Orgill’s commitment to getting products into your store is paramount. Our modern, private fleet of 400+ trucks are all driven by Orgill employees. Not only do our drivers keep things running smoothly, but our operational model controls our expenses and we pass these savings along to our dealers.

We’ll go the extra mile for you. Contact us today.

TOP SHOWROOMS

36 In Nebraska, a gem of a showroom.

TECHNOLOGY

24 Get up to speed on decking trends and products.

32 Do it Best streamlines online lumber sales.

PRODUCT CENTRAL

38 A snapshot of handy items worth a look.

REGULATORY UPDATES

50 EPA grants: Who gets what?

51 U.S. almost doubles Canadian lumber tariffs.

SPECIAL REPORT

42 LMC’s legacy of strength.

FROM THE BLOG

54 Winning the talent and turnover game.

28 An expert dishes on wood-based composites. 30 The most in-demand homebuilding materials. TOP WOMEN

40 Inspiring a new generation of builders.

IN EVERY ISSUE

6 Here’s what’s online.

12 Product knowledge.

56 People in the news.

58 Quikrete Industry Dashboard.

See more and share more when you follow us on LinkedIn.

When you connect with us, you connect with the industry @HBSDealer

There’s more than one way to tell a story. Case in point: HBSDealer’s Storyscape — a highly visual, interactive, video-rich presentation of business information. Check out the latest example, “Technology: The Great Equalizer” at HBSDealer.com

The numbers support a familiar concept: what goes up, must come down. For industry highlights and the listing of the Top 150, visit the online Leaderboard Report, sponsored by Epicor, at HBSDealer.com/report.

Meet Jay Short, the third-generation owner of award-winning Short & Paulk Supply of Southern Georgia. “We’ve got a lot of irons in the fire right now,” he said. Watch the video at HBSDealer.com/video

As editor of HBSDealer, the forerunner of Home Center News and National Home Center News, I’ve been listening to earnings calls from the nation’s giant home centers since the early 21st century.

One thing I’ve learned: there’s a big difference between listening to the earning call, and reading the transcript. A jarring takeaway from listening in on the most recent double-play of second-quarter earnings calls was the echo of different ways executives can describe sales declines:

“Incremental pressure on consumer demand”

“Persistent pressure in bigger ticket DIY discretionary projects

“Uncertainty around underlying consumer demand.”

“Weaker spend across home improvement.”

“A slightly more cautious demand environment.”

That last phrase (from an analyst) may be described as slightly optimistic given the comp-store sales numbers in the chart below.

Ken Clark Editor-in-Chief

these earnings calls work. Let’s go over some of the other ways executives looked at the quarter.

At Lowe’s, there was a 2.9 percent increase in comp sales growth online and “mid-single digit” positive pro comps. The company added Uber Eats to a list of delivery partners that included DoorDash, Shipt and Instacart. The MyLowe’s Rewards DIY loyalty program was just launched nationwide in March, (with an assist from Lowe’s ambassador and soccer star Lionel Messi.)

“Our efforts to transform the pro customer experience are working,” said Bill Boltz, executive vice president of merchandising for Lowe’s.

With paint being the number one home improvement project, Lowe’s has now partnered with Sherwin-Williams to offer customers free same-day delivery nationwide.

At Home Depot, there was no sense of panic, either. Mostly, there was optimism over the SRS Distribution acquisition, which added $1.3 billion to the top line.

“We are incredibly excited about what we can achieve together by leveraging our combined assets, capabilities, and competitive advantages,” said Home Depot CEO Ted Decker.

550 W. Bryn Mawr Ave., Ste. 225, Chicago, IL 60631 (773) 992-4450 Fax (773) 992-4455 www.HBSDealer.com

BRAND MANAGEMENT

SENIOR VICE PRESIDENT John Kenlon (516) 650-2064 jkenlon@ensembleiq.com

EDITORIAL

EDITOR-IN-CHIEF Ken Clark kclark@ensembleiq.com

EDITOR Robby Brumberg rbrumberg@ensembleiq.com

ADVERTISING SALES & BUSINESS

ASSOCIATE PUBLISHER Amy Platter Grant

MIDWEST & SOUTHERN STATES (773) 294-8598 agrant@ensembleiq.com

DESIGN/PRODUCTION/MARKETING

ART DIRECTOR Bill Antkowiak bantkowiak@ensembleiq.com

PRODUCTION MANAGER Patricia Wisser pwisser@ensembleiq.com

MARKETING MANAGER Kathryn Abrahamsen kabrahamsen@ensembleiq.com

SUBSCRIPTION SERVICES

LIST RENTAL mbriganti@anteriad.com

SUBSCRIPTION QUESTIONS contact@HBSDealer.com

Source: Compnay reports

After looking at the numbers, both companies lowered full-year comp-store sales expectations. Home Depot now expects comp decline of 3.0 percent to 4.0 percent for scal 2024. Lowe’s is looking at declines in the range of 3.5 percent to 4.0 percent [Read more at HBSDealer.com]

Was there a sense of panic on the line in reaction to these numbers?

Ladies and gentlemen, that’s not how

Billy Bastek, executive vice president of merchandising, hammered on in-store innovations, the life-blood of home improvement retailing. Positive comps in ooring, a simpli ed value proposition in water heaters, and battery powered outdoor power equipment were winning, he said. Bastek even enthused about a berglass door that at the touch of a button transforms from see-through glass to frosted privacy.

Two hours of business discussion cannot be contained in this space. So let’s bottom line it. The big guys are looking ahead, and they’re reloading.

CORPORATE OFFICERS

CHIEF EXECUTIVE OFFICER Jennifer Litterick

CHIEF FINANCIAL OFFICER Jane Volland

CHIEF OPERATING OFFICER Derek Estey

CHIEF PEOPLE OFFICER Ann Jadown

CHIEF STRATEGY OFFICER Joe Territo

EDITORIAL ADVISORY BOARD

Levi Smith, CEO, Franklin Building Supply

Steve Sallah, former CEO, LBM Advantage

Christi Powell, Women & Minority Business Enterprise Market Manager, 84 Lumber

Neal DeLowery, Store Projects and Merchandise Manager, Aubuchon Co.

Brad McDaniel, Owner, McDaniel’s Do it Center

Joe Kallen, CEO, Busy Beaver Building Centers

Tom Cost, Owner, Killingworth True Value

Permissions: No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or information storage and retrieval system, without permission in writing from the publisher.

connect with us

Imagine the possibilities. MoistureShield® offers code compliant aluminum railing and composite decking with superior slip resistance. So, you can safely take your adventures to the edge without having to compromise your view.

Walter Foxworth, the former owner of Texas-based Foxworth-Galbraith Lumber Company and widely respected lumber dealer and industry advocate, died Aug. 2.

Foxworth is a past chairman of the National Lumber and Building Material Dealers Association and a recent Lifetime Achievement Award honoree from the Lumber Association of Texas. He was 89.

In a 2023 article, Foxworth described his involvement with the LAT:

“I started my career in 1959 and attended my first LAT Convention,” said Foxworth. “I have found that engaging and investing in the LAT mission is critical for each of our individual businesses and our industry. The friendships I made along

the way have been some of the most meaningful of my life. As I look back at my over 60 years of involvement, I am committed to supporting the next generation and to giving back to an organization that I am so proud to belong to.”

Foxworth and Foxworth-Galbraith received numerous industry awards and accolades. He served as president of LAT’s Board of Directors in 1990, was recognized as “Dealer of the Year” in 1993, and has over six decades of volunteer engagement. Under Walter’s leadership, Foxworth-Galbraith was the 2000 HBSDealer ProDealer of the Year. He also was recognized as inaugural Texas Unity Dinner honoree.

During the 2016 ProDealer Industry Summit, Foxworth received recognition for his contributions to the industry and to

Recent updates to the HBSDealer News Map, powered by Epicor, include some notable closings: Crest Hardware in Brooklyn, New York; Glen Park Hardware in San Francisco and Mansfi eld Hometown Hardware in Mansfi eld, Mass. Meanwhile, Massachusetts-based Aubuchon Company acquired from Michael Mott four Ace Hardware stores in eastern Pennsylvania. For more activity coast-to-coast, visit HBSDealer.com/map.

the community, including his support of the Taos Day School in New Mexico.

