Eran Ebert, of Teva Pharmaceuticals shares insights into the company’s integrated approach to supply chain transformation by digitalisation.

Eran Ebert, of Teva Pharmaceuticals shares insights into the company’s integrated approach to supply chain transformation by digitalisation.

Welcome to our jam-packed June edition of CHAIN Magazine packed with five cracking interviews.

For our cover interview this month I chat with Eran Ebert from Teva Pharmaceuticals Industries Ltd. about the three stages in the company’s new global supply chain strategy that is improving the lives of patients through innovation and transformation by digitalisation (p6).

Amer Wahab joins us from Kettlemans Bagels Company to share insights into how the business thrives by bringing together culinary innovation and supply chain optimisation in a resilient recipe for success (p34).

I sit down with Timothy Leight and Anil Som from Infinera to discuss the company’s sustained period of digital transformation and product transitions which is propelling the company towards long-term business plans to revolutionise telecommunications networks (p58).

I speak to Mike Brooman from Community Fibre about bringing London fast, affordable broadband and the company’s strategies for supply chain innovation, sustainability and community service (p78).

David Latten from Logitech tells us how he and his team deploy technology to drive value for the business, do more with less and implement procurement strategies as an engine for global societal good (p104).

Our features this month cover a new global cold chain logistics deal in the Middle East (p24) and how to secure the tools to build a bionic supply chain (p48).

Last, but not least, we are thrilled to unveil a new recurring feature to CHAIN Magazine. In the company of… puts a spotlight on leaders and innovators in the supply chain, procurement and logistics industries. We kick things off by chatting with Karl Zelik, Chief Scientific Officer at HeroWear – check it out on p118.

Please enjoy our latest edition. As always, if you would like to be considered as an interviewee or if you have a story for us to contemplate including, do get in touch.

TRANSFORMATION

BY DIGITALISATION AT TEVA, A GLOBAL PHARMACEUTICAL COMPANYEran Ebert, Head of Global Supply Chain Transformation and Center of Practice at Teva Pharmaceuticals on the company’s commitment to improving the lives of patients through transformation and innovation.

BASED IN TEL AVIV, ISRAEL, TEVA PHARMACEUTICALS INDUSTRIES LTD. SERVES

200 MILLION PATIENTS PER DAY IN MORE THAN 60 COUNTRIES AROUND THE WORLD. THE COMPANY EMPLOYS APPROXIMATELY 40,000 EMPLOYEES WORLDWIDE AND OPERATES OVER 50 MANUFACTURING FACILITIES AND 12 R&D SITES.

n March 2021, Teva launched a new supply chain strategy that aims to manage and optimise the post-Covid changes and consequences that have affected the pharmaceutical industry.

Representing the company’s Global Operational Division is Eran Ebert, Teva’s Head of Supply Chain Transformation and Center of Practice, who sheds light on this exciting chapter of transformation and innovation at the business.

Eran and his team are responsible for the governance and rollout of the new supply chain strategy across the entire company and they are

also in charge of the company’s Supply Chain Center of Practice – an innovation hub where strategies are refined into new methodologies, processes, standards and tools at Teva.

“Our strategy is all about transformation by digitalisation,” answers Eran. Elaborating on the process, he explains that there are three stages to changing the company’s supply chain strategy: first is strengthening the foundation, the second involves enhancing connectivity, and the last stage is forward-

“OUR STRATEGY IS ALL ABOUT TRANSFORMATION BY DIGITALISATION”

Eran Ebert, Head of Global Supply Chain Transformation and Center of Practice

looking, towards 2030 and beyond – “looking to the future.”

Each stage entails several projects and initiatives relevant to the respective time frames.

Eran explains that Teva used to focus on transformation efforts within the Planning Excellence

team, but the culture and vision have since shifted to channelling this quality on the ground and making things happen. Hence, the rebranding from a Planning Excellence team to working as the Supply Chain Center of Practice, where the focus gravitates around executing procedures and methodologies, putting things into

practice, not just preparation and theories.

Expanding on the first stage of Strengthening the foundation, Eran explains the background of how for the past 30 years Teva’s growth strategy relied on external

acquisitions. Acquiring other companies brought a lot of value to Teva, yet there was not enough standardisation of processes and tools between Teva’s entities. For example, several different ERP systems. At some point, a few years ago Teva decided to make a brave and transformational move, to unify the way all the business

units are working, to have one language, one process, one supporting platform: ‘One Teva’.

“We really put a lot of effort into the integration,” says Eran. “We worked diligently with our partners from IT to make sure Teva operated on the same platform, speaking the same language to coordinate the same processes across the board, creating standardisation. We put our focus on ensuring that all manufacturing sites, all other business units and all our markets were on the same

system executing the same way of working. It was and still is a huge change, a real transformation.”

“In order to strengthen the foundation, we needed to ensure that all the manufacturing sites and commercial markets moved to the one Teva platform, using the same system and blueprint. That has a lot to do with changing the way people used to do their dayto-day work while showing them the value for them or for the

company. In fact, that was the real transformation, going through this change management journey with the people. And it is not always easy, sometimes you have to pay more attention to certain areas and put more focus and resources to support the journey. Implement Consulting Group provided us with advanced support on this piece.”

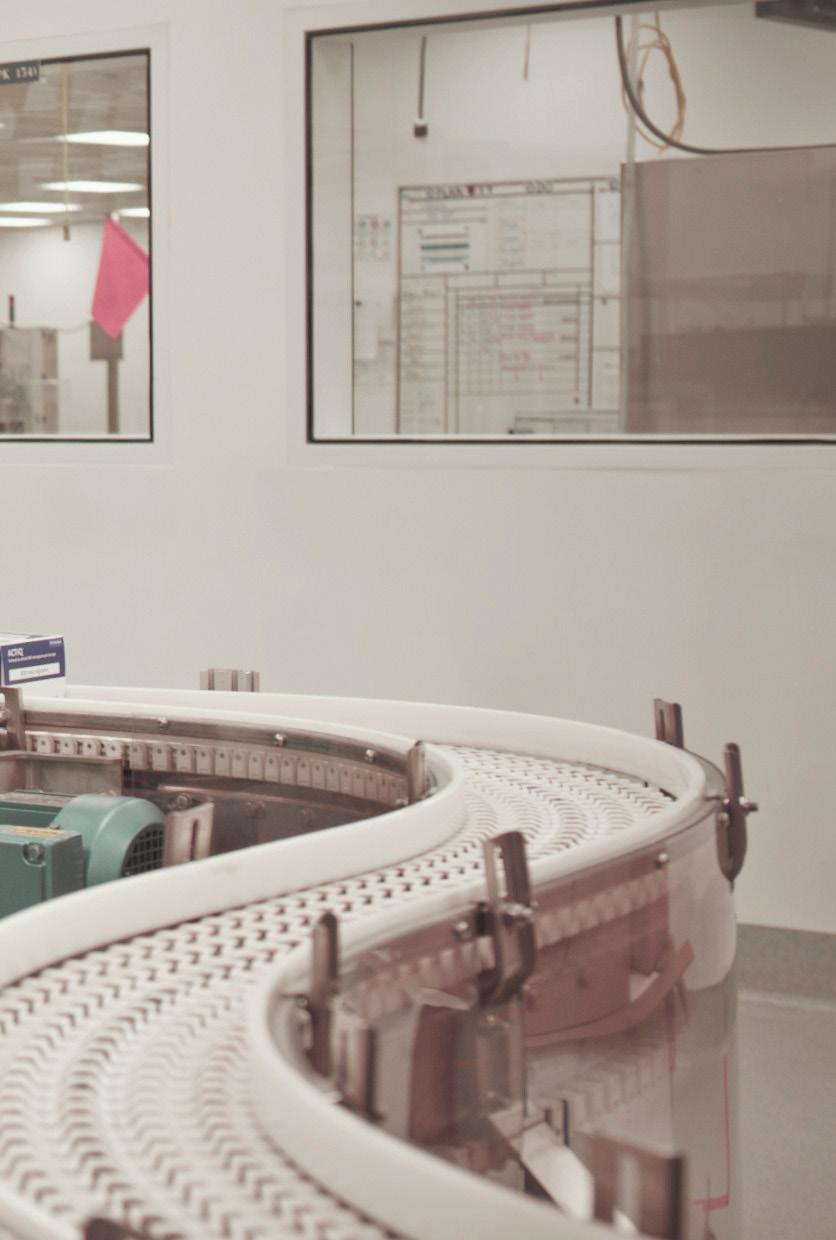

Streamlining to one system across multiple manufacturing sites at Teva went hand in hand with transformation to the logistical side of the company’s operations.

