Chemical Visit to download the full and correct content document: https://ebookmass.com/product/chemical-product-formulation-design-and-optimizatio n-methods-techniques-and-case-studies-ali-elkamel/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Hydrogen Sulfide: Chemical Biology Basics, Detection Methods, Therapeutic Applications, and Case Studies

Michael D Pluth

https://ebookmass.com/product/hydrogen-sulfide-chemical-biologybasics-detection-methods-therapeutic-applications-and-casestudies-michael-d-pluth/

Program Evaluation: Methods and Case Studies 9th Edition, (Ebook PDF)

https://ebookmass.com/product/program-evaluation-methods-andcase-studies-9th-edition-ebook-pdf/

Psychoanalytic Case Formulation 1st Edition, (Ebook PDF)

https://ebookmass.com/product/psychoanalytic-caseformulation-1st-edition-ebook-pdf/

Towards Sustainable Chemical Processes: Applications of Sustainability Assessment and Analysis, Design and Optimization, and Hybridization and Modularization 1st Edition Jingzheng Ren

https://ebookmass.com/product/towards-sustainable-chemicalprocesses-applications-of-sustainability-assessment-and-analysisdesign-and-optimization-and-hybridization-and-modularization-1stedition-jingzheng-ren/

Tools For Chemical Product Design From Consumer Products to Biomedicine 1st Edition Mariano Martín

https://ebookmass.com/product/tools-for-chemical-product-designfrom-consumer-products-to-biomedicine-1st-edition-mariano-martin/

Stochastic Global Optimization Methods and Applications to Chemical, Biochemical, Pharmaceutical and Environmental Processes 1st Edition Ch. Venkateswarlu Satya Eswari Jujjavarapu

https://ebookmass.com/product/stochastic-global-optimizationmethods-and-applications-to-chemical-biochemical-pharmaceuticaland-environmental-processes-1st-edition-ch-venkateswarlu-satyaeswari-jujjavarapu/

Chipless RFID Authentication: Design, Realization and Characterization Zeshan Ali

https://ebookmass.com/product/chipless-rfid-authenticationdesign-realization-and-characterization-zeshan-ali/

Tidal Energy Systems: Design, Optimization and Control 1st Edition

https://ebookmass.com/product/tidal-energy-systems-designoptimization-and-control-1st-edition/

Numerical Methods and Optimization in Finance [2nd ed.]

Manfred Gilli

https://ebookmass.com/product/numerical-methods-and-optimizationin-finance-2nd-ed-manfred-gilli/

ChemicalProductFormulationDesignand Optimization Methods,Techniques,andCaseStudies AliElkamel

HeshamAlhumade

NavidOmidbakhsh

KeyvanNowruzi

ThomasDuever

Authors

Prof.AliElkamel UniversityofWaterloo DepartmentofChemicalEngineering 200UniversityAvenueWest N2L3G1NK Canada

Prof.HeshamAlhumade KingAbdulazizUniversity ChemicalandMaterialsEngineering 21589Jeddah SaudiArabia

Dr.NavidOmidbakhsh Johnson&JohnsonCompany R&DAdvancedSterilizationProducts 33TechnologyDrive CA UnitedStates

Dr.KeyvanNowruzi Johnson&JohnsonCompany AssociateResearchFellow 33TechnologyDrive CA UnitedStates

Prof.ThomasDuever ProfessorofChemicalEngineeringand DeanofEngineering TorontoMetropolitanUniversity 350VictoriaStreet Toronto,ON M5B2K3,Canada

CoverImage: Shutterstock

Allbookspublishedby WILEY-VCH arecarefully produced.Nevertheless,authors,editors,and publisherdonotwarranttheinformation containedinthesebooks,includingthisbook, tobefreeoferrors.Readersareadvisedtokeep inmindthatstatements,data,illustrations, proceduraldetailsorotheritemsmay inadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-PublicationData Acataloguerecordforthisbookisavailable fromtheBritishLibrary.

Bibliographicinformationpublishedbythe DeutscheNationalbibliothek TheDeutscheNationalbibliothekliststhis publicationintheDeutsche Nationalbibliografie;detailedbibliographic dataareavailableontheInternetat <http://dnb.d-nb.de>

©2023WILEY-VCHGmbH,Boschstr.12, 69469Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).Nopartof thisbookmaybereproducedinanyform–by photoprinting,microfilm,oranyother means–nortransmittedortranslatedintoa machinelanguagewithoutwrittenpermission fromthepublishers.Registerednames, trademarks,etc.usedinthisbook,evenwhen notspecificallymarkedassuch,arenottobe consideredunprotectedbylaw.

PrintISBN: 978-3-527-33264-9

ePDFISBN: 978-3-527-68963-7

ePubISBN: 978-3-527-68964-4

oBookISBN: 978-3-527-68962-0

CoverDesign ADAMDESIGN,Weinheim, Germany

Typesetting Straive,Chennai,India

Contents

Preface ix

AbouttheAuthors xi

1Introduction 1

1.1ChemicalProductEngineering 1

1.2ChemicalProductDesign 2

1.3ProductDesignandComputer-AidedProductDesign 4 References 6

2SomeTypicalApplicationsofChemicalProductDesignand IntellectualProperty 7

2.1NaturalFiberPlasticComposites 7

2.2WheatStrawPolypropyleneComposites 10

2.3ModelingNaturalFiberPolymerComposites 12

2.4GrapheneComposites 14

2.5CorrosionProtectionUsingPolymerComposites 15

2.6IntellectualProperty 17 References 19

3MathematicalPrinciplesforChemicalProductDesign 23

3.1FactorialandFractionalFactorialDesign 23

3.2ResponseSurfaceMethodsandDesigns 25

3.3D-OptimalDesigns 26

3.4BayesianDesignofFractionalFactorialExperiments 27

3.5RegressionAnalysis 27

3.6ArtificialNeuralNetworks 28

3.7MixtureDesignofExperiments 31

3.8MultiwayPrincipalComponentAnalysis 35

3.8.1Model-basedPrincipalComponentAnalysis(MB-PCA) 37

3.8.2MPLSAnalysisUsingNIPALS 38 References 39

4DisinfectantFormulationDesign 41

4.1Introduction 41

4.2DisinfectantsCharacteristics 42

4.2.1AntimicrobialTests 42

4.2.2StabilityTests 43

4.2.3CorrosionTests 43

4.3ToxicityofDisinfectants 44

4.3.1Harmful(Xn) 45

4.3.2SevereEyeDamage,Xi(R41) 45

4.3.3EyeIrritant,Xi(R36) 46

4.3.4SkinIrritant,Xi(R38) 46

4.3.5RespiratoryIrritant,Xi(R37) 47

4.4ExperimentalDesignforAntimicrobialActivity 47

4.4.1PriorKnowledge 48

4.4.2HistoricalDataAugmentation 49

4.4.3LinearLeastSquaresRegressionAnalysis 49

4.4.4ArtificialNeuralNetworks 51

4.5ExperimentalDesignforStabilityofHydrogenPeroxide 54

4.5.1HistoricalDataAnalysis 54

4.5.2HistoricalDataAugmentationUsingBayesianD-optimality Approach 55

4.6ExperimentalDesignforCorrosion 61

4.6.1PreliminaryExperimentalDesign 62

4.6.2ResponseSurfaceMethodology 63

4.6.3ArtificialNeuralNetworks 64

4.7FinalFormulationOptimization 66

4.7.1Optimization 67

4.7.2OptimizedFormulationVerification 69

4.7.3ComparingtheOptimizedFormulationstoanAvailableProduct 70

4.8Conclusion 70 References 71

5StreptomycesLividans66fordevelopingaMinimalDefined MediumforRecombinantHumanInterleukin-3 73

5.1Introduction 73

5.2MaterialsandMethods 74

5.2.1MicroorganismandMedium 74

5.2.2AnalyticalMethods 74

5.2.3ExperimentalDesignandDataAnalysis 76

5.3ResultsandDiscussion 78

5.3.1StarvationTrails 78

5.3.2ScreeningMixtureExperiments 80

5.3.3DefinedMediumOptimizationbyMixtureDesignMethod 82

5.4Conclusion 87 References 87

6MultivariateModelingofaChemicalTonerManufacturing Process 91

6.1Introduction 91

6.1.1ProcessandDataDescription 92

6.1.2ModelCross-Validation 93

6.2ResultsandDiscussion 97

6.3Conclusion 101 References 102

7WheatStrawFiberSizeEffectsontheMechanicalProperties ofPolypropyleneComposites 105

