TSG Charge / Centrica Energy Storage / Harbour Energy / Harlyn Solutions Rapid Rollout Will See Global Nuclear Capacity Triple by 2050 ALSO IN THIS ISSUE: Exclusive Interview with Dr Sama Bilbao y Leon, Director General of the World Nuclear Association

Maximise your Drilling Potential with Deep Casing Tools Deep Casing Tools Unit 5 Enterprise Drive, Westhill Industrial Estate Westhill, Aberdeen, AB32 6TQ E: sales@deepcasingtools.com T: +44 (0) 1224 572070 www.deepcasingtools.com Learn more about how technologies from Deep Casing Tools are revolutionising global operations and saving operators time, money, and emissions across all projects, contact the experienced team today. At Deep Casing Tools we deliver simple, sustainable innovations designed to streamline your drilling, completion, and plug & abandonment processes. Our unique solutions across the well life cycle including cutting-edge tools such as the TurboCaser, TurboRunner, MechLOK Drill Pipe Swivel, SelfLOK Flotation Device and the Rubblizer are engineered to navigate challenging wellbore environments, ensuring reliability and efficiency at every stage.

EDITOR Joe Forshaw joe@energy-focus.net

PROJECT MANAGER Tommy Atkinson tommy@energy-focus.net

PROJECT MANAGER David Hill david@energy-focus.net

PROJECT MANAGER Chris Bolderstone chris@energy-focus.net

ACCOUNT MANAGER Isabel Murphy isabel@energy-focus.net

LEAD DESIGNER Aaron Protheroe aaron@energy-focus.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Karl Pietersen

CONTRIBUTOR David Napier

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

EDITOR’S LETTER

Looking longer-term, as net-zero targets approach, companies are building strategies that look beyond the horizon and focus on delivery of changes that will significantly impact greenhouse gas emissions. Here, the energy sector is critical as one of the top emitting industries globally.

The World Nuclear Association is clear. Director General Dr Sama Bilbao y Leon tells us that nuclear generating capacity must triple by 2050. Cleaner in terms of emissions than fossil fuels, and now with proven methods for recycling used fuel, the industry is setting out a strong case as the link between net-zero and the phase out of carbon intensive generation.

Zenobe is hard at work in Scotland, and other parts of the world, bringing innovative battery storage systems that help eliminate wastage of clean power (curtailment) so that more can be used when it is needed most.

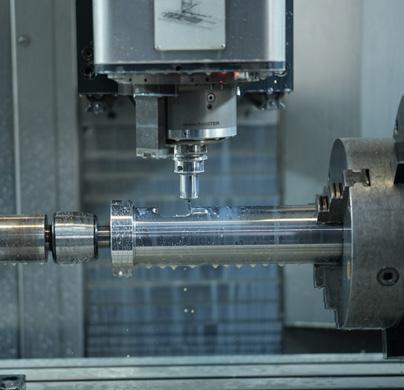

Deep Casing Tools, the Aberdeen-based manufacturer of complex tools for offshore drilling, detail recent innovations that drastically improve efficiency for clients, allowing wells to be drilled quicker and reducing CO2 emissions and cost.

TSG Charge is busy building the charging network of tomorrow. As the EV transition kicks into top gear, the requirement for supporting infrastructure remains large and TSG is an industry leader, capable of providing a turnkey solution. The company continues to rollout technologically advanced systems that provide power for cars, buses, fleets, and more.

Pace CCS is looking at the other end of greenhouse gas emissions – storing CO2 that has been created through industrial processes. The company designs networks that take CO2 deep underground for sustainable, longterm housing in geological formations. An industry leader, Pace is already working alongside the best in the world to drive industry standards.

Published by

Chris Bolderstone – General Manager

Fuel Studios,

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of

All are looking at the long-term, all are focused on a challenging problem, and all are pioneering new ways of thinking. With much demanded of the energy sector, these are just a handful of companies that are doing really great things to ensure a brighter future.

Tell us what you are doing, and why. We’re online at LinkedIn.

