers.

What has been the biggest highlight of your career to date?

The main highlight was a visionary project some years ago. The challenge was to build a lighthouse factory for a new product that demanded modern production mechanisms, data-driven processes and a deeply integrated IT landscape. Our team was involved in thought leadership, strategic concepts, political discussions, defining stakeholders, including the technical implementation.

Which emerging trend do you think will be most crucial in your industry in the next ten years?

It’s undoubtedly Gen-AI. My wish is that the trend will be “raising business benefits through the responsible, trustful and sustainable use of technology.” People must be trained and comfortable using artificial intelligence to realise its full potential. This needs a mindset change, aligning IT/Digital with the needs of each business department. There should be no more reactive IT – instead, the focus should be on defining and integrating value-generating use cases. The value will only appear with a clear strategy, long-term roadmaps, and well-shaped, scalable enterprise architectures.

If you could spend a day in the life of another profession, what would it be and why?

Coaching primary school kids on handling challenges and staying focused, giving them an authentic foundation for lifelong success, and making a worthwhile contribution to the world could be rewarding. A value-driven and people-centric education for the next generation could motivate me to step out of my role for one day.

Outside work, what helps you feel like the best version of yourself?

I spend my free time with my wife, two wonderful daughters, and old but also new friends. They give me fresh perspectives and show me how to get the most from life. Enjoying the beauty of the forests and mountains while walking, mountain biking, or skiing is great for recharging my batteries and grounding myself.

PwC Germany