WELDING & CNC CUTTING MACHINES

TOTAL WELDING & CUTTING SOLUTIONS SINCE 1958

HG Hugong™ Ltd is a world leading company manufacturing welding and cutting equipment. Established in 1958, Hugong™ is a team of over one thousand employees committed to producing heavy duty, high quality products. HG Hugong™ is now the largest welding machine exporter in the world.

All HG Hugong™ welding machines are covered by a 3 year commercial warranty and are equipped with quality digital inverter technology which delivers outstanding performance. All HG™ machines are built using superior componentry sourced from across the globe and are then assembled under unyielding quality standards which ensures product consistency.

Every Hugong™ welding or cutting machine carries with it the full support and back up of passionate local welding experts.

• 100% Inverter Technology

3 Year Commercial Warranty

• High Duty Cycles

• Generator Friendly

• Compliance to: ISO9001 / ISO14001

• C-Tick Certified

‘Shanghai Gas Welding and Cutting’ factory is established, and begins manufacturing the first CG1-60 straight cutting systems.

As ‘Shanghai Gas Welding and Cutting’ company develops they design and manufacture the first 1.8 Mach Number high-speed cutting nozzle.

‘Shanghai Gas Welding and Cutting’ re-name to Shanghai Hugong Electric Welding Machine Mfg Co.

‘Hugong’ brand is listed as a Shanghai famous trademark. Hugong is the first company in the welding field to receive such an award. Hugong products are listed as brand-name products in Shanghai.

HG contribute 500,000 RMB (NZD$105,300) to Shanghai Charity Foundation and set up what’s now known as the “Hugong” Charity Foundation.

HG Hugong Group is officially recognised as an Academician Expert Workstation.

Established Hugong Intelligent Technology (Suzhou) Co., Ltd.

Release 10KW fiber laser machine.

HUGONG 10m width - format Gantry style fiber laser cutting equipment. HUGONG-IOT-SYSTEM for fiber laser cutting machine.

‘Shanghai Hugong’ is awarded the HNTE qualification (High and new Technology Enterprise)

The HG group company is set up with core companies of Shanghai Hugong Electric Welding Machine Mfg Co. and Shanghai Gas Welding Equipment Co. The group company is named ‘Shanghai Hugong Electric (Group) Co.’

The R&D centre of HG Hugong Group is named Shanghai Enterprise Technology Centre.

Shanghai Hugong Group is publicly listed on the main board of Shanghai Stock Exchange, it becomes the highest value company in its field.

Hugong trademark was selected into the first batch of Shanghai key trademark protection list.

When the construction of the first phase of Hugong Intelligent Technology (Suzhou) Co., Ltd. was completed, and the factory was moved and put into use. Hugong developed beveling cut & auto sorting on plasma cutting machine.

MMA/ARC WELDERS

ACCESSORIES:

ACCESSORIES:

EXTREME 140 III/EXTREME 160 III

The EXTREME 140III/160 III is a robust, ultra-portable, inverter Arc welder. Weighing only 4Kg it is an ideal site machine. This is a true 140/160amp with a high duty cycle and will run 1.6mm - 4mm electrodes.

IGBT Inverter

Step-less Current Adjustment

Thermal Overload Protected

Fan Cooled

Single Phase

/ Hot Start Arc Force

POWER STICK 200W III

The POWER STICK 200W III is an industrial level 200amp Arc welder. It features a very solid construction but remains very portable at

6.7Kg. This is the ideal choice for a welder working in

IGBT Inverter

Step-less Current Adjustment

Thermal Overload Protected

Fan Cooled

Single Phase

Digital Display

TECHNICAL DATA:

/ Hot Start Arc Force

Open Circuit Voltage Generator Safe Lift Arc Tig

INVERDELTA 400

The INVERDELTA 400III is a heavy duty 3 phase Arc welder. It offers 15 - 400 amps of welding current and features Hot Start and Variable Arc Force. This is the ultimate machine for running large diameter rods or air arc gouging. Excellent Weldability with Rutile (6013), Basic (7018) and Cellulosic (6010) Type Electrodes. With a true 60% Duty Cycle and Thermal and voltage Protection, this machine will handle the demands of site work and weighing in at only 19kg makes it a breeze to carry around the worksite.