“To achieve the new Teva strategy, we, in supply chain, needed to adjust and change the way of working by using a centralised and consistent approach,” says Eran. “It is then a question of deploying the second stage of transformation where we enhance connectivity by bringing in advanced new technologies to enable the digitalisation of our operations.”

Before Teva could embark on the second phase of transforming its supply chain strategy by enhancing connectivity, Eran and his team brought in new technologies within the strategy rollout during the foundationStrengthening first stage to prepare themselves for the transformation.

“We decided on a few technologies that would really take us to the next level

“TO ACHIEVE THE NEW TEVA STRATEGY, WE, IN SUPPLY CHAIN, NEEDED TO ADJUST AND CHANGE THE WAY OF WORKING BY USING A CENTRALISED AND CONSISTENT APPROACH”

Achieve unprecedented levels of supply chain automation through the digitalisation of critical data and processes, including GxP validated automated product release. Our platform, services and advanced IoT devices are trusted by pharmaceutical and logistics companies to make their operations significantly more automated, effective and sustainable.

You can’t improve what you can’t see. Single-source-of-truth visibility of product status and supply chain performance empower you to monitor and respond to minimise product rejections and downstream effects

We help you reach your sustainability goals with reusable IoT devices and a circular business model. Comprehensive insights enable you to optimise quality, automate data-driven decisionmaking and make it easier to reduce waste and logistics costs.

Our vision is to deliver zero-waste supply chains for our partners and the planet. But ultimately, it’s about people and their health. Our solutions help get quality-assured medicines to more patients, more quickly, all around the world.

Learn more about how to optimise the value of supply chain automation

of planning and supply chain capabilities. These were things like direct seamless connectivity with external suppliers, machine learning and AI for savings predictions and better forecasting, robotic process automation (RPA) for some of our processes and process mining and advanced analytics for identifying areas to improve.”

Eran also describes how Teva has made significant strides in terms

One of the most impactful projects within the digital transformation process is Teva’s Integrated Business Planning (IBP) project which aims to enhance connectivity across all functions an advanced End-to-End platform.

“IBP is the next generation of our sales and operations planning (S&OP). While many times S&OP is more a set of sequential

of digitalisation around shipping visibility and monitoring in the past few years as compliance and regulatory standards evolved. “Here we built a partnership with Controlant who came in with a digital solution that allows us to monitor the location, temperature and security of our shipments in real-time,” says Eran. “We work together and use their sensors to provide patients with the highquality products they need in the safest manner possible."

separated steps taken by finance, commercial and supply chain to get a consensus on the rolling business plan, IBP is about a truly integrated, mutual and simultaneous planning by all functions with real-time data of volume and value. For a company the size of Teva, to guarantee seamless connectivity between all the relevant functions, this vision has to be supported by the right technologies, putting everyone in one platform,”

“WE BUILT A PARTNERSHIP WITH CONTROLANT WHO CAME IN WITH A DIGITAL SOLUTION THAT ALLOWS US TO MONITOR THE LOCATION, TEMPERATURE AND SECURITY OF OUR SHIPMENTS IN REAL-TIME”

elaborates Eran. “This is an important, significant and transformational project in Teva. In order to gain future integrated planning, this programme is actually being led by leaders from finance, from supply chain and from IT, working together towards one goal.”

Eran further explains that the traditional process would normally start with supply chain departments providing their predictions and data, and then they would work with the commercial teams to agree on the numbers for the future plan – meanwhile, other departments like finance generate similar inputs based on their own considerations and findings, related to the financial targets. The issue is, that multiple teams provide several recommendations, and it can pull a company in too many directions – which the traditional S&OP process tries to mitigate.

And it is not an easy task. The goals for this project are very aspirational but crucial for Teva: align planning processes and calendars between functions, achieve shorter and more effective cycles, business decisions based on real-time data across the organisation, one set of numbers to enable clarity and transparency with scenario planning as an enabler.

multiple teams – such as global supply chain, operations, finance and commercial – involved in strategy decisions come together to use one system and advance the company forward leveraging SAP IBP and SAC technology.

“KPMG was selected as the leading partner for the implementation of our IBP project. There’s a great team over there and we’ve

However, for a company like Teva which generates approximately $15 billion in annual revenue, it is imperative there are high levels of visibility to ensure that decisions are made optimally and effectively for the company as a whole. Eran applauds how the company now achieves a real global optimum for decisions. With its innovative IBP project, Teva is embracing a cohesive planning approach where the

established a fantastic way of working together.”

But how does a large, global company like Teva take widescale transformation efforts like the IBP project or implement unified technology platforms in its supply chain and ensure that these strategic initiatives are unfolding on the ground?

Eran says that change management is always challenging, and it begins with a

“KPMG WAS SELECTED AS THE LEADING PARTNER FOR THE IMPLEMENTATION OF OUR IBP PROJECT. THERE’S A GREAT TEAM OVER THERE AND WE’VE ESTABLISHED A FANTASTIC WAY OF WORKING TOGETHER”

clear vision and direction for the strategy. Then it requires unified, consistent messaging at all levels to execute transformation successfully, so it is understood and embraced at all levels.

“So first of all it was about establishing the right vision in a

way people will relate to and feel close to,” explains Eran. “We had the entire supply chain leadership aligned and conveying the same message. Then we identified who are our stakeholders, who should hear about our new strategy? Who are the key influencers? Who are the people that can support us?

“IN ORDER TO STRENGTHEN THE FOUNDATION, WE NEEDED TO ENSURE THAT ALL THE MANUFACTURING SITES AND COMMERCIAL MARKETS MOVED TO THE ONE TEVA PLATFORM, USING THE SAME SYSTEM AND BLUEPRINT. IMPLEMENT CONSULTING GROUP PROVIDED US WITH ADVANCED SUPPORT ON THIS PIECE”

Who should do something about it? Who will be most impacted? And so on. It's not just about you and your team, it's about us as a company, the people on the ground. We structured a very tight communication programme with different channels like town halls, road shows to all functions in Teva, webinars, newsletters and gamification to promote the vision and strategy for our digital

transformation. The goal was to ensure people understand what's in it for them, what's in it for Teva and what’s in it for the patients.

“One of the reasons that my team tries to visit the sites around the world constantly is to talk to and work with the people in the markets and manufacturing sites. Having a face-to-face meeting is much, much different than virtual meetings. The

impact is different. That's why for us it's super crucial to go there and see the transformation with our own eyes, understand problems and lean into opportunities. Again, we want to put things into practice, we want to make sure that the vision becomes a practice.”

Stage three of the digital transformation at Teva is looking to the future, 2030 and beyond.

“The pace and speed of change is staggering, not only in supply chain, but generally in our world in terms of technology, people, economics and more,” says Eran. “At Teva we believe that by 2030 the global supply chain in the industry won’t look the same.

“Everything will be completely different. We cannot predict the future, but we would like to be as ready as we can for it.

leaders and scientists to try and come up with possible scenarios for the future of supply chain we can proactively anticipate and adapt our long-term plans accordingly. We are just trying to be ready.

“One of the reasons we are looking so far ahead is that Teva is a giant company and if we want to make big changes for 2030, believe it or not, we have to start the planning now because it’s a huge ship to turn.

“So we established a dedicated stream for supply chain innovation. The sole goal of this team is to try and anticipate and plan for 2030 and beyond. Their job is to talk to professors, tech companies, researchers, thought

“For example, one of our visions for the future is to have seamless real-time connectivity through the entire supply chain, vertically and horizontally. Meaning, we believe that in the future we will be able to get a real-time signal the second someone purchases our product in a specific pharmacy in a specific city around the world. Gathering all these signals will allow us to identify trending demands which will flow to our planners at the markets and our manufacturing sites, while this trend will also be translated to requirements from our suppliers so they can be ready on time to ship the necessary materials.

Needless to say, we will probably also have full transparency of our

suppliers’ ability to commit to our needs so we will know exactly the status of each node in our supply chain. All of this will happen automatically using, most probably, a mechanism based on ML and AI capabilities, real endto-end connectivity and real-time

demand sensing. That’s the dream, that’s the vision.”

Learn more about Teva Pharmaceuticals at their website tevapharm.com.

Eran recently read the article ‘Maverick Research: The Digital Era — The End Of S&OP?’ by Pia Orup Lund and Cristina Carvallo which he found fascinating.

“I keep thinking about this article because it raises a challenging question, prompting readers to think outside the box about planning,” says Eran. “Everything changes so quickly nowadays, and the article questions if the monthly cycle for the S&OP process is now redundant. Why are we still working according to a monthly cycle? Should we be working with no cycle?”

