July 2023 www.energy-focus.net ALSO IN THIS ISSUE: THE BUSINESS MAGAZINE FOR ENERGY LEADERS Survitec / Levidian / Copeland / Forze Hydrogen Racing Guiding You On Your Solar Journey Exclusive interview with SIG Building Solutions Business Development Manager Solar Canopies, Guy Chilvers, and Commercial Director, Samantha Jones

Join the Renewable Energy Revolution!

Make an impact and profit from the energy transition with Southern Cross Britannia's large and material, exclusively owned Lithium Project

100% Ownership

Vast Mineral Property Package: Spanning 600 km2.

Prime Location: Situated in the Hombre Muerto Basin, renowned for the highest lithium concentration brines in Argentina.

Proven prospectivity: Hosted within the same structurally controlled NW-SE elongate basin as Galan Lithium’s Candelas project.

Abundant Fresh Water: Our project benefits from an abundant supply of accessible freshwater resources.

Join us as we shape the renewable energy landscape, contributing to a sustainable future.

Southern Cross Britannia is offering equity in this material lithium opportunity. info@southerncrossbritannia.com

$35M Market Cap $5.8B Market Cap $1.6B NPV $8.8B Market Cap $385M investment for 50% interest $1.2B preTax NPV Sold for $460M $16.2B Market Cap Sold for $265M Sold for $962M

EDITOR Joe Forshaw

joe@energy-focus.net

PROJECT MANAGER Tommy Atkinson

tommy@energy-focus.net

PROJECT MANAGER David Hill

david@energy-focus.net

PROJECT MANAGER Chris Bolderstone

chris@energy-focus.net

PROJECT MANAGER Terry Hanley

terry@energy-focus.net

PROJECT MANAGER Ekwa Bikaka

ekwa@energy-focus.net

FINANCE MANAGER Isabel Murphy

isabel@energy-focus.net

LEAD DESIGNER Aaron Protheroe

aaron@energy-focus.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Karl Pietersen

CONTRIBUTOR David Napier

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

Sustainability was the buzzword in June within the European energy sector, with Brussels hosting European Sustainable Energy Week 2023. Important topics such as addressing skills challenges in the renewables sector and ensuring inclusivity in the clean energy transition were covered in depth during a fascinating hybrid event. There was a forum for young people to share their vision for the energy future across the continent, and leading innovators recognised in an awards segment – notably the Alqueva Floating Solar Farm being awarded the European Sustainable Energy Award 2023 in the Innovation category for bringing together solar energy, hydropower and battery storage in innovative scalable technology to reduce emissions and protect nature simultaneously.

This month’s edition looks at several industry pioneers helping to transform various aspects of the energy market. Our front cover story explores the innovation on display at SIG Building Solutions, part of the SIG Group, and their development of Solar Canopy Support Structures helping the construction industry respond to the climate emergency and rising energy costs.

Leading player in survival technology and PPE since the 1970’s, Survitec tell a story of inclusion and innovation having recently won an award from Shell for the work they are doing to ensure women have access to comfortable and appropriate resources in a traditionally male dominated offshore environment. We look at what this means for their plans for further growth and expansion.

We revisit the remarkable story of the Forze Hydrogen Racing team, comprised entirely of students on a voluntary basis aiming to utilise hydrogen fuel cell technology in a competitive racing environment, as they “aim for race-winning performance at a level that has never been reached before”.

Coming up very soon of course is ADIPEC 2023 – stay tuned for exciting and exclusive content that we are producing for the event. Are you planning to attend or exhibit? We are and we would love to meet you and help to tell your story. It’ll be a busy few weeks, so let us know where you will be! We’re on LinkedIn.

Published by

Chris Bolderstone – General Manager

E. chris@cmb-multimedia.co.uk

Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX +44 (0) 1603 855 161 www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© CMB Media Group Ltd 2023

EDITOR GET IN TOUCH +44 (0) 1603 855 161 joe@energy-focus.net www.energy-focus.net

EDITOR’S LETTER Joe Forshaw

www.energy-focus.net / 3

4 / www.energy-focus.net 6 14 20 26 32 38 CONTENTS SIG BUILDING SOLUTIONS Guiding You On Your Solar Journey SURVITEC Trusted, Safe, Secure –Growing Survitec Open to new Partnerships LEVIDIAN LOOP to Power Circular Economy and Decarbonisation COPELAND Innovating for Sustainable Present and Future FORZE HYDROGEN RACING The Future of Motorsports Is Green TRADING LINE Transforming the Shipping Industry Through Waves of Innovation 12

44 50 54 60 66

SEAGREEN WIND ENERGY

Seagreen Set to Power Majority of Scottish Homes

VITA GROUP

Energy-Aware Environments Where People Can Thrive

SNAM

Three Ds Build Secure, Sustainable Energy System

DELTATEK GLOBAL

Access to Global Footprint Accelerates International Ambitions

HELLENIQ ENERGY

Solar Beacon of Complete Commitment to Change

www.energy-focus.net / 5

30

SIG BUILDING SOLUTIONS

Guiding You On Your Solar Journey

PRODUCTION: David Hill

A group of manufacturing businesses trading separately for well over a decade, SIG Building Solutions represents the customer-facing brand bringing this wealth of experience and expertise together under a single umbrella to deliver true innovation in the solar canopy space.

6 / www.energy-focus.net

INDUSTRY FOCUS: MANUFACTURING

//SIG Building Solutions offers a wealth of products and solutions, commensurate with the breadth of its talent and expertise. A wide range of Zed, Cee and Eaves Beam sections and accessories are manufactured to customer requirements, while its single skin steel cladding is suitable for a wide range of buildings and situations, from warehousing and industrial applications to agricultural and home outbuilding uses.

Furthermore, twin skin steel cladding roof and wall systems offer rapid coverage and swift completion of a weatherproof building envelope, to produce a high-performance building, and insulated composite panels are self-supporting making them ideal for building roofing and cladding.

SIG Building Solutions also manufactures bespoke architectural

fabrications and flashings in aluminium, steel and other metals to specific designs, as well as a comprehensive range of accessories and components such as rooflights, gutters and flashings to furnish any building with its finishing touches. “Fabrications are not limited to use in building and construction only,” the company clarifies, “if it can be fabricated from metal, we can make it.”

NIMBLE DIVISION

SIG Building Solutions resides within the Specialist Markets Division of SIG plc, who are the leading supplier of specialist insulation, roofing materials and sustainable building products to customers across Europe known for its expertise, quality service and reliability.

A group of specialist distribution businesses, SIG works in partnership with the construction industry via an extensive branch network of over

440 sites across seven European countries - in the UK alone, SIG has well in excess of 3,000 employees and close to 200 trading sites.

Inspired, rather than overshadowed, by its association with the major multinational, it is clear that SIG Building Solutions is a relatively unique part of the wider group, playing to their manufacturing strengths and working within their own clear identity and philosophies.

“SIG Building Solutions combines the powerhouse capabilities of SIG with a relationship-driven, solutions- focused dynamic,” is how Guy Chilvers, Business Development Manager for Solar Canopy Structures, best describes the relationship.

“We are a single-point communication solution, removing complexity for customers while increasing efficiency and adding value.”

8 / www.energy-focus.net

What SIG Building Solutions offers is a bespoke service, with decades of manufacturing experience and expertise, backed by the robust supply chain and extensive capabilities of a major PLC with 6,700 employees across 425 sites, Chilvers unpacks.

“One of the great things about SIG Building Solutions is that it does

exactly what the name suggests,” he says. “We actually manufacture, in-house, and we have access to three factories within this division, the main one of which is in Carlisle and which we use to make all of the structures.

“We represent a nimble little group within a much bigger PLC, and we really pride ourselves on that; we are very close to our customers, and ultimately we like to think of ourselves as incredible flexible,” adds Samantha Jones, Commercial Development Director. “The fact that our products are both designed and manufactured in the UK is also huge, as are our rapid response times compared to those of our competitors.

“Even the site at which we produce our solar canopies has over 100 years’ experience of manufacturing products into the construction sector,” Jones continues. “These products then lend

themselves perfectly to their solar applications, and it is to these solutions that we are dedicating much of our thinking and investment at present.”

SOLAR SOLUTIONS

As countries around the world plan to ban the sale of fossil-fuelled vehicles in the years to come, and reductions in carbon emissions used around the Paris Agreement become ever-more pressing, the development by SIG Building Solutions of its Solar Canopy Support Structures starts to look more intuitive and adept by the day.

“As the construction industry responds to the climate emergency and rising energy costs, we are accelerating our own response and partnering with suppliers to ensure sustainability is at the forefront of our industry,” Jones states. “Using our Solar Canopy Support Structures will help improve the

www.energy-focus.net / 9

BUILDING

SIG

SOLUTIONS

// AS THE CONSTRUCTION INDUSTRY RESPONDS TO THE CLIMATE EMERGENCY AND RISING ENERGY COSTS WE ARE ACCELERATING OUR OWN RESPONSE //

INDUSTRY FOCUS: MANUFACTURING

sustainability of any organisation and, in turn, build a better planet for everyone.

“Using our insight and specialist know-how, we are supporting our customers and manufacturers to make tangible steps towards a greener future.” Jones and Chilvers jointly bring a vast amount of experience in their respective sectors, we learn, crucial to SIG Building Solutions’ ability to bring this offering to market. “Guy joining our team last year is what has made the difference for us,” Jones opines. “Of course, we have always had the

manufacturing capability, but Guy has brought the experience and industry knowledge - and contacts - to enable us to bring this offering to market.

“My background is in traditional construction, I have worked in and around the industry for 25 years; Guy, supported by our trusted supply partners and design team, are the ones who bring the experience in this particular sector.”

Maximising routes to market is high on the agenda for SIG Building Solutions at the current moment, Jones explains,

10 / www.energy-focus.net

// AS THE CONSTRUCTION INDUSTRY RESPONDS TO THE CLIMATE EMERGENCY AND RISING ENERGY COSTS WE ARE ACCELERATING OUR OWN RESPONSE

//

and finding ways to link in with the SIG businesses throughout Europe, which is partially exciting when it comes to solar. “You only have to look at France, for example, where a new ruling stipulates that all car parks must henceforth have these canopies,” Chilvers informs, “and I have already priced up hundreds of thousands of car parking spaces for big automotive groups.

