57 minute read

The Fundamental Series: CPD Learning

MARK THROWER MANAGING EDITOR

SERIES 18 | MODULE 09 | BEHAVIOUR CHANGE

Advertisement

Plan for behaviour change

by James Brittain, John Mulholland and Jes Rutter, Approved EnCO Practitioners

Leonard Bernstein, the wellknown American composer, once said: “To achieve great things, two things are needed: a plan and not quite enough time”.

The time organisations have to accelerate towards Net Zero is shrinking. As part of this, there are increasing pressures on energy users from employees, customers, shareholders, regulators, and other interested parties to significantly improve levels of energy efficiency throughout their operations and processes.

Evidence suggests that behaviour change offers around 50 per cent of the total potential energy savings available. The other 50 per cent comes from technology and yet, as important as it is, technology typically gets 95 per cent of the focus.

A better balance is required to ensure that the hidden and largely untapped savings available from behaviour change are realised.

Behaviour change is considered in its broadest sense, targeting attitudes, behaviours and decisions implemented by those who influence energy performance as well as those who have direct hands-on control of equipment and systems. Getting behaviours right also enhances and protects the legacy benefits of technology investments as they rely on sociotechnical systems for success.

Energy Conscious Organisation (EnCO) is a framework developed by Energy Services & Technology

Association and the Energy Institute to help incorporate people measures into energy management strategies and plans.

The vision is to excite and equip enough colleagues to challenge the norm and to encourage widespread adoption of energy efficiency good practices throughout the organisation.

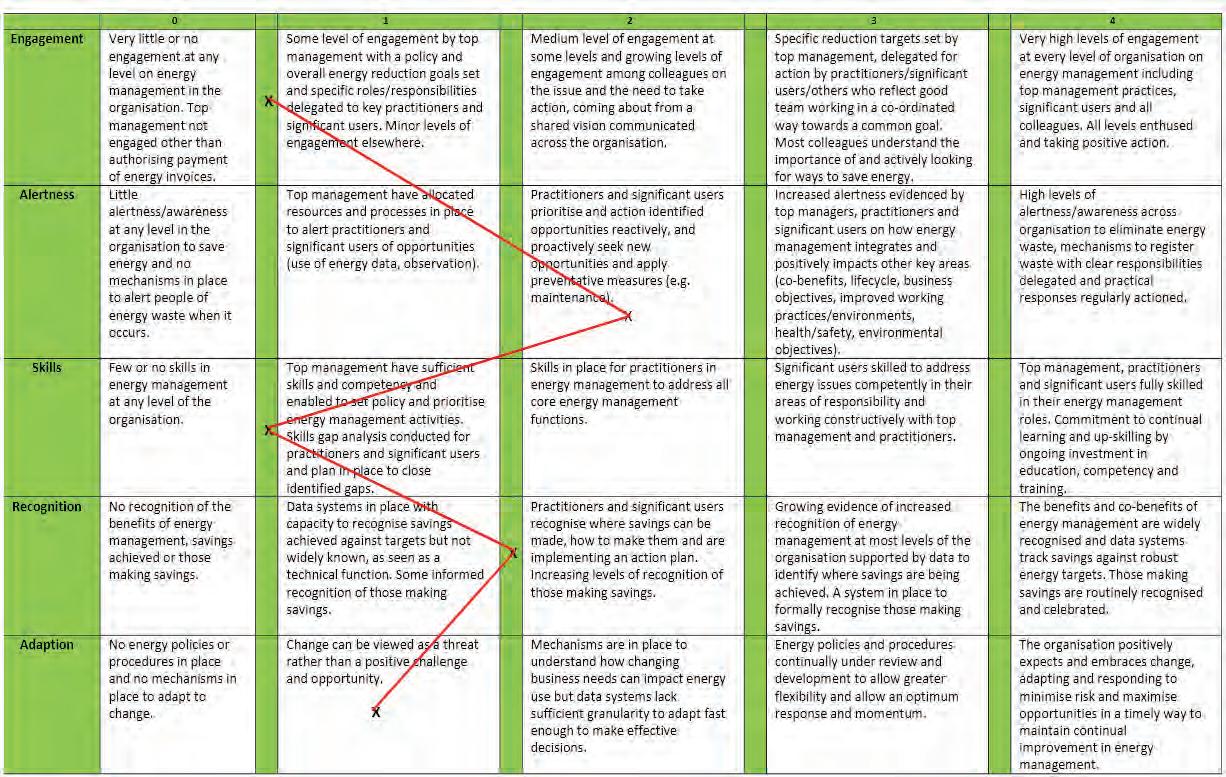

At the heart of the EnCO framework is the EnCO Matrix. This can be used to review the effectiveness of approach across five key pillars: engagement, alertness, skills, recognition and adaption (EASRA).

The matrix is based on the concept of ‘congruence’ to facilitate balance across the five pillars so behaviour change interventions support and reinforce each other holistically.

A visual profile is made by marking points across the grid for each pillar against the improving scale of achievement. The shape of the profile then demonstrates how strategies can be better balanced and improved in delivering outcomes.

Fig. 1 (see page 18) shows the EnCo matrix with an example ‘jagged’ profile.

Learning objectives include: • consider the imperatives for change; • describe how to highlight reality; • explain key features of a balanced approach; and • create a plan that propels momentum.

A useful feature of the Matrix is that it facilitates conversations with colleagues about current levels of energy performance, opportunities and challenges. One helpful way to do this is to focus on capabilities, opportunities and motivations to change behaviour (COM-B).

The matrix is sufficiently simple that any organisation can adapt the wording to better suit their goals, culture and operations.

The imperative for change, of course, is not driven by Net Zero targets alone but also needs to take into account and balance other stakeholder needs and expectations such as better customer service, cutting costs and enhancing reputation.

You could ask three questions: • if we are to achieve Net Zero, where on the Matrix do you need to be? (B) • where are we now? (A) • how do we get from A to B?

In practice, there can be significant differences in observations described by a target audience, particularly from those with differing roles and perspectives. A constructive use of the matrix is to take the differing views, discuss why they are different and use this discussion to form a consensus reality position on the EnCO Matrix. This will give agreement on ‘where are we now?’

The EnCO profile and score, often along with anecdotal observations, forms a benchmark to measure future progress against.

A Balanced High EnCO profile across all pillars is associated with

a mature energy management programme that accelerates progress towards sustainable Net Zero goals.

Low scores across some or all pillars are indicative of significant opportunities to improve an approach.

A strategic gap analysis is therefore used to compare the ‘desired’ position (often targeting three to five years ahead) with the current profile, to feed into the development for the catalyst for change.

To bridge the gap, change makers need to understand what motivates the people involved on a personal level. People’s actions are often driven by emotive connections that come about from connecting with colleagues, having fun, a better workplace, better skills, achievement, recognition and reward. A successful catalyst often includes targeted co-benefits resulting in a ‘win-win’.

The business case is set up by focusing on the key strategic activities which make the biggest difference in delivering the required goals. This should address the organisation’s readiness to deliver change (available resources, knowledge etc), key barriers (capabilities, attitudes etc) and its ability to sustain change.

To develop a good plan, focus on overcoming any deficiencies across the EASRA pillars, rather than specifically following a framework.

Figure 2 shows the variety of different possible Matrix profiles.

1) ‘Balanced Low’

Profile 1 is uniformly low across all pillars. This is often underpinned by low overall engagement. Energy performance, for example, may have been marginalised because it has been overly delegated to a specialist, service partner or aM&T system.

Having top managers on board is essential. They need to demonstrate their commitment by defining a compelling vision, providing the resources needed and taking interest in progress made.

