LAB PROFILE

Saskatchewan Research Council: Where science meets industry

APPLICATION NOTE

Phycus Biotechnologies developing biome-friendly cosmetics ingredients

BUILDING SUSTAINABILITY THROUGH BIOTECHNOLOGY

Bioscience innovation leading to a safer, healthier tomorrow

Genecis: Getting the most out of waste

BioLABmag.com VOLUME 38, ISSUE 2 • SUMMER 2023

PICK OF THE CROP

14

MustGrow Biologics Corp.’s plant-based technology platform is revolutionizing crop production. standard SUZUKI MATTERS 7 CANADIAN NEWS 8 WORLDWIDE NEWS 10 LABWARE 32 feature LOOK INSIDE FOR YOUR COPY OF GUEST EDITORIAL 5 UNLOCKING THE POTENTIAL OF THE CANADIAN RNG MARKET Enzymatic pretreatment of agricultural waste could lead to enhanced biogas production. FEATURE 11 THINKING INSIDE THE BOX University of Saskatchewan Insect Research Facility promises new research into agricultural threats. NEWSMAKER 19 GETTING AHEAD OF PARKINSON’S DISEASE New scientific research uncovers an early alarm system for high-risk patients. . LAB PROFILE 21 FACILITATING INNOVATION AND SOLUTIONS THROUGH SCIENCE AND TECHNOLOGY The Saskatchewan Research Council is helping industries solve technology problems, make improvements, and seize economic opportunities. COMPANY PROFILE 25 GENECIS: GETTING THE MOST OUT OF WASTE A Toronto-based biotechnology company is turning organic waste into sustainable and biodegradable materials. APPLICATION NOTE 29 BIOME-FRIENDLY INGREDIENTS FOR A HEALTHIER FUTURE Phycus Biotechnologies Inc. is developing alternatives to toxic cosmetics ingredients.

ENSURING A HEALTHIER, SAFER FUTURE

PUBLISHER & CEO Christopher J. Forbes cforbes@dvtail.com

MANAGING EDITOR Sean Tarry starry@dvtail.com

COPY EDITOR Mitchell Brown

CONTRIBUTORS

Animesh Dutta Ian Hanington Robert Price David Suzuki

SENIOR Marlene Mignardi ACCOUNT mmignardi@dvtail.com

EXECUTIVE

ART DIRECTOR Sharon MacIntosh smacintosh@dvtail.com

SECRETARY/ Susan A. Browne TREASURER

MARKETING Stephanie Wilson MANAGER swilson@dvtail.com

PRODUCTION Crystal Himes MANAGER chimes@dvtail.com

BioLab Business is published 4 times per year by Jesmar Communications Inc., 205 Riviera Drive, Unit 1 Markham, Ontario L3R 5J8

905.886.5040 Fax: 905.886.6615

Thereare a number of challenges that are currently facing the world’s population, some of which present potentially severe consequences. From fallout resulting from economic uncertainty and the next global pandemic to ramifications posed by artificial intelligence and machine learning, the list is lengthy and somewhat troubling. Despite the challenges, however, none can compare to the significance of threats related to the future health of our planet.

With the urgent need to enhance environmental sustainability efforts across industries in mind, within this issue of BioLab Business we explore some of the most cutting-edge biotechnological innovations and scientific breakthroughs that are aimed at protecting current and future life on Earth.

With the help of Sean Prager, we take a peek inside the newly built University of Saskatchewan Insect Research Facility where the associate professor in the university’s College of Agriculture and Bioresources and his team work on new research in efforts to better understand possible threats to farmer's fields and the country’s agriculture industry at large.

From aiding in the development of an enhanced understanding of the threats to crops, we turn our focus to the game-changing technologies that are helping to protect against them. In highlighting the incredible work being done by agriculture biotechnology company MustGrow, we shine a spotlight on the advancement of its biological technologies and products and facilitation of more sustainable agriculture and improved soil health for farmers.

www.BioLabmag.com

One year subscription: Canada $35, US $35 and foreign $95. Single copies $9. Please add GST/HST where applicable. BioLab Business subscription and circulation enquiries: Garth Atkinson, biondj16@publicationpartners.com (Fax: 905.509.0735).

Subscriptions to business address only. On occasion, our list is made available to organizations whose products or services may be of interest to you. If you’d rather not receive information, write to us at the address above or call 905.509.3511.

The contents of this publication may not be reproduced either in part or in whole without the written consent of the publisher. GST Registration #R124380270.

PUBLICATIONS MAIL AGREEMENT NO. 40063567

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT.

205 RIVIERA DRIVE, UNIT 1 MARKHAM, ON L3R 5J8 email: biond@publicationpartners.com

BioLab Business is a proud member of BIOTECanada and Life Sciences Ontario

Peering inside the Saskatchewan Research Council, we explore the work being conducted by scientists and researchers within its Environmental Analytical Lab and their continued development of innovative testing and techniques that are helping to improve the environmental impact of numerous industries.

And we feature Toronto-based biotechnology company Genecis, which works toward turning organic waste into sustainable, biodegradable materials that can be used in place of harmful petroleum-based plastics, limiting their environmental impact while presenting a circular economy solution for many products’ beginning and end of life.

The challenges that threaten the future of our planet may be considerable, to say the least. However, as consumer interest in and demand for an enhanced focus on environmental stewardship among industries increases, a tipping point is fast approaching, driving greater adoption and need for the technologies and innovations being developed by scientists and researchers across the country—technologies and innovations that will help ensure a healthier, safer tomorrow for all.

Chris Forbes PUBLISHER & CEO

Publisher of BioLab Business Magazine

Printed in Canada

BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023 EDITOR’S NOTE 4

Funded by the Government of Canada

UNLOCKING THE POTENTIAL OF THE CANADIAN RNG MARKET ENZYMATIC PRETREATMENT OF AGRICULTURAL WASTE COULD LEAD TO ENHANCED BIOGAS PRODUCTION

BY OMID NOROUZISAFSARI, SENIOR R&D AND IP MANAGER, ANAERGIA INC AND ANIMESH DUTTA, PROFESSOR OF CHEMICAL ENGINEERING, UNIVERSITY OF GUELPH, SASHA ROLLINGS-SCATTERGOOD, VP TECHNOLOGY, ANAERGIA INC

Agricultural waste management has emerged as a critical challenge globally. In Canada, a country with a significant agricultural sector, finding sustainable solutions to the disposal of agricultural waste has become even more crucial. One innovative technology that holds great promise in this regard is enzymatic pretreatment, a process that can revolutionize the anaerobic digestion of agricultural waste. By harnessing the amazing abilities of bacteria to solubilize cellulosic biomass, enzymatic pretreatment offers distinct advantages over conventional thermal hydrolysis processes. Within this article, we explore the potential of enzymatic pretreatment in the anaerobic digestion industry and highlight the abundance of agricultural waste and its environmental impact.

ENZYMATIC PRETREATMENT AND BACTERIAL SOLUBILIZATION

Enzymatic pretreatment involves the use of specific enzymes to break down complex organic matter present in agricultural waste such as crop residues, animal manure, and food processing byproducts. These enzymes act on the cellulosic biomass, degrading complex carbohydrates into simpler, soluble sugars. The solubilization of cellulosic biomass by bacteria is truly remarkable, as they possess an array of cellulolytic and hemicellulolytic enzymes capable of breaking down even the most recalcitrant plant material.

ADVANTAGES OVER THERMAL HYDROLYSIS PROCESSES

Enzymatic pretreatment offers several advantages over traditional thermal hydrolysis processes. First, enzymatic pretreatment is carried out under milder operating conditions, reducing the energy requirements compared to thermal processes. Lower energy consumption translates into cost savings and a smaller carbon footprint. Moreover, the enzymatic approach is highly specific, targeting the

breakdown of cellulose and hemicellulose, while leaving other valuable components of the biomass, such as lignin, intact. This specificity enhances the overall efficiency of the anaerobic digestion process.

Additionally, enzymatic pretreatment improves the accessibility of the biomass to subsequent microbial degradation. By converting complex carbohydrates into soluble sugars, the enzymatic process enhances the bioavailability of the organic matter for the microorganisms responsible for anaerobic digestion. This increased accessibility leads to higher biogas production and more efficient conversion of agricultural waste into valuable energy resources.

POTENTIAL OF AGRICULTURAL WASTE IN ANAEROBIC DIGESTION INDUSTRY

Agricultural waste represents an abundant and underutilized resource in Canada. According to Statistics Canada, the country generates approximately 26 million tons of agricultural waste annually. This vast amount of waste holds enormous potential for the anaerobic digestion industry. By converting this waste into biogas, a renewable energy source, Canada can significantly reduce its reliance on fossil fuels and decrease greenhouse gas (GHG) emissions. Furthermore, anaerobic digestion of agricultural waste offers environmental benefits beyond energy production. By diverting organic waste from landfills, where it would otherwise decompose and release methane, a potent greenhouse gas, into the atmosphere, anaerobic digestion can significantly mitigate GHG emissions. Methane produced during anaerobic digestion can be captured and used as a fuel, thereby reducing the release of this potent GHG. The digestate, a nutrient-rich residue remaining after anaerobic digestion, can also be used as a high-quality fertilizer, closing the loop on waste management and supporting sustainable agriculture practices.

GUEST EDITORIAL 5 BIOLABMAG.COM

STATISTICS ON AGRICULTURAL WASTE AND GHG EMISSIONS

To underscore the magnitude of the agricultural waste challenge and its impact on GHG emissions, consider the following statistics:

• In Canada, the agricultural sector is responsible for approximately 10% of the country’s total GHG emissions.

• The livestock industry alone generates millions of tons of animal manure annually, which can be a valuable feedstock for anaerobic digestion.

• Crop residues such as corn stover and wheat straw account for substantial amounts of agricultural waste and are ideal candidates for enzymatic pretreatment and subsequent anaerobic digestion.

CURRENT INITIATIVES IN CANADA

Anaergia, in collaboration with the University of Guelph and Tiden Lipid Biotech Solutions Inc., has pioneered a groundbreaking biological pretreatment technique for the production of renewable natural gas (RNG) from agricultural waste. This innovative technology, supported by the National Research Council-Industrial Research Assistance Program (NRC-IRAP),

holds significant potential to revolutionize the RNG industry in Canada and beyond. To further drive its implementation, we are actively seeking additional funding and grants from various Canadian governmental bodies. Our aim is to introduce this technology for the first time in Canada and subsequently expand its application to other countries, marking a major stride towards sustainable energy production and waste management.