“Through SIG we already have subsidiaries in France, as well as in the likes of Poland and Germany,

and our cold-rolled steel sections lend themselves well to being manufactured here in the UK and despatched throughout Europe. Currently there are companies in Spain and Denmark sending canopies to the UK; there is no reason why we cannot expand into Europe.”

Solar car parks are going to be one of the main drivers for SIG Building Solutions moving forward, Jones opines, with the move to electric mobility necessitating infrastructure for EV chargers around the world to keep customers and employees on the move. “Generally, when putting up these canopies, clients are thinking in terms of EV charge points underneath them,” she details. “That entails digging up the carpark, putting trenches and plinths, and then adding barriers.

“What we have done is to integrate what we call an EVB,” Jones resolves. “With this solution a steel beam runs across the underside of the canopy, onto which the EV

charge point is mounted, and then all the cabling is housed within the canopy. The initial feedback that we have had has been resoundingly positive, and this is something that nobody else has ever offered.

“Utilising the new customerfacing SIG Building Solutions brand has opened up so many new sectors for us,” adds Jones. “It has allowed us to take a really credible offer to market in a way that we never could before, and facilitates our being able to operate in ways that would until now have been beyond us.

“Nothing embodies that more than the solar structures package solution, which brings together all of the elements in which we have excelled for so many years, and presents it in a fresh way to a new market.”

www.energy-focus.net / 11 SIG BUILDING SOLUTIONS

SIGBUILDINGSOLUTIONS.CO.UK

// WE ARE SUPPORTING OUR CUSTOMERS AND MANUFACTURERS TO MAKE TANGIBLE STEPS TOWARDS A GREENER FUTURE //

INDUSTRY FOCUS: MANUFACTURING

HELICAL PILE SOLUTIONS: QUALITY. SERVICE. EXPERTISE

Helical Pile Solutions is built on solid foundations and can provide your project with the same lasting strength. Operations Director Peter Farr explains how the company work with SIG to achieve lasting success onsite for a blue chip client.

Steel helical pile foundations are both strong, in terms of long-term durability, and flexible in terms of application. Steel shafts with helical flights, these foundations can anchor the heaviest topside without fear of movement or deterioration – when done right.

Helical Pile Solutions Ltd (HPS), the company of industry veterans Peter Farr and Nic Brooker is growing quickly to become the leading authority on the correct usage and delivery of helical piles, and Peter Farr is keen on promoting the benefits that can be achieved when using this alternative to traditional, laborious concrete foundations.

“It’s about getting engineers on board and changing their approach on how they build things,” he says.

Using helical piles is fast and easy, quiet, cost effective, versatile, and requires no heavy machinery. They can be installed in all weather conditions as well as sites with poor ground conditions.

A recent project completed in Milton Keynes, UK alongside SIG Building Solutions saw HPS install 140no. specially designed foundations for a 1Mw solar carport onsite for a major international automotive manufacturer. Steel structures sit on HPS foundations, safely holding solar panels that keep cars in shade, while generating significant energy resources at the same time. This is becoming a major focus area for HPS, and Peter Farr is enthusiastic about the potential.

“In the UK, there is potential for the energy market to grow for helical foundations to approximately £20 million per year should the UK adopt the same approach as Europe. In Europe, taking France as an example, we know that the requirement is huge given the recent change in legislation. We are working to expand HPS into the European markets, offering our services alongside what we currently do here in the UK. Although we are not currently focussing on solar arrays due to standard solutions (not in our portfolio), we plan to venture into this market as the business grows. We currently specialise in Solar Carports, Wind Turbines and Overhead Transmission Line upgrades. Energy has been a game-changer for helical piling over the years. I personally have carried out numerous projects on substation upgrades over the last 15 years, we are excited to demonstrate how we can improve current standards whilst leading the industry using our live data monitoring systems (Intelli-tork) in partnership with Pro-Dig Europe, which we together have integrated into the UK market since 2021 to mitigate manual logging of data.”

The HPS Founder and Director has been an advocate for helical piling after learning the industry top to bottom for the past two decades.

“We offer full knowledge from soil information, installation of helical piles and their versatility, through to design packages and in-house creation of fully bespoke products. Our business benefits from my extensive experience having worked in every role from the ground up to build a pioneering business, with clear vision to better and expand the helical piling industry.”

The company’s portfolio is large, including design, in-house manufacture in our 50,000sq ft facility, supply, and installation of bespoke helical pile foundation solutions. “We work closely with clients, offering services that are tailored to their needs to make sure everything works for them,” says Peter Farr.

The deep and solid foundations within the business make for a reliable partner that stands strong, withstanding the test of time. “We’re a small business but we deliver for big projects with our 40 years of manufacturing and 20 years of helical piling experience, providing the attention to detail and ongoing support that every client deserves to ensure the project runs smoothly,” states Peter Farr.

Contact HPS today to learn more about helical piling and how it can improve and elevate your projects. www.helicalpilesolutions.co.uk | 01223 652155

12 / www.energy-focus.net

www.energy-focus.net / 13 SIG BUILDING SOLUTIONS HELICAL DESIGN HELICAL PILE FABRICATION SUPPLY OF PILES INSTALLATION OF PILES 01223 652 155 info@helicalpilesolutions.co.uk Helical Pile Solutions specialise in the design and manufacture of helical piles, also known as screw piles, serving customers with exceptional service and unparalleled expertise. No project is too big for us to handle or too small for us to value. Solid Foundations Turnkey Solutions for your Solar PV, Solar Battery Energy Storage Systems and EV Charging Projects www.rsr.co.uk Design Build Maintain RSR’s

Solar Carport Project for a Prestigious Car Manufacturer in Milton Keynes

Trusted, Safe, Secure –Growing Survitec Open to new Partnerships

Trusted to Protect Lives is the strapline at Survitec. A culture of innovation developed over a century in business has helped the business become a global industry leader. Survitec is now expanding in the renewable energy space with exciting new products. Energy Focus recently spoke with Survitec to learn more about the opportunities for this laser-focused company.

SURVITEC

PRODUCTION: David Hill

14 / www.energy-focus.net

INDUSTRY FOCUS: SAFETY

the MK50 and latterly, the new Survitec Halo Lifejacket systems, which are supporting offshore transportation in the Americas, Middle East, and APAC regions.

The new Halo lifejacket is a ‘constant wear’ lifejacket designed and approved for use on helicopters operating to or from helidecks located in a hostile sea area. With its sculpted bladder, ergonomic Fusion 3D shape and compact EBS - which provides 80% more breathable air than the minimum standard - the Halo provides operators with an enhanced level of safety, comfort and in-water performance not currently available in the energy aviation sector. Post-certification and introduction in 2020, the Halo lifejacket and EBS system is meeting growing demand, with over 6,000 units safely supporting offshore training and over 1 million passenger movements annually.

The North Sea is, without a doubt, a harsh operating and working environment which requires trusted, high-performance PPE technology to ensure the safety of our customer’s offshore workforce.

Survitec has supported the oil & gas sector in the North Sea since the 1970s with immersion suits and lifejackets for offshore helicopter transportation, offshore emergency abandonment and offshore work requirements. At Survitec, survival suits, lifejackets, and PPE products have evolved over this time in relation to new fabric, component and design technology and further reacting to new legislation and certification demands.

Survitec were the first manufacturer to introduce a CA-EBS lifejacket system

for the UK North Sea in 2014; the MK50 lifejacket met with the UK CAA CAP 1034 demand for an integrated lifejacket system c/w compressed air emergency breathing system.

Post the strategic acquisition of Hansen Protection in 2021, Survitec command a market-leading position supporting the offshore helicopter transportation sector throughout the North Sea in Norway, the UK, Netherlands, Denmark, and Germany.

Besides the North Sea, Survitec supports operations in cold water regions such as Canada, Azerbaijan, Argentina, and Italy (seasonal).

Survitec also supports other operating environments throughout the global energy sector with helicopter passenger and crew lifejacket systems,

Within Survitec are the marketleading brands Hansen Protection, Crewsaver, Survitec HeliPPE, SurvivalOne and the Survitec brand itself, amongst others. The company boasts some of the best products available with these four brands. Lifejackets, protective suits, liferafts, fire protection, servicing and maintenance, and a range of related services – are available to purchase or hire.

As the global energy sector transitions into the renewable energy market, Survitec has remained at the forefront of PPE design technology and certification demands. While complimenting the Survitec offer, the Hansen Protection acquisition provided access to a market-leading range of immersion suits designed to meet customer, market, and legislative demands within the Offshore Wind sector. The SeaWind II, SeaWind III and SeaBreeze suit ranges are designed to meet the crossover usage demand for helicopter and crew vessel transfer. The SeaWind suits are tri-approved to ETSO, SOLAS and ISO 15027 standards.

Survitec provides PPE product and rental support to the offshore wind sector in the UK, Europe, the

16 / www.energy-focus.net

//

Isabel George, Marketing Manager Credit: Julia Mills

// SURVITEC SET OUT TO IMPROVE THE IMMERSION SUIT EXPERIENCE FOR ALL. THE SOLUTION INVOLVED THOROUGHLY REVIEWING THE PHYSICAL PRODUCT AND THE PROCESSES SURROUNDING RECEIVING AN IMMERSION SUIT //

USA and Taiwan. Survitec recently celebrated the opening of a new service and logistics site in Providence, Rhode Island, USA, to target the offshore wind market in the US.

AWARD-WINNING

Significant success has been achieved recently in adapting widely-used immersion suits, including the 1000 series passenger suit, to comfortably fit more shapes, sizes, and forms as the offshore energy workforce of tomorrow changes in nature.

“We are working with Ørsted to support their efforts to achieve a 40% female workforce and foster an environment where women can thrive. We have been engaging with our inhouse expert team to discuss the insights we’ve collected from our survey to date on “women working offshore.” We’re positive to see how the responses we’ve received so far will shape the future of offshore personal protective equipment (PPE). Our mission is to make the offshore industry a safer and more inclusive space for women”, said Jim Cook, Head

of Business Development at Survitec. Already proven in this area, Survitec won an award in March 23 alongside Shell, who conducted an insights survey in 2022 to better understand the current immersion suit experience for those travelling offshore. This followed anecdotal comments about the fit of immersion suits and what this meant in practice for women in a male-dominated and male-created environment. The challenge addressed the immersion suit fit issue for all genders and body types.