Tributes from around industry emphasized Foxworth's contributions.

U.S. LBM President and CEO L.T. Gibson saluted Foxworth's many contributions: "Walter was an extraordinary leader in the building materials industry, a passionate businessman and advocate for our industry for more than 60 years, even continuing that advocacy work after he retired from Foxworth-Galbraith in 2022,” said Gibson. “Walter will be deeply missed, and our heartfelt thoughts and condolences go out to all his family and friends.”

“Walter was a true industry icon, and this is truly a great loss to many,” said Jonathan Paine, NLBMDA President & CEO. ”I will personally miss Walter for his friendship, generosity, wisdom and incredible passion for doing everything in his power to advocate on behalf of NLBMDA and the entire industry."

“With every recollection shared, we see proof of Walter's legacy,” said Mireya Zapata, executive director of the LAT. “For decades, he has quietly yet powerfully propelled others to succeed with his mentorship, passion and incomparable business acumen. A force at state legislatures across the country and in Washington D.C., his voice and determination propelled pro-LBM policies that will be felt for generations. Let's honor his memory by picking up the torch to advocate for an industry—and its people—that he loved to his very core."

“Walter dedicated much of his life to being politically and civically engaged, more than anyone I’ve known,” said Scott Yates of Denver Lumber and, like Foxworth, a past chairman of the NLBMDA. “He was a tremendous friend and mentor.”

LL Flooring Holdings, Inc., formerly known as Lumber Liquidators, has "commenced voluntary Chapter 11 reorganization proceedings in the U.S. Bankruptcy Court for the District of Delaware," according to the company. LL Flooring aims to use the proceedings to pursue a sale of its business.

Here’s how CEO Charles Tyson explained it:

“After comprehensive efforts to enhance our liquidity position in a challenging macro environment, a determination was made that initiating this Chapter 11 process is the best path forward for the company,” said the CEO. The move “is intended to provide LL Flooring with additional time and fi nancial fl exibility as we reduce our physical footprint and close certain stores while pursuing a going-concern sale of the rest of our business. As we

pany owes $100 million to $500 million to up to 100,000 creditors.

In addition, LL Flooring entered into an agreement with Hilco Merchant Resources, LLC, to assist the company in its recently initiated store closing sales at 94 of its locations. Those 94 stores will remain open through this closing process, per LL Flooring.

Product: Paleblue lithium-ion rechargeable batteries.

Manufacturer: Pale Blue Earth of Park City, Utah

move through this process, we are committed to continuing to serve our valued customers, and to working seamlessly with our vendors and partners. I am appreciative of our associates for their ongoing hard work in providing the best experience for our customers.”

According to media reports, the com-

The nation’s largest prodealer adjusted downward its sales projections for the full year 2024. The updated expectation is for net sales to be $16.4 billion to $17.2 billion. Compared to the previous range of $17.5 billion to $18.5 billion. (In 2023, sales were $17.1 billion.)

Here are some key soundbites from CEO Dave Rush:

“Installed sales increased by 15% year-over-year as we focus on helping customers address labor challenges.”

“The single-family growth momentum, occurring earlier in 2024, has stalled as the interest rate cuts have not materialized and starts have come in lower than expected. In addition, the value of a new start has fallen as the market has adapted to affordability challenges.”

“Our M&A pipeline remains healthy, and we believe we can continue to acquire in a fragmented market.”

Knowledge: Employing the easy and familiar USB to USB-C charging method (just like a phone), batteries deliver 1,000-plus charge cycles. Features a built-in LED charging indicator. The environmental case for recyclable batteries is powerful, as Americans throw away more than 3 billion single-use batteries each year.

Price: About $30 for AA pack.

Deep-space fact: Name refers to a photo of the earth as seen from the Voyager 1 space probe. In his book

“Pale Blue Dot,” astronomer Carl Sagan wrote that the miniscule image in the vastness of space “encourages us to preserve and cherish the pale blue dot, the only home we've ever known.”

WORKING TO BE A ‘A TENANT OF CHOICE.’

Ace Hardware Corp.’s Jason Hipskind, vice president of new business, during a session at Ace’s recent convention titled “Branching out into multi-store ownership,” shared the co-op’s goal to be a top national retail tenant of choice. He elaborated: “If a landlord has available real estate, we want them to consider Ace as one of the top five [businesses] that they want to have as a tenant.”

The co-op’s focus is to find locations in grocery-anchored neighborhood centers, as well as locations that are former pharmacies and former discount retailers — think Walgreens, CVS, Rite Aid, Dollar Tree and Family Dollar.

“Those buildings make awesome hard -

ware stores,” he said.

The co-op believes there are thousands of open development areas for new stores.

“Over the course of the last two

A group of Portland, Oregon-area knife manufacturers want the world to know that they mean business.

The five Portland knife brands— Benchmade, CRKT, Gerber Gear, Leatherman and Steelport Knife Co.— established the Portland Knife Center of Excellence. It aims to establish the metro area as a “destination that connects and celebrates a passionate knife community, while building pride in American craft, education and innovation.”

The group claims that there are more knife

companies headquartered in Portland than any other city in the United States. Over 50

years, 3,000 pharmacies have closed,” Hipskind said. “If we can bring Ace to those stores and help those communities, that’s our goal.”

During the session, four Ace dealers shared their experiences in branching out to multiple locations. Among the themes were the importance of staffing, and the idea that adding more stores brings the ability to add more specialized roles to the organization.

Alan Walter, owner of five Ace Hardware stores in Texas and Oklahoma, had this advice: “Going from one to two is the hardest,” he said. “Later, you’ll have people you can lean on, and you’ll have experience and expertise.”

percent of knives sold domestically are manufactured in the Portland Metro area.

A joint statement from founding members reads:

“We represent more than 200 years of combined experience in knife design and manufacturing here in Portland, where the competition is fierce. We've long admired each others' dedication to excellence and innovation. Now, we are proud to unite and uphold a spirit of collaboration that will spotlight Portland's impact on the knife industry.”

THE

W ma iz d® Outd r® W d wit Barami ® is id a f r a ur utd r ivi pr j ts.

For over 15 years, SaberDrive has been the trusted brand that retailers rely on to give their customers premium fasteners. SaberDrive products don’t just function great, they also look attractive in any lumberyard, home center, or any location that sells fasteners- giving it that consistent, uniform look across your aisle.

A brand built around the idea that if it will work for the best, it’ll work for the rest. A value-driven brand built for contractors that has all features you need and nothing you don’t. Providing customers with value-driven products in easy-to-find packaging makes this brand the perfect fit for any store.

By Ken Clark

he entrepreneurial spirit is deeply embedded in Short & Paulk Supply’s DNA. The business came to life as Taylor Hardware & Furniture in 1912 in Tifton, Georgia. The company later embraced the agricultural supply business. Its early years also experimented as a distributor of Diamond-T trucks.

Fast forward to 2024. The five-location Southwest Georgia family business is reshaping its footprint, building a door shop and millwork facility, reorganizing logistics, jumping into new merchandise categories and settling into its new headquarters in Sylvester, Georgia.

“We’ve got a lot of irons in the fire right now,” said Jay Short, who represents the third generation of family ownership. “But things are good.”

A sign of the company’s success is its selection as the 2024 Independent ProDealer of the Year by the National Lumber and Building Material Dealers Association and HBSDealer.

The credentials are strong. The Southwest Georgia family business has earned a reputation as a strong local player during its 80-year run. (The timeline goes back

Past honorees of the Independent ProDealer of the Year award include Hilltop Lumber of Minnesota (2023); Espy Lumber (2022) of Hilton Head, South Carolina; and Dakota County Lumber Co. (2021) of greater Minneapolis.

about 100 years if you count the acquisition of the company’s Sylvester store, which has been in continuous operation since the 1920s.) And not satisfied to rest on its reputation, Short & Paulk is building for the future and building on efficiencies while serving its local markets.

