LAB PROFILE

BRIL working toward a bio-renewable future

APPLICATION NOTE

New discovery identifies novel method to produce hydrogen from seawater

LAB PROFILE

BRIL working toward a bio-renewable future

APPLICATION NOTE

New discovery identifies novel method to produce hydrogen from seawater

Revolutionizing traceability with nature′s DNA

PUBLISHER & CEO Christopher J. Forbes cforbes@dvtail.com

MANAGING EDITOR Sean Tarry starry@dvtail.com

COPY EDITOR Mitchell Brown

CONTRIBUTORS Jana Manolakos Robert Price Raj Saxena David Suzuki

SENIOR Marlene Mignardi

ACCOUNT mmignardi@dvtail.com

EXECUTIVE

ART DIRECTOR Sharon MacIntosh smacintosh@dvtail.com

SECRETARY/ Susan A. Browne TREASURER

MARKETING Stephanie Wilson MANAGER swilson@dvtail.com

PRODUCTION Crystal Himes MANAGER chimes@dvtail.com

BioLab Business is published 4 times per year by Jesmar Communications Inc., 30 East Beaver Creek Rd., Suite 202, Richmond Hill, Ontario L4B 1J2

905.886.5040 Fax: 905.886.6615

www.BioLabmag.com One year subscription: Canada $35, US $35 and foreign $95. Single copies $9. Please add GST/HST where applicable. BioLab Business subscription and circulation enquiries: Garth Atkinson, biondj16@publicationpartners.com (Fax: 905.509.0735).

Subscriptions to business address only. On occasion, our list is made available to organizations whose products or services may be of interest to you. If you’d rather not receive information, write to us at the address above or call 905.509.3511.

The contents of this publication may not be reproduced either in part or in whole without the written consent of the publisher. GST Registration #R124380270.

PUBLICATIONS MAIL AGREEMENT NO. 40063567

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT.

202-30 EAST BEAVER CREEK RD RICHMOND HILL, ON L4B 1J2 email: biond@publicationpartners.com

BioLab Business is a proud member of BIOTECanada and Life Sciences Ontario

Overthe course of the past couple of years, the world has been undergoing an accelerated digitization of epic proportions, influencing behaviour and modifying environments across the globe. It’s impacted industries and sectors of business and innovation everywhere. However, the impacts of our current digitization may be most significant on the work and research being conducted by life sciences professionals.

Within this issue of BioLab Business magazine, and the ways in which digital technologies and advancements are supporting this incredibly valuable work, the positive impact that enabled discoveries have on life all over the world, and the potential these technologies and innovations pose in helping to sustain improvements happening across the entire life sciences sector.

We take a look at the groundbreaking glycomics and metagenomics research being conducted by Avivo Biomedical to support its discovery of a way by which blood types can be converted, and discuss ways in which its technology may revolutionize blood transfusion and organ transplant procedures. We also dive into the development of a structure that uses graphene oxide, presenting a potentially new and improved method for producing hydrogen from seawater.

In addition, we highlight the work being done by Index Biosystems which uses baker’s yeast as an organic carrier of information, connecting physical product to supply chain data through the use of its proprietary technology. And, the latest in bio-renewable creativity and innovation is uncovered within the Bio-Renewable Innovation Laboratory at the University of Guelph.

These are just a few of the examples of the positive ramifications resulting from technological advancement within life sciences, but do well to illustrate the range of impact that it’s currently influencing.

With an eye on the future and overcoming some of the biggest challenges that we face in ensuring sustained human advancement, the role that technology plays is critical. Connecting research and researchers, enhancing laboratories with the latest equipment and technological tools, and providing a means by which to generate and store valuable research data, technology is enabling the life-changing, awe-inspiring work happening across the country and the world. And, for the sake of humanity, long may the innovation and advancement of digital technologies continue.

Chris Forbes PUBLISHER & CEOPublisher of BioLab Business Magazine

Printed in Canada

A revolution is coming—one that will forever change the ways we treat Canada’s most pressing healthcare problems. Are you ready?

BY RAJ SAXENA, EY CANADA PARTNER, NATIONAL LIFE SCIENCES PRACTICE LEADER

Thecountry’s healthcare and biomanufacturing sectors, which have been evolving for decades, are finally gaining momentum as innovation accelerates. But to capitalize on this momentum and protect the future of the life sciences industry, these sectors need to increase their manufacturing capabilities and modernize how they serve Canadians through technology by overhauling traditional systems and optimizing business operations to deliver better outcomes and long-term growth.

Fostering innovation is key to creating and testing effective blueprints for new structures and processes by using data and technology. Bringing the life sciences industries into the digital future will require major investments, coupled with equally big changes in strategy and thinking. And this starts with keeping intellectual property and knowledge on Canadian soil to build up medical excellence.

Entrepreneurs and start-ups have the building blocks needed to spark innovation—from great research facilities to academic institutions and access to top talent. Next, we need to enable them to scale up to compete and capture global market share, helping to position Canada as a leader in the fast-growing life sciences industry.

A consistent theme that emerged during a recent EY Life Sciences webcast was how executives in the sector are grappling to scale digital designs, concepts, solutions and technologies due to lack of funding and adherence to traditional operating models and older platforms. When it comes to Canada’s response to COVID-19 and the vaccine rollout, for example, the pandemic has underscored the need to move more rapidly in developing and adapting new products and strategies.

To make this happen, supply chains need to be more secure and reliable, and Canadian product development needs to be able to pivot to respond quickly to address areas of immediate need. Increasing

investment in the growth of early-stage biotech and medtech companies, along with research and development initiatives, will not only protect Canadians but also provide economic benefits to businesses, especially in the manufacturing sector, while connecting researchers with start-up companies.

In response to the pandemic, a deep vein of virtual care arose, showing us that technologies are the bridge to building smarter health systems. Canadians learned a lot about their own healthcare system and other global systems during this time, and virtual care and telehealth offered a new way forward for clinical and operational models, leading to greater efficiency, more personalized healthcare and improved experiences.

As life sciences organizations consider their path forward, creating an effective data environment that supports a more human-centered approach will be an urgent need. To transition to a connected health ecosystem, organizations need to get the technical, operational and cultural changes right. That will enable them to capitalize on the potential of massive health data sets to drive actions and ultimately lead to improved health outcomes, better clinical outcomes, more efficient care delivery, and lower healthcare costs.

Today, data models do more than report data to providers—they are used to inform clinical decision-making, reduce unnecessary medical errors and provide care continuity across multiple care settings. At the enterprise level, intelligence functions convert data into actionable insights around population health, clinical decision support and streamlining operations for greater efficiencies.

Of course, there are still major challenges to realizing the vision of a personalized health ecosystem. But healthcare organizations that turn data actions into economic results by focusing

on creating truly patient-centred, datadriven products and offerings have the greatest opportunity to lead the transformation of health and wellness in Canada.

Healthcare organizations will achieve success when they see that the way forward is built around data, technologies and human capacities that grow the business of tomorrow, rather than just repeating today’s procurement and training cycles. To avoid ceding value in the future, health and life sciences organizations need to consider how their products and services will align with the emerging data infrastructure. This may mean identifying the right talent to work with—or being bold and making the first move to build that infrastructure.

Bringing new products to market in a digital world will require collaboration across a range of disciplines, including software and product development, branding and pricing, data engineering, scientific research, tax and legal. It will also require agile new product development through rapid prototyping, testing and refinement. Organizations that want to stay one step ahead will need to develop a workforce strategy that addresses the shifts in workforce supply and demand resulting from automation, shifting skillsets and the nature of job roles. And finally, a new mix of leadership skills will be needed to lead talent in the digital era.

Implementing future-proof infrastructure and capabilities will be critical to laying the foundations for the next generation of patient-centred products and services, and health-related start-ups. By enabling innovation, tapping into digital and increasing investment, the Canadian life sciences sector can bulldoze obstacles and reframe itself to underpin a better future.

