IntroductiontoChemicalEngineering

C.M.van ’tLand Enschede,TheNetherlands

Copyright©2024byJohnWiley&Sons,Inc.Allrightsreserved.

PublishedbyJohnWiley&Sons,Inc.,Hoboken,NewJersey. PublishedsimultaneouslyinCanada.

Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmittedinanyformorbyanymeans, electronic,mechanical,photocopying,recording,scanning,orotherwise,exceptaspermittedunderSection107or108 ofthe1976UnitedStatesCopyrightAct,withouteitherthepriorwrittenpermissionofthePublisher,orauthorization throughpaymentoftheappropriateper-copyfeetotheCopyrightClearanceCenter,Inc.,222RosewoodDrive, Danvers,MA01923,(978)750-8400,fax(978)750-4470,oronthewebatwww.copyright.com.Requeststothe PublisherforpermissionshouldbeaddressedtothePermissionsDepartment,JohnWiley&Sons,Inc.,111River Street,Hoboken,NJ07030,(201)748-6011,fax(201)748-6008,oronlineathttp://www.wiley.com/go/permission.

Trademarks:WileyandtheWileylogoaretrademarksorregisteredtrademarksofJohnWiley&Sons,Inc.and/orits affiliatesintheUnitedStatesandothercountriesandmaynotbeusedwithoutwrittenpermission.Allother trademarksarethepropertyoftheirrespectiveowners.JohnWiley&Sons,Inc.isnotassociatedwithanyproductor vendormentionedinthisbook.

LimitofLiability/DisclaimerofWarranty:Whilethepublisherandauthorhaveusedtheirbesteffortsinpreparingthis book,theymakenorepresentationsorwarrantieswithrespecttotheaccuracyorcompletenessofthecontentsofthis bookandspecificallydisclaimanyimpliedwarrantiesofmerchantabilityorfitnessforaparticularpurpose.No warrantymaybecreatedorextendedbysalesrepresentativesorwrittensalesmaterials.Theadviceandstrategies containedhereinmaynotbesuitableforyoursituation.Youshouldconsultwithaprofessionalwhereappropriate. Further,readersshouldbeawarethatwebsiteslistedinthisworkmayhavechangedordisappearedbetweenwhenthis workwaswrittenandwhenitisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitoranyother commercialdamages,includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

Forgeneralinformationonourotherproductsandservicesorfortechnicalsupport,pleasecontactourCustomerCare DepartmentwithintheUnitedStatesat(800)762-2974,outsidetheUnitedStatesat(317)572-3993orfax(317) 572-4002.

Wileyalsopublishesitsbooksinavarietyofelectronicformats.Somecontentthatappearsinprintmaynotbe availableinelectronicformats.FormoreinformationaboutWileyproducts,visitourwebsiteatwww.wiley.com.

LibraryofCongressCataloging-in-PublicationData

Names:C.M.van ’tLand,1937– author.

Title:Introductiontochemicalengineering/C.M.van ’tLand.

Description:1stedition.|Hoboken,NJ:Wiley,2024.|Includes bibliographicalreferencesandindex.

Identifiers:LCCN2021035195(print)|LCCN2021035196(ebook)|ISBN 9781119634089(hardback)|ISBN9781119634096(adobepdf)|ISBN 9781119634126(epub)

Subjects:LCSH:Chemicalengineering.