7.1Introduction 105

7.2MaterialsandMethods 108

7.2.1Materials 108

7.2.2FiberPreparationandSizeMeasurement 108

7.2.3FiberThermalandChemicalAnalysis 109

7.2.4CompositeSamplePreparationandPropertiesMeasurement 109

7.3ResultsandDiscussions 110

7.3.1FiberFractionationandSizeMeasurement 110

7.3.2FiberThermalandChemicalAnalysis 113

7.3.3FiberSizeReductionDuringCompoundingProcess 114

7.3.4CompositeFlexuralProperties 117

7.3.5CompositeImpactProperties 118

7.3.6Composite-SpecificProperties 120

7.4Conclusion 122 References 122

8FrameworkforProductDesignofWheatStrawPolypropylene Composite 125

8.1Introduction 125

8.2ProductDesignFrameworkforWS-PPComposite 128

8.3ResponseSurfaceModels 130

8.3.1TheDesignofMixtureExperiment 131

8.3.2MaterialsandMethods 133

8.3.3ResultsandDiscussion 134

8.3.3.1FlexuralModulus 134

8.3.3.2IzodImpactStrength 136

8.3.3.3OtherProperties 137

8.4CaseStudy 138

8.5Conclusion 144 References 145

9ProductDesignforGasolineBlendstoControlEnvironmental ImpactUsingNovelSustainabilityIndices:ACaseStudy 147

9.1Introduction 147

9.2Methodology 148

9.2.1TheImpactsofGasolineBlendsonOctaneNumber(ON) 148

9.2.2TheImpactsofBlendingEthanolandGasolineonMileage 149

9.2.3TheEffectsofEthanol,Methanol,andIsooctaneontheOctaneNumber ofGasolineBlends 150

9.2.4TheImpactsofE5,M5,andI5onHeatValue,Mileage, andPrice 150

9.2.5ImpactsofE5,M5,andI5onEnvironmentinPotentialEnvironmental Impacts(PEIs) 152

9.2.6TheImpactsofE5,M5,andI5onSafetyRisk 154

9.2.7SelectingtheBestBlendThroughtheAnalyticHierarchy Process(AHP) 155

9.3Results 158

9.4Conclusion 160

References 161

10CorrosionProtectionofCopperUsing Polyetherimide/GrapheneCompositeCoatings 163

10.1Introduction 163

10.2Experimental 164

10.2.1Material 164

10.2.2CompositePreparation,Coating,andCuring 165

10.2.3MorphologyCharacterization 165

10.2.4Adhesion 165

10.2.5ElectrochemicalMeasurement 166

10.3ResultsandDiscussion 167

10.3.1Morphology 167

10.3.2Adhesion 170

10.3.3PotentiodynamicMeasurements 170

10.3.4Impedance 174

10.4Conclusion 177

References 177

11OptimizationofMechanicalPropertiesofPolypropylene MontmorilloniteNanocomposites 181

11.1Introduction 181

11.2Methodology 183

11.3MathematicalModels 183

11.4OptimizationMechanism 183

11.5ResultsandDiscussion 185

11.5.1MinimizingtheCostofPP-OMMT 185

11.5.2MinimizingtheVarianceBetweenDesiredProperties 187

11.6Conclusion 192

References 193

12ProductSelectionandBusinessPortfolioforLong-Range FinancialStability:CaseStudyfromthePetrochemical Industry 195

12.1Introduction 195

12.2ManufacturingStrategyandProductSelectionTools 196

12.3ModelDevelopment 199

12.4IllustrativeCaseStudy 201

12.5Conclusion 205

References 205 Index 207

Preface Chemicalproductdesignisaveryimportanttopicinthechemicalindustry.While commoditychemicalshavebeenthemainareaforchemicalengineeringfocusinthe pastseveraldecades,specialtychemicalshavebeengainingmoreandmoreattention inrecentyears.Therefore,acceleratingthedevelopmentprocessandoptimizingthe formulationofchemicalproductswouldbeofgreatbenefit.Withthischangealready happeningintheindustry,chemicalengineeringeducationandtraininghavenot changedenoughtotrainengineerstofillpositionsintheproductdesignfield.

Thisbookaimsatprovidingthereaderwithadetailedunderstandingofthe productdesign,relatedstatisticaltechniques,andoptimization,andgivesreal-life casestudiesfordisinfectantformulations,optimizationofdefinedmedium,the formulationofbiocomposites,etc.Thisbookcanbeusedasasupplementaltextbookforchemicalengineeringstudentsinachemicalproductdesigncourseorto R&Dproductformulationengineerssothattheybecomefamiliarwiththeefficient techniquesusedindevelopingnewformulations.Thebookcontains11chaptersas follows:

● Chapters1and2:Introductiontothecurrentproductdesignprocess

● Chapter3:Backgroundtotherelatedmathematicalandstatisticaltechniques

● Chapters4–12:Casesstudies

Chapters1and2introducethereadertothecurrentmethodologiesusedfor designingnewproductsinchemicalindustriesandoutlinesthedisadvantagesof thecurrentprocessesandtheneedforimprovement.

Chapter3givesabackgroundaboutthetheoriesofthemethodologiesused toacceleratenewproductdevelopment.Thesemethodologiesincludefactorial designs,mixturedesigns,optimaldesigns,linearandnonlinearregressionanalysis, machinelearningtechniques(i.e.artificialneuralnetworks),andmulti-way principalcomponentanalysis.

Chapters4–11presentsevencasestudiestoillustratetheprocessofproduct designanditspracticalimplications.Thefirstcasestudycoversoptimizationof adisinfectantformulation,thesecondonepresentsoptimizationofadefined medium,thethirdcasedealswithproductimprovementinachemicaltoner manufacturingprocessusingmultivariatemodeling,thefourthcasepresentsover twochaptersthedesignofwheatstrawpolypropylenecomposites,thefifthcase

x Preface

employssimulationtoformulategasolineblends,thesixthcasepresentsthedesign ofacorrosionprotectioncoatingusingpolyetherimide/graphenecomposites, andfinallytheseventhcasestudydealswiththeoptimizationofthemechanical propertiesofpolypropylene-organicallymodifiedmontmorillonite(PP-OMMT) nanocomposites.ThebookendswithChapter12thatillustrateshowtoproceedin selectingproductstoinvestforbusinesssustainability.

Allchaptersareequippedwithclearillustrations,figures,andtablestohelpthe readerunderstandtheincludedtopics.

Manypeoplecontributeddirectlyorindirectlytothisbook.Wewishtopayour gratitudeandourrespectstothelateProfessorParkReilywithwhomwehave collaboratedonresearcharticlesrelatedtothetopicsinthisbookandhavelearned agreatdealfromhim.Also,thisbookwouldnothavebeenpossiblewithoutthe interactionswehadwithpastgraduatestudents.Althoughwegivecreditandreferencesintheappropriatechapters,wewouldliketovouchourwordsofappreciation toRoisFatoni,HosseinOrdouei,YoussefAlHerz,andHassanKhorami.Special thanksgoalsototheWileypublishingteam(ElkeMaase,KatherineWong,and LesleyJebaraj)fortheirprofessionalworkandforbeingpatientwithus.Lastbut notleast,weextendgreatappreciationtoourfriendsandfamilies.

AbouttheAuthors AliElkamel isProfessorofChemicalEngineeringattheUniversityofWaterloo. Heisalsocross-appointedinSystemsDesignEngineering.Prof.Elkamelholdsa BScinChemicalEngineeringandaBScinMathematicsfromColoradoSchoolof Mines,MScinChemicalEngineeringfromtheUniversityofColorado-Boulder,and PhDinChemicalEngineeringfromPurdueUniversity–WestLafayette,Indiana. Hisspecificresearchinterestsareincomputer-aidedmodelling,optimization,and simulationwithapplicationstoenergyproductionplanning,carbonmanagement, sustainableoperations,andproductdesign.Prof.Elkamelsupervisedover90 graduatestudents(ofwhich35arePhDs)andmorethan30post-doctoralfellows/researchassociates,andhistraineesallobtaingoodjobsinthechemical processindustryandinacademia.Hehasbeenfundedforseveralresearchprojects fromgovernmentandindustry.AmonghisaccomplishmentsaretheResearch ExcellenceAward,theExcellenceinGraduateSupervisionAward,theOutstanding FacultyAward,theBestTeacherAward,andtheIndustrialengineeringand OperationsManagement(IEOM)OutstandingServiceandDistinguishedEducator Award.Hehaswrittenmorethan370journalarticles,145proceedings,and45 bookchaptersandhasbeenaninvitedspeakeronnumerousoccasionsatacademic institutionsthroughouttheworldandatnationalandinternationalconferences. Heisalsoaco-authoroffivebooks;tworecentbookswerepublishedbyWileyand entitled PlanningofRefineryandPetrochemicalOperations and Environmentally ConsciousFossilEnergyProduction

HeshamAlhumade isaskilledengineerwithexperienceinchemicalindustry andenthusiasticassistantprofessorofchemicalandmaterialengineeringwith extensiveresearch,teaching,supervision,andadministrationexperience.Heis meticulousandmethodicalinapproachtoalltasks,guaranteeinghigh-quality resultsinlinewithlearningspecifications.Dr.Alhumadewasrecentlyappointedas thepresidentofthechemicalengineeringchapteroftheSaudiCouncilofEngineers. Hisresearchinterestsincludepolymernanocomposites,renewableenergy,catalyst, solarsystems,andfuelcell.Heiscurrentlyworkingondevelopingpyrolysis techniquesforbiomassconversiontobiofueltomeetthegrowingglobaldemandfor alternativeandgreensourcesofenergyinadditiontothecurrentindustrialdemand foradequatewastemanagementprocess.Inoilandgasindustry,hehasconducted promisingresearchinthefieldofsynthesisandfunctionalizationofcatalystfor

hydrocarbonconversionandoilupgradingpurposes.Hisresearchinterestsinclude modelingandsimulationoffluiddynamicsinporousmediaandsynthesisof nanocompositesmaterialsforvariouselectrochemicalapplicationsincludingfuel cells,supercapacitors,batteries,andcorrosionmitigation.Dr.Alhumadereceived theSABICDistinguishedAwardin2006.

