ENCOURAGING INNOVATION AND EMBEDDING SUSTAINABILITY

IN THE CONSTRUCTION INDUSTRY AT TARMAC

PROJECT PARTNER

ENCOURAGING INNOVATION EMBEDDING SUSTAINABILITY

CONSTRUCTION INDUSTRY AT

PROJECT PARTNER

Ben Garner, Head of Logistics Development & Standards at construction materials giant Tarmac, on the company’s sustainable solutions and the role of logistics in facilitating them.

he company has contributed to some of the UK’s biggest construction and infrastructure projects, including Wembley Stadium, Heathrow Terminal 5 and London Olympics 2012.

As new environmental legislation comes into play, the company is building new partnerships to facilitate sustainable innovation in the construction industry. Here to tell us more is Ben Garner, Head of Logistics Development & Standards at Tarmac.

“Innovation is driving change as the industry continues to make progress to support the UK government’s legally binding commitment to net zero by 2050,” says Ben. “As requirements for zero-emissions vehicles move closer, we need to be proactive in our

transition. To facilitate this, Tarmac is prioritising supporting first-of-a-kind demonstrations to help members of our supply chain network take the first steps towards sustainability.

“We have an EV discovery programme that we developed in partnership with Renault Trucks. The idea behind this is our suppliers get to effectively try before they buy – leasing the truck for a six-month period. This approach is very low risk for them, and gives them an opportunity to understand the vehicle, the different cost mechanisms behind it and the kinds of operating processes that they’ll need to have in place. Ultimately, this de-risks the first step for them.

“At the end of the six-month period, they can decide if they want to buy the

vehicle. If they don’t want to, we’ll give the truck to someone else to trial. At some point in the more distant future, we’ll have to mandate the use of electric vehicles but before that process begins, we want to create an understanding within our supply chain of how electric vehicles can work within their business to make that long-term transition much smoother.”

However, while Tarmac’s EV discovery programme is helping to encourage that first step into electrification, developments in the charging infrastructure will be a key part of shaping the direction of the construction sector in the next few years. So, how is Tarmac navigating these changes?

“The government is committed to decarbonising the grid by 2030, which is a mammoth task,” says Ben. “Within Tarmac and our sister company NAL, we supply solutions that support the charging infrastructure – making it scalable to build a low carbon model of construction. To further progress this, we are developing a partnership with EV innovator Fleete, and they’ve been able to help us identify opportunities to improve in this area.

Partnerships such as this have fostered innovation within the company and led to exciting new developments –including the creation of the UK’s allelectric mixer (e-mixer).

“A couple of years ago we held an innovation competition, and Renault

“IT’S REALLY IMPORTANT TO NOTE THAT NONE OF OUR INNOVATIONS HAVE BEEN DONE IN ISOLATION. PARTNERSHIP IS ALWAYS GOING TO PLAY A ROLE IN PROGRESS”

Ben Garner, Head of Logistics Development & Standards

and TVS Interfleet came to us with the outline for an e-mixer,” says Ben. “What excited us about this particular project was that they came to us and said ‘This isn’t about just electrifying a piece of kit. This is about redesigning it for the 21st century.’ They took a close look at the problems with concrete mixers today, and how deploying new innovations could fix them.

“Concrete mixers are much more unstable than a traditional truck. The liquid concrete that’s being spun around can increase the risk