Read more insights at www.ey.com/en_ca/life-sciences

Astrophysicist Adam Frank and colleagues say the scientific shift changed the historical observer status assigned to the scientist. He writes that we can no longer expect to know the world “in itself, outside our ways of seeing and acting on things. Experience is just as fundamental to scientific knowledge as the physical reality it reveals.”

Labatut writes, “Physics ought not to concern itself with reality, but rather with what we can say about reality.” What we say about reality is, in other words, our stories, borne from our relationships with the world(s) around us.

Quantum mechanics describes nature in a way that is different from how we usually think about science.

As Heisenberg explains, “When we speak of the science of our era, we are talking about our relationship with nature, not as objective, detached observers, but as actors in a game between man and the world.”

Almostweekly, we’re glimpsing deeper into our universe through increasingly fine-tuned telescopes and lenses. Astronomers recently released the most detailed images of the distant Orion Nebula 1,300 light years away. Earlier this past summer, they discovered 21 “white dwarf” candidate stars and the most distant galaxy ever observed.

The amount we have to learn is endless—as vast as the universe, or multiple universes, in which we and our planet spin. It’s exciting and sometimes discomfiting to realize how much we don’t yet know.

Surprisingly, when the lens is flipped to observe the underpinnings of life rather than the galaxy’s outer limits, there’s even less certainty.

In When We Cease to Understand the World, Benjamin Labatut describes how the arrival of quantum mechanics upended the linear path that, up to that point, had exponentially increased our scientific success in reducing the world to smaller and smaller known pieces.

At a conference in 1927 of the world’s greatest scientists, Labatut explains, Werner Heisenberg and Niels Bohr presented their startling vision of quantum mechanics. It describes how “an electron is not in any fixed place until it is measured; it is only in that instant that it appears. Before being measured, it has no attributes; prior to observation, it cannot even be conceived of.” Through this discovery, scientific thinkers came face to face with the limits of our capacity to fully understand life’s building blocks in concrete terms.

Heisenberg also introduced the “uncertainty principle,” which states that the position and momentum of a particle can’t both be measured with precision. The more accurately you know one value, the less accurately you know the other.

Quantum mechanics changed the trajectory of science. As Wikipedia explains, “Quantum mechanics describes nature in a way that is different from how we usually think about science. It tells us how likely to happen some things are, rather than telling us that they certainly will happen.” Although its arrival changed the reductionist nature of some scientific paths, its inherent uncertainty didn’t make it less valuable. Quantum mechanics is foundational to chemistry and cosmology.

Although we find ourselves in between two poles of uncertainty—the infinitesimally small and the infinitely grand—our (even nominal) understanding of quantum mechanics can help us gain perspective.

To start, we can embrace with humility the realization that we’re far from fully understanding, and will likely never fully understand, the mechanisms that determine nature and reality. Science is not absolute, but we can learn to thrive within this lack of certainty. It can help us to approach the world with more curiosity and wonder.

As writer Marilynne Robinson says, we should look to “sciences whose terms and methods can overturn the assumptions of the inquirers” rather than that which “simply insists on the truth value of its assumptions.”

And we can act in accordance with what we do know, such as our ever expanding appreciation of the profound interactions that make life possible—from the elaborate mycelial networks underground to the global carbon cycle, from quantum to cosmic. We continually observe our world and describe it back to each other, revising understandings over time.

Our experiences will always be a part of our “reality.” The two cannot be teased apart. And we always face uncertainty. But in the absence of certainty there lies probability, between countless series of possible outcomes. Collectively, we can change the world by striving for the best of what is possible, through our relationships with nature and each other.

Two researchers from Dalhousie University in Halifax, have won Canada’s top award for research excellence, the $100,000 Killam Prize. Françoise Baylis is a leading voice in human genome editing for reproduction, and Jeff Dahn is a major force in battery science creating urgently needed sustainable energy solutions.

As one of the world’s leading bioethicists, Françoise Baylis says that using her platform as an academic to raise awareness about injustice has been a driving force of her career.

“At one time I thought I could change the world—and then I grew up. I realized the most I could hope for is to influence people who have a whole lot more power than me. It was an important reframing of what my contribution could be—and that’s to make the powerful care,” said Baylis, who was the Canada Research Chair in Bioethics and Philosophy for 14 years.

Making people care is the mantra that she says pushes her to weigh in on some of the world’s most hotly contested issues. Most recently, it has taken her into a leading role in the debate about the ethics of using human-genome editing for reproduction.

“People seem to think that the only question is whether the science is safe and effective,” she says. “But that doesn’t answer the more important question of what kind of world we want to live in. That isn’t a question about facts; it’s a question about values.”

In 2019, she became a member of the WHO Advisory Committee on Developing Global Standards for Governance and Oversight of Human Genome Editing. Currently, she is a member of the planning committee for the Third International Summit on Human Genome Editing scheduled for 2023. In 2020, she won the PROSE Award in Clinical Medicine for her book Altered Inheritance: CRISPR and the Ethics of Human Genome Editing It’s one of 18 other books, 100 peerreviewed articles and more than 40 expert testimony appearances and briefs for the Canadian federal government. She is a member of both the Order of Canada and the Order of Nova Scotia, and a Fellow of both the Royal Society of Canada and the Canadian Academy of Health Sciences. In 2017, she was awarded the Canadian Bioethics Society Lifetime Achievement Award, and in 2021 she was elected to the Governing Board of the International Science Council.

Building a bigger, better battery has driven Jeff Dahn’s research for the last 40 years. A global expert in lithium-ion batteries, Dahn’s pioneering research has driven innovation in the field and helped create the science necessary for lithium-ion batteries to become a preferred power source for such things as portable electronic devices and electric vehicles. Now, he is focused on building the technology to make the batteries last even longer, possibly even

In 2019, Dahn was awarded the Royal Society of Canada’s prestigious Henry Marshall Tory Medal for outstanding research. And in 2020, he was named an Officer of the Order of Canada.

Two spinoff companies have come out of his Dalhousie lab: DPM Solutions, a supplier of custom-designed machine solutions, and Novonix, a battery and technology company that brings better battery technology to market rapidly. It produces and sells high-precision battery test equipment and synthetic graphite for use in lithium-ion batteries. Dahn says he will use his Killam Prize to support the Jeff Dahn Bursary in Physics, and to aid a new start-up from his lab, Zen Electric Bikes.

Photo credit: Nick Pearce

for decades.

“Over the years, we have made many useful contributions in all areas of lithium-ion battery technology, ranging from faster charge, higher energy density, improved safety and most recently, longer lifetime,” said Dahn, referencing the work of his lab at Dalhousie. “Positive electrode materials that were actually invented in the labs of Dalhousie are used in some lithium-ion batteries today.”

Dahn’s work has covered fundamental physics in insertion compounds, as well as technical engineering issues in batteries.

“The lithium-ion battery is a multidisciplinary puzzle,” he explains. “There is lots of great science to do with a huge payback to society. I have been in the game since the beginning and have witnessed lithium-ion batteries take over and dominate so many different markets.”

Dahn has co-authored over 750 refereed journal papers and has coinvented 73 inventions with patents issued or filed. He is a winner of both research and technology awards of the Battery Division of the Electrochemical Society. In 2017, he received the Natural Sciences and Engineering Research Council’s Herzberg Canada Gold Medal—Canada’s top science prize.

Scientists at Simon Fraser University have developed a new science-based indicator that measures oceanic biodiversity to help with marine management. While loss of species, ecosystems and genetic diversity on land is documented, the extent to which these patterns appear in the oceans is not yet known. The researchers examined seven decades of records on the extinction risk of predatory fishes including 52 populations of 18 different species of tuna, billfish and sharks. They found that since the 1950s the global extinction risk of oceanic predatory fishes, particularly sharks, has continuously worsened due to excessive fishing pressure until the late 2000s.