With women being 27% more likely to experience this. The most common area of improvement, as reported by 25% of respondents, was finding a suit with suitably fitting neck and wrist seals that also fit the body in terms of height and width. Survitec set out to improve the immersion suit experience for all. The solution involved thoroughly reviewing the physical product and the processes surrounding receiving an immersion suit.

Richard Gordon, Sales Manager at Survitec, said, “The key outcomes included adjustments of the sizing

and seals, increasing readily available sizes by 30%. This modular design means any size of a suit can be fitted with any size of wrist and neck seals. In addition, pre-flight fitting is offered as standard. This is perfect for those who have not travelled offshore before or for anyone with a physical disability who may need a bespoke alteration. These bespoke suits are stored for the individual when not in use and issued like all other suits at the heliport.

“It reduces the time spent on finding and fitting the right immersion suits, ultimately leading to fewer delays and a smoother, more comfortable journey offshore. This translates into a more productive use of time, enabling colleagues to focus on the jobs they’re there to do”.

GLOBAL PARTNER

Survitec was established in 1920 and has ever since been inventing and innovating to provide critical survival and safety solutions. Floatation bags were the initial idea, and with the addition of new brands through merger

www.energy-focus.net / 17 SURVITEC

Image: Christopher Heaney

INDUSTRY FOCUS: SAFETY

and acquisition over the past century, Survitec is today a global partner.

“We are over 3,000 people located in 96 countries around the world, with 2,000 ports covered through servicing – our offering is truly global,” states Gordon.

Even with suggestions that the North Sea could be facing the end of oil and gas production in the mediumterm future, with more offshore wind energy coming online, there is no slowdown for Survitec. In fact, as the global focus on safety increases, there is an opportunity galore for offshore transfer and operation. The company’s Energy Solutions division is one receiving increased focus as these markets grow in national importance, with energy security high on the agenda for most.

“We have suits specifically designed for helicopter transfer, CTV transfer, a full customer range for whoever they are, however, they are transferring, and wherever they might be. For example, the Survitec immersion suit ranges cover all operating extremities, our suits

are designed to offer alternate levels of thermal protection appropriate to the operating and sea temperature environment” highlights Gordon.

“We remain very active and busy with UK clients,” adds Jim Cook. “We are working closely with our mature Energy clients as they consider or have already commenced their energy transition journey. We are further embedded within the Offshore Wind supply chain supporting wind farm owner, developer, vessel operator and O&M customers. The recent Hansen Protection acquisition provided strategic access to the Survitec HeliPPE business who specialise in the rental of an extensive range of transportation and working at height PPE equipment, providing for leading market position in this sector.

Estimates suggest that the world’s big six energy majors (ExxonMobil, hevron, Shell, BP, Eni and TotalEnergies) are now in control of around 30% of total global offshore wind energy production, with output increasing by 715% from 2009 – 2020.

For Survitec, a diverse and widespread client portfolio is key to managing through the transition. The products need no introduction, and the company’s brand clout is powerful. Ensuring quality and end-user satisfaction while achieving volume is the key to future success.

Alongside Maritime, Defence & Government, and Aerospace, Energy Solutions is a critical market. “We have an industry-leading team and are attending more and more events that are energy related to showcasing our offering,” says Cook, speaking of recent displays at OTC, Wind Europe, Global Offshore Wind and an upcoming placement at Offshore Europe.

GLOBAL GROWTH

Our existing presence worldwide provides for expansion opportunities with major international clients, offering global contracting initiatives. Quickly, freely, and effectively, the company can provide world-class products for offshore wind, oil and gas, or any of its key sectors. Areas of growth right now include the UK, Europe, America, Taiwan and Japan, where offshore wind growth continues to flourish or is expected to boom in the coming years.

“We are looking to grow into new markets,” confirms Cook. “We have strong, stable markets where we are leading, for example, Norway, because of Hansen Protection and their heritage in this market. Looking to the USA, we recently built a new location in Rhode Island to support our business operations, we are further working with the global GWO training providers including in Japan with a training centre there following the launch of the first offshore wind farm. Global growth is a strategic target for Survitec, given our worldwide footprint. We have so many in-house products and can truly offer a global solution. In September, one of our messages at Offshore Europe will be around our total coverage of offshore immersion suits globally.”

Headline products like the Halo

18 / www.energy-focus.net

Image: Christopher Heaney

lifejacket and 1000 series passenger suit are easier to market because of their well-proven international status. But the complete range on offer sets Survitec apart from others who are often single-line suppliers and do not offer the same flexibility and scale.

In addition to our leading range of PPE equipment, Survitec provide a wide range of leading products and inspection services to the O&G and Offshore Wind sectors, including Lifeboat, Life Raft, MES, Firefighting equipment and prevention systems

Buying patterns changed after the pandemic and global shutdowns, and only those able to operate with agility could meet new demands. Here, Survitec promoted its rental contracts to ensure clients could access the best safety technology anywhere in the world without significant initial capex.

“People are purchasing differently, but we see so many opportunities simultaneously,” added Gordon. “We offer a package as much as possible to provide the full circle. We are wellknown for our suits and lifejackets

because we have advanced technology; for example, the industry-leading Halo lifejacket. We are committed to continuous service improvement and product innovation and offer a service-return contract to ensure that there isn’t massive investment required to help energy customers thrive.”

“We have a brand – Crewsaver –which is a lifejacket specialist. They are continuously innovating and investing in new designs for jackets,” explains Isabel George, a Survitec Marketing Manager. “We have a range that came from ocean racing which was then adapted into a military jacket, and it has now been adapted into a wind jacket as it offers harnessing and more. The official launch will happen in September, and it has gone through years of planning and development. It recently gained its SOLAS approval certificate, making it one of the most advanced life jackets in the industry – it is an incredible product,” George says.

Life can be dangerous in the challenging but necessary offshore wind and energy industries, where

people work hard on 12-hour shifts for many consecutive days. Conditions are unpredictable, and when safety and protection are a must, it pays to partner with the best. Survitec is trusted to protect lives.

“It is a very competitive market,” admits George, “but we have the biggest footprint because of our brand portfolio.”

As safety culture has been embedded in oil and gas, and project owners have carried that culture into wind, Survitec continues to stand as a pillar of strength and reliability as a world-leading manufacturer and supplier of life rafts, Marine Evacuation Systems (MES) and offshore rental PPE. For now, George and the team are happy with the progress in the UK market and excited about expanding elsewhere. “It would be a dream ambition to one day have every person transferred offshore in a Survitec lifejacket or immersion suit.”

Content sponsored by Survitec

www.energy-focus.net / 19 SURVITEC

WWW.SURVITECGROUP.COM

Image: Christopher Heaney

LEVIDIAN

LOOP to Power Circular Economy and Decarbonisation

PRODUCTION: David Hill

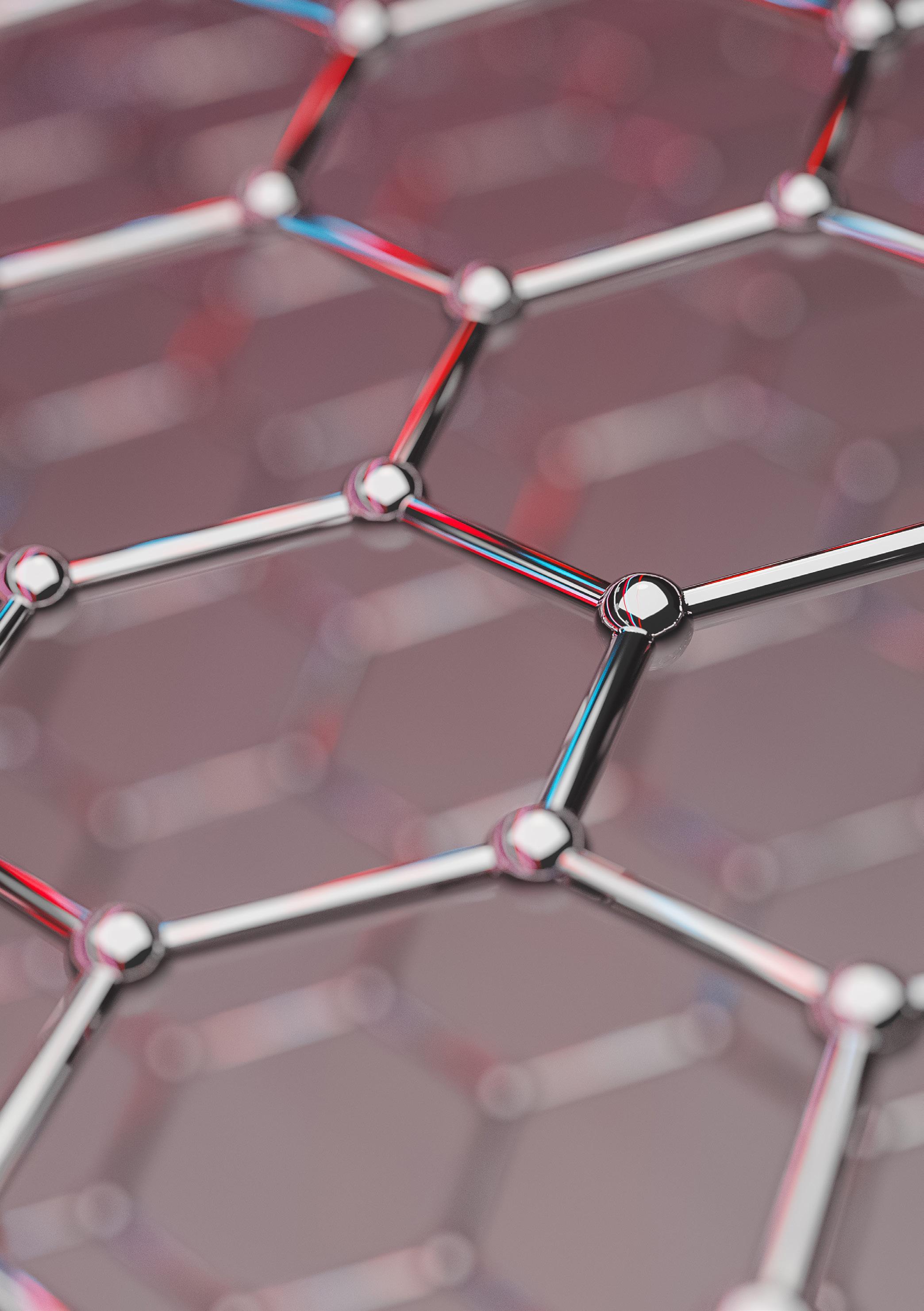

UK climate technology business, Levidian, is growing quickly thanks to strong fundraising and an unrelenting focus on innovation. Technology that cracks methane into hydrogen while locking carbon into high-quality green graphene is helping Levidian build a brand that is in demand around the world. Marketing Director Rebecca Zeitlin talks to Energy Focus about success growth.