IGBT Inverter

Step-less Amperage Adjustment

Thermal Overload Protected

Fan Cooled Three Phase

Suitable for Air Arc Gouging

TECHNICAL DATA:

Digital Displays Arc Force Hot Start

Constant Current DC (CC)

Generator Safe

ACCESSORIES: ACCESSORIES:

Current | 1eff’ (A)

(A)

(KVA)

(V)

(A)

EDGE 190L

The EDGE 190L is a 190amp petrol engine driven welder / generator. It is well suited for harsh, on-site environments and is powered by a reliable 4-stroke Loncin engine. It features a 30 litre fuel tank for extended run time and will run 1.6 - 5mm electrodes.

Step-less Current Adjustment

Thermal Overload Protected 13 Hp Loncin 4-Stroke Single Phase

MIG/MAG WELDERS

ACCESSORIES:

FC 100

The FC 100 is a 100amp Fluxcord Gasless welder only, ideally suited to the home workshop. It contains quality inverter technology and features step-less amp/volt control. This little welder packs a real punch for its size and is capable of welding 0.5-6mm thick steel.

Inverter

Amp / Volt Adjustment

Safe

ACCESSORIES:

EXTREMIG 180W

The EXTREMIG 180W is an entry 180amp Mig/Stick/Tig welder. It contains quality inverter technology and features step-less amp/volt control which delivers very smooth current. It caters for both gas and gasless. Ideal for Welding mild steel, stainless steel and aluminium.

Inverter

Amp / Volt Adjustment

EXTREMIG 200W III

The EXTREMIG 200W III is an industrial quality, 200amp portable Mig / Stick / Tig welder. It caters for both gas and gasless welding and includes a Euro Connect gun. This is a versatile compact welder which delivers very smooth current. Ideal for welding mild steel, stainless steel and aluminium.

IGBT Inverter

Step-less Amp / Volt Adjustment

Thermal Overload Protected

Fan Cooled

Single Phase

Digital Display Mig / Stick / Tig Function

Gas / Gasless Capable

Generator Safe 2 / 4 Step Spot Time

(A)

TEKMASTER MIG 200

The TEKMASTER MIG 200 is a fully synergic, industry ready, 200 amp multi-function welder. It is compact and portable, making it the ideal onsite machine. Including Mig, Stick and Lift Arc Tig functions, this smooth DC inverter welder performs well on mild steel, stainless steel and aluminium. It features reversible polarity, for gasless mig welding and also caters for spool gun welding.

IGBT Inverter

Digital Step-by-Step Control Setup

Thermal Overload Protected

Fan Cooled

Single Phase

Anti-Stick / Hot Start

Variable Arc Force / Arc Control

ACCESSORIES:

MIG/STICK Series

The MIG/STICK Series welders range from 200 - 250amp and produce extremely smooth current. Featuring both Mig and Stick functions they are a compact trolley configuration with the ability to run 0.6 - 1.2mm wire through the 4 roller drive system. They have the capacity to exceed the demands of any high performing workshop.

Inverter

Amp / Volt Adjustment

INVERMIG Series

The INVERMIG Series separate wire feeder Mig welders are heavy duty machines with unprecedented duty cycles. Featuring top end inverter technology and solid construction, they are built to last. Ideal for heavy fabrication, gouging, build-up and maintenance work. Machine sizes include 350 and 500 amps.

ACCESSORIES:

ACCESSORIES:

ARAMADA N

The ARAMADA Subarc auto tractor is a stable and ideal machine for heavy industries such as shipyards. This machine can work as STICK, MIG, SAW, and as a gouging power sauce. Armada N has a smooth DC output, PLC control and has up to 30% energy saving. This machine boasts functionality, with having three phase, IGBT control, DC SAW power fan cooled, thermal overload protection and its welding cart has its own control system.