There also needs to be a strategy to engage Significant Energy Users (SEUs), those who can impact on or influence significant energy use. This includes HR, procurement and development colleagues as

Fig. 1. The EnCO Matrix with a ‘Jagged’ profile

well as building users, facilities and operational teams. Don’t forget consultants, suppliers and contractors.

All Energy Users (AEUs) also need to understand the energy policies in place, the benefits of improved energy performance and their roles and responsibilities.

The overall plan and channels used should achieve engagement and also momentum for a balanced approach.

A high profile launch event can create a good splash to raise awareness but has little momentum. Digital or print communications also often have limited shelf-life. Training, performance appraisals, incentives and suggestion schemes are all examples of channels that offer more momentum.

Fig. 2 The variety of different possible Matrix profiles

1) Balanced Low 2) Unbalanced

3) High Peak 4) Low Valley

5) Jagged 6) Balanced High 2) ‘Unbalanced’

A profile highly developed in Engagement and Adaption but which lags in other areas operates in a positive atmosphere but lacks substance.

Colleagues being alert to avoidable energy waste, before investing in clean and green technologies, is a fundamental principle of the energy hierarchy.

AEUs need to be alert to the impact of their activities on energy performance. An SEU may negatively impact on overall performance, due to increased energy use, when making operational decisions for seemingly good reasons.

Command and control approaches with too many organisational procedures can reduce alertness. Nudge, prod or persuasion techniques are generally more effective; sharing energy consumption profiles, for example, can help highlight opportunities.

Critical mass theory implies that we need at least 2-5 per cent of colleagues taking simple actions every day to reach a tipping point of energy consciousness for lasting change. For an organisation of 4,000 people, this means involving at least 80 SEUs.

Energy champions can influence others by example. A network of volunteers can promote energy saving values and connect colleagues together. To be effective, they need to be carefully recruited, trained and supported.

For a balanced approach, colleagues need to be highly motivated and highly aware. Asking people to rate their awareness and motivation levels can be a useful way to track levels of alertness while getting them to think more about opportunities and getting new champions on board.

3) ‘High Peak’

Profile 3 is highly developed in one pillar only. This could be any element and is most commonly related to the style or strengths of the manager leading the programme.

As well as motivation and opportunity, people need to have the capability to deliver change. Teams need to have a balance in skills to implement an integrated approach, highly developed across all pillars.

Training is often a key strategic

activity that helps raise the other pillars simultaneously. A training strategy should be driven by a training needs analysis, mapped across the key audiences. Colleagues need to know what they are expected to do and be competent so actions are quick, easy and intuitive for those involved.

The whole team has a key role to communicate the vision and to lead by example. It is important to be able to communicate well with colleagues to gain and build trust. Collaborative workshops and events are effective ways to bring people and teams together to develop alertness, desire and capability and trial solutions at the same time.

HR colleagues are often essential key connector champions for continual learning and up-skilling.

4) Low Valley

Highly developed in all but one pillar highlights the need to develop this one aspect to fully benefit from the other activities.

This could be any element but quite often what’s lacking is recognition. Robust data systems are needed to track savings against baselines and targets. Ideally, this should disaggregate interventions for detailed evaluation. Longer-term monitoring and targeting is essential because impacts can dissipate over time, but this doesn’t have to be complex.

Full adherence with the International Performance Measurement and Verification Protocol (IPMVP) is desirable but is not always practical; it is the most widely used protocol for quantifying results from investments.

A measurement and verification (M&V) plan should be agreed prior to the programme. Involving stakeholders to develop the methodology ensures it’s owned by the people involved. Methods to adjust baselines for both routine (e.g. weather) and non-routine adjustments (e.g. changes in floor area) should be considered.

A balance of measures is also required to sustain and propel momentum. At high level, energy performance can be measured in absolute terms at whole-facility level. This verifies total savings but, as this is a lagging (output) measure, this can’t influence momentum.

Indicative measures are used to explain why performance has changed. System energy productivity or utilisation intensity measures require investment in sub-metering and a sufficient run-up period to calibrate baseline models.

Leading (input) indicators offer an opportunity to control momentum but do not guarantee success; it can be difficult to define which measures are best. Scorecards can track observed behaviours and team actions against targets. The repertoire would be specific to the organisation, site or team.

Dashboards, balanced scorecards or crediting systems can be used to help facilitate quicker and better decisions, incentivisation and celebrating success. Do not rely too heavily on incentivisation as there’s a risk of reversal if the incentive is taken away.

Focus on a simple strategic set of concise measures for which everyone understands how they contribute to strategic goals. Beware of data overload, data rich and information poor (DRIP syndrome).

5) ‘Jagged’

A mix of some developed pillars with others not so developed is likely to be typical for most organisations. An uneven profile highlights the weaknesses that can undermine the strengths.

Organisations need to be able to continually adapt to plug the gaps and respond to minimise risk and maximise opportunities in a timely way to sustain and propel momentum.

The energy landscape is continually changing and this is becoming more dynamic as the pressures to improve energy performance increase.

Surveillance controls monitor changes in stakeholder requirements as well as internal factors and external threats. Continually check that goals are still realistic and achievable, now and in the future.

A good plan needs to be agile focused on the key strategic activities, with a clear line of sight to the strategic objectives.

Adaptations are about continually increasing the means and reducing barriers to increase capability, opportunity or motivation.

ISO 50001 is the energy management system standard that helps target the key activities. As well as energy policies, processes and action plans, the standard focuses on operational controls and design procurement standards to sustain behaviours. Energy and management reviews, objectives and targets and strategic controls are used to self-propel momentum.

General George C Marshall, famous for his World War 2 planning and his plan to rebuild Europe, said: “The one great element in continuing the success of an offensive is maintaining the momentum.”

6) ‘Balanced High’

Highly developed across all pillars generally at levels 3 or 4 is indicative of the well balance and mature approach of an EnCO.

EnCOs are more sustainable, cost effective and collaborative. The business case for interventions to get to the EnCO level comes from defining and questioning reality by asking the right questions at the right time, and the EASRA framework can facilitate this process.

Is everyone engaged in the right way? Are all teams alert to the energy opportunities? Do they have the right skills to exploit them? Are you recognising, measuring and reporting results? Do you need to adapt your policies/ processes to drive continual improvement? What’s next to guarantee momentum?

There needs to be a compelling vision and clear balanced plan in place with the sense of urgency. Align big ideas with strategy in a way that will excite decision makers and colleagues alike.

There also needs to be a strong team in place, with clear roles and responsibilities. Remember people often don’t like change. Don’t expect results too quickly – it may take time.

Don’t overcomplicate it, keep it simple. Aim to balance quick wins with longer-term actions. Pareto’s 80/20 principle encourages us to target the 20 per cent of the scope that yields 80 per cent of the results.

Overall, the plan will depend on the organisation; there’s no silver bullet, every organisation is different. The focus often should be on blending people and technical solutions, with targeted organisational strategic controls alongside.

Tactical techniques support strategic activities and there are many to choose from; EnCO defines over 140 different interventions. Organisations will need their own unique combination to deliver change for themselves.

Any organisation can become an EnCO by demonstrating ‘Balanced High’ achieving outcomes cross the five EnCO pillars: Engagement, Alertness, Skills, Recognition and Adaption.

EnCO registration and display of the logo act as evidence of good practice to shareholders, regulators, customers and colleagues through externally verified recognition. Becoming part of the wider EnCO community also enables sharing of good practice to further drive the continual improvement mindset needed.

Registered EnCO Consultants (status gained through training) and Approved EnCO Practitioners (with proven experience) can support organisations to achieve the EnCO status.

