Celebrating Safety Newsletter

First Quarter 2024, Issue 5

First Quarter 2024, Issue 5

Shady Grove CUP Expansion Project –Demolition of existing boiler to make space for new boiler

Transportation Electrification Team

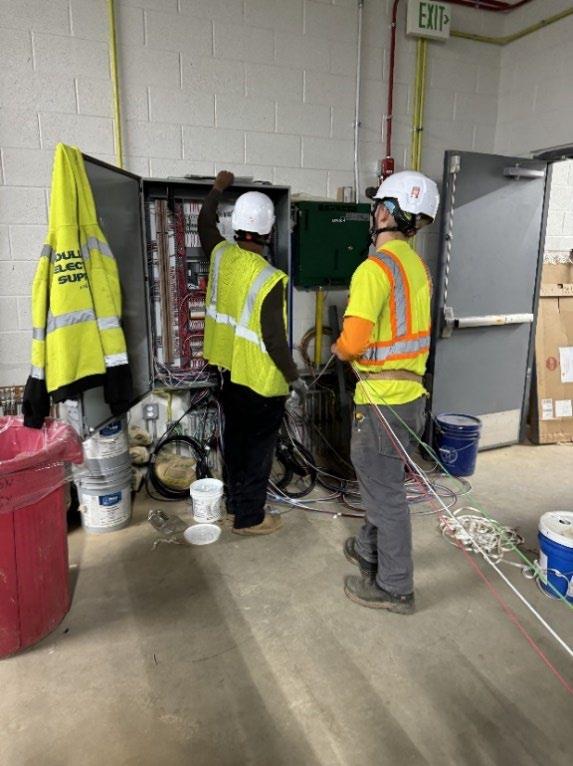

Prologis Project –Conduit going in at Denker

Shady Grove CUP Expansion Project –Forming electrical equipment pads for electrical tie in

The Trio Safety Committee meets monthly throughout the year in an effort to continually promote safety throughout the workplace and at home. The Committee focuses on employee training, new safety programs, safe workplace recognition, and safety trends in the industry.

If you are interested in joining the Trio Safety Committee, please reach out to any of the Safety Committee members listed on Page 8.

Safety is Trio’s No. 1 Value. The mission of the Workplace Safety Committee is to maintain a safe work environment that actively involves all employees in identifying, preventing, and correcting workplace safety issues. This will help eliminate accidents, near misses, injuries, and elevate our safety-first culture. We are committed to creating awareness around health, wellness, and personal safety through ongoing education and initiatives as we work together to address safety issues and concerns.

We are always looking for additional EO Group Team members who would be a good fit for this professional certification. To date, we have 7 EO Team members who have earned this valuable safety certification. Please reach out to Steven Verdi at Steven.Verdi@EdisonEnergy.com if you are interested in learning more.

We want to recognize Byron Howard for achieving his Designated Design-Build Professional certification as of April 2, 2024! This identifies Byron to design-build end-users and the community at-large as a professional in the design-build field, including demonstrated hands-on experience in post-award design-build.

This program, which has been endorsed by the Design-Build Certification Board, is intended to create an accepted and recognized educational standard for experienced, professional, and knowledgeable practitioners who possess a qualified and quantified level of expertise in designbuild.

We encourage team members to recognize those who are going above and beyond in the name of safety. A dedicated email address has been set up so Trio team members can submit nominations: SafetyRecognition@EdisonEnergy.com

Your email for the 2nd quarter of 2024 (April-June) nominations should include:

· Name of nominated team member

· Why you are nominating this team member

· Details around how this individual went above and beyond in the name of safety. Photos can be included in submissions

The Safety Committee will review all submissions and select a winner at the end of each quarter. The winner will receive a $50.00 Visa gift card.

Be on the lookout for individuals who practice safety in action and get your nominations in!

Ed Ivy from Perlectric, our electrical contractor at the Shady Grove Upgrade and Expansion Project in Rockville, MD is the winner of the Trio Safety Recognition award for 2024-Q1. In recognition of his outstanding efforts to uphold safety standards on our jobsite, Ed's unwavering commitment to safety, his proactive attitude, and his dedication to excellence make him a truly deserving candidate for this prestigious recognition.

Throughout his time with us, Ed has consistently demonstrated exemplary safety practices, consistently impressing his less-tenured coworkers with his vigilant attention to safety protocols. His dedication to ensuring the safety of himself and his colleagues sets a standard for others to emulate, creating a culture of safety consciousness within our team.

Not only does Ed prioritize safety in his own work, but he also looks out for the safety of other contractors working around him. His proactive approach to safety extends beyond his immediate responsibilities, as he is always willing to share valuable insights and lend a helping hand to mitigate potential hazards.

Furthermore, Ed has made invaluable contributions to the Trio team by consistently providing recommendations for safety improvements on the jobsite. For example, when we recently energized electrical systems in the plant, Ed recognized the need for additional safety measures to prevent unauthorized access to potentially hazardous areas. He went out of his way to request the installation of a door, effectively minimizing the risk of accidents for individuals not trained to handle hot electrical equipment.