GOING FORWARD

Enzymatic pretreatment has the potential to revolutionize the anaerobic digestion of agricultural waste in Canada. By harnessing the remarkable abilities of bacteria to solubilize cellulosic biomass, this innovative technology offers numerous advantages over conventional thermal hydrolysis processes. The vast amount of agricultural waste generated in Canada, combined with its significant environmental impact, presents an opportunity for the anaerobic digestion industry to contribute to sustainable waste management and renewable energy production. By embracing enzymatic pretreatment and leveraging the power of bacteria, Canada can pave the way towards a greener and more sustainable agricultural sector while mitigating GHG emissions and reducing dependence on fossil fuels.

BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023 GUEST EDITORIAL 6

Crop residues, including corn stover and wheat straw, are ideal candidates for enzymatic pretreatment and anaerobic digestion.

BY DAVID SUZUKI with contributions from The David Suzuki Foundation's Senior Editor & Writer, IAN HANINGTON (including weekly Science Matters column)

THE WORLD CAN’T AFFORD FOSSIL FUELS

Support for oil and gas projects is often justified on economic grounds: they fuel the economy and create jobs. But do those arguments hold up?

Even leaving aside the enormous costs of climate-related disasters such as flooding, drought and increasing water scarcity, and pollutionrelated health impacts and premature deaths, fossil fuel operations cost society more than they bring in. Owners and shareholders are raking in massive amounts of money—but at what cost to the rest of us?

Consider the Trans Mountain pipeline twinning project, which the Canadian government bought from Kinder Morgan for $4.5 billion in 2018, promising to build it for a total of $7.4 billion. As Andrew Nikiforuk points out in The Tyee, “That figure … soon ballooned to $12.6 billion in 2020. Last year it climbed to $21.4 billion. It now stands at $30.9 billion and counting.”

Most pipeline employment is during construction only. That’s a lot of money to pay for a limited number of short-term jobs. But Houston-based Kinder Morgan is doing okay—its profits are rising in step with global conflicts. And the fact that the company is poised to increase bitumen shipments from the Alberta oilsands to the coast for export should also benefit it, especially with generously low fees, or “tolls,” they pay to use the pipeline.

And, as Nikiforuk writes, thanks to a deal the companies signed, “shippers will only have to pay 22 per cent of the actual cost of overruns beyond the original $7.4-billion budget,” which means “you the taxpayer, are liable, at this point, for 78 per cent of the overruns.”

Consider also the many old oil and gas wells in Alberta (and elsewhere) that continue to pollute land, water, and air long after their owners have moved on—including leaking the potent greenhouse gas methane. Companies are legally required to clean up after themselves once operations are finished, but many don’t for various reasons. Sometimes they just declare bankruptcy when they’re done, with owners moving on to new ventures, leaving farmers, ranchers, and communities to live with the messes.

Now, Alberta’s government wants taxpayers to dip into their wallets for cleanup. The government has proposed a three-year pilot program that would “offer $100 million in royalty credits to companies that clean up inactive, suspended, or partially abandoned wells at least 20 years old and drilled prior to 1980,” The Narwhal reports.

On top of the Alberta plan, the federal government gave the province $1 billion in cleanup grants in 2020, according to The Narwhal , much of it going to oil giants Canadian Natural Resources Limited and Cenovus “Estimates for the total cost of cleaning up Alberta’s oil and gas liabilities range from $58 billion to as high as $260 billion.”

Those are just two of many examples of tax dollars being used to subsidize the most profitable industry in history. As it rakes in record profits, in part by capitalizing on global conflicts like Russia’s invasion of Ukraine, it continues to wreak environmental damage, from oilsandsrelated earthquakes and toxic tailings pond leaks to air and water pollution and life-threatening greenhouse gas emissions.

Meanwhile, those who run the companies cover up the damage, downplay or deny the climate risks and offer “greenwashing” in place of real efforts to reduce their dangerous impacts.

It makes twisted sense in an economic system that prioritizes constant growth, ever-increasing profits and maximizing shareholder return above all else. But it makes no sense in light of the overwhelming evidence that burning fossil fuels could spell humanity’s demise. As the Intergovernmental Panel on Climate Change warns in its sixth assessment report, we have very little time to shift from coal, oil, and gas to cleaner energy sources, and to reduce our wasteful consumption.

The world can’t afford to build any more fossil fuel infrastructure or continue exploiting and burning these fuels—and we certainly can’t afford to subsidize them with tax dollars. Many affordable, reliable solutions are readily available—solutions that will save money and give us cleaner air, water and soil, better health, good jobs and a chance at long-term survival.

Moving away from fossil fuels will squeeze industry executives with annual multi-milliondollar compensation packages and shareholders reaping the benefits of generous buybacks and dividends, but it will be good for everyone else.

It’s time for change!

SUZUKI MATTERS 7 BIOLABMAG.COM

Dr. David Suzuki is a scientist, broadcaster, author, and co-founder of the David Suzuki Foundation. Learn more at davidsuzuki.org.

Genomics research focused on hereditary cancers and genetic disease diagnosis receives boost

Accelerating Canadian biotechnology innovation

In an effort to provide much-needed support for biotechnology innovators across the country, the launch of a new accelerator was recently announced. The accelerator, a collaborative effort and offering of MaRS Discovery District and adMare BioInnovations, is based in Toronto and aims to help early-stage Canadian biotech ventures overcome the fundamental barriers that they’re faced with, particularly with respect to a distinct lack of lab space and financial backing.

Located in the Toronto MaRS building, the accelerator will, according to Yung Wu, CEO of the MaRS Discovery District, “prepare a universe of our most promising biotech companies to scale up in Canada and form the foundation of a national biotech industry with global impact.”

The application process for the first cohort of the MaRS-adMare Therapeutics Accelerator was completed at the end of March 2023 with five ventures chosen to take up residence in the lab. These ventures will be provided access to a range of services, including scientific and regulatory guidance for preclinical and clinical studies; coaching and

expertise in business development and IP strategy; access to a digital community platform, C-suite executives, industry partners and investors; access to financial support for ventures to scale and achieve growth-related milestones; and access to state-of-the-art wet laboratory facilities in the MaRS Centre.

It’s a program that will attempt to build on the success of the adMare National Accelerator with Regional Partners. And, according to Gordon McCauley, President and CEO, adMare BioInnovations, it’s one that is set to contribute to the continued growth of Canada’s life science and biotechnology sectors.

“With over 100 business and science professionals focused on commercial drug development at our Toronto, Vancouver, and Montréal centres, we are excited to bring all that we’ve learned to this new program. The Ontario ecosystem represents a major innovation hub in Canadian biotechnology and adMare is proud to partner with MaRS to support the growth of these ventures and contribute to making Canada a worldwide life science leader. The fit is clear.”

In order to bolster the efforts of those working on life-saving research, Genomics Canada announced $9.6 million of federal funding will be provided to Genome British Columbia to support two late-stage research and development projects aimed at tackling major public health challenges through genomics.

The cutting-edge work is centred around enhancing diagnosis of hereditary cancers and genetic diseases for patients, including providing the necessary screening of critically ill newborns for genetic diseases, and the evaluation of a new technology that could pose the potential to aid in the identification of genetic variants for hereditary cancers, determining the side of the family from which it derives, thereby improving screening for other family members at risk.

The projects, which are among 11 other backed projects announced in April by François-Philippe Champagne, federal Minister of Innovation, Science and Industry, are set to play a critical part in Canada’s aim to grow and enhance the country’s biotechnology capacity. And, says Champagne, they will serve to be just as important in helping to keep Canadians from coast to coast to coast healthy and safe.

“Genomics is a key technology that is instrumental in responding to national and global challenges. Projects like those celebrated today with Genome British Columbia are central to make sure the Canadian research system grows and remains at the forefront globally, leading to more cutting-edge genomics science that delivers real impacts for the health and economic growth of Canadians.”

8 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023 CANADIAN NEWS

Protecting at-risk species in the country

When it comes to protecting the habitats and lives of at-risk species in Canada, scientists and researchers are often challenged when considering which should receive priority and intervention in order to save them from extinction. In fact, the topic was at the core of discussion during the recent Conference of the Parties (COP15) to the United Nations Convention on Biological Diversity (CBD), held in Montreal in December of last year, during which Canada committed to protecting at least 30 per cent of its land by 2030.

In an effort to meaningfully contribute to the dialogue and provide critical insights to help guide and direct the decisions that are made in conjunction with the land protection commitment, researchers at McGill University overlayed maps of species at risk in order to identify hotspots where many species live together. Published within the Proceedings of the Royal Society B: Biological Sciences, the research found that hotspots for at-risk species often overlap.

As a result, it’s been supposed by researchers that by leveraging the overlayed maps, in combination with the identification of at-risk species hotspots, Canada may actually be able to save an innumerable number of species from extinction by strategically protecting relatively small parcels of land.

“If protected areas are put in the right places, protecting a small fraction of Canadian land could protect habitat for many at-risk species,” explains the study’s co-author and McGill University Biology Professor Anna Hargreaves. “Most hotspots are in southern Ontario and Quebec where there is little natural land left and what remains is threatened by ongoing clearing and development.”

Psilocybin trials to begin in Canada

The commencement of a landmark study was recently announced by KGK Science, a wholly owned subsidiary of Wellbeing Digital Sciences, which secured institutional review board (IRB) approval in Canada to begin a Phase IIA trial meant to assess the efficacy of psilocybin to treat adults with fragile X syndrome (FXS), which is understood to be the primary genetic cause of autism spectrum disorder (ASD).

The trial, which will be led collaboratively by KGK Science and Canadian-based biotechnology company Nova Mentis Life Science Corp. will include a joint evaluation of the effects of microdose psilocybin on the cognitive and autism behaviour spectrum symptoms related to FXS.

