Visit to download the full and correct content document: https://ebookmass.com/product/waste-valorization-for-bioenergy-and-bioproducts-hw ai-chyuan-ong/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Waste Biorefinery: Integrating Biorefineries for Waste Valorisation Thallada Bhaskar (Editor)

https://ebookmass.com/product/waste-biorefinery-integratingbiorefineries-for-waste-valorisation-thallada-bhaskar-editor/

Outsourcing Repression Lynette H. Ong

https://ebookmass.com/product/outsourcing-repression-lynette-hong/

Algal Biotechnology: Integrated Algal Engineering for Bioenergy, Bioremediation, and Biomedical Applications Ashfaq Ahmad

https://ebookmass.com/product/algal-biotechnology-integratedalgal-engineering-for-bioenergy-bioremediation-and-biomedicalapplications-ashfaq-ahmad/

Waste and Biodiesel: Feedstocks and Precursors for Catalysts Bhaskar Singh And Abhishek Guldhe (Eds.)

https://ebookmass.com/product/waste-and-biodiesel-feedstocks-andprecursors-for-catalysts-bhaskar-singh-and-abhishek-guldhe-eds/

Biomass Valorization: Sustainable Methods for the Production of Chemicals Davide

Ravelli https://ebookmass.com/product/biomass-valorization-sustainablemethods-for-the-production-of-chemicals-davide-ravelli/

Biofuels and Bioenergy: A Techno-Economic Approach

Baskar Gurunathan

https://ebookmass.com/product/biofuels-and-bioenergy-a-technoeconomic-approach-baskar-gurunathan/

Advances in Bioenergy and Microfluidic Applications Mohammad Reza Rahimpour

https://ebookmass.com/product/advances-in-bioenergy-andmicrofluidic-applications-mohammad-reza-rahimpour/

Valorization of Microalgal Biomass and Wastewater Treatment Suhaib A. Bandh

https://ebookmass.com/product/valorization-of-microalgal-biomassand-wastewater-treatment-suhaib-a-bandh/

Electronic Waste: Recycling and Reprocessing for a Sustainable Future Maria E Holuszko

https://ebookmass.com/product/electronic-waste-recycling-andreprocessing-for-a-sustainable-future-maria-e-holuszko/

WoodheadSeriesinBioenergy TheWoodheadSeriesinBioenergypublishestitlesonthetopicofbioenergyasitrelatesto renewablesourcesofenergy.Theseriesnotablycoversbiologicalresources,chemicaland biologicalprocesses,andbiomassproductsforenergyproduction,alongwiththeenvironmental, social,management,andeconomicaspectsofbioenergy.

Alsointheseries:

• HwaiChyuanOng,IslamMdRizwanulFattah,andTMIndraMahlia, WasteValorizationfor BioenergyandBioproducts,2024,9780443191718

• JeyabalanSangeethaandDevarajanThangadurai, MicroalgalBiomassforBioenergyApplications,2024,9780443139277

• LinaMaríaGrajalesAgudelo,JuanCarlosValdésSerra,andErichCollicchio, Agroenergy, 2024,9780443214301

• SonilNandaandAjayK.Dalai, BiomasstoBioenergy,2024,9780443153778

• StefanoFerrariInterlenghi,JoséLuizdeMedeiros,andOféliadeQueirozFernandesAraujo, SustainabilityofMethylicandEthylicBiodieselProductionRoutes,2024,9780443219429

Editedby HwaiChyuanOng

DepartmentofEngineering,Schoolof EngineeringandTechnology,SunwayUniversity, JalanUniversiti,BandarSunway,PetalingJaya, Selangor,Malaysia;CentreforTechnologyin WaterandWastewater,SchoolofCiviland EnvironmentalEngineering,Facultyof EngineeringandIT,UniversityofTechnology Sydney,Ultimo,NSW,Australia

IslamMdRizwanulFattah

CentreforTechnologyinWaterandWastewater, SchoolofCivilandEnvironmentalEngineering, FacultyofEngineeringandIT,Universityof TechnologySydney,Ultimo,NSW,Australia

T.M.IndraMahlia

CentreforTechnologyinWaterandWastewater, SchoolofCivilandEnvironmentalEngineering, FacultyofEngineeringandIT,Universityof TechnologySydney,Ultimo,NSW,Australia

WoodheadPublishingisanimprintofElsevier 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates 125LondonWall,LondonEC2Y5AS,UnitedKingdom

Copyright © 2024ElsevierLtd.Allrightsarereserved,includingthosefortextanddata mining,AItraining,andsimilartechnologies.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorage andretrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowto seekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandthe CopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightby thePublisher(otherthanasmaybenotedherein).

Notices Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professional practices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribed herein.Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafety andthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatter ofproductsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods, products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-443-19171-8

ForinformationonallWoodheadPublishingpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MeganBall

AcquisitionsEditor: PeterAdamson

EditorialProjectManager: TeddyA.Lewis

ProductionProjectManager: SharmilaKirouchenadassou

CoverDesigner: ChristianBilbow

TypesetbyTNQTechnologies

Listofcontributors MohamedAboughaly FacultyofEnergySystemsandNuclearScience,University ofOntarioInstituteofTechnology,Oshawa,ON,Canada

MuhammadSaifullahAbuBakar ChemicalandProcessEngineeringDepartment, FacultyofIntegratedTechnologies,UniversitiBruneiDarussalam,BandarSeriBegawan,Brunei

CristobalN.Aguilar BioprocessesandBioproductsResearchGroup,Food ResearchDepartment,UniversidadAutonomadeCoahuila,Saltillo,Mexico

R.M.Alamelu DepartmentofMechanicalEngineering,AmritaSchoolofEngineering,AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

KassianT.T.Amesho InstituteofEnvironmentalEngineering,NationalSunYatSenUniversity,Kaohsiung,Taiwan;CenterforEmergingContaminantsResearch, NationalSunYat-SenUniversity,Kaohsiung,Taiwan;TshwaneSchoolforBusiness andSociety,FacultyofManagementofSciences,TshwaneUniversityofTechnology, Pretoria,SouthAfrica;TheInternationalUniversityofManagement,CentreforEnvironmentalStudies,MainCampus,Windhoek,Namibia;DestiniesBiomassEnergy andFarmingPTYLtd,Swakopmund,Namibia;RegentBusinessSchool,Durban, SouthAfrica

VinayAtgur DepartmentofMechanicalEngineering,KoneruLakshmaiahEducationFoundation(KLEF),KLDeemedtoBeUniversity,Guntur,AndhraPradesh, India

R.Bahru InstituteofSustainableEnergy,UniversitiTenagaNasional,Kajang, Selangor,Malaysia

K.Balaji DepartmentofMechanicalEngineering,AmritaSchoolofEngineering, AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

N.R.Banapurmath CentreforMaterialScience,K.L.E.TechnologicalUniversity, Hubballi,Karnataka,India

MuhammadKhalidBhat MultidisciplinaryCentreforAdvancedResearchand Studies,JamiaMilliaIslamia,NewDelhi,India

MuhammadRoilBilad ChemicalandProcessEngineeringDepartment,Facultyof IntegratedTechnologies,UniversitiBruneiDarussalam,BandarSeriBegawan,Brunei

RattananBoonmee DepartmentofChemicalEngineering,FacultyofEngineering, KingMongkut’sUniversityofTechnologyNorthBangkok(KMUTNB),Bangkok, Thailand

AthanasiosBourtsalas EarthEngineeringCenter,ColumbiaUniversity,NewYork, NY,UnitedStates

CarlosN.Cano-Gonzalez BioprocessesandBioproductsResearchGroup,Food ResearchDepartment,UniversidadAutonomadeCoahuila,Saltillo,Mexico

PollawatCharoenkool DepartmentofChemicalEngineering,FacultyofEngineering,KingMongkut’sUniversityofTechnologyNorthBangkok(KMUTNB),Bangkok,Thailand

ChingakhamChinglenthoiba DepartmentofChemistry,NationalUniversityof Singapore,Singapore

SantiChuetor DepartmentofChemicalEngineering,FacultyofEngineering,King Mongkut’sUniversityofTechnologyNorthBangkok(KMUTNB),Bangkok,Thailand;Biore fineryandProcessAutomationEngineeringCenter(BPAEC),KingMongkut’sUniversityofTechnologyNorthBangkok,Bangkok,Thailand

B.Deepanraj DepartmentofMechanicalEngineering,CollegeofEngineering, PrinceMohammadBinFahdUniversity,AlKhobar,SaudiArabia

OrlandodelaRosa BioprocessesandBioproductsResearchGroup,FoodResearch Department,UniversidadAutonomadeCoahuila,Saltillo,Mexico

RahulDutt DepartmentofMechanicalEngineering,AmritaSchoolofEngineering, AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

GauravDwivedi EnergyCentre,MaulanaAzadNationalInstituteofTechnology, Bhopal,MadhyaPradesh,India

E.I.Edoun TshwaneSchoolforBusinessandSociety,FacultyofManagementof Sciences,TshwaneUniversityofTechnology,Pretoria,SouthAfrica

I.M.R.Fattah CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Ultimo,NSW, Australia

MaheshGanesapillai MassTransferGroup,SchoolofChemicalEngineering, VelloreInstituteofTechnology,Vellore,TamilNadu,India

K.Govardhan DepartmentofMicroandNano-Electronics,SchoolofElectronics Engineering,VelloreInstituteofTechnology,Vellore,TamilNadu,India

ManarHamdy EnvironmentalSciencesDepartment,FacultyofScience,AlexandriaUniversity,Alexandria,Egypt

S.DineshShriHari DepartmentofMechanicalEngineering,AmritaSchoolof Engineering,AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

ZiaulHasan DepartmentofBiosciences,JamiaMilliaIslamia,NewDelhi,India; CentreforInterdisciplinaryResearchinBasicSciences,JamiaMilliaIslamia,New Delhi,India

M.M.Hasan SchoolofEngineeringandTechnology,CentralQueenslandUniversity,Rockhampton,QLD,Australia

MasjukiHjHassan DepartmentofMechanicalEngineering,FacultyofEngineering,InternationalIslamicUniversityMalaysia,KualaLumpur,Malaysia

YuhanHuang CentreforGreenTechnology,SchoolofCivilandEnvironmental Engineering,UniversityofTechnologySydney,Ultimo,NSW,Australia

SioniIikela TheInternationalUniversityofManagement,CentreforEnvironmental Studies,MainCampus,Windhoek,Namibia

SimeonOlatayoJekayinfa DepartmentofAgriculturalEngineering,Ladoke AkintolaUniversityofTechnology,Ogbomoso,Nigeria