The Canadian Alliance for Skills and Training in Life Sciences has officially opened their new biomanufacturing training facility in Charlottetown. Equipped with laboratories and classrooms, the new centre contains state-of-the-art pilot-scale bioprocessing equipment that will allow employees to gain practical skills that are immediately transferable to process, scale-up and clean room environments.

A new collaborative research centre of excellence will develop ultra-precise measuring devices that could enable game-changing science, such as better medical screening technologies and carbon emissions monitoring. RMIT University in Melbourne, Australia, will lead a consortium of universities and industry partners in the new $72 million ARC Centre of Excellence in Optical Microcombs for Breakthrough Science (COMBS).

The consortium will focus on bringing optical frequency comb technology—which translates electronic signals into light waves for high-precision measurement—out of the lab and into a wide range of real-world applications.

Centre Director and RMIT Distinguished Professor, Arnan Mitchell says it's a major milestone in the growing momentum of optical frequency comb technology: “A photonic chip industry has finally emerged and the unique technology it produces will transform many fields of science.”

The multi-disciplinary COMBS team includes worldleading experts from eight Australian universities (Australian National University, Monash, Swinburne, University of Technology Sydney, University of South Australia, Adelaide and Sydney) and 23 global partner organizations including The Garvan Institute, Advanced Navigation and the National Measurement Institute.

Investment in the centre will support the development of a diverse researcher workforce engaging collaboratively across fundamental science and technology, enabling advances in multiple application areas.

“The power of real-time information delivered by microcomb technologies is truly transformative. Microcombs will transform the way we measure everything around us, and in doing so change how we communicate, travel and live our lives,” said RMIT Deputy Vice-Chancellor Research and Innovation and Vice-President, Professor Calum Drummond.

Researchers from the British universities of York and Warwick have captured video evidence of a wild chimpanzee showing an object to its mother simply for sharing’s sake—social behaviour previously thought to be unique to humans. They examined more than 80 similar leaf-grooming events in order to rule out alternative explanations for the behaviour, including food sharing and initiating grooming or playing. Researchers suggest that the discovery could have implications concerning our understanding of the evolution of human social cognition and what makes human minds unique. Next, they will conduct further research on communities of chimpanzees to see if they can observe other chimps engaging in this showing and sharing behaviour.

MIT engineers have unveiled new stamp-sized ultrasound adhesives that produce clear images of a patient’s heart, lungs, and other internal organs. With the potential to eliminate the cumbersome wands and probes currently in use by trained technicians, the new technology might make getting an ultrasound as simple as buying a band-aid at your local pharmacy. If the devices can be made to operate wirelessly—a goal the team is currently working toward—the ultrasound stickers could be made into wearable imaging products that patients could take home from a doctor’s office. The researchers applied the stickers to volunteers and showed that the devices produced live, high-resolution images of major blood vessels and deeper organs such as the heart, lungs, and stomach, for 48 hours, even while volunteers were active.

University of Oregon scientists have shown that microorganisms are essential for normal social behaviours in zebrafish because they influence brain development. The transparent skin of zebrafish larvae offered the scientists a rare window into their neural development. It enabled them to investigate the larvae, reared with or without the presence of their normal microbiota, for the first seven days of development. According to the study published in the open access journal PLOS Biology, they found that larvae without their microbiota had fewer immune cells in their forebrains and denser, more complex neural branching patterns, which affected their neural and social development.

Enzyme-based technology changing the medical world, one blood type at a time

BY SEAN TARRY

BY SEAN TARRY

Whenit comes to breakthroughs and innovations that present the potential to completely transform the way healthcare professionals work and administer their services, there are few companies that can boast more significantly than Avivo Biomedical. The B.C.-based preclinical stage company is currently revolutionizing blood transfusion and organ transplant practices through the development of its uniquely innovative technology that enables the conversion of blood types, creating universal donors. According to John Coleman, the company’s President and CEO, it’s technology that is not only set to transform healthcare, but is set to transform lives as well.

“Blood transfusions and organ transplants are often lifesaving procedures,” he said. “And anyone who receives this type of care have their lives transformed as well, especially for people who are on chronic dialysis for kidney failure. Many people essentially end up getting their lives back. We believe that by making sure that there are more O [blood type] organs available increases their usability given the fact they are universal type organs. Currently, there are an inordinate amount of organs that are not utilized to their full potential because they are the wrong blood type for transplant. In fact, because of this, many of them aren’t even harvested. Our technology alleviates this issue and enables the transplant of more life-saving and transforming organs.”

Advanced research

Avivo’s technology, which can convert whole human blood and organs from Type A to Type O, represents a massive breakthrough and the emergence of a number of different opportunities when considering the ways in which it can help the purveyors of healthcare all over the world. And, as Coleman explains, it’s technology that was borne from the years of research that’s come before it. It had been observed by Dr. Peter Rahfeld, Professor Stephen G. Withers and Professor Jayachandran Kizzhakedathu of the Michael Smith Laboratories at the University of British

Columbiathat Type A patients who had sepsis would display what’s called acquired B syndrome, which simply means that their blood type seemed to somehow be changing as a result of the sepsis.

“It led many to believe that if this was the case, then there must be some enzymes in the human microbiome that are leaking into the gut and causing this transformation,” he says. “So, researchers went looking for the enzymes, and through a glycomic and metagenomic approach, they were able to identify an enzyme pair that’s able to selectively cleave the terminal sugar off of the A antigen and convert it into an H antigen which represents the O type of blood.”

As Coleman points out, a substantial proportion of organs are not utilized because there is a mismatch concerning the blood types between organ and recipient. It represents another bottleneck in the process that he suggests is eliminated

through the development and leveraging of Avivo Biomedical’s technology and platform.

“Our technology addresses the issues related to incompatible transplantation, transplants across the blood barrier, enabling and facilitating the transplant of deceased donor organs,” he says. “Currently, these types of transplants are really only performed using living donor organs in which patients are pretreated for several weeks to desensitize them in order to get them ready for the transplant. With our technology, we’re essentially converting and desensitizing the organ to allow it to go into the patient, signifying a real step change in how organ transplants occur going forward.”

It’s remarkable work that the company has done to this point, building off of years of scientific research and discovery, to stand on the medical precipice of progress when it comes to the advancement and enhancement of organ donation procedures. Its impact seems just as significant when considering the ways in which it can help change the availability of blood for transfusions.

“We see pieces of news every day related to shortages of blood everywhere,” Coleman says. “It’s a chronic problem. And although we’re not able to create more blood with our technology, we’re able to convert A type blood—the second most abundant blood type—to O type blood, which is the blood type that is most chronically in short supply in relation to the number of people in need of it.”

Coleman explains that the company is currently undertaking a series A financing, going out to the market actively looking for investments into the technology. He says that they are generating a considerable amount of interest from a number of different parties. In fact, John Barclay, Avivo Biomedical’s CoFounder and Vice-President of Business Development, suggests that interest is coming from a range of different groups, highlighting the significance and importance of the work that the company has been to this point.

“Our technology’s being greeted with enthusiasm by the transplant community, as well as surgeons and physicians of a number of different stripes,” he says. “They’re obviously really interested in the ways our technology can help support and improve what they do. There are also a number of potential corporate partners who are excited by what we’re doing, in addition to patient advocacy groups, like the National Kidney Foundation in the U.S., who are also keenly interested in the potential our technology promises.”

In order to arrive at discoveries and medical breakthroughs of this magnitude, Coleman says that, in addition to incredible human brainpower, technology and its evolution is critical. He says that the ways in which technological advancement has helped to support the company’s tremendous research, trial and study is incalculable. And, he suggests that the capabilities presented by technology are showing up even faster as we move further into the future.