Further reading

• Case-studies and process, EnCO Website at www. energyconsciousorganisation.org.uk • Making change the norm, by Jes Rutter, Energy in Buildings and Industry Magazine, Feb 2021 • Energy consciousness has never been more important, by Jes Rutter, Energy World, Jan 2021 • Tools and techniques to deliver behaviour change, by James Brittain, CPD module 06, Series 16, Energy in Buildings and Industry Magazine, Nov/Dec 2018 • Energy management systems – Requirements with guidance for use, BS EN ISO 50001:2018 • International Performance Measurement and Verification Protocol, Core Concepts, EVO 10000 – 1.2016 • Behaviour change for low-cost energy savings, by James Brittain, CPD module 02, Series 14, Energy in Buildings and Industry Magazine, June 2016 • Ten steps to change, by John Mulholland, Energy in Buildings and Industry Magazine, July/August 2014.

SERIES 18 | MODULE 09 | APRIL2021 ENTRY FORM SERIES 18 | MODULE 03 | SEPTEMBER 2020 ENTRY FORM SERIES 17 | MODULE 09 | MARCH2020 ENTRY FORM

Please mark your answers below by placing a cross in the box. Don't forget that some questions might have more than one correct answer. You may find it helpful to mark the answers in pencil first before filling in the final answers in ink. Once you have completed BEHAVIOUR CHANGEPlease mark your answers below by placing a cross in the box. Don't forget that some questions might have more than one correct answer. You may find it helpful to mark the answers in pencil first before filling in the final answers in ink. Once you have completed the answer sheet, return it to the address below. Photocopies are acceptable. SMART GRIDS Please mark your answers below by placing a cross in the box. Don't forget that some questions might have more than one correct answer. You may find it helpful to mark the answers in pencil first before filling in the final answers in ink. Once you have completed the answer sheet, return it to the address below. Photocopies are acceptable. SPACE HEATING the answer sheet, return it to the address below. Photocopies are acceptable.

QUESTIONS1) The establishment of the main QUESTIONS QUESTIONS ■ Actual energy users ■ Facilitate the connection of distributed 1) What does EnCO stand for? transmission grid began in which decade? 1. Which is the most common heating media in wet systems? ■ All energy usersrenewable generation and variable loads such as electric vehicles and heat pumps 6. Which is the ‘delivery end’ of a vapour compression heat pump system? ■ Energy Conscious Operative ■ 1940s■ High temperature hot water ■ Actionable energy undertakings ■ The evaporator ■ Energy Conscious Organisation ■ 1930s■ Steam 7) What does the abbreviation VPP stand for? ■ The condenser ■ Environmental Conscious Organisation ■ 1960s■ Low temperature hot water 7) Who are not generally considered to be ■ Volume purchase programme■ The compressor ■ Environmental Community Obligation 2) Which key parameters need to be ■ Cold water significant energy users? ■ Voluntary protection programme ■ Virtual power plant ■ The slinky 2) What is the acronym used by the EnCO framework? ■ AESRA ■ EASRA ■ SRAEA controlled by smart grids? ■ Voltage and frequency ■ Frequency and current ■ Voltage, current and frequency 3) What’s the main source of large-scale 2. What is the most common space heating fuel in the UK? ■ Fuel oil ■ Electricity ■ Natural gas ■ ■ ■ ■ Top managers Operations staff Energy champions Everyone 8) Electricity cannot be stored in large quantities by householders? ■ False as only large utilities and industrial/ commercial energy providers can provide storage facilities 7. Which of these factors is used by a weather compensation control system? ■ Building thermal inertia ■ Time of day ■ Outside air temperature ■ EARAS 3) What percentage of total available renewable generation connecting to the grid? ■ Biomass ■ Coal 3. What is a typical dry bulb space temperature 8) Who are the people we need to engage to raise alertness across an organisation? ■ False ■ True as householders can store electricity in standalone batteries or when charging ■ Date 8. Which of these factors is used by an optimum savings can be delivered through behaviour change? ■ Wind farms ■ Solar farms for a home? ■ 160C ■ Top managementtheir electric vehicles start control system? ■ Level of building occupancy ■ 5 per cent ■ 15 per cent ■ 50 per cent ■ 95 per cent 4) According to the Energy Hierarchy which activities would normally be prioritised 4) What are the main forms of variable electrical loads connecting at the household level? ■ Electric vehicles and heat pumps ■ Smart meters ■ Home automation devices ■ 190C ■ 220C ■ 240C 4. What is currently the most common construction material for panel radiators? ■ Cast iron ■ Operations staff ■ Everyday champions ■ Everyone 9) What aspect of measurement and verification (M&V) should be done prior to 9) What is the main benefit of smart meters? ■ They avoid the need for meter readers ■ They provide accurate and timely information on power flows across the smart grid ■ They facilitate the export of surplus electricity from household solar PV panels ■ Outside air temperature ■ Boiler capacity ■ Boiler flow temperature 9. Which types of space heating system can building management systems be used to control? ■ Any first?5) What is the main threat to smart grids? ■ Pressed steel any programme? 10) What does the technology VtG represent? ■ Wet systems ■ ■ ■ Being alert to avoidable energy waste Investing in clean technologies Investing in green energy sources ■ Cost of implementation ■ Cyber attacks ■ Lack of experience and expertise ■ Cast aluminium ■ Copper ■ ■ Third party verification of reports M&V Plan ■ Variable Geometry Turbochargers - designed to allow the effective aspect ratio of a turbocharger to be altered as ■ Air handling plant ■ Boilers ■ Offsetting greenhouse gas emissions 5) According to Critical Mass Theory, what percentage of a population do we need to (typically) engage to reach a tipping point? 6) What are the main benefits of smart grids? ■ Reduce the need for centralised power generation ■ Encourage connection of electric vehicles 5. Which of these is a key component of a mechanical ventilation system? ■ A fan ■ An atrium ■ A chimney ■ Opening windows ■ Routine adjustments ■ Non-routine adjustments 10) What is the name of the most widely used M&V protocol? conditions change ■ Volume of Trapped Gas associated with respiration ■ Vehicle to Grid enabling EV batteries to discharge to the grid to ‘smooth’ high electricity peak demand profiles. 10. What is a thermostat? ■ A temperature sensitive switch ■ A temperature sensor ■ A proportional control device ■ A digital display device ■ 1 per cent ■ Energy Conscious Organisation Protocol ■ ■ ■ Efficiency Valuation Organization Protocol 2 to 5 per cent 10 to 20 per cent Please complete your details below in block capitals Please complete your details below in block capitals ■ >50 per cent ■ International Performance Measurement and Verification Protocol Name ......................................................................................................................................................................... (Mr. Mrs, Ms) ....................................Name ......................................................................................................................................................................... (Mr. Mrs, Ms) .................................... 6) What does ‘AEU’ stand for? ■ ISO 50001 Energy Management System ■ ProtocolAll energy undertakingsBusiness .................................................................................................................................................................................................................................... Business .................................................................................................................................................................................................................................... Business Address .................................................................................................................................................................................................................Business Address ................................................................................................................................................................................................................. ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ .................................................................................................................................. Post Code .............................................................................................. .................................................................................................................................. Post Code .............................................................................................. email address .........................................................................................................................................................................................................................email address ......................................................................................................................................................................................................................... Tel No. .........................................................................................................................................................................................................................................Tel No. .........................................................................................................................................................................................................................................

PLEASE COMPLETE YOUR DETAILS BELOW IN BLOCK CAPITALS

Name ......................................................................................................................................................................... (Mr. Mrs, Ms) .................................... Business.................................................................................................................................................................................................................................... Business Address ................................................................................................................................................................................................................. ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ .................................................................................................................................. Post Code .............................................................................................. email address ......................................................................................................................................................................................................................... Tel No. .........................................................................................................................................................................................................................................