HBSDealer recently visited the company’s new headquarters to gain insights into Short & Paulk’s strategies and tactics.

Lowe’s entered Short & Paulk’s competitive orbit back when Jay Short’s father was still running the business..

“My dad said when Lowe's came in that you couldn't have two masters,” Jay said. “You couldn't be in the retail business and the contractor business and do a good job. You had to focus on one or the other.”

Jay Short, who took over from his father in 2008, has a different take.

“What we have found is that in the smaller markets, we need both,” Short said.

Short explains that their retail stores are not just points of sale for the general public, but also serve as crucial hubs for contractors. These locations allow contractors to pick up last-minute items or receive quick shipments directly to their job sites, ensuring they have the materials they need without signi cant delays. Additionally, the stores offer a space for contractors to meet with customers, view samples, and consult with outside sales representatives. This dual functionality makes the retail stores vital to both consumer and contractor segments of their business.

The key, he found, was in how the company organized its teams and operations.

To effectively manage this dual model, Short’s company has developed two distinct teams. One team is dedicated solely to contractors, with outside salespeople who actively engage with them, understand their needs, and provide tailored solutions. Meanwhile, the retail team focuses on serving everyday customers and ensuring a quick turnaround for contractors who might need to pick up additional supplies on the y.

Rather than having "two masters" that pull the business in different directions, Short has found a way to make both aspects work in harmony.

Approaching the Sylvester headquarters, one is immediately struck by the sight of a significant construction project: the foundation of a door shop and millwork facility. The 34,000 sq. ft. facility is expected to be operating by the end of the year.

Not only is the Sylvester facility bringing production to the market, it’s bringing a whole new work flow to the business, centralizing distribution to a large extent, with plenty of space to operate forklifts. The Sylvester location also has a new headquarters building that’s a stone’s throw (or golf cart ride) from the yard.

“Here in Sylvester, we were able to start from scratch, and lay it out like we really wanted to,” as opposed to previous iterations that evolved over time haphazardly. “I think it’s going to be a big game changer for us long-term,” Short said. Big projects are just part of the entrepreneurial spirit that lives at Short & Paulk Supply. In the prior handful of years, the company has been fearless in its experimentation with new merchandise categories. Feed and seed, pool supplies, footwear and boots (“good margins,” Short said). The Sylvester store’s full gun shop is under construction.

The annual Independent ProDealer of the Year Award, selected by the editors of Hardware & Building Supply Dealer in concert with the National Lumber and Building Material Dealers Association, is designed to recognize a high-performance independent lumberyard (no more than ve locations) with a commitment to best practices and the best values of the lumber and building material industry.

Here’s what people are saying:

Paul Ryan, LMC President & CEO:

"Short & Paulk Building Supply's recognition as the 2024 Independent ProDealer of the Year is a testament to their unwavering commitment to excellence and their pivotal role in our industry. We congratulate Jay Short and his entire team for this well-deserved honor. Their dedication to best practices and customer satisfaction sets a high standard for independent lumberyards nationwide.”

Jonathan Paine, CEO, National Lumber and Building Material Dealers Association: “I couldn’t be happier to be able to recognize Jay Short and the entire team at Short & Paulk,” said NLBMDA President & CEO Jonathan Paine. “Jay has been an outstanding ambassador to the entire lumber and building material industry and an active member of NLBMDA. Operating 5 locations in Georgia, Short & Paulk is a community leader and epitomizes commitment to providing quality building materials and exceptional service.”

Jay Short, owner, Short & Paulk Supply: “On behalf of the entire Short & Paulk team I would like to thank NLBMDA and HBSDealer for this recognition,” he said. “We are honored and truly humbled. “Over the years, I have had the privilege of serving on several industry boards and the opportunity to participate in numerous dealer groups and roundtables. Much of our success today is a direct result of networking with other dealers and bringing new ideas back from meetings, roundtables, and yard tours.”

Tifton, Georgia-based Short & Paulk Building Supply will accept the 2024 Independent ProDealer of the Year award at the upcoming ProDealer Industry Summit, slated for Savannah, Georgia, Oct. 9-11.

Perhaps the effort most reflective of the company’s opportunistic merchandise approach is its dog food business, supplying the South Georgia plantations that maintain kennels of bird dogs.

“I don’t think there are many lumberyards that sell a truck-and-a-half of corn per week during deer season, or sell pallets of dog food to plantations,” Short said.

Meanwhile, about 75 percent of Short & Paulk’s business is to the pro contractor, 25 percent retail. And to continue to grow the business profitably, analytics have moved into the forefront.

Flashback to 2008 when the global economy was plunged into turmoil across industries. That’s when Jay had just taken over the family business and was facing an emergency.

“By 2010 we thought it would be over, but it wasn’t. It was worse,” Paul said. “So we were chasing business, doing everything we could to get a sale.”

When the dust settled, Short & Paulk sat down and did the math with its various customer types—retail, repair & remodel, custom builders and tract builders. The company began to look at a matrix of factors including distance, product mix, sales and profitability to determine the “sweet spot” for each. Through careful analysis of the data, the

Old and new: the antique truck reveals the dealer's original two-digit phone number: 97. Chris Graddy, Ron Skinner and Jay Short at the company’s corporate office, which opened in Sylvester in early 2024.

1. Expansion and Experimentation

The dealer has centralized their operations for greater ef ciency in the new Sylvester facility. “We have plenty of capacity the way we’re currently structured,” said President Chris Graddy. “We’ve done a lot of new things, but now over the next 5 to 10 years, we’ve got to get as ef cient as possible.”

2. Continuous Improvement

In addition to learning from past mistakes, the company learns from other industry leaders through visits and roundtables. “A lot of our good ideas have been stolen from somebody else,” Short said.

3. The Power of People

One of the driving forces behind Short & Paulk’s success is its people. The company fosters a collaborative environment where employees are encouraged to share their insights and ideas. "A lot of it is employees giving input," Short noted, adding that they often nd the best solutions through simple, common-sense approaches.

4. Embracing Analytics

In recent years, Short & Paulk has made signi cant strides in leveraging technology and analytics to optimize its operations. Tools that track the ef ciency of truck routes and delivery efciencies are one part. More important is the culture of relying on data over hunches and making decisions informed by data.

By expanding and centralizing its operations, learning from past experiences, valuing its people, and embracing data-driven decision-making, the company is well-positioned to continue its legacy of success. As the market continues to change, Short & Paulk remains committed to staying ahead of the curve, ensuring that it can meet the needs of its customers both now and in the future.

understanding and responding to the realities of the market—rather than just reacting to immediate pressures—can make a big difference.

Short describes the biggest differentiator as the people. The company’s 100 employees support a wide array of projects, delivering materials across Georgia, North Florida and Southeast Alabama with their fleet of trucks.

“It may be my name on the building,” he said, “but we’ve got a great team of folks out in the trenches on the lumber yard, the guys unloading the trucks, the guys making the deliveries, the salesman on the road, the guys at the counter — they’re the ones that make things happen.”

company says it found ways to be more efficient while growing market share.

“When it comes to analytics, perception and reality are two totally differing things,” said Chris Graddy, president.

Ultimately, the experience underscored the importance of agility and informed decision-making in business. By adapting their approach and relying on data-driven insights, Short and his team were able to not only survive the economic downturn but also position the company for future growth. The lesson from their experience is clear: in challenging times,

A high preforming waterproof barrier formulated to protect your deck frame

Fast and Clean Application

No mess coverage with less jobsite waste

Dries in Approximately 20 Minutes

Full moisture barrier in 24 hours

Coats Hard-to-Reach Places

Use in corners tape cannot reach

See how Deck Frame

Coating extends the life of your deck

AZEK, parent company of TimberTech and Trex, are two of the big names in the decking industry. The two publicly traded companies reported growth in their recent fiscal quarters, driven by the strength of premium product lines and strategic market positioning.

