PETROGRAPHY CONCRETE CONCRETE PETROGRAPHY

A HANDBOOK OF INVESTIGATIVE TECHNIQUES

A handbook of investigative techniques

A handbook of investigative techniques

SECOND EDITION

SECOND EDITION

SECOND EDITION

Alan B. Poole and Ian Sims

AlAn B. Poole And IAn SImS

Alan B. Poole and Ian Sims

2.5.3 X-ray powder diffraction techniques 33

2.5.4 Fourier transform infrared spectroscopy 3 4

2.5.4.1 S ample preparation 35

2.5.4.2 S pectral interpretation 37

2.5.5 T hermal methods of analysis 37

2.5.6 C hemical methods of analysis 38

2.5.6.1 C hemical analysis of unhydrated blended cements 38

2.5.6.2 C hemical analysis of hardened cement pastes in concrete 3 9

2.5.6.3 Identification of polymer additions in mortars and concrete 41

2.6 C omputer-aided petrographic methods 42

2.6.1 Q uantitative image analysis 42

2.6.1.1 Acquisition 43

2.6.1.2 E nhancement 45

2.6.1.3 S egmentation and thresholding 45

2.6.1.4 M easurement 46

2.6.2 C ase study applications of image analysis 47

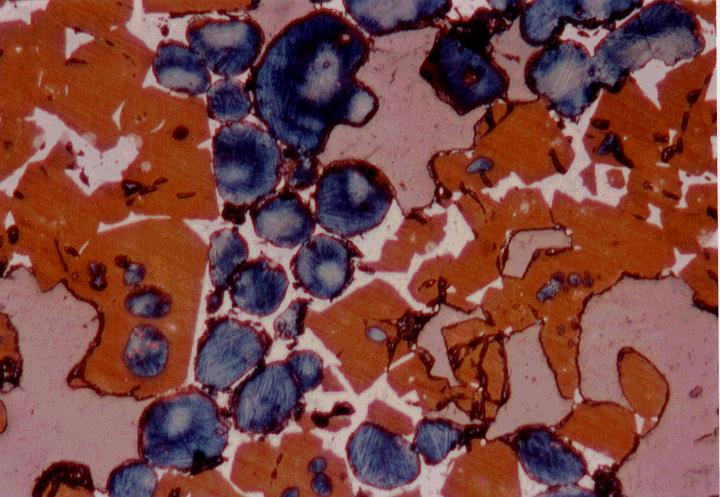

2.6.2.1 E stimation of pyrite content in mudstone aggregate 47

2.6.2.2 Modal analysis of a mortar specimen 47

2.6.2.3 Q uantitative investigation of fractures 49

2.6.2.4 E valuation of shape and distribution of voids 49 References 52

3 Sampling and specimen preparation 57

3.1 S ampling concrete and related materials 57

3.2 Inspection of structures 57

3.2.1 S urface expression of concrete deterioration 58

3.3 R epresentative sample 59

3.3.1 Particulate materials 59

3.3.2 S tatistical considerations 61

3.3.3 E xamination of particulate materials 6 4

3.3.4 S olid samples 6 5

3.3.5 Practical sampling methods for solids 69

3.3.6 Preparation of subsample specimens for investigation 70

3.4 Preparation of thin sections and finely ground or polished surfaces 75

3.4.1 L aboratory methods of cutting concrete 76

3.4.2 L aboratory preparation of ground surfaces 78

3.4.3 L aboratory preparation of polished surfaces 82

3.4.4 R esins for impregnation and mounting concrete specimens 82

3.4.5 Preparation of petrographic thin sections 86

3.5 S pecimen preparation for special purposes 91

3.5.1 S mall selected specimens 92

3.5.2 Powdered specimen 92

3.5.3 Preparations involving etches, stains and dyes 93

3.5.4 D yes for use with resins 9 4

3.5.5 S tains for identification of minerals 95

3.5.6 E tching procedures for cement clinkers 96

References 99

4 Composition of concrete 103

4.1 S cope 103

4.2 C ement types and binder content 103

4.2.1 A nhydrous Portland cement phases and clinker 103

4.2.1.1 C alcium silicates (C 3 S, C 2 S) 106

4.2.1.2 C alcium aluminates and calcium aluminoferrites (C 3A, C 4AF) 108

4.2.1.3 Lime and periclase (CaO, MgO) 108

4.2.1.4 Other phases and gypsum 109

4.2.2 Identification of cement type in concrete 110

4.2.2.1 General principle of optical microscopical methods 111

4.2.2.2 M icroscopical procedure 111

4.2.2.3 Interpretation of the findings and some difficulties 113

4.2.2.4 S EM and other methods 115

4.2.3 Hydrated cement phases 116

4.2.3.1 C SH and the microstructure of cement paste 118

4.2.3.2 Degree of hydration 120

4.2.3.3 Portlandite (Ca(OH)2) 121

4.2.3.4 E ttringite and some other complex phases 124

4.2.4 Blended and special cements 131

4.2.4.1 Portland–limestone cements 131

4.2.4.2 Ggbs and Portland blastfurnace cements 131

4.2.4.3 Pfa, fly ash and Portland pozzolanic cements 135

4.2.4.4 High-alumina cement 138

4.2.4.5 S upersulphated and other special cements 145

4.2.5 B uilding lime and cement/lime mixtures 146

4.2.5.1 B uilding lime 147

4.2.5.2 C ement/lime mixtures 153

4.2.6 C ement or binder contents in concrete 156

4.3 Aggregate types and characteristics 157

4.3.1 Petrographic identity of aggregate 157

4.3.1.1 Typical aggregate combinations 158

4.3.1.2 C rushed rock coarse aggregates 158

4.3.1.3 N atural gravel coarse aggregates 161

4.3.1.4 C rushed rock and natural sand fine aggregates 161

4.3.1.5 R ecycled aggregates 162

4.3.2 Particle size and aggregate size grading 163

4.3.3 Particle shape 171

4.3.4 Particle shape recognition 173

4.3.4.1 Form and sphericity 173

4.3.4.2 Roundness and angularity 174

4.3.4.3 Irregularity 175

4.3.4.4 Use of desktop flat-bed scanners 176

4.3.5 Other particle characteristics 182

4.4 Water/cement ratio 186

4.4.1 Definitions and relationship to concrete properties 186

4.4.2 Indicators of water/cement ratio 188

4.4.2.1 Water voids and bleeding 189

4.4.2.2 C apillary porosity 189

4.4.2.3 M ineralogical features 192

4.4.3 Determination of water/cement ratio by the physico-chemical method 193

4.4.4 D etermination of water/cement ratio by fluorescence microscopy 195

4.4.4.1 Principle of the method 195

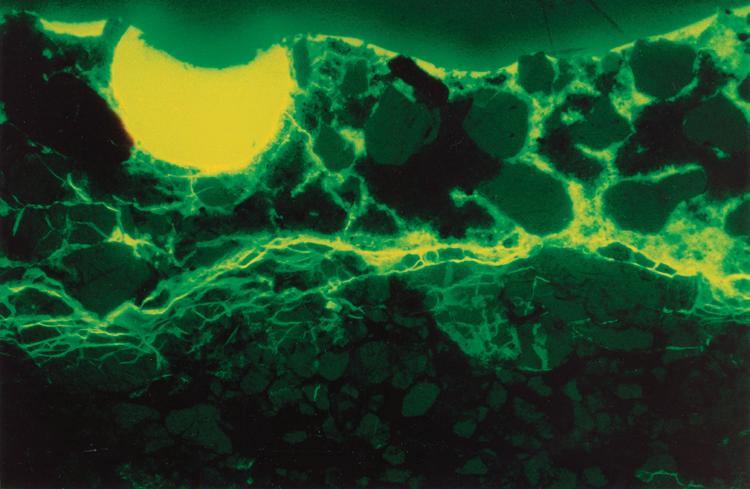

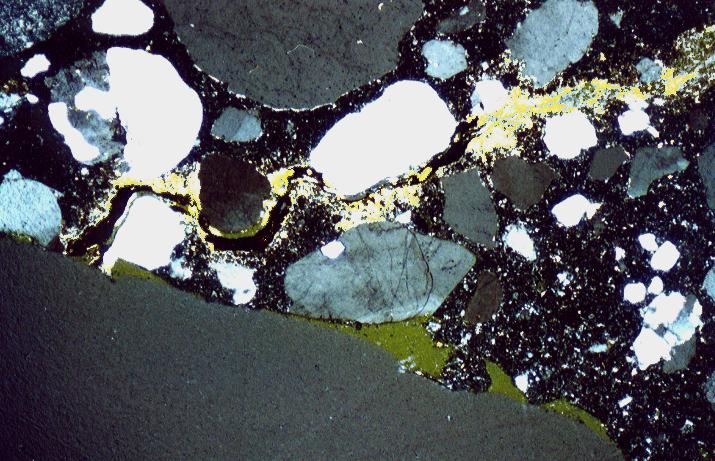

4.4.4.2 Transmitted and reflected light procedures for determination of equivalent water/cement ratio using thin sections 196

4.4.4.3 R eflected light procedure for the determination of equivalent water/cement ratio using ground polished specimens 2 04