Completed answers should be mailed to: Completed answers should be mailed to: The Education Department, Energy in Buildings & Industry, P.O. Box The Education Department, Energy in Buildings & Industry, P.O. Box 825, GUILDFORD, GU4 8WQ. Or scan and e-mail to editor@eibi.co.uk. All 825, GUILDFORD, GU4 8WQ. Or scan and e-mail to editor@eibi.co.uk. All modules will then be supplied to the Energy Institute for marking modules will then be supplied to the Energy Institute for marking

COMPLETED ANSWERS SHOULD BE MAILED TO: The Education Department, Energy in Buildings & Industry, P.O. Box 825, GUILDFORD, GU4 8WQ. Or scan and e-mail to editor@eibi.co.uk. All modules will Produced in Association with Produced in Association with then be supplied to the Energy Institute for marking

20 | ENERGY IN BUILDINGS & INDUSTRY | SEPTEMBER 202024 | ENERGY IN BUILDINGS & INDUSTRY | MARCH 2020 Produced in Association with How to obtain a CPD accreditation from the Energy Institute How to obtain a CPD accreditation from the Energy Institute How to obtain a CPD accreditation from the Energy Institute Energy in Buildings and Industry and the Energy Institute are delighted to Energy in Buildings and Industry and the Energy Institute are delighted to Energy in Buildings and Industry and the Energy Institute are delighted to have have teamed up to bring you this Continuing Professional Developmenthave teamed up to bring you this Continuing Professional Development teamed up to bring you this Continuing Professional Development initiative.initiative. initiative.

This is the ninth module in the eighteenth series and focuses on Behaviour This is the third module in the eighteenth series and focuses on Smart Grids. It This is the ninth module in the seventeenth series and focuses on Space Change. It is accompanied by a set of multiple-choice questions. is accompanied by a set of multiple-choice questions. Heating. It is accompanied by a set of multiple-choice questions.

To qualify for a CPD certificate readers must submit at least eight of the ten To qualify for a CPD certificate readers must submit at least eight of the To qualify for a CPD certificate readers must submit at least eight of the sets of questions from this series of modules to EiBI for the Energy Institute to ten sets of questions from this series of modules to EiBI for the Energy ten sets of questions from this series of modules to EiBI for the Energy mark. Anyone achieving at least eight out of ten correct answers on eight separate Institute to mark. Anyone achieving at least eight out of ten correct answers on Institute to mark. Anyone achieving at least eight out of ten correct answers on articles qualifies for an Energy Institute CPD certificate. This can be obtained, on successful completion of the course and notification by the Energy Institute, free of charge for both Energy Institute members and non-members. The articles, written by a qualified member of the Energy Institute, will appeal to those new to energy management and those with more experience of the subject. eight separate articles qualifies for an Energy Institute CPD certificate. This can be obtained, on successful completion of the course and notification by the Energy Institute, free of charge for both Energy Institute members and non-members. The articles, written by a qualified member of the Energy Institute, will appeal to those new to energy management and those with more experience of the subject. eight separate articles qualifies for an Energy Institute CPD certificate. This can be obtained, on successful completion of the course and notification by the Energy Institute, free of charge for both Energy Institute members and non-members. The articles, written by a qualified member of the Energy Institute, will appeal to those new to energy management and those with more experience of the subject.

Modules from the past 17 series can be obtained free of charge. Send your Modules from the past 16 series can be obtained free of charge. Send Modules from the past 16 series can be obtained free of charge. Send request to editor@eibi.co.uk. Alternatively, they can be downloaded from the your request to editor@eibi.co.uk. Alternatively, they can be downloaded your request to editor@eibi.co.uk. Alternatively, they can be downloaded EiBI website: www.eibi.co.uk from the EiBI website: www.eibi.co.uk from the EiBI website: www.eibi.co.uk

SERIES 17 SERIES 17 SERIES 16

MAY 2019 - APR 2020 MAY 2019 - APR 2020 MAY 2018 - APR 2019 1 Batteries & Storage 1 Batteries & Storage 1 BEMS 2 Energy as a Service 3 Water Management 4 Demand Side Response 5 Drives & Motors 6 Blockchain Technology 7 Compressed Air 8 Energy Purchasing 9 Space Heating 10 Data Centre Management 2 Energy as a Service 3 Water Management 4 Demand Side Response 5 Drives & Motors 6 Blockchain Technology 7 Compressed Air 8 Energy Purchasing 9 Space Heating 10 Data Centre Management 2 Refrigeration 3 LED Technology 4 District Heating 5 Air Conditioning 6 Behaviour Change 7 Thermal Imaging 8 Solar Thermal 9 Smart Buildings 10 Biomass Boilers SERIES 18SERIES 18 SERIES 17 MAY / JUNE 2020 - MAY 2021MAY / JUNE 2020 - MAY 2021 MAY 2019 - APR 2020 1 Energy Efficiency Legislation 1 Energy Efficiency Legislation 1 Batteries & Storage 2 Building Controls 3 Smart Grids 4 Lighting Technology 5 Heat Pumps 6 Metering & Monitoring 7 Air Conditioning 8 Boilers & Burners 9 Behaviour Change 10 Combined Heat & Power* 2 Building Controls 3 Smart Grids 4 Lighting Technology* 5 Heat Pumps* 6 Metering & Monitoring* 7 Air Conditioning* 8 Boilers & Burners* 9 Behaviour Change* 10 Combined Heat & Power* 2 Energy as a Service 3 Water Management 4 Demand Side Response 5 Drives & Motors 6 Blockchain Technology 7 Compressed Air 8 Energy Purchasing 9 Space Heating 10 Data Centre Management*

* ONLY available to download from the website after publication date * ONLY available to download from the website after publication date * ONLY available to download from the website after publication date

Terms: in submitting your completed answers you are indicating consent to EiBI’s holding and processing the personal data you have provided to us, in accordance with legal bases set out under data protection law. Further to this, EiBI will share your details with the Energy Institute (EI) with whom this CPD series is run in Terms: in submitting your completed answers you are indicating consent to EiBI’s holding and processing the personal data you have provided to us, in accordance with legal bases set out under data protection law. Further to this, EiBI will share your details with the Energy Institute (EI) with whom this CPD series is run in Terms: in submitting your completed answers you are indicating consent to EiBI’s holding and processing the personal data you have provided to us, in accordance with legal bases set out under data protection law. Further to this, EiBI will share your details with the Energy Institute (EI) with whom this CPD series is run in contractual partnership. The EI will process your details for the purposes of marking contractual partnership. The EI will process your details for the purposes of marking contractual partnership. The EI will process your details for the purposes of marking your answers and issuing your CPD certificate. Your details will be kept securely at your answers and issuing your CPD certificate. Your details will be kept securely at your answers and issuing your CPD certificate. Your details will be kept securely at all times and in a manner complaint with all relevant data protection laws. For full all times and in a manner complaint with all relevant data protection laws. For full all times and in a manner complaint with all relevant data protection laws. For full details on the EI’s privacy policy please visit www.energyinst.org/privacy. details on the EI’s privacy policy please visit www.energyinst.org/privacy. details on the EI’s privacy policy please visit www.energyinst.org/privacy. • To hear more from the EI subscribe to our mailing list: visit https://myprofile. • To hear more from the EI subscribe to our mailing list: visit https://myprofile. • To hear more from the EI subscribe to our mailing list: visit https://myprofile. energyinst.org/EmailPreferences/Subscribe energyinst.org/EmailPreferences/Subscribe energyinst.org/EmailPreferences/Subscribe

Kieron O’Toole is head of IIoT at Abtec Building Technologies

Building Energy Management Systems

Making the right connections

The Industrial Internet of Things is perhaps the biggest trend since the transition from steam to electricity. It has much to offer industry in terms of energy management, as Kieron O’Toole explains

Definitions are wide and varied but, in short, the IIoT (or Industry 4.0) refers to the connection of physical assets, analytics and people to improve insight, automation and outcome.

