37 minute read

The Fundamental Series: CPD Learning

MARK THROWER MANAGING EDITOR

SERIES 18 | MODULE 08 | BOILERS & BURNERS

Advertisement

Boilers and burners

By Paul Stevenson, Larkdown Environmental Ltd

Boilers are everywhere. They fall into three main sectors: • residential and domestic: generally small scale and often gas, but can be: a) electric-powered, especially in high-density buildings; b) electric/ oil/ solid-fuel/ bio-mass: mainly for buildings off the gas grid; c) larger, central boiler with district heating systems (DHS - e.g. multistorey or mixed-use buildings); more common in central/ east Europe, former Soviet states and China than

UK; • commercial and service: often larger, centralised boilers servicing the hot-water (HW) and space heating needs of offices, hospitals and care-homes, retail and warehousing, hotels, sports and leisure centres, etc; and • industry: lots of large scale and bespoke boilers for chemicals, food and drink, metals, apparel and engineering sectors. Several industries have technical uses for steam or HW. This article does not cover energy efficiency (EE) in steam boilers.

This article focuses on moderate to large fossil-fuel boilers, used for

HW and space heating found in the commercial and service sectors.

Natural gas is the predominant fuel, because the unit cost per kWh is much lower than other fuels and its exhaust gases are “clean”. It explores energy and CO2 savings technologies and techniques, covering: • improving efficiency away from the boiler: what can one do to reduce the demand for space heating and HW? This should always be the first thing to consider in any energysaving/ low-carbon initiative; • energy efficiency and gas boilers: there are many gas-boilers that are going to be around for decades, so what can be done to improve their efficiency?; • boiler design: if and when installing or replacing a (gas) boiler, what

Photo courtesy Remeha/Owen Mathias

should one consider?; and • boilers of the future: briefly exploration of the options for large scale de-carbonisation for space heating and HW. The UK Government recently pledged to ban fossil fuel boilers for all new residential builds from 2025; other sectors will likely follow.

There are many good publications, available on the internet, that will give a wider coverage of specific areas. Sources are provided towards the end of this article.

When carrying-out a general energy audit, it is good practice to work backwards from end-use(s), via the distribution system to the point of generation. Boilers and hot-water systems follow the same logic; for instance, it is pointless installing and operating a super-efficient boiler if the building is only partoccupied, has badly fitted windows and doors, hot-water is leaking from a tap, or much of the heat is lost via poorly insulated pipes. This may seem obvious, but the author has encountered numerous instances where focus was given solely to the boiler without first considering the end-uses and the distribution system that takes it there.

Attention should be given to the building fabric including: wall and roof insulation, double-glazing, draft-proofing. Clearly, it is better to design-in from the start rather than retrofit, but retrofits of older style windows (that need replacing anyway), enhanced loft insulation or cavity wall insulation and attention to external doors to ensure they close properly all help reduce the load on the boiler (and the air-con).

The boiler’s performance over time should be monitored to compare its consumption against meaningful measures of activity, such as building occupancy and heating degree-days. This creates a good base line against which any progress can be measured.

Compare performance

A building energy management system (BEMS) that has the boiler and HW system as one of its key energy centres allows the energy manager to compare performance on a like-forlike basis as well as identify recurring issues that cause high consumption. This systematic approach also allows the energy manager to measure “before” and “after” performances. From this he/she can quantify the benefits, which is a key step in any formal energy management system (EnMS), such as ISO50001.

With the BEMS the energy manager should, where practical,

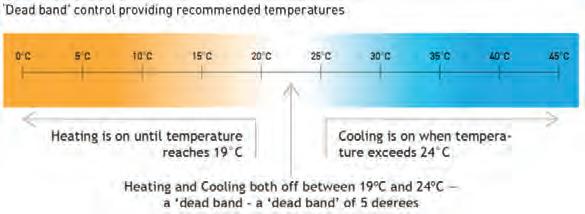

disaggregate the building into meaningful zones. There is no point heating unoccupied or infrequently used areas. If it can’t be controlled automatically, can it at least be controlled manually, for instance, are there valves to shut-off radiators or entire floors? In addition, the BEMS should be programmed to introduce a “dead-zone” – i.e. no heating or cooling between 20-24°C.

Both CIBSE and Carbon Trust advice is that warming should be needed only if temperatures fall below 19°C. Cooling should only kick in when temperatures rise above 24°C and there should be a “deadband” between these temperatures where neither heating nor cooling takes place.

Temperature control should be automatic and tamper free, ideally controlled by the BEMS. This eliminates potential conflict - where the heating is trying to warm the building whilst the AC is trying to cool it. Yes, this does happen!

Engage with staff to explain what is being done and why. People need to be aware of their impact and understand how they can help; once aware they are more likely to “buy-in” and even replicate it at home.

When it comes to hot-water distribution eliminate leaks and misuses of both water and heat e.g. washroom taps. Insulate pipework and HW tanks, introduce controls and sensors, such as passive infra-red (PIR) to prevent unnecessary room heating, etc. Again, all this sounds obvious, but there are plenty of examples where it doesn’t happen.