20 / www.energy-focus.net

INDUSTRY FOCUS: CLIMATE TECH

In May, at Innovation Zero - the UK’s premier climate tech conference – in London, the changemakers and disruptors of technology, energy, and policy came together to demonstrate intention, invention and thought-leadership as the UK looks to take a front seat in the journey towards Net Zero.

Cambridge-based Levidian led the conversation around decarbonisation and production and use of ‘miracle material’ graphene and hydrogen. Levidian is the sciencebased company behind LOOP, a containerised engineering system that fuels decarbonisation of methane.

At the Working Group on decarbonisation, Levidian CEO, John

Hartley chaired a discussion titled: “Scaling Up: Unlocking Cement and Concrete Innovation and Deployment”. He said that financing and cross sector collaboration are key in driving progress.

Marketing Director Rebecca Zeitlin agrees, saying that Levidian has done everything required to make itself appealing to partners, growing aggressively in the process.

“We have two advantages,” she states. “On graphene, our internal expertise and our track record of producing high-quality, consistent material makes us easy to work with for companies who want to explore graphene. We still have a hurdle to get people to want to explore graphene, but when we get over that we have the best

available team to deliver good results.

“With LOOP,” she adds, “our technology is so unique that a lot of companies are very interested in how they can have it. We have spoken to a lot of companies about LOOP, and in many cases they need to process a lot of gas. We’re working to be able to deliver that scale.”

Scale is the immediate challenge, and Levidian is building quickly.

LOOP, GRAPHENE, HYDROGEN

Operating since 2012, the initial focus of the company was to complete research projects around the commercial application of graphene. Graphene is prized because of its strength and flexibility. 200 times stronger than steel but a million times thinner than a human hair, it is a brilliant conductor of heat and electricity, and can be made water resistant. The possibilities are endless for this relatively new material, with some expectations of

22 / www.energy-focus.net

//

// WITH LOOP, OUR TECHNOLOGY IS SO UNIQUE THAT A LOT OF COMPANIES ARE VERY INTERESTED IN HOW THEY CAN HAVE IT //

a market worth €550m by 2025.

Levidian produces graphene and hydrogen through its LOOP technology, which was previously not presented in the deployable, convenient form that it is today. A proven method, developed inhouse, helps Levidian to create graphene at scale. The only required input is electricity and methane .

“We put methane gas in one end, we blast it with microwaves to ‘break it’, and you end up with pure carbon atoms that are reformed to be graphene,” explains Zeitlin. “Some methane remains, and you get hydrogen - rich blend - gas which is 70% hydrogen by volume. It’s an efficient way of making hydrogen at point of use and if you’re using waste methane – in Luxembourg we will use methane from anaerobic digestion from food waste – you are producing decarbonised energy from a waste source. By using LOOP in the middle, you are producing much less CO2 and you are getting solid carbon as a benefit which can be sold or utilised.

“It is carbon capture but before combustion,” she adds, highlighting LOOP as an intervention technology, stripping carbon out of methane and reducing the amount of CO2 that enters the atmosphere. “It provides a significant decrease in the end amount of carbon being emitted,” she furthers, “and the technology is relatively uncomplicated, unintensive, and unassuming, and you can literally plug it into the wall.”

CONTAINERISED

Installation of LOOP can help businesses to reduce CO2 potential of their natural gas by up to 40% instantly by replacing it with hydrogen which, when produced sustainably, is much more ecological. The technology is housed in a standard-size container (not essential) and runs without disturbance. Zeitlin says that it’s no more intrusive than a ‘slightly noisy air conditioner’ and because of this, interest is growing.

“It provides a degree of flexibility that other technologies don’t have,”

Zeitlin highlights. “Essentially, any place that you would want to deploy it would already have the methane source and probably electricity, and that is all it needs. It doesn’t use water, and it only needs a very small amount of argon gas for maintenance which is included in the container. You don’t need major infrastructure overhaul – especially for the smaller units.

“We have one in Abu Dhabi. We have several on site in Cambridge, and we have one imminent in Scotland. We have another booked in the UAE, and another in Luxembourg.”

With major clients, including water treatment companies and other big utilities, Levidian is looking at the potential of unboxing the technology and installing ‘large warehouses full

of LOOPs’ to process the large amount of gases that are produced in these operations. It is simply inefficient to have a whole field full of containers and a single large system would provide significant space saving. However, most clients are industrial scale but SMME in size, meaning a containerised unit is perfect.

Zeitlin gives credit to the company’s new shareholders for the vision around selling LOOP technology for use on site with clients. When Chairman Jamie Edmiston acquired Levidian in 2020 – against an unpredictable economic backdrop – he identified a need to redefine the company’s longer-term strategy, becoming a climate technology business.

“With that came a refocusing

www.energy-focus.net / 23 LEVIDIAN

Rebecca Zeitlin, Marketing Director

INDUSTRY FOCUS: CLIMATE TECH

remains the same – it’s what we have proven over a decade. We have just slightly shifted what it will do in the world. The executive team is new and brings experience from energy businesses. We are rapidly expanding our senior management team to cover everything from supply chain to project management across all of the elements required to fully commercialise. We recently renovated the office as we ran out of room to put people.”

VERY POSITIVE PEOPLE

and the realisation that the LOOP technology on its own is really useful even without the graphene. Our whole business since then has been pivoting towards a broader overarching theme of decarbonisation,” she says.

Today, the company is home to more than 50 of the best minds in climate tech, with one of the original founders, Professor Krzysztof Koziol, still holding the position of Chief Science Officer.

“We have an applied technology team that does R&D projects with customers to develop uses for graphene, and we also have an entire R&D team scaling up the LOOP technology so that it can process more gas more quickly. We are deploying LOOPs around the world to do decarbonisation jobs as well as producing graphene,” details Zeitlin, adding that the team continues to grow as companies reach out to partner.

“The DNA of the company

The vision of Levidian is to contribute to a circular economy by converting greenhouse gases into innovative solutions and materials. To do this, people must advance the knowledge that is already held and create new solutions. Levidian is very much a people business, and the values of the business reflect the people within: Science led, innovative, smart, and collaborative.

Zeitlin says that within this fastgrowth environment, people have

24 / www.energy-focus.net

always been at the core of problem solving. “Every time we identify a challenge, we take quick action to address it through people - that is central to our strategy. We know the technology is good, but for us to make it work as a commercial enterprise, we have to have the right people in the right roles. We have made some incredible hires with people with amazing experience. That is the exciting bit – you go from a few guys in a room to having ISO accreditation and achieving the mass that works.”

Right now, focus remains on the two key offerings: graphene and LOOP. Advancing R&D with both, and understanding more about potential applications alongside clients is at the heart of every action as the company accelerates towards its goals.

“On the graphene side, there are different challenges. The material has been around for a long time but commercialising it is challenging. We are focused on finding the early adopters at volume. We are going to be producing huge amounts of graphene when we have all of the LOOPs deployed, and we need to find homes for it all,” says Zeitlin.

Concrete is just one of six areas currently under the microscope at Levidian. Graphene can be added to mortars and cement to increase strength and reduce cost. Battery and energy transfer technology, paints and coatings, composites, thermoplastics, and rubber are also key focus areas, where the addition of graphene can have big benefits, already proven in early tests.

“On the LOOP side, the more in the field the better. Internally, we are heavily focused on R&D to make LOOP bigger and able to process larger gas volume – that is critical to our success as a business,” Zeitlin highlights.

This is why the business is quickly building its outreach, to ensure it meets as many people as possible – individuals, scientists, researchers, companies, corporates, governments, investors etc – to build partnerships and collaborate as it moves forward into the unknown. Zeitlin is confident and buoyant going forward as Levidian proves its strength through innovation.

“Overall, the feeling is very positive and driven to meet our ambitions. Every week feels like a new discovery is being made, and the speed at which our R&D teams are delivering is very fast – that is thrilling,” she concludes.

Content sponsored by Levidian WWW.LEVIDIAN.COM

www.energy-focus.net / 25 LEVIDIAN

// EVERY WEEK FEELS LIKE A NEW DISCOVERY IS BEING MADE, AND THE SPEED AT WHICH OUR R&D TEAMS ARE DELIVERING IS VERY FAST //

Innovating for Sustainable Present and Future

Innovation, efficiency, and sustainability are built into the DNA of Copeland. The company’s central promise is around developing inventive new solutions that advance client offerings across commercial and residential heating, ventilation, air conditioning and refrigeration. Sandro Matic, President of Copeland Europe, tells Energy Focus more about the company’s ongoing growth.

COPELAND

PRODUCTION: David Hill

26 / www.energy-focus.net

INDUSTRY FOCUS: ENGINEERING

//With estimates suggesting that around one third of all greenhouse gas emissions and 40% of global energy consumption come from the built environment (homes and commercial property), the sector is under pressure to change. While much has been modernised, the systems used in the industry remain traditional. Heating systems feed off fossil fuels, construction is emissions intensive, materials are the same as they have been for decades and centuries. With so much innovation and adoption of technology happening across all industry sectors, the time for the built environment to adjust is now as its importance sits atop the priority list for most.

There isn’t a single answer or individual invention that can provide complete overnight overhaul, but every step is essential in the wider journey towards net zero.

At Copeland, the focus is first and foremost around modern equipment that can have a real impact on the footprint of a building. The company

works in the commercial and residential space, and is a recognised innovator in technology for heating, ventilation, air conditioning and refrigeration (HVACR).

Matic tells Energy Focus that the company is growing to become a complete solutions provider with a product and knowledge base that is leading the industry across each of its HVACR units.