ThitiratJiradechakorn DepartmentofChemicalEngineering,FacultyofEngineering,KingMongkut’sUniversityofTechnologyNorthBangkok(KMUTNB),Bangkok,Thailand

TimoteusKadhila FacultyofEducation,DepartmentofHigherEducationand LifelongLearning,UniversityofNamibia,Windhoek,Namibia

M.A.Kalam SchoolofCivilandEnvironmentalEngineering,FacultyofEngineeringandIT,UniversityofTechnologySydney,Sydney,NSW,Australia

KonstantinosKalkanis DepartmentofElectricalandElectronicsEngineering, UniversityofWestAttica,Egaleo,Greece

SujeetKesharvani EnergyCentre,MaulanaAzadNationalInstituteofTechnology, Bhopal,MadhyaPradesh,India

MohammadShahzebKhan CentreforInterdisciplinaryResearchinBasic Sciences,JamiaMilliaIslamia,NewDelhi,India

NaveenKumar DepartmentofChemistry,MaharshiDayanandUniversity,Rohtak, Haryana,India

MohdNizamLani DepartmentofChemistry,NationalUniversityofSingapore, Singapore;MicroplasticResearchInterestGroup(MRIG),UniversitiMalaysiaTerengganu,KualaNerus,Terengganu,Malaysia;FacultyofFisheriesandFoodScience, UniversitiMalaysiaTerengganu,KualaNerus,Terengganu,Malaysia

OpeyeoluTimothyLaseinde DepartmentofMechanicalandIndustrialEngineering Technology,FacultyofEngineeringandBuiltEnvironment,UniversityofJohannesburg,Johannesburg,SouthAfrica

MuneeraLateef DepartmentofAgriculturalGeneticEngineering,FacultyofAgriculturalSciencesandTechnology,NigdeOmerHalisdemirUniversity,Nigde,Turkey

AlaaElDinMahmoud EnvironmentalSciencesDepartment,FacultyofScience, AlexandriaUniversity,Alexandria,Egypt;GreenTechnologyGroup,Facultyof Science,AlexandriaUniversity,Alexandria,Egypt

PeterRamashadiMakgwane CentreforNanostructuresandAdvancedMaterials (CeNAM),CouncilforScientifi candIndustrialResearch(CSIR),Pretoria,South Africa

G.Manavendra DepartmentofMechanicalEngineering,BapujiInstituteofEngineeringandTechnology(BIET),Davangere,Karnataka,India

M.Mofi jur CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Ultimo,NSW,Australia;MechanicalEngineeringDepartment,PrinceMohammadBinFahdUniversity, AlKhobar,SaudiArabia

K.Neha DepartmentofMechanicalEngineering,AmritaSchoolofEngineering, AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

SaifuddinNomanbhay InstituteofSustainableEnergy(ISE),UniversitiTenaga Nasional(UNITEN),Kajang,Selangor,Malaysia

OyetolaOgunkunle DepartmentofMechanicalandIndustrialEngineeringTechnology,FacultyofEngineeringandBuiltEnvironment,UniversityofJohannesburg, Johannesburg,SouthAfrica

ChristopherTunjiOloyede DepartmentofAgriculturalEngineering,Ladoke AkintolaUniversityofTechnology,Ogbomoso,Nigeria

MeiYinOng InstituteofSustainableEnergy(ISE),UniversitiTenagaNasional (UNITEN),Kajang,Selangor,Malaysia

AshutoshPandey DepartmentofBiotechnology,AKSUniversity,Satna,Madhya Pradesh,India

AtinKumarPathak RINAClassi ficationandCertificationIndiaPvt.Ltd.,Auditor ClimateChangeandSustainability,Mumbai,Maharashtra,India

ErickM.Pena-Lucio FacultaddeCiencias,UniversidadAutonomadeSanLuis Potosí(UASLP),SanLuisPotosí,Mexico

JirapornPhojaroen DepartmentofChemicalEngineering,FacultyofEngineering, KingMongkut’sUniversityofTechnologyNorthBangkok(KMUTNB),Bangkok, Thailand

P.Pranay DepartmentofMechanicalEngineering,AmritaSchoolofEngineering, AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

S.PrawinSubrajith DepartmentofMechanicalEngineering,AmritaSchoolof Engineering,AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

ConstantinosS.Psomopoulos DepartmentofElectricalandElectronicsEngineering,UniversityofWestAttica,Egaleo,Greece;EarthEngineeringCenter,Columbia University,NewYork,NY,UnitedStates

R.L.Rag DepartmentofMechanicalEngineering,SCMSSchoolofEngineering& Technology,Cochin,Kerala,India

NeeluRaina DepartmentofChemicalEngineering,FacultyofEngineering,King Mongkut’sUniversityofTechnologyNorthBangkok(KMUTNB),Bangkok,Thailand

BoggarapuNageswaraRao DepartmentofMechanicalEngineering,Koneru LakshmaiahEducationFoundation(KLEF),KLDeemedtoBeUniversity,Guntur, AndhraPradesh,India

M.M.Rashed SchoolofCivilandEnvironmentalEngineering,FacultyofEngineeringandIT,UniversityofTechnologySydney,Sydney,NSW,Australia

MdMohsinRaza MultidisciplinaryCentreforAdvancedResearchandStudies, JamiaMilliaIslamia,NewDelhi,India

G.Rishiyadhav DepartmentofMechanicalEngineering,AmritaSchoolof Engineering,AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

S.Rupesh DepartmentofMechanicalEngineering,BiofuelResearchInformation andDemonstrationCentre,PESCollegeofEngineering,Mandya,Karnataka,India

R.Sakthivel DepartmentofMechanicalEngineering,AmritaSchoolofEngineering,AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

ChidchanokSereenonchai DepartmentofChemicalEngineering,FacultyofEngineering,KingMongkut’sUniversityofTechnologyNorthBangkok(KMUTNB), Bangkok,Thailand

SyfullahShahriar DepartmentofSoilScience,Sher-e-BanglaAgriculturalUniversity,Dhaka,Bangladesh

SumarlinShangdiar InstituteofEnvironmentalEngineering,NationalSunYat-Sen University,Kaohsiung,Taiwan;CenterforEmergingContaminantsResearch,NationalSunYat-SenUniversity,Kaohsiung,Taiwan

R.MaanuShree DepartmentofMechanicalEngineering,AmritaSchoolofEngineering,AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

HarMohanSingh DepartmentofEnvironmentalSciences,ShardaSchoolofBasic SciencesandResearch,ShardaUniversity,GreaterNoida,UttarPradesh,India

GhassanFadhilSmaisim DepartmentofMechanicalEngineering,FacultyofEngineering,UniversityofKufa,Kufa,Iraq;DepartmentNanotechnologyandAdvanced MaterialResearchUnit(NAMRU),FacultyofEngineering,UniversityofKufa, Kufa,Iraq

ManzooreElahiM.Soudagar InstituteofSustainableEnergy,UniversitiTenaga Nasional,JalanIKRAM-UNITENKajang,Selangor,Malaysia;Departmentof MechanicalEngineering,UniversityCentreforResearch&Development,Chandigarh University,Mohali,Punjab,India

GuangcanSu DepartmentofMechanicalEngineering,FacultyofEngineering,UniversitiMalaya,KualaLumpur,Malaysia;CentreforEnergySciences,Universiti Malaya,KualaLumpur,Malaysia

S.Sujay DepartmentofMechanicalEngineering,AmritaSchoolofEngineering, AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

N.Tamilarasan DepartmentofMechanicalEngineering,AmritaSchoolofEngineering,AmritaVishwaVidyapeetham,Coimbatore,TamilNadu,India

AdhithiyaVenkatachalapatiThulasiraman MassTransferGroup,Schoolof ChemicalEngineering,VelloreInstituteofTechnology,Vellore,TamilNadu,India

AnwarUsman DepartmentofChemistry,FacultyofScience,UniversitiBrunei Darussalam,BandarSeriBegawan,Brunei

PuneetVerma SchoolofEarthandAtmosphericSciences,QueenslandUniversity ofTechnology, Brisbane,QLD,Australia

IbhamVeza MechanicalEngineeringDepartment,UniversitiTeknologiPETRONAS(UTP),SeriIskandar,Perak,Malaysia

BidattulS.Zainal InstituteofSustainableEnergy,UniversitiTenagaNasional, JalanIKRAM-UNITENKajang,Selangor,Malaysia

M.F.M.A.Zamri InstituteofSustainableEnergy,UniversitiTenagaNasional, Kajang,Selangor,Malaysia

NurinWahidahMohdZulkifl i DepartmentofMechanicalEngineering,Facultyof Engineering,UniversitiMalaya,KualaLumpur,Malaysia;CentreforEnergy Sciences,UniversitiMalaya,KualaLumpur,Malaysia

Foreword Theenergysectorisundergoinganimportanttransition,tomeettheworld’senergy needs,toreducegreenhousegasemissions,tosupportclimatechangemitigation, andtoprotectourplanetforfuturegenerations.Amajorelementoftheenergytransitionistheintegrationoflarge-scalerenewableenergysources,includingbioenergy,in theenergymixofcountries.

Bioenergyisthetransformationofbiomass,derivedfromrecentlylivingorganic materials,intoelectricity,heat,andtransportationfuels.Alongwithwindandsolarenergy,bioenergyispoisedtoplayasignificantroleintheenergytransition.

Insupportoftheglobalresearchcommunityandthecommercialbioenergysector, the WoodheadSeriesinBioenergy publishesresearchandapplication-orientedbook titlesonthetopicofbioenergyasitrelatestorenewablesourcesofenergy.Theseries coversbiologicalresources,chemicalandbiologicalprocesses,andbiomassproducts forenergyproduction,alongwiththesustainabilityofbioenergy,namelytheenvironmental,social,management,andeconomicaspectsofbioenergy.

Buildingontheirextensiveresearchandeditorshipexperiences,Prof.Ong,Dr.Fattah,andProf.Mahliahaveeditedabookthatdocuments,inasinglevolume,the varioustechnologiestotransformbiologicalwastestreamsinbioenergyproduction.

WellanchoredintheUN’sSustainableDevelopmentGoal7,AffordableandClean Energy,thisbookpresentsabroadperspectiveofbioenergyprocessesinthevalorizationofbiologicalwastes.Besidesdocumentingthescientificandtechnological elementsoftransformingwastesintobioenergy,thisbookintroducesthechallenges andopportunitiesintheproductionofwaste-to-energyprocesses,alongwithaddressingthelifecycleperspectiveoftheseprocesses.

Consideringthescopeofthetopicscovered, WasteValorizationforBioenergyand Bioproducts:Biofuels,Biogas,andValue-AddedProducts isabookofinterestfora broadrangeofreaders,including,postgraduatestudents,academicandindustrial researchers,andindustrialpractitionersworkingonthevalorizationofbiological wastefeedstocksforbioenergyandbioproductapplications.

