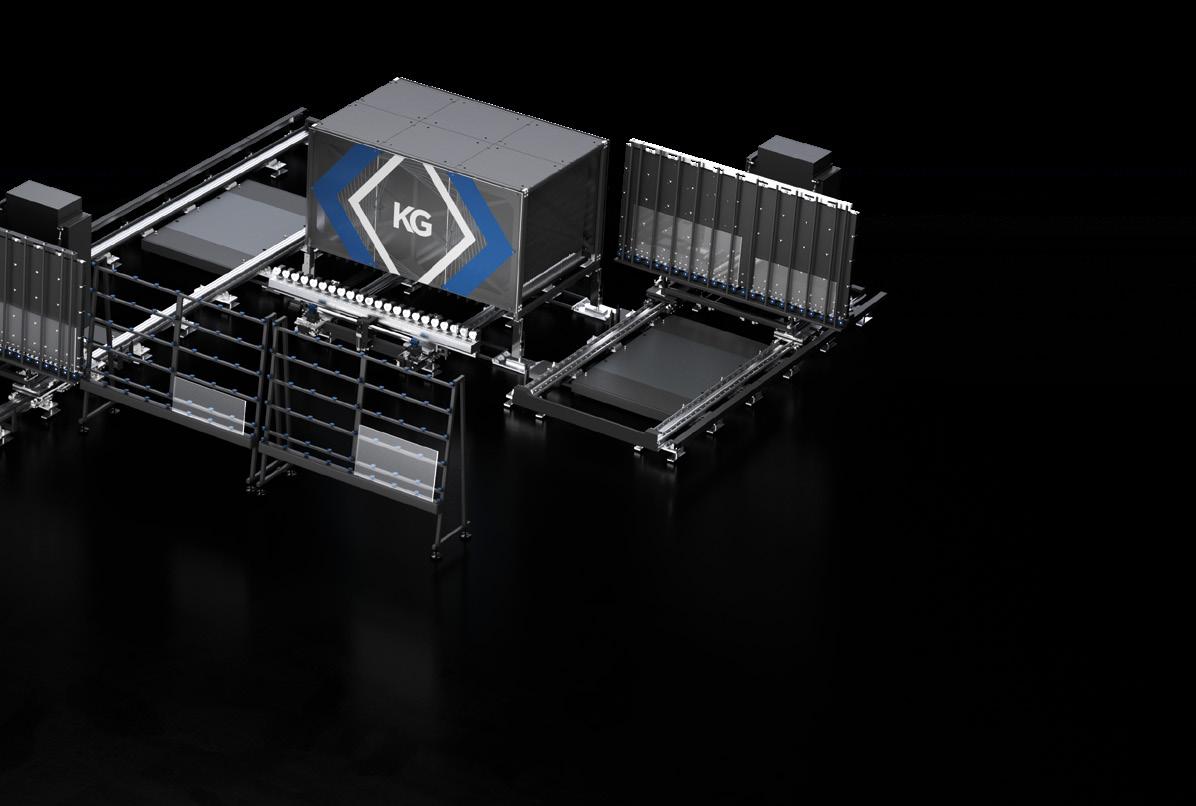

Smart system for glass sheet handling, storage, and production process integration

Smart system for glass sheet handling, storage, and production process integration

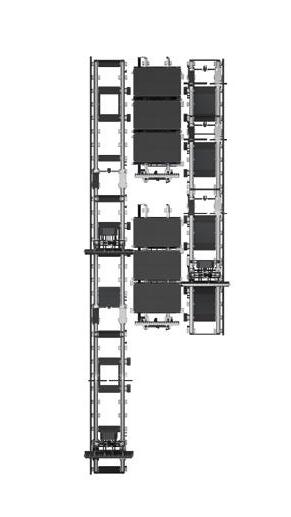

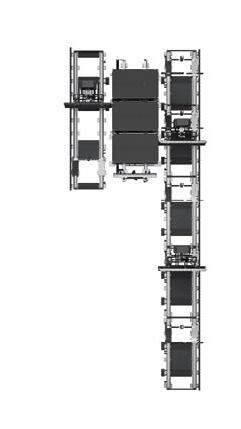

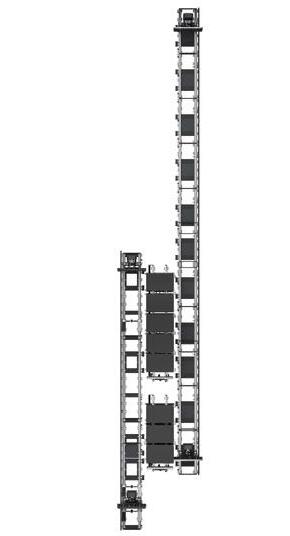

The Klass system (Sorting System) uses an automatic process for glass handling and storage, also integrating the various processing lines with the downstream production phases. The system's modular design meets the specific needs of each plant, managing and organizing the flow of glass. The system is equipped with Kerasoft, a dedicated and customized production application capable of optimizing the process according to the production program, the automatic loading of tempering furnace and more.

