15 minute read

WorkSafe Victoria offers a free silicosis health assessment program. And the latest products from Cleanspace, Farnese and Safety Equipment Australia

SILICOSIS SAFETY AND PROTECTION

WorkSafe Victoria provides tools to help create a safe and healthy workplace. As a statutory authority of the Victorian state government, it asks: Are you a worker or an employer in the stonemason industry?

In the last year, Victoria has seen a significant increase in workers diagnosed with silicosis and about 80% of these have worked in the stonemason industry.

When workers do things like cut, grind, drill or polish products that contain crystalline silica, it releases very fine dust. Some of the dust is so small they may not be able to see it.

When breathed in, this dust can cause silicosis and other related diseases. These diseases don’t discriminate. They can affect young workers just starting out in their trade, tradespeople in the prime of their working lives as well as older workers looking forward to retirement.

Those in the stonemasonry, construction and the extractive industries may all be exposed to crystalline silica dust. Benchtop fabrication workers are at higher risk because they regularly work with engineered stone; a product that can contain up to 95% crystalline silica.

In response to the alarming silicosis rates, Worksafe has developed a free silicosis health assessment program for all past and present workers in the Victorian stonemason industry.

It is really important stonemasons and other industry professionals have a respiratory health assessment if they have worked with or still work with crystalline silica. It’s easy to register by calling WorkSafe Advisory on 1800 136 089 (option 1, option 3) or email healthscreening@worksafe.vic. gov.au and leave your name and contact number.

The health assessment program has helped Worksafe identify workers who have silicosis or associated diseases, such as lung cancer and autoimmune disorders. Early detection of these diseases can lead to far better health outcomes.

Since the program began in May last year, close to 700 stonemasons have registered for a free health assessment. Sadly, there has already been over 60 positive diagnosis (all data is accurate as of March 2020). A number of stonemasons are still progressing through the health

30

Cutting, grinding or polishing?

Silica dust can be toxic from the first cut.

Don’t risk it.

SILICOSIS SAFETY AND PROTECTION

assessment program because completion can take up to three months.

No Victorian worker should feel unsafe at work. Worksafe is taking the necessary steps to ensure workers in the industry are provided with safe and healthy workplaces. Its silica action plan includes an increased focus on compliance, enforcement, awareness and education. Some core outputs of the plan ensure Worksafe can help businesses prevent this disease in the workplace and support stonemasons through the health assessment program.

There is still a lot that is unknown about silicosis and its associated diseases. However, Worksafe is committed to ongoing research so it can provide the stonemason industry with the best support and knowledge. As part of its continuous support for this industry, WorkSafe has introduced a fast-tracked claims process, support for workers throughout the assessment program and those with accepted claims — including psychological support for them and their families — and re-training for those who, for their own health, need to down tools for good and seek new employment.

There are controls available to reduce exposure to crystalline silica dust. Ensure you and your co-workers:

use tools with water suppression on tool extraction wear fit-for-purpose respirators carry out air monitoring regular health checks

Cutting, grinding or polishing?

Everyone | Every workplace

REGULATION CHANGES The Victorian Government amended the Occupational Health and Safety Regulations 2017 to give workers in the stonemasonry industry have greater protection. Uncontrolled cutting, grinding and abrasive polishing of engineered stone with power tools is prohibited. The amendments came into effect on 20 August 2019.

Industry professionals must ensure they understand the changes. Visit worksafe.vic.gov. au/crystalline-silica for further information.

NEW COMPLIANCE CODE Victoria’s first silica compliance code “Managing exposure to crystalline silica – engineered stone” is now available. This code provides critical guidance for employers working with engineered stone. It includes information to assist with compliance with the ban on uncontrolled dry cutting and how to monitor workers’ health. This code applies to all workplaces where engineered stone is being handled.

If you are an employer, contractor, supplier or manufacturer please read this code and implement the required changes to your workplace.

Contact Worksafe about a free health assessment. Please call WorkSafe Advisory on 1800 136 089 (option 1, option 3) or email: healthscreening@worksafe. vic.gov.au to find out more and register for the health assessment program.

For further information, please visit Worksafe’s dedicated crystalline silica webpage for more information and guidance: www. worksafe.vic.gov.au/crystalline-sili ca. n

Silica dust can be toxic from the first cut.

