ONE HUNDRED YEARS

EJOT moment 01 >> 2022 1 01 //2022 moment Magazine

Unit Construction Quality – and sustainability

W. Kocherscheidt A visionary with foresight and the courage to take risks Market Unit Industry Much more than just a screw

Market

Hans

Editor

EJOT Holding GmbH & Co. KG

Im Herrengarten1

D-57319 Bad Berleburg

Phone +49 2751 529-0 www.ejot.de

Editorial staff

Andreas Blecher

Annemarie Bremer

Eva-Maria Hormighausen

Heinrich-Georg Homrighausen

Christian F. Kocherscheidt

Jutta Rathmann

Katrin Strübe

Andreas Wolf

Design

reaze GmbH, Siegen

Print

Vorländer GmbH & Co. KG, Siegen

Copyright

All contributions published in the magazine (texts, photos, graphics, logos and tables) are protected by copyright. The copyright lies with EJOT Holding GmbH & Co. KG – if not stated differently. Reproduction, inclusion into databases, online services and Internet pages as well as duplication on data carriers are subject to prior written approval by EJOT Holding GmbH & Co. KG.

Frequency of publication

moment is published semi-annually

Acquisition

Phone +49 2751 529-0 or at www.ejot.com

Cover: reaze GmbH, Siegen

Dear partners of the EJOT Group,

the title of this issue of moment gives it away, it is a special year for our group. We have joined the circle of centenarians. This is a point where we pause, look back, but also look forward. A year full of activities, projects and celebrations. However, it is also a year in which the war in Ukraine made it clear how easily things can slip away and what has been achieved can be jeopardized. So once again, a year that will not be easy to navigate.

This year, we are also paying tribute to the many activities with this copy of moment, because instead of two issues, we will only produce one issue in this anniversary year – but a substantial one! To this end, we have settled somewhere between a “commemorative magazine” and a look into the future.

Where do we come from? The long road from “nail shack” to a technology and industry leader in fastening technology is outlined. The discovery of application technology as a “gamechanger” that highlights the greater benefit of eliminating expensive processes over the smaller benefit of a ‘slightly lower price’.

In the course of the 100 years, people have always shaped us and led our group on new paths, which is why we would also like to introduce you to some of these people in this anniversary issue. It is people that make the difference, because we – and all our competitors – can use the same raw materials, machines, tools and equipment. These are usually available to everyone – and yet there is a difference, which we experience in the finished product or in the product’s development. If all other things are equal, it is us humans who make the difference. At EJOT this has been a success story.

We want to courageously continue this into the future: To the next 100!

Yours sincerely

Christian F. Kocherscheidt Managing Director

01 >> 2022 EJOT moment 2 Imprint

Editorial

Hans Werner Kocherscheidt

4 Lawyer and entrepreneur

7 A visionary Company anniversary

10 And so the next one hundred years begins

Market Unit Industry

14 The way to the top – industry leader as a matter of principle

16 Market Unit Industry – much more than just screws

Market Unit Construction

22 Highest quality – sustainable

24 Professional applications for the building envelope

Technology

30 From nail to functional part

Quality management

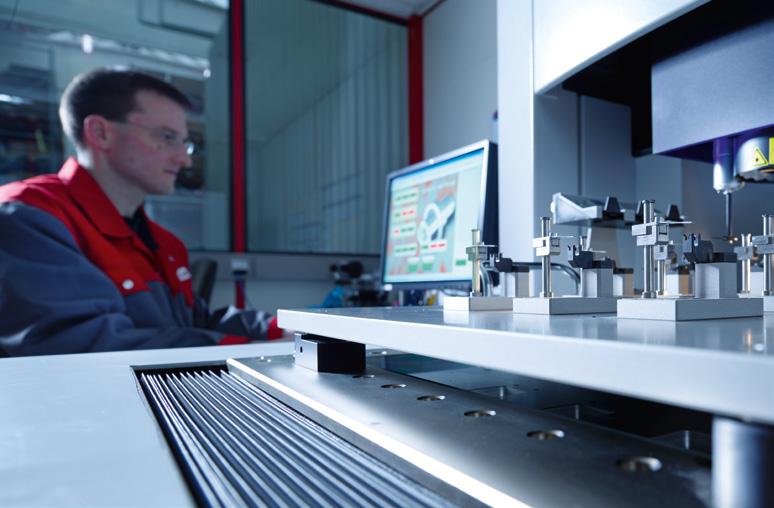

32 Quality remains a prerequisite for success

Advisory board

54 The advisory board – an important control body for the company’s success

Corporate Design

56 The colour doesn’t matter, as long as it’s white

58 The EJOT architecture

60 EJOT and Triathlon: An unprecedented success story

People at EJOT

64 Women and technology – that’s the way

66 From shop floor to Head of Maintenance

68 Georg Dickel – A sought-after specialist for 53 years

70 From apprentice to technical manager

License Management

72 Machines are his passion

74 Around the world in 30 years

76 EJOT is a family matter for the Hauer household

78 Balancing act between Germany and the Middle Kingdom Digitalization

History

EJOT moment 01 >> 2022 3 CONTENT

and logistics – now and in the future

EJOT becomes carbon neutral

Project Treeathlon® – EJOT reforests

Expanding

in global growth markets

of license management

staff children

34 Consequent use of digitilization opportunities Logistics 36 SCM, purchasing

Sustainability 40

44

EJOT International 46

presence

48 Potential and benefit

Family-owned company 50 Holiday camp for

Vocational training 52 Focusing on “career through apprenticeship” again

The

course

PT

screw revolutionises the fastener market

Success story EJOT in Tambach

Portraits of the subsidiaries

80 How it all began at the “nail shack” 84 The cradle of the clever (EJOT) heads 86 A strategic coup:

merger of Böhl and Jaeger 90 Historically grown: EJOT on expansion

92

®

96

98

Hans Werner Kocherscheidt lawyer and entrepreneur

His great passion was pleading in court – especially when it came to criminal defence. He also convinced with his speeches – not just his employees, but also many others in the course of his long life.

Hans Werner Kocherscheidt was born on 7 October 1928 in Kleinhammer (Werdohl), in today's Märkischer Kreis region, along the Lenne river. He died at the age of 88 on Good Friday 2017 in Bad Berleburg as a result of a serious operation. His father was an elementary school teacher, his mother a housewife. When Hans Werner was just five years old, his father died young, leaving the family, which also included a brother and a sister, with only a small pension. His brother died in the war and his sister died of cancer in her mid-50s. Hans Werner Kocherscheidt once told me that it would have been even more difficult without having a vegetable garden, so it was good that his mother still had many relatives in Wittgenstein, especially in Berghausen. They helped, especially the uncle, Adolf Böhl, who had no children and was happy to take care of his nephew Hans Werner. The visits to Wittgenstein took place by train. With a train connection that no longer exists in this form, namely from Altenhundem through a tunnel that connected the Lenne river with the Eder river back in the 1930s. Uncle Adolf had been a master wainwright, but then from 1922 he started producing nails in Berghausen, and quickly changed to making screws. This then became the Adolf Böhl company and later the EJOT company, as we know it today.

The war years were stressful for the high school student Kocherscheidt at the high school in Altena, he had to enlist as an anti-aircraft warfare helper at the age of 14 and had a very intense experience of the last year of the Second World War. But then came graduation (the German “Abitur”) in 1949. Hans Werner Kocherscheidt decided to study law in Mainz and Bonn with Uncle Adolf’s help, he passed his first state exam and then spent

his legal traineeship in the district of Siegen. After the second state examination, the decision was made: Hans Werner Kocherscheidt wanted to become a lawyer. He spent the time that was still necessary as a trainee lawyer in Essen, where he married his wife Gisela in 1959. Although she lived in Essen at the time, she was born to the Frank family in Laasphe-Banfe. The young couple first moved to Laasphe, but then soon after to Berleburg. In 1959, Hans Werner Kocherscheidt was initially employed in the Glöde law firm on Bismarckstrasse before founding his own law and notary's office at Bahnhofstrasse 1a. The law firm continues to exist today in the same premises as the lawyer company Bald and Henk.

As a lawyer and notary, Hans Werner Kocherscheidt was extremely successful. Within a few years, together with the employed lawyer Elisabeth Achinger and his partner Hartwig Achinger, and later with my college friend Albrecht Beitzel, he had one of the most renowned law and notary’s offices in South Westphalia. Hermann Josef Terahe in Olpe, Waldemar Grotepass and the law firm Schleifenbaum in Siegen were well-known law firms. I met him at the end of 1975. As a young assessor, I became his employee for a few months and almost stayed because he would have liked to have me as his partner. He had the room directly to the left of the entrance. He could be heard as soon as he entered the house. Then there was a fresh start among the complete team.