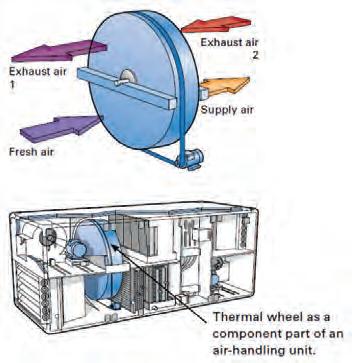

Introduce a strategy to maximise heat recovery. Building heat-recovery is already well established, for instance plate heat exchangers, thermal wheels and run-around coils to pre-heat incoming air.

Hot water is not as easy, but for frequently used showers in sport and leisure facilities, hotels and homes, one can retrofit waste-water heatrecovery (WWHR), which captures heat from the discharge to pre-heat make-up water.

Attention to these opportunities offers excellent savings of 20-30 per cent or more, especially if the area hasn’t had attention for many years. They also offer excellent financial returns, with paybacks typically < 5 years and sometimes < 1 year.

Figure 1: Use of the dead band can cut energy use

It also helps future-proof the building against ever-tightening legislation on efficiency minimums. For instance, “F” and “G” rated buildings will soon be unrentable; over the next 10-20 years this will likely apply to “E” then “D”. The author’s advice would be to consider what the requirements are likely to be needed 20-years hence, and make EE interventions that meet these requirements, even if the payback is between 5-10 years.

Finally, any new investment in a new boiler will now be correctly sized. The boiler no longer needs to be 20-30 per cent bigger to service 20-30 per cent avoidable waste!

Millions of gas boilers

There are millions of gas boilers in the UK and they are likely to be around for decades to come. An audit of the boiler can often identify numerous no/low-cost energy (and water) savings, typically between 5-20 per cent. If the boiler is very old, poorly sized for the site’s current needs, or has not been properly maintained for years, then saving potential can be even greater.

Most equipment operates best when new. Regular and effective maintenance is needed to sustain optimum performance. Most boilers and their burners are serviced at least annually for continued safe operation. This is mandatory. The other reason for maintenance is optimum performance. This is not mandatory and therefore is considered less important, but attention can lead to reductions in energy and operation costs.

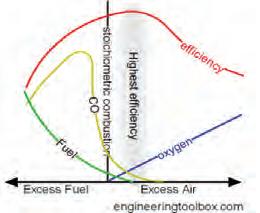

Maintenance needs to address three main areas where the efficiency can worsen over time: • combustion efficiency: releasing the heat from fuel, i.e. the burners; • heat transfer efficiency: getting heat from products of combustion into the water; and • reducing boiler heat loss.

A first step is to optimise burner’s gas air ratio or balance. In effect, “tuning” the burners. Too little air, and one gets incomplete combustion, poisonous carbon monoxide emissions and poor efficiency. Too much air, one gets complete combustion, but lots of heat is lost in the excess air. Just right, and one has complete combustion but with minimum heat lost up the exhaust. Ideally, one wants to reduce excess air ideally to <5 per cent O2 in exhaust.

One approach is oxygen trim control. This is an on-line analyser of O2 in flue gas, with computerised control that opens/closes air damper. Boiler efficiency improves 1-5 per cent, with a typical payback <2 years.

Variable speed drive (VSD) motors for the air inlet (or exhaust – depending on the set-up) can be used to control the gas:air balance. Furthermore, VSD control reduces the electricity required to drive the fan, offering power savings of 10-30 per cent compared with valves or dampers.

Flue-gas dampers should be considered. During boiler stand-by, natural convection creates air flow through the boiler to the flue, resulting in heat transfer from the water and equipment to this air, which is then lost via the chimney. If boilers are put on stand-by regularly, total losses can be large. A shut-off damper restricts airflow through the flue and prevents heat loss. Dampers are particularly suited to intermittent use, or where regular on/off boiler cycling is needed to maintain the required pressure/ temperature. Automatic, gas-tight, shut-off dampers or automatic, air-sealing damper at the combustion-air fan inlet are both widely available.

An “economiser” is a gas-to-water heat exchanger located in the exhaust gas flue. It captures heat from the exhaust, typically at 200°C, to pre-heat cold make-up water going into the boiler. During normal boiler operation, the economiser receives a continuous flow of make-up water, matching heat “source” with heat “sink”. Typical energy savings are 3-5 per cent, with payback of 2-4 years.

Excess heat can also be used to pre-heat the air going to the burners. Raising the air temperature by 10°C offers approx 1 per cent boiler energy efficiency. This is more common in large, continuous industrial boilers.

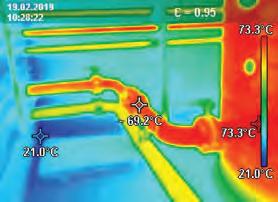

Heat is lost from the surface of the boiler through a combination of convection and radiation heat loss. In a modern, efficient system, radiation loss from the boiler should be less than 1-2 per cent. However, this can reach 10 per cent for older boilers that have degraded, or with poor insulation/ loss of casing.

Figure 2: Thermal imaging can identify areas of boiler heat loss Renewable energy options

Explore renewable energy (RE) options: such as solar thermal or air-sourced or ground-sourced heat pumps (ASHP or GSHP) to pre-heat make-up water going to the boiler. Look at capturing heat from other sources to pre-heat water, such as refrigerant or air compressors.