4.4.5 Determination of water/cement ratio using scanning electron microscopy 2 07

4.5 A ir-void content and air entrainment 2 09

4.5.1 Types of voids in concrete 2 09

4.5.1.1 E ntrapped air voids 210

4.5.1.2 E ntrained air voids 211

4.5.2 Q uantification of air-void content in hardened concrete 216

4.5.2.1 Visual assessment of excess voidage 216

4.5.2.2 Other methods for assessing air-void content 219

4.5.2.3 Use of desktop flat-bed scanners 2 20

4.5.3 M icroscopical measurement of the air-void system 2 24

4.5.4 A erated and foamed concrete 2 31

4.6 M ineral additions and pigments 2 33

4.6.1 Fly ash and pulverised-fuel ash 2 33

4.6.1.1 Identifying fly ash or pfa 2 34

4.6.1.2 Q uantifying the content of fly ash or pfa 2 35

4.6.2 Blastfurnace slag materials 2 38

4.6.2.1 Identifying ggbs 240

4.6.2.2 Q uantifying the content of ggbs 243

4.6.3 Ultra-fine additions 244

4.6.3.1 M icrosilica (condensed silica fume) 245

4.6.3.2 M etakaolin 249

4.6.4 N atural pozzolanas and other additions 2 50

4.6.5 Pigments 251

4.7 C hemical admixtures 2 53

4.8 F ibre reinforcement 2 56

4.8.1 S teel fibres 260

4.8.2 Glass fibres 262

4.8.3 Polymer and other organic fibres 262

4.9 A nalysis of concrete 265

4.9.1 Q uantitative analysis of concrete composition 265

4.9.2 E stimation of cement replacement by pfa or ggbs 268

4.9.3 A pplications of concrete composition by petrography 270

4.9.3.1 C omparison of actual and design concrete mixes 270

4.9.3.2 C oncrete in a murder case 273

References 274

5 Appearance and textures of cementitious materials 297

5.1 Introduction 297

5.2 O ptical observations of the hardened Portland cement paste matrix 298

5.2.1 Typical composition of hardened Portland cement 300

5.2.2 R emnant or oversize cement clinker grains 301

5.2.3 C olour of hardened concrete 304

5.2.4 E ttringite in hardened concrete 305

5.2.5 C alcium hydroxide in hardened cement paste 307

5.2.6 M odification of calcium hydroxide in Portland cement concretes 314

5.3 C oncretes containing mineral admixtures 317

5.3.1 Portland limestone cement concrete 317

5.3.2 Pozzolanic and Portland slag cements 317

5.3.3 Petrographic examination of slags and pozzolanas 325

5.4 High-alumina or calcium aluminate cement concretes 327

5.5 C arbonation of Portland cement concretes 331

5.5.1 Effects of carbonation on porosity and strength 333

5.5.2 Typical textures of carbonation 334

5.5.3 C arbonation of the outer layers of concrete 336

5.5.4 C arbonation associated with crack systems 337

5.5.5 C arbonation associated with aggregate types in concrete 338

5.5.6 S urface exudations and efflorescence 339

5.6 Interfaces within concrete 3 41

5.6.1 Aggregate/cement paste interface 3 42

5.6.2 S teel reinforcement/cement paste interfaces 3 44

5.6.3 F ibre reinforcement/cement paste interfaces 3 45

5.6.4 R ender interfaces 3 46

5.6.5 Other cementitious interfaces 3 46

5.7 Voids in concrete 3 47

5.7.1 E ntrapped air voids 3 49

5.7.2 E ntrained air void systems 350

5.7.3 C apillary and gel pores 352

5.7.4 Other air voids in concrete 352

5.7.5 A erated and no-fines concretes 354

5.8 C racking in concrete 355

5.8.1 C racks resulting from tensile strain 356

5.8.2 D ifferentiating between structural and non-structural cracks 356

5.8.3 Non-structural cracks in concrete 358

5.8.3.1 C racking subparallel to, and restricted to, the near surface 358

5.8.3.2 C racking approximately perpendicular to, and restricted to, the near surface 361

5.8.3.3 C racking reflecting interior expansion of the concrete 365

5.8.3.4 C racking limited to the interior of the concrete 368

5.8.4 Petrographic examination and the interpretation of crack systems 370

5.8.5 C racking as artefacts of sampling and preparation 373

References 375

6 Examination of deteriorated and damaged concrete 385

6.1 Introduction 385

6.1.1 Background to concrete durability 385

6.1.2 D urability investigation and classification 387

6.1.3 Q uantification of deterioration and damage 390

6.1.3.1 M ethodology 391

6.1.3.2 Interpretation and reproducibility 393

6.1.3.3 A lternative methods 395

6.2 Plastic and drying shrinkage 396

6.2.1 O verview 396

6.2.2 M acroscopic effects of plastic and drying shrinkage 396

6.2.3 Petrographic examination of shrinkage cracking 397

6.2.4 S hrinkage of aggregates in concrete 398

6.3 C orrosion of steel reinforcement 4 02

6.3.1 Role, depth and quality of concrete cover 4 04

6.3.2 S teel reinforcement corrosion mechanisms and factors 4 06

6.3.3 C arbonation, loss of alkalinity and corrosion of reinforcement 4 09

6.3.4 C hlorides and corrosion of steel reinforcement 411

6.3.5 Prevention of reinforcement corrosion 416

6.4 F rost and freeze–thaw action 416

6.4.1 F reeze–thaw mechanisms and factors 418

6.4.2 M acroscopic and microscopic evidence of freeze–thaw action 418