The professional focus of Hans Werner Kocherscheidt certainly was the commercial and corporate law. Many enterprises in Wittgenstein are still working well with the partnership agreements

1922

In the workshop behind his parents' house in the village of Berghausen near Berleburg, Adolf Böhl began producing nails in 1922. He got the nail press from his friend Wilhelm Herberg from Altena.

1924

In the issue of the Wittgensteiner Kreisblatt newspaper from 11 February 1924, an official announcement states that Adolf Böhl applied for 'approval from the trade police to erect a factory building with a turbine system' on his property in Trufte. The

01 >> 2022 EJOT moment 4

HANS WERNER KOCHERSCHEIDT

>>Text: Winfried Schwarz

water from the Trufte stream was to be dammed up in an existing feeder and used to drive a turbine.

1926

In 1926, Adolf Böhl moved production to a small new building in the Trufte, where he could rely on licensed hydroelectric power. Pictured is the small production facility in the village centre of Berghausen.

1928

In 1928, Adolf Böhl succeeded in hiring Heinrich Henk, a native from Wittgenstein with knowledge of wire processing. Henk had acquired his knowledge at the company Knipping in Altena. The company Knipping later became Lennewerk. Another

skilled worker was the locksmith Wilhelm Wagner from Berghausen, who was soon able to make pinching tools for the pin presses.

EJOT moment 01 >> 2022 5

that he had designed. But his real passion was actually criminal law. He was a genius defence lawyer. He fought for his clients and was proud when his defence strategy had been successful. He was then on an equal footing with the famous criminal defence lawyer Rolf Bossi, against whom he had to appear twice and was able to successfully reject an appeal in one case.

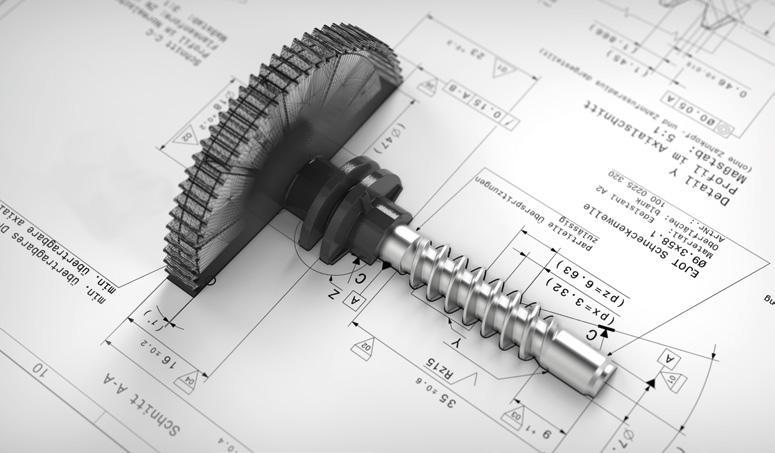

As I later heard from his children Christian and Kathrin, the time for EJOT actually was the Saturday morning. In 1960 his uncle Adolf transferred his company to him, and Eberhard Jaeger joined in 1965. On Saturdays he talked to his foreman Adolf Sonneborn and his managing director Kurt Machate in the office. In 1922, Adolf Böhl was persuaded by his comrades-in-arms to go into screw production. The specialists for this came from the cradle of German screw production, from the Lenne valley. Sonneborn was from Wittgenstein, but Machate came from Altena and was a knowledgeable screw specialist. The Mister EJOT, Hermann Großberndt, also came from there. In 1977, after laborious and time-consuming preliminary work, he succeeded in inventing the PT® screw and 20 years later the Delta PT®. As chief developer in the 1980s and 1990s, Großberndt was responsible for the development of the entire range of screws at EJOT.

Hans Werner Kocherscheidt was good with people. He had a charisma that captivated those around him. Somehow he knew who and what could help him and his company. The outsourcing of the construction screw and the first European branch offices made the company continuously larger. He knew them all personally, his managing directors and many employees anyway, but above all the foreign managing directors, who can often report on personal experiences with him.

I have even seen employees ask him for legal advice several times. That went without saying for him. This often resulted in a special relationship of trust, which ensured good employee loyalty.

He was lucky to have his son Christian as his successor who has been fascinated by the topic of cold forming the same way as he was. Christian had just graduated with a degree in business administration and was planning to work as a trainee in an American screw factory for a year. Through various customer contacts, he and his father met Don Surber at a trade fair in Atlanta. Mr. Surber, owner of the company Accurate Threaded Fasteners (ATF) and

then chairman of the American Screw Association, drove with the guests to the ATF headquarters in Chicago, where Christian then worked for a year. ATF then became a licensee and partner in other companies, most notably for the founding of Asyst in Kenosha. Not only did a good business relationship develop with ATF and the Surber family, but also a close friendship.

The acquisition of qualified employees was almost like a hobby for him. Once he invited me to go sailing with him and his wife on the Edersee. In addition to the sailing boat ‘Sophie’, he also had a small holiday home there. He had invited an applicant from Thuringia there, whom he wanted to get to know and employ for a job at the Tambach plant. Mrs. Kocherscheidt was sent on a ship of the ‘white fleet’ with the wife who was travelling along. The three of us then cruised on the Edersee and got to know each other very well. A hearty barbecue in the holiday home was the perfect way to end the day. The employee was hired. He advanced an important invention for years and is now Managing Director.

An entrepreneurial feat was the takeover of the Tambach screw factory from the trust agency in 1993. The promise to employ 202 people has not only been kept: In fact, there were more than 300 from day one. Tambach has now hit the bull's eye both in the manufacture of screws and in the hardening and tempering of screws and in the production of technical plastic parts. But here, too, it was and became very personal. Hans Werner Kocherscheidt appeared regularly with his wife Gisela, stayed in one of the three apartments set up for the family and guests in the factory and spoke to the people. And of course, he was there at the Christmas party. That went without saying for him.

And EJOT grew and grew. However, such a continuous growth also caused problems. Crises are always good when they can be overcome successfully and when you have learned from your mistakes. That happened to us in 2002 and 2005 but also in 2008 like to many other companies. We approached the employees with great openness, but above all the works councils and trade union IG Metall, and finally got the problems under control with important employee agreements and company wage agreements. That would not have been possible without Hans Werner Kocherscheidt. True to the motto – if the company is doing well, the employees should also do well – the old-age pension program SENECA and the contingent commission SENECA PLUS were introduced.

1935

In 1935, when the company had four employees, Adolf Böhl hired a 16-year-old young man, Adolf Sonneborn from Berghausen, who later had a decisive influence on the company's fate for over 50 years.

1935

Between 1935 and 1939, sales revenues for nails deteriorated. The company switched to the production of screw nails. A manually operated flat jaw roller was purchased for this purpose.

1937

At the end of the 1930s, the production of wood screws with a one die single header for screws with 2.4 and 2.7 mm diameter and 10 to 20 mm shank length was started. The business is expanded, new machines are purchased.

01 >> 2022 EJOT moment 6

HANS WERNER KOCHERSCHEIDT

EJOT really lives the topic of work and family. There is a flexible response when there are problems with the employees. It is particularly important that young mothers are reintegrated into working life after a pregnancy. And Hans Werner Kocherscheidt wanted it all, helped shape it and supported it.

He had a special way to approach his employees. It always included a bit of a demand. He recognised that the quality of the work goes along with education very early on. That’s why he

initiated and founded what was then the industrial training workshop Wittgenstein, today’s Wittgenstein Training Centre (BZW), more than 40 years ago. Qualified training for young people in all trades was important to him and he was really proud when, in 2016, an EJOT trainee became the best tool mechanic in Germany for the first time.

None of us expected his sudden death on Good Friday 2017, he will be fondly remembered by many. E

Schwarz Manager

A visionary with foresight and a particular instinct for people

The first encounter with the lawyer Hans Werner Kocherscheidt dates back to 1964. Kurt Machate, CEO at Adolf Böhl in Berghausen, whom I know professionally from our time together at the Lennewerk Altena, invites me to visit Berleburg and introduces me to Hans Werner Kocherscheidt.

The first impression: Almost the same age, very eloquent, decisive, conversational, follows words with deeds: When I leave his house, I have an employment contract in my pocket. On my first working day at the Böhl company, I drive to his office to personally announce that I will be starting work.

As we continue to work together, I find out that he knows his company inside and out and also surprises others with his indepth knowledge: We are at a meeting of the German Screw Association in Düsseldorf, where he makes it clear to the group that he is a lawyer and not a screw specialist like the participants

of the meeting. A few minutes later, when the conversation turns to special headers and technical details, Mr. Kocherscheidt gives a presentation on double-blow headers from various manufacturers. He goes into detail about wire dimensions, speed and section lengths and even supplies accurate price information. Never again did anyone believe that he was just a layman in the screw business.