Inevitably, a boiler will come to the end of its serviceable life. For the immediate future, most organisations are going to replace with gas boilers. The first thing to do is to

pay attention to the system losses previously mentioned.

Then, ensure the boiler is correctly sized (capacity-rating) for its application, with a little (but not excessive) over-capacity. It’s difficult for an oversized boiler to work close to its optimum efficiency if it is regularly operating at only 10-20 per cent of capacity.

Always target an “A” rated boiler, ideally on the enhanced capital allowance (ECA) scheme’s energy technology list (ETL). This is a peerreviewed list of the most efficient equipment, including boilers.

The ECA’s Tax Credits Scheme has now come to an end. Although this eliminates the tax benefits, the assessment of high-performing equipment is still valuable.

For organisations with large seasonal variations consider boiler “cascade” systems, which comprise two or more smaller boilers. These are set up in a modular manner to allow individual boilers to work closer to max efficiency. Also, one can carry out planned maintenance on one or two units while others are doing the work. An example is Worcester-Bosch GB162 (each unit 50-100kW thermal output). For larger heat demands, the GB162 can be set-up in any combination of 2 to 8 boilers either in-line or back-to-back, using the Bosch cascade kits.

These units can operate individually and are efficient at a high turn-down (i.e. can operate close to max efficiency at only 20 per cent capacity pull), which offers greater seasonal flexibility.

Consideration can be given to biomass boilers that generate heat from burning logs, wood chips or wood pellets. Properly sourced biomass is considered a renewable (i.e. carbon neutral) alternative to fossil-fuelled boilers and currently attracts the renewable heat incentive (RHI). This makes their uptake attractive, especially in areas not on the gas grid. To attract the RHI, the boilers must meet the current legislation controls for air quality, plus other Ofgem requirements.

Many countries, including UK, have committed to being “net zero” carbon by 2050. This is a challenging target, but it is achievable. Clearly, there will still be a need for HW and space heating, and most likely this

Figure 3: Boosting the temperature of boiler supply air can save energy

will still come from boilers. Looking forward, there are several routes towards no/ low CO2 boilers.

Overall building e iciency

The first step is to take insulation and overall building efficiency to the next level as detailed earlier.

All-electric boilers - with electricity from RE sources - are on the horizon. Immersion heaters and inline/ instantaneous electric water heaters are an established technology. The reason they aren’t widely adopted is cost. Electricity is 3-5 times the unit cost per kWh than natural gas.

However, the financial impact from CO2 emissions is currently only being felt gently. The UK is constantly increasing its proportion of RE electricity, phasing out coal and gaspowered stations, so CO2/kWh for electricity will continue to fall, but gas will remain at 0.185 kg/kWh (more like 0.20 – 0.24 per kWh thermal). For 2019, electricity emitted 0.256 kg/ kWh, compared to 0.460 in 2012 and >0.5 in 2008. It is predicted to fall below gas sometime in the 2020s.

Electric heating can be augmented with air-sourced and groundsourced heat pumps (= renewable energy). These still use electricity, but generate between 2-4 times the thermal output per unit electricity. Realistically, they are only viable as underfloor heating in modern, well-insulated buildings. Also, their efficiency in the coldest parts of winter is poor and they will need some augmenting for HW.

The idea of using gas boilers with carbon capture and storage (CCS) is a non-starter. For CCS to work effectively, it needs large point sources of clean CO2 emissions. Trying to capture the CO2 from lots of smaller boilers will be impossible.

Bio-gases, such as syngas or anaerobic-digestion methane, are more likely to be generated large scale and applied to industrial processes where zero/low-carbon technologies - such as steel, ceramic or cement manufacture - are particularly “hard to reach”.

Being part of a larger district heating scheme can make use of: • energy-from waste schemes, either heat only or CHP; • heat recovered from industrial sites or large heat-sinks, for example underground transport systems; and • bio-gases and other RE sources. These are happening, although as mentioned, the UK is not well geared-up for DHS.

Hydrogen-fuelled boilers have been much heralded (hyped?). It is more akin to gas-air burners, but hydrogen has very different flame characteristics, so the boilers would need new burners.

Figure 4: Creating combustion efficiency

In addition, one has to consider the source of hydrogen. The first method is steam methane reforming (SMR) of natural gas i.e. “blue” hydrogen. However, the SMR process is energy intense and not all the CO2 is captured, so it’s only low-carbon. Also, the CO2 needs CCS: which is both energy intense and still unproven at large scale.

The second method is hydrolysis with RE electricity = “green” hydrogen. The issue this raises is: why not maximise direct use of this RE electricity and eliminate the intermediate processing?

Finally, there needs to be a method of delivering hydrogen to its to pointof-use. This would mean either taking over the gas network (huge logistical challenge), or compressed hydrogen cylinders at 300-700 bar. This would require extra energy for compressing then transporting the hydrogen.

Hydrogen could be used for cracking oil, ammonia manufacture, heavy goods/long-distance transport, perhaps metal refining, plus some accessible storage during winter months. But it isn’t a panacea. Hydrogen will be energy intense and (for SMR + CCS) appears a risky route to de-carbonisation.