As a result of a constant R&D investments, Klass improves operational efficiency, guarantees plant stability, production flexibility and continuity; it manages space rationally, reduces manual operations, giving the finished product superior quality levels.

The overall view that makes the difference. What characterizes Keraglass and has driven the company to establish itself as a global leader in the sector is its “all around” approach to the glass industry. Starting from a concrete and direct analysis, the company develops innovative, functional and targeted solutions. Keraglass offers a wide range of machinery in the main sectors of glass processing: automation, tempering, lamination and decoration.

The headquarters in Baiso (RE), with a surface area of 10,000 square meters, includes management offices, R&D and a technological showroom. Thanks to its achievements, the company has opened a second, third and fourth plant over the years, increasing production, personnel and the occupied area which now extends over 15,000 square meters.

Product traceability starts with an automatic measuring device installed in the initial phase of glass sheet processing. Each glass is subjected to dimensional checking after the breakout phase and before the downline processing operations. A subsequent high definition and high-speed UV laser marker can be installed to ensure the traceability of each individual piece by engraving a very small data matrix/QR code. In this case, during one process and the following, code readers enhanced by artificial intelligence are placed and will provide all the information necessary for the correct functioning and traceability of the product.

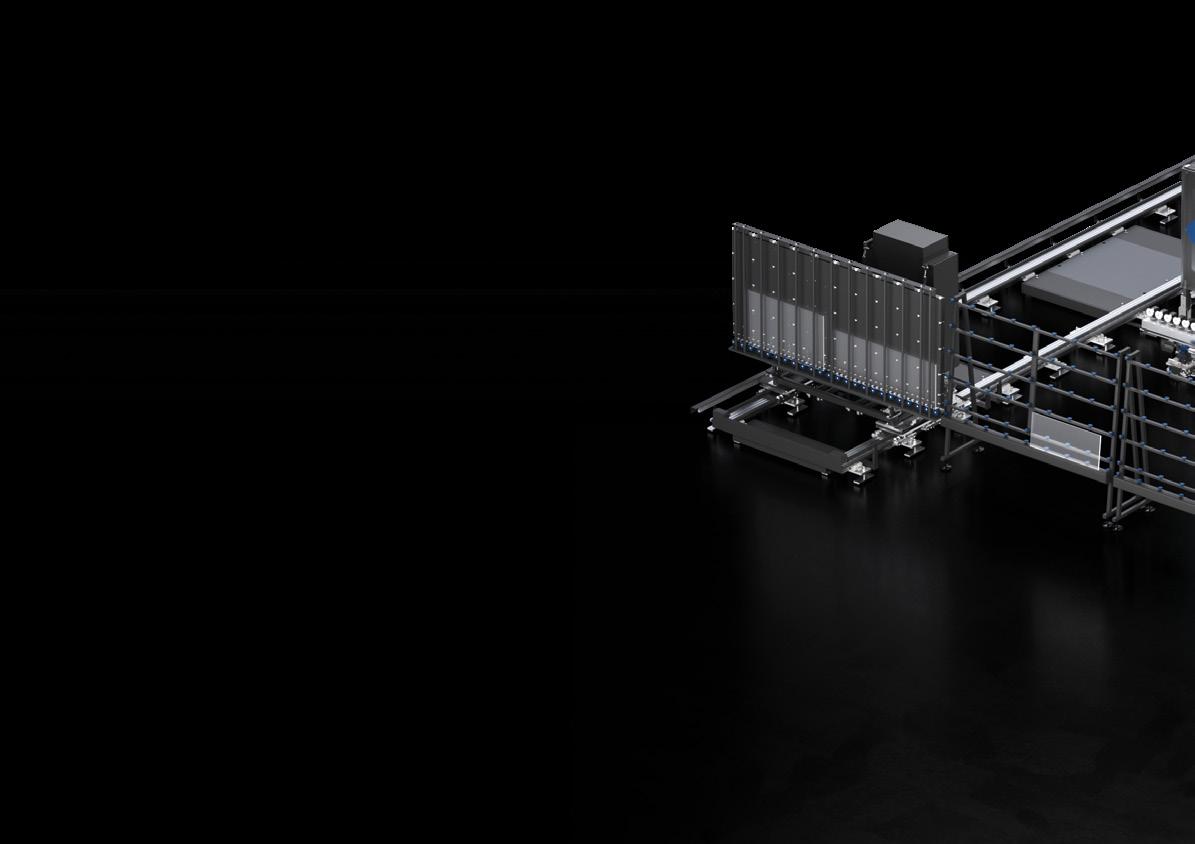

The glass vertical and/or horizontal shuttle transport system is designed for high speed, safe and efficient handling of glass sheets used in many sectors, including construction and furniture.