Hans Werner Kocherscheidt is inquisitive, and even the smallest details do not go unnoticed. His favourite “tool” is the telephone: He is on the phone with all his senior employees – but not only

1938

In 1938, 16 years after the company was founded, it was entered into the commercial register in Siegen. Production stagnated during the Second World War, and operations were temporarily suspended towards the end of the war.

1945

As mayor and local group leader of the NSDAP, Adolf Böhl was classified as 'NS-incriminated' by the American occupation authorities and was detained from 1945 to 1948. During this time, the company was under the trusteeship of Otto Stahlschmidt.

1946 /1947

Eberhard Jaeger (right) establishes a screw factory near the Bad Laasphe train station and begins manufacturing commercial screws - with a Hilgeland double-blow header, a slotting machine and a thread rolling machine.

EJOT moment 01 >> 2022 7

Winfried

at EJOT Holding GmbH & Co. KG from 2000 to 2017

>>Text: Bruno Kayser

them – anywhere from once to several times a day. You may ask yourself how he knows all these things. After all, he is a lawyer and also represents and processes contracts for company employees; and while he already has them in his office, he also knows the necessary questioning techniques in order to get all the information that interests him and absorbs it like a sponge.

He is the “boss”. All major investments in machines, cars, buildings, etc. are co-determined and negotiated by him. Hence, his detailed knowledge. Nevertheless, his senior employees are free to come up with their own ideas, projects and developments. Hans Werner Kochscheidt wants to know them all, and then supports them. He accompanies the development of contacts to new customers, expansions and operational innovations, e.g. the development of facade screws, PT® screws and later also the EJOWELD® research project. This also includes the establishment of new sales offices and branch offices abroad. Hans Werner Kocherscheidt came up with the idea of going into the processing of plastics in addition to screw production. He’s quite an entrepreneur with the courage to take risks, because this is a new area of production that the company has no experience in.

He receives daily reports from sales about incoming orders, with the names of the most important clients. And he wants to know how to increase sales. He contributes his own ideas and makes suggestions. An important concern for him is to utilise the full capacity of plants, the running time of the machines and minimisation of the set-up times due to larger order quantities per dimension.

During an evening or weekend walk with his dog, he often stops by my apartment for a short visit. The conversation quickly turns to company business. He always gives suggestions and explains his ideas. He wants the companies Böhl and Jaeger to grow, also abroad. The umlauts in the company names bother him. This is how the idea was came about to create a common name: EJOT –but not the former sign of Eberhard Jaeger. A few designers are commissioned to create drafts for a company logo. A draft by the designer and graphic artist Ulf Höppner from Berleburg impresses the most. From now on, the red EJOT logo applies to all business papers and can be seen on every company building and on every car. No matter where a building is rented or built, at home or abroad, Hans Werner Kocherscheidt is there to ensure that his ideas about the image are implemented, because corporate identity is important to him.

Hans Werner Kocherscheidt is a visionary and thinks ahead. In his early years, he invested in machines in the hope that his sales team would take care of the orders incoming. For example, he buys a rolling machine with attachment devices for several washers, but there is no need for them yet. There are certainly other similar examples. He is constantly on the lookout for suitable experts and also invests beyond current needs. Ultimately, his decisions are always right.

Over the years, Hans Werner Kocherscheidt was aware of how many fates depend on his decisions: He likes to celebrate – also with his staff. Also on the occasion of his 60th birthday. During the

1948

The development of the Adolf Böhl plant is extremely sluggish under difficult conditions. Single-blow headers and rollers, cutting machines and head slitting machines are available. The economy mostly runs on barter transactions only.

1950

In the beginning of the 1950s the economic situation improves at Adolf Böhl. By 1960 the number of employees had been increased to about 60, with sales of DM 2 million per year.

1953

Eberhard Jaeger invests in a new building at the location In der Bienhecke in Bad Laasphe with production hall and office building. The customers come from the electrical industry and purchase slotted screws according to DIN. At this time, the company has six employees.

01 >> 2022 EJOT moment 8

HANS WERNER KOCHERSCHEIDT

1957

The first galvanizing plant is built at Jaeger at the Bienhecke location. Zinc, copper, brass and nickel coatings can be applied to the screws. Even then, the operation of this plant was associated with the obligation of wastewater detoxification and neutralization, but by no means to today's standards.

preparations, we consider how many people will come together (including spouses). I tell him: “We have about 400 employees.” He replies quite harshly: “But now you've really ruined my day.” The explanation for this statement follows immediately: “You forgot the women and children who are all attached to the company and for whom I am responsible.”

Hans Werner Kocherscheidt came from a very Christian home, which he openly stated. No matter who he invited, for example a business dinner at home or in a restaurant, before the meal he bowed his head and folded his hands in a short, silent prayer of thanks. In the Monday talks with his senior staff, he reported on his Sunday visits to one of the churches in Wittgenstein, after which he liked to visit the plants (he had a master key) in order to inform the plant manager on Monday about everything that caught his eye.

Twice in all those years I've seen something upset him: When the electro-plating shop at the Bienhecke site in Laasphe caught fire and we helplessly watched on as it burned – he had tears in his eyes. He didn’t let anything get in the way of his closest colleagues and friends, especially Adolf Sonneborn. When someone said something negative about the plant manager in a meeting when he was not present, Hans Werner Kocherscheidt could not keep quiet. Rarely have I seen such fiery eyes and heard this sharpness in his voice.

He came up with the idea of visiting East Germany to find out about their screw industry shortly after the fall of the Berlin Wall in 1989. The negotiations and deliberations both in Tambach and later in Berlin with the Treuhandanstalt were usually led by him. The acquisition of the Tambach screw factory was the largest investment to date, with the number of employees suddenly doubling from 650 to 1,050 and with it the feeling of growing responsibility.

He loved personal contact and also wanted to get to know the people in Tambach-Dietharz quickly, which is why he invited the department heads and foremen to a relaxed get-together at the local sports club, which at the time belonged to the screw factory, and everyone had to introduce themselves by name, position and career. He wanted to create trust. He also expressed this, by aiming the first investment directly at the workforce: it was the renovation of the washrooms and toilets. Only then did the renewals in operation and administration follow.

1958

For the time, the Adolf Böhl company had quite a considerable machine park, including double-blow headers for metric threaded and sheet metal screws.

EJOT moment 01 >> 2022 9

E

Gisela and Hans Werner Kocherscheidt, Winfried Schwarz and Bruno Kayser (f.l.).

1960

Adolf Böhl passed away in 1960 at the age of 71. As the legal heir, his nephew Hans Werner Kocherscheidt takes over the company. Hans Werner Kocherscheidt invests and, among other things, creates the basis for a modern, more competitive production with the purchase of two high-performance double-blow headers from National.

1962

Addition of a production hall and manufacture of extra-long slotted screws. As the market for slotted screws is under pressure, the product portfolio is converted to stainless steel screws.

1963

Kurt Machate joins Adolf Böhl from Lennewerk Altena as the new Managing Director. Together with Adolf Sonneborn, who is responsible for the technical part, they form a very successful team in the production and marketing of sheet metal and chipboard screws.

01 >> 2022 EJOT moment 10 101 100

ANNIVERSARY

And so the next one hundred years begins

“Great

their shadows

as the saying goes. The same goes for the celebration of a great anniversary, even if, at first, it seems a long way away. But the more we think about it, the more we realise that a centenary is something worth celebrating. But the question is, how exactly?

It soon becomes clear that the aim here is not to throw as much money as possible in the shortest time possible at the centenary event, but instead to link the celebration of the centenary with a future vision that will carry us into the next century. A vision that says “To the next 100 years.” We didn’t want to focus on the past, as significant as it has been for our company's development. Instead, we wanted to affirm that, even 100 years on from the foundation of our company, we remain a vibrant organisation with great hopes and aspirations. Our team around the world should take confidence from this fact and feel encouraged to continue developing and improving products and processes which provide additional benefits to and improve the experience of customers, thus strengthening our relationships even further.

At the same time, the occasion will of course be used to celebrate the past 100 years of EJOT. Initial thoughts on this go all the way back to 2019. We invited event planning agencies to workshops, listened to their ideas and compared them to our own ideas, as well as having what were at times heated discussions as to which direction the project should take. And, yes, we even asked around to find out how other companies have commemorated similar anniversaries. This proved to be an important process, during which it became increasingly clear that we could do a lot ourselves, even without an event planning agency. Our centenary celebration shouldn’t be an event full of glitz and glamour and just be for show. We should stay grounded, as EJOT always has done.