Including ten subjects which will be selected this year, the data generated by the study will be leveraged to assist Nova’s drug development programme and represents one of the first approved studies to allow subjects to take home the drug for dosing. And, according to Wellbeing and KGK Science CEO Najla Guthrie, it’s a study that should prove to be extremely beneficial with respect to our continued understanding of psilocybin and its potential going forward.

“We believe the first-ever Phase IIA clinical trial will be an impactful assessment of the potential of psilocybin in a disorder that truly affects the lives of many families. We look forward to contributing to the science alongside Nova Mentis.”

CANADIAN NEWS 9 BIOLABMAG.COM

Breakthrough in rehydration technology announced

The results of groundbreaking collaborative research conducted by a team at Entrinsic Bioscience (EBS) and the University of Florida were recently shared, revealing significant findings related to our understanding of amino acid combinations that could revolutionize oral rehydration solutions. The research demonstrated that the team’s advanced rehydration formulation, which is void of glucose and consisting of a precise, patented blend of amino acids, is superior to traditional oral rehydration solutions in increasing electrolyte and fluid absorption in the presence of cholera toxin, decreasing epithelial anion channel activity and improving intestinal barrier function.

They are results that, according to research lead, Sadasivan Vidyasagar, associate professor of the Department of Radiation Oncology, University of Florida, represent the future of oral rehydration solutions.

“We are thrilled to announce the results of our latest research study and share statistically-significant data to demonstrate the superiority of this oral rehydration solution in the total absence of sugar,” he says. “The findings not only validate the effectiveness of this amino acid product, but also represent the next generation of oral hydration solutions and will inform our future development and innovation.”

THE RISE OF THE "BIOCOMPUTER"

An international team of leading scientists are collaborating in a collective effort to create the world’s first "biocomputer". Powered by what the team is calling “organoid intelligence,” the computer’s hardware is proposed to be driven by an array of human brain organoids—microscopic, three-dimensional neural structures that are grown from human stem cells—that are connected to sensors and output devices and informed through the use of machine learning, data input, and other advanced techniques.

The team, led by Johns Hopkins University, says that their work may represent a massive breakthrough with respect to computing, and could feasibly develop a biological computer with the potential to outperform silicon-based machines while consuming far less energy.

The impetus behind the work of the team of scientists is to create a system of superior efficiency that possesses the ability to solve problems that are currently beyond the reach of conventional digital computers. In addition, if the team is successful in their endeavour, their work could serve to facilitate further development within neuroscience and other areas of medical research.

REPROGRAMMING THE AGING PROCESS

Aging: the very idea of it, consumes many people. Efforts to prevent or reverse its inevitability have been at the core of beauty product claims, the impetus behind Hollywood screenplays, and the bread and butter of most cosmetic surgeons. However, could human beings be on the verge of, well, at least understanding aging? A group of researchers at the University of California San Diego think so.

The team of researchers conducted a study which recently concluded, revealing that they were able to successfully increase the lifespan of yeast cells by 82 per cent, posing the potential for the same to be done on a cellular level in humans.

In order to conduct the study, researchers rewired yeast cells, which are single-celled microorganisms that undergo an aging process similar to that of human cells, causing them to fluctuate between two states of aging (molecular decline and mitochondrial decay), increasing their life span by more than 80 per cent.

Although human cells are significantly more complex than those of yeast, researchers are still optimistic that their work will help to start paving the way toward its application to other life.

“Our work represents a proof-ofconcept, demonstrating the successful application of synthetic biology to reprogram the cellular aging process and may lay the foundation for designing synthetic gene circuits to effectively promote longevity in more complex organisms,” the researchers wrote.

WORLDWIDE NEWS 10 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

THINKING INSIDE THE

BY ROBERT PRICE

BY ROBERT PRICE

BIOLABMAG.COM

of Saskatchewan Insect Research Facility promises new research into agricultural threats

University

FEATURE STORY 11

BOX

SeanPrager has been in love with bugs for a long time. He began researching bugs during his undergraduate years at Clark University in Massachusetts in the early 2000s. Given a choice between studying fish and mosquitos, he chose mosquitos.

Today, Prager is an associate professor in the College of Agriculture and Bioresources at the University of Saskatchewan. He’s the lead researcher at University of Saskatchewan Insect Research Facility (USIRF), a newly constructed laboratory dedicated to the study of insects and plant pathogens. USIRF isn’t the first of its kind in Canada, but the impressive facility promises to advance research into the bugs that can hurt Canada’s food supply.

Inside the Box

Prager describes the USIRF as “a really big box” with other boxes inside it. Inside those boxes are bugs.

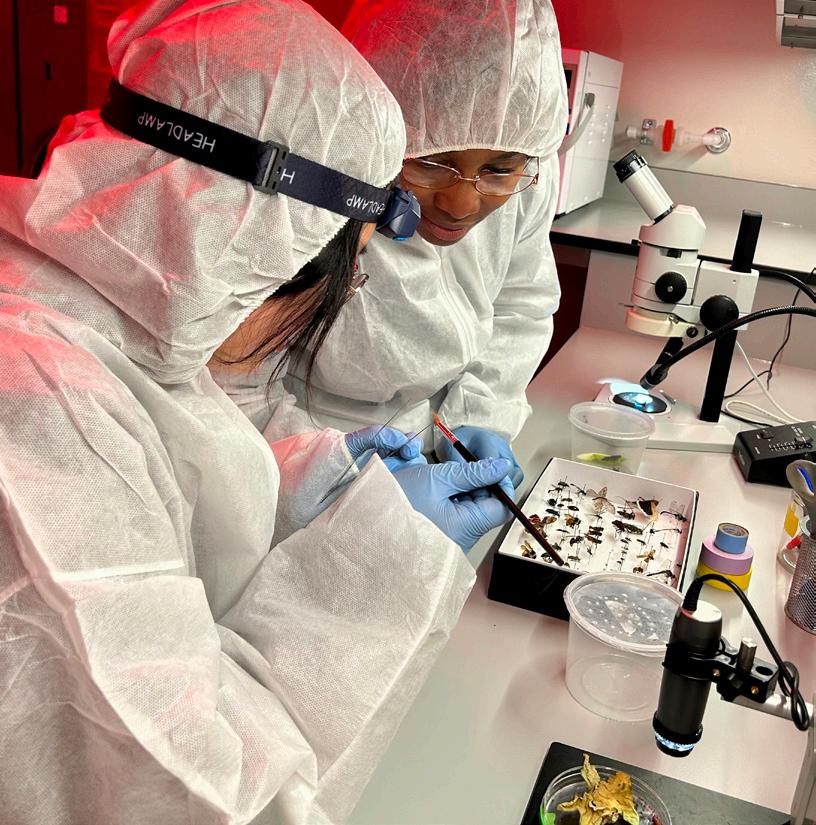

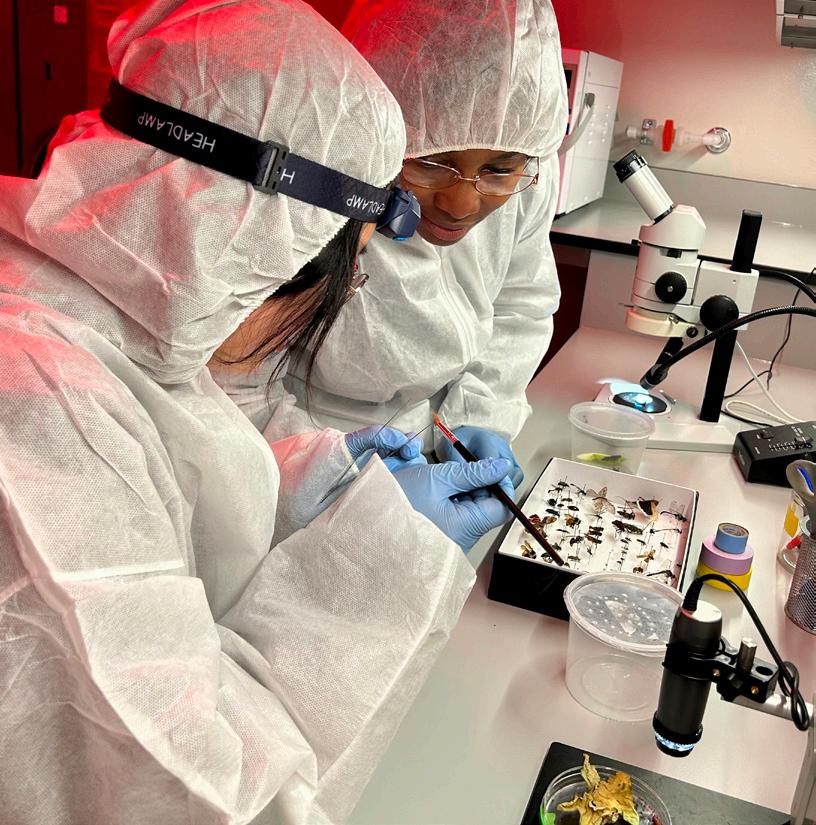

Prager’s explanation of what the 500-sq.-ft. USIRF looks like sounds simple. In reality, the Level 2A containment facility is a startlingly complex ecosystem of pathogen habitats, quarantines, and security measures.

The facility contains rearing chambers for plants and insects. It has freezers, temperature controls and humidity controls, screens and HEPA filters, and workspaces. Traps attract insects and keep them from escaping. Near the doors, negative airflows suck air back into the boxes. Special materials—materials that can be bleached and that are for the most part inorganic—ensure that hungry insects and fungal pathogens cannot eat their way out of the box. The lighting also controls the bugs. Standing inside the facility is like standing inside a dark room: all the lights are red. Insects cannot see the colour red, and so the insects think they’re living through an eternal night.

“Everything inside there is built to prevent things from escaping,” says Prager. “It’s very secure. It’s bio-secure.”

The USIRF serves many purposes. The value of the facility is in, Prager says, “the kinds of research it allows us to do.” A chief concern for researchers is how well invasive species can adapt to Canadian environments. Could a beetle that currently breeds in Australia survive in Canada if it somehow found its way to our shores? Could a plant pathogen survive Saskatoon’s -40C winters?