NavidOmidbakhsh isDirectorofEarlyR&DandAdvancedResearchfor AdvancedSterilizationProducts(ASP),whereheleadstheinnovationandtechnicalfeasibilityofnewconceptsforfutureproducts.PriortojoiningASP,Navidwas VicePresidentofOpenInnovationandIntellectualPropertyforViroxTechnologies andheldakeyroleinthedevelopmentofVirox’sgloballyregisteredproducts andcompany’sexponentialgrowth.BeforeVirox,NavidwasanR&Dengineer forHenkelinsurfacetechnologyfield.NavidhasearnedhisPhDinchemical engineeringfromtheUniversityofWaterloo,Waterloo,Ontario,Canada,wherehis mainresearchareawasonthedevelopmentofasystematicmethodtooptimize chemicalproducts/formulations.Navidholdsseveralpatentsandpeer-reviewed publicationsintheareaofproductdesign,disinfectants,andsterilizationformulationsandsystems.NavidisalsoanalumnusofHarvardBusinessSchool,where hecompletedprogramsonbusiness,management,andinnovation.Heisalsoa licensedprofessionalengineerofOntario,Canada.

KeyvanNowruzi isaprincipalscientistatASP.HehasaBSinchemicalengineeringfromSahandUniversityofTechnology,Tabriz,Iran;anMScinchemical engineeringfromTehranPolytechnicUniversity;andaPhDinbiochemicalengineeringfromtheUniversityofWaterloo,Canada.PriortojoiningASP,hehasserved asapost-doctoralfellowattheUniversityofGuelph,Canadaforfouryearsanda staffscientistforAkkimKimyaSan.VeTic.A.¸S.foroneyear.HehasbeenwithASP forsixyears.Dr.Nowruzihascontributedinfewinventionspatentedworldwideand hasseveralpublicationsinpeer-reviewedjournalsandinternationalconferences.

ThomasDuever isDeanoftheFacultyofEngineeringandArchitectural ScienceandaprofessorofchemicalengineeringatTorontoMetropolitanUniversity (TMU).PriortohisroleatTMU,Dr.DueverservedaschairintheDepartment ofChemicalEngineeringattheUniversityofWaterloofornineyears,navigating thedepartmenttowardunprecedentedgrowth.Hehasalsotaughtindustrialshort courseinexperimentaldesignandpolymerreactionengineering.

Dr.Dueverisanaccomplishedresearcherwithinterestsincludingappliedstatistics,experimentaldesign,polymerreactionengineering,andproductdevelopment. Hehaswrittenmorethan100articlesinjournalsandconferenceproceedingstohis creditandhassupervisedtheresearchprojectsofover35graduatestudents.

Dr.DueverisaregisteredprofessionalengineerintheProvinceofOntario,a fellowoftheChemicalInstituteofCanada,andafellowoftheCanadianAcademyof Engineering.HeholdsPhD,masters,andbachelordegreesinchemicalengineering fromtheUniversityofWaterloo.

1.1ChemicalProductEngineering Currentglobalizationtrendshaveresultedinafiercecompetitionbetween multinationalcompaniesforgainingmoremarketshare.Startupcompanies,onthe otherhand,alsotrytoplayinthisgamebyofferingdifferentiatedordisruptiveproductsthatwouldpotentiallychangethegameanddynamicsineachmarketsegment. Themaintoolfortechnologicalcompaniestocompete,however,remainstheir productofferings,andhowtheycanservethecustomersandaddresstheirneeds. Anyprofitablemarketinvitesnewentrantswhichcreatescompetition.Companies trytoacceleratetheirproductdevelopmentprocessestolaunchmoredifferentiated productstostayaheadofthegame,whileevenreducingtheircosts.Thisisof coursenotatrivialtaskforscientistsandengineerstotakeon.Furthermore, customersnowadayshavebeenpoisedtoseenewerproductsandcanquickly switchtoothercompanieswithbetterproductofferingsifthe“newer”productsare notcommercializedquickenough,asthelifecycleofthecurrentproductskeeps becomingshorter.Brandloyaltydoesnotexistasitusedtobeafewdecadesago, andcustomerscanquicklyswitchiftheyfindaproductwithbetterfeatures.An obviousexampleisthesmartphonemarket,andthatcompaniesfiercelycompete tointroducenewproductseveryyear.Imagineoneoftheincumbentsmissesone productlaunchbyafewmonths,andhowcatastrophicfinancialoutcometheycan encounter.Inmanycases,thesenewproductsareonlysimplemodificationsto existingtechnologies,buteventhese“smallmodifications”shouldcarryenough valuepropositiontoconvincebuyersamongallchoicestheyhave.Thiscompetition isofcoursenotlimitedtoelectronicsmarketandiswidespreadinallindustries, fromcosmeticstopharmaceuticalsandconsumertoagriculture.Inallthesemarket segments,researchanddevelopmentteamsworkcloselywiththeirmarketing counterpartstoidentifymarketneedsandtrendstostayaheadofthecurve.There isnoexaggerationtosaythatinthecurrentmarket,innovationislikeoxygenfor thebusiness,andwithoutthatanybusinesswillsoonbecomeirrelevant.Naturally, innovationcanonlybemonetizedifitistranslatedintoanewproductandcapture revenue.Thisiswhyfreshnessindex,i.e.theratioofnewproductscontributing totherevenueofthecompanyovertotalrevenue,isconsideredasakeysuccess metricformostcompanies.Afastercommercializationcannotbeachievedwithout ChemicalProductFormulationDesignandOptimization:Methods,Techniques,andCaseStudies, FirstEdition.AliElkamel,HeshamAlhumade,NavidOmidbakhsh,KeyvanNowruzi,andThomasDuever. ©2023WILEY-VCHGmbH.Published2023byWILEY-VCHGmbH.

aleanandagileproductdevelopmentprocess,andthereforeitisveryimportant thatcompaniesspendtheirR&Ddollarsverywiselyandtrytoavoidlessefficient developmentmethodologies.

Productdesigncanhavevariousinterpretations,amongthemisthedefinition astheentireproceduresrequiredtodeliveraproductwithdefinedpropertiesthat serveaspecificneedinsocietyorindustrybasedoninputsfromvarioussegments. Forinstance,inputsfromtheindustryofhowtheproductmayserveandwhatspecificationsshouldbeconsideredduringthemanufacturingprocess.Itemsthatcanbe consideredincludeenvironmentalandregionalregulations.Anexampleofenvironmentallyfriendlyproductdesignisthemanufacturingofagreenhouseventilation system,wherethehouseisdesignedtoattenuateenergyconsumptionandmaintain requiredrateoffreshairexchange.Insuchaprocessofproductdesignofahousehold airexchanger,variouselementsneedtobeconsideredincludingheatandhumidity. Inaddition,materialselectionisasignificantfactorinthemanufacturingofsucha devicetotakeintoconsiderationenvironmentalimpactssuchasenergyconservation,corrosion,andexhaustgases,ifany.Thetopicofproductdesignhasbecome evenmoreimportantwiththegrowingchangesinindustryandregulationtoprotecttheenvironment.Forexample,themanufacturingprocessofsynthetictextile fiberhasbeencontinuouslydevelopingsince1950.Startingwthaglobalproductionoflessthan10millionmtinthe1950andundergoinga10-foldincreaseby 2017,theeffectiveutilizationoffibersinvariousapplicationswasachievedthrough productdesignstudiesthatwerecariedoutonthedevelopmentofvariousprototypesutilizingstatisticalsoftwarepackages.Ingeneral,theprocessofproductdesign encompassesthefollowingsteps:marketneeds,ideas,materialselection,andfinally manufacturingandprocesscontrolandoptimization.

Manyoftheproductswetouchandfeeltodayhavecomeoutofachemicalplant onewayoranother.Theseproductscannotbemissedeveninanyquickvisittoa grocerystore.Consumerproducts(e.g.detergents),cosmetics,healthcareproducts (e.g.disinfectants,sanitizers),adhesives,pharmaceuticals,etc.,areallexamplesof chemicalproducts.Therefore,chemicalproductdesign(CPD)isaveryimportant marketsegmentanddeservesenoughattentioninimprovingproductdevelopment methodologies.Chemicalproductengineeringisthescienceandartofcreating chemicalproducts,amuchlargerconceptencompassingCPD.Inotherwords, chemicalproductengineeringcanbeseenasthegeneralbackgroundofknowledge andpracticesupportingtheconcretetaskofdesigningchemicalproductsandtheir manufacturingprocesses.