6.5 S ulphate actions 422

6.5.1 O verview 422

6.5.2 G round and groundwater sulphates 423

6.5.3 C onventional sulphate attack 429

6.5.3.1 Properties of concrete relating to sulphate attack 429

6.5.3.2 E xternal appearance of concrete attacked by sulphate 430

6.5.3.3 Internal textures of concrete attacked by sulphate 432

6.5.4 S eawater attack 439

6.5.5 S ulphate attack in sewerage systems 4 43

6.5.6 T haumasite sulphate attack (TSA) 450

6.5.6.1 N ature of TSA 450

6.5.6.2 Petrography of TSA 454

6.5.7 Internal sulphate attack 4 61

6.5.8 M undic problem 4 66

6.5.8.1 Background to the mundic problem 4 66

6.5.8.2 Petrographic examination of mundic concrete 4 69

6.5.8.3 R ICS classification scheme 471

6.5.9 Delayed ettringite formation (DEF) 475

6.5.9.1 Background and mechanism of DEF 477

6.5.9.2 Petrographic investigation of DEF 4 81

6.6 Acid and alkaline attacks 4 89

6.6.1 N atural acid waters and ‘aggressive carbonation’ 491

6.6.1.1 Petrographic textures 493

6.6.1.2 E stimation of rates of attack 496

6.6.2 C arbonation and corrosion by geothermal fluids 501

6.6.2.1 Textures of grouts exposed to geothermal fluids 501

6.6.3 Acid-type attack from sulphates, sulphides, brine and microbial action 503

6.6.4 Industrial chemical attack 504

6.6.4.1 Petrographic investigation 506

6.7 Weathering and leaching 507

6.7.1 General aspects of weathering and deterioration 507

6.7.2 Water leaching 508

6.7.3 S alt weathering 509

6.8 A lkali-aggregate reaction (AAR) 510

6.8.1 O verview 510

6.8.2 C hemistry of the alkali–silica reaction 512

6.8.3 E xternal appearance of concrete affected by ASR 514

6.8.4 M icroscopic textures and features of concrete affected by ASR 519

6.8.4.1 Observations on cores and polished slices 521

6.8.4.2 Observations on thin sections 523

6.8.4.3 R eactive aggregates 531

6.8.4.4 Lightweight aggregates 542

6.8.5 E xamination of concretes suspected of ASR 544

6.8.5.1 Interpretation of ASR textures 544

6.8.5.2 Practical examination 547

6.8.5.3 Other considerations 548

6.8.6 International schemes for assessment, diagnosis and specification 550

6.9 A AR involving carbonate aggregates 553

6.9.1 Background and current position on ‘ACR’ 554

6.9.1.1 De-dolomitisation 554

6.9.1.2 A lkali–silica reaction 555

6.9.1.3 De-calcitisation 556

6.9.1.4 N atural de-dolomitisation 557

6.9.2 Practical examination of concretes suspected of ACR 558

6.9.2.1 General features 559

6.9.2.2 R eaction rims in aggregates 560

6.9.2.3 C arbonate haloes in cement paste 562

6.9.2.4 A lkali–silica gel 563

6.9.2.5 C ryptocrystalline quartz 565

6.9.3 A ncillary techniques for assessing ACR potential 566

6.9.3.1 Acid-insoluble residues 566

6.9.3.2 C rystallinity index (CI) of quartz 567

6.9.3.3 Uranyl fluorescence method 567

6.9.3.4 C hemical test 567

6.9.3.5 Rock cylinder test 568

6.9.3.6 C oncrete and mortar expansion tests 568

6.10 Damage from thermal cycling and fire 569

6.10.1 T hermal expansion and cracking of concrete 570

6.10.2 Effects of fire damage on concrete 572

6.10.2.1 Colour changes 573

6.10.2.2 S urface spalling 574

6.10.3 Investigation of fire-damaged concrete 576

6.10.3.1 Petrography 576

6.10.3.2 Other methods of investigation 580 References 582

7 P recast and special concretes 613

7.1 S tandard precast concrete units 613

7.2 Precast, block, brick, tile and pavers 614

7.3 Precast concrete pipes 617

7.4 R einforced precast concrete units 620

7.5 S team-cured precast concrete units 621

7.6 C omposite precast concrete units and reconstituted (artificial) stone 622

7.7 F ibre-reinforced products 624

7.7.1 A sbestos–cement products 624

7.7.2 Synthetic fibre–reinforced concrete products 629

7.7.3 N atural fibre–reinforced concrete products 6 32

7.8 Polymer cement products 6 33

7.9 S pecial floor coatings 6 35

7.10 S elf-compacting concrete 6 37

7.11 Lightweight aggregates and concretes 6 37

References 643

8 Portland cement mortar, screeds, renders and special cements 647

8.1 Mortar and related materials 6 47

8.2 Floor screeds 6 47

8.2.1 Terrazzo 651

8.2.2 Tiled surface finishes 6 52

8.3 R enders and cementitious plasters 6 54

8.3.1 C ementitious plasters 6 54

8.3.2 Petrographic methods of examination 6 55

8.4 Jointing and bedding mortars 6 56

8.5 S pecial cements and grouts 6 57

8.5.1 C ementitious grouts 6 58

8.5.2 O il-well cements 6 59

8.5.3 Petrographic investigation of oil-well cements 6 60

8.5.4 White and coloured Portland cements 6 61

8.5.5 Other Portland-based cements 6 62

8.6 S prayed concrete 6 62

8.7 C ementitious repair materials 6 65

8.8 C ementitious levelling compounds 6 65

8.9 C ementitious adhesive compounds 6 66

References 666

9 Non-Portland cementitious materials, plasters and mortars 669

9.1 Lime-based materials and products 6 69