Prof.YvesGagnonPEng,DSc UniversitédeMoncton,Canada SeriesEditor,WoodheadSeriesinBioenergy

Preface Inaworldgrapplingwithenvironmentalsustainabilityandenergysecuritychallenges, wastevalorizationemergesasabeaconofhopeandinnovation. WasteValorizationfor BioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts takesyou onatransformativejourney,exploringtheuntappedpotentialofwastestreamsassourcesofrenewableenergyandvaluableresources.

Astheglobalpopulationcontinuestogrow,sodoeswastegeneration.Wemust seekalternativesolutionstoaddressthismountingcrisiswhileminimizingenvironmentalimpact.Thisbookisaninvaluableresourcethatdelvesintostate-of-the-art technologiesandstrategiesforconvertingwasteintoenergyandvaluableby-products.

Ourauthorshavemeticulouslyexamineddiversewastestreams,fromfoodand agriculturalresiduestowastewaterandindustrialorganicwaste.Theirexpertiseand insightsshedlightonthetechnicalintricaciesandchallengesoftransformingthese wastesintobiofuels,biogas,andothervalue-addedproducts.

Thiscomprehensivevolumeoffersacriticalanalysisofthecurrentwaste-to-energy processesandhighlightsthetransformativepotentialofemergingtechnologies.Each chapterscrutinizesthefeasibilityofwastevalorization,addressingitsmarketability andacceptabilityinourevolvingeconomy.Moreover,thisbookemphasizesthe importanceofsustainabilityandenvironmentalimpactindevelopingandimplementingtheseinnovativesolutions.

Thepathtoagreenerandmoresustainablefutureispavedwithgroundbreaking researchandinnovativeideas. WasteValorizationforBioenergyandBioproducts signi ficantlycontributestothistransformativejourney.Itisdesignedtoserveasa valuablereferenceforgraduatestudents,researchers,andengineersengagedinwaste managementandrenewableenergy.Webelievethisbookwillignitepassionand inspirethenextgenerationofthinkersandpractitionerstousherinaneraofwaste valorizationandsustainableprogress.

Wesincerelyhopethat WasteValorizationforBioenergyandBioproducts: Biofuels,Biogas,andValue-AddedProducts willsparkcuriosity,innovation,and collaborationamongresearchers,policymakers,andindustryleaders,drivingusalltowardagreenerandmoresustainablefuture.

Happyreading,andonwardtoabrighterandmoresustainablefuture!

Sincerely, Prof.Dr.HwaiChyuanOng Dr.IslamMdRizwanulFattah Prof.Dr.T.M.IndraMahlia

Introductiontowasteto bioenergy 1 R.Sakthivel,S.DineshShriHari,RahulDutt,S.Sujay,R.MaanuShreeand R.M.Alamelu

DepartmentofMechanicalEngineering,AmritaSchoolofEngineering,AmritaVishwa Vidyapeetham,Coimbatore,TamilNadu,India

1.1Introduction Manynationsaroundtheworldnowplaceahighpriorityonthesustainablemanagementofsolidwaste.Lowfundsorsubparadministrationmaybetoblame.Another sizablefractionofsolidwasteneedstobecollectedordisposedofcorrectly.Asa result,substantialtrashisdepositedwithoutanyrestrictions,whichseriouslydegrades theenvironment(Achtenetal.,2007).Effectivelytreatingwasteisinevitableinthe presentsituation.Wastetreatmentisalsoknownaswastecollection,processing,recycling,ordeposition,andwasteclassi ficationisbasedontheoriginsandcompositionof thewaste.Theprimarygoalofmanagingwasteisthereductionofthetoxiceffectsof wasteontheecosystem,withhumansocietyincluded.

Alargeportionofwastemanagementisfocusedonmunicipalsolidwaste,whichis generatedbyindustries,commercialactivities,householdtasks,agriculture,andmany othersources.Despitethefactthateffectivewastemanagementiscriticalforcreating viableandliveablecities,manydevelopingcountriesandcitiescontinuetostruggle withsustainablewastemanagementanddisposal.Thesesourcesgeneratethreekinds ofwaste:biodegradablewaste,industrialwaste,andhazardouswaste.Wastemanagementprotectsbiodiversity,resourcesofnature,andhumanlife.Managingwasteseffectivelyalsomakeapositiveeconomicimpactasemploymentpossibilitieswillincrease duetomanaginganeffectivewastemanagingsystem.Wasteisfrequentlydumped uponroadsandinemptysurroundingsindevelopingneighborhoods,contrarytothe garbagedumpsitesindevelopedeconomies.Thisunprocessedwasteaffectstheframeworkandthreatenstheecosystemwhendischargedintotheatmosphere.Wastemanagementhasbeengivenutmostimportanceovertimefordevelopingeconomies’ surroundingandexpandingsectors.Sometypicalwastemanagementstrategiesinclude minimization,reuse,recycling,andconvertingwastetoenergy.Amongthesestrategies, convertingwastetoenergyisachiefmethodofextractingwealthfromwaste.

Bioenergyisatypeofrenewableenergysourcethatisobtainedbyprocessing biomass(whichisalsoknownasbiowaste)likeagriculturalcropresidues,land fill gases(gasesthatarereleasedintotheatmospheremainlyasmethane),andbiogenic materialwastethatareusedforenergyasfueltoproduceheatorelectricity.Typically, “biomass” referstoaplant’snonfoodcomponents.Agriculturalandindustrialwaste,

aswellastrashfromwoodyandherbaceousspecies,areallincluded.Thethreecrucial organicsubstancesarecellulose,lignin,andhemicellulose.Energyfrombiomasscan beextractedinfourmainways:anaerobicdigestion,pyrolysis,gasification,anddirect combustion.Thehighlyconvenienttechniqueofwarmingandcookingisthecombustionofdrysolidwaste,primarilyagricultural.Itcanalsoundergoagasificationprocess toresultinmethane,hydrogen,andcarbonmonoxide,aswellaspower(Sadefetal., 2016).Thechapterwilladdressseveralthermal,biological,andchemicalconversion processesthatcanbeusedtorecoverenergyfromvariouswastesources.

1.2Solidwastes Themajorityofmunicipalandindustrialtrashgoestowardcreatingbiomasssources. Trashofdurableandnondurableitems,containersandpackaging,foodwaste,and otherinorganicwastefromhouseholdsourcesareallclassi fiedasapartofmunicipal solidwaste(MSW).Wastedepictsimproperresourceallocationandtheinefficiencies ofanymodernsociety.Around3.4 4billiontonnesofmunicipalsolidgarbageare generatedannually,and120 130billiontonnesofnaturalresourcesareconsumed globally(Songetal.,2015).Solidtrash,industrialgarbage,electronicwaste,food waste,andmanyothersallpresentparticulardif ficulties.Industrialoperationslike miningandfactoriesproduceindustrialwastes.Duetotheeffects,ithasonbothhumanhealthandtheenvironment.

Illegaldumpingattractspossibleenvironmentalthreats.Notallindustrialtrashgets collectedandhandledastheproductionofgarbagerises.Electricalequipmentand electronicgadgets,or “e-waste,” aretherapidlygrowingwastesourceontheplanet. Glass,metal,andothermaterialsareusedtomakethem.Peopleareexposedtovarious harmfulchemicals,resultinginissuessuchascutaneousexposureandinhalation.Food thatcannotbeadequatelyutilizediswhatisreferredtoaswaste.Itmightbecausedby humanfoodwaste,agriculturalwaste,etc.Itnegativelyaffectstheenvironment,such asfoodwastealongthesupplyandconsumptionchains.Climatechangeisacritical factor.Fossilfuelsareessentialtothefoodandagriculturalsystems.Foodisthe maincomponentofmaterialsdumpedinland fillsandtheprimarysourceofland fill gas(Daskalopoulosetal.,1997).

1.3Agriculturalresidues Cropresidues,straws,husks,nutshells,andmanymoresourcesareexamplesofsignificantagriculturalresidues.Theycangenerallybeclassifiedintotwodifferentgroups:(1) fieldresidue,whichreferstomaterialleftinorchardsfollowingharvesting;and(2)processresidue,whichreferstothematerialsleftoverafterturningthecropintoauseable product.Becauseofitsmagneticcomponentsandbiochemicalmakeup,agricultural biomasshasbeentoutedasoneofthemosteffectiveproductsandbiofuels.Additionally,someaffordablerenewableresourcesareaccessible.Anaerobemicrobesbreak 2WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

downintobiogas,nutrients,andothermaterialsthroughbiomethanation.Numerous usesforbiogasincludetheproductionofheatorpower,theconversionofbiogasinto methane,andtheproductionofcompressednaturalgas(CNG).Thedigestivesystem, amongotherthings,directlyaffectsbiogascompositionandmethaneoutput.Farmers burnallwasteproductsduetothebiomethanationprocess,whichcausesairpollution. Anaerobedigestionreducestheemissionofgasessuchasmethane(Wilsonetal.,2009). Thereareseveralprocessesinbiomethanation,includingtheacidogenicphase,acetogenicphase,hydrolysisphase,andmethanogenicphase.

1.4Pulpandpaperindustrywaste Bark,leaves,needles,andsludgearejustafewofthebiomassresiduesthatareproducedbythepulpandpaperindustry’sprocesses.Biomassthatisnotsludgeserves asafantasticsourceofbiofuels.Blackliquorisaby-productwithahighenergyvalue becauseitcontainslignin.Thepapermillnowusesligninasafuelsourcetocreate energy,andanyextraenergyisusedtoincreasetheplant’selectricaloutput.Thepaper andpulpindustrieshavehistoricallybeenexpectedtousemoreenergyandnaturalresources.Threebasiccategoriesofpollutants liquideffluents,solidwastes,andair emissions havebeenproduced.Samplingandanalyzingpulpandpaperwaste,determiningtheappropriatedosageofpulpandpaperwaste,determiningtheappropriate reactiontimefortheremovalofheavymetalsfromwastewaterproducedbymetal finningusingpulpandpaperindustries,anddeterminingtheabilityofheavymetals insedimenttoleachfromthesedimentareallpropertiesofpaperandpulpfactory wastes.Followingsamplecollectionandpulpandpaperwasteexamination,thesamplesarespreadoutontrays,allowedtoairdryforawholenight,andthenstoredin plasticbags.Wecanusethatinformationtodeterminethesubstance’spHandchemicalmakeupofanyheavymetalspresent.Wastewateriscollectedinpolyethylenebottlesforcollectionandanalysisofmetal fishingwastewater.