1.2ChemicalProductDesign Oneofthecrucialchallengesfacingmoderncorporationsandindustryisthe growingcompetitiveanddynamicsmarket.Asuccessfulbusinessrequirescontinuousmonitoringofconsumers’needsanddeliveringvaluableproductsat competitivepricesandhighquality,whileaddressingenvironmentalregulations. Therefore,researchersfromvariousfieldsofindustryincludingbutnotlimited

tomanagement,marketing,andengineeringdesignalwaysdevoteattentionto developmentofnewproductsandissuesassociatedwiththefabricationofthe productssuchasenvironmentalconcerns.Whendesigninganewproduct,different factorsareusuallycombinedsuchasstrategicandtechnicaleffort.Here,strategic planningisrequiredtodeliverasuccessfullaunchoftheproduct,whiletechnical effortfocusesondesign,manufacturing,control,andprocessoptimizationaspects. Therefore,agrowingnumberofresearchersfromdifferentfieldsofengineering includingchemicalengineeringhavedevotedattentiontotheareaofefficient designofnewproducts.

Specialtychemicalproductsincludepetrochemicals,pharmaceuticals,green chemicals,foodproducts,householdcareconsumables,andcosmetics.Indifferentsectors,chemicalproductsareundergoingcontinuouschangestomeetthe expectationsoftheconsumersinadditiontocontinuouslystricterenvironmental requirements.Thefabricationofachemicalproductisamultistageprocessstarting fromsynthesis,design,optimization,operation,andcontrol.Thesuccessfulexecutionofthepreviousstepswouldtransformrawmaterialsintovaluableproducts. Furthermore,thedesignofachemicalproductrequiresdeepunderstandingof thepropertiesofthematerialsandusagefunctions.Chemicalproductscanbe classifiedintosixcategoriesasfollows:specialtychemicals,bioproducts,formulated products,devices,technology-basedproducts,andvirtualchemicals,whereeach categoryhasaspecialidentity.Forexample,specialtychemicalscanbedefined aspurecompoundsthataredeliveredinsmallquantitiesandmayservespecific functions.Formulatedproductssuchascosmeticsandfoodrepresentalarge marketandcanbedefinedascombinedsystemswherevariousrawmaterialsare blendedtogethertodeliveramultifunctionalproductwithspecificappearanceand properties.Continueddevelopmentinhealthcareapplicationstriggerstheneed todevelopbioproductsthatincludebiomaterials,tissue,andmetabolicelements. Mostofpharmaceuticaldrugsarenowderivedfrombiologicalsourcesratherthan traditionalsyntheticchemicals.Moreover,productsthatcannotbeclassifiedaspure compounds,mixture,orfabricatedbiomaterialsmayincludedevicesthatcarryout aphysicalorchemicaltransformation.

Therehavebeenmajorchangesinthechemicalindustryduringthelasttwo decades.Thedominanceofcommoditychemicalshasbeenerodedbyanewer emphasisonproductssuchasspecialtychemicals[1].Thesechemicalsincludebut arenotlimitedtodetergents,cosmetics,pharmaceuticaldrugs,fertilizers,adhesives,andmanymore.Today,therearemanycompaniesandindustriesthathave focusedondevelopingsuchproductsandareinfiercecompetitionwitheachother formarketshare.Chemicalprocessindustrieshavealwayslaunchedsuccessfulnew products.However,thedynamicanddemandingmarketsrequirecompaniesto adoptamoresystematicapproachtobringthenewproducttothemarketfasterand cheapertoguaranteecompetitiveness.ChemicalProductDesignandEngineering isbecomingmoreimportantasaconsequenceofthischange.Whilecustomer needsandproductdifferentiationforcompetitionpurposesaresignificantdrivers tofasterdevelopproducts,globalwarmingandclimatechangerequirenewer productstohavelessenvironmentalimpact.Increasedawarenessbybothpeople

andgovernments,andmedia’sincreasedattentiontothisimportanttopic,hasled governmentstoimposemorestringentenvironmentalregulationswhichputseven morepressureoncompaniestotrytoreducewasteandcarbonfootprint.Itwould beobviousforcompaniestotrytooptimizeprocessesandproductformulationsto deliverthesameperformanceusing“less”chemicalsinafastertimeandusingless resources.Themillion-dollarquestiontoaskishowtoachievethis,orsimplyhow todomorewithless?Inthisbook,wearetryingtoanswerthisquestionpartially andourfocuswillbeonchemicalandbiologicalproductmixtures.

Insummary,thedynamicnatureofthechemicalandbiochemicalindustries, intensecompetitionformarketshare,andemergenceofmorestrictenvironmental regulationsrequiredeploymentofinnovativeproductdevelopmentmethodsto addressincreasingdemandsforfaster,leaner,andoptimizedproducts.

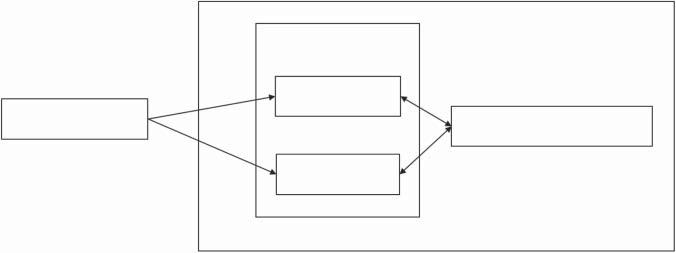

1.3ProductDesignandComputer-AidedProductDesign CPDcanbedefinedasasystematicprocedureorframeworkofmethodologies andtoolswhoseaimistoprovideamoreefficientandfasterdesignofchemical productsabletomeetmarketdemands.Fromthepracticalstandpoint,Cusslerand Moggridge[2]simplydefinedproductdesignasaprocedureconsistingoffoursteps: (i)definingtheneeds,(ii)generatingideastomeettheneeds,(iii)selectingthebest ideas,and(iv)manufacturingtheproduct.Generatingideasandselectingthebest ideasarethemosttime-consumingsteps.Thesetwostepstraditionallyinvolved anexhaustivesearchbytrial-and-errormethodswhichoftenendedupwithno significantresults.Onewaytoovercomethisproblemisbyusingcomputer-aided techniquestoidentifyveryquicklyasetofpromisingcandidatesandselectasubset oflikelyfinalproducts,fromwhichthedesiredpropertiescanbeidentifiedthrough experiments(Figure1.1).

ThefirststepinFigure1.1isthepredesign,orproblemformulationstep.Steps2 and3represent,respectively,twotypesofproductdesignproblems:molecular designandmixture/blenddesign.Inthemoleculardesign,theobjectiveistofinda chemicalproductthatexhibitscertainfunctionalproperties.Theinventionofnew fueladditivesandsolventsinorganicsynthesisareexamplesofthistypeofdesign. Inthemixture/blenddesign,theobjectiveistofindarecipeofchemicalingredients whichgivedesirablefinalproductproperties.Examplesofthistypeofdesignare thedesignoffuelblendsandpolymerblends,includingpolymercompositesand additives.Theassociatedcomputer-aideddesignsforthetwoCPDsarecalled computer-aidedmoleculardesign(CAMD)andcomputer-aidedmixture/blend design(CAMb D).

Chemicalproductsarejudgedbyconsumersnotfromtheirtechnicalspecificationsbutratherbythefunctionalandperformanceattributeswhichareusually describedbyasetofperformanceindices.Theseindicesaredeterminedbythreefactors:(i)thecompositionandphysicochemicalpropertiesofmaterialsthatconstitute theproduct;(ii)productstructure,whichisdependentonthemanufacturing process;and(iii)productusageconditions.Therelationshipbetweenperformance

Figure1.1 Thedesignprocessforproductdesign.

Property prediction:

Given:

Information on compound structure

Given:

Information on desired properties and type of compound

Obtain:

Properties of the compound

CAMD & CAMbD

Obtain:

Compound structures having the desired properties and their “recipe”

Figure1.2 Chemicalproductdesign(CAMD,CAMb D)are“reverse”ofpropertyprediction problems.

indicesandproductcomposition,productingredients’properties,andproduct structurehasbeenmathematicallysystematizedthroughtheconceptofproperty function.Ingenericterms,theCPDcanbedefinedas:givenasetofdesired (target)needs,determineachemicalproduct(moleculeormixture)thatsatisfies theseneeds.Basedonthisdefinitionandtheconceptofpropertyfunction,the CPDproblemcanbedescribedasa“reversepropertyprediction,”asillustratedin Figure1.2,wheretheneedsaredefinedthroughproductproperties[3].

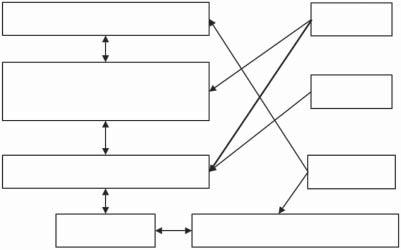

AsimpleframeworkforCPDisillustratedinFigure1.3.DifferentaspectsofCPD arerepresentedbymethodsforCAMD,CAMb D,analysis,andmodelvalidation, whiledifferentcalculationoptionsarerepresentedbytoolsofprocesssimulation, purecomponentpropertyestimation,mixturepropertyestimation,andsearch enginesfordataretrievalfromdatabases.Althoughthetwo-directionalarrowsin Figure1.3showtheconnectionbetweentwoadjacentmethodsortools,theyare meanttoindicatethatallthetoolsandmethodsareconnectedtoeachother.