Joe Forshaw EDITOR GET IN TOUCH +44 (0)20 3097 1743 joe@energy-focus.net www.energy-focus.net

www.energy-focus.net / 3

E. chris@cmb-multimedia.co.uk

Kiln House, Pottergate, Norwich NR2 1DX +44 (0)20 3097 1743 www.cmb-media.co.uk

transmitted

by

the prior written consent of the publisher.

Ltd 2024

information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or

in any form or

any means without

© CMB Media Group

4 / www.energy-focus.net

16 26 34 44 50 CONTENTS 26 WORLD NUCLEAR ASSOCIATION Rapid Rollout Will See Global Nuclear Capacity Triple by 2050 CENTRICA ENERGY STORAGE Essential Element of UK Energy Resilience

CCS Pace Drives Momentum in CCS Network Rollout

ENERGY

Ambition & Safety Excellence Boost Harbour

CASING TOOLS

Edge Well Technology Fuels Efficiency

Collaborative Solutions for Maximum Asset Value

6

PACE

HARBOUR

Healthy

DEEP

Cutting

HALLIBURTON

54

64

68

74

80

HARLYN SOLUTIONS

Difficult, Challenging, and Complex? ‘We Speak Engineering’

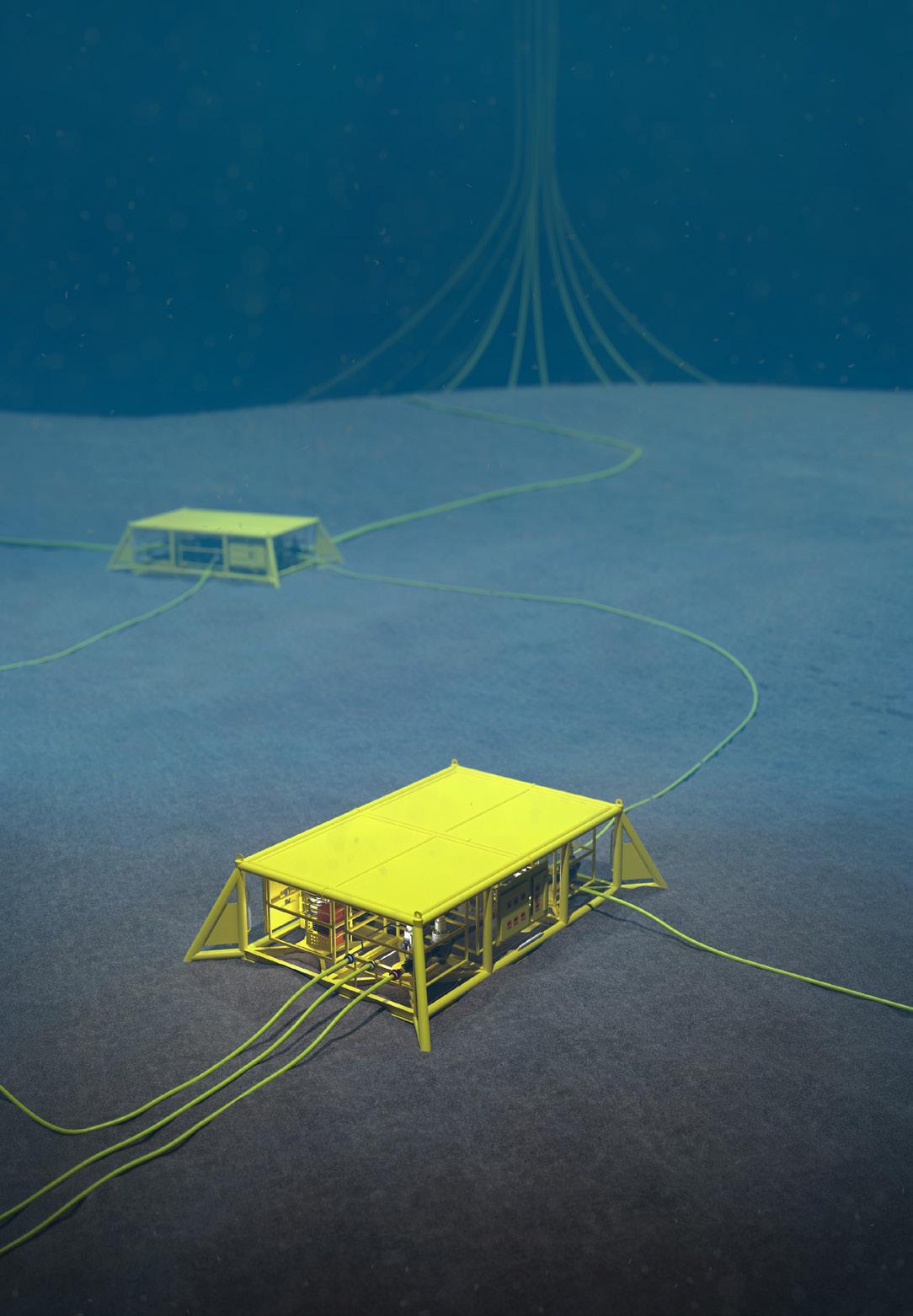

OCEAN INSTALLER

Offshore Projects Executed Flawlessly

TSG CHARGE

Enabling the Electric Future, One Connection at a Time

ZENOBĒ A New Era for Energy

RBN ENERGY

Virtuoso Network Delivers Insightful Analysis in Style

www.energy-focus.net / 5 54

WORLD NUCLEAR ASSOCIATION

Rapid Rollout Will See Global Nuclear Capacity Triple by 2050

PRODUCTION: David Hill

Dr Sama Bilbao y León, Director General at World Nuclear Association is happy to announce the pledge of tripling nuclear capacity by 2050 by a group of 120 companies headquartered in 25 countries. The pledge, announced at the UN climate change conference, COP28 in Dubai, under the Net Zero Nuclear initiative launched with the Emirates Nuclear Energy Corporation, sets a goal of at least tripling global nuclear capacity to accelerate the clean energy transition.

6 / www.energy-focus.net

//At COP28 in Dubai, the nuclear industry came to the fore more than ever before. The world’s premier multilateral decisionmaking forum on climate change saw a pledge from various organisations across different regions to expand the contribution of nuclear in the world’s energy generation mix.