LowmoisturecontentandabasicpHaretheoutcomes.HeavypHvaluesarecaused bycarbonatecomponents,whichalsointeractwithheavymetalstogeneratemetalcarbonates.WastewaterfrommetalpolishinghasaverylowpHvalue.Theeliminationof heavymetalsfrommetal finishingeffluentwasanalyzedusinglimemudandboilerash recoveredfromthepaperandpulpindustriesatninedoselevels.Thebulkofheavy metalshadlowerremovalefficiencieswhenthereactiontimeexceeded45min.The prolongedresponsetimepassedthepointatwhichanynoticeableremovalincreaseoccursmayhelpexplainthisoutcome.Beyondthispoint,efficiencydeclinesandplateaus,andcontacttimesincrease.Aleachabilitytestwasperformedtodetermine whethercopper,chromium,lead,andzinccouldprecipitatefromthesedimentunder anychosentreatmentconditions.Thesedimentwastestedforleachingwithoutany priorpreparation.Theleachingtestfoundtracequantitiesofchromium,copper, lead,andzinc.Thestatisticalanalysisdemonstratedthatthetreatmentwithvarious pulpandpapermanufacturingwastesaffectedtheleachingbehavioroftheseheavy metals.

4WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

1.5Woodandforestwaste Oldstandsoftimberandpulpingareamongtheforestwastes,andtheyarehighlyhigh inenergy.Itbecomesvitalandcost-effectivetodecreasethedensityofthebiomassin theforestsincewastesfromtheforesttypicallyhavealowerdensity,andthefuel valuesmaintainhightransportationcosts(Oudaetal.,2016).Thecoreelementsof wood,acomplexmaterial,arecellulose,polysaccharides,andlignin.Water,lignin, andcellulosemakeupthemajorityofanobject.Lignocellulosicmaterialsundergo thermaldegradationthroughcomplexchemicalreactionslinkedwithamassand heattransferprocess.Theactivationenergyforthewholepyrolysisofwoodhasregularlybeenshowntoclusterarounddiscretevalues.StudiesonpyrolysiswereconductedusingTGAstandardequipment(YorulmazandAtimtay,2009).Allexperiments wereperformedusinganinertnitrogenenvironmentatstandardatmosphericpressure andwitha flowrateof50mL/min.Thesamplewasindirectcontactwithathermocoupleenablingustomeasurethesample’stemperatureatanytimeandreducemeasurementerrorsbroughtonbytemperaturegradients.Amechanicallyoperated elevatorwasdevelopedandconnectedtotheTGA’sovenforquickspecimenheating (BrancaandDiBlasi,2003).Theoven’sdisplacementmayberegulatedtoadesired speedandheight.Tocomparetheresults,twodifferenttypesofexperimentswereperformed.Theyaredynamicandisothermal(Reinaetal.,1998).

Ifisothermalexperimentsareconductedinintervalsbetween225and325 C,To keepaconstantlow-temperaturegradientbetweenthesampleandtheoven, isothermalrunsareperformedbyslowlyheatingthesample.Oncethesetpoint wasattained,theoven’ stemperaturewasmaintaineduntiltheisothermalrun’ s completion.Theforestwoodhasthehighestpyrolyzableproportionat250 C.The intervalwasbetween700and900 C,Theseinvestigationsusedashpyrolysisand wereperformedattemperaturesof700 C/min.Whenthesampletemperature reached150 C,theovenwasraisedto3cm/min.Then,toguaranteesystemstabilizationleftinthispositionforafewminutes.Wemeasuredthetimetoattainthetemperaturesetpointandtheweightlossthatoccurredduringtheperiod(Adleretal., 2009 ).Woodwithamaterialwithlowheatconductivitycanproducesigni fi canttemperaturegradientswithinthesampleathighheatingrates.Underthecircumstances, heattransfercontrolsreactionsinsteadofchemicalprocesskinetics(Yorulmazand Atimtay,2009).

1.6Algae Algaearegainingpopularityasapotentialfuelsourceduetotheirhighlight-tobiomassefficiency.Theirrapidgrowthallowsthemtocompleteanentiregrowingcycleinamatterofdays.Themajorityofalgaecontainmuchoil.Duetotheirhighoil contentandhigh-speedbiomasssynthesis,microalgaehavealsobeenidenti fiedasan excellentsourceforthemanufactureofbiofuels(Popperetal.,2011).Modernscience andtechnologyprovidemanypathwaystoconvertsolidwasteintovaluableenergy sources.Eachpathwayhasitsuniquemeritsanddemerits.Thecommonpathways fortheconversionofbiomassintovaluableenergyarediscussedbelow.

1.7Mechanismstoconvertsolidwastetoenergy 1.7.1Pretreatmenttechnologies

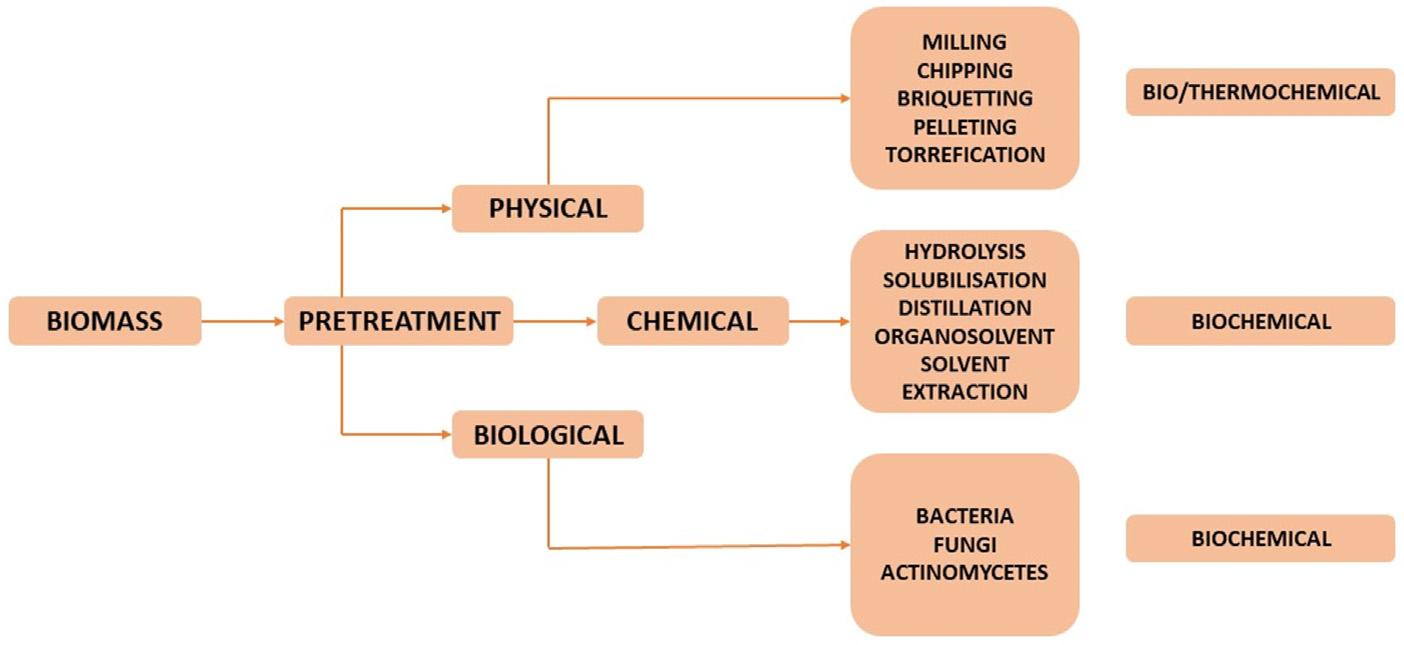

Anybiomasshastobepretreatedbeforeusingitinanyconversionprocesstogetits maximumrecovery.Pretreatmentoflignocellulosicbiomassisanessentialprocessin thebiomassconversionprocess.Theconstituentsoflignocellulosicbiomasswillcontrolthedegradationabilitythroughoutthepretreatmentprocess.Ontheotherhand,the componentsofthenonlignocellulosicbiomasswillactasacatalystandspeedupthe pretreatmentprocessbyincreasingtheperformanceoftheconversionprocess.The pretreatmentmethodsaregivenin Fig.1.1

1.7.1.1Physicalpretreatment

Beforecarryingonwithanyconversionprocesses,wehavetotreattheavailablebiomassesasaresource.Inthephysicalpretreatmentprocess,thesizeofbiomassparticles isintendedtobedecreasedfortheenlargementofsurfaceareaandtheporesize.This stageoftheprocessdoesnotusechemicals,andhugevolumescouldbeused(Karimi etal.,2013).Theoperationwouldbesimpleandeasy.Butbeforewedothepretreatmentprocess,theapplicationofthebiomassshouldbeanalyzed,basedonwhichitcan bedeterminedbywhichmethodtheconversionprocesscancarryon.Forexample, millingoperationscanreducethesizeinbothbiochemicalandthermochemicalconversions(Bhaskaretal.,2011).Thebiochemicalconversionprocessisdoneto improvehydrolysis,andtheThermochemicalconversionprocessrequiresmilling forthedensifi cationprocess.Thedecreaseinsizeisnecessarytoeliminatethelimitationsofthemassandheattransfer(Maitloetal.,2022).

1.7.1.2Chemicalpretreatment Thisprocessinvolvesusingorganicandinorganiccompoundstoalterthestructureof thebiomass,whereallthebondsoftheorganiccomponentsarechanged.Intheprocess ofthechemicalpretreatment,intheLCB,thereductionofcelluloseandthebreakdown

ofthelignin,depolymerization,andthedegradationofthecellulosetakeplace(Norrrahimetal.,2021).Itincreasestheaccessibility,changesthestructure,andhydrolysesthe biomassintovarioussugarfractions.Nevertheless,thismethodconsumesmuchtime, andtheequipmentmayhavecorrosion-relatedissues(Hsu,2018).

1.7.1.3Biologicalpretreatment Thistreatmentmethodhasseveraladvantagesovertheothermethodsasahighyieldof neededproductisobtained,andnotoxicsubstancesarereleasedintotheenvironment duringtheprocess.Apieceofsimpleequipment,lowenergy,andalargeareaare requiredforthispretreatmentprocesscompletion.Therateofhydrolysisisprolonged asitisessentialtohavealongresidencetimeofabout10 14daystogettheremarkablequalityoftheproduct(Sharmaetal.,2019).Thisprocessismoresuitableforboth highandlowbiomassmoisturecompounds.Biologicalpretreatmentstypicallychange thechemicalmakeupofthelignocellulosefeedstockbyusingfungithatbreakdown wood(soft,brown,andwhiterot).Typically,soft-rotandbrown-rotfungimainly destroyhemicellulosewhileslightlyalteringlignin.Thelignincomponentismore activelyattackedbywhite-rotfungus(Vasco-Correaetal.,2016).