Classification:LCCTP155.L262024(print)|LCCTP155(ebook)|DDC 660–dc23

LCrecordavailableathttps://lccn.loc.gov/2021035195

LCebookrecordavailableathttps://lccn.loc.gov/2021035196

CoverDesign:Wiley

CoverImage:CourtesyofC.M.van ’tLand

Setin9.5/12.5ptSTIXTwoTextbyStraive,Pondicherry,India

Contents Preface xvii Prologue xix

PartITransportPhenomena 1

1MassBalances 3

1.1Introduction 3

1.2Theory 5

1.3AdditionalMaterial 9 Reference 10

2EnergyBalances 11

2.1Definitions 11

2.2TheGeneralEnergyBalance 12

2.3ApplicationsoftheGeneralEnergyBalance 13

2.3.1Pump 13

2.3.2AirOxidationofCumene 14

2.4TheMechanicalEnergyEquation 17

2.5ApplicationsoftheMechanicalEnergyBalance 18 References 22

3Viscosity 23

3.1Definition 23

3.2NewtonianFluids 25

3.3Non-NewtonianFluids 25

3.3.1TheViscosityisaFunctionoftheTemperatureandtheShearRate 25

3.3.2TheViscosityisaFunctionofTime 28

3.4Viscoelasticity 29

3.5ViscosityofNewtonianFluids 29

3.5.1Gases 29

3.5.2Liquids 30 References 32

4LaminarFlow 33

4.1Steady-stateFlowThroughaCircularTube 33

4.2RotationalViscosimeters 37

4.3AdditionalRemarks 39

5TurbulentFlow 41

5.1VelocityDistribution 41

5.2TheReynoldsNumber 42

5.3PressureDropinHorizontalConduits 42

5.4PressureDropinTubeSystems 45

5.5FlowAroundObstacles 47

5.5.1Introduction 47

5.5.2DispersedSphericalParticles 48

5.6TerminalVelocityofaSwarmofParticles 53

5.7FlowResistanceofHeatExchangerswithTubes 53 References 54

6FlowMeters 57

6.1Introduction 57

6.2Fluid-energyActivatedFlowMeters 57

6.2.1Oval-gearFlowMeter 57

6.2.2OrificeMeter 57

6.2.3VenturiMeter 60

6.2.4Rotameter 60

6.3ExternalStimulusFlowMeters 61

6.3.1ThermalFlowMeter 61

6.3.2UltrasonicFlowMeters 62 References 62

7CaseStudiesFlowPhenomena 63

7.1EnergyConsumption:CalculationofthePowerPotentialofaHigh ArtificialLake 63

7.2EstimationoftheSizeofaPumpMotor 64

8HeatConduction 67

8.1Introduction 67

8.2ThermalConductivity 68

8.3Steady-stateHeatConduction 71

8.4HeatingorCoolingofaSolidBody 75 References 78

9ConvectiveHeatTransfer 79

9.1HeatExchangers 79

9.2HeatTransferCorrelations 84 References 86

10HeatTransferbyRadiation 87

10.1Introduction 87

10.2IR 87

10.3DielectricHeating 91

10.3.1GeneralAspects 91

10.3.2RFHeating 93

10.3.3MicrowaveHeating 94