Without the facilities like USIRF, researchers can only guess what might happen. The quarantined space made possible by the “boxes” that comprise USIRF allow researchers to grow plants, infest them with various strains of pathogens and serve them to exotic insects, and freeze them to see if they can survive a Canadian winter. They can assault the invasive species with pesticides and identify the natural enemies of these invasive species—the predators that will eat those pests. The biological controls inside the facilities allow researchers to play out these insect war games to determine what bug will dominate, and which might dominate us.

“We can bring [novel pests into Canada] and we can kind of expose them, and we can see what we should expect,” says Prager.

12 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

FEATURE STORY

Sean Prager—Lead Researcher at the University of Saskatchewan Insect Research Facility (USIRF).

The facility uses rearing chambers custom-manufactured by Conviron, a Canadian company. What’s unique about this facility is that the control systems and the insides of the freezers and computer components are all on the outside of each box. This design allows easy access for repair people who could never break the quarantine to enter the chambers.

All the chambers are wired together to what Prager calls a “central brain”—a central management system that’s run by full-time staff. The central management system controls the temperature, lighting, humidity, and other elements of each chamber. If something goes wrong—if quarantine is broken, if there’s a power outage, if a temperature rises above tolerance levels—the alert system texts a person monitoring the research to let them know that something has gone wrong.

“That practice is important in general, but it’s also important for something like this because it’s a quarantine,” Prager says. “You don’t always have people do it all right. So just like a lot of things, there are mechanical safeguards—the last line of defense beyond good practice.”

plants or killing beneficial insects. If you don’t have a registered insecticide that can kill those bugs, then the agricultural industry will have to go through a long process of obtaining a legally controlled insecticide. Farmers might have to register for an emergency exemption. They might be denied. The entire process could take four to six years before farmers can mount an aggressive attack on the pest, and those years could devastate entire farming communities.

With the research being done at USIRF, researchers can identify possibilities that could confront farmers and help develop plans to counter them. Plant breeding takes decades, but if researchers know that such a bug might appear one day, whether by accident, by circumstance, or through the machinations of climate change, they can breed robust cultivars, formulate and gain approval for new insecticides, and plan for what to do in an emergency.

“You need to be way ahead of them,” he says. It is work that can take decades, as Prager knows well. “I’ll be like, you know, at the back end of my career before anything is released that anyone actually uses,” he says.

Building the Dark

The construction of the facility took almost six years to complete. When Prager arrived at Saskatchewan in 2017, he was shown where his lab could be. The space had been carved out originally for a facility like the one they’ve built, but at the time the space was used for storage.

Prager had a blank slate and set about building what became the USIRF. The first step in building the facility was gathering the funds. They obtained funding through the Western Grains Research Foundation, the Canada Foundation for Innovation, the Saskatchewan Canola Development Commission, the Saskatchewan Pulse Growers, the Saskatchewan Wheat Development Commission, and the University of Saskatchewan. Delays during the COVID pandemic led to an increase in costs and Prager had to go searching for more money. He found it.

Getting ahead of the bug

This research has long-term implications. Researchers determine what strains of cultivars prove resistant to particular pathogens and insects. A breeding program gives researchers the time to cultivate new strains of seeds and grains to get ahead of invasive species. This work is important because, as things currently exist, the response to insects and invasive species can be long and frustrating.

As it is now, if a bug were to show up somewhere in Saskatchewan—let’s say it traveled by truck from a potato farm in Idaho and set up its colony in a field 150 km outside Saskatoon—farmers would first have to find that bug, and they might only discover the bug when they see their crops are under attack. An investigation would begin. Researchers would have to determine what type of bugs they were dealing with, map the pest’s locations, and then determine what kind of insecticide is best able to kill the bug without harming

Now, after six long years, they have the facility ready to go. After a few more checks and approvals still to come, and once all the journalists have finished taking their pictures, Prager will establish quarantine and the bugs will be locked in a dark box.

13 BIOLABMAG.COM

FEATURE STORY

Pick of the crop

MustGrow Biologics Corp’s plant-based technology platform is revolutionizing crop production

BY SEAN TARRY

BY SEAN TARRY

14 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

FEATURE STORY

There are few things that pose a greater impact on the future health and wellbeing of the planet and people living on it than the quality of the crops being grown all over the world. Unfortunately, the pesticides and herbicides that have been used through the years, many of which are currently being restricted or deregulated by governments, have caused significant damage to soils, water, turf, and surrounding vegetation by virtue of the toxic chemicals that they contain. In light of this challenge, and in an effort to provide a natural and organic substitute for these harmful controls, MustGrow Biologics Corp. continues to advance its plant-based technology platform solution.

“A lot of the chemicals that have been used over the past number of decades are harsh and have a severely detrimental effect on the health of soil,” says Colin Bletsky, COO, MustGrow Biologics Corp. “We’re essentially utilizing something that nature’s given us, harnessing it and making it more efficient in a usable form, and putting it back into the soil. It provides farmers with the opportunity to replace some of the harmful chemistries that they use and could help the entire agricultural sector improve the health, quality, and yield of the crops that everyone depends on.”

15 BIOLABMAG.COM

“We’re essentially utilizing something that nature’s given us, harnessing it and making it more efficient in a usable form, and putting it back into the soil. It provides farmers with the opportunity to replace some of the harmful chemistries that they use and could help the entire agricultural sector improve the health, quality, and yield of the crops that everyone depends on.”

FEATURE STORY

—Colin Bletsky, COO, MustGrow Biologics Corp.

Evolution of agriculture practices

An agriculture biotechnology company, MustGrow is focused on the development and commercial ization of natural biological technologies and products that can be derived from the mustard seed in order to help create more sustain able agriculture and improve soil health for farmers. It’s an endeavour of obvious importance to the continued evolution of agriculture practices. And, it’s one that Bletsky and the company’s President and CEO, Corey Giasson, understand all too well. The pair each grew up in farming families, providing added impetus to fulfill the promise of MustGrow’s technology.

“Agriculture is in the blood of both Corey and myself,” he asserts. “We both grew up farm boys and have been involved in the agriculture industry our entire lives. I still farm with my family in eastern Saskatchewan. We understand the challenges that are involved in running a healthy and success ful operation. And, we’ve been around the world and have seen what’s going on, the dead soils and issues in many areas where there’s sig nificant problems with the toxicity of the chemicals

16 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

FEATURE STORY

that they’ve used or are using. And so, it really drives us to continue improving our natural-based biosolutions in an effort to replace or complement synthetic chemistries and fertilizers.”

Development of technologies

Bletsky goes on to explain that farmers have been utilizing the mustard seed and the Brassica family of plants to promote the health of their crops for centuries because of the natural molecules that they contain which serve as a natural defense mechanism, providing protection from diseases and pests. The technology that MustGrow leverages was developed by Agriculture and Agri-Food Canada, which was then advanced by the company’s predecessor, MPT. Bletsky and Giasson recognized the opportunity that it represented and became involved in 2015 to see it through to fruition.

“This is a great technology that has a lot of promise,” he says. “It presents a ton of opportunity on the financial side as well as from an environmental and sustainable perspective. In order to realize its potential, we’ve brought in some incredible investors and are now working with some large partners to grow the company beyond servicing the needs of farmers in the province of Saskatchewan and Canada to help benefit farmers globally also.”

How it works

MustGrow’s biofumigant and biopesticide technology has resulted in TerraMG—a patented liquid product that’s made up of a two-part formula involving a sinigrin (glucosinolate)

(glucosinolate) formulation and myrosinase (enzyme). Upon mixing the sinigrin and myrosinase formulations together with water, a hydrolysis reaction occurs in which the myrosinase cleaves off the glucose group from the glucosinolate, and the remaining molecule quickly converts to allyl isothiocyanate (AITC)—the molecule that’s central to the effectiveness of MustGrow’s technology.

“AITC, which is within food grade product and something that we eat, when used within our formula, acts as a natural biofumigation product for the soil,” he explains. “It’s what enables the replacement of some of the harsher synthetic chemicals that are currently being used to control nematodes which cause approximately $100 billion of crop loss globally every year. It’s also used to prevent diseases that impact crops. Because we use a natural-based technology, it doesn’t pose any threat or harm to the soil, water, nearby vegetation, or to the health of animals and humans. And, as it has a very short half-life, meaning that it breaks down quickly, it’s not only helping to control harmful diseases and pests like nematodes, it breaks down into food for the soil microbiome, presenting a dual benefit.”

Tremendous opportunity

The molecule can also be used to ensure post-harvest food preservation, displaying a tremendously positive effect in controlling sprouts in potatoes and other root and tuber vegetables, in addition to its impact in helping to control diseases. And, because chlorpropham—one of the most commonly used chemicals that’s used within agriculture around

17 BIOLABMAG.COM

FEATURE STORY

the world—has been banned from use within the European Union, there seems to be opportunity for MustGrow to expand its reach and technology even further. And, as Bletsky explains, it’s not the only area of opportunity that the company hopes to exploit.

“Within mustard, you can think of it as a mini bioreactor,” he says. “It allows us to extract and to do many different things, presenting a range of potential applications. Mustards have over 41 different glucosinolates, and when you mix and match those with a different enzyme, different properties can be derived. We extracted one of the glucosinolates called sinalbin, and when mixed with the enzyme it creates a bioherbicide that’s able to control weeds. So, by leveraging the natural properties of the mustard seed, we’re able to support pre-plant soil fumigation and bioherbicides for disease and nematodes, as well as post-harvest food preservation. We’re also working on creating natural products in the areas of soil amendment and biofertility, which are also presenting us with incredible opportunity.”

Additional applications

In addition to the use of AITC in agriculture, Bletsky notes that this type of technology could also be leveraged to benefit human and animal health as a result of its

anticarcinogenic, antimicrobial and anti-inflammatory properties. But for now, he adds, the focus of MustGrow is very much around helping farmers improve the health of their soils, enhance agriculture production, control pests and nematodes, bolster soil fertility, and optimize post-harvest preservation, while ensuring a positive environmental impact for years to come.

“I’m here to realize some of the tremendous economic opportunities that MustGrow and our technology represents. However, I’m also here to make a positive impact. Soils in areas all over the world have become so depleted as a result of an extreme overuse of harsh chemicals and fertilizers. There’s a lot of opportunity for our technology, as well as other forms of sustainable technology, to change things for the better, reduce the industry’s impact and improve the health of our planet. And, looking ahead, we’re going to be concentrating our efforts on working with our global partners—NexusBioAg, Sumitomo Corporation, Bayer CropScience and Johnson & Johnson—to really drive our technologies forward, continue our expansion and accelerate the work we’re doing.”