1.7.1.4Alkalinepretreatment

Alkalinepretreatmentinvolvesusingbaseslikecalciumhydroxide(lime),potassium hydroxide,sodiumhydroxide,andmanyotherscombinedwithhydrogenperoxideor otherchemicals.Thebreakageofthechemicalbondsthatareholdingtogetherlignin andcarbohydratesincreasesthevulnerabilityofcarbohydratestoenzymaticattacks.

1.7.1.5Thermalpretreatment

Thermalpretreatmentistheheatingoffeedstockbetween150and180 Ctodegrade hemicelluloseandlignin.Examplesincludesteampretreatment/steamexplosion,hot water,theexplosionofammonia fi ber,andCO2 explosion.Itisessentialnottopretreat thefeedstockinswelteringconditionssince,athightemperatures(over250 C), phenoliccompoundsareproducedthatslowdownthefermentationprocess.

1.8Thermochemicalconversionpathway Thethermochemicalpathwaycomprisestechniquesthatusethermalenergyasasignificantdrivingsourcetoconvertbiomassintouseableenergy.Someoftheprimary techniquesusedareincineration,gasi fication,andpyrolysis.

1.8.1Incineration Incinerationisatechniqueofburningtheorganicsubstancepresentinthewasteina controlledmanner.Itisoneofthemajorthermochemicalconversionprocessesin modern-dayindustries.Theprimaryobjectiveofincinerationistoreducethevolume 6WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

Introductiontowastetobioenergy7

ofwasteandproduceenergyfromwaste.Theorganicsubstancepresentinthewasteis convertedasenergy,andinorganiccomponentssettledownasash.ThreeT’s(time, temperature,andturbulence)playanimportantroleinachievingoptimumefficiency. Asincinerationisalow-costandhighlyreliabletechnique,itisawidelyusedwaste removalprocess.

1.8.2Gasification Gasifi cationisatechnologicalprocedurethatturnscarbon-based(carbonaceous) fundamentalresourcesintovaluablegaseousfuels.Inagasi fier,chemicalreactions occurwhenoxygenandsteamdirectlycontactcoalathightemperaturesandpressures, convertingthefeedintosyngasandmineralwaste.Syngasisgiventhatnamebecause itisastepinproducingsyntheticnaturalgas.Syngasisoneoftheprimarysourcesproducinghydrogenfuel.Manyprocessesforproducingenergyandothervaluableproductsfromfeedstockslikecoalandbiomasscanbereplacedbygasification.Thereare severalbenefitstogasification,especiallyintheproductionofcleanelectricity.Coalis theidealfeedstockoptionbecauseofitsconstantpriceandsuf ficientsupplyanywhere intheworld(Abdulkadir,2009).Thefollowing flowchartshowsthegasi ficationprocessforcoal(Fig.1.2).

Integrationofadvancedprocessandconceptscanleadtopotentialconceptslike UNIQUEreactor,whichhasconditioning,gascleaning,andintegratedgasi fication assingleunitwherethereductionoftarusingcatalyticactivitycanbecarriedoutin theprimarybed(HeidenreichandFoscolo,2015).UnderthisUNIQUEgasifi er concept,thereductionoftarusingcatalyticactivityintheprimarybed.Filtration andscrubbingaretypicallyusedduringgasifi cationfacilitiesthatarecurrentlyin

Figure1.2 Gasificationprocessofcoal.

8WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

operationtoreducethenumberofparticulatesandtarintherawsyngas.Inthis approach,puregas,suchasfuelgas,isgivenaccesstotemperaturesnearthesurroundingtemperature.Thegasengineisthemostpracticalalternativeforpowergeneration immediately.Toencouragehighefficiencyforindustrialpurposeinthegasifi cationof biomassfortheproductionofenergyandtoproducechemicals,gascleaningwithhigh temperatureandconditioningusingcatalystsareinthemainfocus.Gastreatmentsare tobecombinedwithconvertingbiomassandachievingitatatemperaturerangethat doesnothaveabigdifferencetomaintaintheenergybuiltupduetoheatcontentinthe biomassgas.Recentadvancementsinnovelcatalysts,sorbents,and filteringmediaat hightemperaturesmakeitpossibletoputtogethertheentireprocesstogenerateaclean andgreenfuelfrombiomassthatpromisesinstantaneousandeffectiveconversioninto power.

TheUNIQUEgasifierconceptisanideathatwasinitiallydescribedinpatents;it wasthenappliedinsubsequentdevelopmentsandindustrialtestingcampaigns.The conceptforatightcollaborationofbiomassgasi ficationwithhotsyngascleaning andaddedconditioningsystemswasthoroughlyexaminedinitsvarioustechnicalaspectsthroughacollaborativeEuropeanR&Dproject.Althoughsteamreformationof highmolecularweighthydrocarbonsisinvestigatedtobethesuitedapproachfortheir removal,chemicalkineticsofthehomogeneousreactionsinthegaseousphaseare excellentathighertemperatures(Ragauskasetal.,2006).

1.8.3Torrefaction Torrefactionisathermochemicalprocedurethattriestoreducethepresenceofmoistureandvolatilecontentinthebiomasstoenhanceitsfuelqualities,likeincreasedenergydensity,betterhydrophobicbehavior,removalofbiologicalactivity,effortless grinding,increasinguniformcomposition,andmanyotherproperties.Torrefaction isfrequentlyreferredtoas “mildpyrolysis” becauseitoccursattemperaturesbetween 200and350 C,lowerthanpyrolysis(Abdulyekeenetal.,2021).However,itbehaves similarlytopyrolysisinaninerttypeorareducingatmosphere,thatis,withoutoxygen.Typically,ambientpressureservesastheoperationalpressure.Hemicellulose, cellulose,andlignin,threelignocellulosiccomponents,areintroducedtodegradation duringtorrefaction,whichtypicallyresultsintheresultofCO2 andH2O.Then,the followingchangesareseen,adropinHandOcontentsandanincreaseinCcontents areseenintheresidueproduced(Thanapaletal.,2014).

Themoisturecontentofthetorrefiedmaterialrangesfrom1%to3%onawetbasis (w.b.).Thebiomassbecomeshydrophobicduringtorrefactionbecausethehydroxyl groupislost.Thetorrefiedbiomassiseasiertogroundbecauseofitsbrittlecharacter. Theproximaland finalcompositionsarealteredbydevolatilizationandcarbonization reactions.Thebiomass’scarboncontentriseswhileitshydrogen,oxygen,andnitrogen contentsfall(Heetal.,2018).Torrefactiontechnologyhasexceptionalqualities,but commercializationisdif ficultbecauseofproblemscausedbythereactor’sdesign andtheproduct’squality.Fixedbed,rotatingdrum,microwave, fluidizedbed,horizontalmovingbed,andverticalmovingbedarethereactortypesfrequentlyused forbiomasstorrefaction(Tumuluruetal.,2021).

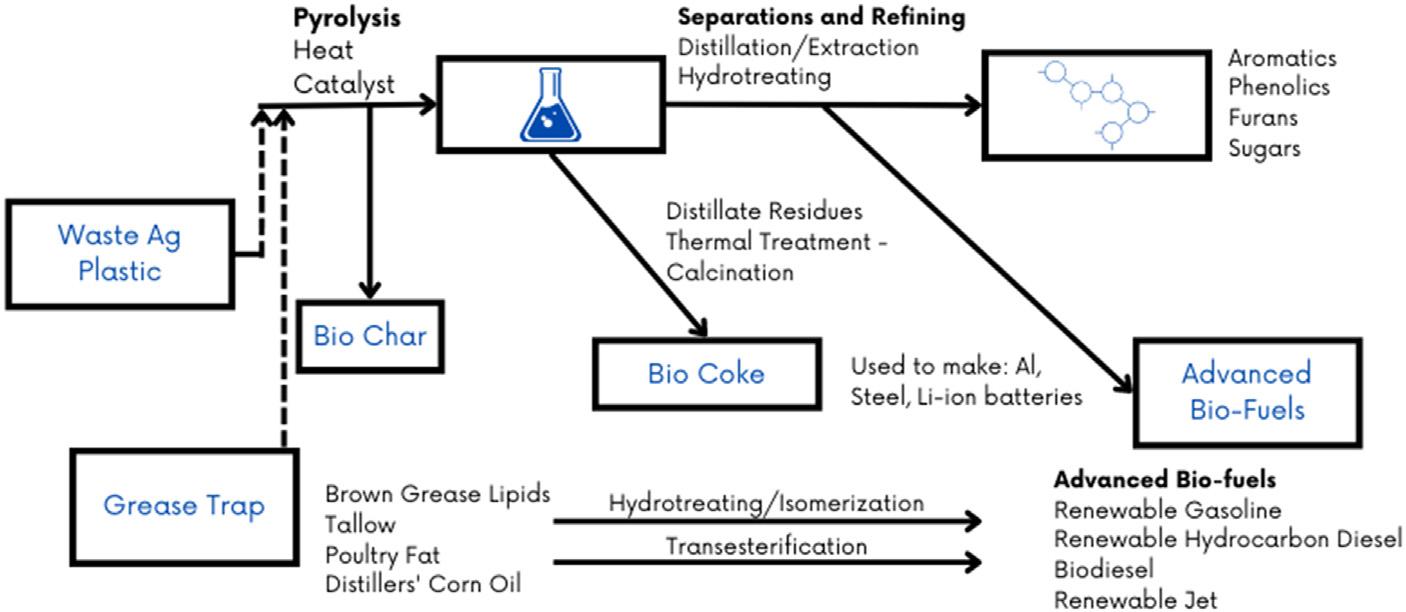

1.8.4Pyrolysis Itistheprocessofheatingorganicmaterialsinthevacancyofoxygencalledpyrolysis. Fig.1.3 showsthe flowchartoftheprocess.Typically,biomassispyrolyzedattemperaturesof500 Cormore,whichishotenoughtodegradethestrongbiopolymers.The biomassthermallybreaksdowntoreleasecombustiblegaseswithcharcoalinsteadof burningsincethereisnopresenceofoxygen.Pyrolysisisonetechniqueforturning biomassintoanintermediateliquidsubstancetobelaterusedtocreatedrop-inhydrocarbonbiofuelsandotherpetrochemicalreplacements.Althoughthepresenceofpersistentgases,suchasCO2,CO,H2,andlighthydrocarboncompounds,isignitedto producesomeofthethermalenergysuppliedtotheprocess,thebulkofthesecombustiblegases,throughcondensingtopyrolysisoil,acombustibleliquid(biooil)(Demirbas andArin,2002).Asaresult,three finalproductsareproducedwhenbiomassispyrolyzed:biooil,aliquid;biochar,asolidsubstance;andsyngasinthegasphase.The compositionofthefeedstockandtheprocessingparametersaretwofactorsthatimpact theproportionoftheseproducts.However,biooilproductionismaximizedunderfast pyrolysisconditionsatapyrolysistemperatureof500 C,andthecombinedrateofheatingisincreasedtoabout1000 C/s(Solaretal.,2016).Inthisenvironment,atypical biomassfeedstockgeneratesbiocharyieldsof15% 25%andbiooilyieldsabout 60% 70%ofthecan.Syngasaccountsforthe final10% 15%.Theprimarybyproductofslowpyrolysisprocesses,whichuseslowerheatingrates,isoftenbiochar. Sincethesyngasplussomecharcoaloroilmaybeburnedtocreatealltheenergyneeded tofuelthereaction,thepyrolysisprocesscanbeself-sustaining(Inguanzoetal.,2002).