In the three months ended June 30, AZEK's Residential segment saw net sales increase by approximately 18 percent year-over-year. This growth was fueled by strong performance in Deck, Rail, and Accessories, which experienced double-digit sellthrough growth among professional dealer and retailer partners.

Looking ahead, AZEK is reaffirming its outlook for the second half of fiscal 2024 and raising the bottom end of its full-year guidance. “We continue to assume Residential sell-through growth to be in the mid-single digits in the fiscal fourth quarter, as our initiatives drive continued outperformance relative to anticipated softer trends in the broader repair and remodel markets,” said AZEK CEO Jesse Singh. Despite some choppiness in the broader construction economy, AZEK expects its channel to end the fiscal year at or below historical inventory days on hand. The company remains confident in its ability to drive long-term double-digit growth, citing strong growth in internal digital and engagement metrics as well as pent-up demand that is expected

to be realized as the broader market improves. Trex also reported positive results in its second quarter, with sales increasing at a mid-single-digit rate. This growth was led by the company's premium products, including Trex Transcend Lineage and Trex Signature decking, which saw double-digit sell-through rates and contractor lead times averaging six to eight weeks.

However, sales of Trex's lower-priced product lines were below expectations, reflecting lower-than-anticipated purchasing by consumers in this segment. The company anticipates additional softness in this market in the second half of the year. Despite this, Trex's premium product sales continue to outperform entry-level products, and pro channel inventories are aligning with projected demand. aluminum.

Trex introduced All-In-One Post Kits for its Trex Select and Trex Enhance railing. Budgetfriendly kits are designed to simplify the railing purchase and installation process.

Deckorators, a provider of outdoor living solutions, explored emerging trends in the summer edition of its Outdoor Living Report, curated in collaboration with insights from leading deck, dock and interior design professionals. Trend highlights from the Summer Edition of the Outdoor Living Report include:

1. The Homeowner’s Mindset: Homeowners are engaging in much more product and builder research, carefully contemplating their decisions and being far more intentional about their design ideas and inspiration.

2. The Business of Outdoors: Homeowners are taking the time to do more of their own product research, seeking out multiple builder quotes and focusing on getting things done right the first time.

"As the market leader, Trex is the primary beneficiary of longterm secular trends," said Bryan Fairbanks, President and CEO. He highlighted the large number of decks in the U.S. that are at or beyond replacement age, the record growth in U.S. homes eligible for remodel projects and what he sees as the ongoing shift from wood to composites. Trex is also making progress on its railing strategy and expanding into adjacent product lines, with the modular build-out of its Arkansas capacity poised to meet long-term incremental demand.

According to a recent analysis by Grand View Research, the North American decking market was estimated at $4.1 billion, with a forecasted compound annual growth rate (CAGR) of 5.7 percent from 2023 to 2030. At this rate, the industry could be worth $6.35 billion by 2030.

While wood still dominates the decking market, holding over 71 percent of the revenue share, non-wood decking is expected to rise in popularity. Estimates predict the composite decking market could exceed $12.6 billion by 2031, up from just $3.8 billion in 2023. As composite decking technology advances and competition

3. Outdoor Wellness: Homeowners have demonstrated a growing interest in activating health and wellness in the outdoor living space, incorporating features like hot tubs, saunas and plunge pools.

4. Architectural Features: Composite decking can be transformed into design elements that offer an ideal way to integrate lighting, greenery and decor.

5. Color Blocking with Decking: Color blocking with unique color combinations creates a stark contrast that can add depth, definition and a touch of personality to the deck space.

6. Retractable Decks: Homeowners can add an entirely new outdoor living zone with furniture, decor and more—all integrated with an inground pool.

7. Front Porch Design: In today’s digital world, the opportunity to create a sense of community and connection in-person is priceless. Front porches are becoming social hubs again—and people are looking to create comfortable, inviting spaces that encourage neighbors to socialize.

Envision Outdoor Living Products, manufacturer of Envision composite decking and Fairway Railing collections, launched the V310 railing, described as the industry’s only wood-look vinyl deck railing.

increases, prices are expected to decline in coming years. This trend is also expected for wood, with the average price of decking projected to decrease by 2 percent per year through 2027, due to reductions in the prices of southern yellow pine lumber, cedar and redwood as supply chain issues are resolved.

CUTEK® is a high-performance exterior wood care system designed as a two-step prepare and protect process. It delivers powerful protection while enhancing wood’s natural beauty, even in extreme environments.

CUTEK prepare products are formulated to clean, strip, or restore exterior wood to its original state. For long-term protection penetrating deeply into the wood, CUTEK offers a self-healing oil that remains permanently mobile, actively driving out moisture to minimize warping, cupping, and splitting. No peeling or flaking. An optional transparent color with UV protection can be added to help retain or alter the color of the wood.

Build customer loyalty and boost your sales with CUTEK. Become a supplier today.

Contact us at cutekstain.com or call 1-833-MY-CUTEK (692-8835)

Wood is the backbone of building throughout much of the world. However, not all wood products and practices are created equal.

To get insights into the latest research regarding sustainable, climate-friendly woodand wood-based products, HBSDealer reached out to the Wood-Based Composites Center (WBC), which is a coordinated research partnership between major North American universities. The center “educates and trains students for careers in the wood-based composites and adhesion industries,” among other things.

Chip Frazier, who has worked as a professor in Virginia Tech’s Department of Sustainable Biomaterials since 1992 and as director or co-director of the WBC since 2005, shared share some science-backed guidance on what’s shaping the climate-friendly, ef cient and effective building materials of the future.

ted gum project is perhaps my favorite. But our members have great excitement over mass-timber and mass-plywood type materials, which includes primary manufacture, as well as mass-timber structures, including their durability and seismic performance.

Q: What would you say is currently the most environmentally-friendly wood-based composite available for purchase?

Frazier: Personally, I’ve purchased just about everything, except CLT, glulam and mass plywood.

According to the U.S. Department of Agriculture: “Adhesive bonding of wood plays an increasing role in the forest products industry and is a key factor for efficiently utilizing our timber resource. The main use of adhesives is in the manufacture of building materials, including plywood, OSB, particleboard, fiberboard, structural composite lumber, doors, windows and frames, and factory-laminated wood products. Adhesives are also used in the assembly of furniture and cabinets, manufacture of engineered wood products, and construction of residential and commercial structures. Adhesives transfer and distribute loads between components, thereby increasing the strength and stiffness of wood products.”

adhesives, and this is another strong interest among our members.

Q: What are some key trends you foresee in the wood-based composite industry?

Chip Frazier, professor, Department of Sustainable Biomaterials, Virginia Tech

Q: Can you share some research you’re working on currently that you’re particularly excited about?

Frazier: Yes. For instance, some woods bond easily while others do not, and our members want to know why.

Currently, we are studying a resinous, high-density Australian wood, spotted gum (Corymbia citriodora). It’s a gorgeous wood, and we think it is the single most dif cult wood for adhesive bonding; it’s partly due to the extractives, the natural compounds that give wood its odors, colors and avors.

Of our current WBC projects, the spot-

My point is that all contemporary wood-based composites are environmentally friendly. However, I believe the life-cycle assessment for OSB is very favorable for carbon storage, but that is application speci c, as it should be.

I consider them all Earth-friendly because current composite technology provides extremely ef cient utilization of our timber resources. Without our current petrochemical wood adhesives, log utilization ef ciency would be only about 45%, as it was in the 1940s. Today, it’s over 99% mainly due to composite technology and wood adhesives. As for non-structural materials like MDF and particleboard, formaldehyde emissions are a regulatory concern. Nobody has yet found any viable alternatives to our current wood adhesives. But our industry has consistently met the increasingly stringent formaldehyde emissions standards since the mid1980s. It’s a slow train, nding viable alternatives to petrochemical wood

Frazier: I believe building supply folks will be dealing much the same materials in the near future, but as we use more and different kinds of wood, they will be concerned about the normal things: cost and supply.

There is a great desire to reduce the density and weight of wood composites, while maintaining performance. But again, this boils down to cost.

Q: What message would you share with people in the building supply, hardware and lumber industries who perhaps haven’t given much thought to wood-based composites or are maybe skeptical of selling new products?