Further reading

“Steam and high temperature hot water boilers”, Resource Efficiency Scotland. https://energy.zerowastescotland. org.uk/sites/default/files/Module%20 2%20%20Steam%20and%20High%20 Temperature%20Hot%20Water%20 Boilers%20-%20Energy%20Efficiency%20 E-module.pdf CTV052 “Steam and high temperature hot water boilers” Carbon Trust, 2012 (no web link) GPG 382: “Energy efficient operation of heat distribution systems” Carbon Trust 2005 (no web link) Energy Efficiency: Steam, Hot Water and Process Heating Systems, Victoria State, 2015. https://www.sustainability. vic.gov.au/-/media/SV/Publications/ Business/Efficient-business-operations/ Energy-efficiency-for-business/Energyefficiency-best-practice-guidelines/SRSBBPG-Heating-Manual-Mar-2015.pdf?la=en. “Heat Pumps: Integrating technologies to decarbonise heating and cooling”, Copper Alliance, 2018. https://www.ehpa.org/ fileadmin/user_upload/White_Paper_Heat_ pumps.pdf “A Guide to Hydrogen” Energy Institute - Energy Essentials, 2020. https:// knowledge.energyinst.org/__data/assets/pdf_ file/0008/742625/Energy-Essentials,-A-UserGuide-to-Hydrogen,-Energy-Institute-2020. pdf#Energy%20Essentials%20PDF

Please mark your answers below by placing a cross in the box. Don't forget that some questions might have more than one correct answer. You may find it helpful to mark the answers in pencil first before filling in the final answers in ink. Once you have completed BOILERS & BURNERSPlease mark your answers below by placing a cross in the box. Don't forget that some questions might have more than one correct answer. You may find it helpful to mark the answers in pencil first before filling in the final answers in ink. Once you have completed the answer sheet, return it to the address below. Photocopies are acceptable. SMART GRIDS Please mark your answers below by placing a cross in the box. Don't forget that some questions might have more than one correct answer. You may find it helpful to mark the answers in pencil first before filling in the final answers in ink. Once you have completed the answer sheet, return it to the address below. Photocopies are acceptable. SPACE HEATING the answer sheet, return it to the address below. Photocopies are acceptable.