Over the entire centenary year, there will be celebrations at each respective EJOT site with events including family days,

1965

In 1965, Hans Werner Kocherscheidt acquires the Eberhard Jaeger company in Laasphe. The company Jaeger also produces metric slotted screws, but those screws were sold in other market segments. For the company Adolf Böhl this meant a market expansion.

1965

At Jaeger, 22 employees with relevant knowledge are available. Another important aspect in the course of the takeover was the fact that Jaeger was authorised to operate a galvanic plant, which could be used for both companies after a necessary expansion.

1967

The company name EJOT is "born": With the investment in a teleprinter at Jaeger, a name abbreviation must be set as the address. At Eberhard Jaeger the first letters E and J where used and the J was then amended to JOT due to the phonetic pronunciation in German.

EJOT moment 01 >> 2022 11

events cast

ahead,”

>>Text: Christian Kocherscheidt and Andreas Wolf

music festivals and centenary concerts as well as steamboat trips and open factory doors. At some sites, the centenary celebrations will be combined with the inauguration of new production halls or new production buildings.

We also want to take this opportunity to give something back to all the people at EJOT sites who have helped the business successfully grow over the last decades. For this purpose, the employees at our locations have come up with charity campaigns, which focus on how we can help people and do our bit to help protect nature and the environment. The result has been numerous local projects, in which employees have gotten involved in a wide variety of ways, including campaigns supporting social institutions and athletes with disabilities as well as one which donated an electric vehicle to make the daily working lives of employees with disabilities easier. Another important aspect of these charity campaigns has been the commitment to protect nature and the environment, demonstrated, for example, by both reforestation and planting campaigns as well as a waste collection campaign in a nature reserve. Many of the campaigns are designed to be sustainable and are to carry on beyond the celebrations.

Right at the beginning of the centenary year, we went live with our centenary platform: At www.ejot100.com the EJOT family can meet to exchange stories, pictures, videos, music, take part in games or even competitions. The platform is the heart of the centenary year celebrations. The EJOT song “Bringing it together”, composed and produced by the band Billenial Collective made

up of three young musicians from Bad Berleburg, Germany, also helps people to connect and engage with the company’s history. The audio version of the song is available to stream on all streaming services. The video, shot at our production site Herrenwiese in Bad Berleburg, is also available to view on our platform, on our social media pages as well as on Youtube.

We have also completely rewritten – and put to film – the history of the screw, which, believe it or not, dates back far beyond our 100year company history to the Stone Age, a time shortly before EJOT arrived on the scene as a fastening technology specialist. A satire, not entirely serious but humorous story.

One of the questions at the heart of this centenary year is: How can we carry our success of the past decades into the future? The answer to this question is connected to the realisation that ideas for products or processes do not simply come from nothing, but instead emerge when we get to know the practical tasks of our customers and initiate a subsequent development process. Not only that, the more demanding the goals of our customers as industry leaders in their respective segments, the better. Demanding goals require sophisticated solutions – solutions which we can invest in going forward.

The question is will we continue to find these customers at home in Germany, or Europe, our core markets, or do we have to look further afield? And if we do have to look further afield, will it still be the case that the questions to all of our most demanding

www.ejot100.com/de/birthday-videos

1968

Addition of a new production and storage hall at Bienhecke for the production of drilling screws with sealing washer. Also at this time, the first self-made packaging line is built. A roller conveyor picks up the transport containers from the production

line. In front of the scale, a tipping device is installed which can hold and slowly tilt a container allowing controlled filling of the screws. The filled cartons are then transported on roller conveyors and labeled and closed at the same time.

1970

“Birth year” of the Engineered plastic Components Business Unit. For strategic reasons, the screw segment is expanded to include a further mainstay. But it is a long way to implementation.

1971

Powder metallurgy – A powder metallurgical process is used to produce contact tubes for gas-shielded welding technology. The driving force behind this development is Horst Dieter Klees.

01 >> 2022 EJOT moment 12

ANNIVERSARY

customer goals will have to continue to be addressed and answered by German employees in a German holding company? Or could more diversity, more experience and novel ways of thinking hold the key to our continued success?

This thought experiment turned out to be the start of a fundamental organisational topic, a topic which we have called “EJOT 2025”. Consequently, a global matrix organisation with a strong regional substructure was created, which, going forward, will replace the previous EJOT structure in the following years. This includes the transformation of EJOT GmbH & Co. KG to EJOT SE & Co. KG –a legal form that strengthens the character of the family business of European origin: The preservation of the family business EJOT, which as a company independent of the capital market with a broad clientele retains its independence and can pursue its own strategies.

Another important aspect is increasing technological dynamics, such as digitalisation, emerging changes in the mobility industry, as well as requirements to make climate change policy work for us all. In order to remain at the forefront of these technological changes, the EJOT Group will focus more strongly on markets in North America and Asia and intensify cooperation with demanding and dynamic customers based there. This approach is necessary for EJOT to remain a technological leader in industry. Technology leadership and innovative strength are – and will remain – the key guarantors to our success.

We should not rest on our laurels and bask in the success of the last 100 years, but instead should boldly move forward with the courage to welcome change, look at the new world of today and see what tools we should take with us on our path into the future.

With the development of application technology for direct fastening of thermoplastics over 40 years ago, we as a company embarked on a path to become technological leaders in our field. We did so because we realised that there was not yet any purchasing demand for our first important product development, the

EJOT PT® screw, and we first had to convince the customer designers of the advantages of this product. So it was up to us to show our customers the savings they could realise and how much they could improve the quality of their own components by using this screw. According to Michael E. Porter's theory, which became famous at the time, this approach was called “quality leadership”. Shortly thereafter the EJOT slogan was born: “EJOT. The Quality Connection”.

Over the years, we learned that other companies from all over the world were more than happy to copy our products and patents. In Chinese culture, for example, if a manufacturer copies a product it is seen as recognition of the other manufacturer's achievement. Other companies were also not shy to reuse our slogan under their own company names. As a result, support steadily grew to update our company claim, and to make it as internationally applicable as possible. As we did not want a potential change to our existing claim to be taken lightly, the decision was made to do so as part of a greater brand update. The centenary year lent itself perfectly as an appropriate time for such a change. Decorated with fresh secondary colours to the classic “EJOT red on white”, these aspects now come together under slogan for the 100th anniversary, “Bringing it together”, expressing how EJOT brings together parts and components, people, customers and suppliers.

We believe we can look ahead to the future with optimism and confidence. Even if two long years of the COVID-19 pandemic, the resulting problems for our supply chains, and now Russia's invasion of Ukraine are all repeatedly denting our confidence.

With our product and service solutions, we are keeping speed with the major developments of our time: thermal insulation, energy efficiency, renewable energies, electromobility and digitalisationwe can provide support for all these topics. For this reason, in this centenary year we are building a TecCenter for our Construction Division in Bad Laasphe, Germany, a new large screw production site in Çerkezköy (Türkiye), a second site for our profile production for thermal insulation composite systems in Croatia and a new building for EJOT SORMAT in Finland. We are also unveiling new revolutionary technology developed to enable the coating of even the smallest of screws using a zinc flake process at the site in Tambach-Dietharz, Germany.

Because when our customers are counting on us for success, we want to be ready with the appropriate solution. EJOT. Bringing it together. E

1971

Foundation of the construction screw sales department headquartered in Laasphe. The construction screw product is new to the market and therefore requires explanation to customers. Salespersons who are trained in construction technology are employed as field representatives.

1973

Construction of the production hall in Berghausen with the start of the first plastics production. The injection molding machines of the time require individual operation and great skill on the part of the machine setters. The product range at that time consisted, among others, of small plastic containers, packaging for small beer kegs or boxes for long-playing records.

1976

Construction of the warehouse at the Laasphe site for shipping with an area of approx. 600 square meters. For the finished goods warehouse, five-story pallet racks are installed, operated by fork trays.

EJOT moment 01 >> 2022 13

www.spotify.com/de

The way to the top – industry leader as a matter of principle

It can be assumed that at the beginning of its economic activities, every company thinks about which individual path it would like to take in the market. That of extensive renunciation in order to always be among the cheapest providers. Or the path to always be among the best; with excellently trained employees, in-house development and ideas for innovative, high-quality products, outstanding services, the best production conditions and many other things.