9.1.1 Limestone and lime 6 69

9.2 Lime plasters, mortars and screeds 6 71

9.3 G ypsum-based wall plasters and plasterboard 6 75

9.3.1 Petrographic investigation of hemihydrate and anhydrite products 6 79

9.3.2 G ypsum and plaster finishes 6 79

9.4 Historic materials 6 81

9.5 C alcium silicate products 6 86

9.6 S pecial flooring finishes 690

9.7 S urface coatings 690

References 691

Glossary of minerals 695

Foreword

In the past, many a book opened with a foreword written by a grand old man in the author’s subject who took it upon himself to promote the work and to laud the author, not infrequently his protégé. Nothing could be further from the truth in the present case.

First of all, by no stretch of the imagination am I grand, although I am undoubtedly old. Furthermore, I am not a concrete petrographer, although in my study of concrete and of concrete structures I often rely on petrographic information and I have used the first edition of Concrete Petrography. As Poole and Sims rightly say, petrographic techniques provide insights into mineralogical, chemical and microstructural features of concrete. The very wide range of these techniques makes them very valuable but, at the same time, creates difficulties for a non-petrographer.

The authors have done an admirable job of presenting in a clear and orderly manner the petrographic methods and procedures, starting with sampling and including statistical treatment.

The concretes considered are wide-ranging, including fibre-reinforced concrete, polymer concrete, terrazzo, as well as oil-well cements. In addition, lime-based materials, of interest in the repair of historic buildings, are discussed by A. Leslie.

What impressed me is the cohesion of the book: unlike books written by several authors, this one seems seamless, and this makes it particularly valuable. It is not my task to be an advertiser or a salesman, but I have to praise the quality of the English and the rarity of spelling mistakes – a situation unusual in this day and age.

So, the book is encyclopaedic in character but very lucid and readable and I can truly recommend it to those who seriously investigate concrete, and especially problems in concrete in service. I know no better book on concrete petrography.

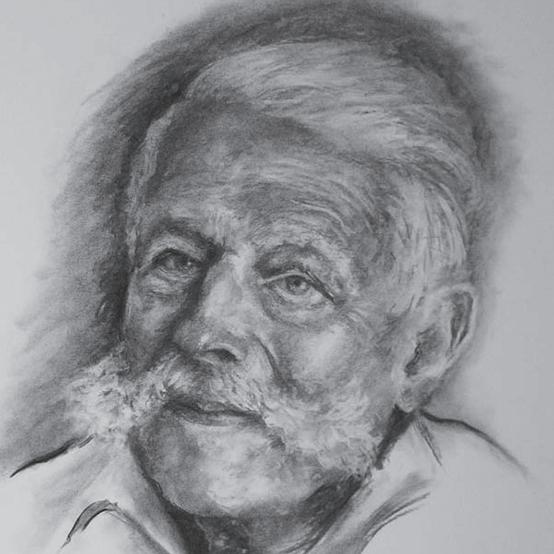

Adam Neville, CBE, TD, DSc, FREng, FRSE London, England

Background note: Dr Adam. M. Neville was, before retirement, professor of civil engineering at Leeds and then Dundee Universities, also principal and vice principal at the University of Dundee, United Kingdom, and now a civil engineering consultant. He is a CBE, DSc (Eng.), DSc, PhD, FIStructE, FICE, FEng and FRSE.

Po rtrait of Ad am Neville (2009)

Preface

Since the three authors completed the first edition of Concrete Petrography in 1998, there have been major advances in the understanding of concrete and its problems. The intervening years have also brought remarkable improvements in equipment and the methods of petrographic investigation relevant to concrete. Additionally, the variety of cementitious materials available and the range of applications they now cover have similarly increased dramatically.

Consequently, the first edition, though still providing a sound basic review of concrete petrography, has increasingly been in need of revision, updating and indeed improvement. With the passage of years, Don St John did not feel able to embark on a second edition. The remaining two authors, who readily recognised the important contribution Don St John made to the first edition, considered that the new petrographic information, methods and techniques, including a number of critical discoveries and developments in concrete technology since the first edition was published, merited a complete reappraisal of the original book. They discovered that the magnitude of the task they had set themselves was just as formidable as it was with the first edition. Nevertheless, thanks to the encouragement, unstinting help and advice from numerous experts from around the world, the task has been completed and provides a new and up-to-date balanced review of concrete and related materials, together with the modern petrographic approaches used in their investigation.

As with the first edition, the authors have emphasised the value and importance of the polarising microscope and the related petrographic techniques as fundamental to the understanding of cementitious materials and as basic tools for the scientific investigation of these materials and their properties. However, they have also included increased reference to the allied use of scanning electron microscopy and integral microanalysis as this powerful technique has become much more accessible to practising petrographers since the preparation of the first edition.