QUESTIONS1) The establishment of the main QUESTIONS QUESTIONS ■ Waste water heat recovery from showers ■ Facilitate the connection of distributed transmission grid began in which 1. Which is the most common heating media in ■ Solar thermal panels to pre-heat boiler water renewable generation and variable loads 6. Which is the ‘delivery end’ of a vapour 1) What would be the most sensible order of decade? wet systems? such as electric vehicles and heat pumps compression heat pump system? actions to improve the overall efficiency of a building’s thermal energy needs? ■ 1940s ■ 1930s ■ High temperature hot water ■ Steam 6) Which of the following would help improve the energy performance of a building? 7) What does the abbreviation VPP stand for? ■ The evaporator ■ The condenser ■ ■ ■ “(a) Tune” existing boiler, (b) buy new boiler, (c) attention to EE at end-uses, (d) distribution system (a) Attention to EE at end-uses, (b) distribution system, (c) “tune” existing boiler, (d) buy new boiler (a) “Tune” existing boiler, (b) attention to EE at end-uses, (c) distribution system, (d) buy new boiler ■ 1960s 2) Which key parameters need to be controlled by smart grids? ■ Voltage and frequency ■ Frequency and current ■ Voltage, current and frequency 3) What’s the main source of large-scale ■ Low temperature hot water ■ Cold water 2. What is the most common space heating fuel in the UK? ■ Fuel oil ■ Electricity ■ Natural gas ■ Establishing a formal EnMS with boilers and HW/ space heating as a key centre ■ Attention to the BEMS, ideally with maximum feedback and minimum staff interference ■ Regular servicing and maintenance of the boiler and HW system ■ All of the above 7) What is the CIBSE and Carbon Trust ■ Volume purchase programme ■ Voluntary protection programme ■ Virtual power plant 8) Electricity cannot be stored in large quantities by householders? ■ False as only large utilities and industrial/ commercial energy providers can provide storage facilities ■ The compressor ■ The slinky 7. Which of these factors is used by a weather compensation control system? ■ Building thermal inertia ■ Time of day ■ Outside air temperature ■ (a) Attention to EE at end-uses, (b) “tune” existing boiler, (c) buy new boiler, (d) distribution system renewable generation connecting to the grid? ■ Biomass ■ Coal 3. What is a typical dry bulb space temperature recommended “dead band” or zone where not building heating of cooling should take place? ■ False ■ True as householders can store electricity in standalone batteries or when charging ■ Date 8. Which of these factors is used by an optimum 2) What savings might one reasonably expect from paying attention to the thermal system away from the boiler? ■ 5-10% ■ 10-20% ■ 20-30% ■ 30-50% 3) Which of these in NOT a good reason for paying attention to the space-heating and HW requirements of a building? ■ Makes energy cost and CO2 emission reporting easier ■ Helps future proof the organisation against tightening low-carbon legislation ■ Means any new boiler purchase in the future will be correctly sized for its needs ■ Wind farms ■ Solar farms 4) What are the main forms of variable electrical loads connecting at the household level? ■ Electric vehicles and heat pumps ■ Smart meters ■ Home automation devices 5) What is the main threat to smart grids? ■ Cost of implementation ■ Cyber attacks ■ Lack of experience and expertise for a home? ■ 160C ■ 190C ■ 220C ■ 240C 4. What is currently the most common construction material for panel radiators? ■ Cast iron ■ Pressed steel ■ Cast aluminium ■ Copper 5. Which of these is a key component of a ■ 18-25°C ■ 20-24°C ■ 19-21°C ■ 20-22°C 8) Which of the following is a mandatory EE intervention? ■ Flue gas dampers for when boiler is on stand-by ■ Regular maintenance and tuning of the boiler ■ Variable speed drive fans for the inlet air ■ Installing an economiser to recapture heat from the exhaust gases 9) What is “green” hydrogen? ■ Hydrogen from hydrolysis using electricity ■ Hydrogen from hydrolysis using RE their electric vehicles 9) What is the main benefit of smart meters? ■ They avoid the need for meter readers ■ They provide accurate and timely information on power flows across the smart grid ■ They facilitate the export of surplus electricity from household solar PV panels 10) What does the technology VtG represent? ■ Variable Geometry Turbochargers - designed to allow the effective aspect ratio of a turbocharger to be altered as conditions change start control system? ■ Level of building occupancy ■ Outside air temperature ■ Boiler capacity ■ Boiler flow temperature 9. Which types of space heating system can building management systems be used to control? ■ Any ■ Wet systems ■ Air handling plant ■ Boilers 10. What is a thermostat? ■ Saves energy costs and reduces site CO2 emissions 4) Currently, which of these EPC rating are considered minimum for most new rentals? 6) What are the main benefits of smart grids? ■ Reduce the need for centralised power generation ■ Encourage connection of electric vehicles mechanical ventilation system? ■ A fan ■ An atrium ■ A chimney ■ Opening windows ■ ■ electricity Hydrogen from steam methane reforming Hydrogen from steam methane reforming + CCS ■ Volume of Trapped Gas associated with respiration ■ Vehicle to Grid enabling EV batteries to discharge to the grid to ‘smooth’ high electricity peak demand profiles. ■ A temperature sensitive switch ■ A temperature sensor ■ A proportional control device ■ A digital display device ■ ■ 10)Which of these is least likely to be seen as a boiler in 2050? ■ Hydrogen boilers burning “blue” hydrogen Rating = D ■ Rating = E Rating = F ■ Rating = G Please complete your details below in block capitals Please complete your details below in block capitals 5) Which of these in NOT an energy-saving ■ All electric boilers: either immersion or action? inline/ instantaneous ■ ■ Biomass boilersFixing a dripping hot-water tapName ......................................................................................................................................................................... (Mr. Mrs, Ms) ....................................Name ......................................................................................................................................................................... (Mr. Mrs, Ms) .................................... ■ Waste-heat recovery from exhaust air via ■ Local CCS for capturing the boiler’s CO2 emissionsa thermal wheelBusiness .................................................................................................................................................................................................................................... Business .................................................................................................................................................................................................................................... Business Address .................................................................................................................................................................................................................Business Address ................................................................................................................................................................................................................. ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ .................................................................................................................................. Post Code .............................................................................................. .................................................................................................................................. Post Code .............................................................................................. email address .........................................................................................................................................................................................................................email address ......................................................................................................................................................................................................................... Tel No. .........................................................................................................................................................................................................................................Tel No. .........................................................................................................................................................................................................................................

PLEASE COMPLETE YOUR DETAILS BELOW IN BLOCK CAPITALS

Name ......................................................................................................................................................................... (Mr. Mrs, Ms) .................................... Business.................................................................................................................................................................................................................................... Business Address ................................................................................................................................................................................................................. ........................................................................................................................................................................................................................................................ ........................................................................................................................................................................................................................................................ .................................................................................................................................. Post Code .............................................................................................. email address ......................................................................................................................................................................................................................... Tel No. .........................................................................................................................................................................................................................................

Completed answers should be mailed to: Completed answers should be mailed to: The Education Department, Energy in Buildings & Industry, P.O. Box The Education Department, Energy in Buildings & Industry, P.O. Box 825, GUILDFORD, GU4 8WQ. Or scan and e-mail to editor@eibi.co.uk. All 825, GUILDFORD, GU4 8WQ. Or scan and e-mail to editor@eibi.co.uk. All modules will then be supplied to the Energy Institute for marking modules will then be supplied to the Energy Institute for marking

COMPLETED ANSWERS SHOULD BE MAILED TO: The Education Department, Energy in Buildings & Industry, P.O. Box 825, GUILDFORD, GU4 8WQ. Or scan and e-mail to editor@eibi.co.uk. All modules will Produced in Association with Produced in Association with then be supplied to the Energy Institute for marking

20 | ENERGY IN BUILDINGS & INDUSTRY | SEPTEMBER 202024 | ENERGY IN BUILDINGS & INDUSTRY | MARCH 2020 Produced in Association with How to obtain a CPD accreditation from the Energy Institute How to obtain a CPD accreditation from the Energy Institute How to obtain a CPD accreditation from the Energy Institute Energy in Buildings and Industry and the Energy Institute are delighted to Energy in Buildings and Industry and the Energy Institute are delighted to Energy in Buildings and Industry and the Energy Institute are delighted to have have teamed up to bring you this Continuing Professional Developmenthave teamed up to bring you this Continuing Professional Development teamed up to bring you this Continuing Professional Development initiative.initiative. initiative.