Eran channels tremendous passion for the work he and his team do at Teva.

“I have the best team with the best people one could ask for, and you know, I am really passionate as a supply chain transformation lead, I am fuelled by the combination of having a great team with driving significant change, problemsolving, collaboration, continuous improvement, and the global perspective that comes with my role. These factors make my job fulfilling, intellectually stimulating, and essential for the success of Teva.”

A new global rental agreement aims to provide the broadest range of cold chain products for pharmaceutical customers around the world.

SAUDIA CARGO HAS ADDED TOWER COLD CHAIN TO ITS APPROVED ROSTER OF TEMPERATURE-CONTROLLED CONTAINERS FOR SHIPPING PHARMACEUTICAL, BIOTECH AND LIFE SCIENCE PRODUCTS, IN A NEW GLOBAL RENTAL AGREEMENT.

he deal reinforces Saudia Cargo’s commitment to having the broadest possible selection of cold chain products (both in terms of cargo size and temperature requirements) to serve the growing requirements of pharmaceutical customers from around the world.

A key benefit of Tower Cold Chain’s technology is its reliability in maintaining product integrity without the need for electricity

“A KEY BENEFIT OF TOWER COLD CHAIN’S TECHNOLOGY IS ITS RELIABILITY IN MAINTAINING PRODUCT INTEGRITY WITHOUT THE NEED FOR ELECTRICITY EVEN IN EXTREME HEAT”

even in extreme heat, meaning that a robust solution is required to prevent temperature excursions.

“Given these conditions, we have an extra duty of care to customers to ensure due diligence in choosing our pharmaceutical cold chain partners,” commented Adel Elshazly, Global Product Manager at Saudia Cargo. “Tower’s passive

solutions are proven to maintain temperatures for up to 120 hours, without any need for intervention or external power.”

The Tower range offers effective physical and temperature protection for internal payloads from 3,075 litres down to 26.4 litres – the latter made possible by the launch in 2022 of the KTEvolution,

the company’s first hand-held container, ideal for small-batch, direct-to-patient shipments.

Tower containers ensure up to 120-hour protection for

products that require an internal temperature of -80°C (ultracold), -60°C (ultracold), -20°C (frozen), +5°C (refrigerated) or +20°C (controlled room temperature).

“THE TOWER RANGE OFFERS EFFECTIVE PHYSICAL AND TEMPERATURE PROTECTION FOR INTERNAL PAYLOADS FROM 3,075 LITRES DOWN TO 26.4 LITRES”

“The breadth of the Tower range means we can extend our network and provide customers with greater choice, including the ability to ship pharmaceuticals on narrowbodied as well as wide-bodied aircrafts,” Adel Elshazly stated.

With hubs in Saudi Arabia’s three biggest airports – Jeddah, Riyadh and Dammam – Saudia Cargo is a key partner for companies shipping pharmaceuticals into the Middle East. The European market in particular is a major source of pharmaceutical and life science cargo, a factor that was integral to Saudia Cargo’s selection of Tower Cold Chain.

“Tower has a growing network of hubs, including locations

“THE EUROPEAN MARKET IN PARTICULAR IS A MAJOR SOURCE OF PHARMACEUTICAL AND LIFE SCIENCE CARGO, A FACTOR THAT WAS INTEGRAL TO SAUDIA CARGO’S SELECTION OF TOWER COLD CHAIN”

where much of our business hails from airports such as Frankfurt, Zurich and Milan. The proximity and availability of Tower containers at these hubs means we can offer seamless and direct delivery to our airports,” added Adel Elshazly.

Customers wanting to use Tower containers should discuss their requirements with Saudia Cargo, who will then lease the chosen solution using Tower’s intuitive 24/7 online ordering system.

“We choose our partners carefully and we know Tower is a pillar of the pharmaceutical container market, we are delighted to announce this partnership which will take us to new heights for global

customer satisfaction” summarised Adel Elshazly.

Tower’s Chief Executive Niall Balfour said, “As a global company, this partnership is a vital part of our

“AS

GLOBAL

IS A VITAL PART OF OUR COMMITMENT TO CUSTOMERS. SAUDIA CARGO GIVES US A VALUABLE GATEWAY INTO THE MIDDLE EAST”

Niall Balfour, Tower’s Chief Executive

commitment to customers. Saudia Cargo gives us a valuable gateway into the Middle East, and in turn we are honoured to be able to help them meet customer demand for robust, reliable and

reusable pharmaceutical cold chain solutions.”

For more information on Tower Cold Chain, click here: www.towercoldchain.com.

Amer

Kettlemans Bagel Company started in 1993, when Founder Craig Buckley had the idea to bring Montreal bagels to Canada’s capital city Ottawa.

he business makes its bagels by hand rolling, kettling and baking them in wood-burning ovens. Kettlemans serves them alongside 16 spreads, an array of sandwiches and baked goods at its restaurants which are open 24 hours a day, 7 days a week.

Here to share more insights into the culinary innovation and supply chain optimisation that allowed them to grow during the COVID pandemic and ever since is Amer Wahab, President and Chief Operations Officer at Kettlemans Bagel.

The repercussions of the COVID pandemic reverberated across many industries and the food and hospitality sectors were no exception. But Amer is immensely proud that Kettlemans navigated this challenging time without having to close its doors or laying off a single member of staff.

When asked how the company managed this, Amer says, “I’m going to have to quote my wife here because she deserves the acknowledgement. I said at the time we were very lucky, we never closed and we continued to operate. But she corrected me. She said no – ‘Luck is just what happens when preparation meets opportunity.’”

Amer attributes the company’s resilience to the work culture at Kettlemans.

“We were

in a way that

us to ride it out,” explains Amer. “We did everything in our ability to ensure we did not let anybody go and at the time we were a company of 300 people.

“It's in our DNA to grow as a company but also in terms of

built

allowed

developing people – even when everything around you is shutting down,” says Amer. “We have a culture that is truly built on a passion for what we do and the purpose that gives everyone within our organisation lets us provide people the opportunity to grow.”

But Kettlemans not only kept all their restaurants open and retained all staff, but it also opened four new establishments during the COVID pandemic.

Employment security and business stability were not the only ingredients in

“We have a culture that is truly built on a passion for what we do and the purpose that gives everyone within our organisation lets us provide people the opportunity to grow”

Kettlemans’ recipe for success. Culinary innovation and supply chain optimisation were major components as well.

“There's a bit of a fine line, especially when you're working with unit economics being front of mind. You want to create jobs but you also have to maintain a balance for your costs of goods with respect to food and your labour so you can have healthy margins,” says Amer.

Crucial to this was transitioning to a central kitchen while working with supplier partners to enhance the Kettlemans products and make

its supply chain leaner and more sustainable.

“We were able to centralise, for example, with the production of our cream cheese from Skotidakis,” explains Amer. “We buy the base from them and add our own flavour profiles to it. We have 16 different flavours of cream cheese – dill pickle, hot pepper, blueberry, just to name a few.

“That took the burden off individual stores creating their own products. We centralised the process and decreased the economic costs of labour in some

areas by creating efficiencies and having ingredients from a single source, made within our four walls. We also reassessed production and now have certain items made for us, for instance some of our pastries and cakes.

“Another example is how we shifted our salmon supplier because they could provide a superior product that was consistent and send us the product in a sliced format, again saving time, reducing labour costs and improving efficiency. But we also wanted to ensure that the product was 100 per cent Canadian.

“The supplier told us that the 1,500kg of salmon we buy from them every month created four new full-time jobs and that’s what it’s all about – a high tide raises all ships.”

Kettlemans shifted its purchasing patterns to buy more products in advance and adjusted its periodic automatic replacement (PAR)

levels at its establishments. The company also took an intelligent approach to the timelines for opening new restaurants.

“As soon as you open a restaurant, they need supplies,” explains Amer. “Those supplies may not have been accounted for when your supplier did their initial purchasing. Transparent communication ensures our suppliers are fully aware of when we schedule openings, allowing our partners to adapt to our volume increases and provide a steady flow of products. Crucial to this is ensuring that we agree good, fair terms so the people who pay the bills are the people who get what's needed first. Always being current with your partners and honouring your commitments is fundamental.”

Culinary innovation and supply chain optimisation have gone hand in hand with promoting a sustainable agenda at Kettlemans.

Here, Amer highlights the importance of education, efficiency

“We were able to centralise, for example, with the production of our cream cheese from Skotidakis. We buy the base from them and add our own flavour profiles to it”

and supplier-partner collaboration.