InanyCPDproblem,propertyfunctionsandpropertymodelsplayimportant roles.WhiletheframeworkisflexibleenoughtohandlealargerangeofCPD

Figure1.3 Asimplified frameworkforcomputer-aided chemicalproductdesign.

problems,thecurrentlyavailablemethodsandtoolscanonlysolvearelatively smallpercentageoftheseproblems.Thisisbecausethepropertymodelsthatare currentlyavailableareunabletopredicttheneededpropertieswithinanacceptable limitofuncertainty.

Theframework,however,cangiveagreatcontributiontocreatingpropertymodelsanddatabasedevelopmentinasystematicway.Thiswillreducetimeandeffort intheearlystagesoftheproductdesignprocessandsubsequentlybringtheproduct tothemarketcheaperandfaster.

Theremainderofthisbookisorganizedasfollows:Chapter2surveysavariety ofapplicationsassociatedwithCPD,whileChapter3coverstoolscommonlyused toaccelerateproductdevelopment.Chapters4–12provideillustrativecasestudies relatedtoCPDandformulation.

References 1 Lee,N.-J.andJang,J.(1997).Performanceoptimisationofglassfibremat reinforcedpolypropylenecompositesusingstatisticalexperimentaldesign. Polym. Test. 16:497–506.

2 Cussler,E.L.andMoggridge,G.D.(2011). ChemicalProductDesign.Cambridge UniversityPress.ISBN:9781139035132.

3 Halvarsson,S.,Edlund,H.,andNorgren,M.(2008).Propertiesofmedium-density fibreboard(MDF)basedonwheatstrawandmelaminemodifiedurea formaldehyde(UMF)resin. Ind.CropsProd. 28:37–46.

2.1NaturalFiberPlasticComposites Theuseofnaturalfibersasreinforcementincompositematerialsdatesbackto 3000yearsagowhenancientEgyptiansusedclayreinforcedwithwheatstrawas materialstobuildwallsoftheirhouses.Intheautomotiveindustry,HenryFord developedthefirstprototypecompositecarmadefromhempfibersin1942.Dueto economicconstraintsatthattime,however,thecarwasnotcommerciallyproduced. Sincethen,numerousattemptshavebeenmadetoincorporatenaturalfibersinto automotivecomponents.Thepressuretoproducefuel-efficient,low-polluting vehicleshasbecomethemajordrivingforcefortheincreasinguseofnaturalfibers inautomotiveparts.Theinclusionofnaturalfiberswillmakeitpossibletoreduce theutilizationofpetroleum-basedpolymericmaterials.Itwillalsoincreasethefuel efficiencyduetocar’slighterweightandwillresultinaneasierproductend-of-life, i.e.wastemanagement.Today,severalcarmanufacturersareusingnaturalfiber compositesintheirproducts.Someexamplesoftheapplicationsarepresentedin Table2.1.

Boththermoplasticandthermosetresinswerebeingusedinautomotive industries.However,sincethermoplasticresinsareeasilyrecyclable,theyexhibit lessenvironmentalimpactthanthethermosetresins.Therefore,industriessuchas automotiveindustryisusingmorethermoplasticsthanthermosets.Forautomotive industry,thekeyadvantageofthermoplasticsisthattheycanbereprocessedor recycled,thusreducingtheamountofscrapmaterialduringmanufacturingand allowingeasyrecoveryandrecyclingofmaterialsattheend-of-lifecycle.Duetothe lowerthermalstabilityofnaturalfibers,thenumberofthermoplasticswhichcanbe usedtomakecompositematerialsislimitedtothosethermoplasticswithprocessing temperaturesthatdonotexceedthetemperaturefordegradationorburningthe plantfibers(typicallybelow210 ∘ C).Polypropylene(PP)andpolyethyleneare themostcommonlyusedthermoplasticpolymermatriceswithplantnatural fibers.

Therearevariousnaturalfiberswithbroadrangesofsizesandproperties availabletobeusedasfibersincomposites,suchascotton,jute,flax,hemp,sisal, coir,bamboo,wood,pineapple,ramie,coconutleaves,andsoon.Thechoiceof fibersmainlydependsonthefinalcompositeproductspecificationsandtheir ChemicalProductFormulationDesignandOptimization:Methods,Techniques,andCaseStudies, FirstEdition.AliElkamel,HeshamAlhumade,NavidOmidbakhsh,KeyvanNowruzi,andThomasDuever. ©2023WILEY-VCHGmbH.Published2023byWILEY-VCHGmbH.

8

2SomeTypicalApplicationsofChemicalProductDesignandIntellectualProperty

Table2.1 Automotivemanufacturers,model,andcomponentsusingnaturalfibers[1].

ManufacturerModelandapplication

AudiA2,A3,A4,A4Avant,A6,A8,Roadstar,Coupe:Seatback,sideand backdoorpanel,bootlining,hatrack,sparetirelining

BMW3,5,and7seriesandothers:Doorpanels,headlinerpanel,boot lining,seatback

Daimler-ChryslerA,C,E,Sclass:Doorpanels,windshield/dashboard,businesstable, pillercoverpanel;

Aclass,Travegobus:exteriorunderbodyprotectiontrim;Mclass: Instrumentalpanel

(NowinSclass:27partsmanufacturedfrombiofibers,weight43kg)

FiatPunto,Brava,Marea,AlfaRomeo146,156

FordMondeoCD162,Focus:Doorpanels,B-piller,bootliner

OpelAstra,Vectra,Zafira:Headlinerpanel,doorpanels,pillarcover panel,instrumentalpanel

PeugeotNewmodel406

RenaultClio

RoverRover2000andothers:Insulation,rearstorageshelf/panel

SaabDoorpanels

SEATDoorpanels,seatback

VolkswagenGolfA4,PassatVariant,Bora:Doorpanel,seatback,bootlidfinish panel,bootliner

VolvoC70,V70

MitsubishiSpacestar:Doorpanels;Colt:Instrumentalpanels

application.However,flax,hemp,andkenaffibersarefavored,becausetheyhave excellentcombinationsofeconomicandfunctionalproperties[1].

Thebasicruleofreinforcementisthatstressestothematerialmustbetransmittedfromthepolymermatrixtothefiber.Togettheoptimumreinforcementtothe polymermatrix,afibermusthavecertainattributes.Thelengthofthefibersand theaspectratio(length/diameter)ofthefibersshouldbecontrolledtoeachspecific typeofresinandapplication.Muchoftheresearchintheareaoffiber-reinforced plasticshasbeendoneusingglassfibers.Glassfibershaveuniformdiameterand canbemadetoanyrequiredlength.Therefore,thelengthandaspectratioareeasily controlledinthecaseofglassfibers.Thefiberalignmentisalsoasignificantfactor forcompositestrength.Fibersrandomlyorientedwilllosetheirreinforcementeffect byupto80%.Incaseswhereusageofcontinuousfibersisprohibitedduetoprocess constraints,discontinuousfibersareused.Inthiscase,stresscannotbetransmitted fromthematrixpolymertothefibersacrossthefiberends.Fiberswiththesizelonger thanacriticalminimumlength lc arerequiredforthesediscontinuousfibers[2].

Sincestressesmustbetransmittedacrosstheboundariesbetweenpolymermatrix andthefiber,thepropertiesoffiber–polymercompositesareinfluencedbythe

2.1NaturalFiberPlasticComposites 9 strengthofthebondbetweenthephases(interface).Providingstronginterfacial bondscanbeverychallengingbecauseitisnoteasytowethydrophilicnaturalfiber surfaceswithgenerallyhydrophobicviscous(molten)polymers.Couplingagents playanimportantroletobindthematrixandthefiberstogetherattheinterface.

Couplingagentsformoreinertpolymerslikepolyolefinsareoftenacid-modified versionsofthematrixpolymer,withmaleicanhydride-graftedpolypropylene (MA-g-PP)asaprimeexample.MA-g-PPiswidelyusedasacouplingagentin compositesreinforcedwithcellulosefibers.Thetreatmentofcellulosefiberwith hotMA-g-PPcopolymersprovidesthecovalentbondsacrosstheinterface.

Themechanismofthereactions,whichisbasicallydividedintotwosteps:activationofthecopolymerbyheatingandesterificationofcellulose,isillustratedin Figure2.1.Afterthistreatment,thesurfaceenergyofthefibersalmostreachesthe surfaceenergyofthematrix.Thus,abetterwettabilityandahigherinterfacialadhesionareobtained.ThePPchainpermitssegmentalcrystallizationandcohesivecouplingbetweenthemodifiedfiberandthePPmatrix.

Somerecentresearchpublicationsshowthatoneofthefocusesoftheongoing researchactivitiesistounderstandtheeffectofcouplingagentsonpolymerblends andcomposites.Withtheaidofscanningelectronmicroscopy(SEM),thecoupling ordispersionmechanismandthefracturebehaviorcanbeevaluatedbyobserving

Figure2.1 Illustrationofcouplingmechanismofcellulosefiberandmaleicacid-grafted polypropylene:(a)copolymeractivationand(b)celluloseesterification.