References 97

11CaseStudiesHeatTransfer 99

11.1BulkMaterialsHeatExchanger 99

11.2HeatExchanger 100

11.3SurfaceTemperatureoftheSun 102

11.4GasIRTextileDrying 102

11.5HeatLossbyIRRadiation 103

11.6MicrowaveDryingofaPharmaceuticalProduct 103

References 104

12Steady-stateDiffusion 105

12.1IntroductionandDefinitionoftheDiffusionCoefficient 105

12.2TheDiffusionCoefficient 106

12.3Steady-stateDiffusion 107

References 112

13ConvectiveMassTransfer 113

13.1PartialandOverallMassTransferCoefficients 113

13.2MassTransferBetweenaFixedWallandaFlowingMedium 116

13.3SimultaneousHeatandMassTransferatConvectiveDrying 118 References 121

14CaseStudiesMassTransfer 123

14.1EquimolarDiffusion 123

14.2DiffusionthroughaStagnantBody 123

14.3SublimationofaNaphthaleneSphere 124

Reference 126

NotationI 127

GreekSymbols 131

PartIIMixingandStirring 135

15IntroductiontoMixingandStirrerTypes 137 References 142

16MixingTime 143

16.1Introduction 143

16.2ApproachofBeeketal. 144

16.3ApproachofZlokarnik 147 References 151

17PowerConsumption 153 References 156

18Suspensions 157

18.1Introduction 157

18.2PowerConsumption 162

18.3FurtherWork 163 References 164

19Liquid/LiquidDispersions 165 Reference 167

20GasDistribution 169

20.1Introduction 169

20.2Turbine 169

20.3Pitched-BladeTurbinePumpingDownward 175

20.4TurbineScaleUp 176

20.5BatchAirOxidationofaHydrocarbon 177

20.6Remark 178 Appendix20.1 178 References 179

21PhysicalGasAbsorption 181

21.1Introduction 181

21.2kl aMeasurements 181

21.3PowerConsumptiononScalingUp 184

21.4Remarks 184 References 184

22HeatTransferinStirredVessels 185

22.1Introduction 185

22.2HeatTransferJacketWall/ProcessLiquid 185

22.3HeatTransferCoilWall/ProcessLiquid 188

22.4HeatTransferJacketMedium/VesselWall 190

22.5HeatTransferCoilMedium/CoilWall 192

22.6BatchHeatingandCooling 192 References 193

23ScaleUpofMixing 195

23.1Introduction 195

23.2Homogenization 196

23.3Suspensions 198

23.4Liquid/LiquidDispersions 198

23.5GasDistribution 198

23.6kl a 198

23.7HeatTransfer 199 References 199

24CaseStudiesMixingandStirring 201

24.1MixingTime ComparisonofStirrers 201

24.2MixingTime ScaleUpofProcess 202

24.3Suspensions 202

24.4AirOxidationOptimization 203