This system is particularly suitable for those who need to transport glass sheets safely within glass factories in order to integrate production processes and adapt them to customer needs. It guarantees process efficiency while increasing personnel safety.

Our shuttles move on guides that do not require structural interventions and can be installed on any type of surface, even with significant level differences. The guide system is equipped with automatic lubrication technology for the racks, reducing maintenance to a minimum. The guide with steel rollers was developed to support high loads without oscillations offering maximum stability and precision. This system is designed to ensure high speeds and optimal operation over time, while maintaining a low level of maintenance.

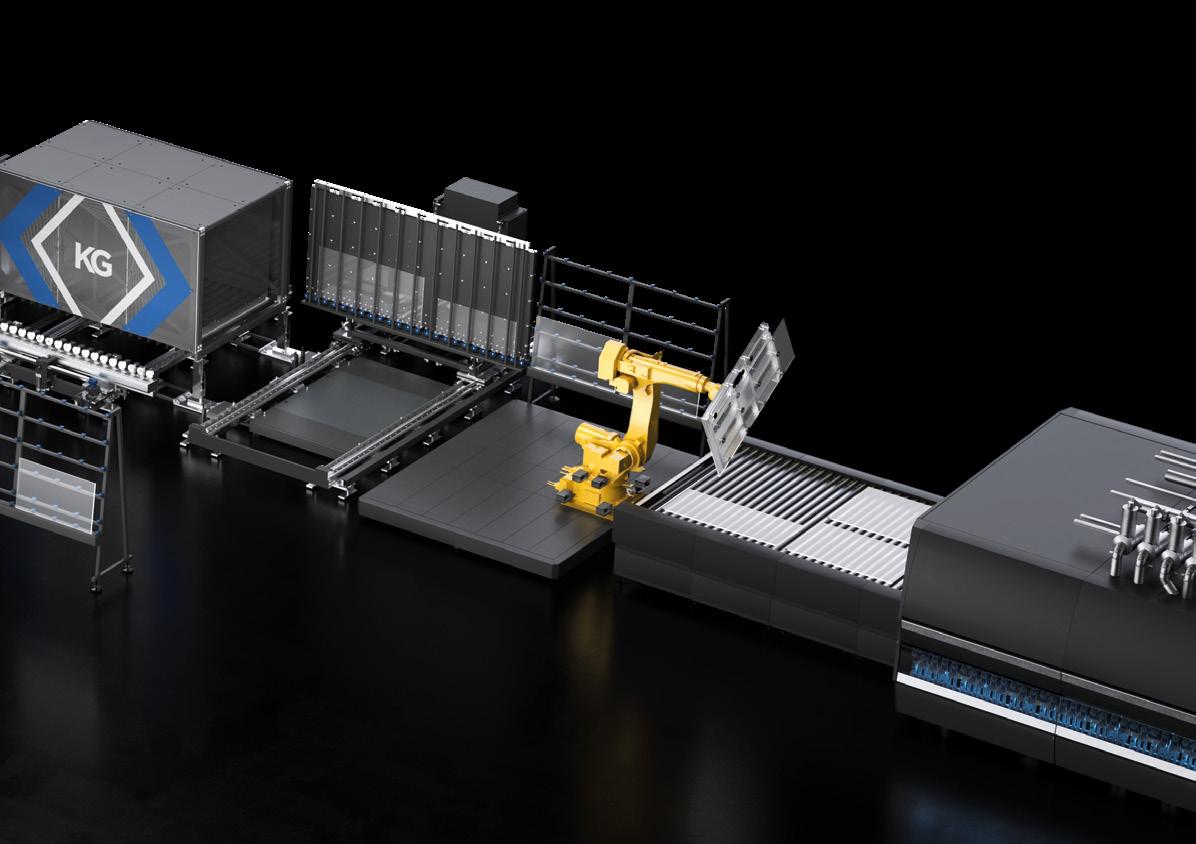

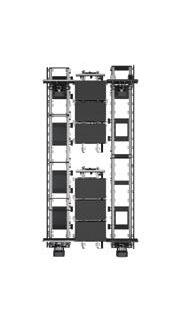

It is a mobile transport system that allows loading and unloading glass of various sizes and thickness inside the storage. It is a solution designed to facilitate loading and unloading operations inside the storage, improving safety and efficiency in glass handling.