Today, 2545 TWh of electricity comes from nuclear generation. Most in the industry have known for some time, and many politicians have privately understood, that nuclear generation capacity must be increased if the climate crisis is to be tackled. Now, publicly, the message is clear. Triple capacity by 2050. To do so will require developing a thriving, highly skilled supply chain to support an efficient rollout. Use nuclear – a proven, reliable, safe industry – to feed growing demand,

partnering with renewable energy, to create a low carbon energy mix.

Director General at the World Nuclear Association, Dr Sama Bilbao y León, tells Energy Focus that the landmark Net Zero Nuclear Pledge is ambitious and exciting.

“We must always be ambitious,” she smiles. “The climate crisis is urgent and enormous. The goals need to match the size of this problem. The fact we are putting in place what is necessary to make the ambition a reality is critical. Policies, financing frameworks, and industrial capabilities that are coming together is very important to deliver this expansion in nuclear energy.”

Fossil fuels – coal, oil, gas – burnt to produce energy release carbon dioxide and other harmful emissions. These industries are responsible for 75% of global greenhouse gas emissions

and nearly 90% of CO2. It’s well documented that greenhouse gases in the atmosphere trap heat from the sun. Nuclear generation produces large amounts of energy from a relatively small footprint, and minimal CO2 emissions across its whole lifecycle.

A desire for transition to low carbon generation, an energy security crisis, and a raft of pricing issues have turned many to the nuclear industry as a viable alternative to fossil fuels.

NET ZERO NUCLEAR

Alongside political leaders, industry heads, and government policy makers, Bilbao y León sat in Dubai at COP28, as nations committed to the goal to triple global nuclear capacity. Nuclear reactors provide 10% of global electricity, and demand for electricity is only going in one direction. By 2030, the International

www.energy-focus.net / 7

INDUSTRY FOCUS: NUCLEAR

Energy Agency (IEA) expects there to be ten times the number of electric cars on roads. Growing generating capacity is essential, and doing so without fossil fuels brings nuclear to the fore.