24.5Calculatingkl a 205

24.6HeatingTolueneinaStirredVessel 206

24.7OverallHeatTransferCoefficientofaJacketedReactor 207

24.8ScaleUpofMixing 209 References 210

NotationII 211

GreekSymbols 213

PartIIIChemicalReactors 215

25ChemicalReactionEngineering AnIntroduction 217

25.1FluidizedCatalyticCracking(FCC) 217

25.2KineticRateDataandTransportPhenomena 218

25.3ReactorTypes 219

25.4BatchReactionsVersusContinuousReactions 221

25.5AdiabaticTemperatureRise 222

25.6Recycle 223

25.7ProcessIntensification 224 References 226

26AFewTypicalChemicalReactors 227

26.1TheCarbo-V-ProcessofChoren 227

26.2CoalGasification 227

26.3Biofuels 229

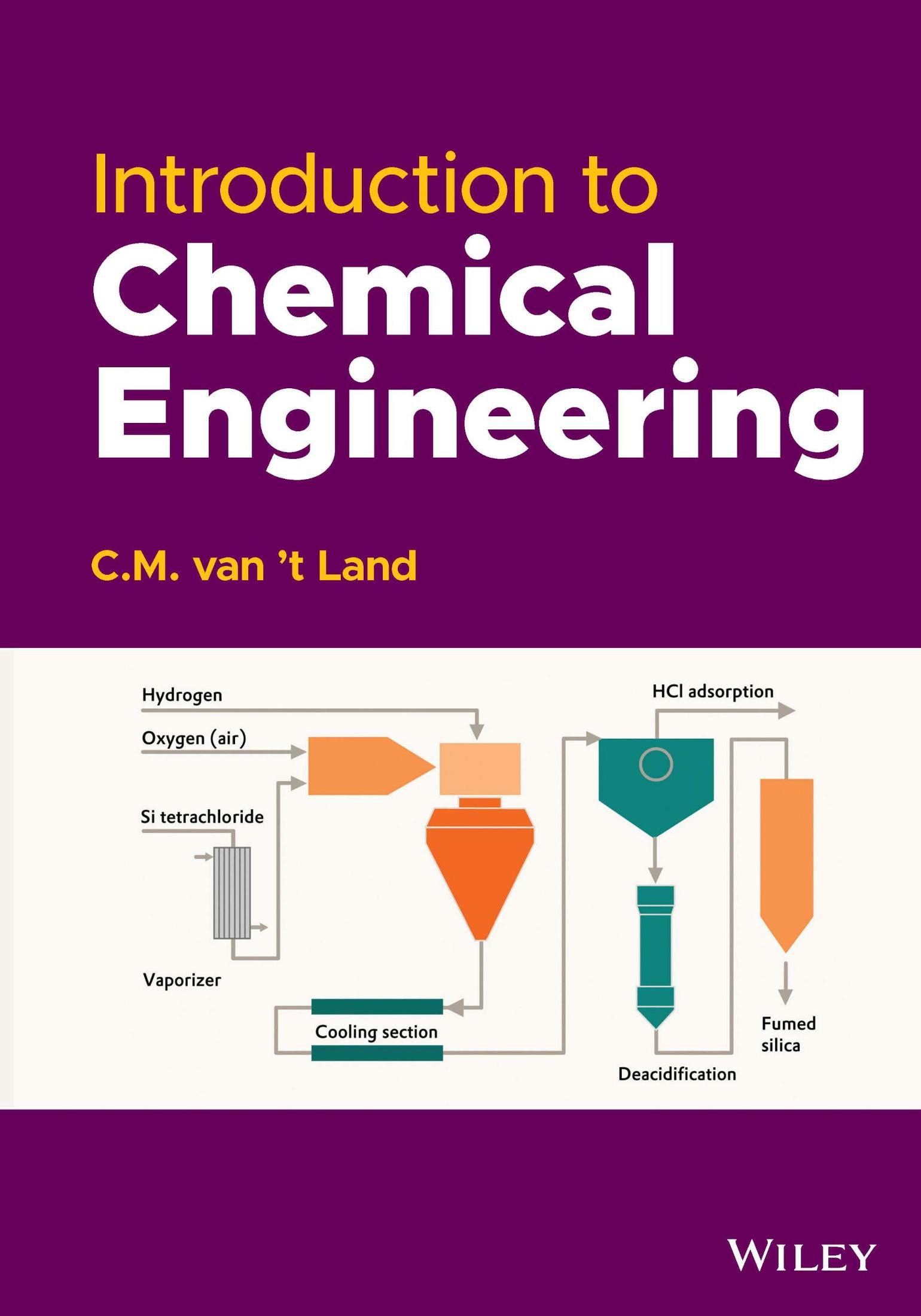

26.4PyrogenicSilica 230

26.5Microwaves 231

27TheOrderofaReaction 233

27.1TheRateofaReaction 233

27.2IntroductoryRemarksontheOrderofaReaction 233

27.3First-OrderReaction 234

27.4Second-OrderReactions 236 References 239

28TheRateofChemicalReactionsasaFunctionofTemperature 241

28.1Arrhenius’ Law 241

28.2HowtoInfluenceChemicalReactionRates 242 Reference 243

Contents

29ChemicalReactionEngineering—AQuantitativeApproach 245

29.1Introduction 245

29.2BatchReactor 245

29.3PlugFlowReactor 247

29.4ContinuousStirredTankReactor(CSTR) 248

29.5ReactorChoice 251

29.6Staging 251

29.7ReversibleReactions 253

30APlantModification:FromBatchwisetoContinuousManufacture 257

30.1Introduction 257

30.2BatchwiseProduction 257

30.3ContinuousManufacture 257 Reference 258

31IntrinsicContinuousProcessSafeguarding 259

31.1Summary 259

31.2Introduction 259

31.3TheProductionofOrganicPeroxides 260

31.4IntrinsicallySafeProcesses 260

31.5IntrinsicProcessSafeguarding 261

31.6ExtrinsicProcessSafeguarding 261

31.7AdditionalRemarks 261

31.8PracticalApproach 262

31.9Examples 263 References 265

32ReactorChoiceandScaleUp 267

32.1Introduction 267

32.2ParallelReactions 267

32.3PhysicalEffects 269

33CaseStudiesChemicalReactionEngineering 271

33.1OrderofaReaction 271

33.2ChemicalReactionRateasaFunctionofTemperature 273

33.3ReactorSize 273

33.4ReversibleReactions 274

33.5CompetingReactions 276

33.6TheHydrolysisofAceticAcidAnhydride 276

33.7CumeneAirOxidation 277 References 278 NotationIII 279 GreekSymbols 280

PartIVDistillation 281