It facilitates logistics operations by reducing handling times and the risk of damage to the material, ensuring a smooth and safe process.

Based on customer requirements, the number of mobile transport system can be increased to allow simultaneous loading and unloading between the various work processes.

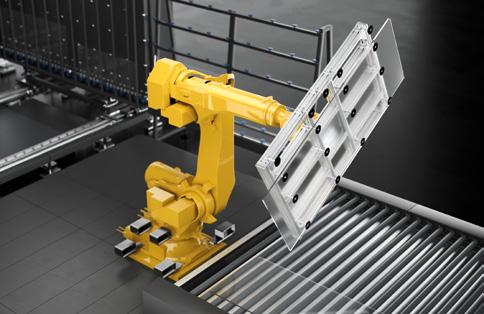

The loading/unloading system with anthropomorphic robot (flexible based on customer requirements) is managed by internal optimization software (Kerasoft).

Kerasoft allows to position the glass in order to optimize the efficiency of the load in the furnace, to manage the priorities within the sorting and to automate the loading and unloading operations

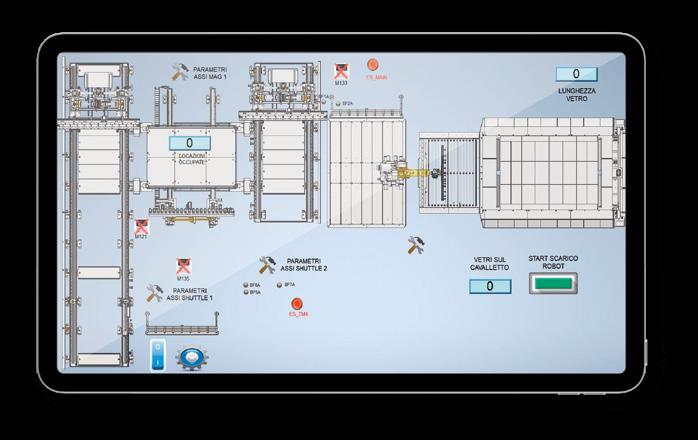

The HMI allows the operator to check each station by monitoring the operating parameters and the progress of the product in real time. In addition, the operator can use this interface to resolve alarms or faults on single machines.

The monitors are strategically positioned based on the customer's layout; they can be connected via wi-fi to mobile devices to facilitate the operator in viewing the phases in real time and provide for the configuration of remote teleassistance.

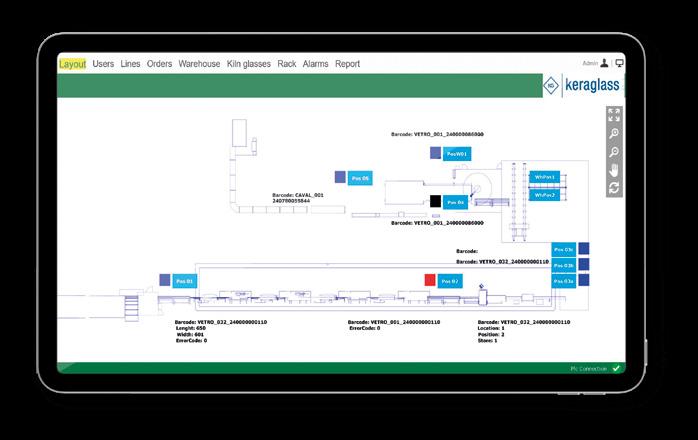

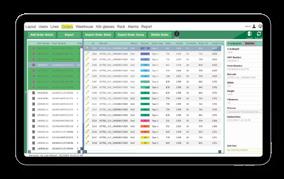

Kerasoft (MES) is a customized production management software application.

Kerasoft accepts orders from the customer’s ERP system, plans as needed based on priorities, manages the work processes during the various phases, organizes the position of the glass in the storage and makes the parts available for the downline process, optimizing the flow of pieces in each section.

03. Production Plan Control → 04. Energy Consumption Data ERP PRODUCTION ORDER OFFICE PO PROCESS DATA KERASOFT

01. Order Progress → 02. Rack Optimizer →

↓

DOUBLE GLAZING AREA

LAMINATING AREA

TEMPERING AREA

STORAGE AND BREAKOUT AREA CUTTING

SORTING SYSTEM

AREA MULTIPROCESSING