“Going back to the work that researchers had done around the metagenomic analysis of the microbiome, there are millions, if not billions, of different bacteria in the gut microflora,” he says. “They were able to use these incredibly sophisticated genomic technologies in order to tease that apart and identify the specific bacteria that are producing these enzymes. And then, once they were identified, they were able to get the DNA from those enzymes, get them into a production system and transposed into E. coli. These are technologies and resulting abilities that a decade ago would have been unthinkable. But today it’s almost becoming routine. The genesis of our company is really based on these technologies and those who have come before, pushing them forward.”

Given the fact that the company is still at the preclinical stage of development of its technology, there is still some work to do in order for Avivo Biomedical to realize the full potential of its breakthrough and the meaningful ways in which it can help to transform blood transfusion and organ transplant procedures. However, as Coleman points out, it seems to be on the verge, with plans to be in human clinical trials soon, followed of course by the technology’s resulting revolution.

“Within the next three years, we should be in the position in which we’ve completed in human clinical trial organ transplants. We’re working diligently right now to raise the capital that will allow us to manufacture the enzymes needed to complete our preclinical requirements to enter the clinic. So, we’re really approaching the proof-of-concept phase of development when it comes to organ transplants. And, on the blood side, we continue to work with our academic founders to continue moving this project along in order to prepare it for future studies and use. We’re all extremely excited to be in this position, and are really looking forward to experiencing the ways in which our work helps to positively change the way organ transplants and blood transfusions are administered going forward, resulting in tremendous outcomes for patients and their healthcare practitioners all over the world.”

Avivo’s technology, which can convert whole human blood and organs from Type A to Type O, represents a massive breakthrough

In Prince Edward Island, researchers are using machine learning and advanced sensor technologies to improve crop productivity and reduce agricultural waste—all with the goal of helping farmers and fighting climate change

BY ROBERT PRICE

BY ROBERT PRICE

Asthe cost of fertilizer skyrockets and warnings of drought and famine continue to sound, the agricultural industry looks for new ways to squeeze greater productivity from fewer inputs, all while minimizing agriculture’s drag on the environment.

It seems like an impossible task, but farmers and agricultural engineers are finding new uses for off-theshelf technologies and deploying custom technologies and machine learning to optimize the farmer’s shrinking resources, reduce waste and chemical pollution caused through farming, and maximize crop yields in creative ways.

One of the people connecting technology to agriculture is Dr. Farooque, an Associate Professor and Associate Dean of the School of Climate Change and Adaptation at the University of Prince Edward Island.

Raised on a farm in Pakistan, Farooque watched his father farm three crops a year of beet, sugarcane, rice, soybean, and the occasional quick corn. It was his experience on the farm that sparked an interest in technological interventions into agriculture.

He completed an MSc and PhD at Dalhousie before joining UPEI in 2015. His graduate research focused on blueberries. When he settled in P.E.I., he switched to studying potatoes.

“That was a natural fit,” he says.

Today, the agricultural engineer receives significant funding from provincial and federal sources to develop, test, and evaluate technologies to help farmers deal with variability in crop characteristics, soil, yield, weather, geography, topography, and more.

It’s work that he says helps farmers “to optimize operations, to be efficient, and to develop the new operations and systems which save the inputs and resources and, at the same time, protect the environment.”

Farooque accomplishes this work by networking a range of technologies to show farmers what’s happening under the farm’s surface. Many of these technologies, like drones, are off-the-shelf tech.

Farooque uses drones to take images that capture the crop growth parameters. These images show erosion paths and potential paths that snow meltoff might take in the spring. After the spring, researchers can collect soil samples from those areas and see how much of the topsoil was lost. That information feeds into the prediction models to help farmers know where and how to seed fields. The drones also image the crops to investigate its overall health. Is the crop green enough, is it yellow, is it water stressed?

Ultrasonic sensors deliver researchers another important data point. When mounted on a harvester boom or on a sprayer boom, ultrasonic sensors allow researchers to map the height of plants. As the height of the plant varies, so does the root zone. If the fruit is on the top 10 cm of the plant, as it is with blueberries, farmers will need to adjust the harvester to avoid causing damage to the plant. These sensors automate a precision operation, complementing various others sensors and technologies that measure soil quality. Soil moisture sensors, for example, record the soil moisture continuously. If a farm goes seven days without rain, what is the moisture level? How will the moisture levels impact plant growth? Together, these sensors deliver granular detail that allow farmers to fine-tune adjustments to their operations.

Yet another complementary technology is the yield monitor. Yield monitors measure the yield of a crop and geo-reference it to produce a map showing the high-performing areas of the acreage. The farmers and researchers can then focus on the low-yield areas and find ways to improve the yield, and with greater precision than simply eyeballing a field and listening to intuition—which is important to newer farmers who may not have developed an eye and don’t trust their intuitions.

Farooque uses drones to take images |that capture the crop growth parameters. The drones also image the crops to investigate its overall health. Is the crop green enough, is it yellow, is it water stressed?

Farooque and his team are developing prototype technologies to help farmers understand their land better. One of these prototypes is a machine vision product. This machine surveys crops and uses machine learning to characterize individual plants to determine whether it is weed, a diseased plant, or a healthy plant. When the machine identifies a weed, a message is sent to the solenoid valves that then open and spray herbicide on the targeted weed. If the machine identifies fungus, the sprayer shoots a fungicide on the offending mushroom.

The machine integrates with the deep learning and artificial intelligence programs Farooque has been developing. Each decision the machine makes adds to the machine’s experience.

“The systems not only measure, but they also act on decisions in the real time,” says Farooque.

Off-the-shelf technology needs tweaking for Canadian topographies, and that’s what Farooque does. Conductivitybased sensors scan fields to measure the depth and strength of a soil. These work fine in Europe. But in P.E.I., where farmers deal with a different climate and topographies—P.E.I. potato farms are not flat—the sensors do not work easily, and so they are underused.

Over the past several years, Farooque has tested conductivity in the slopes in P.E.I., characterized and quantified the measurements, and evaluated the environmental benefit and crop productivity. Now there is significant acreage throughout the province that’s currently mapped with that technology.

“The technology was already commercially available, it just needed a bit of a tweak to make it work for us,” says Farooque.

Combined, these technologies optimize resources, especially when it comes to fertilizers. Take the resource optimization available through variable rate seeding as an example. P.E.I. has an uneven surface, with hilltops and depressions that cause topsoil erosion. By gathering so much detail about individual portions of the acreage, farmers can seed differently. Rather than seeding uniformly across the field, they can space out seeds in areas where topsoil is thin and allow a smaller number of plants to thrive and produce more. They can ration fertilizer according to soil and crop needs, rather than blanketing the field with fertilizer, which in some areas of the field might be too much and in other areas too little. This informed change to seeding saves on seeds and it also reduces emissions. If you put less nitrogen into the field because you’ve planted fewer seeds, there will be fewer emissions, less phosphorus runoff in the water, and fewer fungicides and pesticides sprayed into the air.

“Yes, it’s going to cost you more labour, but at the end of the day, if it is profitable, and covers that expense for itself, and it’s good for your crop, it’s where you want to go,” says Farooque.

The adaptability of many of these technologies remains an issue. Like the adoption of any new technology, it will take time before adoption is widespread, unless or until academics like Farooque evaluate the technology and show the operational and financial benefits of investing in advancements.

And that’s one of the personal strengths people with farming backgrounds like Farooque brings to the ag-tech sector. Farmers are practical, by necessity.

“Farmers like to see the numbers,” says Farooque. “Seeing is believing. Once you can prove to them that this is going to be profitable for them, then they will jump on it.”