34ContinuousDistillation 283

34.1Introduction 283

34.2Vapor–LiquidEquilibrium 283

34.3TheFractionatingColumn 286

34.4TheNumberofTraysRequired 288

34.5TheImportanceoftheRefluxRatio 292

34.6ATypicalContinuousIndustrialDistillation 293 References 294

35DesignofContinuousDistillationColumns 295

35.1SieveTrayColumns 295

35.2PackedColumns 299 Note 302 References 302

36VariousTypesofDistillation 303

36.1BatchDistillation 303

36.2AzeotropicandExtractiveDistillation 309

36.3SteamDistillation 311 References 312

37CaseStudiesDistillation 313

37.1McCabe–ThieleDiagram 313

37.2DiameterofaSieveTrayColumnandSieveTrayPressureLoss 316

37.3TheDistillationofWine 317

37.4SteamDistillation 320 Reference 321

NotationIV 323 GreekSymbols 325

PartVLiquidExtraction 327

38LiquidExtraction – Part1 329

38.1Introduction 329

38.2TheDistributionCoefficient 333

38.3CalculationoftheNumberofTheoreticalStagesinExtractionOperations 334 References 336

39LiquidExtraction – Part2 337

39.1CalculationoftheNumberofTransferUnitsinExtractionOperations 337 Reference 342

40Flooding 343

40.1General 343 References 345

41TheTwoLiquidsExchangingaComponentArePartiallyMiscible 347

41.1TriangularCoordinates 347

41.2FormationofOnePairofPartiallyMiscibleLiquids 348

41.3ContinuousCountercurrentMultiple-contactExtraction 353 References 355

42CaseStudiesLiquidExtraction 357

42.1ASeriesofCentrifugalExtractors 357

42.2ExtractionbyMeansofAnIonicLiquid 359

42.3OverallTransferCoefficient/HeightofaTransferUnit 360

42.4CalculationoftheColumnHeight 362

42.5TwoPartiallyMiscibleLiquidsExchangeaComponent 363 References 365

NotationV 367

GreekSymbols 369

PartVIAbsorptionofGases 371

43AbsorptionofGases 373

43.1Introduction 373

43.2DeterminationoftheNumberofTheoreticalStagesatAbsorptionofGases 374

43.3EstimationoftheDiameterofanAbsorptionColumnforNaturalGas 377

43.4TheAbsorptionofCarbonDioxide 378

43.5DesignofAbsorptionColumns 379 References 381

NotationVI 383 GreekSymbols 384

PartVIIMembranes 385

44Membranes AnIntroduction 387

44.1General 387

44.2Membranes 387

44.3ThreePressure-DrivenMembraneSeparationProcessesforAqueousSystems 389

44.4AMembraneSeparationProcessforAqueousSolutionsWhichIsDrivenbyan ElectricalPotentialDifference 390