“First of all, we invest in our people, that's key. Because investing in your people and ensuring they are educated means we can source our products better, smarter, closer and cleaner. Then it’s a question of aligning yourself with people along that supply chain who have the same values as you – we always look for responsible partners.

“We believe in progress, in chasing perfection. It’s about the benchmark you set and how you strive towards it.”

Since the world moved on from the grips of the COVID pandemic, Kettlemans has managed to maintain its momentum even with a downward trend in foot traffic to stores in a context of hyperinflation and increased costs of living: a challenge for

“We believe in progress, in chasing perfection. It’s about the benchmark you set and how you strive towards it”

businesses around the world, not just in Canada.

“We have been refocusing on the core of the business, what we call our Big Four,” says Amer. “These are incredible hospitality, amazing food, unwavering cleanliness and sanitation and superior speed of service. We are very guest-centric.

“Focusing on our customers and our stability as a company gives us the freedom to innovate and look towards expansion”

“Focusing on our customers and our stability as a company gives us the freedom to innovate and look towards expansion,” summarises Amer.

Culinary innovation and supply chain optimisation would not be possible without employee buy-in to facilitate successful deployment. For Amer as the

company President, he relishes the responsibility his leadership role presents to motivate and empower his colleagues towards achieving the company’s goals.

Elaborating on his leadership style, Amer says, “Here's a little acronym that I use myself: LAF. It stands for listen, align and follow-up. So we listen to what our people have to

say. We align ourselves to ensure we're all aiming at the same goal. Then we do the follow-up with the great people that we've hired as they do what they're best at doing.”

So what are the principal ambitions at Kettlemans for 2023 and beyond?

Amer reiterates Kettlemans mission to create lifechanging opportunities for employees and champion a guest-centric approach with the Big Four at the forefront of their operations.

The company is always considering new site locations and how to innovate its operations. Kettlemans is contemplating deploying a franchising model and assessing the commercial viability of opening smaller restaurants or stores using a hub and spoke approach where larger establishments would support these satellite outlets.

For more information, visit www.kettlemansbagels.ca.

A BIONIC SUPPLY CHAIN which harnesses the best that humans and machines have to offer – may sound like something out of science fiction, but according to SAPICS (The Professional Body for Supply Chain Management in Southern Africa), it is what businesses should be building, to future proof their supply chains in an increasingly volatile, uncertain and complex environment.

The latest technology that is being leveraged in bionic supply chains will be in the spotlight at the upcoming 45th annual SAPICS Conference, the organisers have announced.

The conference, which takes place in Cape Town from June 11-14, 2023, is Africa’s foremost knowledge-sharing and networking event for the supply chain profession. Local and international experts will examine technology like Artificial Intelligence (AI), autonomous drones and business intelligence tools, and share their insights on how and why these advances are revolutionising supply chains. This year’s SAPICS Conference features an exciting collaboration between SAPICS and the South African Association of Freight Forwarders (SAAFF), which will co-host the event.

Photo by Claire Photography

Photo by Claire Photography

AI is the focus of the 2023 SAPICS Conference presentation

by

Nomsa Nteleko, Chief Commercial Officer atAmathuba AI. Her vision is to change people’s lives through AI technology, and she contends that embracing AI will “help to advance African humanity.”

“At Amathuba AI, we believe Africa is full of opportunities and that African people should fully embrace and take advantage of all of these. More importantly, we want to make these opportunities that may traditionally not have been possible for an African child possible and attainable,” Nteleko says.

Amathuba means “opportunities” in isiZulu. Nteleko explains that the company was founded in 2020 with the intent to advance African culture and humanity through the assimilation of artificial technology.

“AI is the science of having humans and computers working better together than any group of computers, or

“AUTOMATED INVENTORY BY SELF-FLYING DRONES CONFERENCE

group of humans have ever done before,” states Nteleko. “We recently conducted a very successful AI implementation with a municipality in KwaZuluNatal. It was a smart contract management solution, driven by machine learning technology. We discovered that up to 80 per cent of vendor invoices were being paid without sufficient evidence that the contracted work was satisfactorily completed. Our AI solution provided a conversational AI chatbot that provides real-time information on queries such as the total contracts under review, financial values and expiry dates. The team can now see on one dashboard the total procure-topay process.”

Nteleko’s accolades include being named one of the Mail & Guardian’s Power Women of 2022, receiving the GCPIT Top 100 Global Women in Leadership Award in 2021 and topping the Inspiring Fifty SA list in 2018. The latter is a global initiative that recognises inspiring role models in technology. Automated inventory management powered by

MANAGEMENT POWERED

IS ON THE 2023 SAPICS PROGRAMME”

self-flying drones is on the 2023 SAPICS Conference programme in a presentation that will focus on pushing the boundaries of inventory management through innovation.

“A zero-error warehouse is no longer a luxury. Improving inventory accuracy has become an imperative for big-box retailers, 3PLs (third-party logistics providers) and manufacturers competing for customer loyalty,”

“Drones can scan inventory in warehouses and distribution centres during nights and weekends - literally while we sleep - and they can identify inventory discrepancies and distil that data into valuable insights. They offer a sustainable way in which to manage our man-hours and resources. This presentation

says presenter Judy Bezuidenhout, who is the national inventory manager at DSV Solutions.will highlight the importance of inventory management and what the benefits are when you have the correct stock in the correct location physically and systematically,” Bezuidenhout explains. She will address the downstream impact of inventory errors and the potential risks, while introducing conference attendees to the innovation of fully autonomous drone cycle counting.

“This technology is awesome because it can replace unsafe

and arduous manual barcode scans, provide accurate inventory reporting and reduce inventory investigation,” Bezuidenhout stresses.

Big data and analytics have been ranked among the most important topics in supply chain in 2023. They are also on the agenda for this year’s SAPICS Conference. Supply chain specialist Lee-Ann Bartlett will share her experience and expertise on leveraging data

“BUSINESSES ARE MAKING USE OF SEVERAL INFORMATION SYSTEMS TO MANAGE THEIR RESPECTIVE BUSINESS FUNCTIONS”

analytics to optimise supply chain management.

“Businesses are making use of several information systems to manage their respective business functions, for example transport management systems, enterprise resource planning systems and warehouse management systems,” Bartlett notes.

“A lot of data is captured and gathered by these systems daily. This data is then used by management to create the management reports required monthly. They typically do this by using spreadsheets to consolidate the data and transform it into an acceptable format. However, the problem is that these spreadsheets can be corrupted and finger errors are unavoidable,” she says.

“Using business intelligence tools, this process can be streamlined by automating the gathering of data, calculations and the transformation of the data to drive insightful decision-making. Investing in these tools will provide organisations with peace of

mind regarding data cleanliness and standardisation of key performance indicators (KPI) calculations,” Bartlett states.

Her SAPICS Conference presentation aims to create awareness about the amount of data gathered daily and enable supply chain professionals to understand what is useful and what is not. She will explain the flow of data from the myriad of information systems to create insightful reports and will outline how to merge the continuous improvement and data analysis cycles to achieve high process efficiencies. “The savings that can be achieved through investing in data analytics outweigh the cost associated with the development,” Bartlett stresses.

For further information, or to register for the 2023 SAPICS Conference, call the Conference Secretariat at Upavon Management on 011 023 6701 or email info@upavon.co.za.

Up-to the-minute information is also posted on the SAPICS conference website: conference.sapics.org.