New Generation Advanced IGBT Inverter Technology

Multi- Process with Submerged Arc Welding (SAW), MIG (GMAW), MMA (SMAW) and Gouging

Excellent welding with steel and flux cored wires

Digital welding current, welding voltage and tractor’s speed display

Equipped with voltage and thermal protection

PMIG 200III

The PMIG 200III is an advanced IGBT Multi-process Synergic Inverter Welder. Manual and Synergic controls. Multi process with single pulse/ double pulse. Excellent welding for carbon steels, stainless steels and aluminium. Light weight and compact design.

Multi-Process Synergic Inverter Welder

Pulse/Double Pulse Mig (GMAW), Stick SMAW)

Equipped with voltage and thermal protection

IP21S Proection Class

Adjustable ending current/ voltage and inductance

TECHNICAL DATA:

|

Stepless welding wire feeding speed (A) and voltage (V) adjustment knobs

Digital welding parameters display

Built-in soft wire feeding, postgas burn-back and ball cutting

Adjustable: Hot start, Arc Force for MMA welding

ACCESSORIES:

INVERMATRIX 251

The INVERMATRIX 251 is a Single-Phase Double Pulse Mig. This heavy-duty machine has unprecedented duty cycles. Featuring top inverter technology and solid construction, they are built to last. It offers Standard Mig, Single & Double Pulse Mig as well as Lift Arc Tig, Pulse Tig and Stick mode. Its full Synergic control makes it a breeze to set up for any material, Steel, Stainless Steel, Aluminium, Silicon Bronze, Aluminium Bronze. You can choose to programme your set up with Amps, Wire Feed Speed or Material thickness. The internal memory holds 250 Programmes allowing you to save your favourite parameters for future use.

IGBT Inverter Step-less Amp / Volt Adjustment Thermal Overload Protected

TECHNICAL DATA:

with Hot Start

ACCESSORIES:

SUPER MATRIX 500 PULSE

The SUPER MATRIX 500 PULSE is a digital multi-function 3 phase machine which caters for industry demanding precision pulse mig application. Featuring top end inverter technology and solid construction, they are built to last. Ideal for large scale workshops working with all metals. With synergic control and the ability to store ideal settings this machine takes the hard work out of the ‘set-up’.

Inverter

TIG WELDERS

ACCESSORIES:

ETIG

160 III

The ETIG 160 III is a basic DC Tig / Stick welder. This machine features high frequency start tig and step-less amperage control. It is a great, no frills machine which will fulfil the needs of any light steel/ stainless steel fabrication.

IGBT Inverter Step-less Amp Adjustment Thermal Overload Protected Fan Cooled Generator Safe Tig / Stick Hot Start Torch Switch

ACCESSORIES:

ETIG 200DP III

The ETIG 200DP III is a fully equipped 200 amp DC Tig / Stick. This machine features high fequency start & step-less amperage control. Being light weight and compact, makes it the ideal on-site machine. The digital set-up and display caters for the precision work while the stick function, with variable arc force, provides versatility.

IGBT Inverter Pulse Ratio and Frequency Thermal Overload Protected Fan Cooled Single Phase Generator Safe Digital Display Tig HF / Stick / Lift Arc 2 / 4 Step Up / Down Slope Pre / Post Flow Variable Arc Force Torch Switch / Remote Amperage Control

ACCESSORIES:

WAVE 203 PFC

The WAVE 203 PFC is the ultimate 200amp AC/DC Tig welder. Now with PFC Power Factor correction, more stable supply on site, extension cords and variable AC and Pulse frequency, it caters for the more technical aluminium jobs. It features a complete set of control functions for the more demanding jobs and includes a stick function to add to its versatility. The ideal welder for the aluminium welder fanatic.

IGBT Inverter AC / DC Remote Adjustment Torch Switch/AMP Control or Foot Pedal Pulse Ratio and Frequency

TECHNICAL DATA:

Peak / Base Current

Variable AC Frequency / Balance Thermal Overload protected Fan Cooled (on demand) Single Phase

(A)

ACCESSORIES:

WAVE 315D III

The WAVE 315D III is an industrial water-cooled three phase AC/DC Tig / Stick welder. Powered by modern inverter technology means it requires less power to run than traditional transformer welders and produces exceptionally smooth arc characteristics. With variable AC and Pulse frequency, it caters to the more technical aluminium jobs. The ideal welder for those larger aluminium workshops.