44.5GasSeparation 391

44.6Pervaporation 392

44.7MedicalApplications 392

44.8AdditionalRemarks 393 References 394

45Microfiltration 395

45.1Introduction 395

45.2MembraneTypes 396

45.3MembraneCharacterization 397

45.4FilterConstruction 397

45.5OperationalPractice 398 References 399

46Ultrafiltration 401

46.1Introduction 401

46.2MembraneCharacterization 401

46.3ConcentrationPolarizationandMembraneFouling 402

46.4MembraneCleaning 406

46.5UltrafiltrationMembraneSystems 407

46.6ContinuousSystems 408

46.7Applications 409 References 411

47ReverseOsmosis 413

47.1Osmosis 413

47.2ReverseOsmosis 414

47.3TheoreticalBackground 415

47.4ConcentrationPolarization 417

47.5MembraneSpecifications 417

47.6MembraneQualities 417

47.7ReverseOsmosisUnits 418

47.8MembraneFoulingControlandCleaning 419

47.9Applications 420

47.10NanofiltrationMembranes 421

47.11ConclusionsandFutureDirections 421 References 421

48Electrodialysis 423

48.1Introduction 423

48.2FunctioningofIon-ExchangeMembranes 424

48.3TypesofIonExchangeMembranes 424

48.4TransportinElectrodialysisMembranes 425

48.5PowerConsumption 427

48.6SystemDesign 427

48.7Applications 428 References 429

49GasSeparation 431

49.1Introduction 431

49.2TheoreticalBackground 431

49.3ProcessDesign 436

49.4Applications 437 References 441

50CaseStudiesMembranes 443

50.1GelFormation 443

50.2OsmoticPressure 443

50.3MembraneGasSeparation 444 References 445

NotationVII 447 GreekSymbols 448

PartVIIICrystallization,Liquid/SolidSeparation,andDrying 449

51Crystallization 451

51.1Introduction 451

51.2Solubility 451

51.3Nucleation 452

51.4CrystalGrowth 453

51.5CrystallizersandCrystallizerOperations 454

51.6ThePopulationDensityBalance 457

51.7InterpretationoftheResultsofPopulationDensityBalances 463 References 466

52Liquid/Solidseparation 467

52.1Introduction 467

52.2Filtration 467

52.2.1Introduction 467

52.2.2CakeFiltration 468

52.2.3FilterAids 471

52.2.4Deep-BedFiltration 472

52.2.5FiltrationEquipment 472

52.3Centrifugation 475 Reference 478

53ConvectiveDrying 479

53.1Introduction 479

53.2FourImportantContinuousConvectiveDryersintheChemicalIndustry 480

53.3AFirstExampleofConvectiveDrying 482

53.4TheAdiabaticSaturationTemperature 483

53.5TheWet-BulbTemperature 485

53.6TheMollierDiagram 486

53.7DryingVacuumPanSaltinaPlugFlowFluid-BedDryer 488

54DesignofaFlashDryer 489

54.1Introduction 489

54.2Design 489 Reference 491

55ContactDrying 493

55.1Introduction 493

55.2ScalingUpofaConicalVacuumDryer 493

55.3AnAdditionalRemarkConcerningVacuumDrying 497

55.4TestingaSmallPlateDryer 498

55.5TestingaContinuousPaddleDryer 500

55.6ScaleUpofaThin-FilmDryer 503 Reference 506

56CaseStudiesCrystallization,Liquid/SolidSeparation,andDrying 507

56.1Ultracentrifuges 507

56.2Le2/3 507

56.3ConvectiveDrying-1 508

56.4ConvectiveDrying-2 509

56.5AnalysisofaSpray-DryingOperation 509

56.6EstimationoftheSizeofaContactDryer 512 References 515

NotationVIII 517

GreekSymbols 519

PartIXGas/SolidSeparation 521

57Introduction 523

58Cyclones 525

58.1Introduction 525

58.2SizingandProcessData 525 References 527

59FabricFilters 529

59.1Introduction 529

59.2Fabrics 529

59.3BaghouseConstructionandOperation 531 Reference 532

60Scrubbers 533

60.1Introduction 533

60.2Packed-BedScrubbers 534

60.3VenturiScrubbers 535

60.4MechanicalScrubbers 536 References 537

