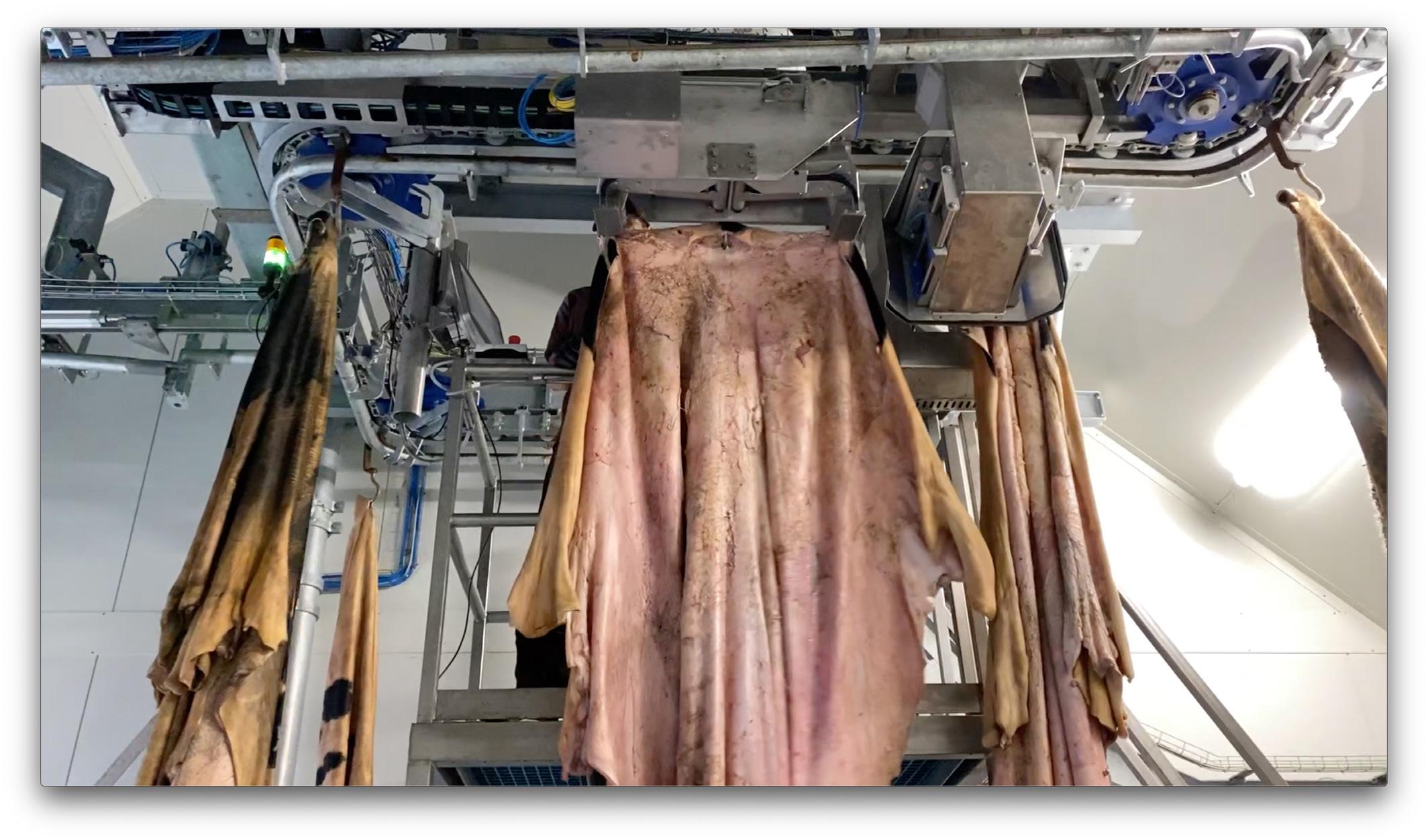

BRITISH RENEWABLE FUELS Keeping the home fires going it is one that happens entirely within Britain. First, the timber is purchased from UK forests and delivered to their yard. Depending on the size of the timber the wood is then cut and split into 8-10 inch slats before being placed in a kiln and dried for a period of 7-10 days. At this stage they test the moisture content with an aim to get it down to a reasonable level of 12-14% moisture. The slats are then put through the shredding process where the wood is broken down into particles of 10mm sizes. It is also during this stage where the pulped wood can dry further. From here the pulp is transferred to the briquette presses where it is hydraulically pressed into either long or round briquettes. These are then bagged and stacked on a pallet.

British businesses are being called upon to do their part to lighten the UK’s carbon footprint and bring the country to a new era of sustainability. To effectively achieve this goal, these businesses are scrutinising the operations and philosophies of their supply chain. This has provided the perfect opportunity for new businesses with a real understanding of the requirements, to establish themselves and make a real change for the better. Founded in 2017 by managing director Paul Gibbon, British Renewable Fuels is a proudly British supplier of wooden based fire fuels to the UK market. Producing a range which includes kiln dried logs, briquettes, eco logs and natural firelighters as well as a range of renewable energy focussed consultancy services, the business plays an important role in keeping this fuel as green as possible.

HOW DO THEY DO IT? Far from being just chopped wood, the process of manufacturing briquettes and eco logs is one of patience and care and for British Renewable Fuels

British Renewable Fuels works with a staff contingent of seven employees and are responsible for managing the process at all the key points. As a small business their production capacity is around 7-10 metric tons a day which accounts for roughly 1% of the country’s overall output. “Quality counts for a great deal,” he says, “Like good timber, businesses should be given enough time to mature properly.” Once the various products are packaged and prepared, be them briquettes, eco logs or fire starters they are palletised and shipped out to the various customers and retailers via outsourced fleet.

THE APPROACHING CHANGE Expected to come into force in February 2021, the upcoming government legislation will put restrictions on burning house coal or wet wood in stoves, open flames and wood burners. This stands to affect over two and a half million people in the UK who use such fuels either for warmth during the winter or as an important part of their business.

21