IGBT Inverter AC / DC Pulse Ratio & Frequency Thermal Overload Protected Fan Cooled

Phase

/ Frequency

Hot Start / Arc Force

PLASMA CUTTERS

ACCESSORIES:

ACCESSORIES:

CARICUT 40 III

The CARICUT 40 III is an IGBT inverter plasma cutter with thermal overload protection, a Trafimet torch and a built in air compressor. This easy to use plasma cutter has the power to clean cut up to 10mm. A pilot arc that makes cutting expanded metal possible.

IGBT Inverter

Thermal Overload Protected Fan Cooled Single Phase

Generator Safe HF Pilot Arc S45 Torch Built-in Regulator

POWERCUT 50 HF III

The POWERCUT 50 HF III is a great little Plasma Cutter capable of clean cutting up to 12mm mild steel. This is a very compact lightweight unit, ideally suited to the serious home workshop or light engineering sector. Included is a P80 torch and features a High Frequency Pilot Arc.

IGBT Inverter Thermal Overload Protected Fan Cooled Single Phase

Generator Safe HF Pilot Arc P80 Torch Built-in Regulator

TECHNICAL DATA:

ACCESSORIES:

POWERCUT 70 HF III

The POWERCUT 70 HF III is a great little Plasma Cutter capable of cutting up to 16mm mild steel. This is a very compact lightweight three phase unit ideally suited to the light engineering sector. It includes a P80 Torch and features High Frequency Pilot Arc.

IGBT Inverter

Thermal Overload Protected Fan Cooled Three Phase

TECHNICAL DATA:

Maximum Cutting Thickness (mm) 16 Clean Cut / 25 Sever Cut

LASER WELDING SYSTEM

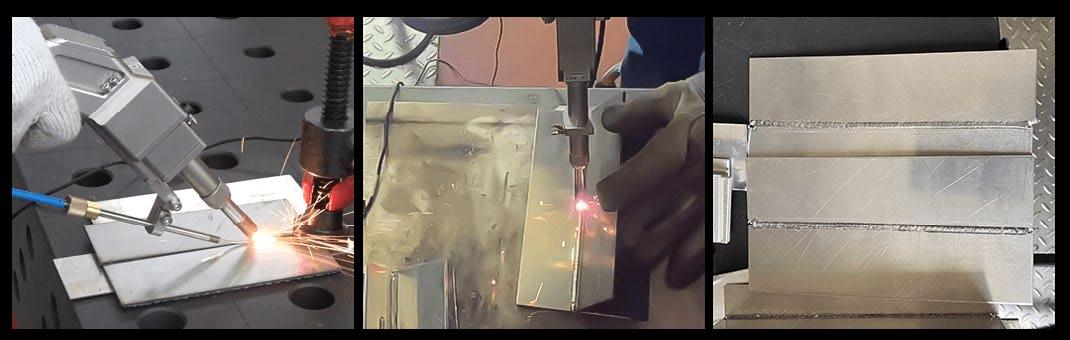

The Hugong Laser Welding system is compact, featuring a user-friendly design that lets any worker without any welding experience learn how to use it within half a day. Superior technology, safety switches and circuits ensure operator safety. Extremely fast welding speed. Much faster than traditional arc welding, up to 120mm/s. Welding efficiency increased by 2-10 times compared with arc welding. Easy installation and easy to transport.

Very Fast Welding Speed Low Welding Heat High Accuracy Easy to Operate

TECHNICAL DATA:

Power Supply

Low Power Consumption Low Fume and Smoke Single Phase

1P/220V/50HZ

Typical Welding Thickness 0.5 to 8mm

Emission Wave Length 1070 - 1090nm

Laser Resonator 1KW

Positioning

Red light positioning

Power Modulation Rate 20Khz

Weight (KG) 400

Operating Voltage, Single-phase AC 200~240V, 50Hz

Maximum Power Consumption 6500W

Typical thickness of Stainless Steel 1 - 4mm

Typical thickness of Mild Steel 1 - 6mm

Typical thickness of Aluminium 1 - 3mm

CNC CUTTING SYSTEMS

INTECUT 3 - PORTABLE CNC

INTECUT is built using strong alloy to achieve portability and reliability. CNC is with 7” colorful displayer and interfaces. 44 shapes are in CNC library. It is easy for the user to choose and set the parameters. Functions are for both flame and plasma cutting.