PITTCON IS A CATALYST OF SCIENTIFIC ADVANCEMENT for you, your research, your career, your organization, and together, our world. Our aim is to provide you with unparalleled access to the latest advances in laboratory science, to the instrumentation enhancing your work, and to an international assembly of scientists experimenting, discovering, and innovating throughout the foremost areas of focus.

Philadelphia, PA, USA | March 18-22, 2023

LEADING IN THE LAB STARTS AT PITTCON.ORGIn the ongoing fight against the disruptive virus, a breakthrough has been made through study and research

BY SEAN TARRY

BY SEAN TARRY

Aswe enter into year three of the COVID-19 pandemic era—a frame of time that has restricted social activities and blighted economic progress in communities all across the globe—studies being conducted with the help of the Canadian Light Source at the University of Saskatchewan are enabling scientists to make meaningful breakthroughs.

Molecular biologist; Mark Paetzel, who conducts his research at Simon Fraser University, along with University of British Columbia structural biologist Natalie Strynadka, and colleagues Jaeyong Lee, Calem Kenward and Liam Worrall, have recently been studying a significant protein and its underlying structure and characteristics in order to determine the reasons that makes it such an attractive target for antiviral drugs.

Like many RNA viruses, explains Paetzel, SARS-CoV-2 synthesizes a significant number of its proteins as one long polypeptide chain called a polyprotein. A critical step in the virus’s replication and assembly is the dicing of this polyprotein into the individual functional viral proteins. SARS-CoV-2 uses a protease called main protease (M Pro ) to essentially cut itself out of the polyprotein and to cut at nine other positions along the polyprotein. The intramolecular self-cleavage reaction of M Pro results in the protease having the specificity residues required for its self-cleavage at its own carboxy-terminus. He says that the work he and the team have conducted have revealed a number of important insights.

“Previously, we captured crystal structures of M Pro bound to the carboxy-terminus of neighbouring molecules within the crystal due to the high local effective concentration within the crystal,” he says. “This provided insights into how Mpro recognizes its own C-terminus and how it can chop its way out of the polyprotein by recognizing its carboxyterminal tail. In our latest work, we have used site-directed mutagenesis to change the Mpro carboxy-terminal tail to each of the polyprotein cut-site sequences. We have managed the capture of these cut-sites bound within the active site of Mpro. These structures have revealed how the Mpro active site structurally adapts to each polyprotein cleavage site.”

In addition, Paetzel says that through the work and research conducted, he and his colleagues learned that the protein in question is remarkably adaptable, highlighted most significantly by the way in which it binds other target proteins inside of a pocket that opens and closes like a trap of sorts, enabling it to accommodate the wide variety of differently shaped proteins it has to bind with and cut. Through this discovery, it was revealed that by blocking the protein, the virus’ ability to replicate is disabled.

As Paetzel points out, the work and study that’s been conducted thus far has yielded a number of revelations concerning the protein that has resulted in an enhanced understanding of its behaviour.

And, it’s an enhanced understanding that the molecular biologist believes will benefit COVID-19 drug treatments and their effectiveness going forward, allowing drug developers to design new treatments that can take advantage of the protein’s flexibility.

“Mpro is an important target for antiviral drugs,” he asserts. “By having more structural information on how Mpro recognizes all its polyprotein cut sites, medical chemists can design drugs that bind with greater specificity and affinity, and this may lead to a more effective drug with fewer side effects and drug resistance. Knowing all the different ways that the enzyme active site interacts with its cleavage sites will provide valuable insights for drug design.”

It’s important to note that the discovery made by Paetzel and his colleagues not only poses the potential to improve drug treatments related to the COVID-19 virus, but can be applicable to a number of other viruses as well. It’s a breakthrough that he acknowledges is a profound one, perhaps benefitting drug researchers and manufacturers, as well as healthcare workers, for some time to come.

“This in crystallo high-local effective concentration strategy for producing structures of viral protease complexes with their cleavage sites is applicable to any virus that produces its gene products as a polyprotein,” he explains.

In order to execute the work and study that enabled this breakthrough, Paetzel and his colleagues leveraged the powerful X-rays of the CMCF-BM beamline at the Canadian Light Source at the University of Saskatchewan. Paetzel describes the technologies available at the facility as “vital” toward achieving the study’s results and in gaining their enhanced understanding of the protein and its behaviour. Most significantly, he explains, it enabled the research team to conduct the screening of the more than 500 protein crystals that was required in order to find the ones they were looking for.

“Access to the CMCF-BM beamline at CLS was critical to the success of this project,” he says. “We had to screen many crystals to find those that had the cleavage-site bound within the active-site. The intensity and resolution of the X-rays and the speed of the data collection available at CLS made this project possible, enabling us to more efficiently analyze the many crystals needed to capture these complexes.”

Inthe search to discover or develop anything new, pioneers are often required—people who will turn over new stones, ask the unasked questions and venture into the unknown. One of the pioneers within the Canadian bio-renewable space is Dr. Animesh Dutta, current Director of the Bio-Renewable Innovation Lab (BRIL), a multidisciplinary research facility with the School of Engineering at the University of Guelph. Founded in 2014, the laboratory conducts the majority of its research on valorization of various organic wastes to promote sustainability through the concept of the circular economy. The lab has already been recognized through its development of thermochemical conversions of macromolecules present in organic waste resources to energy and value-added materials. And, by virtue of its focus on leveraging a range of clean and sustainable-renewable energy technologies, it aims to develop a wide variety of bioproducts, including biochemicals, bio-carbon (which poses the potential to be a replacement for coal) bio-oil (which could present as a substitute for petroleum) and

syngas, from bioresources through green thermo-chemical and bio-chemical processes.

Dutta explains that the entire goal of the laboratory and everyone who conducts work and research within it is to help reduce the negative impact that energy consumption has on the planet through the development of more environmentally friendly processes while also allowing for the generation of revenue for the farmer, processor, or anyone else.

“We conduct all of our research and work with an advanced biorefinery approach,” he says. “It’s unique in that it allows us to target the recovery of value from every co-product of biomass conversion, supporting our efforts to sustainable solutions for a more sustainable tomorrow. To do this, to achieve the goal of greater, long-term sustainability and a cleaner, healthier planet, the development of innovative technological solutions is required and a determination to develop cleaner sources of energy.”

We conduct all of our research and work with an advanced biorefinery approach,” he says. “It’s unique in that it allows us to target the recovery of value from every co-product of biomass conversion, supporting our efforts to sustainable solutions for a more sustainable tomorrow.

To do this, to achieve the goal of greater, longterm sustainability and a cleaner, healthier planet, the development of innovative technological solutions is required and a determination to develop cleaner sources of energy.

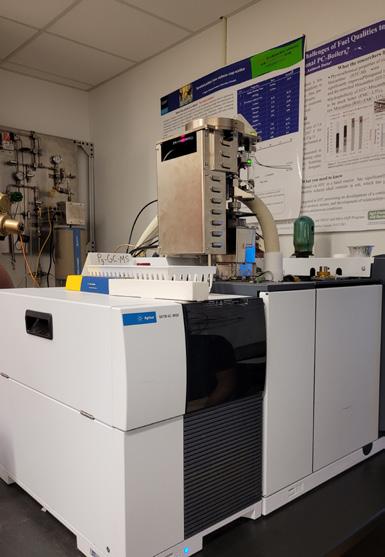

The laboratory boasts a number of different facilities that support the work and research conducted at BRIL, including those for sample storage, dry storage, desiccation, refrigerated storage, frozen samples, sample processing preparation, bench top characterization, spectroscopy, chromatography, and integrated process and analytical systems. It’s a robust environment that houses a treasure trove of technologies and equipment as well, including a mass spectrometer for gas chromatography, a total organic carbon analyzer, an ultraviolet visible spectrometer, an atomic force microscope, a hydrothermal reactor, a hydrothermal continuous reactor, a CHNS-O analyzer, as well as a host of other cutting-edge tools.