Frazier: Get on board. But I suspect they already are. Wood-based composites are superior to solid wood in many respects. They have issues, just as solid wood does. However, we live here and now. We need to build more homes, economically and sustainably, and we need to store more carbon in more, and new, kinds of wood composite. New composite technologies are always emerging, some obviously better and others not. My observation over 30 years is that the industry is constantly improving old materials and creating new ones.

The Census Bureau’s most recent Survey of Construction (SOC) offers keen insights for building materials pros from coast to coast.

For instance, the data shows that stucco continues to edge out other materials as the siding material of choice. Of the new single-family homes built in 2023, 26.8 percent featured stucco siding. Stucco was followed by vinyl siding at 25.6 percent, fiber cement siding (like Hardie Plank or Hardie Board) at 21.7 percent, then by brick or brick veneer at 18.5 percent, according to the National Association of Home Builders (NAHB). Just over 5 percent of single-family

homes built in 2023 featured wood or wood products as the principal exterior material used, and that number was even smaller (1.2 percent) for stone, rock or other stone materials.

Wall material preferences appear to be shifting, depending on where you are in the U.S. According to NAHB, which has been closely tracking this data for nearly 25 years: "The strongest trend has been the growing popularity in fiber cement siding. The share of exterior siding material for fiber cement siding has increased by five percentage points in the last 10 years and by 14.2 percentage points in the past 20 years."

The data also shows a vinyl siding

Color of Census Division is based on the most popular home exterior type.

Highest share in:

Stucco

Vinyl siding

Brick or brick veneer

decline overall. "Although it has remained steady in recent years, this share has seen a 5.3 percentage point drop in the last 10 years and has had a 12.8 percentage point drop in the last 20 years,” according to the SOC. However, vinyl siding is still quite popular in some colder climates (especially New England). "Vinyl siding was used on 83.1% of the new homes started in New England, 67.4% in the East North Central, 65.3% in the Middle Atlantic, and 43.2% in the West North Central," per NAHB. Stucco, meanwhile is increasingly used in the Pacific, Mountain and South Atlantic divisions, while brick and brick veneer remain the primary exterior material used in East and West South Central divisions.

The Bureau also includes more highlights of the 999,000 single-family homes completed in 2023, including:

2 percent built for sale in the West were built without air-conditioning.

11 percent had two or less bedrooms, and 45 percent had four or more bedrooms.

9 percent of contractor-built homes in the Northeast are modular.

3 percent of homes in the South had two or more fireplaces.

18 percent had a full or partial basement, and 72 percent had a slab or other type of foundation.

25 percent in the Northeast were built with only a porch, and 8 percent in the Northeast were built with a porch and patio.

63 percent of contractor-built homes in the Northeast were two stories, and 9 percent of contractor-built homes in the Northeast were three stories or more.

The median size of a completed single-family home was 2,233 square feet.

Unrivaled dealer support comes from understanding a high-quality product means nothing if it means headaches to get it on your shelves. For five decades now, we’ve built a trusted reputation for going above and beyond to deliver on the extras that make a difference. Like near-by facilities for timely product deliveries. A seasoned sales support team. Or stand-out advertising that drives higher demand for products. That’s just the beginning of a very long list that only we do. See all the other ways the YellaWood® brand has your back. Visit yellawood.com/for-dealers

Fort Wayne, Indiana-based Do it Best is expanding capabilities for selling lumber online, with the aim of offering customers a more streamlined, efficient shopping experience.

“Our data showed that lumber was among the top searches on our site, indicating a clear market demand,” said divisional manager of ecommerce: marketing & merchandising Brianna Wells. “Many of our members sell lumber, and we saw an opportunity to boost their sales by catering to consumers who prefer to pre-buy online before visiting the store.”

According to Wells, the initiative provides additional sales channels for members and should streamline the shopping experience for their customers: “Our enhanced platform features over 1,500 lumber items, and we’re adding

new products daily based on member requests. Customers need detailed product information to make quick decisions, and our online listings provide that.”

Do it Best collaborates with its members to ensure their unique product offerings are available online. This includes integrating their POS systems with the ecommerce platform for

Do it Best’s Brianna Wells and Corbin Prows are helping to bring efficient ecommerce to the co-op’s members.

The enhanced platform now features more than 1,500 lumber items.

real-time updates on pricing and inventory. “We're committed to maintaining current inventory and pricing to ensure a reliable and accurate shopping experience for customers,” explained Corbin Prows, divisional manager of ecommerce platform operation.

This initiative aims to meet the evolving expectations of modern consumers. “It's not just about convenience anymore,” explained Wells. “It's about necessity. If customers cannot find what they need online, they’ll seek out retailers who provide that information.”

Do it Best will monitor key performance indicators such as direct online sales and overall site traffic to measure the success of the online lumber sales. Additionally, the company will track the influence of online visibility on in-store purchases.

“We've already seen a positive trend with customers placing same-day pickup orders, then buying additional items in-store,” said Prows. “This integration significantly benefits our members.”

“We’re dedicated to collaborating with our members to broaden the variety of lumber products available for online purchase,” Wells stated. “Our goal is to help our members remain competitive in a dynamic market, and by consistently improving our online offerings, we can equip them with the necessary tools for success.”

By Robby Brumberg

Don’t scoff at old-school marketing tactics like sponsoring local ball clubs or events, says Courtney Zalesak, who owns a digital marketing agency that’s focused on the home services industry. Also, being charitable can go a long way toward building brand loyalty and awareness.

“Donating materials to improve community spaces raises brand awareness and referrals” she says. “One hardware store I worked with saw sales climb 15 percent after starting community outreach.” Another tip she offers is to focus on high-margin or custom specialty items that perhaps aren’t always available or in stock at big-box stores, such as countertops, flooring or cabinets.

Zalesak’s suggestions are part of a collection of marketing and merchandising tips solicited by HBSDealer from a variety of experts. Many support the idea that trying something new or revisiting a tactic from days gone by are ways to generate a sales lift.

Jason Lamprey, owner of Lamprey Construction, casts another vote for focusing on specialty items and active community outreach. It also pays to provide flexibility for customers. In his business, he offers 24-

hour emergency services and free delivery for large purchases. Making other people’s lives easier “builds loyalty and attracts new customers through word of mouth.”

He’s also found success sponsoring or participating in community and charity events like “renovation days,” where companies donate materials and labor to improve local spaces like playgrounds. “Events raise brand awareness, especially with younger homeowners, and it can be a way to showcase expertise.”

Magee Clegg, CEO of Cleartail Marketing, offers more specific evidence on the potential fruits of investing in marketing. According to Clegg, his company helped a kitchen supply store increase sales by crafting content highlighting its specialty bakeware and cutlery. “Their organic social media traffic increased over 600 percent in six months,” adding that he helped “boost a client's revenue by 278 percent in a year by optimizing their website and Google My Business listing.” It’s all about being visible and near the top of the page when people search “hardware store near me.”

In-store events are also worth consideration. Clegg recommends "DIY Workshop Day" events where experts demonstrate

building popular items (like planters) or hold tutorials on how to use certain power tools (that just so happen to be on sale that day, perhaps). Bonus points for co-hosting a crossover event with a different company in town that perhaps provides complementary services to your own to tap new customers.

Another marketing expert who works with hardware stores, Haiko de Poel Jr., touts the tangible impact of hosting events. He claims DIY workshops boosted one of his client’s store’s sales by over 25 percent that month. “People came for the experience and stayed to shop,” he says. It also makes sense to capitalize, maximize and potentially monetize space. For instance: turning a store section into a “maker’s space” or gallery to showcase local artisans’ work. “One store created an area for woodworkers and saw a 12 percent increase in lumber sales,” he says. You might not be equipped for hosting weddings or a beer garden, but why not try something different?