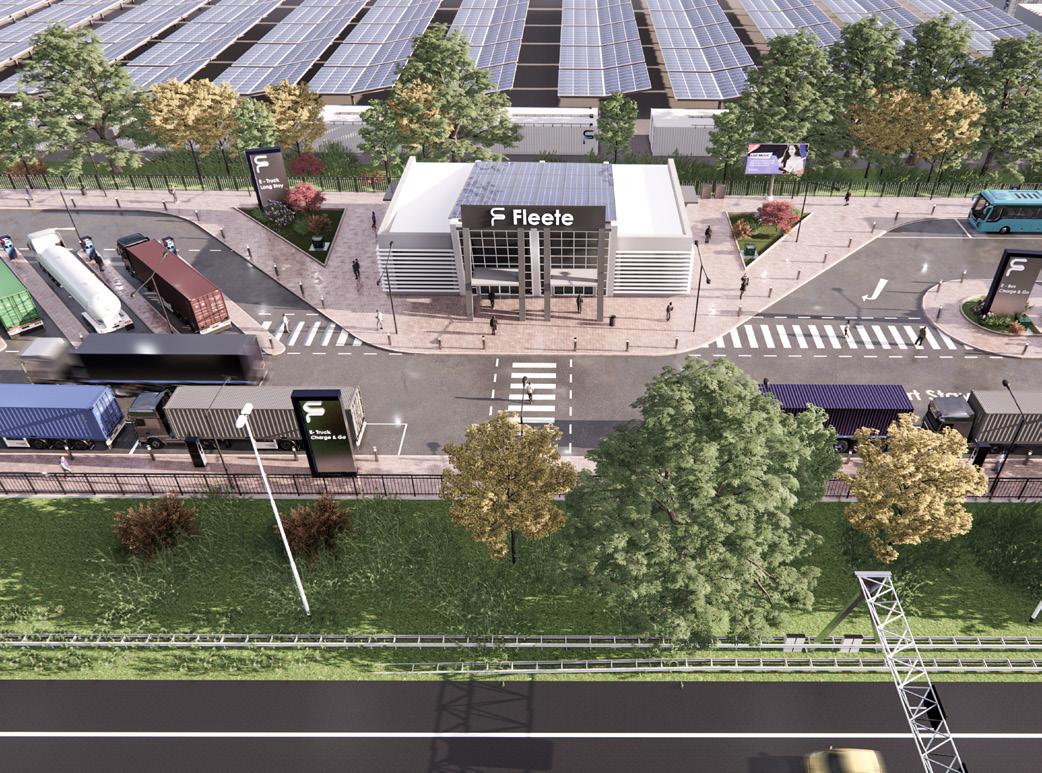

Fleete Group is at the forefront of the revolution in commercial vehicle electrification. Established by Macquarie Asset Management, a global asset manager and the world’s leading infrastructure investor. Macquarie’s expertise in long-term, sustainable investments has allowed Fleete to build a business rooted in innovation and scalability, driving real change in the transportation and logistics sectors.

Fleete was created with a clear mission: to simplify the process of fleet electrification for businesses. As part of Macquarie’s commitment to sustainable infrastructure, Fleete’s shared infrastructure hubs and unique digital platform are uniquely positioned to offer smart, efficient charging solutions that meet the complex needs of commercial operators.

We recognize that the energy transition requires more than just advanced technology; it requires an ecosystem of infrastructure that can meet the diverse

needs of commercial operators. From small businesses to large enterprises, Fleete removes the financial and logistical barriers associated with electrification, allowing companies to make a seamless transition to zero-emission transportation.

Our collaboration with Forth Ports marks our first major milestone with the opening of a 5MW state-of-the-art Fleete Hub charging facility at the Port of Tilbury. It’s designed to support up to 12 heavy duty commercial electric vehicles and 6 light to medium vehicles with ultra-fast charging speeds. The Fleete Hub provides reliable

and rapid charging for the Port’s customers, and operators.

Importantly, this hub forms a key part of the eFREIGHT 2030 consortium, a pioneering project that Fleete is proud to be part of. Led by VOLTEMPO and backed by the UK Government’s Zero Emission HGV and Infrastructure Demonstration (ZEHID) programme, eFREIGHT 2030 aims to accelerate the uptake of zero-emission heavy goods vehicles (HGVs) across the UK. With a £49 million investment from the Department for Transport (DfT) and Innovate UK, the initiative is expected to unlock £500 million of private investment into EV and charging hubs by 2030.

As part of the ZEHID programme, Fleete will deliver four commercial charging hubs across the UK, providing cutting-edge digital platform software integrated with

VOLTEMPO hardware. This will allow realtime network management across sites, benefitting both the Port of Tilbury and consortium members. Work on the eFREIGHT 2030 project has already begun and will continue over the next six years, driving forward the UK’s zero-emission future.

Fleete’s hub will not only benefit the Port’s customers but will also play a significant role in reducing Forth Ports’ Scope 3 emissions, showcasing the impact that innovative, shared infrastructure can have on sustainability goals.

At Fleete, we believe that electrification is the key to a sustainable future. Our pioneering infrastructure and forwardthinking solutions make the transition to EVs practical and cost-effective. Backed by the strength of Macquarie Asset Management, we are committed to driving the future of clean energy in commercial transport. Join us as we continue to empower businesses to make the switch to cleaner energy and accelerate their journey toward net-zero emissions.

For enquiries email contact@fleete.com

www.fleete.com

“WE ARE DEVELOPING A PARTNERSHIP WITH EV INNOVATOR FLEETE, AND THEY’VE BEEN ABLE TO HELP US IDENTIFY OPPORTUNITIES TO IMPROVE IN THIS AREA”

of rollovers, and with 20 to 30 mixer rollovers in the UK each year, this is happening far too regularly. So TVS Interfleet and Renault decided to see how they could reduce that risk.

“An electric truck already has a lower centre of gravity thanks to the weight of the batteries, which is a big tick in the box already. They then looked at a number of videos of concrete mixers toppling over and realised that what was happening was the mixer drum started to spin off its axis, which triggered the truck to fall over due to the shift in the centrifugal force.

“The drum sits on an open cradle. What they’ve done to prevent the drum spinning off its axis is implement a retention bracket, so it can’t spin off

centre unless the bracket breaks. With the e-mixer, it requires three times as much force to roll the vehicle over – so something really straightforward has massively improved that truck’s safety characteristics.”

By working with other businesses on projects like this, Tarmac is championing new innovations and de-risking these developments for suppliers.

“CRH, our parent company, set up a $250m venturing and innovation fund a couple of years ago to encourage innovation across the Group.

“The e-mixer was the first project supported by the fund and we’re building on that success by working on a number of new projects across Tarmac to drive forward innovation in a range of areas.”