For more information about MustGrow and its natural plant-based agriculture solutions, visit https:// mustgrow.ca

18 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

FEATURE STORY

Getting ahead of Parkinson’s disease

New scientific research uncovers an early alarm system for high-risk patients

BY SEAN TARRY

There’s no doubting that scientific study and research is the lifeblood of the medical community, enabling discovery and advancement, fuelling new ideas and practice, enhancing current understanding, and continuously driving a next generation of innovation and breakthrough. That’s an apt description of the impact that the work of scientists and technicians results in on an ordinary day. On a good day, it can mean much more, touching and improving the lives of so many. It’s certainly the case for researchers who recently released the findings of a study that reveals a breakthrough that could forever change the way Parkinson’s disease is detected and treated.

Revolutionary technique

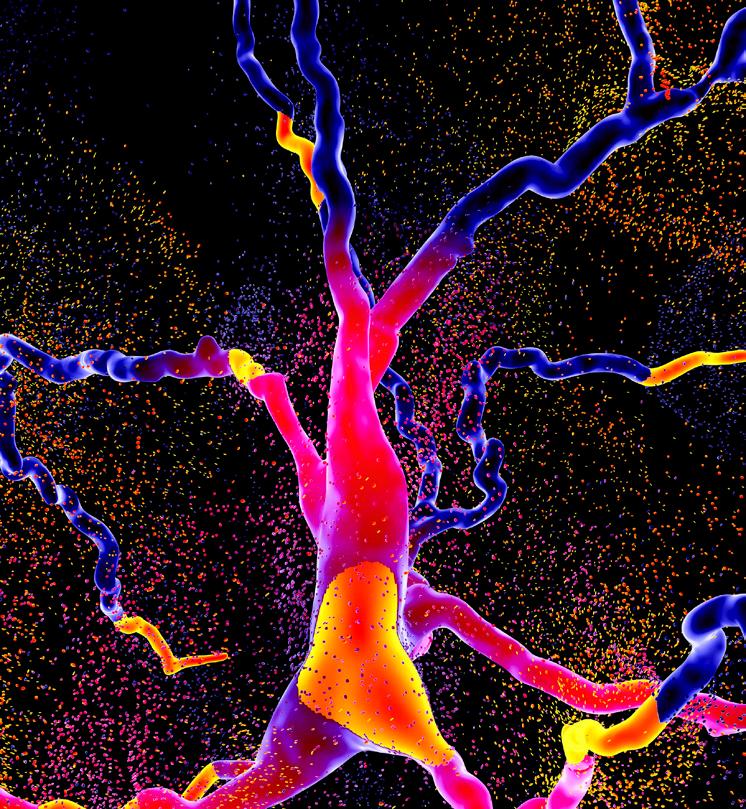

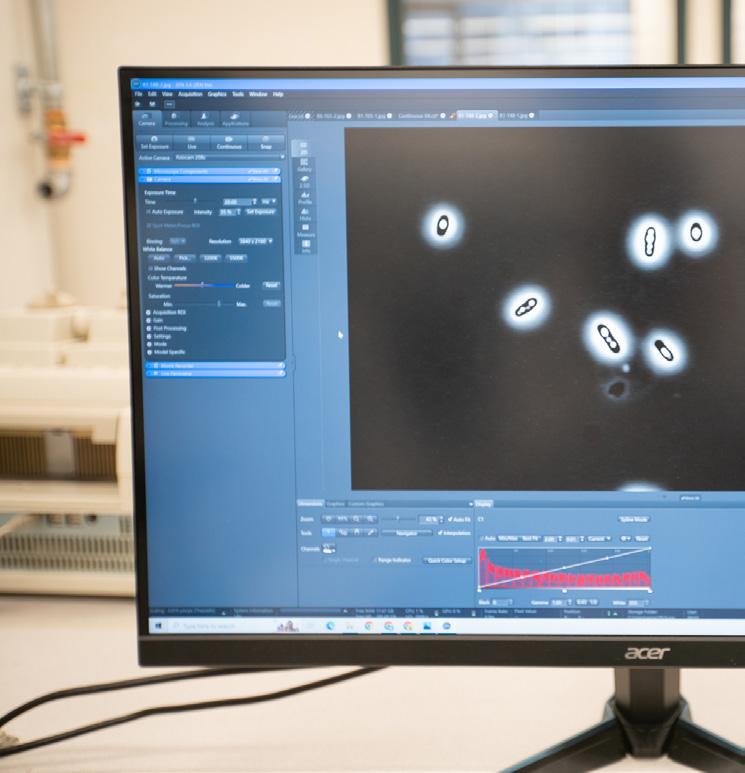

The breakthrough, which was discovered as part of a largescale clinical study called the Parkinson’s Progression Markers Initiative (PPMI), involves the development of a new technique that enables the identification of a key signature of the disease within the brain and body cells of living people.

Conducted by an international coalition of leading scientists and financially supported by the Michael J. Fox Foundation, the study and its findings, details of which were published on April 12, 2023, within the medical journal The Lancet Neurology, present incredible potential concerning current understanding of Parkinson’s disease among

BIOLABMAG.COM 19

NEWSMAKER

the medical community and could significantly change the impact of symptoms on the patients suffering from the degenerative brain disorder.

Determining high-risk patients

The new technique that’s been developed, called a-synuclein seeding amplification assay, allows for the identification of an abnormal protein that’s known to be a link to the disease within patients, both symptomatic and non-symptomatic. As a result, researchers are proposing that it could provide doctors with a means by which to determine patients who are at high risk of developing the disease long before any of its effects take hold.

Within the published details of the study, researchers reveal that the assay is able to recognize the presence of abnormal alpha-synuclein, also known as Parkinson’s protein, within most patients suffering with Parkinson’s, with an astounding 93 per cent accuracy.

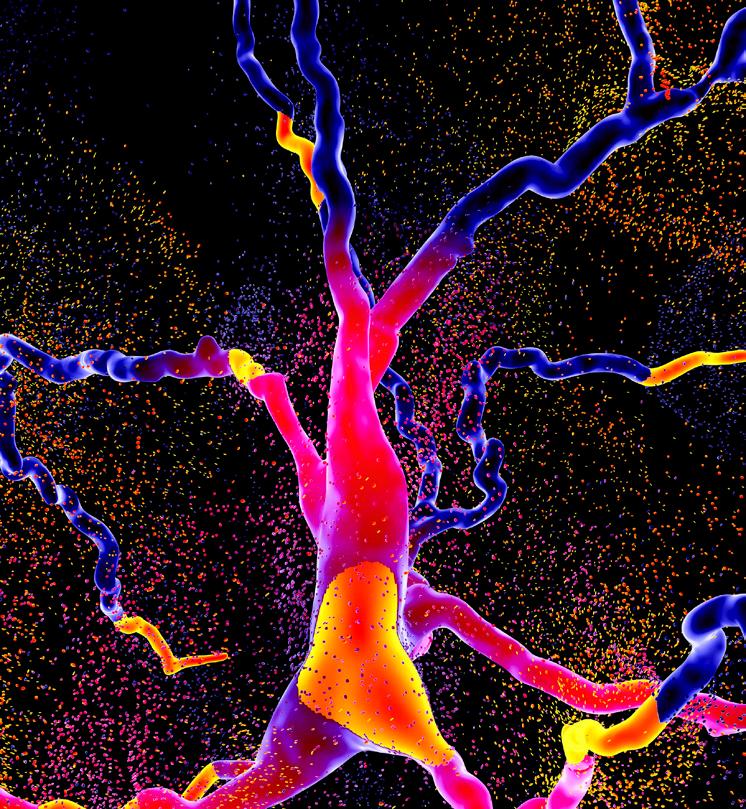

It’s a particularly interesting and, perhaps revolutionary, breakthrough given the fact that alpha-synuclein is a protein that’s commonly found in the human nervous system, in very much the same way as amyloid is in the case of Alzheimer’s disease, which has a tendency to misfold and clump together, causing neuron damage and laying the foundation for the onset of Parkinson’s disease.

Remarkable promise

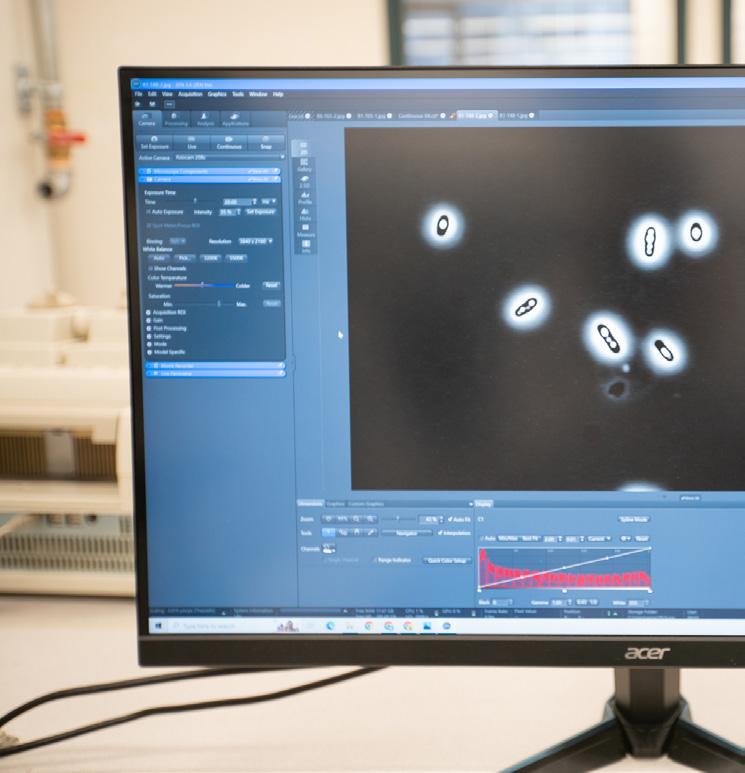

The technique developed by researchers leverages a quality of abnormal alpha-synuclein to the advantage of scientists and medical professionals—a quality that triggers normal alpha-synuclein in the vicinity to also misfold and clump. To take advantage, samples of spinal fluid are subjected to a fluorescent contrast agent which lights up, alerting researchers of the formation of alpha-synuclein clumps.