Even if you’re not a fan of the camera, you may have a budding star in your midst. CEO of Business Builders, Jay Owen, recommends trying video or audio content to build buzz. “Start an entertaining and educational YouTube channel showing how to tackle common DIY projects,” he says. Alternatively, you can leverage other people’s star power by sponsoring rising renovation influencers or folks with smaller but dialed-in followings. Owen’s also found success with podcasts. “We saw a 30 percent increase in new customers after starting a home renovation podcast and promoting it across social media. The podcast built authority and trust, and many listeners ended up shopping in our stores.”

Eco-conscious or local offerings have been at the center of successful marketing strategies. According to Josh Qian, COO of Best Online Cabinets, “Hardware store owners can create a niche by specializing in eco-friendly or locally-sourced products that appeal to environmentally conscious shoppers.” These products vary tremendously: from low-VOC paints to windows that are safer for birds.

One more idea: “Organize community-driven events like fairs where locals can bring broken items for repair advice,” says Qian. That’s the sort of personal, meaningful touch that increases referrals and word of mouth—and turns customers into brand ambassadors.

By Connie Gentry

The recently reinvented design showroom inside the well-established Builders store in Kearney, Nebraska, was created with a focus on customer feedback. It’s all about making the selection process convenient and comfortable for contractors and homeowners alike, while also providing a comprehensive arrangement of the vast array of options for exteriors and interiors.

A team effort from its inception, Stacy Andersen Bivona, Chief Culture Of cer at Builders, says the process began with input from focus groups that included representatives from all of their different customer segments.

“We sought input from our pro customers, the contractors; we had third-party interior designers in Nebraska who chimed in; we had our own sales team weigh in on what was being shown and the sales process; and, of course, we got input from our vendors, what they’re seeing in sales from the Midwest and from different areas around the nation,” she says.

The Builders team assessed the feedback from focus groups to help identify trends on the rise and which ones might be losing steam or dying off, all with the intention of creating a design center that fully aligned with their strategy: “This is 100 percent designed to elevate the customer’s experience,” Bivona emphasizes.

The Kearney showroom was completed in November and is catering to building projects of all sizes, from remodels of kitchens and baths that easily run $8,000 to $10,000, to new home construction that can top $1.5 million.

She tapped Adam Goodwin, who works in marketing and advertising at Builders and has a strong background in design, to oversee the layout of the project and assimilate the various ideas and brainstorming sessions into a functional and inviting design that “made sense” within their selling process.

“Selecting things for big projects is very overwhelming, so we wanted to nd ways to minimize that and make it approachable and more user

Builders Builderscorp.com

Founder: Myron Andersen Started: 1977

Employees: 400

Builders Kearney 4600 2nd Avenue Kearney, Nebraska

Builders Grand Island 824 South Webb Road Grand Island, Nebraska

Builders Colorado 17600 East Smith Road Aurora, Colorado

Wholesale Manufacturing

Operations: Spelts Schultz – Countertops Spelts Schultz – Trusses

friendly,” Goodwin says.

It starts from the moment customers arrive at the dedicated entrance of the Design Center, which encompasses a third of the footprint in the 67,000-sq.-ft. Builders Kearney store. On entering the

ef cient for our sales team and we’re able to move through the process quickly,” Bivona says.

In a similarly unique innovation, the Kearney Design Center also features a long wall of large-scale slabs of quartz countertops.

“Because we also own the wholesale countertop division, Spelts Schultz, we’re able to display a third of a slab for each of the countertops — we ended up with around 25 samples on the quartz wall — and that has been a huge element for customers,” she says. “It’s a game-changer, because instead of making countertop decisions from a 12-inch by 12-inch sample, they see nearly the full slab.”

In addition to doors and windows, on the exteriors side of the showroom customers also nd millwork, siding, stone, decking, replace, shingles, samples for every component of the home’s exterior. The interiors section is similarly out tted but with fully out tted kitchen displays, cabinetry and other elements important to today’s homeowners per the focus group studies: “We have a mud room, laundry room, and pet-friendly stations like a dog-washing element in some of those displays,” Bivona says.

showroom space, customers are greeted by the Design Center coordinator who welcomes them into the space, offering refreshments for what often turns into lengthy visits with the Design Center professionals.

The Design Center draws from a wide swathe of Nebraska, from Ogallala in the west, as far east as York, and even some from Northern Kansas and South Dakota. While locals may come more frequently for 30-minute or one-hour visits, others are known to spend three and four hours at a time, depending on what they want to accomplish that day.

“One of the things that’s unique to our showroom is a pull-out system that my father and another gentleman designed for our selection of windows and doors,” says Bivona, who — along with her brother — are now the second-generation owners of the business their father launched in 1977. “I’m in the Nebraska market and my brother is in the Colorado market.”

The ef cient pull-out system makes the selection process much easier and more accessible for customers, as well as cuts down dramatically on the footprint necessary to showcase the products.

“With our unique pullout system, customers can view three styles of the Shaker or Mission door at one time, and know which one they want. Not only is it quick and easy for the customer, it’s also wildly more

While kitchen and bath remodels are always trending hot, Goodwin says, “Something we’re seeing that’s a new trend is an uptick in custom closets, homeowners are elevating those spaces with custom lighting, islands, and cabinetry. If you don’t show it, people may not think of it, so we’re showing more organizational options, like for pantries, and we’ve featured displays with good, better, best closet options.”

Large tables in the Design Center selection area provide ample space for house plans as well as samples. The end result is clean and clutter-free, helping to take the anxiety out of a situation that often produces sensory overload from the breadth of options available.

“For all of our selection areas within the design center it was important to have a single vantage point so you could be standing anywhere within a particular selection area and see all of your options without having to walk all over. Again, it’s all about convenience for our customers,” Bivona says.

Builders Kearney has everything needed for home construction from the basement to the roof, including all the nishing touches like hardware, light xtures, window coverings, decorative plumbing, and a full Benjamin Moore paint center. “From the center of the design area our customers can see a majority of cabinetry, door styles and colors, and they can pivot slightly to see countertop selections, and backsplash options,” Bivona concludes. And from that centralized vantage point, customers easily narrow the options to their preferred choices.

HBSDealer’s editorial team is always on the lookout for products that appeal to homeowners or DIY enthusiasts, help the contractor or bolster business for the hardware and building supply dealer.

Below you can nd a handful of items that may help boost sales or make life (and work) a bit easier for customers. For more handy products to peruse or use, subscribe to the HBSDealer Daily newsletter, featuring Product Central every day.

Arrow Fastener’s new MH1 Marker Holster is a handy accessory meant to make life a bit easier for contractors and DIYers alike.

“For years, Arrow Fastener has taken pride in offering innovative tools and accessories that help our customers get the job done,” said Christopher Woolley, the company's VP of product and brand management. “Continuing that proud tradition, our new MH1 Marker Holster may be small in size, but it is huge in its ability to support ease of operation at the jobsite.”

The new clip-on marker holster features a universal clip to t any belt. Designed for one-handed use and compatible with most well-known marker brands, it also replaces the marker cap, ensuring that the marker will not dry out. Manufactured with durable material, the holster stands up to daily use, even in tough working conditions, according to the company. arrowfastener.com

Festool's new ExoActive exoskeleton supports users under the arms, taking the effort out of strenuous work on walls or ceilings.

Whether sanding drywall, painting, wallpapering or installing on walls and ceilings, the ExoActive provides essential support by reducing strain on users' bodies. By signi cantly reducing the load on shoulder muscles, the ExoActive enhances endurance and reduces fatigue. Its 18V battery provides extra power during tiring overhead work, and it provides each underarm with an added boost of up to 11 pounds.

Quickly set the support level from three prede ned working areas for targeted support precisely where needed: from the waist up, from chest height or overhead. Using the Festool Work App, available on the Apple Store or Google Play Store, users can select additional pro les for optimal support in a matter of seconds. Whether a user is removing a fastener, getting tools from their vehicle, or mixing paint, the ExoActive is free of restrictive straps and components, offering maximum freedom of movement and comfort. festool.com

DAP’s new 20-ounce touch-up texture repair cans join its 2-in-1 Wall & Ceiling Spray Texture line for Orange Peel and Knockdown textures. DAP has also rolled out a 16-ounce texture repair can for its Popcorn texture. The new spray texture repair assortment provides quick, seamless repairs to wall and ceiling texture in minutes, according to the company.