Protect the lives of your employees and yourself.

Use tools with water suppression Wear a fit for purpose respirator Use on tool extraction

Learn more at worksafe.vic.gov.au

SUPPORTING INDUSTRY SAFETY

Since its establishment almost 20 years ago, Farnese Australia said it has always met the demands the stone fabrication industry has had to face to improve the way professional end-users process stone.

As the industry faces its biggest challenge, silicosis, this is turn affects how it continues to ensure stone fabricators are protected and work more safely than ever before. Everyone’s health remains a priority and this is balanced with the need to grow and maintain a viable business, the company said.

Compliance with new regulations is mandatory and won’t be easy but necessary going forward. With the issues of dry cutting and grinding at the centre of most work practices, most stone work will now need to be performed by wet processing to reduce the considerable amount of risk to the fabricator.

Fortunately, Farnese Australia said it has a forward thinking approach in terms of its range of affordable stone processing machinery. It places an emphasis on easy to use machines that eliminate the need to work dry and assist in improving production whilst working more safely. Most of its machinery keeps the operator at a distance and reduces any further risk, according to the company.

As most dry cutting and grinding predominantly operates around cutting drop in or undermount sink work, Farnese has a range of CNC machines that can address these operations and increase production.

Preventing silicosis also means water recycling has become a necessity to ensure all the stone slurry that drops onto the factory floor is removed while wet, and processed immediately. This means the final waste is collected into mud bags and disposed of while it remains wet, cutting down on factory water consumption at the same time.

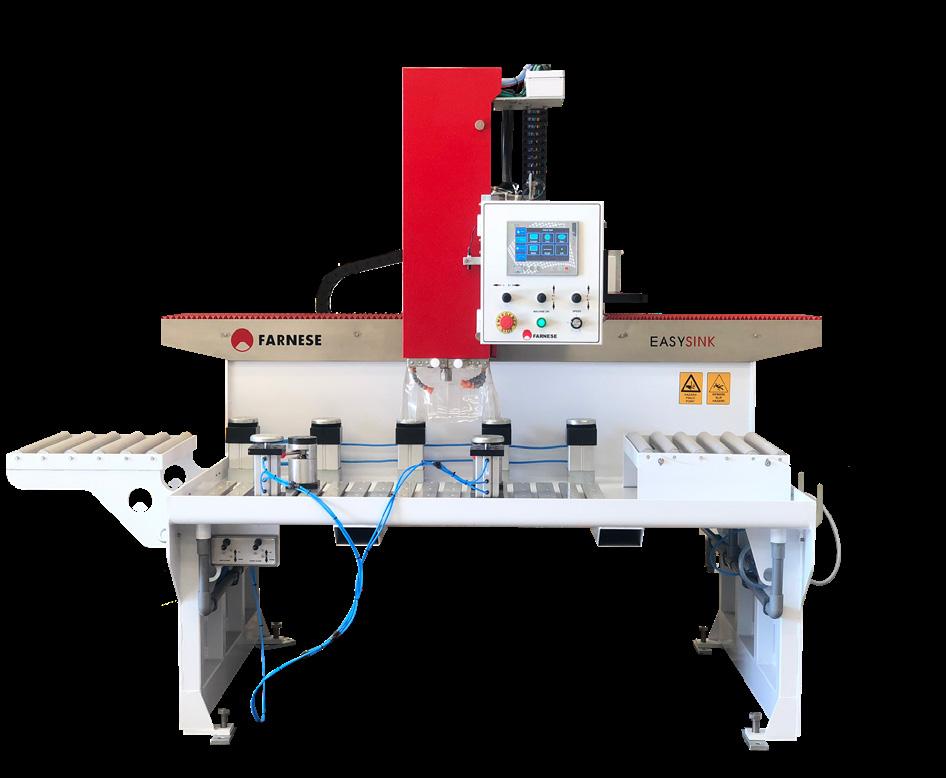

EASYSINK This compact CNC machine is designed to simplify the task of doing sink cutouts at an affordable price.

The EASYSINK comes with a user-friendly touch screen interface to machine sink cutouts parametrically. It allows users to machine non-complicated shapes such as squares, circles and oval shapes, changing dimensions and the radius for corners with common sink templates. For other non standard shapes, these can be supplied on demand.