At this stage, normal alpha-synuclein is added to the spinal fluid sample. If the sample contains the presence of abnormal alpha-synuclein, the formation of clumps will be facilitated among the newly-introduced normal alpha-synuclein. And, if this is the case, the fluorescent dye lights up.

The newly developed technique shows remarkable promise in advancing Parkinson’s screening and enhancing the treatment of the disease, representing a massive step forward concerning its related research. It wasn’t until these studies were conducted and findings were revealed that scientists and researchers were able to detect the Parkinson’s biomarker within a live person. Previously, in order to confirm the presence of abnormal alpha-synuclein clumps, the

subject would need to be deceased and undergo a post mortem analysis.

Time for hope

Given that Parkinson’s disease is a progressive disorder that affects the brain, post mortem analysis has to date not yielded any benefit for patients currently living with the disease. There’s been no way in which to get ahead of the symptoms that can include the frequent occurrence of involuntary bodily movements, physical tremors, stiffness, varying difficulty related to balance and co-ordination, behavioural changes, problems sleeping, depression, memory loss, fatigue, and more. That is, until now.

According to the study’s findings, detection of the biomarker in live patients will help medical professionals to diagnose the disease significantly earlier than traditional analysis has historically allowed, potentially enabling intervention and treatment to occur soon enough to save some newly diagnosed patients from some of the fully advanced symptoms associated with the disease.

Enormous opportunity

The breakthrough has obviously been recognized and applauded by the Michael J. Fox Foundation. In fact, the actor and long-time Parkinson’s sufferer who was diagnosed with the disease in 1991 at the age of 29 released a statement the day following publication of the study’s findings.

“I’m moved, humbled, and blown away by this breakthrough, which is already transforming research and care, with enormous opportunity to grow from here,” he said. “I’m so grateful for the support of patients, families and researchers who are in it with us as we continue to kick down doors on the path to eradicating Parkinson’s once and for all.”

A statement from the Foundation goes on to further explain that it's hopeful the work and efforts put in by scientists and researchers will not only help to improve the lives of patients suffering with Parkinson’s, but that it could potentially allow for a greater understanding of the disease and the ways in which it progresses and advances at different biological stages.

The Michael J. Fox Foundation aims to find a cure for Parkinson’s disease through an aggressively funded research agenda, which includes large, open data studies like the PPMI. For more information about its work, visit www.michaeljfox.org.

BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023 20 NEWSMAKER

FACILITATING INNOVATION

AND SOLUTIONS THROUGH SCIENCE AND TECHNOLOGY

THE SASKATCHEWAN RESEARCH COUNCIL IS HELPING INDUSTRIES SOLVE TECHNOLOGY PROBLEMS, MAKE IMPROVEMENTS, AND SEIZE ECONOMIC OPPORTUNITIES

BY SEAN TARRY

BY SEAN TARRY

21 BIOLABMAG.COM LAB PROFILE

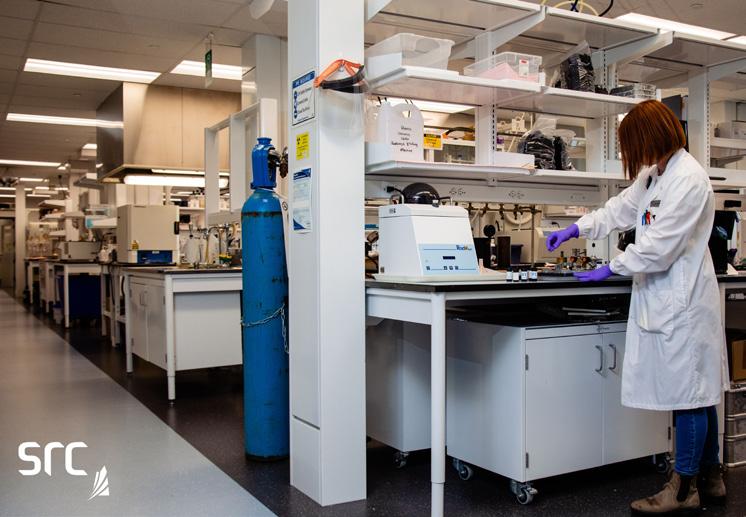

We’recurrently living during extremely interesting times. Faced with a number of different challenges, yet equipped with a plethora of tools and resources to address and solve them, humankind has never before enjoyed such a wealth of capabilities and know-how. Aided in large part by the digitization of the world around us and the diligent work and research conducted by scientists and technicians in labs all across the globe, innovation and discovery abound. It’s a confluence of science and technology that’s fuelling much of our progress and development on the planet. And, it’s also one which, when leveraged properly, can yield economic opportunities as well.

Range of services and expertise

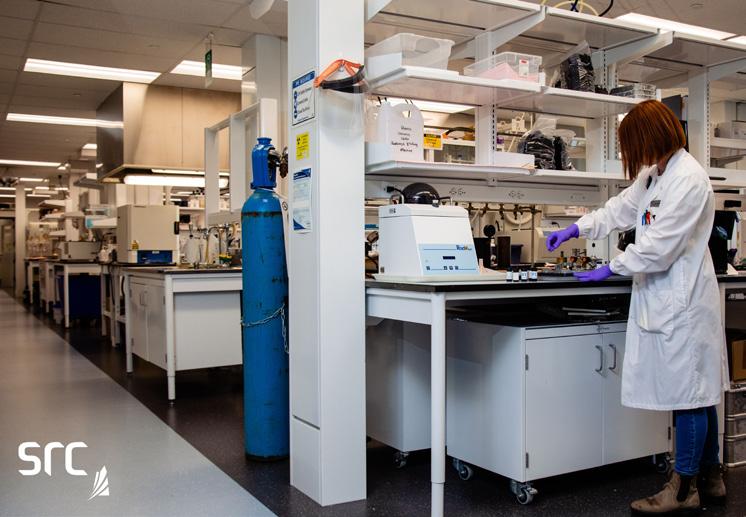

In order to help facilitate growth and fulfill the full economic potential of Saskatchewan—one of the country’s most resource-rich provinces—the Saskatchewan Research Council (SRC) connects science and industry, working with clients all over the world to support innovation and industrial commercialization. And, according to Jeff Zimmer,

SRC’s Environmental Analytical Laboratories Manager, the Council is able to do this through a wide range of services and expertise.

“We offer a really diverse array of services that support the province of Saskatchewan in a number of important ways,” he explains. “Of note, we recently developed a Rare Earth Processing Facility to support the development of critical minerals in a green economy. We also happen to house the world’s largest diamond lab, a world-renowned Pipe Flow Technology Centre, as well as geo-analytical labs that support mineral exploration efforts. And, in our lab, which is the Environmental Analytical Lab, we provide a range of services to industry, mining firms, engineering and environmental consultants, municipalities, and more, in order to support environmental monitoring programs and processes, and to solve a variety of challenges that are faced.”

A diverse organization

Founded in 1947, the SRC has grown through the years from

22 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

LAB PROFILE

Laboratories and facilities at the Saskatchewan Research Council work to connect science with industry, facilitating innovation and industrial commercialization.

just three employees during its earliest years to the more than 350 employees that contribute toward the breadth and scope of work that it undertakes today. Working to support efforts within the agricultural and biotechnology, energy, environment, mining, and nuclear industries, the Council provides a multitude of services, ranging from air quality monitoring and mineral analysis to process development and water quality testing, and including dozens more in between. It’s an ecosystem of research and services that is as massive as it is impressive. And it’s one that Zimmer says provides those working at the SRC with continuous challenge, ensuring sustained innovation and creativity.

“As you realize when you look at the work that we do at the SRC, it’s an incredibly diverse organization,” he says. “And because we’re oriented around service, there are always a lot of new and unusual client challenges that we need to find solutions for. We’ve got a number of different facilities and so the opportunity for collaboration is ever-present. And, because we’ve got a number of people working here with varied backgrounds who bring different perspectives to the

SRC LABS AND FACILITIES

The SRC operates a number of special testing labs and research facilities in order to support the needs of its clients across Canada and the world, including the following:

LABS & PILOT PLANTS

Environmental Analytical Laboratories

Geoanalytical Laboratories

Diamond Laboratory

Pipe Flow Technology Centre™

Mineral Processing Labs and Pilot Plants

TSVX Laboratory

Advanced Microanalysis Centre™

FACILITIES

Rare Earth Processing Facility

Climate Reference Stations

Centre for the Demonstration of Emissions Reductions

work we do, we’re never short of fresh ideas and new ways to solve problems and address challenges.”

Finding solutions to challenges

The services that it provides and people and facilities that support them makes the SRC Canada’s second largest research and technology organization. And, with one of Canada’s most complete analytical chemistry laboratories, its Environmental Analytical Laboratories offers clients environmental test services and expertise in organics, inorganics and radiochemistry. And, within its own suite of services and analytical offering, Zimmer emphasizes that it’s all done with the goal of solving the plethora of environmental challenges that the SRC’s clients face.

“In the end, we’re primarily helping clients solve their environmental challenges by providing them with the data that they need to support key decisions and to answer some critical questions, like is this water safe to drink?” he says. “We also help to assess land for agricultural and industrial purposes, determining the impact of their operations on the

23 BIOLABMAG.COM LAB PROFILE

SRC’S ENVIRONMENTAL ANALYTICAL LAB

As a means to provide the expert help that SRC’s clients are looking for when it comes to managing their environmental impact, the Environmental Analytical Lab provides a range of services related to the following:

Agriculture Products Testing

Water Quality Testing

Custom DNA Analytics

Cannabis and Hemp Testing Laboratory

DNA Testing Services

Lead in Drinking Water

Environmental Analysis and Testing

Potash

Midge-Tolerant Wheat Refuge Testing

Microbial Cannabis Testing

environment. In order to answer these questions properly and accurately, some type of analysis is required, which includes a range of testing. We do a lot of routine monitoring which helps prevent environmental contamination from arising. And we’ll often be involved when there are spills and emergencies, too, providing analyses and results when they are needed immediately.”