In more simple terms, some view it as the ‘nervous system’ of a factory or building, and of the business as a whole. Such is its potential that the

European Parliamentary Research

Service suggests governments are expecting a 10 per cent lift in

GDP from digitalisation, while a report by McKinsey estimates that value created from the IIoT will hit between $1.2 and $3.7tn by 2025.

There are a multitude of drivers at work here, including technology advancements such as artificial intelligence (AI) and machine learning (ML), current economic uncertainty, and the desire for better energy and CO2 management. Effective energy management is a real pain point as, on average, around 3 per cent of total business costs are attributable to energy consumption. However, by moving to smart infrastructure, energy savings in the realm of 30 per cent are commonplace.

A simple example of the IIoT in practice is the use of sensors to detect and monitor the amount of natural light present in a space.

This data can help determine how much supporting artificial lighting is required, with the same thinking applicable to heating.

For many, shifting to the IIoT can appear daunting, especially for manufacturers busy trying to uphold stringent delivery schedules. For this reason, the expertise of a full-service building technologies specialist can pay dividends with regard to accelerating and simplifying the entire process, particularly through the provision of thought leadership at each step of the project: design, implementation and ongoing system support.

Rapid growth in the IIoT is coinciding with a technology shift in building management systems

In practical terms, the first stage of any transition to intelligent building automation is the underpinning of IIoT infrastructure, which includes best-practice cyber security. With the core digital infrastructure in place it is possible to introduce functionality such as condition monitoring, way finding and asset tracking. By tagging goods, companies can improve their movement through facilities and along supply chains.

Sophisticated functions

The natural progression of IIoT projects can subsequently expand to more sophisticated functions, such as energy usage, personnel presence maps, and workflow. A factory building, for example, can start using its digital twin (a digital version of the entire system) to try new layouts and flows (without incurring large real-world costs) to see which result in the greatest efficiency and productivity gains. Ultimately, the IIoT generates highly intuitive improvement in how staff interact with their work, while simultaneously becoming more people-centric, via functions such as tracking, safety, personal environmental control and workspace analytics.

It is clear that the IIoT extends way beyond energy management and CO2 reduction, although these factors remain major drivers. Even energy management functions can expand past lighting, heating and ventilation control by, for instance, identifying parasitic loads such as energy-waste hotspots. An example being coffee machines or PC screens left on standby. Here, the IIoT would reveal the amount of energy consumption and its associated cost, prompting action where appropriate.

Landmark IIoT projects within our own portfolio include The Crystal, a building on Royal Victoria Dock in east London that houses a sustainable development exhibition. The Crystal, owned by the Greater London Authority and operated by Siemens, utilises a fully integrated building control system featuring KNX technology

to facilitate one of the greenest buildings in the world. Control of internal and external lighting, heating, variable air volume and windows are among the many functions.

Another example is the 21st century Eclipse factory of brick manufacturer Ibstock in Leicestershire, where sustainable infrastructure in energy utilisation and management is saving 50 per cent in lighting costs alone thanks to technologies such as automated natural light sensors and LUX adjust.

Rapid growth in the IIoT is coinciding with a technology shift in building management systems (BMS), which today use more IP-based Ethernet networks to accommodate different communication protocols. These systems are becoming increasingly complex, particularly when factoring in cyber security and other sub-systems, such as heating control. Comprehensive support for factories and buildings beginning their journey to the IIoT and ongoing efficiency optimisation, is therefore essential.

Previously, advanced manufacturing led the way on the IIoT as the efficiency gains and value-added to the end product and profits were so significant, but now every sector in the economy is seeking the same step change in value creation through smart IIoT infrastructure, smart buildings and smart spaces. Manufacturing, healthcare, services, retail and consumers have all started this change at scale in the past two years – you just need to look at the rows of smart bulbs now available on supermarket shelves. The advantages of the IIoT are not just improved energy and operational management, but in how it unlocks innovation and business agility, and leverages an organisations investment in assets, workforce and partnership.

Building Energy Management Systems

Terry Sharp is president of the Building Controls Industry Association

Training for a new normal

Terry Sharp discusses the importance of training and what lockdown has taught us about effective building management

The world is certainly a very different place today than it was a little over a year ago. As we need to learn to adapt so too do our buildings. Many will have been left empty for some time and a good proportion of general office spaces will still only be operating at a much-reduced occupancy level. The current crisis situation aside, the principles of automatic adjustment based upon demand has been at the heart of building control philosophies for years. Scaling a setpoint back or ramping a speed up based on a sensor measurement is exactly what building controls do.

Keeping occupants at a comfortable temperature is a given, but we also consider the amount of fresh air, the humidity, light levels, noise, smells and the new agenda topper... occupancy level! Where once owner occupiers were concerned about people density per square metre, it is now a case of space between people….per square metre. Where once building control technology was used to guide an occupant to a free hot desk, this same technology can be used to guide occupants through less dense areas of a building, avoiding crowds to clear, and cleaned, work spaces.

All of the above relies on the building control systems, the vast majority totally hidden from sight. Doing all of the above efficiently relies on the skills and experience of the control system design engineers. To achieve logical operation is one thing, to achieve that in a superefficient way requires training, experience and the tools, software and equipment that deliver reliable and precise control of the mechanical and electrical systems within our buildings.

There is a common assumption that a building energy management system (BEMS) will magically take care of the running of a building, whether it’s occupied or not, and lockdown has exposed some of the disconnect between building control

Coronavirus has emphasised the need for healthier and better ventilated indoor spaces

systems, occupation and comfort. Many unoccupied buildings still appeared as though they were fully open for business during lockdown because they still had all of their lights on. In contrast, building managers with secure remote connectivity in place were able to make immediate adjustments and scale everything back to a more stable pattern based on little or no occupancy.

Ability to respond quickly

Facilities managers with the ability to self-serve without the need to call on systems specialists were able to respond very quickly as they had the controls to put their building into setback modes or vacant modes easily. Clients without that level of integration had to call out different specialists in various disciplines. With an already heavy workload there were inevitably going to be delays in getting the required work scheduled. The same problem would also present itself when people start returning to work and they need to recommission the control systems and bring them back online.

Coronavirus has of course emphasised the need for healthier and better ventilated indoor spaces, and these will be vital factors for building owners to consider going forward. At the same time, we mustn’t lose sight of the long-term aims of building controls as we look to reduce the energy wastage

and carbon emissions from our built environment. We should use this time to simplify our buildings’ operation and change some attitudes towards efficient building management.

The industry is ever-evolving and the need for the existing pool of engineers to upskill and adapt is just as important as the training of young talent embarking on a career in building controls. The BCIA’s ambition is to ensure that the industry has access now, and in the future, to the skills and talent it needs for continued success by helping to unlock opportunities across all areas of the industry.

To help promote this ambition, and to commemorate its 30th Anniversary, the BCIA has nominated 2021 as its Year of Training. The value of good training should not be understated, and the interruption brought about by COVID-19 has of course affected the education sector significantly.

Last March, as we headed into lockdown for the first time, schools, colleges and training centres all over the UK were forced to close, including the BCIA’s own training centre in Peterborough. Fortunately, we were able to move all of our courses online very quickly, which allowed our aspiring engineers to continue with their development. However, as brilliant and vital as the Internet continues to be in helping us through this pandemic in many ways, online learning is not the same as sitting in a room with classmates, whether it’s at primary school or college. I am sure teachers and students alike will agree.