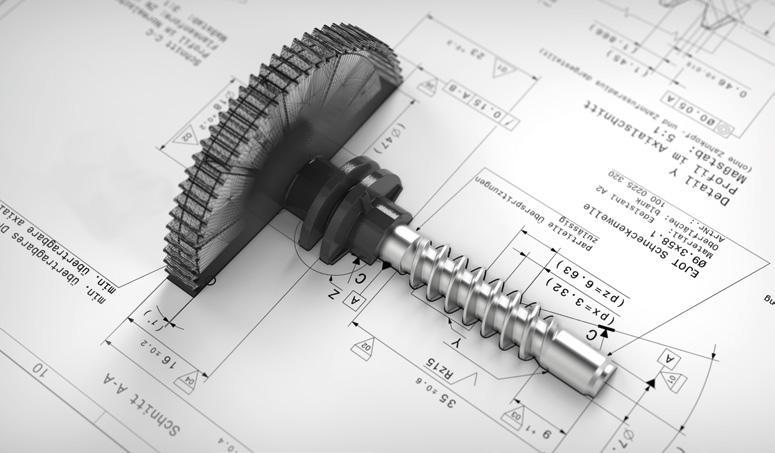

1977

Development of the EJOT PT ® screw for thermoplastics. A special threaded screw, tapping its own female thread. The patent application follows in 1978.

1978

At the end of the 1970s, EJOT receives a manufacturing license from Parker Kalon (USA) for the production of self-drilling sheet metal screws (DrillKwick). With this product EJOT gradually becomes the most important manufacturer of these screws in Germany.

1979

The strategy of diversification was continued with the inclusion of a plastic injection moulding company, where technical moulding, fastening elements in the combination plastic / metal, are produced. At the end of the 1970s this product range is expanded

01 >> 2022 EJOT moment 14

>>Text: Heinrich-Georg Homrighausen

MARKET UNIT INDUSTRY

The environment in which you find yourself undoubtedly plays a major role. In a country with high social standards and a remarkable tax burden, it is difficult to imagine being a price leader and being economically successful at the same time.

Of course, there are other directions to choose from at the “decision crossroads” described above. The middle ground, for example, where you can choose a little bit of everything. Perhaps one saves on the training of the team, or even on the quality of the materials and is then satisfied with an average end result. But the path of this “happy medium” is paved with well-known examples of failure, because of some properties, quality is mentioned here as the most concise, only the maximum is of interest to the customer.

Hans Werner Kocherscheidt stood at this crossroads after taking over the entrepreneurial responsibility from his uncle Adolf Böhl and decided to follow the “path of the best”. He found other allies willing to make the products, sales activities and manufacturing the best in the market. The consistent expansion of production at the highest level, the large number of own patents and innovative market ideas over the past decades illustrate this claim.

The strategy of this performance management can be described particularly impressively using the example of plastic direct fastening. Plastics were used in more and more products because, in many respects, they were superior to the traditional materials. Those responsible at EJOT not only noticed the market development, but also the fact that users were often content with compromises when it came to fastening solutions. It was not uncommon for the screw connections to come loose as a result of thermal and mechanical loads, or the so-called plastic tubes failed as soon as they were fastened.

It took many thousands of manufacturing and screwing tests to determine the best possible thread form with the relevant fastening parameters for the different plastic materials. However, the result of this time-consuming and costly development process has given EJOT a strong impetus for today’s market position. In all modesty, it may also be mentioned here that the essential details of the original PT® screw served as a template for many competitive solutions and is still a very common and successful thread form on the market today.

It was also successful because the marketing strategy was further developed alongside the product launch. In addition to the well-known commissioned sales representations, more and more

EJOT engineers now visited the customers, often with degrees from renowned universities with a focus on plastics technology. It was their strategic task to competently advise the customer's developers and designers in the early phases of product development. Many years later, Hans Werner Kocherscheidt looked back with amusement on his decision for the engineers in the screw sales department, because some of his competitors initially ridiculed the idea and then envied him later.

In principle, the way to the top never ends, because the challenges on the market are always new. The latest generation of the plastic direct fasteners, the EVO PT®, is currently showing how, for example, digital tools can be used to map the behaviour and effect of the fastening elements on the customer's components under different load cases and derive corresponding recommendations for dimensioning from this.

A few years ago, the entrepreneur and consultant Dr. Christoph Weiß titled his guide book for entrepreneurs “Doomed to Excellence” (published by Unternehmer Medien, Bonn). Presumably, he wanted to express that once you’ve decided to lead in performance, there’s no turning back. It is put quite provocatively, but still describes the situation at EJOT realistically. The decision for the best products and the best service has been made and customers can rest assured that it will remain so in the future. E

1980

In this sector,

The year was marked by a number of conversions, including the rebuilding of the head office in Berghausen and the construction of a new hardening plant at Bienhecke in Laasphe. The photo shows the shipping department in Laasphe.

EJOT moment 01 >> 2022 15

by elements for the fastening of insulating elements to thermal insulation in house construction.

EJOT develops into the market leader in Germany

Market Unit Industry –much more than just screws

Closeness to customers and their needs is a key success factor for the Market Unit Industry. This close coordination is one of the foundations for the development of an ideal fastening technology solution.

1982

EJOT acquires the company Timper with a turning shop in Laasphe – with the aim of improving the machining operations and the associated knowhow. Powder metallurgy is outsourced there.

1983

“EJOT” is introduced as the new company name and a new logo is presented

1984

Separation of the construction screw department and foundation of EJOT Baubefestigungen GmbH. The origin of the distribution of construction screws is at “Untere Bienhecke” in Bad Laasphe. Sales team, finished goods warehouse and part of the production leaves the parent company facilities and moves to the plant acquired in 1983 at Stockwiese in Bad Laasphe.

01 >> 2022 EJOT moment 16

MARKET UNIT INDUSTRY

>>Text: Andreas Blecher

Essential for this is a broad product portfolio from which the customer can draw in order to be able to implement his specific requirements in the best possible way.

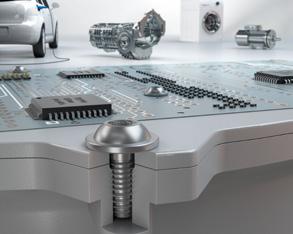

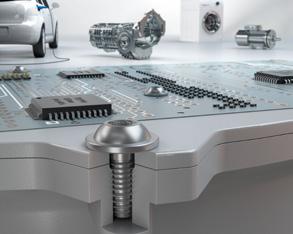

Direct fastening in plastic

Hardly any industrially manufactured component can do without plastics. Since the 1980s thermoplastic materials have experienced an unprecedented boom, in which EJOT participated from the beginning with the PT® screw (Plastic Thread). Previously, there had been no reliable fastening solution for plastics on the market. And the PT® family was continuously improved. In addition to enhanced fastening properties, the DELTA PT® was the

first self-tapping screw to enable predetermination of the screw joint using the DELTA CALC® prognosis program. The latest evolutionary stage in plastic direct fastening is the EVO PT® screw, which offers high standardization potential in production due to its special thread forming zone and also provides the user with FEM-supported component optimization. Special fasteners for foamed thermoplastics and thermoset materials complete the EJOT application range in the field of plastic direct fastening.

Direct fastening in metal

EJOT offers a wide portfolio of different fastening solutions for metal materials. What they all have in common is their self-tapping

1985

The first high rack warehouse is built at the Stockwiese site in Bad Laasphe. Due to the somewhat unusual façade design, the new building has also long been referred to as the "chipmunk".

1985

Foundation of the subsidiary Ecofast, Glasgow, today EJOT U.K. L.t.d., Leeds Sherburn-on-Elmet, GB

EJOT moment 01 >> 2022 17

1985

Acquisition of EJOT Festesystem

A/S, Oslo, Norway. Initially, only self-drilling and sealing screws are offered. In the following year, a 36-page catalog with an expanded range of construction products is already published

1986

Relocation of the Construction Fasteners branch office in Unna, founded in 1978, to the new building. Thanks to an advantageous location close to several highways, customers can be served faster.

capability, which offers economic advantages in industrial assembly because, compared with metric screws, there is no need for time-consuming part preparation and the number of work steps can be reduced. For example the ALtracs® Plus screw, which is specially designed for light alloys and other non-ferrous metals, can be fastened directly into the cast hole of transmission housings or steering columns. For applications with the ALtracs® Plus screw, the ALtra CALC® prognosis program provides further valuable support, and FEM-supported component design is also possible. The self-tapping SHEETtracs® screw is most suitable for the process-reliable assembly of pre-punched thin sheet joints. A typical application for the SHEETtracs® screw is fastening of housing walls of washing machines or dryers. And for direct fastening into thicker steel materials, the Spiralform® screw guarantees a secure and long-lasting connection.