2SomeTypicalApplicationsofChemicalProductDesignandIntellectualProperty

themorphologyofthefracturedsurfaceofthecomposite.Differentialscanning calorimetry(DSC)isusuallyappliedtoexaminethecrystallizationbehavior.

However,tothebestofourknowledge,noliteratureexistsdiscussingtheoptimumproportionofsuchcouplingagentsinsystemscontainingPPandwheatstraw toprovidemaximumbenefitsofcompositemechanicalproperties.Thepreciseinformationrelatedtotheoptimumproportionisabsolutelyneededwhenwewantto commerciallyproducethenaturalfiberplasticcomposite.

Anotherimportantissuethatneedstobeaddressedisthefiberquality.Compared tomineralandsyntheticfibers,naturalfibershaveabroaderrangeoffibersizeand mechanicalproperties.Thatisbecauseofthedifferencesinvarietyandmaturity oftheplants,handlingthestrawbeforeprocessingthefiber(balesandstorage), andthemethodformanufacturingthestrawfiberbygrindingandsieving.There isarealneedforaqualityassuranceprotocolfornaturalfiberstobeestablished, especiallywhenfibersaretobeusedintechnicalapplicationsliketheautomotive parts.

2.2WheatStrawPolypropyleneComposites Theuseofwheatstrawasafillerinplasticcompositeshasreceivedconsiderable attentioninrecentyears.Manyfactorshavecausedthisinterest,suchasthelimited supplyofwoodfibers,environmentalimpacts,andgovernmentpolicies.However, themainattractivenessofusingwheatstrawinplasticcompositescomesfromits potentialtobecomeaseriouscompetitortotheothernaturalfibers:itslowerprice andfeedstockstability.Theestimatedworldwideproductionofwheatstrawwas approximately540milliontonsin2007.Thepriceofwheatstrawin2008,inOntario, basedontheannualaveragewasaroundUS$0.20–0.30/kg.InAugust2010,theprice ofrawjuteinIndiawasaboutUS$0.65–0.80/kg.

Currently,themajorapplicationofwheatstrawinOntarioisforhorsebedding ormushroomcomposting.Wheatstrawfiberisalsousedtomakepanelandother buildingsystemcomponentssuchaswallsandroofs.Extensiveeffortsarestillin progresstodiscovernewapplicationsofwheatstrawinsectorswhichneedhighly engineered,structuredmaterialssuchastheautomotiveindustry.

Manyresearchersfromdifferentdisciplineshavestudiedwheatstrawpolypropylenecomposites(WSPPCs).Despitethedifferentobjectives,focus,andscalesof observations,allthestudiesfollowedtypicalapproachesincompositescience. Ingeneral,thestudyofcompositematerialsinvolvesthreeaspects:composition selection,manufacturingprocess,andpropertyinvestigation.Asummaryofthe studiesofWSPPCsystemispresentedinTable2.2.

Variousmechanical[3],chemical[4],thermomechanical[5],chemo-mechanical [3],andbiological[6]techniqueshavebeenusedtopretreatwheatstrawfiberbefore theyarecompoundedwithPPmatricesfromdifferenttypesandgrades.

Ingeneral,therearethreetypesofPP:PPhomopolymer,PPrandomcopolymer, andPPimpactcopolymer.ThechoiceofPPtypesdependsonmanyfactorssuchas theprocesstobeused,theestheticandmechanicalfunctionofthefinalproduct,and

Table2.2 Examplesofvariablesintheformulationandmanufacturingofwheatstrawpolypropylenecomposites.

Compositionselection MatrixsystemFillersystemAdditives

Polypropylene(properties)

● Variousgrades(meltflow index,MFI)

● Blends(mixturesofgrades)

● CombinedwithrecycledPP

Wheatstraw(properties)

Chemical properties–composition:

● Cellulose

● Hemicelluloses

● Lignin

● Waxes

Physicalproperties:

● Fiberlength

● Aspectratio

Fiberpretreatment:

● Mechanical:groundfiber, longfiber

● Chemical:acid hydrolysis,chemical pulping

● Thermomechanical: steamexplosion

● Chemo-mechanical

● Biological:fungi, enzymes

Productstructurepurpose:

● Couplingagent: Productmanufacturing purpose:

● Antioxidant

● Lubricant

Productusagepurpose:

● UVstabilizer

● Colorant

● Heatstabilizer

Manufacturing process Property investigations

Processingtechniques

● Extrusion

● Injectionmolding

● Compressionmolding

● Thermoforming Fiberarchitecture

● Fiberorientation

● Web/wovenfiber

Mechanical

● Tensilestrength

● Flexuralstrength

● Flexuralmodulus

● Impactstrength

Thermal

● Deflectiontemp.

● Crystallizationtemp.

● Meltingtemp.

● Degreeofcrystallization

Other

● Rheological

● Waterabsorption

● Dimensionalstability

● Acoustical

Components’proportion:volumepercentage,weightpercentageProcessingvariablesVariousmethodsand standards

2SomeTypicalApplicationsofChemicalProductDesignandIntellectualProperty

specialadditiverequirements.Homopolypropylenesuitableforinjectionmolding wasthemostfrequentlyusedtypeofPPreportedinliteratures,withmeltflowindex rangesfrom3to30.

PPmatrixwasalsocombinedwithotherpolymermatricesforaspecificpurpose, suchasrecycledPPforenvironmentalpurposesandpolyethyleneterephthalate (PET)fortechnicalpurposes.Extrusionandinjectionmoldingarethemostfrequentlyusedmethodsformakingthecomposites,whilecompressionmoldinghas alsobeenreported.Moststudiesusedfiberswithlengthof0.5–5mm,whiletheuse offlourwheatstrawwithparticlesize <0.5mmormechanicallysplitwheatstraw fiberresultinginupto10-cm-longfiberhasalsobeenreported[7].

Manykindsofadditiveshavebeenaddedtomaintainortoimprovecomposite structural,processing,andusageproperties.Thetypeofadditivesprimarilydepends ontherequirementoffinalapplications.Forexample,applicationsexposedtosunlightrequireUVstabilizerandapplicationsexposedtohightemperaturesrequire heatstabilizers.

DespitetheextensivestudiesresultinginbetterunderstandingofWSPPCsystem anditspotentialapplicationinsectorswhichneedhighlyengineeredmaterials,only afewsuccessfulapplicationshavebeenreported.Thisisprobablyduetothelack ofsystematicdatabaseandreliablepropertymodelsneededinmanufacturingprocesses.Productdesignapproachandcomputer-aidedproductdesignmethodsare probablyoneofthebestsolutionstoovercomethisproblem.

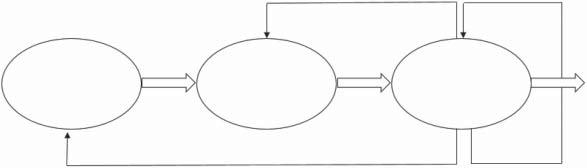

2.3ModelingNaturalFiberPolymerComposites Traditionally,modelingacompositesystemiscarriedoutbydividingthesysteminto threemainparts:compositecompositionselection,processingcondition,andfinal compositeproperties.Followingthisframework,threedifferentkindsofmodeling strategieswereconductedasillustratedinFigure2.2.

First,thefinalcompositepropertiesaremodeledasafunctionofcomposition selection.Theseobtainedmodelsarecommonlycalledstructuralpropertymodels. Second,thefinalcompositepropertiesaremodeledasafunctionoftheprocessing conditions.Thesemodelsarecalledprocessingpropertymodels.Finally,basedon

Figure2.2 Schematicpresentationofcompositesystemandcompositemodelingstrategy.

Table2.3 Discrepanciesbetweentheoryandexperimentalworkinnaturalfiber composite[9].

IssueTheoryExperimental

Fibershapeandsize –Uniformshape –Constantdimensions

Fiberorientation

–Unidirectional,or –Isotropy(random orientation)

Fiberinterface –Thefiberandmatrixarewell bonded

Fibermodulus

–Assumefibermodulusisthe sameinalldirections

–Non-uniformshape –Distributionsoflengthand thickness

–Somedegreeof misalignment,or –Notcompletelyisotropic

–Imperfectbondingbetween thefiberandmatrix –Introductionofcoupling agentisdifficulttobe mechanicallymodeled

–Fiberorfillerisanisotropic

Matrixconsiderations –Assumematrixisisotropic–Polymerchainorientation –Presenceofpolymer crystallites

Fiberconcentration effects

–Ignoresparticle–particle interactions

–Ignoreschangeinviscosity –Ignoresagglomerations

–Particle–particleinteractions andagglomerations

–Changesinviscositycanalter morphologyduringinjection molding

–Changesincrystalline morphology

thelevelofcorrelationbetweenpropertiessuchasthetrade-offrelationshipbetween strengthandtoughnessofcomposites,thefinalcompositepropertiesareinvestigated todevelopmodelsthataddresssuchcorrelationsbetweenproperties.Oncethevariousmodelswereconstructed,theycanbemanipulatedandthenbecombinedto simulatethecompositesystem[8].