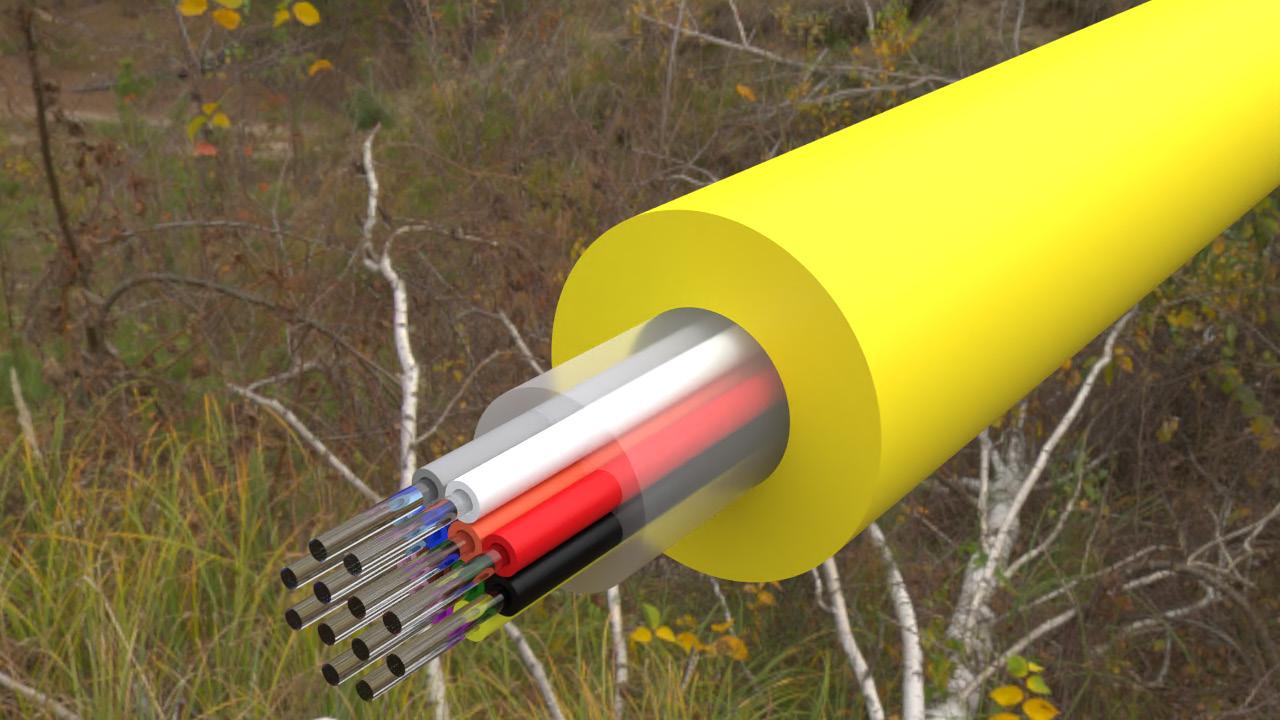

Infinera is a global supplier of leading-edge optical networking solutions and advanced optical semiconductors that enable telecommunications network operators to scale bandwidth and accelerate service innovation.

ocused on excellence, Infinera provides solutions that deliver industryleading economics and performance in longhaul, submarine, data centre interconnect and metro transport applications. Infinera’s agile, open, compact and modular networking platforms enable network operators to rapidly and easily take advantage of best-in-class technology.

Headquartered in Silicon Valley, California in the US, Infinera is revolutionising telecommunications networks by developing innovative, industryleading connectivity solutions including systems for network infrastructure, automation software, high-end subcomponent

technology and professional services.

As the company expands its horizons, Infinera is undergoing a sustained period of digital transformation and product transitions aligned with long-term business planning.

Here to share insights into how supply chain innovation underpins digital transformation and spans multiple business teams are Timothy Leight, Vice President of Supply Chain and Anil Som, Senior Director of Operations.

The supply chain innovation underpinning the digital transformation at Infinera

comprises supply- and demand-side developments.

To understand the current digital transformation efforts at Infinera from the demand side, Anil takes us back to 2018 when the company acquired Coriant, a privately held global supplier of open network solutions for the largest global network operators. The deal positioned Infinera as one of the largest vertically integrated optical network equipment providers in the world.

“One of the first goals for us was to make sure we could get all the IT systems together,” recounts Anil. “Similar to other acquisitions, multiple ERP systems needed to be integrated, so we immediately got all that in place. But then we realised that we needed to transform our sales and operational processes and as part of that redefine our demand and supply planning. Even though we did have what we used to call the sales and operational planning process in place, it was rudimentary in nature. We were largely focused on demand planning in the near term. We would ask what's happening this quarter, maybe what's happening next quarter as opposed to looking further ahead – four, eight or more quarters into the future.

“So one of the key aspects of the transformation we identified as a

focus was, how do we enable the sales and operational planning to be more strategic? We wanted to be more collaborative in nature, so rather than being an isolated operations or supply chain team, how could we collaborate with our sales operations teams, finance team, direct sales team and product lifecycle management team? We asked how we could all collaboratively come together, look at the various forecast signals and come up with a long-term demand signal that could then be sent to our suppliers. And as part of that, we've

transformed both on the process side and on the technology side.”

Timothy adds that new product introduction (NPI) was a crucial factor in the sales and operation planning (S&OP) process during this transitional phase.

“Seeing that ability for us to look at the NPI programmes in the S&OP process for at least eight quarters out, and to look at better managing the product transitions, was a game changer. These were two areas that really have benefitted Infinera in

“We build products by the thousands or even just hundreds. Getting to tens of thousands is outside of our norm, but that is changing now as we ramp our pluggable transceiver product portfolio”

Timothy Leight, Vice President of Supply Chain

terms of planning in recent years,” summarises Timothy.

Here, Timothy’s background in highvolume manufacturing benefitted his contributions to the digital transformation efforts at Infinera. In particular, Timothy highlights the importance of moving towards better data insights and predictive analytics.

“Infinera and Coriant historically produced at a lower volume,” explains Timothy. “We build products by the thousands or even just hundreds. Getting to tens of thousands is outside of our norm, but that is changing now as we ramp our pluggable transceiver product portfolio.

“In my experience, we spent a lot of time looking at the supply side of things and understanding and looking at our factories and our contract manufacturing and establishing what are the yields, capacities and outputs that we’re getting on a daily, weekly or monthly basis. Gathering that data was an area that we weren’t necessarily mature in, but we’ve made significant progress in that regard.

supply chain road map and I want to make sure we continue on that journey of digital transformation at Infinera.”

Here, Infinera has benefitted from the support offered by Kinaxis, the Canadian supply chain management and sales and operation planning software company.

“Prior to working with Kinaxis, we were doing our S&OP using multiple databases and spreadsheets – it was a tedious process,” admits Anil. “Multiple people were spending days, even their weekends, just collating data, getting it all together to come up with a long-range view of demand. Once we had Kinaxis implemented, demand planning became a much more streamlined and easier process. It gives us great visibility into both demand and supply. Now we also have the ability to adapt our S&OP planning cadence. Before, if there were changes that we wanted to do midcycle, we didn't have that ability. But now with Kinaxis, if there’s a huge demand which comes in between the cycles, we can run a mid-cycle change and we get a new signal out to our suppliers.

“Now the next step would be not just gathering data but striving towards predictive analytics. This is part of my

“So the technological aspect of enabling a new tool like Kinaxis has helped us a lot. In addition to just enabling our sales and operational planning, Kinaxis helps us in getting

all this data together. Before, we had all the data, but it was all in multiple systems that were not tightly integrated. But with Kinaxis we can generate reports and leverage our data simply and easily, and that’s also been a gamechanger for us in the past couple of years.”

Anil notes that Kinaxis offers particularly valuable benefits to Infinera’s operations by enhancing data visibility across the value chain.

The digital transformation efforts at Infinera go hand in hand with promoting operational excellence across all departments at the company.

Timothy relays how the focus on operational excellence stemmed from the COVID pandemic and how it heavily impacted the global supply chain, with semiconductors being particularly hard hit.

“Once we had Kinaxis implemented, demand planning became a much more streamlined and easier process. It gives us great visibility into both demand and supply”

Anil Som, Senior Director of Operations

Recognised as #1 by analysts for supply chain vision and proven value, only Kinaxis gives you the agility to keep your business ready for any future. We’re trusted by innovative brands around the world to accelerate their digital supply chain transformations and empower fast, con dent decision-making. We combine human and arti cial intelligence with our unique concurrent planning technique so you know sooner, act faster and can remove waste.

Recognised as #1 by analysts for supply chain vision and proven value, only Kinaxis gives you the agility to keep your business ready for any future. We’re trusted by innovative brands around the world to accelerate their digital supply chain transformations and empower fast, con dent decision-making. We combine human and arti cial intelligence with our unique concurrent planning technique so you know sooner, act faster and can remove waste.

www.kinaxis.com

But Infinera was able to ride out these challenging circumstances due to their deep and strong supplier relationships, built on a philosophy of credibility through communication.

“One of the things that drew me to Infinera as a company when I joined was their culture and philosophy on how to do supplier management,” shares Timothy.

“We value and strive to build robust supplier relationships, even up to the CEO level. We continue to foster these relationships, so during the pandemic and times of shortages where we couldn't get parts, we might have a brief CEO-to-CEO meeting, or maybe even just an e-mail or a phone conversation. We didn't waste the supplier’s time, but we did have those relationships where we could call as and when needed. We didn't double order when the situation became difficult, and the suppliers were quick to recognise that, building our credibility. In fact, we chose to have daily or weekly working calls where needed and did whatever it took with our key suppliers and

our key partners to talk about our real demand, what it looks like from a forecast perspective. And if there was difficulty in meeting that, we had that open communication about what's our drop-dead quantity and our customer’s lifeline requirements.