61ElectrostaticPrecipitators 539

61.1Introduction 539

61.2PrincipleofOperation 540

61.3ProcessData 540

61.4Construction 540

Reference 542

NotationIX 543

GreekSymbols 543

Index 545

Preface

AftergraduationasachemicalengineerattheUniversityofTwenteinTheNetherlandsin1971I workedinresearchforthemultinationalcompanyAkzoNobel.Myretirementstartedin2000.In 2005,IproposedtheDutchorganizationPAOTechniekenManagementtoorganizeaseminar “IntroductiontoChemicalEngineering”.Thegoalwastoenablechemistsintheprocessindustry toacquireknowledgeofchemicalengineering.TheseminarwasgivensuccessfullyinThe Netherlandsbetween2005and2015anditsscopewasgraduallyextended.Materialfromstandard textbookswascombinedwithmaterialobtainedwhileatwork.Theseminarappearedtobe attractivealsofor,e.g.,mechanicalengineersandphysicists.TheseminarwaswritteninEnglish asthatisthe “linguafranca” oftheprocessindustry.Then,in2015,theinterestdeclined.Itispossiblethatinternetinformationisthecause.IthenproposedJohnWiley&Sonstopublishabook containingthematerialoftheseminar.Anagreementwasmadeandthepresentbookistheresult. Iamgratefulforthepermissionsobtainedfortheincorporationofmaterialfromvarioussources. Thesourcesarementionedinthebook.Iwishtothankespeciallythefollowingpublishers:

DelftAcademicPress/VSSDatDelftinTheNetherlands, ElsevieratAmsterdaminTheNetherlands, McGraw-HillatNewYorkintheU.S.A., JohnWiley&SonsatHobokenintheU.S.A., TaylorandFrancisGroupatAbingdonintheU.K.,and WoltersKluweratAlphenaandenRijninTheNetherlands.

Iamgreatlyindebtedtomywife,Annechien,forherconstantencouragementandpatience.

C.M.van ’tLand

1.ATypicalChemicalProductionSystem

Introduction

Theproductionsystemforcrystallineethylenediaminetetra-aceticacid(EDTA)withinNouryon IndustrialChemicalswillbedescribed.Nouryonisamultinationalcompanymanufacturingchemicals.Thecompanyemploysatpresentapproximately10,000employeesandisactiveinmore than80countries.TheactivitiesofNouryonwerepartofthemultinationalcompanyAkzoNobel till2019.EDTAisachelate,itisalsocalledasequesteringagent.ThecommercialnameoftheproductisDissolvineZ.

Chelates

Theword “chela” meansclawinGreek.Chelateshavetheabilitytoseizemetalionsandcontrol them,makingitdifficultforadifferentsubstancetoliberatethem.EDTAandcompoundsderived fromEDTAarechelates.Forexample,thecalciumdisodiumsaltofEDTAisappliedtodeactivate undesirableheavymetalionsthatcatalyze(promote)thedegradationofvegetableoilsandfats.By preventingthisdegradation,whichmakesfoodandbeveragesrancid,foodqualityispreservedand shelflifeisincreased.TheapplicationofEDTAinboilers,heatexchangers,andotherwatercirculationsystemspresentinpower,brewing,sugar,anddairyindustriesisafurtherexample.Thecompoundformsstable,water-solublemetalcomplexeswithallpotentiallyharmfulmetalions, dissolvingexistingmetalcomplexesandpreventingnewonestoform.

Theothersideofthecoinisthatsequesteringagentscanalsobeappliedtodeliberatelyadministerametal.Forexample,aNouryonironchelatehasbeenapprovedbytheWorldHealthOrganizationandtheFoodandAgriculturalOrganizationtobeappliedasanironsupplementinfood. Theironchelateissolubleinwater.

TheChemistryoftheEDTA-Na4 Synthesis

ThetetrasodiumsaltofEDTAistheintermediateforthemanufactureofEDTA.

Thecompoundismadebythealkalinecyanomethylationofethylenediamine(EDA)bymeans ofsodiumcyanideandformaldehyde:

Thisisanoverallequation.Thealkalinecyanomethylationcomprisesinfactaseriesofconsecutivereactions.