Ed Ivy's dedication to safety and his proactive approach to identifying and addressing potential hazards make him an invaluable asset to our team. He embodies the spirit of the Trio Safety Recognition program, and I wholeheartedly endorse his nomination for this well-deserved honor.

We dedicated our 2023 Trio University monthly sessions to reviewing the Trio Project Safety Manual.

Topics that will be covered in 2024 will be announced soon.

The safety committee is always looking at ways to improve safety for all employees and contractors. During our safety committee meetings, it was the consensus that we wanted to add focus on Hand Safety and therefore we drafted and finalized a policy to clearly state our expectations for using gloves at all times on our projects to help reduce the risk, severity, and frequency of hand injuries. The policy and link to our new hand protection policy is below and has been included in the Trio Safety Manual.

Energy Optimization - Trio Hand Protection Policy.pdf - All Documents (sharepoint.com)

It is the strict safety policy of Trio that field, project management staff, and contractors wear appropriate hand protection (gloves) while in the field at all times. Gloves are considered an essential, mandatory part of your Personal Protection Equipment (PPE). Gloves must be provided free of charge to employees and subcontractors by their employer. Additionally, the employer has the responsibility to train employees in the proper selection, use, and limitations of gloves that they will be using. Employers must also provide replacement gloves when the gloves become damaged or have reached the end of their useful life. Employees have the responsibility and duty to inspect, use as required, and request replacement gloves when necessary.

The OSHA Standard for hand protection is listed in 29 CFR 1910.138(a), General requirements: “Employers shall select and require employees to use appropriate hand protection when employees’ hands are exposed to hazards, such as those from skin absorption of harmful substances; severe cuts or lacerations; severe abrasions; punctures; chemical burns; thermal burns; and harmful temperature extremes.”

1926.28(a)

The employer is responsible for requiring the wearing of appropriate personal protective equipment in all operations where there is an exposure to hazardous conditions or where this part indicates the

need for using such equipment to reduce the hazards to the employees.

Application. Protective equipment, including personal protective equipment for eyes, face, head, and extremities, protective clothing, respiratory devices, and protective shields and barriers, shall be provided, used, and maintained in a sanitary and reliable condition wherever it is necessary by reason of hazards of processes or environment, chemical hazards, radiological hazards, or mechanical irritants encountered in a manner capable of causing injury or impairment in the function of any part of the body through absorption, inhalation or physical contact.

Common hand hazards and exposures present in the field are listed below:

· Cuts, lacerations, and abrasions

Skin absorption of harmful substances

· Chemical Burns

Thermal Burns

· Temperature extremes such as frostbite or burns

Electrical shock

· Stress from repetitive use

As there are a multitude of potential hand hazards, and different hazards require different types of hand protection, Trio employees and contractors are required to perform a hazard analysis taking into account the task at hand, conditions of work environment, duration of use, and potential site hazards before choosing the appropriate hand protection for use.

Examples of appropriate hand protection are as follows:

Cut Resistant Gloves

Electrical Rated Gloves

· Chemical Protection Gloves

Temperature Resistant Gloves

· Impact Resistant Gloves

Additionally, employees are required to review site JHA’s for any recommended or required hand protection for the field work they will be encountering.

It is also a requirement of Trio employees and contractors to routinely perform a visual inspection of their gloves for any issues and replace gloves when they are no longer usable due to wear and tear, rips and tears, manufacturers defect, or have expired

Be on the lookout for new monthly Safety Training sessions in 2024 that will be presented via our ADP portals! “Industrial Fire Protection has been assigned for April 2024.

Also, additional Trio University sessions will be scheduled soon to review our new safety programs!

A special thanks to all who contribute to our weekly Monday morning safety drips. Thank you for helping us to keep safety in the forefront of our thoughts.

Here are some recent regional and national safety incidents for your awareness:

The safety committee is expanding. We would like to welcome two new members to the safety committee starting in February 2024. Welcome abord Alex Crary and Rob McAvoy!

Worker Dies in Trench Collapse at Construction Site in Dubuque, Iowa (usnews.com)

Boise, Idaho, building collapse: 3 killed and 9 injured in hangar collapse at airport, officials say | CNN

UPDATE: Houston County Sheriff's Office investigation determines no foul play in fatal construction accident - 41NBC News | WMGT-DT

Key Bridge collapse: What we know about the six workers killed – Baltimore Sun

Christian J. Bitters

Chris.bitters@edisonenergy.com

Steven Verdi

Steven.verdi@edisonenergy.com

Thabo D’Anjou

Thabo.danjou@edisonenergy.com

Alex Crary

Alex.Crary@edisonenergy.com

Eric Koehler

Eric.koehler@edisonenergy.com

Brian Cartmill

Brian.cartmill@edisonenergy.com

Kerylyn Goldwyn

Kerylyn.goldwyn@edisonenergy.com

Rob McAvoy

Rob.McAvoy@edisonenergy.com