“We built a tremendous amount of credibility through the pandemic with our suppliers. That credibility helped us have more open conversations with them about their sub-tier supply chain,” summarises Timothy.

Moreover, Infinera’s digital transformation, much like any other major business project or enterprise strategy, relies on tangible KPIs and metrics.

“One of our key focuses within our digital revolution was to avoid

transformation just for the sake of transformation,” says Anil. “It's key to understand how we are improving our metrics along the way. For instance, we are really focused on time-to-delivery metrics. This stems from our CEO, David Heard, who has been very passionate about improving the metrics that really affect the customer. So we don't want to improve our performance metrics just for the sake of improving metrics. How are we making sure we meet the commitments that we have made to our customer? What is our performance related to our published lead times? How much order churn are we causing to our customers? We have made excellent progress here by improving the measuring sticks we analyse our performance against. As we have embarked on our planning and S&OP journey, we have

a better idea of what to measure to see whether we are improving or not in terms of our operational effectiveness.”

Adding to this, Timothy emphasises that Infinera defines these performance metrics not only based on what the company sees as operational effectiveness, but by considering how their customers expect them to be performing.

The sustained innovation and improvements to Infinera’s supply chain strategy have become even more important as the company expands its horizons from a traditionally lower-volume approach to components and products towards higher-volume manufacturing.

Here Timothy uses Infinera’s ICE-X intelligent coherent pluggables portfolio as an example.

“We provide our customers an architectural flexibility with these intelligent coherent pluggables

because they can deploy them in a wide set of applications in their networks, and with the software we put on them, they can remotely and dynamically increase, decrease or shift the capacity. They don't have to send out trucks to replace the transponder – with our real-time software, they can remotely and easily adjust where and when they want capacity. And our pluggables are so much more power efficient than other legacy solutions. This is enabled by the point-to-multipoint architecture and the elimination of aggregation sites.

“Some analyses anticipate that by 2025, 20 per cent of the world's power consumption will be in data centres. But with Infinera’s ICE-X intelligent coherent pluggables, we've taken a traditional solution at 100 Gb/s from 50 to 60 watts down to 5 or 6 watts. That’s a 90 per cent reduction. So we have been really focused on helping our customers achieve their goals in both architecture and flexibility and

“The sustained innovation and improvements to Infinera’s supply chain strategy have become even more important as the company expands its horizons from a traditionally lower-volume approach to components and products towards higher-volume manufacturing”

meeting their customers’ needs, but by doing it in a socially and environmentally responsible way.

“Infinera’s ICE-X intelligent coherent pluggables are a highvolume product. This is not our traditional low-volume offering. We'll be coming out of the gate ramping these products with the potential to scale to tens of thousands to hundreds of thousands in the next two to three years. And that is why we prioritise digital transformation because smaller mistakes when you're low volume are usually recoverable. But when you're talking high volume and you're ramping up from a few hundred to tens of thousands within a very short period, you can't afford to make those types of errors. So having accuracy and improved processes is vitally important.”

For Timothy and Anil, one of the proudest accomplishments arising from Infinera’s digital transformation is securing an AA environmental, social and governance (ESG) rating from Morgan Stanley Capital International (MSCI) in 2022.

nominate themselves for it, and it measures a company’s resilience to long-term, financially relevant ESG risks.

Infinera secured recognition for its high standards relating to how it treats staff and customers, its business practices and financial health, along with how the company champions sustainability, diversity and a host of other ESG factors.

But it isn’t just a case of what Infinera does internally – the MSCI ESG rating came in so high because the company raises awareness and promotes ESG issues with their suppliers as well.

Timothy emphasises Infinera’s excellent work towards sustainability and diversity goals in particular.

The MSCI ESG rating is externally awarded, so companies cannot

“Retaining talent during the pandemic was very difficult for a lot of companies,” says Timothy. “We had minimal turnover and we did a great job nurturing and continuing to build supply chain resilience. One of the things that we do is we're working with some historically Black colleges to help pipeline new talent. We also have networks in Infinera for female employees, Black employees and we built a green team that

focuses on the environment. We have eight Infinera sites across the globe that are carbon-free, using clean energy. So there's a lot of different programmes and processes helping us to maintain progress with our ESG agenda, and we have several teams that have been put in place to really focus on these organisational goals.”

Infinera sends products worldwide, so another core component of its ESG strategy is moving towards a unified global distribution centre to enhance its social and environmental credentials as a company.

Anil harkens back to the days when Infinera acquired Coriant, when there was an extensive network of warehouses that were ripe for optimisation.

“A lot of our suppliers are in Asia, so it made sense to have a global warehouse better placed from a network perspective,” explains Anil. “Our planning and logistics teams did a phenomenal job with the transformation over the course of the last two years, and we are almost

done with the transition to a global warehouse. We are starting to reap the benefits of having a consolidated warehouse in Asia. Previously we had to move products from planes, but now because of where our suppliers and our contract manufacturers are located, in a lot of cases we can transport goods via road, which is helping out both in terms of cost reductions and in terms of reducing our carbon footprint.”

“It has given us a lot more consistency with scheduling with our customers,” adds Timothy.

“Our biggest fear was that if we do this, are we going to impact our ability to service our customers? But it has actually had the opposite effect and it's given us a lot of consistency in the way we schedule with our customers and meet their needs. A lot of people have been looking more closely at regional supply chains, but the global distribution centre in Asia has been transformative for Infinera.”

To learn more about Infinera, visit their website at infinera.com.

Anil is excited about the emerging discussions around AI, ChatGPT and blockchain technology.

be more strategic about how we implement some of these new technologies within Infinera,” says Timothy.

“From a supply chain perspective, I’m excited to see how these innovative technologies can help us to get better from an operational perspective. We've seen the basic building blocks emerge, but how do we take the next step? For example, we’ve seen progress in demand planning – but where will we go with intelligent demand sensing and steering?

“Technology is advancing at a rapid rate but it's not just a purely technological question, there have to be process changes with it too to get the true business benefit.”

For Timothy, he is looking forward to seeing how blockchain within supply chain will get some near-term implementations, specifically around logistics. But for him the real exciting potential lies in sub-tier supply chains and being able to have visibility into them.

“As we come out of the pandemic and things ‘normalise’ I do hope that we can start focusing on and spending more time looking to

Both Anil and Timothy are looking ahead to next year with anticipation for the Optical Fiber Conference (OFC) in 2024.

Here, the company showcases the industry’s best optical systems and engines that help operators cost-effectively scale their core, metro and access networks, demonstrating a suite of open automation solutions that enable seamless and efficient multi-vendor operations.

But Anil and Timothy are particularly looking forward to the supplier appreciation event at the 2024 conference, something that started with great success a few years ago at OFC. Here Infinera holds an informal gathering where they bring together all the executives, key account managers and senior leadership representatives to build relationships and express appreciation for the successes achieved together with their partners.

Pharmaceuticals shares insights approach to supply chain digitalisation.

Pharmaceuticals shares insights approach to supply chain digitalisation.

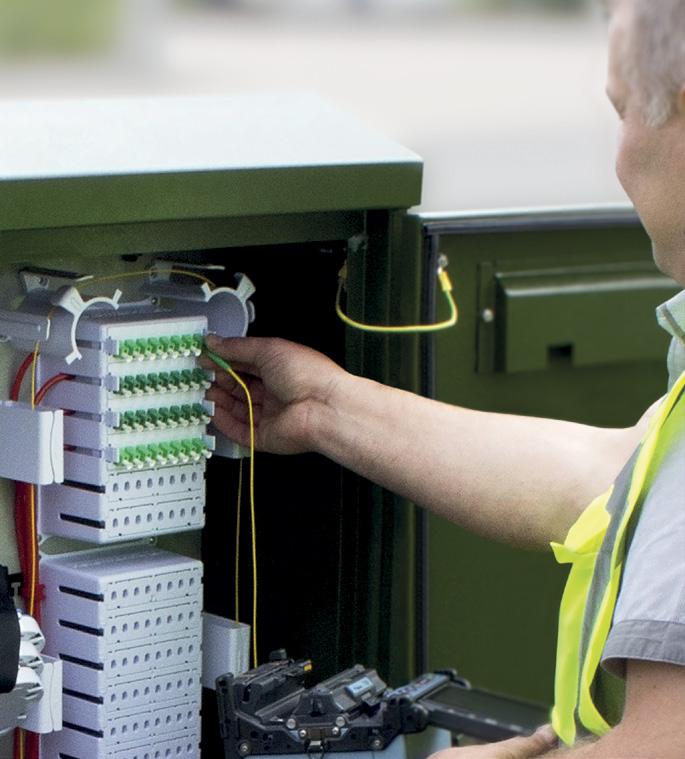

Mike Brooman, Head of Supply Chain at Community Fibre Limited shares insights into the internet service provider’s (ISP’s) strategy for supply chain innovation and sustainability, which never loses sight of serving its communities while in a context of rapid growth.