Many BEMS companies carry out their own in-house training, which can provide huge benefits for both the trainer and the trainee. By shadowing their seniors, apprentices not only learn practical skills first-hand, they can also develop important relationships with their colleagues and clients. The learning doesn’t have to be all one way either. With the advancements in technology our school leavers have grown up with they are already well adapted to take advantage of the myriad innovations going into buildings to help them run more efficiently in the 21st century.

Building Energy Management Systems

Chris Irwin is vice president sales EMEA & VP global marketing J2 Innovations

Lessons in classroom control

Schools need to take advantage of new innovative technologies in building automation and control to drive down energy costs and reduce carbon emissions.

School improvement projects were given a major boost last year when a £560m fasttrack investment fund was given the green light by the UK Government1. The funding, allocated for 580 building projects at academies, sixth form colleges and voluntary aided schools in England, will transform facilities and improve school buildings.

Although a vital and welcome boost for the education sector and schools building programme, the cash-injection must also act as a catalyst for investments in innovative energy-saving technologies to help drive down costs and reduce carbon emissions. There will be projects to upgrade boilers to new green, energy-efficient models as well as the complete refurbishments of classroom blocks but it is possible that there could be an introduction of better controls for buildings. The implementation of ‘smart’ controls would allow schools to track and manage the energy performance of their building environments and improve the overall energy profiles of their sites.

Underserved market segment

To address this underserved segment of the building automation market, J2 Innovations, creators of FIN Framework (FIN) - a state-of-the-art application suite for smart buildings, smart equipment and IoT applications, has developed FIN microBMS application suite - a compact feature-rich management system to control buildings across multiple sites. The entry-level FINbased system is a powerful simpleto-use plug and play solution for efficient building management that has removed much of the complexity found in many of today’s building management systems (BMS).

Maintenance staff can monitor, control and visualise all the operational and energy assets such as HVAC, lighting and security systems inside a building or buildings across numerous sites to optimise the comfort levels, safety and energy efficiency. A dashboard flags the status or health of assets as well as the maintenance requirements of all the connected devices while trend monitoring and utility metering are reported by the system. Plug & play simplifies the installation of any preconfigured hardware solutions. FIN Framework interfaces with BACnet, Modbus, KNX, OPC-UA and MQTT for linking to almost any system.

Functionality retained

This is by no means a pared-down BMS but a compact fully featured management system that retains much of the functionality found in costlier systems; making it ideal

for education settings. Data about energy usage can also be more easily shared via a common data standard, enabling leadership teams to plan more effectively.

Natively built for tags and support for the Project Haystack 4 open standard, FIN provides an intuitive user-experience with intelligent data-management, analytics and simplified workflows. J2 Innovations’ latest Edge2Cloud capability provides operators with a secure remote connection to the microBMS for accessing building data, servicing and upgrading of the system.

Outside contractor help

Budget constraints have often meant school maintenance teams are smaller in size and reliant on the help of outside contractors to come onsite to address issues or breakdowns. While this arrangement has sufficed, the remote management of heating and other controls will dramatically reduce costs and save time. FIN microBMS with Edge2Cloud technology allows engineers or subcontractors to simply log into an Amazon Web Services session to gain access to building systems where they can diagnose faults from anywhere and on any device.

Education set-ups, particularly schools are always under constant pressure deliver to greater efficiencies with limited resources. In the future, we think all schools will need to be connected by intelligent controls to manage lighting, heating and cooling. The use of smart building controls will help us create modern, fitfor-purpose spaces that are more sustainable and meet the needs of tomorrow.

Reference

Building Energy Management Systems

George Catto is client services director at AMR DNA, Energy Assets

Look forward by looking back

As lockdown restrictions draw closer to their end, George Catto looks at how energy managers are facing the challenge of how best to prepare their buildings as workers return to their desks

Increasingly, facilities management professionals are turning to advanced digital technologies, including artificial intelligence (AI), to ‘map’ different energy consumption scenarios that they can implement quickly as occupier levels change or production ramps up.

Many are looking forward by looking back, using AI to interrogate years’ worth of historic half-hourly gas and electricity data to create multiple energy consumption models that reflect differing prevailing operating conditions.

Analysing data on this scale manually would need an army of analysts – but with AI, it can be a matter of hours, even minutes to yield results.

For example, through its AMR

DNA service, metering and data services specialists Energy Assets is enabling facilities managers in multiple sectors, including higher education, retail, local authorities and commerce, to use AI to develop accurate scenario planning linked to the status of the pandemic.

This means managers can adapt quickly to changes in COVID rules and be confident that whether it’s a full lockdown, localised tiered restrictions, a ‘COVID-secure’ normal requiring social distancing, or a return to pre-COVID normality, they are in a better place to maintain optimal energy efficiency.

In scenario planning, Energy Assets uses kWIQly AI architecture to assimilate two years’ worth of half-hourly gas and electricity meter data into a performance model that can be measured against key criteria to identify waste.

Pressing challenge

Identifying and eradicating this waste can be a particularly pressing challenge in an environment of

Covid scenario planning for energy in buildings

Some buildings have always been intended for continuous occupancy, so it is not surprising that not all buildings respond to being unoccupied in the same way. However, given any set of buildings (and an energy management team) some patterns or norms emerge when occupancy levels fluctuate.

This raises questions such as: what is achievable in terms of energy reduction; is the optimal state applicable and uniform across an entire estate; where can it be improved; how will the estate respond to increased ventilation under colder external conditions; and how can energy purchasing decisions best reflect the di erent scenarios?

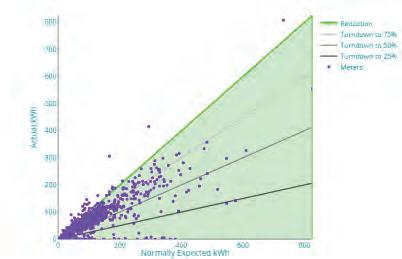

What is needed is a strategic approach. These graphs from AMR DNA illustrate how AI can help.

Fig. 1 represents a set of buildings belonging to one owner where each dot is a gas meter. Some buildings have been switched o entirely (bottom line).

Fig. 1

While it can be seen that one very large building (top-right) and a handful of others have increased consumption, the majority have seen a 20-40 per cent reduction over normal operating conditions, depending on the level of turndown. Having this knowledge means that managers can assess opportunities for additional energy saving measures.

Fig. 2 shows on top a weather adjusted model by time of week and outside temperature (from which daily profile averages given forecast temperature can be calculated).

The section below shows the single daily profile of actual consumption (blue bars) compared with achievable (grey shaded). This immediately illustrates a problem; that although consumption inside occupancy (core hours) has improved, during evenings and before occupancy the consumption has risen.

Having this information to hand enables energy consumption under di erent scenarios across portfolios to be accurately tracked automatically, to identify not just the impact of turning down but also where buildings are not responding as anticipated. As well as enabling follow-up action, this data can greatly assist with budgetary and forecast scenario planning.

Fig. 2 change, when building occupancy levels are fluctuating. In any portfolio, site-by-site performance varies with respect to its indicators, benchmarks and relative to prior performance. For example, by how much consumption falls overnight.

In the case of AMR DNA, AI finds and flags up areas for energy efficiency improvement because the system progressively ‘learns’ what best performance looks like.

From this benchmark, energy managers can use the AI-driven model to develop building profiles that fit multiple contingency planning scenarios and to sharpen their energy procurement strategies.

Since COVID, ‘what is necessary’ has changed, as have metrics of cost. Pre-pandemic it was enough to measure and predict kWh in terms of normal operations and interpret cost around carbon impact and money.

Rarely was health considered a ‘cost factor’. However, requirements to keep a building healthy have changed, and not in one dimension. Today, COVID means that energy and facilities managers need to take account of ideal temperatures, air-change rates, humidity, fresh-air circulation, heat recovery strategy and even comfort. Why comfort? - because breathing through PPE changes ambient requirements.