DAP's new touch-up texture repair line comes in Orange Peel, Knockdown and Popcorn formulas. It provides strong wall adhesion that resists crumbling when painted due to the thick, sag-resistant formula, per the company, and itt also textures and primes in just one step. Orange Peel, Knockdown and Popcorn are available in water-based formulas that feature a 30-minute paint ready time. Orange Peel will also be offered in an oil-based formula that is paint ready in just ve minutes. dap.com

FastenMaster’s Cortex fasteners are now compatible with the stand-up PAMFast Tool for use on advanced PVC decking from TimberTech. The combination of Cortex fasteners and the PAMFast Tool streamlines the installation process and ensures a clean, professional-looking nish.

The PAMFast autofeed system is designed to provide smooth fastener installation, prevent jams and provide maximum fastener engagement and torque to prolong bit life and reduce cam outs. The countersink system is adjustable to 1/64inch, and each strip of Cortex fasteners holds 50 screws for more time driving and less time reloading. Additionally, the PAMFast stand-up installation tool reduces bending and kneeling, minimizing strain and effort for the installer.

The Collated Cortex Fasteners are packaged in boxes of 1,050 screws on 21 collated strips that will enable pros to install 300 square feet of decking, assuming two fasteners installed 16-inches on center. In addition, each box comes with a driver bit, two PAMFast nose guards and a depth guide that allows pros to set fastener depth for consistent installation. Fastenmaster.com

Daich Coatings, a manufacturer of decorative stone and epoxy coatings, has introduced a new version of its DaiHard MAX Industrial Strength Epoxy Floor Coating Kit. The DaiHard MAX Industrial Strength Epoxy Floor Coating Double Kit offers expanded options for providing affordable, high-performance nishes to interior concrete oors. daichcoatings.com

Shurtape Technologies has modi ed the design on its HVAC tape in response to eld feedback that inspectors look for “red-letter tape” when performing HVAC inspections. Shurtape DC 181 will now feature red lettering on silver (metallic) lm tape, replacing the existing silver (metallic) tape with black lettering design.

Shurtape DC 181 lm tape is for use on Class 1 Flex Duct for connecting, joining, sealing and patching exible air ductwork in a residential, commercial or industrial setting. The tape features an acrylic adhesive system, can withstand temperatures ranging from -10 F to 210 F and is clearly printed with the UL Listing that building codes require today.

“We’ve listened to the market and our customers and believe making this simple change to our DC 181 will help homeowners and building inspectors better identify that the proper tape is being used for exible duct work, making life on the job site easier for HVAC professionals,” said Dennis Ineman, Shurtape’s product manager for HVAC & specialty tapes. shurtape.com

Simpson Strong-Tie has introduced its Outdoor Accents DIY pergola kit, which contains all the connectors and fasteners needed for crafting a pergola up to 10' x 10' in size.

The pergola kit includes straps, post bases and angle connectors from the Simpson Strong-Tie Outdoor Accents Avant Collection. The hardware offers clean lines, chamfered corners and a black powder-coat nish. The kit also includes the Simpson Strong-Tie structural fastener and hex-head washer combo, which resembles a bolted connection but installs as easily as a screw, according to the company. Free building plans and cut sheets for an 8' x 8' or 10' x 10' pergola are available online. strongtie.com/pergolakits

Homeowners and DIY enthusiasts seeking a high-quality oscillating blade that matches their tool will nd the search much simpler now thanks to the new line of Dremel Universal True Fit oscillating tool accessories.

Universal True Fit accessories are offered under four main use categories, each designed for speci c materials or applications:

Universal True Fit Wood features both high carbon steel and bi-metal blades designed to cut wood. Ideal for ush cuts and plunge cuts in oors, walls, baseboards, cabinets, and a variety of other applications.

Universal True Fit Specialty features accessories for sanding, scraping, and grout removal. Made for specialty applications that require material removal with precision.

Universal True Fit General-Purpose features bi-metal blades designed for wood, PVC, and general-purpose cutting. Designed to last 3X longer than Dremel high carbon steel blades. Ideal for ush cuts and plunge cuts in oors, walls, baseboards, cabinets, and a variety of other applications.

Universal True Fit Tough Materials features carbide blades designed for cutting tough materials like pipe, metal, and cement board. Designed to last 30X longer than Dremel high carbon steel blades. Ideal for cutting in galvanized and copper pipe, wood trim with nails, plaster, cement board, and a variety of other materials. dremel.com

PAM STOTT HELPS BUILD THE NEXT GENERATION. By Robby Brumberg

Plenty of people bemoan the lack of labor in the trades, but not many are doing something about it. That sentiment can’t be said about Pam Stott, executive director of the Northeast Construction Trades Workforce Coalition and fellow co-founder, Doug Ford, VP at Curtis Lumber. The 501c6 organization was formed late in 2023 but began as just a task force about seven years ago. The group arose from ongoing discussions held at Saratoga Builders Association meetings that always seemed to center on the biggest, most persistent issue each member faced: “How can we get more workers?”

Getting teachers, principals and counselors on board was a huge rst step, but the reaction of the students has helped spur the organization’s momentum even more.

issue. The armed forces, other industries and colleges recruit in the schools, but the trades do not promote themselves.”

Educating parents, many of whom still may hold outdated views of the kinds of opportunities available in construction, remains challenging though Stott says she’s seeing change even on that front. However, it helps to reach people while they’re young.

The NCTWC’s outreach begins in the second grade and goes through high school. The organization’s “toolbox assembly” program, which gives second through fth graders the chance to make their own toolbox under the guidance of an NCTWC member, has been a huge success.

“You get passion when you connect with something personally. Working with kids directly is what ignited my passion, as I didn’t have awareness about opportunities in the trades when I was going to school,” Stott says. Bringing that awareness to students helped solidify the group’s mission and codify the work that led to the creation of the NCTWC.

“We need to reach the students about the trades. They don’t understand the options and opportunities available,” says Stott, who notes that the construction industry still has its work cut out to promote itself to younger generations and to reverse outdated stigmas (too physical, poor pay, unsafe, long workdays, etc.).

The trades are also being outhustled by other industries in terms of school presence, PR and promotion. “It’s an industry

“They’re so engaged in the toolbox program. Afterward, many kids tell their parents they want some wood to make something else on their own,” Stott says. The program has doubled in the last two years, and NCTWC now works with over 40 schools to spread the word about career options available in the trades.

Colleges are now approaching the NCTWC, which touches on another misconception Stott is keen to dispel. “You can get to the trades through college,” explaining that it’s not a oneor-the other proposition. As Stott observes, there’s still that societal pressure to attend college, “just because that’s what you’re ‘supposed to do,’ ” but it’s not for everyone. “Kids are just expected to attend college and eventually gure it out.” But now with soaring tuition rates and the uncertainty of nding work, even with an advanced degree, the trades are increasingly attractive. “Even if they don’t go the trades route, we’re empowering them with knowledge of their options and what’s possible.”

The NCTWC also recently hosted a hugely successful one-week construction camp for girls, which was designed to inspire a new generation of builders and help knock down the formidable gender barriers that exist in the construction industry. The camp, which was put on in conjunction with Whitbeck Construction and WSWHE BOCES, empowered the 22 girls who attended with basic construction tips and techniques, as well as career guidance.

Sure, working in the trades can involve swinging a hammer. “It’s also science, tech, math, creativity, design and all of those things,” Stott says. Not to mention competitive pay and bene ts and more job security than perhaps most people are used to.

“The trades have advanced, and that’s part of our message. There’s also estimating, project management and other jobs that are more in the background but are also part of the trades. We’re there to make kids aware of their options,” Stott says. At the very least, it’s a great way to discover new jobs and elds people didn’t even know existed.

Everything begins with the members.

That’s how LMC leaders in Wayne, Pennsylvania describe the culture of the $7 billion strong lumber industry co-operative.