1.9Biochemicalconversionpathway

1.9.1Fermentation

Toproduceethanolfromcellulosicfeedstock,fermentationisoneoftheprimary methodsemployedcommercially.Fermentationsystemsconsistoftwo, “wet” and

Figure1.3 Process flowchartforpyrolysis.

10WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

“dry” fermentationsclassifiedonthebasisofthepresenceofmoisturecontentintheset ofsamples. “Wet” fermentationisaprocessexclusivefortheliquidsubstrateswherethe presenceofdrymattercontentisnotgreaterthan15%.Fermentationofbiomasswitha higherdrymattercontentisreferredtoas “dry” fermentation.Themajorityofdrymatter presentinsubstratesistobekeptunder40%.Withalesserwatercontent, “wet” type fermentationtechniquesaremainlyruninacontinuousstyle,whichheightensthestabilityoftheprocess;however, “dry” solutionscanworkinacontinuousorperiodicprocedure.Dryfermentationcomparedtowetrequiresasmallerreactorvolume.Streamsof processedmatterarealsolesser.Italsomakesspacefortheprocessingofabroaderspectrumofbiodecomposablewaste(increasednonhomogeneityofthebatchispermitted).

Celluloseandhemicellulosearethetwotypesofpolysaccharidesinafeedstock.Hydrolysisconvertsthemintofreemoleculesofsugar(glucose,mannose,galactose, xylose,andarabinose),producingethanolthroughfermentation.Ligniniseliminated duringtheprocessofconversionasitcannotbeusedtomakeethanol;instead,itisoften usedtopowerorheatanethanolmill(Bain,2011).Pretreatment,alsoknownas firststagehydrolysis,isrequiredtodismantletheprotectivepropertycreatedbyligninand hemicellulose,disruptingthecrystallinestructureandloweringthedegreeofpolymerizationofcellulosetoensureeffectiveenzymatichydrolysisofcellulose.Themixture releasedduringthepretreatmentstageisdividedintoaliquidlikehemicelluloseshydrolyzateandasolid(lignin þ unhydrolyzedcellulose).Theliquidportionofthemixtureis composedofxylose,mannose,andmanyothers,withasmallamountofhydrolyzedcelluloseintheformofglucose.Anotherroundofenzymatichydrolysisisperformedon thesolids(alsocalledsecond-stagehydrolysis)beforeconductingthefermentationprocess.Fermentationistheprocessofanaerobicbreakingofsugarmoleculestoproduce alcohol.Theobtainedsugarinthehydrolysisprocessistreatedwithmicroorganisms likeyeastundercontrolledtemperaturefor2 3days.Thesucroseandzymasepresent intheyeastconvertthesugarmoleculesintoethanolduringthereactionperiod.

Themonomericsugarfermentationisgenerallycontinuedbyrecoveryofethanol fromthefermentationproduct.Generally,themoisturecontentofthebrothislessened toapproximately0.5%byvolumecreatingthepathwayforthecreationofanhydrous ethanolwithaminimumof99.5%byvolume.Theethanol watersolutionhasanazeotropicnatureofconstraintsinthisoperation.Itcanbecarriedoutbyfollowingthedistillationprinciple(i.e.,balancingthedifferenceintheboilingpointofthesolution’s components).Thechallengefacedwiththeazeotropicsolutionisovercomebyadding aseparatingagentthataltersthecriticalcomponent’srelativevolatility.Thetechniques thatareusedtorecoverpureethanolfromthefermentationbrothincludetechniquesof differenttypesofdistillationandchemicaldehydration.Inchemicaldehydration,thefermentedethanolandwatermixtureisheatedtoseparateethanolcommonlyinastill.As ethanolevaporatesrapidlycomparedtowater,theethanolpresentrisesthroughatube, collects,andcondensesintoacontainer,andthenwaterisleftbehind.

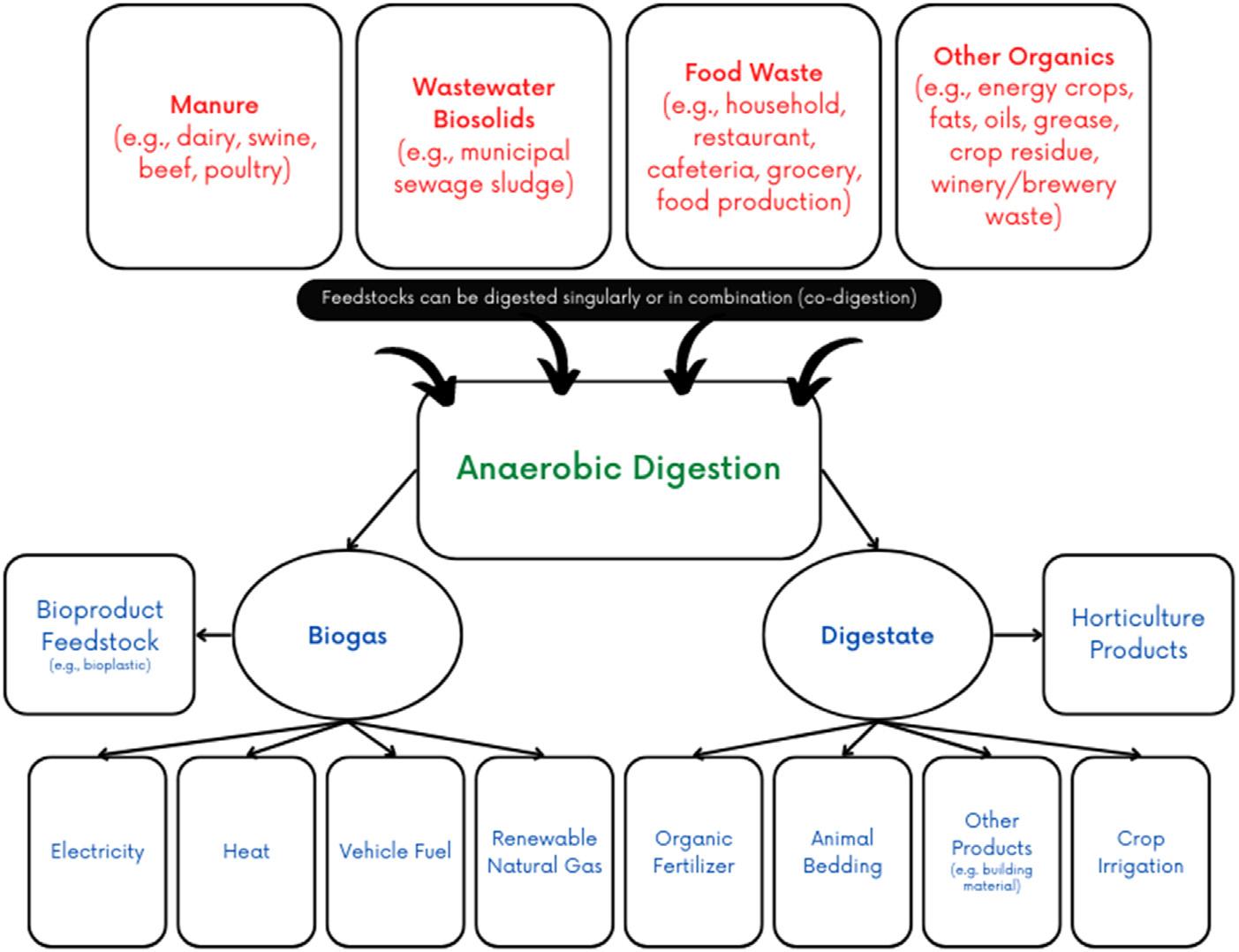

1.9.2Anaerobicdigestion

Anaerobicdigestionisasequenceofprocesseswhereorganicwastematerialssuchas livestockmanure,wastewaterbio-solids,foodscrapsandotherorganicsarebroken

downordecomposedbymicrobialaction(bybacteria)intheabsenceofoxygen.The otherorganicsarefats,oils,cropresidue,energycrops,etc.

Anaerobicdigestionistheleastenergy-consumingofallbioenergyproduction methodswiththeemissionofgreenhousegasses.Thebiomassgeneratedinanaerobic digestionis6/8th-foldlowerthantheproductionoftheaerobicprocess.Fortherelease ofbiogas,anaerobicdigestiontakesplaceinareactor.Asmallerreactorvolumeis enoughforitasitcanhandleahighvolumetricloadingrate.Consideringtheanaerobic treatment,nutrientsupplementisnotrequiredforanaerobictreatmentasonlyaless amountofbiomassisproduced.Thebiomassisfurtherprocessedbythefollowing stepstogetthe finalproduct thestagesofanaerobicdigestionaregivenin Table1.1

Codigestionisatechniquetocombinethemajorityoforganicmaterialstogether intoonedigester.Manure,foodwaste,energycrops,cropresidues,fatsoils,and greasesfromrestaurantgreasetrapsarethemainexamplesofcodigestedmaterials. Low-yieldingorchallenging-to-digestorganicwastecanreleasemorebiogaswhen codigested.Biogasanddigestatearetwovaluableby-productsofanaerobicdigestion (Fig.1.4).

Thedisposalofsolidorganicwastehasbecomeaconcernfortheenvironmentand humanhealth.Theoutputofvegetablewasteisreasonablylargeandcausesincreased municipalland fills.Anaerobicdigestionstandsoutamongthemanyalternativesasa viablesolutionfortreatingorganicwaste.Becauseithaslittleimpactontheenvironmentandhasagreatpotentialforenergyrecovery,anaerobicdigestionisoneofthe treatmentalternativesfororganicsolidwastesthatareparticularlywellsuited.Anaerobictreatmentofsolidorganicwasteislessprevalentthanaerobictreatmentbecause stabilizationrequiresampletime.Duetovariousnovelbioreactordesigns,anaerobic digestionmaycurrentlybeperformedatratesfarhigherthanthosemadefeasibleby employingconventionalmethods.