“We are designing sustainable solutions for the HVACR industry ranging from market segments including air conditioning, heating, refrigeration, where we can deliver any compression technology - for example, compressors, variable speed drives, underlying electronics, and flow controls,” he says. “We see ourselves as a true solutions company by optimizing all of these components to give our customers plug-and-play solutions that allow them to manage their entire system for a more sustainable world. Energy efficiency is so crucial now, not just for OEMs but also for end users, especially in times of very high energy pricing. What we are doing is optimising

components, creating best solutions, and driving energy efficiency.”

AT THE CENTRE OF IT

Copeland boasts an international workforce of 18,000. Researching, refining, developing, manufacturing, and installing, the company’s influence covers major industries including building and construction, facilities management and maintenance, food retail, food service and hospitality, and transportation and shipping. Asked about the importance of sustainability and energy transition in strategy and planning, Matic is clear: “We are at the centre of it.”

Essential work around the technology within air source hydronic heat pumps is beginning to come to fruition as the European public is encouraged to make the switch from traditional boilers. Hydronic heat pumps take heat from air and transfer it to water which is used to warm radiators or underfloor heating, and even hot water cylinders. Greener and with minimal emissions, some reports

28 / www.energy-focus.net

suggest that heat pumps can save around 23 tonnes of CO2 over a decade.

“We are a leading provider of compression technology which eventually goes into heat pumps. In any heat pump, you need a refrigeration circuit, and we supply everything for this. Currently, it is an exciting period for us and our employees because you can clearly see the upturn. If you look at the overall market for hydronic heating systems, every year six to seven million households must decide what sort of heating system they want to use in their new build home or as a replacement. Two years ago, it was assumed that one million of those six million would choose a heat pump. This number is growing at a fast pace. By 2026, all studies predict that more than three million homes will be equipped with heat pumps. This is a high growth sector and a great opportunity for us to create added value,” explains Matic.

The company is completely dedicated to efficiency and is taking heat pump performance, across all metrics, to the next level through

innovation. Typically, these systems use refrigerant gases such as R407C, R32, R410A, R417A and more recently R290. All must be handled and used with care.

“Refrigeration is a mature market where we are working with the industry to see how we can move to other products. However, the picture is different for residential heating in Europe, accelerating at pace as the switch from oil and gas boilers to heat pumps is in full swing, ” says

Matic, emphasising the need for consistent knowledge and upskilling to stay abreast of developments.

REFRIGERANT REPLACEMENT

The current focus in refrigeration is around CO2 as a refrigerant replacement. Gas is used as a heat transfer medium, with a very low boiling point, compressed into a super-heated state by a Copeland compressor. CO2 now allows for

www.energy-focus.net / 29 COPELAND

INDUSTRY FOCUS: ENGINEERING

efficiency at higher temperatures and provides improvements in the Global Warming Potential (GWP) numbers. Propane is another great option because of its promise for efficient use across different conditions.

“We don’t just use sustainability as a buzzword - if you look at our business, we are influencing many things in all the sectors we serve,” Matic says. “Heat pumps are an obvious and straightforward example. We are enabling the industry in the transition from fossil fuel boilers to sustainable, green heat pumps. We are helping the industry shift to environmentally friendly refrigerants. The industry measures refrigerants, and therefore this transition, with a value called GWP. Back in 2015, the average GWP in the industry was 2500. Copeland is developing compression technology which uses natural refrigerants such as CO2 or propane – that lowers our GWP to about 4. That is something we are proud of as it shows we are clearly making a difference. Efficiency is crucial

for us, and a constant driver for us. We are always working to improve, it’s in our DNA and we never stop.”

LOW SOUND TECH

Detailing an example of recent success in product development, Matic highlights the launch of a new low sound compressor for use in heat pumps. With all the environmental and energy saving benefits that come with a system, there is also a noise pollution issue. Typically fixed close to property (or neighbouring property), any reduction in volume is welcomed. The Copeland™ low sound scroll compressors enable exceptionally quiet operation, particularly important for heat pump applications in high density environments.

“In the technology area, we make sure that we are always innovative. We constantly look at our customers’ pain points, identify them together and develop solutions to solve these problems. That’s what our business is about, and that’s what

we will continue to drive,” he says.

“We are launching a lot of exciting products, and recently we introduced our low sound compressor. It’s an outstanding unit which has 10 dBA less than the ones already on the market, and that is a 75% sound reduction. When thinking about heat pumps, sound and efficiency are the big pain points. The sound aspect is getting more important if you think about residential building in Europe. Here in Germany, typically the homeowner’s piece of land is relatively small and you have to think carefully about where you put your heat pump. With this offering, we believe we are tackling a pain point and we are particularly proud to launch this product.”

The all-new portfolio consists of four compressors with capacities ranging from 29 cc (5 kW) to 94 cc (20 kW) but without the need for costly, elaborate noise insulation to be added by OEMs. By excelling in the sound aspect, the company has not compromised in other areas - the

30 / www.energy-focus.net

low sound scroll compressors achieve best-in-class efficiency with an A+++ rating at a reference temperature of 55° C. Also, because of the use of either R290 or R454C refrigerants with a GWP below 150, compliance with the F-Gas regulation is guaranteed, future proofing the product.

EVOLVING AND GROWING

Copeland recently emerged from the Emerson Group’s decision to sell a majority stake in its Climate Technologies division to US investment and asset management company Blackstone, turning Copeland into a standalone business and setting it up for a fresh growth stage. The company’s offering was highlighted with sustainable tech as the flagship element. In fact, “We are engineered for Sustainability” is the Copeland brand promise.

“My key pillars of success are efficiency, sustainability, and technology – that is who we are and what we build our achievements on,” says Matic.

“For me, we are working in an environmental segment that has a clear purpose. This technology contributes to a sustainable future . I am fulfilled by that, and I think it is for this reason that many of our employees are highly engaged and passionate to work in this segment.”

He adds that there is a lot of activity underway in the business and long-term strategies are helping to meet ever-increasing demand.

“There is a lot of investment and expansion happening. We are

adding capacity at factories in Europe, and we have two major projects underway. This is essential to be able to meet any demand in the future.

“We as Copeland are active in air conditioning, heating, and refrigeration – this is where we are strongly positioned. There are a lot of interesting sub-trends and our focus is on making sure we continue to lead in those segments. We are constantly screening adjacent markets and the opportunities there, but first and foremost we want to continue to be the leading partner in our core segments,” he explains.

Leadership will come in the form of market share authority as well as advancement of environmental goals. Success in efficiency will come from innovation around core products. As the heat pump market grows and as the need from OEMs for a simple but comprehensive

solution becomes time critical, Matic is confident of the company’s ability to meet challenges head on.

“I see us as a company that is developing solutions,” he concludes. “We are not a component supplier. We develop solutions which enable OEMs to lead the industry towards a bright future characterised by efficiency and sustainability - this is what gives purpose to anyone who is involved in our business.”

Growing, changing, and adapting, Copeland is a constant force of progress in its chosen markets and will continue to thrive as the built environment seeks a new, more sustainable way forward.

Content sponsored by Copeland

www.energy-focus.net / 31 COPELAND

WWW.COPELAND.COM

// THERE IS A LOT INVESTMENT AND EXPANSION HAPPENING. WE ARE ADDING CAPACITY AT FACTORIES IN EUROPE, AND WE HAVE TWO BIG PROJECTS UNDERWAY //