“We, and various nuclear organisations, have been present at COP

Dr Sama Bilbao y León, Director General

Dr Sama Bilbao y León, Director General

for over 20 years,” says Bilbao y León. “Initially, we were not well-received and, most often, nuclear was sidelined from conversations. But in the last few years, the conversations have been changing and since Glasgow (COP26), more and more countries are starting to realise that they will not achieve their climate goals without nuclear. After the energy crisis at the end of 2021, and the war in Ukraine, energy security became a priority again for many countries. For decades, after the oil crisis in the 70s, we forgot that energy security was something to consider.”

The Association has harnessed the resurgent positivity for nuclear and has developed a number of visibility campaigns, delivered across various platforms, to help build a collaborative effort.

“Net Zero Nuclear was launched together by World Nuclear Association and the Emirates Nuclear Energy Corporation (ENEC) ahead of COP28.

ENEC is very well positioned, with close ties to the UAE government, and they were in a very strong position to be the intermediary with the COP28 Presidency,” says Bilbao y León.

“It was incredibly successful,” she adds. “For the first time ever at COP, nuclear was mentioned in the agreed and negotiated texts – everyone unanimously included nuclear as an energy to be accelerated if we are serious about meeting the Paris agreement goals. We talk to governments often enough, and behind closed doors there is always positive comments from ministers about nuclear – especially in the last few years. But to have 25 countries publicly state the importance of nuclear was new.”

The Net Zero Nuclear initiative was a continuation of work at previous COPs, which led to a very public Ministerial Declaration in December 2023 when heads of state from more than 20 countries placed nuclear at the heart of

8 / www.energy-focus.net

WORLD NUCLEAR ASSOCIATION

future plans, promising decarbonisation of entire economies. But there was more to come. An industry pledge to back up the overarching ministerial declaration, saw more than 120 countries active in some 140 countries, commit to at least triple global nuclear capacity.

“Industry wants to take the challenge from governments because, ultimately, governments will put in place policy and marketplace mechanisms, and perhaps will support financing frameworks, but it is the industry that will triple global nuclear capacity and will operate existing and future nuclear power plants,” highlights Bilbao y León.

She describes progress at COP28 as a 180-degree shift for nuclear, and from here the Association intends to move quickly, bringing support from 200 members on all continents and navigating a complicated geopolitical environment to encourage longterm certainty and collaboration.

ROLL OUT

The 2050 target gives just over a quarter-century to deliver on COP28 pledges. Currently a standard nuclear power plant takes on average around seven years to build. Time is precious and so having multiple technologies and different innovations in parallel are required to deliver on ambition.

“Clearly, we see that some regions and countries have their plans, but we don’t have an integrated global plan that shows exactly where the new capacity will come,” says Bilbao y León.

Already, there is progress around the world as demonstration projects in the US and Canada are underway. GE Hitachi Nuclear Energy, NuScale Power, and X-energy all have interesting projects – many are expected to be up and running before 2030. Czechia has large ambitions for brand new capacity, and China is pushing forward aggressively, building all kinds of reactors with all kinds of technology,

aiming for 150 nuclear units by 2040. India has strong ambitions for nuclear energy, hoping to triple capacity by 2050, and the UK is aiming for quadrupling capacity by 2050. “We are expecting [new build] projects in Romania and Poland. Bangladesh is going from zero to 10% of electricity coming from carbon-free nuclear in less than 10 years. There are also 800 million people in Africa with no access to electricity -clearly there are

// AFTER THE ENERGY CRISIS AT THE END OF 2021, AND THE WAR IN UKRAINE, ENERGY SECURITY AGAIN BECAME A PRIORITY FOR MANY COUNTRIES //

www.energy-focus.net / 9

Lifting the 245-tonne domed roof onto the first reactor building at Hinkley Point C, under construction in the UK © EDF

INDUSTRY FOCUS: NUCLEAR

enormous challenges - but nuclear has potential to meet some of that need in some of those countries. We know that not every country in the world will choose nuclear for their mix, but many will,” says Bilbao y León.

This progress is encouraging and feeds into the carefully planned capacity tripling to around 1200 GWe by 2050. Development of capacity tripling as a target comes from research commissioned by the Association and input from the team that produces the valuable World Nuclear Fuel Report – a comprehensive analysis of the global industry and fuel supply. Using information and predictions gleaned from the Fuel Report, different scenarios were predicted.