Continued innovation

The SRC has also been instrumental in leading the decadeslong clean up and remediation efforts of 37 abandoned uranium mine sites in the northern regions of the province by providing its expert analysis capabilities. It’s a management project that the team at SRC has been involved in since 2006, leveraging the evolution of its technologies and techniques through the years. It’s an evolution that’s critical to the work that the SRC and its Environmental Analytical Lab does, says the Lab’s Supervisor, Tim Tse, who goes on to explain that it’s also a necessary evolution, spurring on continued innovation.

“Some of our clients have interest in monitoring for an invasive species that are currently an issue in Quebec and Manitoba,” he explains. “They’re concerned that the species is going to migrate into Saskatchewan. To address this challenge in a really unique way, we’re currently developing new environmental DNA techniques that will help enhance our capabilities. Essentially, we’re filtering water to extract environmental DNA in order to do some targeted analysis to find out whether or not the specie is present within Saskatchewan’s

Naturally Occurring Radioactive Materials (NORM)

Shock Chlorination for Wells

Petroleum Testing

Livestock Watering Package

Radiochemical Services

Landfill Waste Acceptance Testing

Radon Testing

Road Salt and Liquid De-Icer Testing

Aquatic Toxicology Services

Hydrocarbon and Salt-Impacted Sites

Uranium Mining Analytical Services

aquatic systems. It’s a technique that not only applies to invasive species, but can also be leveraged for community-level monitoring to help track and protect populations of exploited fish. We’re consistently looking ahead and developing newer and better techniques to add to, augment, and complement what we already offer.”

Embracing change

It’s the forward-looking, service-oriented approach that has helped cultivate the SRC’s reputation among its clients as a thorough, trustworthy, and hyper-capable organization that enables industry growth and economic development through its specialized offering. And, adds Zimmer, it does so while embracing the role it serves in improving the impact of its many clients.

“There’s so much change happening at the moment, which I think frightens a lot of organizations. But we really embrace change, working to find solutions for today’s challenges while keeping an eye on the horizon with respect to things that will ensure the future health of Saskatchewan and the rest of the planet. Within our lab, we’ll continue with the development of new tests and techniques while constantly improving the efficiency with which we do things, generating a consistent flow of new ideas.”

For more information about the Saskatchewan Research Council and the services it provides, visit www.src. sk.ca.

BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023 24 LAB PROFILE

GENECIS GETTING THE MOST OUT OF WASTE

A Toronto-based biotechnology company is turning organic waste into sustainable and biodegradable materials

BY SEAN TARRY

BY SEAN TARRY

25 BIOLABMAG.COM

Bioindustries is helping to provide an alternative to harmful petroleum-based plastics and a circular economy solution for products' beginning and end of life. COMPANY PROFILE

Genecis

Whenit comes to the future of the planet, there are few challenges greater than that of limiting the amount of waste that’s created, particularly waste of the plastic variety. Not only are landfills brimming with the petroleum-based discards, but the

impact of microplastics (the extremely small pieces of plastic debris in the environment that results from the disposal and breakdown of consumer products and industrial waste) are posing a significant detriment to the current and future health of natural

habitats and ecosystems all over the world, threatening the overall quality of life on Earth. In an effort to curb the damage that’s being caused, Genecis Bioindustries is developing sustainable and biodegradable materials using organic waste, presenting a circular

26 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

Leveraging science and technology, Genecis Bioindustries serves as both a waste-to-PHA technology company and a biomaterials designer.

COMPANY PROFILE

economy solution for products’ beginning and end of life.

ADDRESSING BOTH ENDS OF THE CLIMATE CRISIS

The company, which derives its name from a combination of the words

genesis (signifying the beginning or creation of something new) and cis (denoting the spatial arrangement of atoms in molecules in polymer chemistries), was founded in 2016 by the company’s CEO Luna Yu. Yu, who completed her Environmental Science

master’s degree from the University of Toronto, began developing the company through the school’s system, gaining access to the facility’s microbiology lab and its shared resources related to bacterial fermentation and strain engineering development. Genecis has since expanded to operate out of two facilities—a downtown Toronto lab which houses the company’s polymer science and a fermentation warehouse in Scarborough which accommodates its large-scale testing reactors.

Operating as both a waste-to-PHA technology company and a biomaterials designer, Genecis serves to address both ends of the climate crisis.

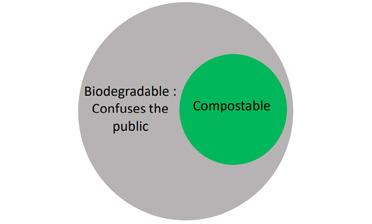

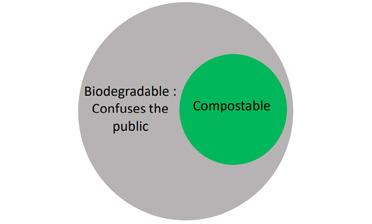

On the front end, it diverts food and agricultural waste streams that would otherwise go to landfill, contributing to methane and carbon emissions, valorizing them to produce PHA—a non-toxic, biodegradable, compostable alternative to oil-based plastics. Through its bacterial fermentation process, carbon from the waste is converted into PHA—a natural energy storage system—which is then extracted and is used to create a plastic-alternative material.

On the back end, it helps companies that are interested in finding sustainable biomaterial solutions for packaging and products that would otherwise be made with petrochemical-based plastics, providing them with the opportunity to use a cleaner, safer, more environmentally friendly material in their supply chains and product lines.

PARTNERSHIPS AND SUPPORT

It’s a revolutionary yet simple idea and approach to waste diversion and the creation of a plastic-alternative material. However, as DeLaine Mayer, Head of Partner Success at Genecis, explains, it’s an endeavour that requires an entire ecosystem of partners and contributors in order for it to scale properly and fulfill optimized potential.

27 BIOLABMAG.COM

COMPANY PROFILE

“We’re currently scaling our technology beyond our lab and warehouse, which are research and development scale,” she says. “We’re doing this through a demonstration unit that will really confirm proof of concept for the waste-to-PHA technology, partnering with StormFisher, one of the largest biogas players in Canada, to integrate a small-scale production facility within one of its biogas plants. The idea is to divert a small portion of the mixed waste that they collect from biogas to be used with our technology. Partnering with biogas plants is the long-term way in which we plan to integrate Genecis technology and scale PHA production within North America and globally.”

PROVIDING SOLUTIONS

With an eye on providing a solution to help alleviate some of the issues around waste management, integration with existing biogas plants is also a way by which Genecis avoids the need to create separate waste collection systems and infrastructure. In addition, the company is also scaling up its technology through toll manufacturing partnerships, explains Mayer, working with partners to produce additional volumes of PHA to help support the fulfillment of orders that it has with consumer packaged goods companies and other clients that are interested in getting the material into their products and supply lines.

“We partner with clients on custom product development,” she says. “We help with product design to replace petroleum-based plastics in existing products with the biodegradable or industrially compostable version of it, executing a like for like design using a PHA-based material. We also produce custom resin for customers who aren’t

looking for a finished end product, but instead want the PHA pellets that they can use within their own equipment.”

WORKING TOGETHER

In addition, Genecis also enters into co-branding agreements and partnerships with companies that are looking to leverage emerging technologies and collaborate to make a real difference. And, says Mayer, it’s work that’s being done with the intention of making improvements to current processes and the materials that are being used in order to ensure a safe and healthy planet well into the future.

“Plastics have a negative impact right through the entire value chain,” she asserts. “It’s incredibly toxic to produce plastic. And, the amount of microplastics that are created during a product or materials, end of life is incredibly hazardous. We don’t yet know the long-term implications of consuming a credit card worth of plastic every week. But that’s what we’re doing. Microplastics are also now found in the placentas of unborn infants. It’s become a ubiquitous problem. And so, we need to design materials that, throughout all stages of its life cycle, consider both the human and environmental impact. The solution needs to offer the same technical and performance functionality of existing plastics, but which are safe and natural. We want to help existing manufacturers. We don’t want to put anyone out of business, but to work with companies to help them incorporate biomaterials into their current materials palette.”

CONTINUED GROWTH

Just three years ago, Genecis employed approximately 20 employees. Today, that number has more than doubled

with more than 50 staff working on the advancement of the company’s technologies and solutions. And, to maintain this momentum, it continues to aggressively grow its business development team, polymer science and product development team, and its fermentation team, working to hone the science, technology and engineering pieces of the PHA puzzle while locking in the partnerships that can help Genecis to sustain its current trajectory and achieve its goals.

The company has also been experiencing interest from some players that are looking to invest in what Genecis is doing and to help facilitate its growth. In fact, it received a portion of Amazon’s $2 billion climate fund earlier this year to help support its work—an investment that Mayer says is representative of growing sentiment among companies concerning the importance of improving their environmental impact.

“Receiving support from a company like Amazon and other incumbent players within industries shows that the market is leaning in the right direction. There’s interest on the materials side as well as the finance side. We’ve never before talked about climate change or environmental, social and governance issues in the same way that we are today. It’s an indication that all of the necessary pieces are starting to converge in a way that results in a nexus of opportunity for companies like Genecis to help other companies that want to do the right thing and begin to improve our collective environmental impact once and for all.”

For more information about Genecis and the work it does, visit www.genecis.co.

BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023 28

COMPANY PROFILE

“The amount of microplastics that are created during a product or material's end of life is incredibly hazardous.”

Biome-friendly ingredients for a healthier future

Phycus Biotechnologies Inc. is developing alternatives to toxic cosmetics ingredients

BY SEAN TARRY

The cosmetics industry has come under a significant amount of criticism in recent years related to the collective negative impact that it has on the environment. From the use of excessive packaging and contributions to plastic pollution, to its unsustainable resource consumption, the manufacturers and purveyors of beauty care products pose a devastating effect on the future health of the planet. And, when considering the fact that most cosmetics products on the market contain ingredients that are derived from crude oil, the hazard that they represent increases significantly. That’s why, in an effort to create safer, more environmentally-friendly cosmetics ingredients, Phycus Biotechnologies Inc. developed an alternative to the harmful toxic contaminants.