Despitethewell-establishedmechanisticmodelingincompositescience, researchersseemtofacemanydifficultiesinusingthemechanisticapproach tomodelnaturalfiberpolymercomposites.Thereareseveralissueswherethe compositetheoriesaredifficulttobeappliedinnaturalfiberplasticcomposite,as summarizedinTable2.3.

Afewmodificationsofavailablecompositemodelshavebeenproposedto overcometheseproblems.Shibataandcoworkersproposedamethodtocalculate thefiberorientationcoefficientinmodelingflexuralpropertiesofPPwithkenafand bagassefiber.TheKelly–TysonModifiedRuleofMixtureandtheBowyer–Bader modelwereusedtointroduceamodelthatcantakeintoconsiderationthesupercriticalandsubcriticallengthdistributionsoffibersinahempfiberPPcomposite[10].

Ageometricalapproachofcuboidalshapehasbeenusedtomodeltheepidermal surfaceandparenchymasurfaceofwheatstrawcompoundedinaPPmatrix.Those modifications,however,onlycoveredtheindividualissueofthecomplexnatural fiberplasticcompositesystem.

2SomeTypicalApplicationsofChemicalProductDesignandIntellectualProperty

Alternatively,someresearchersusedexperimentaldesignmethodstodevelop statisticalmodelsofnaturalfiberplasticcomposites.Adaptingpreviousworkof statisticalexperimentaldesignofglassfibermatPPcomposite,Costaandcoworkers useda22 ⋅31 factorialdesigntodevelopstatisticalmodelsofflexuralpropertiesas functionsoftheamountofcouplingagent,thetypeofPPmatrix,andthecomponents’proportionofPP–woodfibercomposites.Theuseofsemiempiricalmodels andartificialneuralnetwork(ANN)hasalsobeenreported.ANNswereconsidered bymanyasapowerfultoolincompositepropertypredictionandcompositedesign. Neuralnetwork-basedanalysiswasappliedtofiber-length’sprobabilitydensity estimations.TheestimateswerecombinedwithGriffiththeory(theeffectiveness ofnaturalfibers)andHalpin–TsaimodeltopredicttheflexuralpropertiesofPP naturalfibercomposites[11].

Therewereonlyfewreportsonstatisticalmodelingofnaturalfiberplastic composite,andnoneofthosecoveredthecombinationofPPandwheatstraw.

2.4GrapheneComposites Agrowingnumberofstudiesfocusesondevelopingchemicalproductswith advancedpropertieswithminimumimpactsontheenvironment.Examplesof thesestudiesarethedevelopmentofpolymercompositesforwidefieldofapplicationincludingcorrosionprotection.Thedevelopmentoftheincorporationand dispersionofgrapheneparticlesinapolymermatrixhasrecentlyinitiatedstudies invariousfieldsofscienceandengineering.Thisisattributedtotheconsiderable improvementinpropertiesthatcannotusuallybeachievedusingcompositeswith othernanofillersorvirginpolymers.However,theextentoftheenhancementin variouspropertiescanbedirectlyrelatedtothedegreeofdispersionofthegraphene particlesinthepolymermatrix.Furthermore,itisinterestingtoobservethatsuch anenhancementinthepropertiesofapolymermatrixcanbeachievedataverylow loadingofthefillers[12–15].Theseimprovementsintheproperties,forexample, butnotlimitedtotensilestrength,storagemodulus,andelectricalconductivity havebeenobservedonvariouspolymerresinsuchasepoxy,polyethylene,PP, polystyrene,andpolyimide.Thedegreeofdispersionofgrapheneinapolymer matrixplaysanimportantroleinthedegreeoftheimprovementofthevariousproperties.Therefore,variouspreparationmethodshavebeenestablishedtomaximize dispersionofgrapheneforthepurposeofachievingtheoptimumperformances withminimumloadingsoffillers.

Therearethreemainapproachesforincorporationofgrapheneinapolymer matrix.Firstistheinsitupolymerizationmethod,wheregrapheneisfirstswollen withintheliquidmonomer.Thenbasedonthehostingpolymer,asuitableinitiator isintroducedtothefillersolution,andpolymerizationisinitiatedusuallyby thermalenergyorradiation.Thesecondmethodisknownasthesolutionmethod, whereasolventisusedinwhichthepolymerorprepolymerissolubilized,and grapheneisallowedtoswell.Theadvantageofthisapproachisthatgraphenecan beeasilydispersedinvarioussolventssuchaswater,acetone,andtoluenewhich

2.5CorrosionProtectionUsingPolymerComposites 15 areattributedtotheweakforcesthatstackthelayersofgraphenetogether.Here, thepolymeradsorbsontothedelaminatedgraphenethinsheets,andoncethe solventisevaporated,thesheetsreassembleinaformofsandwichingtheresin toformthecomposites.Anotheradvantageofthismethodisthepossibilityof synthesisofintercalatedcompositesusingpolymerswithloworevennopolarity. However,aconsiderableamountofsolventmightberequiredtoachievean optimumdispersionofthefillers,andthisisconsideredadisadvantageofthe approachsincesolventremovalcanbeacriticalissue.Finally,graphenecomposites canalsobesynthesizedusingthemeltintercalationmethodwithouttheneedto asolventasthemainadvantage.Inthistechnique,grapheneismixedwiththe hostingpolymermatrixinmoltenstate.Typically,athermoplasticpolymerismixed mechanicallywithgrapheneatcertaintemperaturesusingconventionalmethods, suchasextrusionandinjectionmolding,andasaresultgraphenecomposites areformed.

2.5CorrosionProtectionUsingPolymerComposites Theimplementationofgrapheneandglassflakecompositeshavebeenwidely reportedinvariousfieldsandapplications[16].However,onlystudiesthathave focusedonusinggrapheneandglassflakecompositesforcorrosionprotection purposesarereportedhere.

Therearedifferentapproachesfortheimplementationofgrapheneandgraphene compositesasprotectivecoatingsonmetalssubstrates.However,themajorityofthe previousstudieshaveusedtheexpensivechemicalvapordeposition(CVD)approach fordepositionofgrapheneonvariousmetalssubstrate.Anothercoatingapproachis electrophoreticdeposition(EPD),whichisacolloidalformingprocess.InEPD,electrostaticallychargedcolloidalparticlesinastablesuspensionaredepositedontoan oppositelychargedmetalsubstratebyintroducingaDCelectricfieldtothesystem. Furthermore,apostEPDtreatment,normallyaheattreatmentisusuallyrequiredin ordertoeliminatethecoatings’porosity[17].IncomparisontoCVD,thisapproach isveryversatile,fast,andcost-effectiveinproducingacoatingwithwell-controlled microstructureonawiderangeofmetalssubstrates.Thisisattributedtoeasiness inthismethodincontrollingvariousvariablessuchasdimensions,stoichiometry, depositiontimeandrate,thicknessinadditiontouniformity.Therefore,thismethod canbeconsideredasubstitutetoothertechniquessuchasslurrydipping,thermal spraying,sputtering,andCVD[18].DespitetheremarkableadvantagesofEPD,it hasanintrinsicdisadvantagecomparedtoothercolloidalapproachessuchasdip andslurrycoating,whereEPDcannotbeusedinapplicationsorfieldswherethe liquidmediumiswater.Thisisduetothefactthatapplicationofavoltagetowater willinitiatetheevolutionofhydrogenandoxygenatthemetalsubstrateandconsequentlyattenuatethequalityofthedeposits.Moreover,itshouldbenotedthat thequalityofcoatingspreparedbyEPDwillalsodependontheelectricalnature oftheelectrodes,wheremetalsubstrateswithlowconductivityareusuallymore difficulttocoat.

Inadditiontographene-basedcoatingpreparedusingCVDandEPD,promising observationshavebeenreportedusinggraphene-basedadhesivecompositessuchas epoxyandpolyimidegraphenecomposites.Thepossibilityofusingadhesivecompositesinvariousenvironmentsinadditiontothelowmaintenancecost,simple preparationsteps,andthepossibilityofapplyingthesecoatingsonvariousmetal substratesexplainswhythesecoatingsareusuallymorepreferablethancoatings preparedusingCVDorEPD.Inadditiontotheseremarkableproperties,theseresins combineotheroutstandingpropertiessuchashighthermalandchemicalstability,temperaturedurability,lowdielectricconstant,andthermalexpansioncoefficient[19–21].Anumberofstudieshavefocusedontheprobabilityofenhancing variousvaluablepropertiesofpolymerincludingcorrosionprotectionbytheincorporationofpristinegraphene[13].Forexample,polyimide/graphenecomposites coatingshavebeenrecentlypreparedbythermalimidization,andtheincorporationofgrapheneresultedinremarkableenhancementinthecorrosioninhibition propertyofthecoating[13].Inparallel,anenvironmental-friendlyanticorrosion epoxy/graphenecompositecoatingoncoldrolledsteelhasbeenpreparedandcured atroomtemperaturewithoutusinganytypeofsolvent[12].Similartotheprevious study,thecorrosionprotectionpropertyofthecoatinghasbeenexaminedusingTafel polarizationandelectrochemicalimpedancespectroscopy(EIS),wherebothtests revealedanenhancementinbothcorrosionprotectionandgasbarrierpropertiesas aresultofincorporatinggrapheneintheepoxyresin.Inaddition,thehydrophobic propertyofthiscoatinghasbeenenhancedbymodifyingthesurfaceofthecoatingusingacast.Asaresultofthissurfacemodification,attenuationonthewater andcorrosivemediaadsorptionhasbeenreportedontheepoxy/graphenecoating surface.