Fastening technology for composite and lightweight design

Lightweight and composite design is continuously being integrated into almost all components of future vehicles. Auto body construction in particular is characterized by a wide range of materials used. If, in addition to one-sided accessibility during assembly, the removability of the fastener is also important, the flow drilling FDS® screw is the fastener of choice. The screw fastens steel sheets and aluminium without the need of a pilot hole and with exceptional quality. The FDS® screw is constantly being further developed; for example, a version with a special sealing function is used for fastening battery systems of electric vehicles. Another option for joining different materials and semi-finished goods is the so-called EJOWELD® “friction welding”. This innovative development now provides the option to join composite designs, in particular lightweight materials and ultra high-strength steels, with a friction element installation tool suitable for robots. With EJOWELD® the joining process is fast, automated, high strength and reproducible.

Fasteners for foam and sandwich structures

EPP (expanded polypropylene) foams are often used in applications that need to be as light as possible or that have to absorb large amounts of energy in a very short time in an emergency, such as crash pads in car door modules. EJOT® EPPsys is a product group specially designed for connections in this material.

1986

EJOT participates for the first time in the construction trade show "Roof and Wall". This leading trade fair for the roofing trade is held every two years.

01 >> 2022 EJOT moment 18

MARKET UNIT INDUSTRY

1987

Foundation of EJOT France S.A.R.L., Villé, France (5 employees). Two main reasons were in favor of the location in Alsace: First, the location halfway between the industrial centers of Lyon and Paris, and second, the bilingualism as an advantage in communication.

These plastic fasteners can be screwed directly into the foam. Going one step further, the EPPsys RSD friction weld dome is inserted directly into the EPP foam using the friction welding process, bonding with the molten material. A similar process is also used by the TSSD® thermal adhesive bonding boss, which penetrates the component by means of rotation and the associated heat input and creates a positive-locking connection. In addition to rear window shelfs and loading floors from the automotive sector, the application portfolio also includes the sandwich and honeycomb structures frequently used in aviation, in which the TSSD® can be used to set fixing points in the aircraft galley, lavatory or baggage racks.

1987

Acquisition of the TORX® license

1987

The operational suggestion and recommendation scheme is introduced. An important innovation, which over the decades has led to permanent improvements in everyday production. Employees whose suggestions are acknowledged receive a “reward.”

EJOT moment 01 >> 2022 19

Fastening solutions for the micro range

The trend toward miniaturisation of components continues across all industries. “Smaller, lighter, more efficient” is also the demand on the fastening technology. With the self-tapping EJOT micro screws significant weight and costs savings can be realised even in the smallest installation space. They have all the advantages of the larger dimensions and, due to their tight fitting thread, achieve high mechanical strength even in difficult installation situations. Due to their self-tapping geometry inserts are unnecessary. In the final assembly of components the EJOT micro screws can be used flexibly. This ranges from manual assembly to automated serial assembly, which is already standard in the numerous industrial micro applications. The field of applications for micro screws is wide. It ranges from small housings that need to be fastened, for example sensors in radar systems or rearview cameras in modern cars, to circuit board screw connections in the sound processor of a cochlear implant.

Individual precision cold-formed parts

The variety of possible applications for cold-formed parts made of steel, aluminium or copper is virtually unlimited. The EJOFORM® cold formed parts are always tailored to the customer's specific

application. They fulfill a wide variety of functions, for example as a bracket, stop bolt, spacer and contact sleeve, adjusting element or safety-relevant component in braking systems. The individual products are manufactured in a multi-stage cold-forming process. With this technology, a wire section is formed into a complex cold forming part over several forming steps. Individual finishing steps and refinements are then possible, for example machining or coating. In many customer applications, this means that instead of several parts having to be assembled to form a complete functional part, only one EJOFORM® part is used. Particularly in comparison to turned parts with a great deal of material input, the customer also benefits from the economic advantages of this manufacturing process, which become greater the higher the production quantity and thus the material savings.

Hybrid parts and components

EJOSYST® is the term for individually developed functional components made by EJOT. In customer applications, these parts can take on a wide range of functions, such as compensating for manufacturing tolerances or thermally induced length changes, fastening, positioning, sealing or even transferring motion and torques. Various sized headlamp adjustment systems are also part of the EJOSYST® portfolio. Both manual and motorised adjustments are possible. The range of applications includes a wide variety of lighting systems such as halogen, LED or laser applications in cars and trucks. EJOSYST® products are based on plastic injection molding and cold forming technologies. Focus of the development is always the individual solution for customer-specific requirements. The assemblies are found, for example, in electronic parking brakes, car seat adjusters or in the onboard electronics of electric vehicles.

Functional plastic parts

In the field of functional plastic parts, EJOT develops and produces high-precision metal-plastic composite parts using insert

1988

1987

The first international PT ® license meeting is held in Cologne. These meetings serve as a mutual exchange of information on both market developments and technical innovations.

1988

Foundation of the Joint Venture Hi-Tec Fasteners, Haslev, Denmark. Hi-Tec Fasteners is founded as a joint venture between EJOT Verbindungstechnik and Vereinigte Schraubenwerke. Initially, the focus is on the sale of industrial products, followed a few years later by the sale of construction products.

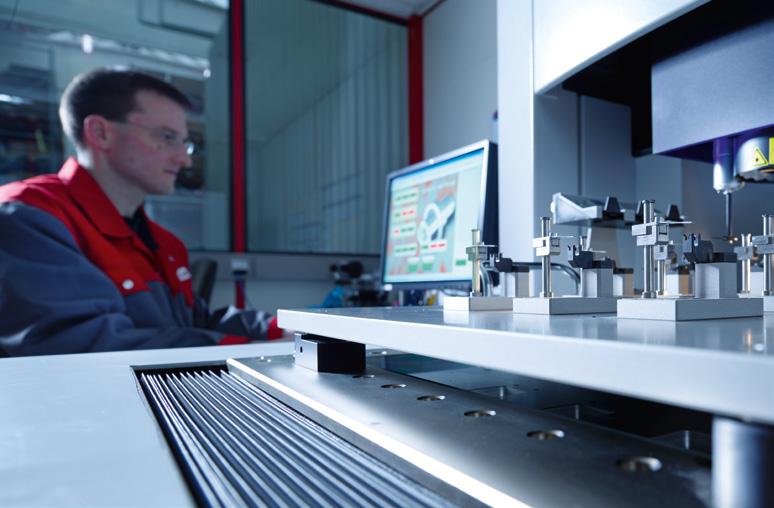

The first fastening laboratory, APPLITEC, is built at Bienhecke in Bad Laasphe. The beginnings date back to 1980, when Stephan Weitzel developed a test stand for component testing.

01 >> 2022 EJOT moment 20

MARKET UNIT INDUSTRY

technology. After a detailed observation and analysis of the customer's requirements, a product that can be implemented in terms of production technology is developed in close project coordination. This product is then transferred into a defined process flow and can be produced at the various EJOT locations worldwide. High-performance thermoplastic materials are used, which are manufactured in a single-stage production process without pre-molding. Housings for sensors and driver assistance systems as well as covers and housings with direct insert moulded metal contacts are the main focus of the product portfolio. The components meet the highest demands in terms of dimensional accuracy, dimensional stability, load-bearing capacity, tightness and appearance – even in constantly changing, demanding areas of application. E

1989

Foundation of the joint venture EJOT & Avdel System AB –together with the renowned blind rivet manufacturer Avdel. The official inauguration takes place in 1990.

1990

The first issue of the company magazine “WirVerbinder” is produced. To this day, the "Verbinder," as it is commonly known, is printed four times a year. Acceptance of the magazine among the employees is high. The picture shows the title page of the first edition.

EJOT moment 01 >> 2022 21

Highest quality –sustainable

In the Construction market unit, global quality leadership in the Building Fasteners and ETICS Fasteners customer segments

Of course, this also applies to the “Distribution” customer segment that was newly created at the beginning of 2022.

“Highest quality – but also sustainable,” one would add today, even if the topic of sustainability is not a trend that came about only recently. Quality and sustainability are by no means contradictory. They are the basis for many innovative products and further developments. With numerous business areas, the Construction market unit is much broader than its well-known competitors. “Everything from a single source” is the customer-friendly idea behind it, which includes not only high-quality application solutions, but also comprehensive services.

In the Building Fasteners area, the original concentration on fastening solutions for the building envelope of industrial buildings (industrial lightweight construction (ILB), flat roof (FLD) and rainscreens (VHF)) was initially supplemented by applications for solar, window and glass facade technology (FGF). Timber as a material has been noticeably gaining in importance for industrial buildings for years, so that EJOT Construction is also taking up this challenge. Especially since the other young business field of anchoring technology is full of synergy effects for timber construction and rainscreens.