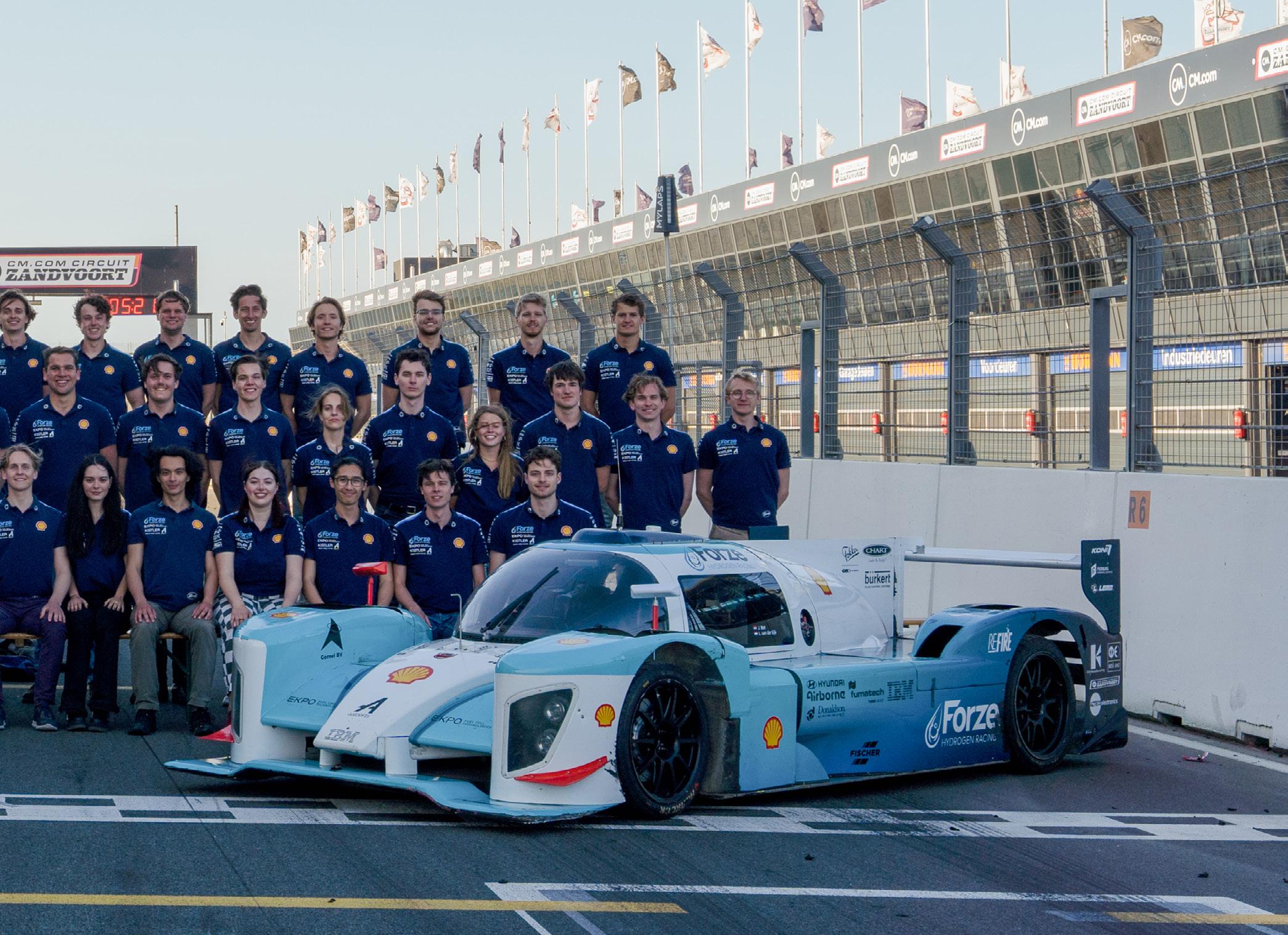

FORZE HYDROGEN RACING

The Future of Motorsports Is Green

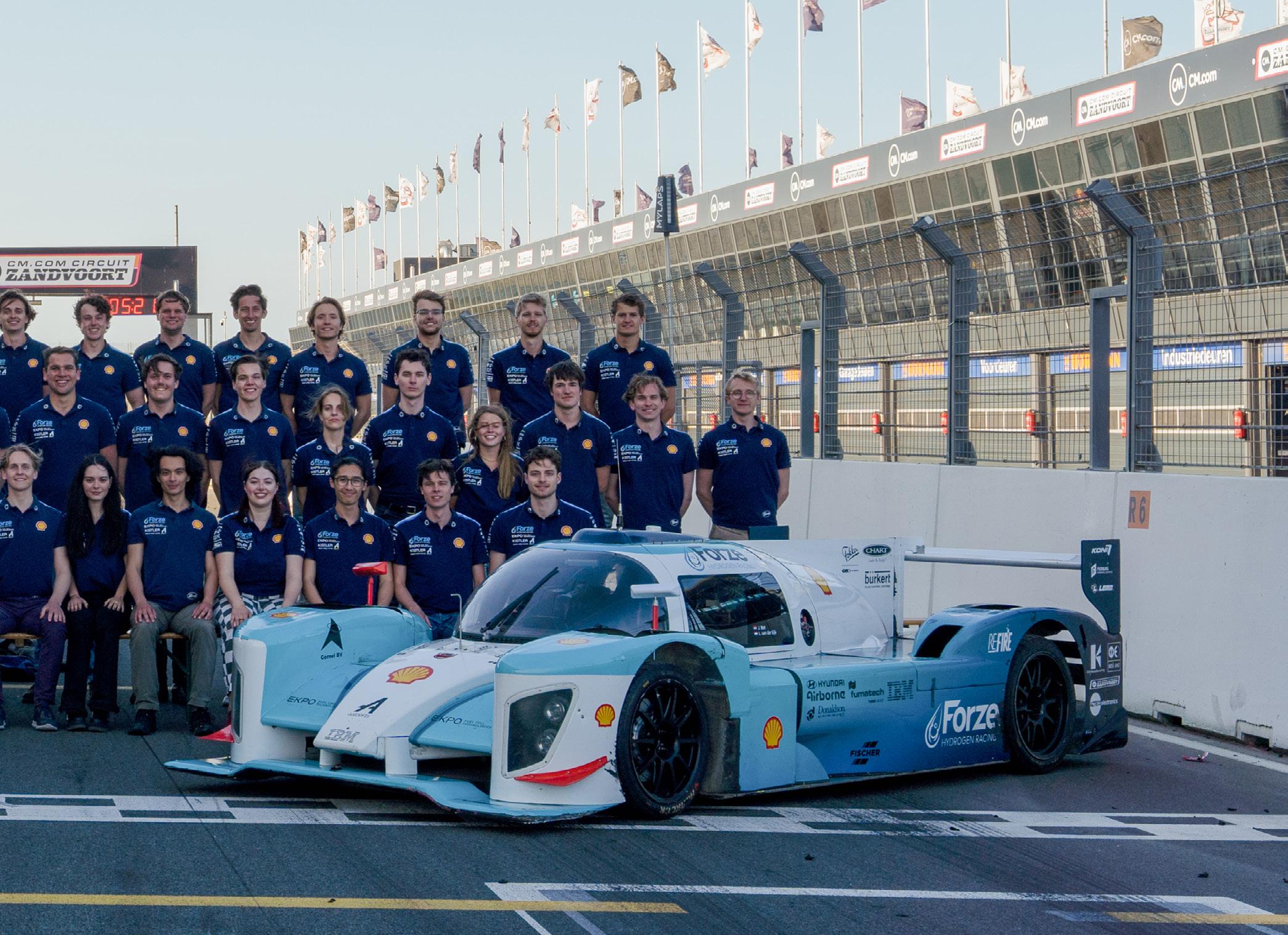

Forze Hydrogen Racing (Forze) designs, builds, and races hydrogen-powered race cars, pushing the limits of all that is possible for hydrogen in motorsports, mobility and beyond. Having built the world’s first hydrogen electric race car eight more have since followed with each outstripping its predecessor, and now the ninth stands poised to dominate on the competitive track.

PRODUCTION: Tommy Atkinson

PRODUCTION: Tommy Atkinson

32 / www.energy-focus.net

INDUSTRY FOCUS: HYDROGEN

//Named after the Formula Zero competition, Forze was founded in 2007 by Edgar van Os. Now, some 16 years later, Forze has grown remarkably quickly from building go-karts to Le Mans Prototype racing cars performing in official competitions. Its growth is made even more startling considering that Forze is a team comprised entirely of students - 60 of them, to be precise - lending their passion and talents honed at Delft University of Technology, Holland’s oldest and largest public technical university.

“The goal of the team is to promote the use of hydrogen technology in motorsports, and beyond. We try to accelerate developments in sustainable fields in general, not only in motorsports.” Thomas Noordzij, Public Relations & Marketing Manager, informs. “Over the course of Forze’s 15 year existence, nine race cars have been built, each one quicker than the previous.”

“Something as extraordinary as this is only possible with real dedication, which the students at Forze have proven year after year; they and their ambitious goals have made Forze what it is today.”

“All our team members decided to join Forze to work voluntarily with their passion for sustainability, technology, and hydrogen.”

RARE PROPOSITION

Historically, multiple types of fuels have been used to power vehicles, and today petrol, diesel, bio-fuels, natural gas, electricity and hydrogen are some of the most noteworthy. New, potentially more sustainable systems have been developed over the years, among which the hydrogen fuel cell is arguably the most promising.

34 / www.energy-focus.net

Team XVI

Leading car manufacturers like Toyota, Mercedes-Benz, Honda, and Hyundai are all developing fuel cell cars and many more on top are investigating the technology, bidding to bring fuel cell vehicles (FCVs) to the market with increasing fervour. Following suit are increasing numbers of European countries, investing in hydrogen filling station networks to accommodate these imminent new cars.

Still, though, hydrogen fuel cell race cars are extremely rare, and Forze’s remains proudly the only student team working with high-power automotive

fuel cells worldwide. “At Forze, we stand for a sustainable future for mobility,” affirms Noordzij. “Together with battery electric vehicles we want to compete against petrol-powered cars. “

To make this a reality, a team of hard-working and ambitious people is necessary, he continues, and this team’s passion, enthusiasm and determination

is what makes Forze a success, backed by the many years of knowledge and growth that Forze has seen so far.

It is difficult to picture more ideal, productive work experience, with Noordzij revealing that the entire team changes each August; it effectively constitutes a one-year break from the students’ studies,

www.energy-focus.net / 35

FORZE HYDROGEN RACING

// OVER THE COURSE OF FORZE’S 15 YEAR EXISTENCE NINE RACE CARS HAVE BEEN BUILT, EACH ONE QUICKER THAN THE PREVIOUS //

INDUSTRY FOCUS: HYDROGEN

FIRMLY ON TRACK

usually between bachelor and masters degrees, which they spend at the epicentre of this pulsating sport.

“Every year a new team of students is chosen to continue the work, which also comes with its challenges,” he describes. “It is important to have an efficient transfer of knowledge between two teams, but at the same time it is comforting for new teams to

know that they have the knowledge and support of their predecessors.”

“We have a number of people who partner with us for recruitment purposes,” Noordzij addends, “because they are well aware that we have some of the best engineers in the area; as a result, many students end up finding an internship or indeed a full-on position at one of these partners.”

Speaking with Energy Focus last year, Forze revealed that its ninth car, the aptly named Forze IX, was well into the testing and assembly phase; its design launch came in January last year , Noordzij happily updates. “The initial feedback has been incredibly positive, and we have also garnered a lot of media attention, pleasing, too, given our overall goal of vaunting hydrogen technology in our own unique way - by building a race car.”

“A future of racing without emissions is our dream,” he enthuses. “We want to promote hydrogen as a sustainable alternative to fossil fuels by showing that it can compete

36 / www.energy-focus.net

// ALL OUR TEAM MEMBERS DECIDED TO JOIN FORZE TO WORK VOLUNTARILY WITH THEIR PASSION FOR SUSTAINABILITY, TECHNOLOGY, AND HYDROGEN //

with conventional petrol-powered cars on track.” The Forze Hydrogen Racing team has already more than adequately proven itself by building competitive zero-emission racing cars; in 2019, its eight iterations achieved a podium place in an official race in the Netherlands.

“Ever since launch, we have been pushing to actually produce a car and test and drive it, as this is the point at which we will be able to really practice what we preach and show how well the technology can work and the feasibility of racing with it,” Noordzij outlines.

“We have been focusing almost solely on this over the past year, thinking out things on a deeper level and then producing, assembling and testing, not only on the hydrogen fuel cell but also all of the subsystems of the car, like the drive train, gear

box, motors and electronics.”

Forze is in the final stages of testing of all these various subsystems, Noordzij says, soon to incorporate these within the car itself. “We aim to have a driving car by the end of 2023,” he reveals, “and participate in the first race in 2024.”

Faster, with more power and zero emissions; Forze IX represents yet another breakthrough in sustainable racing, and is surely well on its way to triumphing in its inaugural race - likely to be in the Netherlands’s Supercar Challenge, a semi-professional series with an open class into which Forze IX would slot, according to Noordzij. “Ultimately we aim to compete in the GT Class, the fastest racing division of the series,” he adds, “but because we want to enter a race as soon as possible and the car

will not be at its peak performance we will begin a class below.”