The authors believe that this book will be of practical value to the professional petrographer, providing both background information and details of some of the specialist techniques necessary for the petrographic investigation of cementitious materials. They hope that, as with the first edition, it will also be of value to the technologist, professional engineer and technical legal expert who may have to address materials problems with concrete and similar materials, interpret petrographic findings or decide on the most effective means of investigation of such materials.

Although in general terms cementitious materials are composed of crystalline and amorphous mineral constituents with a range of optical properties similar to those of rockforming minerals that are familiar to all geological petrologists, differences arising from the methods of manufacture, chemical composition, time-dependent factors and environmental effects make the petrographic study of these materials different both in technical detail and in philosophy of approach.

Additional to reviewing the specialist laboratory techniques appropriate to the optical and electron-microscopical examination of cement-based materials, this book addresses the practical problems associated with the inspection and sampling of concrete structures and the special techniques appropriate to the preparation of the material for laboratory examination.

The principal area covered in this book is concerned with the use of the optical polarising microscope in the detailed study of concretes and related materials. It is anticipated that the trained petrographer will already be familiar with the use of the microscope for the examination of rocks in thin section, and so the emphasis is given to the cementitious phases and artificial materials, rather than the natural rock aggregates and fillers that are also used and encountered.

Where appropriate, case study examples taken from around the world are included in the text to illustrate particular points or to show the interrelationships between observed petrographic features, construction history and local environmental conditions.

Two undeniable disappointments of the first edition were the severe limitation on the number of colour photographs and the poor reproduction of a number of the other images in black and white. Thus, the authors are delighted that with the publisher’s support, this second edition is illustrated in colour by a very much larger number of photographs excepting some older photographs and figures which remain in monochrome.

It was found that many petrographers used the first edition as a reference source in relation to a particular problem, in order to identify a particular mineral or form of deterioration. Consequently, the glossary introduced in the first edition has been retained, updated and extended with reference to photomicrographic illustrations where appropriate.

This second edition has been greatly enhanced by the contributions, advice and support from numerous internationally acknowledged experts from around the world, several of whom played a significant role in helping to update and improve particular sections of the book. The authors offer them all their sincere and very grateful thanks. These contributors’ names and affiliations are recorded in the acknowledgements, and some individuals are also recognised in association with particular areas of expertise.

Notes

1. Note the use of the internationally accepted cement chemists’ shorthand notation: C = CaO, S = SiO2 , A = Al 2O3 , and F = Fe2O3 , so that, for example, C3S = 3CaO ∙ SiO2 . This notation is included for individual phases in the glossary.

2 . S ome petrographers prefer to use the terms ‘alite’ and ‘belite’ instead of the chemical terms C3S and C 2 S respectively.

Alan B. Poole

Ian Sims

Acknowledgements

Although Don St John felt unable to embark on drafting this new revised edition, his excellent and major contributions to the first edition formed a foundation on which large parts of this edition are built. They have proved invaluable as an aid to the present authors as an initial basis for their extensive revisions, updating and enhancement of this new edition. A number of Don St John’s classic case study examples are still very relevant today, and some of these have also been retained to illustrate particular points. Consequently, the present authors are indebted to Don for these examples and for his work on the petrographic examination of concrete, which has formed a valuable background that underlies this current edition.

The authors have also been most fortunate in receiving unstinting help and assistance from internationally acknowledged experts from around the world. This help has taken the form of specialist contributions to the text, advice and help with additional up-to-date information on a host of topics, innumerable new photomicrographs and many case study examples. These have been built into the text and have greatly enhanced the value of this book. All this assistance has of course been acknowledged below, and the authors owe a debt of gratitude to all concerned.

The current authors particularly thank the experts who have contributed significant sections of text or equivalent assistance in the various chapters. These contributors, many of whom helpfully also provided images for the book, include the following (in alphabetical order):

Dr Tony Asbridge (IMERYS Minerals LLP): mineral additives, including metakaolin

Paul Bennett-Hughes (formerly RSK Environment Ltd): concrete fire damage

Dr Alan Bromley (consultant, ex-University of Exeter): computer-aided petrography and mundic sulphate attack

Dr David B Crofts (RSK Environment Ltd): chemical and infrared analyses of concrete materials

Dr Alison Crossley (OMCS, Oxford University, Department of Materials): scanning electron microscopy and microanalysis

Mike A Eden (Sandberg LLP, formerly Geomaterials Research Services Ltd): sample preparation, delayed ettringite formation and micrometric analysis

Dr Paddy E Grattan-Bellew (consultant, ex-NRC Canada): general advice and damage rating index

Dr Viggo Jensen (NBTL, Norway): alkali-silica reaction

Dr Tetsuya Katayama (Taiheiyo Cement Corporation, Japan): carbonate aggregate reactivity

Dr Darrell Leek (Mott Macdonald Ltd): reinforcement corrosion

Dr Alec Leslie (ex-BGS, Edinburgh, now Historic Scotland): historic mortars

Anthony Meyers (Microscopes Plus Ltd): petrographic laboratory

Dr Mario R de Rooij (TNO Built Environment, Delft, Netherlands): fluorescence and other microscopy

Dr R G ‘Ted’ Sibbick (W R Grace & Co, USA, also ex-BRE, UK): general advice, plus especially thaumasite sulphate attack and aggressive carbonation

Dr Graham F True (GFT Materials Consultancy): scanning for aggregate shape and concrete air content

Nick B Winter (WHD Microanalysis Consultants Ltd): scanning electron microscopy and lime–cement mixtures.