The program is built in for improving cutting quality, includes speed, pierce time, pulse, motions, etc. Easy switch between a flame and plasma cutting systems. Equipped with a USB port to import and export programs.

Works with nesting software such as FastCAM, MTC, Turbonest, etc. Drawings from AUTOCAD, TEKLA, and SOLIDWORKS can be easily imported. Compatible with Hypertherm PowerMax series also GYS plasma power source.

TECHNICAL DATA: MODEL 3 MODEL 6

Input Voltage (V) Input Power (V)

Monitor

Effective Cutting Size (W x L)

Position

Flame

Cutting

Cutting Gas

LCD 7”with keyboard

x 2000

Acetylene, Propane, LPG-O2

Extremely fast installation

Automatic torch height controller

Compatible to AUTOCAD, TEKLA.SOLIOWORKS and nesting softwares, FastCAM

USB port for Inputting and outputting programs

Languages: English, Russian, Spanish, Portuguese, French, Danish, Korean, Chinese 44 shapes in controller library

Y rail can be extendable

LCD 7”with keyboard

x 6000

Acetylene, Propane, LPG-O2

WONDERCUT - CNC

The Wondercut - strong mechanical Steel structure to ensure cutting speed and cutting precision. With a dual drive motor and automatic torch height controller, CNC has never been so functional. A professional controller for plasma and oxy-fuel cutting.

All in one console - controller and electric cabinet, the angle of the control display has been ergonomically designed with a slim body to save space.

1500mm x 3000mm Cut Size, Includes Automatic THC and Water Bed. Compatible with Hypertherm PowerMax series also GYS plasma power source.

TECHNICAL DATA:

Power Supply (V,Hz)

1PH, 220V, 50HZ

Input Capacity (KW) 180W

Monitor

Cutting WIdth (mm)

Cutting Length (mm)

17” LCD Colour

1500

3000

Cutting Model Flame or Plasma

Positioning Speed (mm/min) 12000mm/min

Recommended Positioning Speed (mm/min) 5000-8000mm/min

Flame Cutting Thickness

Flame Cutting Speed

Oxygen Pressure

Fuel Gas

Plasma

80mm

100-750mm/min

<1.5Mpa

LPG, Propane, Acetylene

GYS and Hypertherm

Plasma THC machines

FLASHCUT - CNC

The Flashcut has a strong steel table body to hold the water bed and ensure durability and precision. High cutting speeds.

1500mm x 3000mm Cut Size, Includes Automatic THC and Water Bed. Steel structure table body to ensure durability and precision with a Dual driving system on Y, linear bearing, helical rack and pinion drive.

Separate driving system on X-axis with covered linear bearing, rack, and pinion. Compatible with Hypertherm PowerMax series also GYS plasma power source.

TECHNICAL DATA:

Power Supply (V,Hz)

Plasma or Oxy cutting Industrial controller with 44 cutting modes Color controller interface

BED OPTIONS

Water Table

Economical version USB port for download Max. speed 12000mm/min

• Water tray for efficient control of sparks and fumes

Removable stainless steel splash guards for side rail protection

• Large drain and tap for quick and easy emptying

240V, 50Hz

Input Capacity (KW) 3

Monitor Screen 17” LCD Colour

Cutting Width (mm) 1500

Cutting Length (mm) 3000

Cutting Model

Plasma(Flame to be optional)

Plasma GYS and Hypertherm Powermax THC machines

Positioning Speed (mm/min) 12,000

Recommended Positioning Speed (mm/min) 6000-8000

Accuracy (mm) Positioning: 0.5/1000/Repeat ability: 0.2/100

Machine size (mm) 4500 x 2700 x 1600

Optional 1 FastCAM, Libellula