Sink cutouts can be processed within the front and rear pneumatic clamps up to 1200 by 600mm on slabs over three metres long by 700mm. A laser indicator can help locate and position the centre of the cutout and the machine is

32 | DISCOVERING STONE #35 | www.discoveringstonemagazine.com.au also equipped with a manual tool changer, lubrication pump and takes up a small footprint, saving valuable factory space.

ALEXIA GEN2 The Alexia automates the cutting, drilling and polishing of sink cutouts. This machine has automatic tool changing with 23 stations.

The main feature of the Alexia is its user-friendly interface, the software has been designed for MS Windows and is intuitive and simple to use. It is pre-loaded with common sink templates listed by brands including Oliveri, Franke, Clark and Blanco. Additional sinks sizes and shapes can be easily created using the parametric section that extends the machine’s cutting capabilities.

The Alexia has the ability to connect directly to the internet which allows the Farnese office to log into a customer’s machine and help them with training and troubleshooting.

Inclined drain grooves can be cut either onto the bench top or incorporated into the polished flat drain board. The width of the grooves are dictated by the tooling selected. The length is inputted on “grooving” selections and is in relation to and in proportion with, the centre of the sink cut out.

The Alexia can also perform edge profile work (for example, Lambstongue, bullnose etc.) subject to tools selected. These can be supplied at additional cost to standard tooling provided. n

YOUR DEFENCE AGAINST SILICA

CleanSpace Respirators exceed minimum requirements for new QLD Code of Practice on silica dust exposure.

CLEANSPACE PROTECTS AGAINST CRYSTALLINE SILICA

Stonemasons, amongst several other industries including construction and mining, still need protection against crystalline silica dust. However the current COVID-19 crisis has made it increasingly difficult for many to source N95 disposable masks.

CleanSpace respirators are reusable, which means the industry can continue to operate safely and efficiently, without supply shortages that could cripple operations or put workers in danger.

Silica dust is harmful when inhaled into lungs. It is 100 times smaller than a grain of sand, so small it can be inhaled without knowing. Respirable crystalline silica exposure can cause silicosis, a debilitating and irreversible lung condition that can cut short careers, reduce quality of life and lead to death. It is also linked to lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease. When looking to protect yourself or your staff from any airborne contaminants, Powered Air Purifying Respirators (PAPRs), offer high and reliable protection, far exceeding disposable masks. CleanSpace respirators are a revolution in the area of respiratory protection because while they provide all the protection of a PAPR, they a free from belts, battery packs and hoses which make them more comfortable and easy to deploy. When used in hot or humid conditions, CleanSpace respirators provide cool, clean air to the user and eliminate fogging and moisture. They are also light, easy to put on, reliably safe and comfortable. These smart powered devices are easily operated using a one-button smart system. Their unique features mean more workers wear these respirators for a full shift every time. CleanSpace assists its clients to be safe and compliant when working around silica dust.

Compared to disposable masks, CleanSpace respirators are high protection reusable devices with economic advantages, as the annual cost of replacing disposables stacks up. Disposable masks are well-known for causing fogging and discomfort, leading to low compliance, frequent stopping or mask changes.

To guard against silica exposure, state regulators have moved to recommending staff wear powered respiratory protection using a minimum of a P2 filter. CleanSpace respirators meet and exceed these requirements with a P3 filter.

Regardless of whether workers see the dust or not, silica is a hazard they cannot afford to ignore. Under the Standards, all worn tight fitting respirators, (regardless of whether it’s a disposable mask or powered

34 | DISCOVERING STONE #36 | www.discoveringstonemagazine.com.au respirator), must achieve a correct fit to ensure the wearer is protected. Facial hair, including stubble, beards, moustaches and sideburns, between the edge of a tight-facing facepiece and the face will prevent the respirator from sealing properly.

CleanSpace offers both half face and full face masks. The full face mask also has a high impact rating. Its respirators are compact systems that have up to six hours run time and fast/ top up charging.