“We aim for race-winning performance at a level that has never been reached before,” is Noordzij’s impressive ambition. “Over the past three years, we have been working on the design of this revolutionary race car. Our engineers have designed the most innovative components and solutions for the Forze IX in order to ensure big achievements in the future.”

“The Forze IX is built to keep growing and innovating, and in the future, it is Forze’s goal to shift towards endurance racing. We believe that is where the power of hydrogen lies.”

www.energy-focus.net / 37

FORZE HYDROGEN RACING

FORZEHYDROGENRACING.COM

TRADING LINE

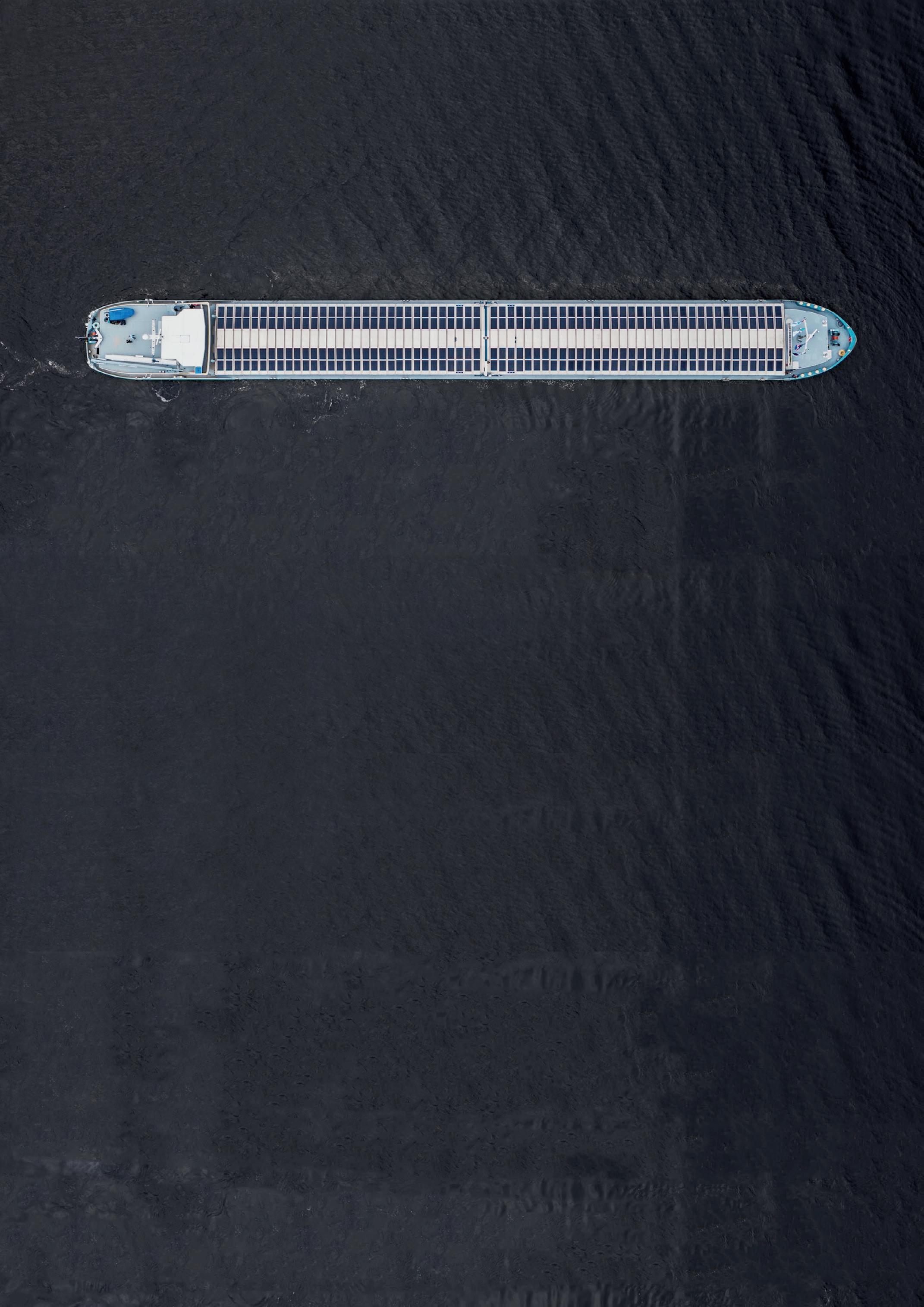

Transforming the Shipping Industry Through Waves of Innovation

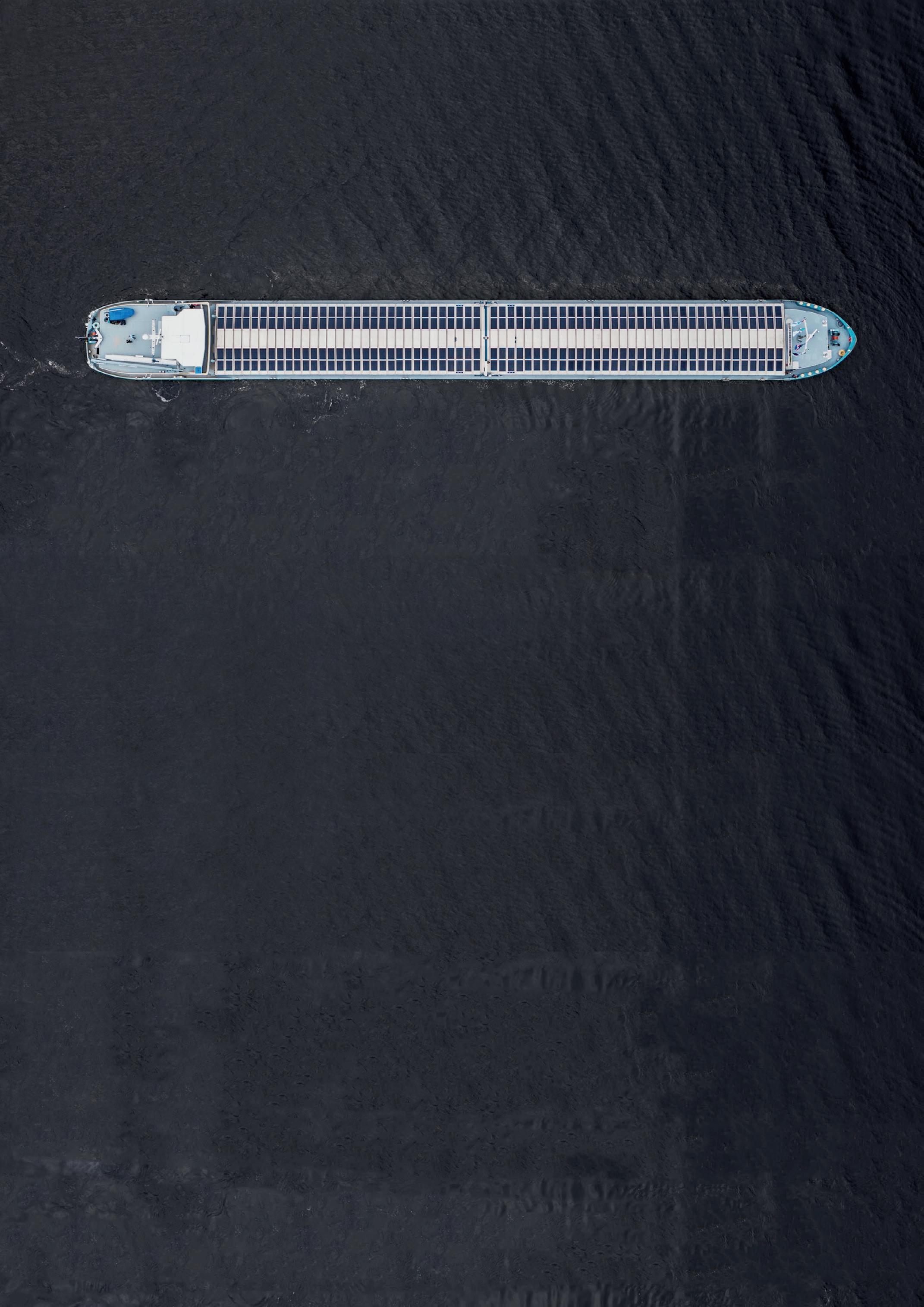

Established in 2012 with Romanian-Dutch joint venture private capital, Trading Line’s river transport activities are most keenly focused on the stretch between Regensburg and Constantza. The company is charged with the efficient expediting of premium cargo along the breadth of the Danube, Europe’s second largest river and the lifeblood of river-based trade across Southeastern Europe.

PRODUCTION: Chris Bolderstone

PRODUCTION: Chris Bolderstone

38 / www.energy-focus.net

INDUSTRY FOCUS: LOGISTICS

Since early history, the Danube has been a principal trading route in Europe, an important source of energy and drinking water as well as being a unique habitat for wildlife and a recreational area. Rising in the Black Forest in Germany the Danube eventually empties into the Black Sea in Romania and Ukraine, 2,415 km of its 2,845 km length navigable, connecting ten riparian countries.

Built in 2008, Romanian-Dutch river carrier Trading Line operates the youngest and arguably most important fleet on the Danube, boasting modern transport units in top condition with a market value of €123 million. “Young and enthusiastic staff offer professional and prompt services, integrating state of the art technology into one of the most traditional means of transportation,” the company sets out

of its unmatched service offering.

“Trading Line is an inland waterway transport solutions provider featuring a high capability and efficiency fleet for both dry and liquid cargo.”

SPECIAL STRETCH

“We started in 2012 with one pusher and 10 barges with a total capacity of 20,000 tonnes,” the company delineates. “Since 2012, we have been growing continuously and by 2022 our capacity stood at 128,000 tonnes of total loading capacity of dry cargo and 20,000 tonnes of liquid, twinned with a pushing power of 55,000 BHP and a 24 hours a day, seven days a week sailing mode.”

Navigation of the Danube is a hugely complex undertaking, the full potential of which can be realised only when the interaction of a system of strongly interrelated elements - the

Danube waterway, the vessels and their cargoes and the ports - is achieved.

In recent decades, ports on the Danube have undergone a substantial transformation from conventional inland ports to modern logistical hubs. In addition to their basic function as transhipment hubs and storage sites, ports today provide a broad range of logistical services including commissioning, distribution and project logistics.