Severalevaluationswiththeidenticalobjectiveofevaluatingthepretreatmenteffectswerepublishedrecently.Mostofthepretreatmentmethodsresearchhasfocused onsludgefromwastewatertreatmentplants,eitherorbothlignocellulosicsubstrates, incontrasttothegrowinginterestinpretreatmentstrategiestopromoteanaerobic digestion(Matanoetal.,2012).Thepretreatmentprocedure’seffectiveness,energy balance,costs,andlong-termviabilitywillbecompared.Almostanyorganicwaste

Hydrolysis stage

MethanogenesisFinalcomponents:CH4 (methane)andCO2, whichareusedasgreen energy Introductiontowastetobioenergy11

Insolubleorganicpolymersaredecomposedbymakingthemavailable toaccessforthenextmicroorganism,whichistheacidogenic bacteria.

AcidogenesisConversionofaminoacidsandsugarsintoCO2,H2,ammonia(NH3) andorganicacids

AcetogenesisConversionoforganicacidsaceticacid(CH3COOH),CO2,H2, ammonia(NH3)

Table1.1 Stagesofanaerobicdigestion.

12WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

canbenaturallytransformedintoanotherformwhilebeingoxygen-freethroughanaerobicdigestion.Asaresultofthediversemicrobialcommunities’ breakdownoforganic waste,biogasandotherorganiccompoundswithhighenergycontentareproducedas by-products(Chernicharoetal.,2015).

1.10Liquidwaste Examplesofliquidwasteincludewastewater,fats,oils,grease,usedmotoroil,liquids, solids,gases,andhouseholdtoxicliquids.Thesesubstancesaredangerousandcould damagethesurroundingsorthehealthofhumansociety.Theycanalsobecommercial productslabeledas “liquidindustrialwaste,” likecleaningagents,pesticides,orremainsfromproduction.Theproducedwaste,storage,transportation,treatment,and disposalofhazardousandliquidwastesaresubjectedtospeciallawsinadditionto standardwasteregulations.Thesewastewaterscanbefurthersplitintocategories: inorganic,organic,RCRAwastewaterwithheavymetals,RCRAwastewaterwithorganics,nonhazardousoilandwatermixtures,CERCLAhazardous,andmanyothers. Thisvarietyofwastewatercanbeusedasasignificantresourcefortheproductionof electricity,water,andotherplantnutrients.Successfulenergyrecoveryfromthese wastewatershasthepotentialtosave54billiongallonsoffuelannuallyinthe

Figure1.4 Overviewofanaerobicdigestion.

transportationindustry.Usingnutrientslikenitrogen(N)andphosphorus(P)inwastewatercouldreducethenumberofmaterialsandenergyneededtomakefertilizers, whichcouldexplainwastewater’spotentialforadditionalenergy.

Theexpandingpopulationandfoodconsumptioninemergingcountries,aswellas improvinglivingconditionsandchangingdietarytastes,havecontributedtosigni ficantgrowthinthedemandforedibleoil.Oilseedsmustbeprocessedandrefi nedto produceedibleoil,whichgeneratessignificantamountsofwastewater,organicsolid waste,andinorganicwaste.Oilmanufacturinggeneratesalotofwasteproducts, includingwastewater,which,ifimproperlytreated,canharmtheenvironment.Often increasedlevelsoftotaldissolvedsolids,totalsuspendedsolids,oilandgrease,lipids, phosphate,andsulfateinthewastewaterfromedibleoilcompanies,whichleadtohigh organicandinorganicloads.Theseeffl uentsmustbetreatedaccordingtoenvironmentalnormsandstandards,takingintoaccountseveralenvironmentalfactorsthat couldleadtoenvironmentalandhumanhealthdegradation.Thewastewaterscanbe effectivelyemployedasrawmaterialsforproducingbioenergyorfactorygoods.Additionally,avarietyoffoodproducts,biopolymers,bioactivecompounds,biofertilizers, andbiopesticidesarecreatedusingeffluentfromedibleoils.

Diversetechniquesareusedtotreatedibleoilwater,includingcomplexoxidation processes,membranetreatment,physiochemicalprocesses,andbiologicaltechniques. Wastefromthefoodsector,andtheeffluentfromedibleoils,frequentlycontainsa largenumberofessentialcompoundsthatcanbesalvagedandutilized.Inaddition torecoveringbioactivecompounds,biopolymers,andfattyacids,wastewatercanbe utilizedtomanufacturebiomass,biotransformitintobiofuels,andproducebiomass itself(Zhouetal.,2012).

1.10.1Wastewatertreatmenttechnologies 1.10.1.1Conventionaltreatment

Wastewatertreatmentemploysseveraltraditionaltreatmenttechnologies.Invarious nations,activatedsludgereactors,stabilizationponds,andup-flowanaerobicsludge blanket(UASB)reactorsarethethreeprimarymethodsthatarefrequentlyutilized. Anaerobictreatmentpondsandfacultativetreatmentpondswereutilizedinstabilizationpondsorlagoons,whichwerearti ficialbasinsmadeduetotheinterventionofman (Behlingetal.,1997).Itismoreextensivelyseeningrowingnations,especiallyin tropicalandsubtropicalareas,whereaccessibilitytolandisveryeasyandinexpensive, anditprovidesenoughheattopromoterapidreactiontimes(BarbosaandSant’Anna, 1989).Thesepondsystemsarerarelyutilizedclosetometropolitanareasbecauseof thehighlanddemand.Themostwidelyusedtechnology,particularlyinindustrialized countries,isactivatedsludge(Mahmoudetal.,2004).

Pretreatment,primarytreatment,secondarytreatment,tertiarytreatment,andwater reclamationarethe fiveprimarydivisionsoftheactivatedsludgeprocess.Tomeetthe requirementsofthefollowingtreatmentprocesses,pretreatmentincludesscreeningfor theremovalofgrit,grease,andgrosssolids.Theessentialprocessthengetsridofthe settleablematerialsandscumthataresuspendedsolids.Theremovalofsuspended Introductiontowastetobioenergy13

14WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

particles,dissolvedorganicmaterial,andspeci ficnutrientsfromliquidwasteisthen accomplishedbysecondarytreatment.Beforewastewaterisdischargedorrecycled, additionaltertiarytreatmentisadded,withanemphasisontheremovalofdangerous compounds,toxicsubstances,anyremainingsuspendedparticles,andbacteria.

TheadoptionofUASB,adevelopingtechnology,hassignificantlyincreased, particularlyinLatinAmericaandIndia.UASBisananaerobictreatmenttypewhere wastewater flowsinatthereactor’sbottomand flowstowardthetopthroughathick layerofgranulesmadeofmicroorganismsboundtooneanotherorsuspendedinthe reactor.Aswastewaterinteractswiththegranules,itiscleaned.Theblanket’sanaerobicenvironmentcausesmethanetobecreated,whichcanthenbecaughttogenerate heatandpower,allowingforenergyrecovery.TheconstructionofUASBreactors doesnotrequirehighlycomplexengineering(Bolleetal.,1986).Duetotheircompact sizeandabilitytoworkonasmallscale,USABsystemsareappropriateforcentralized anddecentralizedapplications.Theactivatedsludgemethod,whichisfortheenormousgrowthofwastewatertreatmentcoverageinLatinAmerica,hasmuchhigher coststhantheUASBprocess,whichismuchlessexpensive(UemuraandHarada, 2000).However,comparedtotheactivatedsludgeprocess,itsrateofnutrientremoval isstillrelativelylow;odorsandgreenhousegasemissionsareaproblem,anditsusesat moderatetolowtemperaturesarelesswellknownandapplied.

1.10.1.2Algae-basedtreatment Itisafactknownthatwastewatersarematerialgoodscontainingadequatequantityof ammoniumornitratenitrogen,organicorinorganiccarbon,phosphorus,andothertrace elementsneededforthegrowthofalgae.Thealgae-basedtreatmenthasdemonstrated considerablecapabilityforcostsaving,decreasedtechnologicalneeds,andnutrientrecoverywithoutproducingextraby-productsofsludges(Bhatiaetal.,2022).Mostresearchershaveworkedtocultivatealgaeusingnumerouswastewaterstotake advantageoftheirhighpotentialinthelarge-scalecultivationofalgalbiomassforbiofuelorotherpurposes.However,theseeffortshavebeenineffectiveduetothespecific characteristicsofphysicalandchemicalproperties.Itisessentialtochoosewastewater withadequatenutrientconstitutionsincenutrientavailabilityinwastewateraffectsalgae’soverallbiomassproduction.Municipalwaterwasteandagriculturalwastewater weredeterminedtobethemostacceptablesourcesamongallformsofwastewater. Suchsourceshavebeenwidelyresearchedwithanemphasisontheremovalofmetals andnutrientsfromwastewater.Itwasacknowledgedthatdevelopingalgaeinwastewaterlookstohavesignificanteconomicadvantages,whichcouldbeapowerfuldriving sourceforcommercializingalgaeforbothwastewatertreatmentandbiofuelgeneration (Mishraetal.,2017).Meanwhile,therearealsosomechallengesanddifficulties,suchas thepropertiesofthewastewater,coloredchemical,C/NandN/Pratios,dissolvedand suspendedsolidsinfluencingturbidity,toxicornoxioussubstances,andcompetingbacteria,warrantmorestudy(Rahmanetal.,2020).

Wastewaterrunoffsfromavarietyofpointedandnonpointedsources,suchashomes, farms,andindustries,carrydangerouspollutantsandcarbon-richresiduesthatcontaminatetheenvironmentandchangethewaterecosysteminawaythatisharmfultohuman

healthandotherenvironmentallife.Nitrificationanddenitrificationaretwobiological processesthatcanbecarriedoutinoneortwowaysandareconsideredessentialsteps inbiotechnologicalprocesseslikewatertreatment,thegenerationofbiofuels,andthe removalofnitrogeninwastewatermanagementfacilities.Theprocessofnitrificationinvolvesmixingwastewaterwithnitrified,whichconvertsthewholeammoniapresentto nitrate.Duringthedenitrificationprocess,whichhappensinananoxicenvironment,nitratesareconvertedintonitrogengas.AmongthedenitrifiersarePseudomonas,Alkaligenes,Bacillus,andseveralfacultativeaerobicheterotrophs.