What is quickly becoming apparent is that COVID is challenging our conventional understanding of energy management systems and how meter data can positively affect scenario planning. This ability to forecast what the future can look like, and adapt quickly to changing circumstances, is gaining a lot of interest because no organisation can afford to burn money unnecessarily in today’s trading climate.

Being able to implement new scenario strategies quickly also gives managers the ability to revise their energy buying strategies with confidence, because they have a clearer understanding of their future requirements based on data-driven insights rather than guesswork.

Building Energy Management Systems

US company uses BACnet controller to bring BEMS up to current standard

Contemporary Controls’ BASpi-Edge cloudconnected BACnet controller and BASview3 standalone, embedded, web-based graphical interface have been instrumental in helping Florida, USAbased Karl Corporation convert an older BEMS in a commercial multi-storey building to current technologies. Because Contemporary Controls is a long-time supporter of open software, the BASpi-Edge and BASview3 do not use proprietary programming languages, programming tools or have licensing restrictions.

Karl Corporation replaced the legacy system in a ten-storey, 9,300m2 commercial office building. Ten BASpi-Edge units were used for the floors, plus one for rooftop control and one for a fresh air unit. The BASpi-Edge series are hardened controllers with enhanced features and data processing at the Edge functionality, powered by Raspberry Pi.

A typical floor has a single BASpi-Edge 6U6R for controlling individual or zoned HVAC units and lighting loads. A BASpi-Edge 6U4R2A was used for control of the rooftop machinery including the fresh air makeup unit, where building managers tracked the temperature monitoring feature and stage on three compressors and two heater strips. Additionally, the BASpi-Edge managed two cooling towers with variable frequency drives providing control over speed and power; two circulation pumps on the tower; an air scrubber for restrooms; common rooftop lighting; and power control of the buildings fresh air makeup units.

A BASview3 was used for scheduling and trending. It simplified day-to-day operations, holiday exceptions, building overrides and trending services that are necessary with a large, busy building. The BASview3’s graphics made final management reports easy to generate and understand.

The BASpi-Edge handles requests from the tenant via a webpage on the internet. Used for after-hours A/C and lighting overrides, the BASpi-Edge allows the default energy consumption to be low. However, tenants can override those settings and that override can be tracked so the building owners can allocate costs. The tenant web-based A/C override uses the BASPi-Edge’s internal REST API, which can be used to interface between third-party, legacy, or non-BACnet devices, applications or data servers.

Compressed Air

Roy Brooks is technical development officer for the British Compressed Air Society

A standard set for success

Roy Brooks explains why operators should carefully consider all parts of a compressed air system during the specification process

In a typical compressed air system, there are a wide range of contaminants that require treatment if the system is to operate safely, efficiently and cost effectively. Selecting the right compressed air treatment equipment is essential as it can affect everything from maintenance schedules to the ongoing costs associated with achieving the required standards.

Compressed air can contain up to ten different contaminants, which need to be treated correctly.

These tend to be combined into three distinct categories: particles (including viable and non-viable microbiological organisms), water and oil. ISO 8573-1 refers to the main contaminants in this format.

When selecting purification equipment, it is important to note that contaminants will be in one of three different phases (states of matter). For example, water and oil in a compressed air system will be found in liquid form, as an aerosol (fine mist) and in a vapour (gaseous) phase. A different purification technology will be required depending upon the phase of the contaminant.

Depending on the application, there are number of different compressed air standards and best practice guidelines which can be used to assist.

ISO8573 series is the most commonly used standard for compressed air (excluding breathing air or medical air). It is made up of nine separate parts. Part 1 refers to air purity (quality), while parts two to nine provide details on the equipment and methodology to be used to measure for different contaminants in a compressed air system (and meet the air purity (quality) classifications shown in part one).

ISO8573-1 – International Standard

Relating to Compressed Air Purity (Quality) ISO8573-1 provides guidance on specifying the air purity (quality) required for the entire compressed air system and/or for individual usage points, based upon

Check list: selecting the right compressed air treatment equipment is essential

application requirements.

In addition, there are also specific requirements for compressed air that comes in to direct or indirect contact with food or beverage products as well as the HTM02-1 purity recommendation for medical and surgical air and HTM2022 for dental air. Finally, BS EN 12021:2014 is the standard for breathable air, indicating maximum permitted contaminant levels in the UK and EU.

Define the air purity required

Whether designing new systems, or reviewing existing systems, the first step should be to define the precise compressed air purity (quality) requirements for the application.

For example, where compressed air comes into direct contact with food/beverage, in particular during production or processing, this requires a much higher level of contaminant control. Particular attention needs to be placed on sources of contaminants entering the system, that may be added during compression or emanating from the distribution system.

Due to the variations in the design of compressors, some require oil in the compression stage, and some do not. For food/beverage production where the compressed air comes into direct contact the amounts of oil present and type of oil allowed are subject to strict controls.

To achieve the degree of air purity (quality) specified by ISO8573-1, a careful approach to system design, commissioning and operation must therefore be adopted.

Best practice is to treat compressed air prior to entry into the distribution system and at critical usage points and application, to ensure that contamination already in the distribution system is removed.

Purification equipment should ideally be installed where the air is at the lowest possible temperature, i.e., downstream of air receivers, but also protected from freezing. Point-of-use purification equipment should be installed close to the application.

To allow correct sizing and selection of purification equipment, operators should have the following operating parameters to hand: • the maximum compressed air flow rate into the filters/dryer; • the maximum operating temperature into the filters/dryer; • the maximum ambient air temperature where the equipment is to be installed (required for some dryer technologies); and • the required dewpoint (dryers).

Individually, each of the primary operating parameters can influence product sizing. However, collectively they can have a major impact on product sizing and performance.

Many manufacturing plants only need a proportion of the compressed air to be treated to a very high purity (quality). In these cases, excellent savings are achievable by treating all the generated air to the minimum acceptable level and improving the purity (quality) to the desired level at the usage point.

To assist users BCAS has launched its new, blended learning workshop for ISO 8573 (http://bit.ly/BCASISO8573), now available with 25 per cent off course fees for customers of BCAS members.1

This latest course in the Society’s portfolio explains the importance of considering all parts of a compressed air system during specification, for suppliers, energy consultants, service providers or end users alike. • Follow the link to learn more about the course https://bit.ly/BCAS-ISO8573. In addition, detailed guidance can be found in the ‘Filtration and Drying of Compressed Air - Best Practice Guide 104 at www.bcas. org.uk/airtreatment.

Reference

1) The free associate membership and 25 per cent discount offer is only available to end-user customers of BCAS members. Trade customers are not eligible.

Alexander Pavlov is general manager, Atlas Copco Compressors UK

Compressed Air

Compressed air and green production

Energy costs make up over three quarters of a compressor’s total cost of ownership. Alexander Pavlov examines the economics of investing in green compressor technology

Recent studies by the Carbon Trust have revealed that despite pandemic disruption and extremely challenging market conditions, over 70 per cent of companies are continuing to prioritise sustainability and environmental management issues.

Since 10 per cent of global electricity consumption goes to generating compressed air, a place where air compressor manufacturers can make a real difference is in developing solutions that make compressing air more energy efficient and that support manufacturers in their journey towards carbon-neutral production.

Energy costs make up 80 per cent of a compressor’s total cost of ownership. So, investing in environment-friendly compressors, and optimising existing air systems that use significantly less energy, can sharply reduce both the production cost of compressed air and a company’s carbon footprint.

Higher purchase price

But how much energy can be saved by going green? This is a particularly important question for smaller companies, which may be concerned about the higher initial purchase price of an energy-efficient compressor. To some, it might seem that the “safe” option would be to take the risk of keeping on using their old compressor even though it attracts a disproportionately high electricity bill.