Since founding the laboratory nearly 10 years ago, Dutta has managed to secure nearly 30 different rounds of funding to support the work that he and his colleagues are conducting, including funds received from NSERC Discovery, NSERC Engage, the Government of Ontario’s Ministry of Research and Innovation, the Government of Canada Foundation for Innovation, the Ministry of Environment and Climate Change, Biomass Canada, and Agriculture and Agri-Food Canada, to name a few. It’s funding that Dutta recognizes as crucial in helping the laboratory function as it does, adding that it’s reflective of the importance of the objectives that it’s attempting to achieve.

“We’ve certainly received quite a bit of generous funding for the work that we do,” he admits. “But it definitely speaks to the critical need for the energy solutions that we’re trying to develop. And, the fact that it’s arrived from so many sources, including government agencies and scientific councils, all in an effort to support the search for cleaner sources of energy, is evidence concerning the level of importance of this type of work and research. The planet is in need of solutions to help reduce carbon emissions and create a healthier planet. It’s a mandate at the provincial and federal levels, as well as being a global issue. Everyone is striving to make these improvements, and the laboratory is seen as a key contributor in the search for cleaner fuels.”

When discussing his laboratory, Dutta is excited, speaking with passion concerning the endless possibilities that his research helps to unravel, and the opportunities it uncovers. He beams with pride when citing some of the exciting projects that he and his colleagues are currently working on, and those that are still being conceptualized. However, when looking ahead, the University of Guelph Director shares that he has even bigger plans for BRIL, with a focus on expanding the laboratory and its function further to include a showroom of sorts where the innovative, state-of-the-art technologies, techniques and processes that have been developed can be

marketed, if you will—an approach that Dutta says will add a significantly important layer to his already impressive set-up.

“My hope for the work that we continue to do is to enable it even further by developing a pilot or demonstration facility. Bringing this kind of laboratory work through to application in the way of a demonstration phase will allow people to actually see the technology and techniques in action and really start to believe in it. It’s a very powerful form of experience-based learning that can’t help but resonate with people. I’m hoping for this to happen within the next three to five years in order to showcase and highlight all of the amazing things that we’re doing to industries to entice them to begin leveraging the solutions that we’re providing. In the end, however, it’s about creating a better tomorrow through a circular economy approach and the right innovations and technological solutions in order to arrive at long-term sustainability for the planet. And I want to make sure that the laboratory continues to meet this mandate for many more years to come.”

Innovative identifying tagging technology allows producers and manufacturers to securely link product to its supply chain data

BY SEAN TARRYTherehave been some obvious and high-profile disruptions and disturbances to the global supply chain of late. Impacts caused by the COVID-19 pandemic, which resulted in port closures and congestion, lost containers of inventory and product, and shortages of supply all over the world, crippled supply chains everywhere, leading to intense discussions concerning the ways in which product should be moved around the globe. It also exposed many companies whose insights into their supply chains are significantly wanting, leaving them unable to properly track and trace their product or validate the authenticity of it or its guarantees. It’s a problem that poses producers and manufacturers with a potential loss of credibility and a general lack of control over their supply. And it’s one that BioTag—a unique traceability technology that leverages nature’s DNA to tag product—promises to quell.

Developed by Burlington, ON-based Index Biosystems, the revolutionary technology replaces older, traditional traceability technologies that rely on packaging, leveraging microscopic fingerprints made from baker’s yeast that can be applied to just about any type of product. It’s a way by which the company has managed to securely connect the digital and physical worlds, enabling the identification and authentication of products and eliminating many of the challenges currently inherent within contemporary supply chains. And, according to David Singer, Co-Founder and VP of Sales the benefits of the technology and flexibility of its use are immense.

“Essentially, what we’re doing is creating barcodes out of baker’s yeast,” he explains. “Through a process that we refer to as inert bioengineering, we produce a unique identifying sequence of DNA to standard baker’s yeast in a way that ensures that we’re not introducing any traits or affecting the inheritable traits of the yeast itself. It’s bioengineering without any gene modification. And there is no limit to the number of unique identifiers that we can create. And because we’re using yeast as a carrier for the DNA signature, we can grow it like any other yeast product, so it’s immensely scalable. It allows us to apply a signature to products that we normally wouldn’t be able to, such as grains and romaine lettuce, to on dosage for pharmaceuticals and animal feed products. In addition, it’s incredibly versatile and allows us to trace product within supply chains, end-to-end, working independent of packaging.”

In addition, Singer goes on to explain that the tags also work independently of product aggregation as well, meaning that individual heads or leaves of lettuce, for instance, can be traced back to the field in which they were grown in order to identify whether they have been contaminated or sullied in any other way. And, this same benefit extends beyond identification to authenticate the safety of food. It can also be used to validate a brand’s sustainable claims and efforts.

“If a producer is employing certain sustainability practices on their farm and customers at the end of the supply chain want proof as to the sustainability of the product that they’re purchasing and consuming, our BioTag will allow for the labelling of grains on farm, follow them through the aggregation of an elevator, through to a mill and still be recoverable in the flour product that’s received by a company,” he says. “In this way, our technology enables brands to validate and measure the carbon footprint of their product without relying on assumptions or having to fully and completely segregate their supply chains.”

In fact, Singer points out that Index Biosystems, by its very nature, helps producers and manufacturers solve for three of the biggest challenges that they collectively face. It’s estimated that the value of the global grey market—the market in which fraudulent and counterfeit goods are bought and sold—is in excess of $1.5 trillion, with the transfer of counterfeit product amassing $500 billion in sales. And, the total annual cost of food fraud—food sold under misleading or false certifications or claims—is $40 billion, with 600 million people falling ill every year as a result of contaminated food. They are areas of the business and supply chain process that Singer says Index Biosystems specializes in helping producers and manufacturers modernize and optimize.

“They are definitely the three pillars that we focus on, and the areas where we think our technology presents the most benefits to the end user,” he says. “Our technology helps brands fend off the threat of counterfeiting, detecting fraudulent or counterfeit products and unauthorized sales. As mentioned, it also allows brands to verify the ethical and sustainable sourcing of their products and ingredients, and mitigates risks associated with health and safety as it relates to food.”

The number of products, industries and verticals that could benefit from Index Biosystem’s technology is extensive, including agrochemicals, animal feed, cannabis, commodities, energy, food, pharmaceuticals, seed, testing and certification, textiles, wine and spirit, and more. Singer goes on to explain that the innovation was borne out of a need to fill very distinct holes within blockchain in order to begin harnessing its full potential, presenting Index Biosystems with the opportunity to develop a means by which it could connect physical products with the digital world by

imbedding data related to those products, linking it all to their supply chains.

“The ‘aha’ moment was when we started to consider whether or not we could use biology to imbed data onto a product in order to meaningfully connect it to supply chain data,” he says. “That was the start of the ideation phase and we’ve essentially been experiencing positive momentum since then.”

The direct result of Index Biosystems’ inert bioengineering approach—part of its proprietary process—each BioTag is made to be uniquely identifiable, much like a microscopic fingerprint. And, the process, from development of the BioTag through to use by producer or manufacturer, is straightforward and involves the following steps once it’s been created:

QUALITY CONTROL The successful creation of each BioTag is confirmed using standard molecular techniques. This quality control step is an added assurance that no genes have been modified, inserted or deleted through its inert bioengineering process, and ensures the safety of each uniquely identifiable BioTag.

REGISTER Once the safety of each BioTag sequence has been confirmed, it is added to Index Biosystems’ customer portal, Trailhead. This serves as the interface between a physical product that has been tagged, and its digital supply chain. Trailhead can be easily integrated with existing traceability software through a simple API to keep all product information in one place.