Community Fibre is London’s largest and fastest 100% full fibre broadband provider for residents and operates exclusively across the capital. Its mission is to bring faster, more affordable broadband to Londoners, and serving its local communities is at the very heart of what it does.

ast year, Community Fibre Limited announced that it had signed a new finance facility of £985m, which will enable the company to continue to execute its rapid rollout of a full-fibre broadband network to 2.2 million London homes by the end of 2024.

Here to tell us more about its strategies for growth, innovation, sustainability

andoutreach is Mike

Brooman, Head of Supply Chain.Speed, service and reliability are at the core of the broadband Community Fibre provides.

“Unlike most other providers, we build, operate and own our dedicated 100 per cent full fibre network, all the way from the cabinet

The Altnets team provides an incomparable service to our clients. Their knowledge of the telecoms industry and strong relationships with our manufacturing partners means they can fully support you through the whole procurement process, save you time and money, and solve any problems arising in the supply chain.

Our team are there through every part of the procurement process. We support customers with future forecasting and strong communication throughout the procurement process in the case of any issues or shortages affecting the supply chain. We are focused on saving customers time and money on their telecoms builds, no matter how large-scale and complex.

We offer bespoke, flexible and scalable supply chain solutions for the UK’s Internet Service Providers (ISPs).

90+ years of industry experience and close ties to manufacturers, industry bodies and ISPs means we understand the challenges Alternative Networks (Alt-Nets) face.

Our mission is simple: to improve reliability and efficiencies for our customers.

By auditing your current supply chain, extensive forward planning and working with our manufacturing partners to provide you the best quality products while maximising return on investment.

We offer internet service providers the ‘full package’: product procurement, supply chain management, planning, forecasting and scheduling.

We set up the business to be a one-stop-shop for telecoms builds, partnering with the UK’s leading manufacturers to reduce product delivery times and carbon emissions across the supply chain.

Our sales team reviews each customer’s current bill of materials, pricing and lead times to ensure they are getting the most out of their supply chain. We will always identify areas where we can speed up product delivery and save our customers money.

We provide complete support to our customers, giving advance warning of any complexities and bottle necks in the supply chain, providing confidence that they will receive the products needed in a timely manner to achieve their network build within required timeframes. Our unique freight-forwarding solutions save time as well as carbon emissions.

A completely tailored service for each client

Unparalleled knowledge of the global telecoms supply chain

Strong relationships with the world’s best fibre optic manufacturers, ensuring you access to the best products

Bespoke product design and development

The best return on your investment

Complete management of the procurement process from start to finish An award-winning team of expert supply chain specialists

to the property, therefore not relying on Openreach or any other provider’s cables,” explains Mike. “While a lot of companies advertise their internet as being fibre, often it's only fibre to the cabinet and then it's copper or coax from the cabinet.

“At Community Fibre, we provide a full-fibre network all the way to the home, allowing us to promise incredibly fast symmetrical speeds to sell to residential customers, with packages up to 3,000 Mbps and businesses up to 10,000 Mbps. Living in southern Lincolnshire, I'm struggling to get above 25 Mbps. I’m very jealous of what we can provide to our customers.”

At Community Fibre, process and technology innovation are essential to securing these speeds and

“By working together with Altnets we were able to come up with new designs, new technologies and to develop a new product range”

reliability. But what does innovation look like at the company?

Mike answers, “We’re always trying to push the boundaries of modern technology and Wi-Fi connectivity for our customers. Considering we can provide 3,000 Mbps speeds into residential customers' homes you clearly need a highly capable product that can keep up with the rest of the connectivity issues customers may have. They're likely to have 10s of devices able

businesses. It provides the Velops which go into the customer's properties to produce the Wi-Fi signals. The way we collaborate with Linksys is game changing, because it’s able to adjust to our forecast on the fly.

“If we see an opportunity in the market where we think we're going to increase sales in a certain product range, Linksys has the flexibility to support us by delivering on shortened lead times, and

to connect around their home and they'll be expecting full Wi-Fi strength throughout their property.

“We work closely with our partners such as Linksys to stay on the front foot of that road map. We are moving forwards onto tri-band Wi-Fi 6, one of the more advanced Wi-Fi capability products. We also have roadmaps leading us towards Wi-Fi 7. We keep on top of that innovation and work with them to bring the best products to our customers.

“Linksys is critical to installation in our customers’ homes or

adjusting its manufacturing systems or processes to deliver faster at different levels of our product range.”

But speed is not the only concern for Community Fibre customers, the reliability of Wi-Fi signal, security and user capability are crucial factors too. This is where innovation in customer service provision becomes important.

Mike explains, “One of the things we really like to see is the ability for our customer services team to proactively resolve issues at customers' homes.

“Linksys is critical to installation in our customers’ homes or businesses”

Reliable & flexible mesh WiFi 6/7 solutions for ISPs

35 YEARS of networking innovation.

“Rather than waiting for the customer to phone up to say they may have a problem with their Wi-Fi, we're able to monitor that network strength and capability across our entire network. When we see issues, we can be proactive against them and hopefully resolve any outages before the customer even notices because we've got such advanced reporting capability.”

Community Fibre is currently undergoing a full change in its Supplier Relationship Management (SRM), Customer Relationship Management (CRM) and Enterprise Resource Planning (ERP).

“We've basically overhauled our entire technical map,” summarises Mike. “Within the last couple of years, we moved from Google

to Microsoft suites. Everything is changing, upgrading and bringing with it some innovative solutions. We're also implementing AI into our customer services to be able to support them and look for patterns. By doing so, we're creating opportunities for our customers to resolve problems themselves without needing to necessarily phone us and speak to us in advance.

“It's those small innovations one step at a time that really make a difference when you add them all up.”

“We're also implementing AI into our customer services to be able to support them and look for patterns”

At Community Fibre, Mike’s role as Head of Supply Chain is to ensure the company uses the best suppliers, offers value for money and is always improving its products and services.

He breaks down their supply chain strategy into five key areas: suppliers, sustainability, quality, value and global community provision.

“The relationships with our suppliers are crucial to strengthening the relationship with our existing supply

chain,” says Mike. “There are suppliers that we've worked with from day one, newer suppliers that have joined us along the journey and there are still suppliers that we haven't yet met that will help us across the finish line. Strengthening those relationships builds the resilience of our supply chain, allowing us to continue to build faster than anyone else and get our targets across the line.

“Supplier relationship management is a key priority for the team, not just this year but probably for the coming years as the shape of the business changes.”

But how do they nurture these relationships with suppliers?

“We strive to be open and transparent in our communications with our suppliers,” responds Mike. “We provide regular feedback and work collaboratively to identify areas where we can support each other and be innovative.”

For Mike and his team, true collaboration means working together closely with suppliers to strive towards mutually beneficial strategic goals. This might

Looking for a reliable supplier of end-to-end fibre solutions?

Melbye’s got you covered!

No company should stand alone when creating smart and sustainable solutions for tomorrow, and neither should they compromise on quality and reliability. Therefore we believe in partnering with the best international manufacturers and offering our high expertise, so that we can create smart relationships that benefit everyone.

At Melbye, not only will we offer smarter and more innovative solutions for our customers, but we will strive to actively contribute to the benefit of society, people and the environment.

Through strong relationships with our partners, we can ensure that you are always up-to-date with the latest industry trends and innovations.

Melbyes history spans all the way back to 1907 and we have become a leading supplier of infrastructure network solutions in Scandinavia. Now we have brought our nordic mindset to the UK – offering one of the widest ranges of top-quality fibre products on the market.

We look for partners who share our values of quality, innovation and reliability, and who are committed to sustainability and ethical practices.

If you are looking for the same – then we are looking for you!

Contact us by scanning the QR code, or visit: www.melbyefiber.com

involve piloting new technology, delivering new methodologies or exploring different operational models. Other times, it is about approaching suppliers with a problem they could not solve internally.

Mike elaborates, “One example is when we approached Altnets with a couple of different product ranges that we were unable to continue to source, but needed to improve and upgrade. It wasn’t necessarily in its catalogue

before we spoke to Altnets, but by working together we were able to come up with new designs, new technologies and to develop a new product range. This allowed us to deploy something that is somewhat unique to our network and the way that we're working, but we believe will be beneficial to the wider alt-net community in the long run.”