But while these projects are significant developments for the industry, one of Tarmac’s most innovative changes in recent years has been the centralisation of logistics within the company.

“Traditionally, logistics in the construction materials sector is a function of the commercial teams –not a separate specialism,” explains Ben. “Tarmac decided to change that

“WE’RE WORKING ON SCALING OUR INNOVATIONS TO IMPROVE OPERATIONAL EFFICIENCY IN THE MOST COSTEFFECTIVE WAY, AND WE WOULDN’T BE ABLE TO DO THIS WITHOUT OUR STRATEGIC PARTNERS”

around two years ago by appointing Graham Waters as a Logistics Director and changing our structure including creating my role as Head of Logistics Development & Standards. The company wanted to transform the way it approached logistics, with a focus on the future.

“This transformation looks at all different aspects of the business including, customer performance, future tech and our people. One of the things Tarmac recognised was that we have some great people in logistics but they were on the fringes of the business. It wasn’t until recently that it’s been seen as a core component.

“The main thing we did to centralise logistics was to create a development and innovation programme for this branch of the company. We took high performers that were ready to take their next steps in the coming years and we created this development and innovation programme around them. There were four sessions, with a project at the end of it. Within these sessions, we gave them the opportunity to get to know one another, explore ideas of innovation within logistics and construction and develop new ways of thinking. The final project in these sessions was focused on transforming our logistics model.

“There were six people on that original course, and four of them have been promoted to new roles in the past year. We’re about to kick off our second year of this programme, and we’re excited to make a difference with our people and

get them to think beyond the day-today, which can be really challenging in logistics, where everything is coming at you all at once.”

One way Tarmac is thinking beyond the day-to-day is to look outside the construction industry while conceptualising and deploying new innovations – particularly when it comes to considering the future of the company’s vehicles.

“Looking at the future of our trucks themselves, we want to make sure that we’re effectively utilising emerging technologies to improve

safety,” says Ben. “What we’ve said now is that we want to see all of our new trucks installed with radar braking systems. So that’s a radar system on the rear that’s activated when you put it in reverse, that will automatically stop the vehicle if there’s any kind of obstruction within a couple of metres of the back of the truck.

“This system is already used on road sweepers and is starting to be used on bin lorries, but to my knowledge, it has never been used on trucks in our sector. So we ran a trial on one of our vehicles, and this new model was so

successful that we’re implementing it across the company.

“I think active safety, where the truck has the mechanism to take over from the person in emergency situations, will be a big trend that we see going forward. It’s very promising technology, and I’m excited to see how it transforms our industry.”

But Ben stresses that innovations such as this are a credit to the company’s partnerships.

“It’s really important to note that none of our innovations have been done

in isolation,” says Ben. “Partnership is always going to play a role in progress. We may have a specific vision, but our supply chain is incredible at designing and creating effective solutions for us that meet our vision.

“Electrification is a great example of partnership in action. Truck manufacturers need to make sure they’re meeting regulations when it comes to selling electric vehicles, which can be challenging. So they could sell them in the traditional way, or they can work with the people who are using them to figure out the best way

Opening up the industry

“I have four daughters and I would love for the logistics and construction materials industries to be a place where they could have a career, if that’s what they chose,” says Ben. “Being a truck driver is a very challenging job. The environment is dirty, it’s stressful and there’s a lot of long hours. We do have a lot of women drivers within our fleet, which is fantastic, but I’d love to see that shift further and I think electrification could be a key enabler of that.

“I recently went for a ride in the brand new Renault T Series electric tractor unit, and it’s beautiful. The seats

to implement these new vehicles into businesses.

“By working together, we can develop new solutions – like longer battery guarantees and streamlined charging infrastructure – which will help unpick the areas that are blocking us from scaling new innovations. We’re working on scaling our innovations to improve operational efficiency in the most costeffective way, and we wouldn’t be able to do this without our strategic partners.”

Learn more about Tarmac here.

are comfortable, the layout is really nice and you can tell that the vehicle manufacturers are putting a great deal of thought into the environment that the drivers are in. I think changes like this are going to play a huge role in opening up this industry to more people.”

“I’ve worked in logistics for my entire career, but my degree was in Geography with Ancient History and Archaeology,” says Ben. “As a part of the geography element, I did an extended essay on climate change. This would have been in 2005, and I remember reading the research at the time and

coming to the conclusion that it was too late to reverse climate change.

“At the time, governments weren’t thinking about it, companies didn’t have an action plan and there was no general consensus. Because of this, it’s been really exciting to be a part of an industry where real sustainable change is now taking place. Climate change is one of the most pressing challenges of our age, and it’s been inspiring to see the world coming together and starting to realise that we need to do something about it.

“With so many new regulations coming into place, it’s easy to see

these changes as a threat, but I see it as an opportunity. More and more companies are taking that first step in the energy transition, which is fantastic to see.

“I attended the Road Transport Expo in June of this year, and I thought the amount of electric vehicles that were there was very telling. It demonstrates that the industry is embracing sustainability, and we’ll soon see huge amounts of change coming off the back of that.”

Connect with Ben

tarmac.com