“There is a bottom-up and top-down approach,” explains Bilbao y León. “The bottom-up approach

came from our Fuel Report from last September which has various scenarios. The scenarios are based on projects which come from things that we know about different countries and what they are planning. There are pessimistic and optimistic scenarios, and the middle of the road. Looking at the optimistic scenario, we are already seeing – based on known plans – that by 2040, we will have more than doubled nuclear capacity globally.”

The top-down approach looks at the goal of keeping a warming figure of 1.5°C and what needs to happen for that to be achieved.

“There are some planned scenarios and they are done by the IPCC, IEA and a Global Banking Network, and we are also working on our own scenarios. Across all of them, we see that nuclear energy must play an increased role in

electricity generated globally by 2050 – for decarbonisation, grid stability, and 24/7 energy availability. So, the Net Zero Nuclear initiative and indeed the goal of tripling global nuclear capacity is about accelerating the clean energy transition.”

The detailed scenarios for Net Zero Nuclear from the Association will be available by the end of 2024, but both the top-down and bottomup approaches are already accepted by many in the industry with the Director General confident that the organisation is on the right track.

KNOWLEDGE SHARE

World Nuclear Association goes above and beyond to involve industry and stakeholders as much as possible, hosting a number of Working Groups that go across the entire fuel cycle, detailing various opportunities that

10 / www.energy-focus.net

are available, as well as giving open and honest commentary on industry best practice. Extended collaboration is the goal, allowing members to grow and thrive through positive partnerships in the industry.

Bilbao y León is particularly proud of progress in recent working groups around skills development and project financing – both essential elements of the Net Zero Nuclear Pledge.

“We need to work on the workforce and that is where public-private partnerships will be very important,” she says. “Governments can incentivise education programmes in certain areas, and industry can invest here, but we are certain that there is a big opportunity to reskill and repurpose people for the clean energy workforce.”

As the contribution of fossil fuels – particularly oil and gas – steadily

WORLD NUCLEAR ASSOCIATION

declines in OECD countries in line with international climate goals, the unique skillset of that workforce could be redeployed in the nuclear sphere to bolster ongoing global rollout. This, says the Association, is an obvious path for growth.

“We do not need to have a nuclear exclusive supply chain,” reiterates Bilbao y León. A nuclear reactor does require specialist knowledge and an increase level of Quality Assurance, but “the maintenance of a [nuclear] plant is not so different from other power plants. In my mind, there is enormous opportunity to take pieces of other supply chains where there are capabilities that could easily be realigned with nuclear and other energies. There are certainly opportunities there.”

Another working group is currently

busy discussing the wider rollout of nuclear and how, beyond electricity generation, the industry can be a service provider for communities. This could be in the form of distributing heat, or planning small modular reactors (SMR) for industry, or helping with financing of nuclear-based projects, or researching and developing projects with contractual agreements in place. The Association’s board was keen to see this working group established so that knowledge sharing can thrive.

“We see major opportunity there,” she confirms. “We need to decarbonise the entire economy, not just electricity generation. The good news is that nuclear can produce heat at the same time as electricity and that can be used in district heating, manufacturing, steel, aluminium, petrochemical etc. We want to innovate, and we want

www.energy-focus.net / 11

INDUSTRY FOCUS: NUCLEAR

to open discussions around the frameworks that will be required for the future. That group only started in September last year, but we are already seeing that eyes are opening and ideas are being generated.”

Another critical working group is deep in discussion around used nuclear fuel. A prominent point of uncertainty for many looking at the industry from the fringes, the way used nuclear fuel is managed is misunderstood. Bringing clarity and transparency to the industry is important. Key misconceptions include notions that nuclear power plants generate large amounts of waste and that the waste is useless.

“Firstly, used fuel management is not a problem,” says Bilbao y León. “The industry is confident and the technologies exist today to handle used nuclear fuel – in many countries this is being done, and the working group is very good at sharing best practice. Secondly, the group is bringing visibility to the fact that used nuclear fuel is recyclable. 95% of the energy remains

in what people often call ‘nuclear waste’. France, Japan and others are developing plans to reprocess used nuclear fuel and use it again. The energy that is still there means it can be made into new fuel and used in reactors.”