“The feedback we get from teams wearing CleanSpace Ultra, full face mask for mining activities, is that the mask is comfortable to wear all day, and the cool fresh air on the face is a dramatic improvement on disposable or reusable half masks,” said CleanSpace CEO Alex Birrell. “They have also told us there is no fogging or hot moisture on their face.”

CleanSpace respirators are available in different models with a range of particulate and combination gas filters depending on the task requirements. CleanSpace EX is intrinsically safe approved and can be worn in potentially explosive environments. Ultra is IP rated 66, making it water tolerant and CleanSpace2 is the standard model suitable for those that do not require the aforementioned features. The newly launched HALO is designed specifically for laboratories and testing facilities.

The company’s team of product specialists can assist with onsite product training, fit testing, trouble shooting and instructions on maintenance. With the renewed focus of regulators and the industry on silica, it is an opportune time to re-evaluate your site’s respiratory program and equipment. n

IP67 PROTECTION INGRESS

e

$0

S.E.A. GROUP INFORMS ABOUT SAFETY

Safety Equipment Australia (S.E.A. Group) provide some respiratory terms, definitions and differences.

What is a negative-pressure respirator? What is the meaning of face-seal? What is the difference between qualitative and quantitative respirator testing?

Many terms in breathing protection might not be clear at first glance. One good place to start decoding the terminology used in the field of breathing safety is the “Australian and New Zealand Standards 1715:2009 – selection, use and maintenance of respiratory equipment”. In it, a glossary explains some important definitions and differentiations used by health professionals, and well worth perusing for all respirator users. Here are some basic terms:

NEGATIVE VERSUS POSITIVEPRESSURE RESPIRATORS In a negative-pressure respirator, the lungs perform the job of drawing contaminated air through a filter. A positive-pressure respirator can work in three ways: clean air is supplied through an air-line from a remote source; clean air can be carried in a cylinder (breathing apparatus); or a fan motor can draw contaminated air through filters (powered air-purifying respirator or PAPR).

AIR-PURIFYING VERSUS AIR-LINE RESPIRATOR An air-purifying respirator cleans contaminated air through a filter or filters.

An air-line respirator supplies clean air from a remote source through a breathing hose.

FULL VERSUS HALF FACE-PIECE A full face-piece (full mask) covers the face, eyes, nose and mouth. It has a visor for clear vision.

A half face-piece (half mask) covers only the nose and mouth. It has no visor.

TIGHT VERSUS LOOSEFITTING FACE/HEAD PIECE A tight-fitting (also close-fitting) device relies on a tight skin seal in order that no surrounding air can leak into the face-piece. Therefore, it requires a clean-shaven face with smooth skin.

A loose-fitting device (often called a head-top) operates on a supply of clean air that maintains a positive pressure inside the device, so that no outside air can enter. It does not rely on face seal, so even people with a stubble or a beard can get adequate protection.

QUALITATIVE VERSUS QUANTITATIVE INDIVIDUAL FIT TEST In a qualitative fit test, the wearer of the respirator is exposed to a test agent with a particular smell or taste. If the wearer can detect the smell or taste, the respirator has failed to provide adequate

protection. Qualitative fit tests can be unreliable, as people’s sense of smell and taste can vary, or if the person has a cold or other affliction that can affect the ability to detect the test agent.

A quantitative test does not rely on sensory abilities. It measures the difference between the (contaminated) air outside the mask and the (filtered) air inside the mask. Thus, the protection factor of the respirator can be established.

MINIMUM VERSUS ASSIGNED PROTECTION FACTOR A protection factor is a guide to how effective a respirator is at supplying breathing-quality air to the user.

A minimum protection factor is the least protection that can be expected of a respirator, intact, complete, correctly assembled and fitted by a trained user, and used according to the manufacturer’s instructions.

An assigned protection factor is given to any respirator of a particular type, regardless of the actual protection factor that can be achieved by that respirator.

For more comprehensive terms and definitions, see Australian & NZ Standards 1715:2009. n

EASYSINK The most affordable sink cutout CNC in the market.

MULTIFLAT Powerfull and simple flat polisher machine.

SA | WA | New Zealand 02 9829 2699 02 9829 2699 +64 4 5268 589 NSW | QLD | VIC02 9829 2699 0408 376 864 03 8786 3113 Head Office +61 2 9829 2699 Australia