InadditiontothesimpleincorporationofpristinegrapheneinpolymercompositesorCVDcoatingwithgraphene,manyresearchershavefocusedonthe functionalizationofgrapheneandtheinfluencesofsuchfunctionalizationon variouspropertiesincludingcorrosionresistance.Forinstance,arecentstudy revealedthatthecorrosionprotectionofepoxyandgrapheneoxide(GO)compositescoatingscanbeenhancedbyattachingtitaniumdioxideontheGOsurfaceusing 3-aminopropyltriethoxysilaneascouplingagents[22].Anotherstudyinvestigated theincorporationoffluorographeneparticlesintopolyvinylbutyralcompositecoatingsforcorrosionprotectionpurposes.Thestudyrevealedthatshieldingproperty couldremarkablyenhancethecorrosionresistanceofthecoatingbyblockingthe diffusionpathsofcorrosiveelementsandmoisture[23].Recently,theinfluences oftheincorporationoffunctionalizedGOinepoxycomposites,throughthewet transferofamino-functionalizedGO,onthecorrosionresistancepropertyofepoxy coatingwereinvestigated.Thestudydemonstratedthatsignificantenhancementin thecorrosionmitigationpropertyofepoxycanbeachievedbyimprovingbothionic resistanceandbarrierproperties.

Agrowingnumberofstudieshavefocusedontheutilizationofglassflakeasfiller inpolymercomposites.Thisincorporationhasdeliveredenhancementinvarious propertiessuchasthermalandviscoelasticproperties[24]inadditiontocorrosion mitigation.Forexample,thelong-termperformanceofepoxy/glasscompositesas

corrosionprotectioncoatingsoncoldrolledsteelwasinvestigatedinchloride-rich environmentwhichillustratedthattheincorporationofglassflakeintheepoxy resinmayextendthelifespanofthecoatedmetalsubstrates.Furthermore,the studyrevealedthatglassflakemaydeliverfurthercorrosionprotectioncomparedto otherfillerssuchasclay[25].Inadditiontoepoxy,theincorporationofglassflake invariouspolymercompositeswasassessedandencouragingcorrosionresistance propertieswereobservedondifferentmetalsubstrates[26–28].Here,reported illustrativecasestudieswilldemonstratethepossibilityofdevelopinggraphene compositeswithadvancedcorrosion-resistantpropertieswithminimumimpactof theenvironment.

2.6IntellectualProperty Apatentisacontractbetweentheinventorandthegovernment,inthattheinventor discloseshisorherinventiontothepublic,forthebenefitofsharingtheknowledge aboutdetailsofanewinventionwiththepublic,inreturnforatime-limitedexclusivity.Patentisonlyenforceableinthecountriesthatithasbeengranted.Patents playaverysignificantroleinthesuccessofcompanies.Imaginethat,ifanideais notpatent-protected,oncefoundtobecommerciallysuccessfulcanbeverysoon copiedbycompetitors.Thiscanbereallybrutalformanycompanies,especiallyfor start-upsorsmallersizecompanies,whodonothavetheluxuryofmarketreach oflargerandestablishedcompetitors.Infact,theselargercompaniescannotonly copytheseproducts,butalsotheycouldimproveproductfeaturessincetheyhave muchlargerresearchanddevelopment(R&D)capabilities,andhavingaccesstoa muchbroadermarket,theywillcrushthesmallercompanywhooriginallycame upwiththeproductconcept.Infact,oneofthemainstrategiesofstart-upsisto patent(oratleastfileforapatent)theirnovelconcept,andoncetheyhavepreliminarytechnicalfeasibilityandpromisingdataforthetruevaluepropositionoftheir product,theycannegotiatewithlargercompaniesforeitherlicensingoracquisition.Itcanalsohappenthatthesecompanieswillattractfundsusuallyfromcapitalventuresallthewayfromconceptdevelopmenttocommercializationoftheir products.

Forthecaseoflargeranddominantcompanies,patentsarealsoextremely important,astheyhelpthemtokeepcompetitorsawayfromlaunchingme-too products,andthereforetheirprofitmarginswillremainveryhealthy.Anobvious exampleisthecaseofpharmaceuticalcompanies,anduntilaproductisstill patent-protected,thedrugpricewillbesignificantlyhigh,butassoonasthepatent expires,the“generic”products(youcanreadit“me-too”products)drivetheprice significantlydown,asaresultofapricewar.Arguably,withoutpatentprotection, itmaynotevenmakeafinancialcaseinthefirstplacetodeveloppharmaceutical products,sincemostofthecostsareassociatedwiththeR&Doftheseproducts. Thatsaid,whilehundredsofmillionsofdollarsarespentondevelopinganew pharmaceuticaldrug,theactualcostofscale-upandmanufacturingarevery minimalrelativelyspeaking,andthepricemarkupismainlytocoverfortheearlier

2SomeTypicalApplicationsofChemicalProductDesignandIntellectualProperty

investmentmadeindevelopingtheproduct,andthereforeitisanimperativeforthe companytocountonthissignificantpricemargintofinallyhaveapositivereturn oninvestment,whichusuallytakesafewyearstohappen.Ifcompetitorscould copythemonday1,thereturnoninvestmentformostoftheseproductswouldbe negativeandnofor-profitcompanywouldbeencouragedtodevelopproductssuch aspharmaceuticals.Inthiscase,theonlysourcefornewpharmaceuticaldrugs wouldbelimitedtogovernment-sponsoredlabsanduniversities.Althoughcapable, theyarenotnearlyasequipped,efficient,andagileaspharmaceuticalcompanies tohavesucharobustcadenceofnewproductsintheirpipelineonaconsistent manner.

Companiesmaydecidetoonlyprotecttheinventionsusedfortoprotecttheir products,toavoidcompetitorsfromcopyingthem.Thisisthemainobjectiveof attemptingtopatentaninventionandisdefinedasdefensivestrategy.Besidesthis, somecompaniesmaytrytoprotectinventivesubjectmatterinadjacentfieldstotryto hindertheircompetitors’productdevelopmentactivitiesinthosefieldsbycreating these“landmines”intherelevantpatentlandscape.Althougheffectiveinslowing downcompetitorsintheseadjacentfields,thisstrategydoesnotgeneratetangible returnoninvestment,andthereforethisapproachisusuallyavoidedindifficult financialcircumstances.Oncepatentsaregranted,itisthepatentownercompany’s responsibilitythattheirpatentswillnotbeinfringed,byconstantlymonitoringthe marketforanyproductsthatmayfallunderclaimsofthepatents.

Althoughpatentfilingandprosecutionprocesscreatesmoreworkfortheir inventors,andthattheymaynotbedirectlycompensatedfortheirvalueaddedby theirinventions,theyproviderecognitionfortheinventorsbytheirpeers.Patents aretypicallyconsideredasoneofthemainmatricesinassessingascientistor engineer’screativity.Themorepatentsascientistorengineerhas,thebettertheir resumewilllooklike,andtheproudertheywillbeinfrontoftheirpeers.Some companiesalsotrytofurtherencouragetheirprolificinventorsbymonetaryawards suchaspayingwhentheirpatentapplicationissubmittedandwhentheyare granted.

Beforeanynewproductdevelopment,itiswisetoperformalandscapesearchto understandthepatentfield,andthetechnologiesandproductfeaturesandmethodsthathavealreadybeenpatentprotected.Thisactivitycanbeextremelyuseful sinceitavoidswastingmillionsofdollarsonnewproductdevelopmentonlytothen realizethatthedevelopedtechnologyisalreadypatent-protected.Itisadvisablethat thelandscapesearchbeupdatedinregularintervalsduringproductdevelopmentto avoidanymissingrelevantpriorartandalsotoidentifynewpublicationsthatmay becomerelevant.Oncetheproductisfullydeveloped,afreedom-to-operate(FTO) searchisalsoperformedtoensurethattheproductdoesnotinfringeanypatents. Companiesoftenalsowatchtheirfieldonaregularbasisfortheemergingtechnologiesandthenewpublishedpatents,andthereforetheirsubjectmatterexpertsare usuallyuptodatewithworkrelatedtotheirexpertise.ItisalsopossibletoguestimatewherecompaniesarespendingtheirR&Ddollarsbyreviewingtheirpatent portfolio,withan18-monthlagofcoursesincepatentapplicationsarepublished 18monthsaftertheyarefiled.Thisprovidesvaluableinsightforcompanieswhen theytrytomonitortheircompetitorsactivitiesandcansomewhatforecastwhattheir nextproductswillbe.