Currently, uranium is the key fuel for nuclear reactors, but is mined mainly from three countries around the world: Kazakhstan, Canada, and Australia. Smaller quantities are mined in other countries, but depressed pricing since 2011 slowed the opening of new sites for some time. However, today, prices are increasing again and many companies are looking at new activities. As the industry picks up and interest in the nuclear sector returns, the expectation is that new mines will start with uranium present abundantly on all continents. However, if a used nuclear fuel recycling industry can grow, it will ease the pressure on existing mines which is positive for the industry.

“The volumes and radiotoxicity will be reduced enormously if we are using most of the fuel rather than

just 5%. Also, if we are re-using the resource, and getting the most out of it, then our need to mine for new material is reduced. We have stock in many interim repositories that could be reprocessed and represents significant new fuel for existing and used fleets. The sustainability of nuclear is all here. The fact we can do this means we have more energy and less waste, and this working group is highlighting this,” says Bilbao y León.

“France is already reprocessing and reusing reprocessed fuels in some units. Japan has the sustainability policy which requires the use of fuel to gain maximum energy. There are other countries doing so – it’s a matter of policy and not a matter of technology.”

POLICY OF PROMISE

Of course, tripling global nuclear capacity by 2050 requires more than skills and money. It is essential that regulation and policy are aligned, and nations collaborate effectively to encourage finance, engineering,

12 / www.energy-focus.net

construction, connectivity, and rollout. World Nuclear Association is the only industry organisation with a global mandate to promote nuclear energy. It is in a unique position to share and advance best practice and common messages globally, working alongside partner organisations and is encouraging long-term policy that appeals to the finance and investment community.

“There is need for financing in new nuclear construction, but there is also need for financing around the entire eco-system for nuclear,” explains Bilbao y León. “We are already seeing a lot of interest in mining at the front end of the nuclear fuel cycle. Also, conversion, enrichment, and fuel fabrication have all received a lot of interest. Across the supply chain, there are investible opportunities in piping, pumps, or many other heavy industrial engineering components. The level of investment can be very different and the speed of returns can also be very different. We are trying hard to make sure the finance community understands that there are different projects, open to different investors, with all appetites of financial risk.”

She adds that any policy must be suited to local conditions while incentivising technologies across the board. Typically, the finance community has been less knowledgeable about nuclear, and only the unsuccessful projects tend to gain newsworthy status. The Association’s working groups are addressing this, and showcasing positive examples that will filter through to those in charge of funds.

“We are making an effort to make clear what the opportunities are, and make sure the finance community understands that we can align different projects with different financial risk appetite of different investors.

“Sometimes the government doesn’t need to do much more – it can present the message that nuclear is here to stay and that clarity incentives both industry and finance to contribute.”

WORLD NUCLEAR ASSOCIATION

In the longer-term, a redesign of power markets is required to embrace a mix of technologies that includes less fossil fuel and more nuclear and renewable energy. Currently, the market is configured for a small number of individual technologies to contribute in a big way. Recognising the importance of dispatchable 24/7 clean tech, like nuclear, in the mix allow investors longer-term vision as to how ideas will come together to make a resilient next-generation energy system.

Of course, any redesign in the market must put the customer at the fore, ensuring the price is fair. The Director General sees coupling of electricity grids with oil and gas pipelines and hydrogen concepts, while using existing infrastructure to support renewable energy rollout. She also sees uniformity across regulators, allowing for easier and

faster rollout while ensuring safety and independence. “We don’t have to repeat the same reviews and assessments across different countries where the same technology will be deployed. Licensing of standard technology should be streamlined globally.”

This idea comes back to policy and the ability of governments to give a clear, lasting roadmap. With certainty comes investment, and with investment comes progress. It’s a tried and tested model, evidenced by offshore wind energy policy in the UK.