GROW AND INACTIVATE At this point, BioTags are ready for production. Standard yeast manufacturing allows for reliable BioTag production at a large scale. Each batch is killed to ensure inactivation prior to any commercial application, with the yeast cell providing a natural barrier that protects the identifying sequence inside. The powdered BioTags are now ready for shipment.

APPLY Unique BioTags can be applied directly to any product at any point or multiple points along the supply chain. They can be mixed with ingredients, sprayed onto products, or integrated directly into existing manufacturing processes. Only trace amounts of BioTag are required for reliable detection, so there is no impact to the taste, colour, or odour of products they are applied to.

DETECT BioTag sequences can be detected onsite, or samples can be sent to Index or a third-party lab for authentication. Standard molecular techniques including PCR are used to detect BioTag sequences, with reliable detection significantly below parts-per-million. Sequence information can be cross-referenced with Trailhead for integrated verification at any point in the supply chain.

The technology, in combination with Index Biosystems’ digital registry, is a complement to any contemporary supply chain, enhancing and elevating a number of different aspects across a brand’s operation. It increases dependability and, according to Singer, helps to propel many brands and their producer and manufacturer partners into the digital age.

“This is absolutely the most cutting-edge innovation and solution out there when it comes to supporting supply chain efficiency and transparency,” he says. “It’s also a way by which many brands, despite the product that they offer, can thrust themselves into a new way of doing things, digitizing their businesses and differentiating themselves from their competitors. In securing reliability and predictiveness for the brand, it also validates and authenticates everything that the end user wants validated and authenticated, often resulting in greater trust and loyalty from consumers who are increasingly looking for increased transparency into the origin and life of their products.”

In addition to the benefits received by the consumer in the way of authentication, and by the brand in the way of a clearer view into their supply chains, there are a number of other benefits to using BioTags.

SAFE Yeast is a commonly used ingredient within food and agricultural products, with a long history of safe use. Index’s proprietary design process ensures each BioTag is characteristically and nutritionally identical to standard baker’s yeast, and is inactivated to ensure the final product is incapable of any further growth. BioTags are edible and have been FDA approved for use in food.

SCALABLE Using nature’s code, DNA, allows for an unlimited number of unique BioTag sequences to be created. BioTags also benefit from the established global manufacturing processes that have been developed for yeast over several decades, which allows for the reliable production of BioTags at any scale.

SECURE The Trailhead digital registry provides a secure digital environment for sequence storage and reference, and is related to manufacturing and intended use information. Using a simple API, Trailhead can be securely integrated with existing traceability software.

CUSTOM BioTags can be added, mixed, sprayed or affixed in trace amounts to any product, allowing for seamless integration into existing production pipelines. By adding unique BioTags at multiple nodes along a supply chain, the chain of custody can be verified throughout a product’s journey. BioTags are customizable to match the strategic needs and operational realities of almost any supply chain use case.

DURABLE Using yeast provides incredible scalability to production and enables a natural durability to each BioTag, allowing for protection of the unique identifying sequence within. This durability has been proven along harsh supply chains, and allows for reliable detection and product authentication.

With respect to current operations, Singer says that Index Biosystems is gaining a lot of traction and interest around its innovative BioTag solution, adding that its researchers and engineers are constantly working toward improving the product. And, he says, it’s all done with the end user in mind.

“We’re aware of the challenges that exist within today’s supply chain, and we also recognize the challenges that are inherent in securing and protecting the authenticity of product. Our BioTags offer users the broadest applications and simplest form of identification currently available, posing the potential to boost any supply chain operation and the credibility of the brands that use them.”

The technology, in combination with Index Biosystems’ digital registry, is a complement to any contemporary supply chain, enhancing and elevating a number of different aspects across a brand’s operation.

Thedrain of using non-renewable energy sources like oil, coal and gas to power communities all over the world has clearly taken its toll on our planet and its environment. In search of alternate, renewable sources of energy, some have hypothesized that hydrogen could present a significant portion of the answer to the planet’s energy conundrum, given the fact that it can be produced from water. But its potential has been muted to date, limited by the current methods used to do so which are costly and inefficient. However, just recently, Marta Cerutti, Professor and Co-Director of the Institute for Advanced Materials at McGill University, uncovered a way by which the process could be made substantially more efficient.

New discovery identifies novel method to produce hydrogen from seawater Scientists at McGill University uncover potential energy game-changer

Cerutti, who’s been working for a number of years with graphene as part of her research involving bone tissue engineering, was attempting to discover a way that would enable the creation of an “easy-to-handle” structure. Instead, what she found was the fact that, because of its characteristics, it could serve to aid in the process of creating hydrogen from seawater.

Graphene is a single sheet of carbon atoms that display unique properties, explains Cerutti, including its electrical conductivity and ability to support incredible amounts of weight. Working together with colleagues Gabriele Capilli and Thomas Szkopek, the team combined graphene with oxygen in a suspension with water to create reduced graphene oxide—an essentially porous, three-dimensional, electrically conductive scaffold—with graphene flakes stacked on the pore walls, creating a membrane that allows water through, without any other molecules entering. And, it was when considering environments in which to test the new and improved scaffold, and seawater electrolysis was suggested, that the team made the discovery.

“Graphene oxide is a very interesting material because you can work with it in a number of different ways,” says Cerutti. “Because sheets of graphene can be assembled at the walls of the pores, creating membranes inside the walls, it results in a filter of sorts that restricts the entry of competitor species into the pores. It prevents the poisoning of the catalyst, allowing only water molecules to enter the catalyst, facilitating the formation of oxygen, which is critical to have present when attempting to produce hydrogen from water.”

In seawater, explains Cerutti, there are a range of different competitor species, including chloride ions that penetrate the electrode in traditional electrolysis, creating hypochlorite ions which interacts with and nullifies the catalyst. It’s actually the primary reason that explains the difficulty in producing hydrogen from seawater and why this discovery is such a significant one, with potentially far-reaching impacts.

“Energy producing companies would likely be those most interested in this discovery and technology,” she says. “Hydrogen would be an extremely clean form of energy and can be used to create the cleanest fuel possible, resulting in a relatively big breakthrough with respect to sustainability efforts currently happening around the world and attempts to find cleaner, renewable sources of energy and fuels that don’t harm the planet as much as the sources we use most predominantly today.”

What’s more, the structure that’s been created using the graphene oxide can be used to house other catalysts as well, and used to have selective electro-oxidation or reduction of a number of other elements beyond water, including methanol electro-oxidation in a raw fuel mix, in addition to a number of other reactions that could benefit from the discovery.

To assist in the research that was necessary in making this discovery, Cerutti and her team leveraged the X-ray phase contrast imaging at the Canadian Light Source (CLS) at the University of Saskatchewan. Cerutti says that the CLS and its equipment was incredibly important in helping her and her team confirm the viability of the new graphene oxide structure, allowing them to consider the next steps for their discovery. However, as Cerutti points out, it’s simply a matter of figuring out how to scale the innovation at this point.

“The prototype has just been made in the lab,” says Cerutti. “We’ve made a structure that’s only a few millimetres in size. So, in order for this to be applicable, the construction of the structure needs to be scaled up. It’s feasible, because the method that we use to make the electrode leverages emulsion. Just like when mayonnaise is produced, there are ingredients—oil and lemon juice—that usually don’t stay together very well. However, because of the proteins in the egg whites, an emulsion is created. In our method, we put water and oil together, and because of the graphene oxide we’re able to create a stable emulsion in which oil droplets are surrounded by water. Then, you remove the oil and you remove the water and are left with an empty space: the pores. So, instead of creating a 1 cm 3 structure, we could make this at an industrial scale”.