“We work very hard to instill in our dealers the feeling that they come first,” said John Keeley, vice president of building materials. “We have the cream of the crop of independent lumber dealers. And it’s important for us to provide them with the service that they expect.”

One part of that formula is pooled buying power. Another is the synergies fostered by collaboration — site visits, educational events, roundtables and other growth-inducing networking opportunities.

To borrow from Rudyard Kipling: The strength of the co-op is the members. And the strength of the members is the co-op.

Over the decades, LMC has evolved with technology, programs, expansion and expertise. And at the heart of it all is the concept of buying power and efficiency.

“The LMC members are looking for this organization — this corporate office here in Wayne Pennsylvania—to pro-

vide that down-the-hall-office concept in overall purchasing,” said Vern Dando, vice president of panels, special wood products and logistics. “That remains the key to making our dealers the most successful they can be.”

It’s an approach that’s produced industry-leading success for nearly a century.

“The strength of the wolf is the pack. And the strength of the pack is the wolf.”

— Rudyard Kipling

During the depth of the Great Depression, a lumber dealer pitched the idea of group buying to his colleagues in the industry. That dealer’s name was Jim Buckley. And on Oct. 1, 1935, a collection of visionary lumber dealers formed Lumbermens Merchandising Corp. Today, LMC is a leading forest products and building materials buying group representing nearly 450 Dealers with over 1,900 locations in all 50 states

Over the years, LMC has cultivated enduring partnerships with top-tier lumber mills and renowned manufacturer brands in America. The cooperative purchasing model introduced by Jim Buckley during its early years revolutionized the lumber industry, reshaping how business was conducted.

Here’s a look back at key events in a 90-year journey of growth and innovation.

• In the beginning: 35 lumberyards joined forces with Buckley’s model and founded LMC. Buckley was appointed as the first general manager, operating with a staff of two other paid employees.

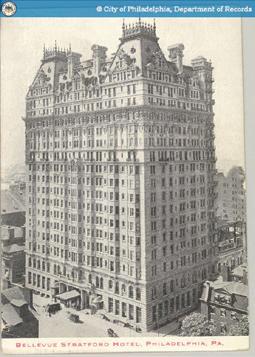

• Year one: LMC held its First Annual Meeting for Stockholders in January of 1936 in Philadelphia. Dividend checks were returned to each stockholder and ranged from a few hundred dollars to well over $1,000, which generated growth in interest within the industry. Another 35 new stockholders joined from New York and New England bringing the total membership to 70. After one year of operations, purchases reached $536,000.

• World War II period: In a crucial moment during the war, LMC played an important role by becoming the distribution arm for Georgia Hardwood (the forerunner of Georgia Pacific) helping to fulfill the urgent need for lumber in the war effort. This move not only contributed to LMC's growth but also sustained local businesses and communities.

• Post-war growth

LMC continued to expand in the 1950’s moving southbound into Florida and West to the Mississippi,

LMC leadership introduced the concept of sole affiliation in 2001. And it was adopted across the full members in 2003.

The bold policy that would require LMC members from belonging to a competing co-op, wasn’t universally embraced initially.

But ultimately, the decision led to growth, success and efficiency, embracing what a co-op is all about: maximizing the purchase volume of the collective membership.

“Sole affiliation really got everybody in the organization rowing in the same direction,” Ryan said. “It really helped us differentiate ourselves from other co-operatives, and made a big difference with our supplier community.”

Vice President of Building Materials John Keeley expands on the benefit of sole affiliation. “It really set us apart from our competition,” Keeley said. “It put us in a position where we were able to build up a lot of goodwill with our supplier community.Because we took that stance where LMC dealers could belong to one buying group, it has benefited us over the years leading to unique programs and offerings that suppliers are willing to provide for LMC and our stockholders.”

expanding to 56 LMC dealers. LMC celebrated its 25th Anniversary at the Shoreham Hotel in Washington, DC. on Nov. 9, 1960, and purchases reached $70 million.

• The seventies

LMC turned 40 with 120 stockholders across the East Coast and as far west as Mississippi with purchases crossing the $100 million mark for the first time.

• Crossing the Mississippi

In the 1970s and 1980s, further expansion drove LMC into the Southeast and Midwest, and parts of Texas and Minnesota – shifting the buying group’s service area across the Mississippi.

• The first $1 billion

The 1980s and 1990s saw LMC move into its current headquarters in Wayne, Pennsylvania. By 1988, LMC had reached $1 billion in purchases with 262 stockholder companies. And nine years later, LMC opened up the Rockies as a new Western Region and surpassed 300 stockholders.

• Into the digital age

In1998, LMC entered the modern communications era by launching its website: lmc.net. Before the turn of the century in 1999, LMC achieved another milestone by surpassing $2 billion in purchases for the first time with 328 stockholder companies.

• Sole affiliation

At its 2000 fall market, LMC announced a bold plan: “Sole Affiliation.” Members were asked to

Vern Dando, VP panels, special wood products and logistics, is a de facto senior statesman of LMC. He has seen a lot of changes at LMC during his long career. He joined in 1979, and remembers back to the old trucking depot that was remodeled for office work back in the seventies.

Behind the scenes, the systems and technology have also advanced significantly.

“When I started in 1979, we didn't have quite the handle that we have today on our dealers’ purchasing needs,” Dando ticked off some of the game changing communication tools that he has seen:

drop affiliations with other co-ops and to purchase through LMC exclusively. The plan was in place in 2003. The move led to record-breaking purchases, pushing LMC across the $3 billion milestone.

• Coast to coast, and beyond

In 2006, LMC expanded internationally with a member in the Bahamas. In 2013, LMC had successfully planted its flag in Hawaii and Alaska, bringing the co-op to all 50 states.

• The $7 billion milestone

In 2021, LMC crossed another milestone: $7 billion in purchasing power.

the fax machine, computers, e-mail, text. “And yes, all that technology has helped move us along. But success is really about our dealer support and their focus of purchases here at LMC.”

Added value for membership, he says, takes a number of different forms, and as supply chain and logistics head, Dando points to the basics.

“Along with that purchasing element comes service,” he said. “We have to get product to our members on time. It's got to arrive correctly. We have to make sure our dealers are positioned well to supply their customers.”

Beyond logistics, there are ancillary services that maximize performance of dealers.

Dando explains: “Can we help them with their technology by putting together and amalgamating opportunities in e-commerce? Can we help them if they're thinking about adding something to their business? Are they adding a door shop, or building a truss plant? Can we provide knowledge through networking?”

By managing and directing these kinds of cooperative services, LMC provides a value and benefit to its members that is both tangible and intangible.

“But you know, our concept of being a purchasing organization, we can't vary from that a whole lot. We have to be as efficient as possible and take advantage of all the opportunities that help us with that efficiency.”

As the LBM industry increases in com plexity and as LMC approaches its 90th anniversary, CEO Paul Ryan embraces a time-honored and crystal-clear message.

“We start with the dealers,” he told HBSDealer. “Our goal is to try to level the playing field or even tilt it in their favor so that they can continue to be leaders in their markets.”

Ryan joined LMC as senior vice president of finance and technology in 2016, and took over as CEO in 2021. In the following Q&A , the CEO expanded on the Wayne, Pennsylva nia-based co-op’s strengths, its goals and its milestone anniversary.

major decisions that shaped LMC?

HBSDealer: How do you describe the strengths of LMC

Paul Ryan: I think our strengths really begin with our dealers. But it’s not just the quality of our dealers, it's how they work collaboratively with our team. And then also being able to work with best-in-class suppliers across the whole product spectrum that we represent. That’s how it all comes together so that our members are incredibly successful — and even better than they would be on their own.

HBSD: When you look across your membership, what do you see as common traits of the members?

Ryan: What makes the LMC members special, to me, is their position in their local markets. They focus incredibly hard on customer service, and they have the same expectations of us here at LMC. They're also not willing to just sit by idly as business evolves. They continue to innovate, grow their business, look for new opportunities and we're here to help them.

HBSD: An evolving industry often brings uncertainties, and that’s certainly the case in the LBM industry. How does LMC guide its members in these times?