The fact remains that not switching to environment-friendly technology is much riskier. It invites a degree of uncertainty about equipment reliability and ability to maintain production processes.

Green air compressors provide stability. They guarantee that a company will lower the production cost of compressed air, protected from fluctuating energy prices. A green compressor offers greater reliability, longer maintenance intervals and ensures compliance with all current and upcoming emissions standards.

Pick the right model

While environment-friendly compressors are all about efficiency, picking the right model still matters. That means buyers have to be aware of their compressed air needs. How much airflow and pressure do they need and for which applications? Will the compressor run constantly or intermittently? How important is air quality? Does the air demand fluctuate or remain steady?

Carrying out a non-intrusive energy audit to measure the efficiency of an existing compressed air installation, involving the use of data logger, is the best way to discover possible energy savings from a compressed air system. Combined with plans for specific future requirements, this data allows plant operators to understand and improve their system’s energy efficiency.

It also answers many of the questions that help to determine the ideal size and type of compressor − whether a model with variable speed drive is better for fluctuating air demand, whether a piston compressor is sufficient for intermittent use and limited air demand, or is a rotary screw compressor best suited for the application need.

If an application requires a constant speed at all times, then a fixed-speed compressor will often get the job done. Once it is switched on, it gives full power. Most industrial applications, however, have a fluctuating air demand. In that case, a variable speed drive (VSD) compressor is the better choice because it matches output to user demand and will realise considerable energy savings in the long run.

Compressors are a prime example of how pronounced the difference can be between initial investment and the total cost of ownership. This comprises the cost of buying, owning, and operating it during its lifetime. As a rule, because of manufacturers’ technology developments embodied in advanced, environment-friendly compressors, these units may carry

Compressors are a prime example of the difference between initial investment and cost of ownership a higher price tag, but they also offer much lower operating costs, which provide payback in the long run.

In fact, the initial investment constitutes only a small fraction of the TCO. Energy costs make up the bulk of it and will likely become an even more important issue in the near future. Therefore, premium quality compressor products capable of energy-saving operation must offer the best investment option.

Apart from the basic function of providing an air supply to production processes, green compressor technology can contribute to comfortable workplace environments while at the same time achieving significant energy savings. This is when its heat recovery role comes into its own.

Instead of letting it go to waste, purchasing a compressor with integrated energy recovery or installing a heat recovery system between the compressor and the cooling- and heating circuits will recover and re-use 70-94 per cent of the energy required to run a compressor. The hot water, heated up to 90oC and recovered from the compressed air system, can be used for sanitary purposes and space heating but is particularly suitable for process-heating applications.

Regular maintenance

A compressed air system should be regularly maintained, continually monitored, and carefully controlled. While the support of the supplier’s scheduled maintenance plans should be mandatory, to ensure the system’s overall health and performance, the compressor user’s day to day operational vigilance is equally crucial.

A simple example is that of the working air pressure. A higher pressure means increased energy use, which means higher production costs. An increase of just one extra bar of pressure results in an average of 7 per cent more power required.

The best way to manage a compressed air system is to install a state-of-the-art master control system that monitors its efficiency, availability, and reliability. Not only can it detect problems, but it can automatically reduce the working pressure – and energy costs - when the air demand is low.

Compressed Air

David Bruchof is product manager for oil-free screw compressors at CompAir

Opting for oil-free

David Bruchof discusses how oil-free compressed air solutions can help energy and facility managers save money while improving site efficiencies too

Often referred to as the ‘fourth utility’, compressed air is vital for businesses in industry. Any supply of compressed air must be consistently available in high volumes, while being of sufficient quality too. This quality is even more important in sites where goods absolutely cannot be compromised, such as in the production of electronics or healthcare sites.

Contamination can disrupt processes such as product drying, material handling and process air, as well as damage air curtains, control valves and cylinders, alongside other tools. As such, this can be a significant challenge for energy managers, with issues resolved at potentially great expense.

Avoiding process contamination is a necessity for sites using compressors. Fortunately, there are rigorous standards in place governing compressed air performance and provision in these environments, ensuring processes remain free from contaminants – or they are reduced to acceptable levels – while minimising unscheduled downtime and the associated costs, too.

These regulations include ISO 8573, a group of international standards stipulating compressed air purity and quality. ISO 8573 consists of nine separate parts, with part one identifying contamination levels that can be tolerated within a single cubic metre of compressed air. Specifically, part one identifies permitted particle count, pressure dewpoint and amount of oil allowed within this sample.

The other eight parts detail testing methods for a range of contaminants, including solid particles, oil vapour, organic solvents, microbiological contaminants, liquid water and gaseous contaminants, alongside humidity levels and aerosol content. They also ensure that air quality test results are comparable within a given tolerance of measurement.

Staying in control: many businesses are switching to oil-free compressors

By design, ISO 8573 is very strict and thorough. However, many site owners and operators are going beyond its standards to guarantee high-quality compressed air, instead adopting the principles of the Hazard Analysis Critical Control Point (HACCP). This ensures facilities are complying with hygiene legislation and either eliminating any potential hazards or reducing them to an acceptable level.

In some cases, high-quality air is achieved by using oil-lubricated compressors, which rely on filtration to protect products and equipment from contamination. However, to guarantee air purity, many businesses are switching to oil-free compressors.

Oil-free systems use a range of technologies that bypass the need for oil. With oil-lubricated compressors using oil in the compression chamber to cool and seal the compressed air, oil-free solutions will never use oil here. This eliminates the risk of contamination and ensures guaranteed air purity.

There are many benefits to oil-free technology, which can help energy managers make valuable cost savings while improving operational efficiencies too. Whole life costs are reduced, with businesses able to save on the cost of oil replacement. Unlike oil-lubricated systems that require oil change intervals throughout their service life, there is also no need to purchase equipment that would clean and separate oil from air, such as oil separators, filtration equipment and condensate treatment.

Improve site efficiencies

The latest oil-free solutions take advantage of innovative technologies to help improve site efficiencies, too. CompAir’s Ultima compressor, for examples, uses its efficient U-Drive concept to maximise compressed air production. Traditional two-stage compressors use a single motor and mechanical gearbox design to drive the low and high-pressure air-ends. In contrast, Ultima replaces the gearbox and single motor with two high-efficiency, permanent magnetic motors, allowing for performance optimisation throughout the complete volume range. This technology offers energy efficiency savings of up to 13 per cent when compared with other traditional, two-stage oil-free compressors. The motors are powered by two separate inverters, so they can be individually driven at different speeds depending on demand. An intelligent digital gearbox design then monitors and continuously adjusts the speeds of each aired, ensuring maximum efficiency and pressure ratios at all times. Most importantly, the compressed air it delivers is 100 per cent oil-free.

Other benefits include its bestin-class noise levels and footprint, which is 37 per cent smaller than the industry standard, as well as the digital platform iConn, which Ultima comes with as standard. This enables operators to take advantage of real-time data to better manage and monitor energy consumption, improve process efficiencies and limit any risks.

Should organisations want to improve their green credentials even further, then heat recovery is also an option, on both air-cooled and watercooled models. With 94 per cent of compressor-generated heat capable of being recovered, this can prove invaluable for businesses looking to make efficiency gains.

The Ultima compressor also comes with a six-year extended warranty, completely free of charge, including all main components such as airends, motors, inverters and coolers.

Finally, with many businesses faced with ambitious sustainability goals, deciding on an oil-free solution is the most eco-conscious choice, and can help contribute towards a site’s green credentials. For example, while oil-lubricated compressors mean oil or oil-contaminated condensate will need to be disposed of, impacting the environment, this is not a concern with oil-free technology.