Looking ahead, as Cerutti and her team continue to hypothesize the various potential uses and applications of the graphene oxide structure, they are already thinking about the testing that will be required in order to scale its production. In addition, she says that, as part of the testing, the mechanical properties of the structure will likely need to be changed and altered to evolve with its growth and ensure that the resilience and sound nature of the graphene oxide holds up at a larger size. And, with respect to its scaling, Cerutti says that she’s simply taking her research one step at a time.

“Once the discovery was announced, I received a lot of interest from a number of different companies, including some that make graphene. I think that we’d just need to find the right partner with the right people who align with our vision. If we’re approached by that company or organization, then I’ll be happy to consider the next steps in making this discovery more applicable at a larger and wider scale.”

• 2 feet x 3 feet foot print

• Compact Automated Fully Integrated System

• Uses room air to produce liquid Nitrogen

• Built in storage tank for ln2

• ECO “no loss” eliminates boil off

• 8L to 1,150 L per day capacity

• Cost effective and environmentally friendly

• Unattended production with annual PM

CALL 1-833 MAKELN2

if your Lab has LN2 delivered

LAB BUBBLE FUME HOODS

• PCR Clean Air for PCR prep

• No Ducting or Exhaust hookup

• HEPA filtration change 2-3 yrs.

• Powder weighing

• 5 Colours to choose from

SAFETY BUBBLE FOR PARTICULATES AND VAPORS, WORKS WITH NANOPARTICLES

“Click for demo –https://lab-bubble.com/producto/ safety-bubble-fume-hood/

GLOVE BUBBLE FOR ISOLATION

• With transfer tunnel for access

• Includes utility (gas) connection

Erlab’s 50 years of expertise in research, design and manufacturing of filtered storage cabinets guarantee superior filtration to keep researchers protected when storing their chemicals. Distributed by Canadian Scientific Lab Systems, the Erlab Captair Smart ductless filtering storage cabinets provide a steady flow of air through the cabinet, capturing hazardous vapours in the filters and returning clean air back to the room. www.erlab.com

Thermo Fisher Scientific recently unveiled its Thermo Scientific Arctis Cryo-Plasma Focused Ion Beam (CryoPFIB)—a new connected and automated microscope designed to advance the pace of cryo-electron tomography (cryo-ET) research. Cryo-ET makes it possible to study how proteins and other molecules operate together in a cellular context,

at resolutions unsurpassed by other microscopy techniques, and has enormous potential for cell biology research, including the study of infectious disease, neurodegenerative disease, and other globally impactful structural biology applications. The Arctis Cryo-PFIB offers advanced automation and new connectivity capabilities within the workflow, significantly increasing throughput for fast, reproducible production of samples for cryo-ET. www.thermofisher.com

The CryoGrinder System from OPS Diagnostics is a total solution for homogenizing, chilling and transporting small samples in-house. An improvement on the traditional mortar and pestle, the CryoGrinder tools retain the strength and durability of porcelain while adapting to the scale of molecular biology. The CryoGrinder mortar and pestle are specifically designed to grind small and difficult tissues (e.g., skin, sclera) at cryogenic temperatures. Their small design allows for grinding up to 100 mg of sample without excessive sample loss.

www.opsdiagnostics.com

Bio-Rad’s QX600 Droplet Digital PCR System offers advanced six-colour multiplexing and absolute quantification of nucleic acid. It allows clear discrimination of multiple targets with assays that are cross-compatible with the QX200 Droplet Digital PCR System. Ideal for applications such as gene and cell therapy or water testing, the system is designed for researchers who need to quantify multiple targets with high accuracy reproducibility. www.bio-rad.com

The Reconyx HyperFire 2 camera is now 4G LTE cellular-enabled so that users can receive images on their Android or iOS from almost anywhere in the world. The Reconyx mobile app enables users to create a custom cellular plan, manage images and check status or change camera settings from anywhere. www.reconyx.com

BioTalent page 2 biotalent.ca

Pittcon page 15 pittcon.org

CPDN page 26 cpdn.ca

Instrucan Scientific page 29 instrucanscientific.com

FCC page 34 fcc.ca/beveragereport

California Fig page 45 & 55 californiafigs.com

Ag-West page 51

............................................................................................................. agwest.sk.ca

BioTalent page 56 biotalent.ca/Co-OpFunds

The Despatch LBB lab oven features a combination of horizontal and vertical airflow that offers excellent temperature uniformity. These ovens are recommended for a variety of laboratory applications including drying, curing, annealing, and materials and asphalt testing. The fan and heater are top-mounted to prevent damage from spills. Maximum temperature is 204°C (400ºF).

www.despatch.com

OVERCOMING FOODSERVICE CHALLENGES THROUGH SMART AUTOMATION

PUBLISHER & CEO Christopher J. Forbes cforbes@dvtail.com

MANAGING EDITOR Sean Tarry starry@dvtail.com

COPY EDITOR Mitchell Brown

CONTRIBUTORS Nicole Detlor

Animesh Dutta

Jana Manolakos

Dana McCauley Omid Norouzi

SENIOR ACCOUNT Leesa Nacht EXECUTIVE lnacht@dvtail.com

ART DIRECTOR Sharon MacIntosh smacintosht@dvtail.com

SECRETARY/ Susan A. Browne TREASURER

MARKETING Stephanie Wilson MANAGER swilson@dvtail.com

PRODUCTION Crystal Himes MANAGER chimes@dvtail.com

CANADIAN FOOD BUSINESS ADVISORY COMMITTEE

Marcia English, Associate Professor, St. Francis Xavier University

Michael Nickerson, Saskatchewan Research Chair and Professor, University of Saskatchewan Hosahalli Ramaswamy, Professor, McGill University

Amanda Wright, Association Professor, University of Guelph

Canadian Food and Business is published 4 times per year by Jesmar Communications Inc., 30 East Beaver Creek Rd., Suite 202, Richmond Hill, Ontario L4B 1J2 905.886.5040 Fax: 905.886.6615 www.canadianfoodbusiness.com One year subscription:

Canada $35, US $35 and foreign $95. Single copies $9. Please add GST/HST where applicable. BioLab Business subscription and circulation enquiries: Garth Atkinson, biondj16@publicationpartners.com Fax: 905.509.0735

Subscriptions to business address only. On occasion, our list is made available to organizations whose products or services may be of interest to you. If you’d rather not receive information, write to us at the address above or call 905.509.3511.

The contents of this publication may not be reproduced either in part or in whole without the written consent of the publisher. GST Registration #R124380270.

PUBLICATIONS MAIL AGREEMENT NO. 40063567

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT.

202-30 EAST BEAVER CREEK RD RICHMOND HILL, ON L4B 1J2 email: biond@publicationpartners.com

BioLab Business, a sister publication of Canadian Food Business, is a proud member of BioteCanada and Life Sciences Ontario.

Consideringthe current state of human life on the planet, there are few challenges or issues posing as great a threat to our collective health and existence as food insecurity. A distinct lack of accessibility to healthy foods and ingredients in communities around the world, in combination with enormous amounts of wasted food, is exacerbating the increasingly critical nature of the situation.

In fact, according to most estimates, almost 60% of the food produced in Canada is wasted, representing the equivalent of 35.5 million tonnes, with 32% of it—or 11.2 million tonnes—edible and totalling $49.46 billion in recoverable waste. It’s a problem that requires solutions, and fast.

With this need in mind, in efforts to overcome this incredible challenge, innovators from across the country are working diligently to develop solutions and, where possible, encourage a renaissance of sorts to inspire new ways of doing things and a changed perspective concerning the potential of some of the latest techniques and technologies.

Within this issue of Canadian Food Business, we explore some of these innovators and the solutions that they’re presenting to enhance food security and the lives of people across the country and all over the world.

Focusing on the latest in the development of smart technologies and automated kitchens, we speak to cutting-edge company Gastronomous about the ways its innovative equipment can help improve efficiencies and find cost reductions for restaurateurs, while dramatically limiting the amount of food that’s wasted.