This is the eighth module in the eighteenth series and focuses on Boilers andThis is the third module in the eighteenth series and focuses on Smart Grids. It This is the ninth module in the seventeenth series and focuses on Space Burners. It is accompanied by a set of multiple-choice questions. is accompanied by a set of multiple-choice questions. Heating. It is accompanied by a set of multiple-choice questions.

To qualify for a CPD certificate readers must submit at least eight of the ten To qualify for a CPD certificate readers must submit at least eight of the To qualify for a CPD certificate readers must submit at least eight of the sets of questions from this series of modules to EiBI for the Energy Institute to ten sets of questions from this series of modules to EiBI for the Energy ten sets of questions from this series of modules to EiBI for the Energy mark. Anyone achieving at least eight out of ten correct answers on eight separate Institute to mark. Anyone achieving at least eight out of ten correct answers on Institute to mark. Anyone achieving at least eight out of ten correct answers on articles qualifies for an Energy Institute CPD certificate. This can be obtained, on successful completion of the course and notification by the Energy Institute, free of charge for both Energy Institute members and non-members. The articles, written by a qualified member of the Energy Institute, will appeal to those new to energy management and those with more experience of the subject. eight separate articles qualifies for an Energy Institute CPD certificate. This can be obtained, on successful completion of the course and notification by the Energy Institute, free of charge for both Energy Institute members and non-members. The articles, written by a qualified member of the Energy Institute, will appeal to those new to energy management and those with more experience of the subject. eight separate articles qualifies for an Energy Institute CPD certificate. This can be obtained, on successful completion of the course and notification by the Energy Institute, free of charge for both Energy Institute members and non-members. The articles, written by a qualified member of the Energy Institute, will appeal to those new to energy management and those with more experience of the subject.

Modules from the past 17 series can be obtained free of charge. Send your Modules from the past 16 series can be obtained free of charge. Send Modules from the past 16 series can be obtained free of charge. Send request to editor@eibi.co.uk. Alternatively, they can be downloaded from the your request to editor@eibi.co.uk. Alternatively, they can be downloaded your request to editor@eibi.co.uk. Alternatively, they can be downloaded EiBI website: www.eibi.co.uk from the EiBI website: www.eibi.co.uk from the EiBI website: www.eibi.co.uk

SERIES 17 SERIES 17 SERIES 16

MAY 2019 - APR 2020 MAY 2019 - APR 2020 MAY 2018 - APR 2019 1 Batteries & Storage 1 Batteries & Storage 1 BEMS 2 Energy as a Service 3 Water Management 4 Demand Side Response 5 Drives & Motors 6 Blockchain Technology 7 Compressed Air 8 Energy Purchasing 9 Space Heating 10 Data Centre Management 2 Energy as a Service 3 Water Management 4 Demand Side Response 5 Drives & Motors 6 Blockchain Technology 7 Compressed Air 8 Energy Purchasing 9 Space Heating 10 Data Centre Management 2 Refrigeration 3 LED Technology 4 District Heating 5 Air Conditioning 6 Behaviour Change 7 Thermal Imaging 8 Solar Thermal 9 Smart Buildings 10 Biomass Boilers SERIES 18SERIES 18 SERIES 17 MAY / JUNE 2020 - MAY 2021MAY / JUNE 2020 - MAY 2021 MAY 2019 - APR 2020 1 Energy Efficiency Legislation 1 Energy Efficiency Legislation 1 Batteries & Storage 2 Building Controls 3 Smart Grids 4 Lighting Technology 5 Heat Pumps 6 Metering & Monitoring 7 Air Conditioning 8 Boilers & Burners 9 Behaviour Change* 10 Combined Heat & Power* 2 Building Controls 3 Smart Grids 4 Lighting Technology* 5 Heat Pumps* 6 Metering & Monitoring* 7 Air Conditioning* 8 Boilers & Burners* 9 Behaviour Change* 10 Combined Heat & Power* 2 Energy as a Service 3 Water Management 4 Demand Side Response 5 Drives & Motors 6 Blockchain Technology 7 Compressed Air 8 Energy Purchasing 9 Space Heating 10 Data Centre Management*

* ONLY available to download from the website after publication date * ONLY available to download from the website after publication date * ONLY available to download from the website after publication date