The inclusion of synergy effects and the system concept with a view to the big picture are particularly important in the Construction market unit. In the future, we want to not only supply high-quality connecting and fastening elements, but also offer our customers comprehensive and holistic systems.

This system concept also requires a fundamental rethinking in sales, because in the system concept this takes place exclusively as a project business. The focus here is on planners and architects in particular – an important task especially for sales engineers.

“Everything from a single supplier” also means that the business activities of the Construction market unit is by no means limited to products. Service related to the application of the products plays a central role, from the pre-dimensioning to the pull-out test on the construction site to the rental or sale of self-developed setting or assembly devices and the offer of software tools such as ANCHOR FIX (a new and convenient dimensioning software for anchoring products) or the ETICS product configurator.

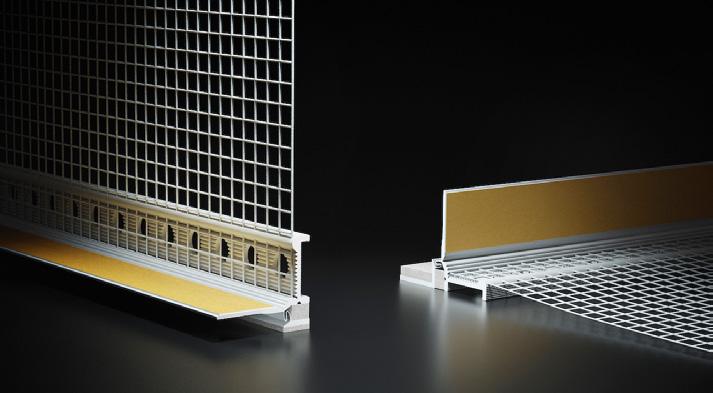

By definition, an external thermal insulation composite system (ETICS) is related to ecology and sustainability. The high-quality products of the customer segment ETICS are sold exclusively through system providers. This ensures that all components in the system work together. In Europe, EJOT is the industry leader in the field of ETICS anchors with many unique selling points. The ISO family for fastening attachments provides additional products that help to improve the overall performance of an external thermal insulation composite system. The ISO-Bar ECO for greening ETICS facades takes the ecological idea into account in a special way. Profiles for all applications complete the ETICS range.

1990

In January 1990, the construction of the 2800 square meter hall at Bienhecke in Bad Laasphe is completed. The setup of the storage space and the EJOMAT department follows. In addition to the shipping, packaging and final inspection departments, space is also created for a new electroplating shop.

1990

The circle of licensees is expanded: in February 1990, the company Camcar receives the PT® license. Camcar is a company of the American Textron Group, Illinois/USA.

01 >> 2022 EJOT moment 22

MARKET UNIT CONSTRUCTION

>>Text: Jutta Rathmann

was and is the driver behind all developments.

How sustainable are EJOT's ETICS and Building Fasteners products really? In the Construction market unit, improvements are constantly being made, like the use of recycled or bio-based plastic. With EPDs (Environmental Product Declarations) which were obtained on a voluntary basis, Construction already enables its customers to objectively evaluate the product-specific carbon footprint.

Being an industry leader, remaining innovative and actively shaping the future – this includes getting involved in committees, boards and trade associations in the construction industry. This is how trends are set and product developments are designed at an early stage – corresponding to the market development of designs and systems. E

1990

Introduction of the TQM organization with various quality circles The aim of this new quality approach is for all employees to discuss and implement improvements in their respective areas of work in various

quality circles. The abbreviation TQM stands for "Total Quality Management" - the model originates from the Japanese automotive industry.

1990

The first construction fasteners catalog is published after five months of intensive work on concept, text and graphics. A new edition is planned every year.

EJOT moment 01 >> 2022 23

EJOT Iso-Bar ECO application

Professional applications for the building envelope

The EJOT Market Unit Construction caters to selected segments of the building industry with professional applications on facades and for the interior construction of buildings. EJOT offers a wide product range, special fastening know-how and customer-specific service in the different core segments.

Industrial Lightweight Construction

This core segment focuses on innovative fastening elements for attaching trapezoidal profiles and sandwich panels to structures made of steel and wood. The classic product in this area is the self-drilling screw JT3-2H-Plus-5.5. For years, it has been an integral part of the EJOT core business.

The optimised and unique tip geometry of the new EJOFAST® Plus self-drilling screws enables safer application to the surface thanks to the even more finely shaped tip. Displacement or slipping is almost impossible. At the same time, the load-bearing capacity values were improved once again. The slim, single-start threaded drill point produces no sharp-edged swarf that gets stuck in the material and require time-consuming removal.

With the new self-tapping screw JZ5-6.3, EJOT offers a twosteel self-tapping screw with a hardened thread-forming zone, which is characterised by a particularly high level of process reliability when thread-forming. It is the strongest EJOT screw on the market so far. Self-tapping screws, also known as thread-forming screws, do not have a drill point. In a preceding work step, a through hole is created. However, the thread is formed automatically when the screw is then tapped in, eliminating the need for work steps and other tools such as tap drills or additional fastening elements such as washers and nuts. Self-tapping screws are mainly used for particularly thick or high-strength steels, where self-drilling screws reach their process limits.

Timber construction

The goal of the Market Unit Construction is to be able to offer solutions for all building areas in which fastening elements are required. It is therefore a logical consequence to include products for timber construction in the portfolio.

Whether for fastening above-rafter insulation, in stair construction or interior construction – T-FAST® wood screws are ideal for the fastening of wooden components in structural and non-structural timber construction.

With the T-FAST® series, EJOT offers a range of zinc-plated wood screws that are regulated by ETA-18/0812 and correspondingly CE-marked. The wood screws with partial thread enable strong contraction and firm connection of the wooden components with rapid work progress. They can be installed in areas that are not weather exposed or in usage classes 1 and 2 according to EC5.

1990

The new electroplating shop, including the wastewater treatment plant, is opened at Bienhecke in Bad Laasphe with an open house day. The plant is the latest state of the art.

1991

In order to cover the expected demand for fasteners in the new German states, the Dresden branch is founded.

01 >> 2022 EJOT moment 24

MARKET UNIT CONSTRUCTION

>>Text: Katrin Strübe

EJOFAST® self-tapping screw JZ5-6.3

EJOT® self-drilling screw JT3-2H-Plus-5.5

Rear Ventilated Facades

The rear-ventilated facade offers great design freedom and versatility. EJOT is a system provider and reliable partner in this area. The various system components, services and comprehensive advice lead to a homogeneous but individual solution.

Our award-winning CROSSFIX® substructure system is a revolution in rear-ventilated curtain wall construction. It is the first stainless steel substructure that can be equally used for horizontal and vertical support profiles. The use of 100 percent stainless steel significantly reduces the thermal bridge allowance in the system. CROSSFIX® increases the flexibility, facilitates assembly and simultaneously reduces storage costs. The system has an ETA rating, which reduces the amount of planning, creates cost certainty and saves time and money.

1991

Construction work at “In der Aue” location: On the former site of the DAXOROL company, the new site in Bad Lassphe is built on an area of 18,000 m2. There is already a 4,000 m2 hall built by the previous owner in 1967.

1991

A new rotary retort furnace with integrated washing system and tempering oven is installed in the hardening shop at Bienhecke in Bad Laasphe. The entire furnace is equipped with an automatic temperature system, and the master computer can control the temperature in five separate heating zones.

EJOT moment 01 >> 2022 25

T-FAST® wood screw JW2-STS-8.0xL

Horizontal assembly of the CROSSFIX® system

Mounted CROSSFIX® system with self-drilling screws

The JT4-LT-XT-3H self-drilling screw is ideal for fastening flat aluminium composite panels to aluminium substructures. A VARIO self-drilling screw is used for pre-punched stainless steel or aluminium wall brackets on aluminium support profiles or to form sliding and fixed points on substructures. Another indispensable classic in the EJOT rear-ventilated facade portfolio is the insulation support anchor DH for fastening insulating materials to all substrates.

Flat roof

In flat roofing the focus is on fasteners and installation tools for the efficient attachment of insulation and waterproofing membranes to flat roofs and slightly sloping roofs. Depending on the substrate there are different fastening materials available,

The core product in the flat roofing area is the HTK-2G tube washer in connection with our roofing screw (Dabo®) TKR/TKE for securing roofing membranes on substructures made of steel trapezoidal profile, wood and wood-based materials. Both products are available in numerous lengths for a wide range of requirements.

The JBS-R/EcoTek combination of a tube washer and a concrete screw is ideally suited for installing gradient insulation on concrete.

In addition to product development and the optimisation of materials and manufacturing processes in the flat roof area, cooperation with manufacturers of roofing membranes and system tests are particularly important.

