6 minute read

logistics

TRANSPORT COMPANY OVERCOMES THE CHALLENGES POSED BY BREXIT

Advertisement

Without the transport and logistics element of our industry, we’d have no trade. So how has Brexit affected the business at ground level? Here, David Dodd, Regional Director (UK & Ireland) for Suttons International, answers Chemical Industry Journal’s questions.

WHAT SORT OF IMPACT HAS BREXIT HAD ON YOUR BUSINESS OPERATION, TRANSPORTING GOODS TO AND FROM EUROPE?

Brexit has had a huge impact on Suttons International. Between our Euro Short Sea, Contract and Fleet Management teams, we ship around 13,000 tank containers to and from the UK and Mainland Europe per annum. The Brexit transition has had a significant effect on the people involved more than anything. Working on the transition with the backdrop of a global pandemic has been really challenging and we’ve seen a tremendous resilience within our employees at this time, notwithstanding the fact that our teams have been pushed to their absolute limits, both physically and mentally. There has been a lot of frustrations around the administrative side of the Brexit transition including new processes, bureaucracy and understanding new requirements. It is safe to say that many customers, suppliers and customs brokers were not ready for the upheaval.

IS IT TAKING LONGER FOR LORRIES TO CLEAR KENT AND GET ON A FERRY?

The majority of the products we ship are in single product tank containers which lift off at intermodal ferry ports, such as Purfleet, Tilbury, Hull, Killingholme, Middlesbrough and Liverpool. This means that we have been able to avoid having trucks stuck in queues in Kent. Despite this, we have still seen queues of up to six hours just to wait to have a container lifted off one of the tank trailers/chassis.

HAS THERE BEEN A SIGNIFICANT INCREASE IN THE BUREAUCRACY INVOLVED?

At Suttons we have seen a significant increase in paperwork and administration. To manage this, we have been keeping electronic documents, as well as moving to EDI with our larger vendors to help speed up the transfer of information. There is no denying that the booking processes are much more complicated which has added some delays, frustration and stress on freight forwarders. We took on an additional member of staff in December and have since increased headcount by a further two individuals. This has enabled us to manage the workload and cope with the additional levels of bureaucracy and administration that we now have to deal with.

HAVE COSTS INCREASED AS A RESULT OF ALL/ANY OF THE ABOVE?

Despite costs to businesses increasing, which cannot be disregarded, we must not overlook the cost that Brexit has placed on society. Leaving the EU during a global pandemic and a national lockdown has posed unprecedented challenges on so many people. There are individuals working on the Brexit transition while home schooling their children and managing the unwavering amount of personal stresses the current climate is putting us under. Costs have increased as a result of Brexit, particularly in customs paperwork. For an Export document, an important clearance in the destination country, as well as a T1 if the goods are transiting another EU country, this can be anything from £90 to £160 to raise the additional paperwork. If permits or licences are required for controlled goods, there are also additional costs for raising those documents and seeking approval. To manage this increased workload many businesses have had to increase overheads by employing more staff, and the cost of this will be passed down and ultimately passed on to consumers.

HOW DID SUTTONS’ TRANSPORT & LOGISTICS DIVISION PREPARE FOR BREXIT?

Suttons International set up a Brexit taskforce. This brought together key individuals from each department including: Operations, Commercial, Business Support, Procurement, Resources, Safety and Training. We had weekly meetings to put plans in place to ensure that we were as prepared as possible for the transition. It is also worth noting that each department had smaller, daily meetings that were held over Skype. The technology really helped us to be able to feel together despite being physically far away from each other. However, there is nothing that can replace that genuine feeling of togetherness as a team when you are not able to be together, especially for such a crucial project.

David Dodd, Regional Director (UK & Ireland) for Suttons International

HAS SUTTONS SEEN SIGNS THAT CUSTOMERS ARE PLANNING TO AVOID HAVING TO CROSS THE BORDER, PERHAPS BY SETTING UP PROCESSING UNITS IN EUROPE INSTEAD?

We have seen customers setting up legal entities in Europe, to help them process transactions differently. Incoterms were something that the EU and UK trades did not have to worry about so much. Now these terms have huge implications for customs clearance. Having a legal entity to process VAT payments and deferrals is a vital part of trading between the UK and EU now. We have also seen some of our customers moving towards UK, UK and EU, and EU businesses to avoid the hassle of shipping outside of the free trading block.

CAN YOU TELL ME A BIT MORE ABOUT SUTTONS’ SUPPLY CHAIN MANAGEMENT, PARTICULARLY IN RELATION TO CHEMICALS?

We have a dedicated Procurement team who have considerable buying power. They are constantly looking for the best routes, prices and service for Suttons International. It is important to recognise that while price is important, we also look to develop long term supplier relationships. We want sustainable partnerships that are based upon trust and a mutual sense of striving for continuous improvement. This involves safety and quality and we seek partnerships that align with our business objectives and core values.

www.suttonsgroup.com/uk

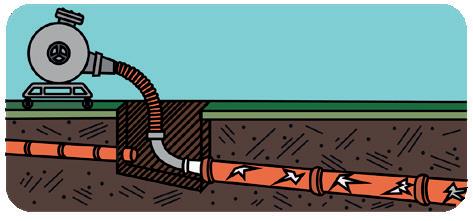

INTRODUCING THE WORLD’S FIRST ANTI-STATIC REPAIR SYSTEM

How do you repair a pipe, crack or displaced joint using a material or method that will still dissipate static charge so that there is no threat of explosion?

The UK national standards body, the BSI, issues standard BS60079-32 for electro-static hazards in potentially explosive atmospheres. All infrastructure repair systems in potentially explosive atmospheres should conform with this standard. They do not and never have! Up to now industry has been effecting repairs to negate environmental risk, unwittingly introducing an explosion risk. This is set to change for the first time in modern industrial history thanks to Conductorliner. McGrath Environmental Services has come up with a ‘world first’ answer, because not only is Conductorliner EN/BS60079-32 standard compliant, but it has also been proven to be the first 100% dissipative infrastructure repair system in the world.

APPLICATIONS

Conductorliner is the ultimate underground infrastructure repair system, best serving those sectors that have a daily need to mitigate explosion risk. It is not only key to preventing the infiltration and/or exfiltration of chemicals or noxious substances, but also contains a special substance to make it the first 100% dissipative infrastructure repair system in the world.

SECTORS

Chemical, Nuclear or any organization with potentially explosive atmospheres needing to mitigate the risk of spark, explosion and chain reaction.

PATCHING

The Conductorliner patching system can be used in any length and diameter of pipe to effect a repair of up to 5m in length.

LINING

The Conductorliner Infinity System relates to longer stretches of pipe repair, from 1m up to 500m.

BEFORE AFTER

SPRAYING

The Conductorliner Spray system is a high-build, spray applied dissipative coating, with excellent chemical and abrasion resistance, ideal for rehabilitation of chambers, tanks, bunds and sumps etc.

Please get in touch to arrange a visit from one of our sales team or to request a brochure. You can either email us at info@conductorliner.com or telephone +44 (0) 330 111 0007. Kindly ask for Tom or Lydia McGrath. McGrath Enviromental Services Limited, Woodside Farm, Wakefield Road, Grange Moor, Wakefield WF4 4DS www.conductorliner.com