29 BIOLABMAG.COM

APPLICATION NOTE

Creating safer ingredients

A sustainable chemical manufacturing company, Phycus Biotechnologies Inc. uses fermentation and engineered microbes to produce chemicals for use within beauty and skin care products. One of the chemicals it produces, which poses the greatest potential, is Purolic Acid—a 100 per cent biobased glycolic acid that’s produced from a naturally derived sugar feedstock. The fermentation ensures the production of a biome-friendly, formaldehyde-free ingredient. It’s an innovation that has many within the cosmetics industry taking notice. And, it’s one that Vik Pandit, the company’s Co-Founder and CEO, says poses a range of benefits as an alternative to traditional petroleum-based ingredients.

“If something is sourced from petroleum, there’s a carbon cost associated with it and its conversion,” he explains. “So, there’s an environmental sustainability concern related to the use of glycolic acid. People are using these products on their faces and bodies, washing it off where it then ends up in wastewater treatment facilities and back into the environment to biodegrade, releasing net CO2 into the atmosphere. When you start with a sustainable feedstock which starts as CO2 in the atmosphere and it biodegrades, it closes the cycle.

Petroleum-based ingredients can also contain traces of formaldehyde, which can be harmful to people, causing dermatitis and other allergic reactions. And, the ethical sourcing of the glycolic acid is also becoming a concern among consumers and brands. Knowing that the feedstock we use is not only good for the planet, but for the people producing it as well, is becoming increasingly important.”

How it works

To produce the Purolic Acid, the Phycus team leverages its proprietary microbe which is engineered to produce the glycolic acid. The glycolic acid is then fed a substrate that comes from certified sustainably-managed forests which then gets converted before cells are separated. At the end of the fermentation process, what’s left is a liquid that contains a crude glycolic acid. The liquid is then put through a purification process, during which impurities are removed, leaving a formaldehyde-free glycolic acid which is then concentrated to 70 per cent. At that point, the Purolic Acid is ready to be formulated by brands into every day skin care products.

Range of potential applications

Because glycolic acid is a building

block molecule, there are a whole range of additional applications for the process and chemicals that Phycus produces. In fact, according to Pandit, the possibilities for potential applications seem limited only by the ability to scale up the technology and process.

“Using this process, we could make polyglycolic acid. And, by creating a larger molecule, it could be applied to packaging. It could also be used to create solvents for more sustainable paints for the automotive industry. And, the possible use of it in adhesives is really interesting because it presents a more sustainable option than the plastic that’s currently used. However, in order to realize the true potential of our process and biochemicals that we can create, we need to expand the market for glycolic acid, and drive the cost down by expanding our manufacturing capacity beyond what we currently have. There’s a lot of potential that our platform technology presents. We’re looking forward to continue growing and helping clients increase sustainability within their own supply chains.”

For more information about Phycus Biotechnologies Inc., visit www. phycusbio.com.

30 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

APPLICATION NOTE

BIOLABMAG.COM Contact us to help you enable sales growth and enhance the customer experience. 1-800-680-3839 • info@cpdn.ca • www.cpdn.ca CPDN provides simple, consolidated, direct and economical pharmaceutical distribution • Manufacturer-led versus Wholesale • Transparent Inventory Control • Nationwide next-day Delivery • Accurate Daily Sales Reporting • First Choice by Hospitals CPDN THANKS ALL HEALTHCARE PROFESSIONALS FOR THEIR EXTRA EFFORTS DURING THE PANDEMIC

Streamlined analysis and verification

The Thermo Scientific™ TruScan™ RM Handheld Raman Analyzer makes use of laboratory-proven Raman spectroscopy to execute precise and trustworthy material identification at the point of need. This helps reduce the requirement for expensive and laborious laboratory sampling tests. The non-destructive point-and-shoot sampling principle of the portable Raman analyzer streamlines quick verification of a broad range of chemical compounds via sealed packaging such as glass containers, plastic bags, blister packs, and clear gel caps to reduce the threat of contamination and exposure. www.thermofisher.com

Enhanced production process control

Bruker’s fully automated, push-button, nuclear magnetic resonance (NMR) solution called FoodScreener performs analysis and reports based on 400 MHz. It can concurrently identify and fully quantify compounds, and requires minimal sample preparation at a lower cost for each sample. The FoodScreener serves as a reliable screening method developed for both non-targeted and targeted multi-marker analyses. It also helps in detecting unpredicted and unknown fraud. With the help of complex statistical models, tasks like production process control, origin authenticity, species purity, sample similarity, and false labeling can be tested. www.bruker.com

Transfer processing systems

The MGISTP-3000 from MGI is a benchtop automated sample transfer processing system that combines tube decapping, barcode identification, tube recapping, automated liquid transfer, and negative pressure protection capabilities. Providing a high torque decapping gripper, 23-inch touch screen, and HEPA filters, the MGISTP-3000 ensures the utmost filtration efficiency of 99.995 per cent at 0.3 µm. Moreover, it enables users to load three types of tubes in the same run. Users can transfer 96 samples from screw cap transport tubes to 96-well microplates in approximately 40 minutes. A HEPA filter purifies inflow and exhaust air to avoid aerosol pollution and ensure a secure working environment for nucleic acid extraction and laboratory technicians. en.mgi-tech.com

Incubation optimized

The Esco Isotherm world-class Refrigerated Incubator is equipped with cutting-edge technologies for optimized performance. It features ergonomic and intuitive interfaces, microprocessor PID controls with programming options, pre-heat chamber technology, a dual auto-defrosting system, UV disinfection, and a precisely tuned and tested ventilation and insulation package, all supported by Esco’s solutions-based sales and service representatives worldwide.

www.escolifesciences.com

Cryogenic freezing without the use of CFCs

PHCbi’s Cryogenic

MDF-C2156VAN-PE

Ultra Low Temperature Freezer is ideally suited for cryogenic freezing and long-term storage in laboratories without the use of harmful CFCs to achieve an ultra low temperature of -150 ºC. The Cryogenic MDF-C2156VAN-PE is a mechanical cryogenic freezer leveraging VIP PLUS technology to maximize storage capacity over conventionally insulated models. Whatever the preservation needs are, PHCbi provides the right equipment to meet exact requirements, with systems employing advanced technology to ensure a high-precision temperature environment.

www.phchd.com/eu/phceu

Sustainable sequencing systems

Illumina’s NovaSeq X and NovaSeq X Plus Sequencing Systems deliver extraordinary throughput and accuracy to perform data-intensive applications at production scale. Purposefully designed to be the most sustainable sequencing system, the NovaSeq X and NovaSeq X Plus Sequencing Systems allow users to propel their research forward to impact the world, not the environment. emea.illumina.com

LIST OF ADVERTISERS & WEBSITES

BioTalent page 2

biotalent.ca/SkilledNewcomers

Canadian Pharmaceutical Distribution Network page 31 cpdn.ca

Ag-West page 48 agwest.sk.ca

Canadian Institute of Food Science & Technology page 53 www.cifst.ca

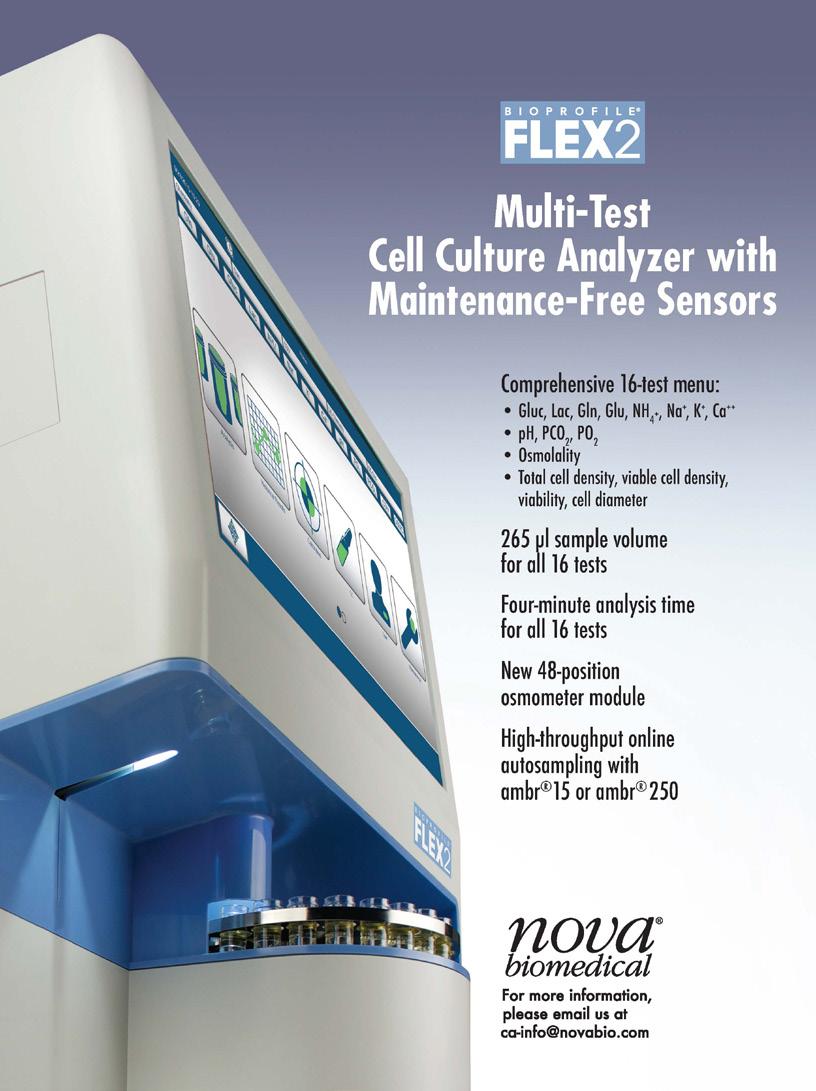

Nova Biomedical page 54 ca-info@novabio.com

LAB WARE 32 BIOLAB BUSINESS VOLUME 38, ISSUE 2 • 2023

» The science of food and beverage VOLUME 38 • ISSUE 2 • SUMMER 2023 FACILITATING CREATIVITY AND INNOVATION AT THE CANADIAN FOOD INNOVATION NETWORK Enhancing food Packaging for positive returns