“Melbye is another recent addition to our supply chain, as a fibre specialist wholesaler based in

“We have been using Melbye to support our growth in our build area, with the supply of ducting”

Scandinavia. We have been using them to support our growth in our build area, with the supply of ducting.

“They have been very quick to react to challenges within our supply chain, and we have been working closely with them in a number of critical product ranges.

“They have only been in the UK market for 4 years so have made great progress and we are excited to continue to work with them over the next stage of our company growth.”

Here Mike also lauds Community Fibre’s relationship with HellermannTyton.

“HellermannTyton has been one of our longstanding suppliers and they're constantly bringing new families of products and

ranges to market. We recently sent our technology team to its manufacturing facility to discuss exactly what we need and where we need it. This helps to shape a road map of development, and they work with us on a lot of our new products that are coming in.

Manufacturing quality equipment is a primary concern, but distribution is also important.

“HellermannTyton is able to store products for us, ship them to us

communications market and so their expertise is invaluable. They're often as much a partner or advisor as a supplier. Our technology team work closely with them, take problems to them and they solve the problem for us.”

“We don't want to just be building fastest, we also want to be very green and take care of our environment – not

when we need them but also deliver them to any number of our subcontractors,” adds Mike.

“Community Fibre work with about 20 different subcontractors in and around London. HellermannTyton has the flexibility and logistical capability to deliver to who we need, when we need and it is hugely beneficial. They've also got a stellar history in the technology industry within the

only in the areas we provide broadband but also the places we are influencing within our supply chain,” says Mike.

“When we buy technology, from the equipment in customers’ homes to the plastic ducting that goes underground, these components are not built in London, they're manufactured around the world. As such our community is not just our

“

HellermannTyton is able to store products for us, ship them to us when we need them but also deliver them to any number of our subcontractors”

London-based boroughs where we work, our community is global.

“We work with our supply chain to drive a sustainability agenda and that's throughout everything operationally and our supply chain. We are trying to promote sustainable sourcing, reduce our carbon footprint, work with suppliers to reduce theirs, develop environmentally friendly technologies, push for

a reduction in our single-use plastic and transition from using virgin material to using recycled materials.”

“In order for us to provide stable, fast broadband we need quality materials,” says Mike. “One of the focuses for my team is to make sure that we aren't just going in and trying to buy the cheapest

and then caring about the quality later. We're in this for the long run. So we buy high-quality products, we make sure that we're achieving the standards that we need to achieve – often exceeding them in the process.

“We cannot provide a customer 1,000 Mbps internet without having extremely stable high-quality products being put into their home. The units that we are putting into

customers' homes are high-end and future-ready technologies. We're constantly looking to push that boundary. We’re looking at what's the next road map along the line for the Wi-Fi whether it's Wi-Fi six-e or seven and where are we going to go from there?”

Value

“Clearly, we can't continue to sell to our customers at a

very competitive price if we’re spending money where we don't need to be – so we do focus on value,” states Mike.

“We like to think that it's not just about the price, it's very much a value piece. But value has to come at competitive pricing. We regularly review tenders on product ranges, partly because of our growth. Often, whatever we said we were going to buy last year, we're buying double. We expect to be able to drive a more competitive price as we have become a bigger player in the market, but also just making sure that we're really keeping an eye on our costs.

“But there's no point in spending money on something that the customer doesn't really care about and isn't interested in. If

“We want to be the biggest fibre to the home provider in London maintain, our best-in-class customer service and continue to support the communities that we work in”

pushing that tech boundary isn't what they're after, if what they need is a competitive price broadband, we pivot. We like to keep our supply chain lean and buy in what we need. We don’t want to have a lot of waste. It's good for keeping our environmental concerns in check, but also keeping our costs down.”

“For us, community stretches all the way from our end users all the way up to our supply chain,” says Mike. “We're a London-based ISP and we recognise the importance of our local communities. But we work closely with our supply chain to ensure they're also respecting the communities they work in,

engaging with them and ensuring we're supporting them where possible too.

“For a lot of our subcontractors that are building and installing in London, they undertake their own community focus work. So they might be going and supporting local food banks, they might be working within schools or providing equipment and we really

help to make that happen and provide those local products and services and enable our supply chain to also focus on their community.”

Outreach

Community might be one of the five elements of supply chain strategy at Community Fibre but

the concept of service extends far beyond this.

Affordability is key. The company offers a range of packages at different price points to ensure their services are affordable for all Londoners, regardless of their economic circumstances. Two of the mantras at Community Fibre are ‘Bridging the digital divide’ and ‘Fairer broadband for all.’

The concept of serving the community is not limited to their broadband packages – it extends far beyond internet provision.

“We provide free 1,000 Mbps broadband connections to community centres in any areas where we're operating. We've connected almost 500 community spaces now in London,” Mike says.

“We offer digital skills training through our digital ambassadors. We train digital ambassadors in the local communities who can then move around in their districts and support anybody – for example vulnerable users, schools or classes – with digital skills training. That might include internet security, using emails, online banking, how to be

aware of avoiding scams and so on. I think that's a vitally important part of what we're doing. We're not just there to sell broadband to people, we're also there to support communities and vulnerable people in them.”

So, what is next for Community Fibre in the coming years?

Mike elaborates, “We want to be the biggest fibre to the home provider in London, maintain our best-in-class customer service and continue to support the communities that we work in and improve the lives of the people that we work with.

“Within this, we're working on improving our supply chain technology. From investing in new tools and systems to give us visibility of our supply chain, to better demand planning and warehouse management systems – we’re hoping that we can use technology to make our supply chain more agile and our inventory leaner. We also want to optimise our logistics to keep our carbon footprint and costs down and enhance our customer experience.”

To learn more about Community Fibre, visit their website communityfibre.co.uk

For Mike, the volunteer days Community Fibre coordinates are a cause worth celebrating.

“Everybody within the company gets an opportunity to spend a couple of days a year volunteering for a cause that is close to them,” explains Mike. “That's been very popular with a lot of our employees recently. We cover a range of causes so people can volunteer flexibly.”

Explore the company’s Community Investment hub at communityfibre.co.uk/ community-connect

Community Fibre has raised more than £7,000 with the Lisa Howie Trophy, a yearly 5-a-side football tournament in memory of Lisa Howie.

Colleagues, landlords and contractors come together to field teams and raise money for causes in the communities served by Community Fibre.

Mike recommends the Chartered Institute of Procurement & Supply podcast.

“They cover a huge range of topics that are very interesting for a lot of people within the UK supply chain, not just within alt-nets. They talk to a lot of logistics companies and retail companies and FMCGs (Fast Moving Consumer Goods) companies. It's a fascinating set of topics that they cover.”

David Latten, Head of Global Indirect Procurement at Logitech discusses how he and his team wield procurement strategy as a force for global good.

FOUNDED IN 1981, LOGITECH IS A CONSUMER ELECTRONICS COMPANY THAT MANY PEOPLE MIGHT KNOW FOR THEIR HARDWARE PRODUCTS LIKE COMPUTER MICE AND KEYBOARDS, BUT THE BUSINESS OFFERS FAR MORE THAN OFFICE ACCESSORIES.

ogitech has expanded into the gaming sector and has positioned itself as an industry leader at the final touch point between people and their digital experiences – for instance with video conferencing or meeting room setups.

The company sells products in almost every country in the world and turns over $4.5 billion in annual revenue, but Logitech is a lean enterprise with a comparatively small workforce of six thousand people.

David Latten, Head of Global Indirect Procurement and Supplier Diversity & Equality, shares insights into how he and his team deploy Logitech’s indirect

procurement strategy as an engine for societal impact, to drive value with external relationships and do more with less.

So how do David and his team approach indirect procurement at Logitech?

David explains that it starts by identifying your purpose as a department.

says David. “Our value proposition for the business in procurement

“It's always fundamentally important for a department to ask why do we exist, what are we looking to do for the business and what is our wider societal impact too?”

is looking to drive value for Logitech in terms of making sure that we're purchasing things at a very costcompetitive price. That's a huge, obvious competitive advantage and we're doing the same for supplier performance, making sure that the right partners are really performing well for us. There's an element of risk management too. These are the

traditional procurement values we work towards.

“But the other big value driver for us is progressing our core values at Logitech around equality and the environment with our suppliers. Here, what we mean is that we're going to have an impact on this world. We want to make sure that impact is a positive one. We want to make sure that we're finding new solutions so we can progress on those big societal challenges with our external relationships.”

How do David and his team do this at Logitech?