Amid key transhipment port locations such as Izmail in Ukraine, Linz in Austria and Romania’s Galați, the seaport of Constantza occupies a special place as one of the main distribution centre for Central and Eastern Europe. It is located at the crossroads of the trade routes linking

Continues on page 42

BLOMMAERT & WATTLAB: Harnessing Solar Power in Inland Shipping: From Cargo Ships to Sailing Solar Parks.

Solarhatches are aluminum shipping hatches with integrated solar panels that efficiently generate onboard electricity. Instead of relying on continuously running inefficient diesel generators, these Solarhatches, in combination with a battery set, offer a cost-effective solution that significantly reduces fuel consumption. They also provide the ability to store ample power for nighttime operations without the need for a generator or shore power.

In addition to the fuel-saving and maintenance benefits, Solarhatches contribute to a more pleasant environment onboard and along the waterfront. By eliminating the noise and odors associated with idling generators, they enhance the overall experience. Furthermore, Solarhatches offer practicality by enabling independence from shore power.

The solar panels are seamlessly mounted on top of the hatches, with a single plug connection on the side of each Solarhatch. The underlying technology is discreetly housed within the hatch’s bottom section. Micro-inverters within the Solarhatches efficiently convert the generated direct current into three-phase alternating current. Through a combination of individual hatch plugs and a central cable, the power is seamlessly transmitted to the engine room. There, a Wattlab Smartbox ensures monitoring, protection, and integration into the onboard grid. Any surplus energy is utilized for battery recharging. Crew members can conveniently monitor the Solarhatch output and battery system performance via a smartphone or laptop application.

Currently, 15 ships are already equipped with Solarhatches. While the use of Solarhatches in inland navigation is relatively new, its adoption is rapidly growing, leading to larger-scale implementations. In early 2024, a diesel-electric vessel is scheduled for delivery, featuring 27 stacked hatches, each equipped with solar panels. The comprehensive system will boast an impressive installed capacity of 117 kWp. The generated solar energy will not only power the onboard grid but also support propulsion.

Investing in Solarhatches becomes even more compelling with subsidies of up to 60% available in various countries. These subsidies cover the purchase of Solarhatches, battery packs, and the associated electronics. This significant financial support makes the decision to invest in Solarhatches highly attractive.

40 / www.energy-focus.net

//

INDUSTRY FOCUS: LOGISTICS

Continued from page 40

the markets of the landlocked European countries to Transcaucasus, Central Asia and the Far East, thereby facilitating trade, and is connected to the Danube via the Danube-Black Sea Canal.

Since the advent of the crisis in

Ukraine the Port of Constantza’s profile has risen even further, giving it new geopolitical and commercial importance with it now challenged to handle extra cargo with speed, efficiency and safety.

The stretch between this, Romania’s largest port, and the Danube’s northernmost point, the Port of Regensburg, is now the focal point and primary interest of Trading Line and where it seeks to effectuate its top-end, cost effective services unmatched by other players in the market.

SMART NAVIGATION

The benefits of inland navigation are well-rehearsed and oft-cited: it features the lowest specific energy consumption and the lowest external costs of any land transport mode, the ability to transport large quantities

of goods per unit (bulk freight capacity) and requires comparably low investment in maintaining and expanding its infrastructure.

In terms of specific energy use, inland navigation can also be described as the most effective and most environmentally friendly mode of transport; an inland vessel is able to transport one ton of cargo almost four times further than a truck with the same energy consumption.

Compared with other land transport modes, Danube navigation offers significantly higher transport capacity per transport unit. A single convoy with four pushed lighters, regarded as the best way to increase capacity, can move 7,000 tonnes of goods, which corresponds to a load of 175 railway wagons each

42 / www.energy-focus.net

]]

// WE ARE LOOKING TO MAKE TRANSPORTATION MORE PREDICTABLE AND ACHIEVE SUSTAINABLE COST SAVINGS FOR THE ENTIRE VALUE CHAIN //

containing 40 net tonnes or 280 trucks each containing 25 net tons.

“Raising the amount of goods transported on the Danube will consequently result in a reduction of traffic jams, noise, pollution and accidents on roads and relieve strain on the railway system,” the company condenses.

In recent years, Trading Line has committed to investments amounting to some €80 million to maximise these benefits even further, primarily in the implementation of smart technology such as artificial intelligence and remotely controlled ships on the Danube. According to Paul Ivanov, CEO, even some years ago there existed already upwards of 40 remotely piloted ships on the Rhine, some of which manned by

artificial intelligence computers, and transformation of a traditional ship can be carried out surprisingly easily.

Additionally, the technology can be more easily implemented on the Danube because the river is wider than the Rhine, and the traffic is not so heavy, he pointed out, with the carrier having already purchased a new ship that is partially remotely piloted following a €6 million investment. “We are involved with multiple different research projects for automated shipping,” Trading Line explains, “and this combines with our continuous growth in line with our long-term vision to grow the company up to 100 vessels and cover all lengths of the Danube from Constantza to Regensburg with services.

“We are going to develop,

launch and scale a proprietary remote piloting platform and service for inland waterways’ shipping vessels,” says Trading Line of this most exciting of ideas.

“We are aiming to transform the shipping industry by introducing a wave of new technologies in what is a rather low innovation area of the global economy. Following a global trend in the automatisation of transportation that includes self-driving cars, trains and remoteplotted drones, we are looking to make transportation more predictable and achieve sustainable cost savings for the entire value chain.”

www.energy-focus.net / 43 TRADING LINE

WWW.TRADINGLINE.RO

SEAGREEN WIND ENERGY

Seagreen Set to Power Majority of Scottish Homes

Scotland’s largest offshore wind farm is close to completion and ready to unleash the full potential of clean, green, renewable energy for Scotland and the UK. With the deepest foundations and most innovative jackets, this is a project that showcases what is possible through the power of wind.

PRODUCTION: Sam Hendricks

44 / www.energy-focus.net

Activity on the UK Continental Shelf, in the cold and deep waters that surround the island, is changing. With the country still largely powered by natural gas and oil, the reserves are prized and precious but becoming more elusive. At the same time, the energy transition gathers pace with many hoping that it can become the base for UK supply. It’s a complicated environment and challenging when planning longer-term strategies.

the North Sea as a ‘cornerstone of the company’s strategy’. “From Glendronach to Tyra, Laggan-Tormore to Johan Sverdrup, we are developing more and more projects in the North Sea, a very promising area with an important role to play in TotalEnergies’ strategy… By building on existing infrastructure, we are creating invaluable hubs in the British North Sea, enabling us to increase our production capacity and thereby meet the energy demand of growing world population,” it says.

well as the UK energy sector.

Currently, Ponticelli employs more than 530 people across nine sites, on and offshore. The lead partner in PBS - an Aberdeen-based consortium of Ponticelli UK, Brand Energy & Infrastructure Services, and Semco Maritime – the company is embracing activity on the UKCS.

Part of the global Ponticelli Group, family-owned and headquartered in France, this regional arm is responsible for managing all TotalEnergies UK

//

INDUSTRY FOCUS: WIND

He details more about a key job at the Shetland Gas plant where Ponticelli’s service portfolio proved invaluable.

“We are handling all of the maintenance and operations on the site there. We just completed a specific project on site to change a compressor where we engineered the internal compressor mechanism to change the process of exporting gas. We are full time there and we have around 50 people handling maintenance of that gas plant. The five-year contract was awarded in February 2020 and there is possibility for extension, which we will discuss next year with our customer,” he says.

“The plant is operated principally by TotalEnergies and is currently powering more than two million households throughout the UK. Initially designed with both HighPressure (HP) and Low-Pressure (LP) operating modes, the plant has been accustomed to operating in HP. To improve late-life recovery and ensure 15 additional years of use, Ponticelli UK, via its PBS consortium, has successfully executed a £10m engineering, procurement, and construction project to allow the use of LP mode.”

UNCOMPROMISING EXPERTISE

The West of Shetland gas project processes product from the LagganTormore, Edradour and Glenlivet, and Glendronach offshore fields. The efficiency of the site is paramount for the wider energy network and, thankfully, Ponticelli UK receives strategic support from a global network so ensure best practice.

“We are independent but we do have the support around commercial activities and technical capability from our headquarters in France. All Ponticelli Freres Group operations are fully aligned in terms of corporate strategy. Ponticelli UK welcomes uncompromising expertise and competencies from the global group yet enjoys autonomy to make its own decisions based on local market forces and requirements in

line with the energy transition. If we find opportunities that bring value to the group then there is no reason we cannot proceed,” says Renaud.

Expansion beyond oil and gas will likely come in the booming UK offshore wind energy space, where turbines are being erected weekly and feeding into the grid as part of a renewable and green policy which hopes to produce 50GW by 2030. With multiple construction and engineering projects underway, this is an attractive market for Ponticelli UK.

“In the offshore wind space, we want to be involved in construction and that is a very similar skillset – welding metal, assembling structures, cable pulling, cable connection, painting, insulation, and scaffolding. When we look at maintenance, there are differences but we are signatories of the CITB (Construction Industry Training Body) and that helps us to stay up to date with the best competencies in the wind industry while transferring our skills from oil and gas,” says Renaud.

He adds that the transition could help the relatively young company to bolster its client base. “We are targeting offshore wind as we participate in offshore wind farms in the South of France where we are part of pilot schemes. We are willing to start this in the UK with ScotWind projects and others coming up. There is also the idea around electrifying oil and gas using offshore wind. We are also in contact with several parties around developing hydrogen infrastructure.”

This is part of a global strategy

www.energy-focus.net / 47 SEAGREEN WIND ENERGY

// SEAGREEN IS CURRENTLY THE LARGEST OFFSHORE WIND FARM IN DEVELOPMENT AND CONSTRUCTION IN SCOTLAND //

INDUSTRY FOCUS: WIND

to ensure relevance of the business in emerging industry sectors, adapting again as the company has done so through its more than one century of successful operation.

“Our strategy will shift in line with changing environmental priorities,” confirms Renaud. “We are already preparing for these changes, putting our people first by ensuring they are Connected Competence compliant. Connected Competence commands a base level of technical competence assurance and aims to recognise skills transfer which will support a resilient, transferable workforce and aid the energy transition.”

LONG-TERM VISION

According to some reports, North Sea oil and gas production might only have 10-15 years left before pressure from climate targets and environmental