Numerous other experts from around the world have also kindly offered advice, specific information, images and editorial comments and made valuable additions to improve sections of the text after reading early drafts. These contributions have proved vital to the authors in ensuring that this book is as accurate and as fully up to date as possible. Reading drafts is an arduous and time-consuming procedure, so the authors owe them a debt of gratitude for this invaluable assistance. In addition to the experts listed earlier, the numerous additional individual experts and companies who have helped the authors in this way include the following (in alphabetical order):

Dr Ian G Blanchard (RSK Environment Ltd)

Dr Maarten A T M Broekmans (Geological Survey of Norway)

Prof Nick Buenfeld (Imperial College, University of London)

Dr Sarah Denton, formerly Huntley, née Hartshorn (Vinci Construction UK Ltd)

Prof Isabel Fernandes (Lisbon University, ex-Porto University, Portugal)

James Ferrari (RSK Environment Ltd)

Prof Benoit Fournier (Université Laval, Québec, Canada)

Martin Grove (retired, formerly of the Cement & Concrete Association, now BCA)

Peter Laugesen (Pelcon Materials & Testing ApS, Denmark)

David F Lawrence (Technical Consultant, Sandberg LLP)

James McAneny (Logitech Ltd)

Chris A Rogers (Consultant, ex-Ministry of Transportation, Ontario, Canada)

Prof Peter Scott (University of Exeter)

Dr Ahmad Shayan (ARRB Group Ltd, Melbourne, Australia)

Prof Mike D A Thomas (University of New Brunswick, Canada)

Richard Wagner (Buehler Ltd)

Dr Barrie Wells (Conwy Valley Systems Ltd)

Readers of this book will soon be aware of the value of the illustrations and of the case history examples. Some of the colour illustrations and photomicrographs that were used in the first edition could not be bettered, so these have been reused. However, a large number of new colour illustrations were required for this edition and the authors have been most fortunate in being allowed to use photographs that other petrographers have provided, sometimes being able to select from lifetime collections. In other instances, special photographs have been taken for the authors in order to show particular features. Although acknowledgements are given where the material appears in the text, the authors thank all the organisations that have provided willing help with the photographic material.

This book could not have been produced without the technical and practical assistance of the publishing team at Taylor & Francis Group and the technical expertise of colleagues at RSK Environment Ltd. Individuals who were of great assistance to the authors during the preparation of this book include A. Hollingsworth, R. Griffiths, M. Cash, A. Moore, and

A. Blalock of Taylor & Francis Group and the tireless organisational, collating and computing skills of especially Claire Bennett, but also Clare Skakle and Siobhan Anderson of RSK Environment Ltd.

The authors have endeavoured to recognise everyone who has helped them during the several years of this revision; should we have inadvertently overlooked anyone, we apologise most sincerely to them and ask for their understanding and forgiveness.

Alan B. Poole Ian Sims

1.1 CO NCRETE PETROGRAPHY

Concrete is an essential and irreplaceable constructional material in the modern world. In recent times, technological advances in the manufacture of cements and the expansion of the use of concretes and related materials in civil engineering have led to a need for a practical, science-based understanding of these materials and the relationships between their compositions and properties.

The very nature of concrete and its innate variability on very small scales requires investigative techniques which allow examination and analysis at microscopic and submicroscopic levels. A wide range of petrographic techniques are currently available, with the polarising and scanning electron microscopes in particular being well-established geological techniques. These same methods have been extended and developed to investigate concrete and related materials. They are unique in providing insights into the mineralogical, chemical and microstructural features of these materials and thus provide a scientific basis of understanding that allows the physical and mechanical behaviour of concrete and related materials to be evaluated and their future behaviour predicted.

1.2 H ISTORICAL BACKGROUND

The cementitious properties of materials such as slaked lime have been known and used since antiquity. The first record of a concrete floor comes from a hut in Yugoslavia dated 5600 BC (Stanley 1979). Slaked lime slowly carbonates and hardens in the atmosphere. It has been used, for example, as a mortar between the masonry blocks in the pyramids. The Greeks and Romans further developed the use of lime by mixing it with pozzolana (volcanic ash) and aggregate to produce the earliest durable concrete, examples of which still stand today (Figure 1.1). Although Smeaton undertook systematic studies of hydraulic lime for construction of the Eddystone Lighthouse commissioned in 1756, the beginning of the modern development of cement and concrete is usually identified with the patent taken out by Joseph Aspdin in 1824 (Gooding and Halstead 1952). Contemporary technological developments have greatly extended the variety and types of cement and concrete available for construction, while the use of cement additives and admixtures have further increased the range of applications of concrete in civil engineering. The investigation of the mineralogy and properties of all these materials form the subject of concrete petrography.

Figure 1.1 (a) The Roman Pantheon, the exterior view and (b) part of the interior of the dome, possibly the first lightweight concrete structure. The 50 m diameter dome was built with pumice aggregate in 27 BC. (Courtesy of A. Ellam.)

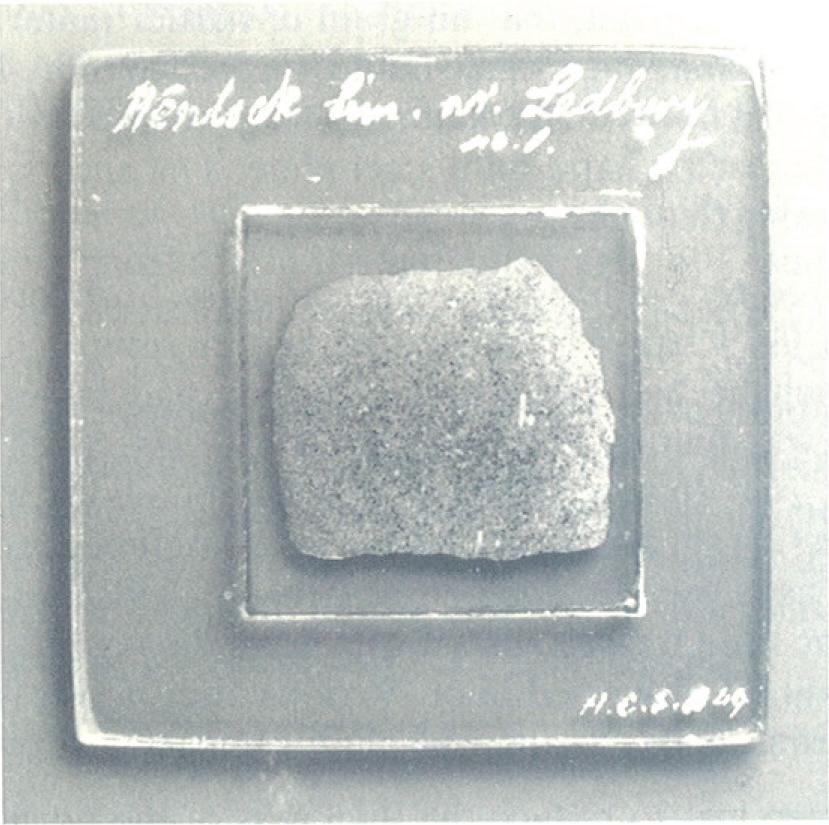

The optical compound microscope was first demonstrated in London by Cornelis Drebbel in 1621. It was developed and used by Robert Hooke who published his Micrographia in 1665. Improvements to lens design in general and the invention of the achromatic lens in particular provided a basis for the development of the petrographic microscope which first appeared in 1856. Its ability to polarise and analyse light led to its extensive use, first as a ‘chemical microscope’ and soon as an essential tool for geologists in their examination of rock-forming minerals. As early as 1849, Sir Henry Clifton Sorby had prepared the first rock optical thin section by hand (Figure 1.2, Humphries 1992).