Terms: in submitting your completed answers you are indicating consent to EiBI’s holding and processing the personal data you have provided to us, in accordance with legal bases set out under data protection law. Further to this, EiBI will share your details with the Energy Institute (EI) with whom this CPD series is run in Terms: in submitting your completed answers you are indicating consent to EiBI’s holding and processing the personal data you have provided to us, in accordance with legal bases set out under data protection law. Further to this, EiBI will share your details with the Energy Institute (EI) with whom this CPD series is run in Terms: in submitting your completed answers you are indicating consent to EiBI’s holding and processing the personal data you have provided to us, in accordance with legal bases set out under data protection law. Further to this, EiBI will share your details with the Energy Institute (EI) with whom this CPD series is run in contractual partnership. The EI will process your details for the purposes of marking contractual partnership. The EI will process your details for the purposes of marking contractual partnership. The EI will process your details for the purposes of marking your answers and issuing your CPD certificate. Your details will be kept securely at your answers and issuing your CPD certificate. Your details will be kept securely at your answers and issuing your CPD certificate. Your details will be kept securely at all times and in a manner complaint with all relevant data protection laws. For full all times and in a manner complaint with all relevant data protection laws. For full all times and in a manner complaint with all relevant data protection laws. For full details on the EI’s privacy policy please visit www.energyinst.org/privacy. details on the EI’s privacy policy please visit www.energyinst.org/privacy. details on the EI’s privacy policy please visit www.energyinst.org/privacy. • To hear more from the EI subscribe to our mailing list: visit https://myprofile. • To hear more from the EI subscribe to our mailing list: visit https://myprofile. • To hear more from the EI subscribe to our mailing list: visit https://myprofile. energyinst.org/EmailPreferences/Subscribe energyinst.org/EmailPreferences/Subscribe energyinst.org/EmailPreferences/Subscribe

Lucy Simpson is head of EV product management at Centrica Business Solutions For further information on Centrica Business Solutions visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 130

Plan for the move to electric

As the 2030 ban on new petrol and diesel vehicle sales approaches fleet operators are moving to electric vehicles. Lucy Simpson explains the key factors in making the switch

Businesses and public sector organisations are taking advantage of financial incentives and economies of scale to lead the move to EV, a transition which is central to their sustainability strategies.

The Latest BloombergNEF analysis predicts that rapidly falling lithiumion battery costs will mean that electric vehicle purchase prices could match those of petrol and diesel cars by as early as 2023. Meanwhile, advances in technology mean that batteries will be able to charge in as little as five minutes.

At Centrica we began electrifying our 12,000-strong fleet over six years ago and are using the lessons we’ve learned to help other organisations to develop cost-effective, scalable and future-proofed EV transition plans.

Some of the key steps to consider are: • Assess your EV needs and feasibility: the first priority is to work out what your EV fleet needs are and how electrification can viably be delivered. You will need a detailed understanding of your vehicle usage, what a typical day’s fleet driving looks like and how charging could fit in to that.

Adequacy of the power supply

Second, work out the feasibility of installing workplace or depot charging from an energy perspective, e.g. the adequacy of the power supply to meet increasing demand and suitability of sites for installation of on-site generation and storage. To accommodate new working patterns post-COVID, you may also need to factor in home charging plans.

Your feasibility study should also assess the strength of support from senior management and employees. Their buy-in and long-term EV commitment is vital. • Understand regulatory drivers and incentives: transport is the UK’s biggest contributor to carbon emissions – accounting for 27 per cent of total CO2 emissions. Therefore, decarbonising transportation is a major policy priority – supported by incentives and regulations, including: 1) UK Office of Low Emission Vehicles (OLEV) Plug-in Grant Scheme, and Workplace Charging Scheme (up to £14,000 to install up to 40 chargers). 2) Ultra-Low Emission Vehicles (ULEVs) are exempt from UK Vehicle Exercise and corporate tax write downs. Qualification for 0 per cent Benefit in Kind (company car tax) for 2020-21, rising to 1 per cent in 2022 and 2 per cent in 2023. 3) Sale of new petrol and diesel cars banned in the UK from 2030. 4) Average emission target for new cars reduced to 95g CO2/km across EU and UK in 2021. 5) Creation of Low carbon emission zones (e.g. Ultra-Low Emission Zone (ULEZ) in London, with plans for other cities. • Factor in total cost of ownership: after clocking up more than 1.75m electric miles across our own fleet, we’ve seen that when you factor in lack of fuel costs and lower maintenance requirements, running an EV is cheaper overall – despite the fact that EVs currently cost about £1,000 more to lease on an annual basis.

Understand the full ongoing costs for your EV infrastructure and energy supply to accurately forecast the total cost of ownership. Validate the financial viability and explore all the funding options for both vehicle purchase and energy and charging infrastructure. Ensure that you make the most of the funding and tax incentives and consider how to maintain visibility and control over usage in order to keep costs under control. • Plan your energy strategy: switching to EV will increase power demand, so if there are supply constraints you may need to consider grid upgrades, self-generating your own clean energy supply, or making use of Renewable Power Purchase Agreements (PPAs).

By integrating your EV infrastructure with renewable onsite distributed solutions, such as solar and battery storage, you can reduce energy costs and enhance sustainability. There’s also an opportunity to earn revenue via Demand Side Response and supply optimisation programmes. This is an attractive option for back-tobase fleets, where vehicles may be plugged in for longer periods. • Implement fleet software & tools to optimise performance: fleet managers need a suite of software to manage charge points, energy use and deal with the commercial aspects of multi-site charging.

The right package of EV management software can optimise costs that support time-of-use tariff flexibility; manage charging access, payments and reimbursements;

The first step in planning electrification is an in-depth understanding of vehicle use monitor driver efficiency and provide full transparency for drivers.

It is essential to use data analytics and alerts to gain real-time visibility and status of your charging network and performance - that can be converted into configurable reports.