Industrial window and facade technology

The window and glass facade technology area deals with high-quality fastening elements for window and door production and their assembly. The portfolio also includes fasteners for use in aluminium/glass facade systems. Also in this business field the product development focuses on more and more complex window constructions. The most essential difference of this field in comparison to the above mentioned fields is the industrial application of the products, for example by automated fastening. The EJOT frame anchor is our fastening solution for window and door assembly. Our frame anchors have proof of burglary-resistant installation according to RC 2 and have also been tested as

1991

Due to the increased number of employees and the ever more complex labor, collective bargaining, tax and social security regulations, automatic time recording is introduced. The traditional time card is replaced by a “plastic ID card”.

1991

The computer-aided quality assurance system “CAQ” will be used in the new factory building at the “In der Aue” site and will automate the previously manual statistical process control (SPC).

1991

Outsourcing of powder metallurgy to Schunk EJOT Metallurgie, Heuchelheim. After 20 years, this business unit is outsourced again, as this technology has nothing in common with the main activities of the Industrial Fasteners Division.

01 >> 2022 EJOT moment 26

MARKET UNIT CONSTRUCTION

EJOT Dabo ® screw TKR-4.8 with HTK2G disc washer

EJOT concrete screw JBS-R with EcoTek stress plate

Direct fastening of windows with the EJOT® frame anchor

fastening elements according to the ETB guideline “Components that protect against falls from heights”.

Fastening systems for solar installations

EJOT offers a large number of high-quality fastening solutions for the correct and secure fastening of solar installations. The product portfolio includes approved fasteners for the assembly of photovoltaic installations on the roof as well as for the assembly of the installations on open spaces.

In the solar business the EJOT Solar Fastenings are the core product. Depending on the requirements for special applications, further fasteners have been developed in the solar business, which usefully supplement the existing EJOT standard range. The EJOFAST® screw JF3-2-5.5x25 is often used in the solar sector for reduced swarf fastening. Due to the reduced formation of drilling chips, the risk of corrosion is minimised and cleaning work is no longer necessary. The material displacement during the assembly process also ensures increased load-carrying capacity. The screw can be used in many ways, e.g. for the

direct attachment of support profiles or for connecting individual assembly components.

Metal and chemical anchors

The fields of application for metal and chemical anchoring technology are versatile, and the respective requirements for the fastening solutions are just as different. Whether for fastening balcony or stair railings or for installing large machines – EJOT products ensure safety and always have high load-bearing capacity values.

The broad product portfolio includes solutions for mechanical installation in non-cracked and cracked concrete as well as chemical and thus expansion pressure-free products for heavy-duty

1992

EJOT moment 01 >> 2022 27

EJOT® Solar Fastener

Through bolt BA-E Plus Concrete screw JC2-KB Plus

Move into the second production site in Bad Laasphe (“In der Aue” plant) and start of production in the converted plant.

1992

Expansion at EJOT Construction Fasteners. As a result of the removal of the powder metallurgy department, the Stockwiese site in Bad Laasphe can be expanded. The areas of shipping and packaging are moved.

fastening in concrete and masonry – so that your projects will be a success.

External Thermal Insulation Composite Systems (ETICS)

EJOT offers comprehensive system accessories for External Thermal Insulation Composite Systems in the areas of anchors, mounting elements and profiles. Together with the cross-segment 360° service, this results in a complete offer tailored to the needs of our partners. Only available from EJOT.

Anchors

The range includes special anchors for fixing insulation in external wall insulation systems.

The ejotherm® STR U screw anchor has been the absolute master product in this business area for many years, thanks to its countersunk installation to avoid anchor marks on the facade and its universal field of application. But existing products are also continuously developed at EJOT. The STR U 2G has recently been supplemented with the possibility of use in insulated ceiling soffits. With the all-rounder ejotherm® STR U 2G, EJOT is the only anchor manufacturer to offer approval-compliant solutions for all areas of application in ETICS. In addition, the product segment was expanded to include another specialist: the ejotherm® S1 short was specially developed for the use of particularly thin insulation boards. It impresses with a short under-head area and a short installation depth. The innovative ejotherm S1 tool enables an optimal setting position and a high level of assembly comfort

Mounting elements

EJOT offers a wide portfolio of mounting elements for securely fastening attachments to external thermal insulation composite systems.

With the Iso Team, EJOT has compiled a product group for the planned and subsequent fastening of attachments to ETICS facades which offers a solution to all fastening problems. For all products in the business area, the focus is on thermal bridge-optimised embedment and reliable sealing to protect against the ingress of moisture. The EJOT Iso-Corner mounting bracket for the planned fastening of, for example, French balconies to floor-to-ceiling windows reduces thermal bridges through thermal decoupling and therefore offers real added value compared to conventional steel solutions. In addition, the product was the first mounting element

1992

New construction of the Engineered Plastic Components plant in Berghausen: The expansion, which is divided into four sections, is completed in 1992. A fire-protected tool store, an anchor testing room on the first floor and offices on the upper floor are built.

1992

Open house day at the In der Aue site in Bad Laasphe with the official inauguration of the new location with all employees and numerous guests. Particularly noteworthy are the large paintings made by architecture students of TH Darmstadt university that are hung in the plant.

01 >> 2022 EJOT moment 28

MARKET UNIT CONSTRUCTION ejotherm ® S1 ejotherm ® STR U EJOT Iso-Corner Iso-Bar ECO

for attachments on the German market to receive zero carbon house certification. The EJOT Iso-Bar is the right choice for subsequent and therefore particularly flexible fastening of marquees, for example. Its material enables a low thermal bridge effect with a high bearing load at the same time. Thanks to the supplied seal, it permanently seals the facade against the ingress of moisture. The product range is completed with the EJOT Iso-Bar ECO, a thermally separated fastening element for subsequent and therefore flexible fastening on thermally insulated facades. This product, which won the DETAIL Product Award, is based on the EJOT IsoBar and enables the flexible and user-friendly installation of cable systems for facade greening in connection with all the known advantages.

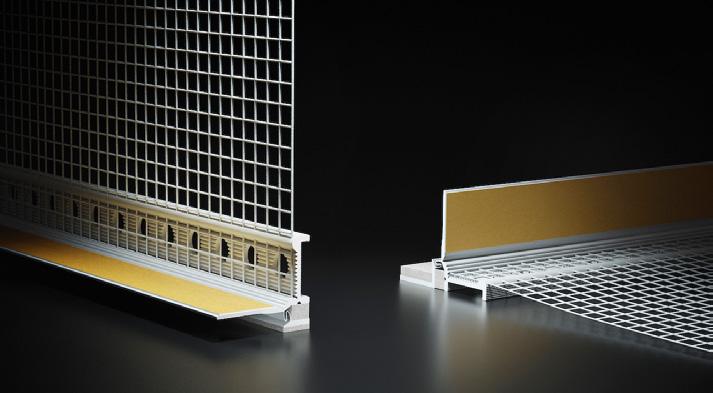

Profiles

With the EJOT ® Pro-Line profiles, EJOT offers profiles for high-quality plaster connections. EJOT Pro-Line profiles are ideal for precise edge formation, for permanently driving rainproof, flexible component connections in ETIC systems and

much more. Reveal beads with mesh represent the transition between the facade surface and building openings such as windows and doors. Different movements of the plaster shell and the window occur at these transitions, for example due to temperature-related effects. These movements have to be taken up by the reveal beads with mesh in order to enable a permanent, driving rain-tight connection of the components. The membrane technology of the EJOT Pro-Line Giga Flex profiles enables an even better three-dimensional movement for the highest requirements, e.g. for windows built into the insulating material or with large windows. The new Giga Flex slim reveal bead with mesh impresses with its narrow construction width of 7 mm and the resulting wide range of applications with simultaneous high movement absorption. The same applies to the roller shutter connection profile RAP Giga Flex slim. It ensures a uniform plaster application even with thin and medium-layer systems. Another plus point: flush mounting on the roller shutter guide rail is now even easier thanks to the stop leg. E

1993

Change of the company names to EJOT Engineered Plastic Components (EJOT Kunststofftechnik GmbH & Co. KG) and EJOT Industrial Fasteners (EJOT Verbindungstechnik GmbH & Co. KG).

1993

EJOT acquires part of the Tambach GmbH screw factory in Thuringia. The contract with the Treuhandanstalt is signed shortly before the turn of the year. This marks the beginning of an exciting new era for EJOT. With the expansion, EJOT becomes the European market leader for thread forming screws overnight.

EJOT moment 01 >> 2022 29

Reveal bead with mesh Giga Flex slim (left) and roller shutter connection profile Giga Flex slim (right)

From nail to functional part