The first application of the polarising microscope to cement clinkers is usually ascribed to Le Chatelier (1882). In the early twentieth century, the microscope was being used to investigate hardened concrete by scientists such as Johnson (1915), but difficulties of the

Figure 1.2 A photograph of the first rock thin section by Sir Henry Clifton Sorby, made in 1849 by manual grinding to transparency with emery and mounted in Canada Balsam complete with a cover slip. (Courtesy of the Royal Microscopical Society, Oxford Science Publications, Microscopy Handbook , 24, Humphries 1992.)

thin-section specimen preparation necessary for a detailed study of the matrix of such heterogeneous materials severely limited its use. Thin sections of hardened concretes and mortars first became practicable when commercially produced epoxy resins became available after 1946, but it was not until the 1960s that satisfactory large-area thin sections of concrete 20–30 μ m thick were being routinely made for examination using the petrographic polarising microscope.

1.3 OVERVIEW OF PETROGRAPHIC METHODS

As has already been noted, petrographic techniques, particularly those using the polarising and scanning electron microscopes, provide a unique and essential means of investigating concretes and related materials to provide definitive information relating to mineralogy, compliance with specification, compositional features, workmanship and quality. These techniques are also used to provide forensic information relating to mechanisms and causes of degradation, decay and damage of many kinds.

The complexity and depth required in a petrographic study will of course depend on the information required from a particular investigation. This is illustrated schematically in Figure 1.3, with complexity increasing sequentially, as the interrelated stages 1–5 are outlined as follows.

Stage 1. Whatever level of information about a concrete structure or manufactured product is required, the scientific investigation will begin with an inspection of the structure and/or manufacturing process itself. In some simple situations, this investigation may provide sufficient information without recourse to more detailed study. However, the great majority of investigations require samples to be taken so that more detailed investigation can be carried out at a laboratory.

Stage 2. If the additional information required is of a simple nature, for example, the rock types and their proportions present in an aggregate sample, in a concrete slab or a mortar, visual inspection by a competent petrographer, perhaps aided by a hand lens, binocular microscope and some simple physical tests, may be all that is required to provide the information. Similarly many loose aggregate samples may be adequately categorised by visual inspection, though issues of a ‘representative sample’ may need to be addressed (see Chapter 3).

Stage 3. The definitive identification of some minerals and fine-grained materials, both particulate admixtures and fine-grained aggregates, require more detailed investigation and appropriate sampling and specimen preparation followed by the skilled use of more sophisticated equipment (see Chapter 3). In particular, the petrographic polarising microscope, which combined with the possible use of a scanning electron microscope, x-ray diffractometer, or other specialised equipment, becomes an essential tool for this type of investigation.

Stage 4. If quantitative information is required, then representative sampling issues will need resolution and the use of specialist equipment of types described in Chapter 2 will be required. A quantitative analysis necessitates a ‘representative sample’ of sufficient size to be statistically viable (see Chapter 3). Numerous methods are now available for the quantitative or modal analysis and can range from simple sieve grading of an aggregate sample, through various mechanical and automated modal analysis methods to elaborate camera-scanned image analysis of the sample controlled by sophisticated software (see Section 2.6).

Stage 1. On-site investigation

Allows the types of concrete materials, their general composition, their general quality and any visible deterioration features in the structure to be identi ed and recorded

Stage 2. Laboratory visual identi cations

e major mineral components within the aggregates, concretes, mortars and related materials can be identi ed, together with any features of deterioration

Stage 3. Con rmatory identi cations

De nitive identi cations of speci c mineral components of aggregates, concretes mortars and other related materials

Stage 4. Quantitative analysis

Statistical quantitative determinations of airvoid sizes, volumes and proportions, aggregate types and proportions, proportions of clinker, y ash, slag, admixtures and similar components

Stage 5. Detailed laboratory investigations

Detailed investigation of speci c components and features of fabric, mineral interactions, composition, deterioration and failures

Figure 1.3 A schematic diagram illustrating the stages of complexity of petrographic investigation depending on the information and detail that is required.

Stage 5. Where more complex investigation becomes necessary, for example, the forensic investigation of concrete failure or confirmation of the presence of specific chemical admixtures used in a particular concrete, consideration as to the approach and type of equipment used is important. Although the initial studies will use the visual and microscopic techniques described earlier, methods involving specialist equipment such as described in Chapter 2 may need to be selected in order to refine the investigation and confirm findings.

One of the most important methods of investigation involves the use of the polarising petrological microscope. This in turn requires the preparation of petrographic thin sections some 20–30 μ m thick, since these are essential for any detailed study of aggregates, concretes and similar materials (see Chapter 3). Alternatively, in some circumstances, polished surfaces for use with a reflected light microscope may be a more appropriate technique and is particularly useful for identifying fine particulate materials, such as anhydrous cements, fillers and cement admixtures. Depending on the type, such sample fragments may be individually polished, but fine-grained particulate materials are sometimes cast into a resin block before polishing (see Chapter 3).

As already noted, more specialised techniques are required in some cases to confirm identifications or to explore interactions and microfabric modifications. A most important and powerful method for the identification and study of very small grains involves SEM, which is usually furnished with an energy-dispersive x-ray micro-analysis system (EDS) allowing chemical elements to be identified and, if calibrated, quantified. X-ray diffractometry (XRD) is another powerful technique for identifying crystalline materials, while infrared (IR) spectrometry or Raman spectroscopy may be used to identify molecular groupings in very small samples. These last methods are not limited to crystalline material.