Theprincipalby-productisNH3,ammonia,whichiscontinuouslyboiledoffduringthereaction. Thereactioniscarriedoutbatchwise.Thereactionisexothermic.Thereactionconditionsare 100–105 Candthepressureisatmospheric.ThepHofthereactionishigherthan12,somefree causticsodaisaddedtothereactor.Thereactionrateishigh,thereactionisbroughttocompletion inseconds.Thereactiondoesnotneedacatalyst.AnexcessofNaCNcausestheformationof sodiumformate.Anexcessofformaldehydecausestheformationofoligomericcompounds.With respecttoEDA,theyieldis95–100%.Forselectivityreasons,itisnotpossibletocarryoutthereactioncontinuously.

Theremovalofammoniaiskeyasammoniareactswithsodiumcyanide,formaldehyde,and watertothetrisodiumsaltofnitrilotri-aceticacid:

NTA-Na3: O

NaOCCH2 O NCH2 CONa

NaOCCH2 O

TheimpurityNTA-Na3 andotherimpurities(likeglycolicacidsalt)arenotdetrimentaltomost applicationsofchelatingagents.

TheIndustrialReactiontoProduceEDTA-Na4

SeeFigure1.First,thereactorwillbedescribed.Itstotalvolumeisapproximately25m3 . Thereactantsaremixedbymeansofaproprietarystirrer.Heatistransferredindirectlyto thereactorcontentsbymeansofacoilinthelowerpartofthereactor.Thecoilisheatedby meansofsteam.Thereactionisanexothermicone;however,extraheatisneededfortheevaporationofwaterandammonia.Therearebafflesinthelowerpartofthereactor,theirheight

equalstheheightofthecoil.Formaldehydeisdosedbymeansofaspargeraroundtheagitator. Formaldehydeisthemostcriticalcomponent.AnaqueoussolutionofsodiumcyanideandEDA aredosedbymeansofdip-pipes.Gaseousammoniaandwaterareremovedoverheadandare condensedinaseriesoftwosurfacecondensers.Inthefirstcondenser,wateriscondensed mainlywhereasNH 3 -25isobtainedinthesecondcondenser.Thesaturatedvaporpressureof NH 3 -25is1baraat25 C.

Second,themanufacturingprocedurewillbedescribed.AcertainamountofEDAisaddedtothe reactor.Smallamountsofwaterandcausticsoda(NaOH)arealsoaddedtoadjustthealkalinity. Next,thestirrerisactivatedandthereactorcontentsareheatedto100 C.Thedosingoftheaqueoussolutionsofsodiumcyanide,formaldehyde,andEDAisstartedandthereactionproceeds. Ammoniaandwaterareremovedoverhead.Thebatchtimeis4–5h.Eachbatchyields15tofa 45%byweightsolutionofthetetrasodiumsaltofEDTAinwaterand4tofa25%byweightsolution ofammoniainwater.Next,thereactorcontentsarepumpedtoasecondreactortobringthereactiontocompletionundermoderateboilingconditions.Bleachingthecontentsofthesecondreactor isthenextstep.TheintermediateistermedDissolvineE-45.Itcanbesoldassuch,itcanbespraydried,oritcanbeconvertedintotheacid.Theconversionintotheacidwillbedescribedinthenext section.

Theaqueoussolutionofsodiumcyanideishighlytoxictohumans.Contactwithanacidconverts sodiumcyanidetohydrogencyanidewhichisahazardousrespiratorypoison.Hydrogencyanide dissolvesinwaterandistransportedviathebloodstreamtotheindividualcellsofthebodywhereit blocksoxygenuptakebycombiningwiththeenzymeswhichcontrolcellularoxidation.Oxygen uptakeatthecellularlevelisblockedaslongasthecyanideispresent.Normalcellularoxygen uptakecanresumeifdeathofthecellshasnotalreadyoccurred.Thecyanidesareparticularlyhazardousbecauseoftheirlowthresholdtoxicitylevelcoupledwiththefactthattheyareodorless. Severaloperatorsaretrainedtobeabletogiveaninjectionwithanantidoteifneedbe.

E‐45 Steam

C.W.

Figure1 EDTA-Na4 reactor.

Prologue xxi