Algaeandbacteriaworkinharmonytoformthestructuralbackboneofthe ecosystem.Vastamountsofbacteriawillbindwithalgaeinsidethewaterhabitat andfunctionasanaturalwaterpuri ficationsystem.Algaeandbacteriaworkedtogether tobreakdowntheinorganicsubstances,andneweutrophicationtechnologywasused. Algae,heterotropicmicroscopicorganisms,andarchaeabacteriaserveasthebiologicalcommunity’ssecondarypillarsandprincipalsourcesofvaluablematerials,respectively,asprimaryproducersanddecomposers.Thetreatmentprocessshouldalso eliminatepathogens,lowernutritionalconcentrations,andremoveotherorganicmatterforeffectivewaterrecyclingandreuse.

Microorganismsusetheoxygenreleasedduringphotosynthesistoseparatenatural compounds.Asbothgreenalgaegrowthandtinycreaturesliveinphycospheresand interactincomplexlinkage,therearealotofopportunitiesforhorizontalgeneexchange.Theadvantagesofalgal-bacterialsymbiosisinwastewatertreatmentsystems includecost-effectiveaeration,pollutionabatement,andgreenhousegasemissions sequestration.Algaefact:Algaehastheabilitytocurediseasesandviruses.Inthetreatmentofpharmaceuticalwastewater,algal-bacterialconsortiaremovechemicalsby bioaccumulationorbiodegradation.Heavymetalsinwastewatercontainthemetals thatareremovedthroughbiosorption,bioconvention,andbioaccumulation(Woertz etal.,2009).

1.11Chemicalpathway 1.11.1Lipidextraction Lipidextractionistheinitialstepinmakingbiodieselfromthesludgeofwastewater treatmentplants.Varioustechniquesarecurrentlyavailableforextractinglipidsfrom biologicalsources.Directuseandblendingofrawoils,thermalcracking,microemulsions,andtransesteri ficationaresomeofthemethodsusedtoproducebiodieselas shownin Fig.1.5.However,themostcommonmethodsusedaretheBlighand Dyermethodandthesoxhletextractionmethod(BlighandDyer,1959).Asludgeto-solventratioof1 6wasusedwith300mLofeitherchloroformortolueneasasolventfor50gofdrysludge.However,forthesoxhletextractionmethod,600mLof solvent(i.e.,chloroformortoluene)wasusedfor100gofdrysludge(Boocock etal.,1992).Theycametotheconclusionthatlipidextractionusingtolueneandchloroformisequallysuccessful.Nevertheless,atoluene-basedextractionmethodis preferredduetoenvironmentalandcostconsiderations. Introductiontowastetobioenergy15

16WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

Amaximumof27.430.98%lipidwasproducedforthreetimesextractionusing60 v%hexane/20v%methanol/20v%acetone,accordingtoDufrecheetal.extractionof lipidsfromactivatedsludgeutilizingpureandmixturesofhexane,methanol,and acetoneassolvents(Dufrecheetal.,2007).

TheyalsoextractedlipidsusingsupercriticalCO2 andsupercriticalCO2 withmethanolasacosolvent,andtheygot3.55w%and13.56w%oflipids,respectively.In comparisontoothersolventsystems,theyassertedthattheextractionoflipidsusing amixtureof n-hexane,methanol,andacetoneproducedthehighestconversionto biodiesel.

Anothermethodwastoextractlipidsfromsewagesludgebyincludingtheuseof toluene,hexane,ethanol,andmethanol(Pokoo-Aikinsetal.,2010).Asludge-to-solventratioof1:5wasused.Thefreefattyacids(FFA),triglycerides(oils),andthesolventandfoundtheyieldofFFAwas24.8w%,24.9w%,25.5w%,25.5w%for toluene,hexane,methanol,andethanol,respectively.Themaximumyieldoftriglyceridewas3.4w%forallfoursolvents.

1.11.2Transesterificationprocess Thetransesteri ficationprocessisthedisplacementofalcoholfromtheester,whichis similartohydrolysis,butalcoholisused.Thismethodiswidelyusedtoreducethe highviscosityoftriglycerides.Insteadofalcohol,ifweusemethanol,theprocessis calledmethanolysis.Transesterificationproceedsbymixingthereactants,itisone ofthereversiblereactions.Ifacatalystispresent,likeacidicorbasic,itwillaccelerate theconversion.Thisfuelisenvironmentallybenefi cial,renewable,andanalternative sourceofenergy.

Alcoholisoneofthemostcruciallyrequiredrawmaterialsforbiodieselproduction. Severalalcoholshavebeeninvestigatedfortheproductionofbiodiesel.Themajorly usedacylacceptorsaremethanolandethanol.Methanolismainlypreferredbecause ofitsphysicalandchemicaladvantages.

Figure1.5 Lipidextraction.

Thelevelofwaterisalsovitalinthemanufacturingofbiodiesel.Thisisbecause,in thetransesterifi cationprocess,thewaterpresentcancausehydrolysisoftriglycerides tofreefattyacids.Thisleadstotheformationofsoapandyieldspoorly.Inthecaseof long-chain,alcoholsaremoresensitivetocontaminationinwater.Inotherinstances, short-chainalcoholscanabsorbmoisturefromtheatmosphere.However,long-chain alcoholsareavoidedduringthetransesteri ficationprocess.Thisisbecauseitleads tothesterichindranceeffect.

Mostofthebiodieselsareproducedfromvegetableoilwhichrequireslessamount ofpressureandtemperatureandhasa98%yieldofconversion.Moreover,ifweuse acidasacatalyst,itslowsdowntheprocess.So,weareusingthetransesteri fication processformanufacturingbiodiesel.

1.12Biofuelupgradation Fulldeoxygenationandconventionalrefiningarerequiredtoconvertbio-oilintotransportationfuellikediesel,gasoline,kerosene,methane,orLPG.Theseprocessesare carriedoutusingeitherintegratedcatalyticpyrolysisordecoupledliquid-phasehydrodeoxygenation(Ragauskasetal.,2006).

Tobenefitfromtheeconomiesofscaleandexpertiseinatraditionalrefinery,there isalsoincreasinginterestinapartialupgradetoaproductthatismanagedcomfortably withrefinerystreams.

Therearethreemainwaystheupgradeisdone.Theyare:

• Hydrodeoxygenation

• Catalyticvaporcracking insituorexsitu

• Synthesisofhydrocarbonsoralcoholsisfollowedbygasificationtoproducesyngas.

1.13Hydrodeoxygenation Alargeclassofcatalyticproceduresknownashydrodeoxygenation(HDO)ofbiomass wastestreamsareessentialtothelong-termproductionofimprovedbiofuels.Metal phosphideshavedrawnmoreinterestinthisregardfortheiruseascatalystsfor HDOofvegetableoil,animalfats,andbioderivedphenolicstreams.Metalphosphides haveagreatlytenablesurfacechemistrythatcanbeproducedusingsimplesynthetic proceduresusinginexpensiveprecursorshisarticleprovidesanimportantanalysisof theenvironmentallyfriendlymanufacturingofadvancedbiofuels.Nickelphosphides arehighlightedascatalystshavingdistinctivepropertiesfortheHDOofbioderived phenolic.Nickelphosphides’ task-speci ficdesignisfocusedonmaximizingcatalyst activity,distributionofproduct,andproductselectivity.Amajorobstacleintheproductionofadvancedbiofuelsisthedeactivationofcatalysts(Antizar-Ladislaoand Turrion-Gomez,2009).

Comparingbiomass-derivedfuelstoconventionalfuelshasseveraladvantages, includingreducedgreenhousegasemissions,localizedproduction,andmore Introductiontowastetobioenergy17

18WasteValorizationforBioenergyandBioproducts:Biofuels,Biogas,andValue-AddedProducts

advantageouseconomics.However,comparedtohydrocarbonfuels,biooilhasapoor heatingvalue,isimmisciblewiththem,hashighacidity,andischemicallyandthermallyunstableduetoitshighoxygenconcentrationand15 30weightpercentofwatercontent.Transitionmetalphosphidesareoneoftheuniquecompositionsbeing studiedinhydrotreatingproceduresasprospectivealternativesfortheCoMoand NiMosul fidedmaterials.Themostusedmethodforproducingphosphidesisthrough temperature-programmedreduction,acomparativelyeasymethodthatcanbecarried outatverylowtemperaturesusingsupportedorunsupportedprecursors.Itrepresentsa signi ficantadvancetousemetalphosphitesorhypophosphitesasprecursorsrather thanphosphates(Lyndetal.,2008).

1.13.1Catalyticvaporcracking Gasoil,heavycrudeoil,andresiduumarejustafewexamplesoffeedstockthatcanbe modi fiedbyputtingitthroughacatalyticcrackingprocess.Catalyticcrackinghasrealworldusesofacatalystthatisbeingusedatarefinerytoincreasetheefficiencyofthe processanditsproductyield.Itissimilartothermalcrackingbutdiffersintheuseofa catalyst,whichis(intheory)consumednegligiblyduringtheprocess.

Inatypicalcommercialprocess,acatalystisbroughtintocontactwithafeedstock (oftenagasoilfraction)whilebeingmaintainedatapropertemperature,pressure,and residencetime.Bydoingso,asizableportion(>50%)ofthegivenfeedstockisoften transformedintogasolineandlowerboilingproductsthroughasingle-passoperation. Meanwhile,thedepositionofcarbonaceousmaterialonthecatalystduringthe crackingevent,significantlylowersitsactivity,andtheremovalofthisdepositis necessary.Thethermaldecompositionofapolarspecieswithhighmolecularweight inthefeedstockresultsinthedepositofcarbonaceouscontent.Burninginthepresence ofairistypicallyusedfortheremovalofthecarbonaceousdepositfromthecatalysttill thecatalystactivityisrestored(Atabanietal.,2012).

1.13.2Emulsification Emulsificationisacheapandviableupgradationprocessthatcanbeemployedfora widearrayoffuels,especiallypyrolyticoils.Itisasimpleprocessofblendingbiofuel withsuperiorfossilfuelbymechanicalorchemicalmethods(JoscelyneandTr€ agårdh, 2000).Typicalbiofuelslikebiodieselandbioethanolhaveatendencytomixwithfossilfuelsreadily.Ontheotherhand,fuelslikepyrolyticoilarecompletelyimmiscible withfossilfuelsowingtotheirvariationsinsurfacetension(Charcossetetal.,2004). Addingsurfactants(Span-80andTween-80)canovercomethis,whichwillneutralize thesurfacetensioneffecttopromotecompleteblending.Blendedfuelgivessuperior propertiesascomparedtorawbiofuel(Raveraetal.,2021).

1.14Conclusion Bioenergy,oftenreferredtoasbiomass,isatypeofgreenenergythatisobtainedfrom recentlylivingorganicmaterial.Concernsoverenergysecurity,energyindependence,