There is a very wide range of modern techniques available which have application for particular specialist aspects of investigation of concrete and related materials. The practical and scientific backgrounds to these techniques are outlined in Chapter 2, and their applications and usefulness in the study of particular materials are considered in the later chapters and summarised in Tables 2.1 and 2.2.

1.4 S TANDARD PROCEDURES

A number of national and international standard procedures and specifications have been developed for the petrographic evaluation of aggregates for concrete. In addition there are also numerous standard and guidance documents concerned with specific types of petrographic investigation of aggregates, for example, ASTM C 33/C33M-08, (2008), C295-09, (2009), BS 7943, (1999) and RILEM AAR-1 (2003) are concerned with specification, petrographic identification of aggregate, or potential alkali reactivity.

Much of the more routine work undertaken by petrographers evaluating aggregate for concrete complies with one or more of the national standards. However, very few standards other than ASTM C 856 (2004) cover petrographic methods relating to the detailed examination of hardened concrete, and reliance is commonly placed on available guideline and code of practice documents or on standardised procedures developed by individual specialised petrographic laboratories. The more general codes of practice for concrete and for mortars, plasters and related materials produced by the Applied Petrography Group, United Kingdom, in 2008 are typical of a number of published documents aimed at providing a unified approach to the petrographic examination of these materials. Additionally, there is a number of available and widely used documents providing standard procedures or guidelines for the petrographic examination of particular problems which may occur in hardened concrete, such as alkali–aggregate reaction. Details of these and examples of their application are given in Chapter 6. Standards for aggregates include ASTM C 295-09 (2009) used to assess natural gravels and sands, solid rock and crushed coarse and fine aggregates. ASTM C 294-05 (2005) provides the nomenclature for the rocks and minerals identified. The European standard BS EN 932-3 (1997) is also concerned with natural and crushed rock aggregates and is generally a qualitative method. British standard BS 812-104 (1994) also deals with aggregates but is a quantitative and statistically rigorous procedure. The standard BS 7943 (1999) is more specific in providing guidance for the interpretation of petrological examinations of potentially alkali-reactive aggregates. Without exception, all these documents state or imply that the petrographic examination must be carried out by a competent and qualified petrographer.

1.5 O BJECTIVES AND COVERAGE

Since the publication of the first edition of Concrete Petrography (1998), major technological advances both in equipment and in computer control and analysis software have enabled the petrographer to undertake investigations and reach definitive conclusions hitherto

unobtainable. Previously, problems of resolution, quantification, limits of detection and composition determination had all placed severe constraints on the results obtainable.

The use of the polarising microscope remains the basic and most important fundamental practical method for the detailed investigation of the mineralogy and microstructure of concrete and the wide range of related materials. Consequently, its correct use is described in Chapter 2. Other special techniques also described in the chapter have been selected because they are most effective in allowing the petrographer to investigate the specific chemical, compositional and structural details of these materials so that clear conclusions can be reached. Additionally, Chapter 2 describes the image analysis systems, currently available, detailing their individual practical applications to the investigation of concrete and similar materials.

Of primary importance in any investigation is the selection of representative or special samples of the appropriate material and also its preparation as a specimen for examination in the equipment to be used. The practicalities of sample selection and details of specimen preparation for the various investigative techniques are covered in Chapter 3.

Chapters 4 and 5 describe and illustrate the normal compositional, mineralogical, textural and visual features of cements, concretes, mortars and similar related materials as observed with the optical and electron microscope. Where appropriate, observational information obtained from more specialised equipment is included with these descriptions.

Chapters 6 through 9 explore, describe and illustrate the range of concretes, mortars and the more specialised but related products. They cover the range, types, mechanisms and appearance of damage, deterioration and failure that can occur in these materials and suggest the most effective methods of diagnosis in each case.

A glossary dealing with the optical and chemical properties of cementitious and related minerals which has proved valuable in the first edition has been retained and is extended, updated and is illustrated with reference to photomicrogaphs where this is appropriate in this edition.

REFERENCES

Applied Petrography Group. 2008: A code of practice mortars, plasters and related materials. APG Special Report SR1 (Available as a download from the APG web-site)

Applied Petrography Group. 2008: A code of practice for the petrographic examination of concrete. APG Special Report SR2 (Available as a download from the APG web-site).

ASTM C 33/C33M-08, 2008: Standard Specification for Concrete Aggregates. ASTM, Philadelphia, PA.

ASTM C294-05, 2005: Standard Descriptive Nomenclature for Constituents of Concrete Aggregates. ASTM, Philadelphia, PA.

ASTM C295-09, 2009: Standard Guide for Petrographic Examination of Aggregates for Concrete. ASTM, Philadelphia, PA.

ASTM C 856-04, 2004: Standard Practice for Petrographic Examination of Hardened Concrete. ASTM, Philadelphia, PA.

BS 812-104, 1994: Testing Aggregates. Procedure for Qualitative and Quantitative Petrographic Examination of Aggregates. BSI, London, U.K.

BS 7943, 1999: Guide to the Interpretation of Petrological Examinations for Alkali-Silica Reactivity. BSI, London, U.K.

BS EN 932-3, 1997: Tests for the General Properties of Aggregates. Procedure and Terminology for Simplified Petrographic Description. BSI, London, U.K.

Gooding, P. and Halstead, P.E. 1952: The early history of cement in England. In Proceedings of the 3rd Symposium on the International Chemistry of Cement, London, U.K., Cement and Concrete Association, pp. 1–29.

Humphries, D.W. 1992: The preparation of thin sections of rocks minerals and ceramics. Royal Microscopical Society Handbook 24. Oxford University Press.

Johnson, N.C. 1915: The microstructures of concretes. Proceedings of the American Society of Testing and Materials 15, Part II, 171–213.

Le Chatelier, H. 1882: Comptes Rendus hebdomadaires des séances de l’académie des Sciences 94, 13. RILEM AAR-1. 2003: RILEM recommended test method AAR-1. Detection of potential alkalireactivity aggregates’ Petrographic methods. (Available as a download from the RILEM web-site: www.rilem.net).

Stanley, C.C. 1979: Highlights in the History of Concrete (reprinted 1982). Cement and Concrete Association, Slough, U.K.