Chargers should have load sharing capabilities to keep you within your site energy constraints and minimise costs. You may also need to consider software systems to optimise and integrate on-site generation and storage solutions. • future-proof your EV fleet strategy: careful planning is essential to ensure that your EV infrastructure offers the flexibility to adapt as your fleet evolves and technologies or business priorities change. Your integrated EV strategy must address many different issues – from design, though to installation, operation and maintenance. Factors to consider include: 1) procurement of key components such as charging hardware and software; 2) support services, including operation and maintenance; 3) service level agreements with EV infrastructure and software providers; 4) additional power needs, e.g. higher capacity grid connections; new or expanded on-site generation infrastructure and grid balancing services; 5) energy estate integration with existing or expanded onsite generation and storage; and 6) flexibility and ‘smart’ optimisation, including preparation for future utilisation of Vehicle-toGrid (V2G). • Select an experienced EV partner: unless you have the right experience and resources available in-house, it’s likely that you will require expert support. This involves coordinating and integrating the many disparate elements of your EV project, including software, hardware and energy provision; planning control; regulation, installation; operation and maintenance, etc.

For further information on EcolightingUK visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 129

Steve Gardner is managing director of EcolightingUK

The perils of the electric transition

Steve Gardner shares his thoughts on how electric vehicles will fit into the Government’s Ten Point Plan sustainability initiative

In November 2020 the UK government unveiled its ambitious aim of a cleaner, greener future via a Ten Point Plan. This has been devised to repair not only the economic damage caused by Covid-19, but also to cement the UK as global leaders in green technologies and aid us in the ongoing fight against climate change.

This will be achieved by actively tackling greenhouse gas emissions and creating new ‘green collar’ jobs in the renewable and sustainable energy sectors.

Point four of the Ten Point

Plan focuses on facilitating and accelerating a nationwide shift from petrol vehicles to zero-emission electric cars. With restricted travel and various social distancing measures in place, the government believes that electric vehicles “can be our most visible incarnation of our ability to simultaneously create jobs, strengthen British industry, cut emissions, and continue travelling.”

With well over a hundred electric vehicle models currently available on the market, it’s easy to take false comfort in the fact that we’re making good progress towards improving our air quality. However, while the growing number of electric vehicles does ignite hope, it does not detract from the fact that cars and vans account for a fifth of all carbon emissions. It becomes clear that, in order to successfully mitigate this shift to electric in the most seamless way possible, as much effort and investment needs to be directed into charging infrastructure as into the manufacture of the vehicles themselves.

Fortunately, the Ten Point Plan has pre-empted this concern. A huge £1.3bn of the overall £12bn investment will be used to establish charging stations across the country, including rapid charge points on major roads and on-street charging

As much effort needs to be directed into the charging infrastructure as into the manufacturing of the vehicles

stations in homes and residential areas. Not only will this make the use of electric vehicles more accessible, but it will also help to build faith in the electric car as a viable alternative to petrol.

Sustainable product options

For the many companies who are already striving towards providing sustainable product options and services to their customers, the Ten Point Plan is a welcome step in the right direction. However, others have noticed flaws in the plan and, for many energy-saving solutions suppliers and electric vehicle charging installers, the government’s proposal simply isn’t compelling enough to undo generations of environmental damage.

Making cycling and walking more attractive, planting trees and making our homes, schools and hospitals ‘greener’ are not groundbreaking tactics and should be a prerequisite of any government instead of being elements of a reactive plan. Achieving true sustainability needs to happen at a grassroots level, with the way that products are designed and the systems we use to install them. Encouraging people to walk and cycle more is one thing, but without tackling the way in which we power our homes, workspaces, factories, offices and warehouses, the changes will only ever be minor.

It is also feared that the proposed plans for the electric car market could be implicated by unforeseen challenges. By ceasing the manufacture of petrol cars, the secondhand car market will explode as many people will not be able to afford electric models. With this being just one issue that could affect the industry, it is crucial that the government answers some pressing questions about the future of vehicle electrification - especially in regards to safety and economic stability.

Concern also lies in the futures of mechanics across the country, most of which have spent their entire careers studying and practising the skill of traditional vehicle maintenance. Electric vehicles need very little maintenance, so what does that mean for the country’s mechanics? Will they be forced to retrain in another trade while a new generation of green collar mechanics is called upon to redirect the industry? The answer is likely to cause an inevitable loss of jobs and force many workers out of a lifelong career.

These concerns are also being echoed by the petrol station industry. Petrol stations currently employ around 100,000 people. However, with a nationwide phasing out of petrol fuelled vehicles, the question is what will become of the industry and the people who work within it?

The dawn of the electric age brings with it a matrix of wider questions, many of which are currently unanswered. This is perpetuating a growing sense of anxiety which could eclipse the efforts of the Ten Point Plan entirely. Understanding the need for change and putting plans in place to facilitate such change is one thing, but without consideration of our old world we run the risk of causing damage in pursuit of a new one.

Certain industries exist on a large scale and can’t be overlooked, regardless of how unsustainable they may be. We must therefore ensure that these industries and the people working within them are allowed to transition into a greener way of working with full governmental support, rather than being completely eliminated to make way for new industries.