“Renewable energy has come a long way, and that is because many governments highlighted it as essential,” says Bilbao y León. “Investments and innovation and industry have worked together to get to where we are, and that is fabulous. Nuclear energy is a proven technology and we have been doing this for more than 50 years.

www.energy-focus.net / 13

SBL Industry Pledge

INDUSTRY FOCUS: NUCLEAR

Newer technologies and different approaches are going to make nuclear better, but we are not starting from scratch. We are already 10% of global electricity generation and we have the largest contribution of clean electricity in OECD countries. We are also, in many countries, the cheapest form of energy generation. We don’t have to come from where renewables were. We can always improve, but it is from a well-established position.”

LINKING THE CHAIN

Apart from generating funding, the one major hurdle that could knock Net Zero Nuclear off course is a slowdown in development of a global supply chain. When the industry was nascent, a successful supply chain grew quickly – it is possible to develop the skills required. But the modern nuclear industry, and the rollout that will triple capacity by 2050, looks different to the sector of the past. Smoothing bottlenecks in

the supply chain is vital, but Bilbao y León is characteristically confident.

“It is not an insurmountable challenge,” she states. “If you think about it, a lot of the components are not that different from a conventional gas power plant. There are many industries that are keeping their eyes on the nuclear industry because if they see that things are starting to happen, they invest in qualifying their products to be nuclear grade. We don’t have to build the industry from the ground up. In many cases, it is repurposed or requalify other industrial supply chains. It won’t be easy, but it’s not as impossible as many think.”

When success is obvious, advancement accelerates. There are several SMR projects happening globally as well as some larger reactors, and when they reach completion, it will be clear to the entire industry, and related sectors, that work in nuclear is a significant opportunity.

“In nuclear, as in many other industries, everyone is conservative and wants to be second. It is good that we have some pioneers who are willing to be first, and it is important that they succeed. When we see this,

14 / www.energy-focus.net

WORLD NUCLEAR ASSOCIATION

the traditional nuclear supply chain will invest in itself because they will see the path forward,” says Bilbao y León.

Discussions are already underway with suppliers exploring the use of nuclear alongside other major industry sectors to drive decarbonisation campaigns. In the oil and gas sector, scope 1 and 2 emissions must be reduced dramatically, and quickly. Nuclear has the ability to drive reductions at the front end of production. If paired with CCUS and other modern systems, supply chains and nuclear technology have the ability to achieve further carbon reductions.

“The money exists and the appetite is there,” Bilbao y León smiles.

“It is the same in the chemical

// THE QUESTION IS NOT WHETHER NUCLEAR IS PART OF THE EQUATION – THAT QUESTION HAS BEEN ANSWERED //

industry. We have already seen DOW Chemical talking with nuclear developers for specific units. We have also seen Microsoft, Google, and Amazon saying they already need enormous amounts of incredibly reliable electricity, with little variability, and accessible 24/7. That demand will increase drastically as they make more use of AI and data driven technologies. They are all thinking of how they can get this energy and they are all talking about how they can access long-term power purchase agreements to access electricity.”

With the level of electrification underway now, tripling global nuclear capacity by 2050 must be seen as integral part of the energy transition. New build projects will come in different forms – some traditional utility grid-based power plants and others innovative modern reactor projects –and some will be driven by the private sector and companies that need supply to fulfil critical operations. However, after COP28 and as a result of the successful Net Zero Nuclear initiative, the Association is pleased that there is no doubt about nuclear’s involvement

in the global mix going forward –government and industry heads are providing exactly what Dr Bilbao y León has asked for – long-term certainty.

“For the majority of countries that we speak to, the question is not whether nuclear is part of the equation – that question has been answered. Yes –nuclear is part of the global energy mix moving forward. What we need to do is make it happen. Much needs to be done and there are challenges ahead, so the question is not whether but how we do it,” she concludes.

Now is the time for rapidly accelerating all corners of the nuclear industry. Developing supply chains, formalising financing frameworks, putting progressive policies in place, and creating capacity for the future. The pledges and promises are in place. World Nuclear Association and its membership are ready to deliver.

Content sponsored by World Nuclear Association

www.energy-focus.net / 15 WWW.WORLD-NUCLEAR.ORG

CENTRICA ENERGY STORAGE

Essential Element of UK Energy Resilience

PRODUCTION: Tommy Atkinson

A key element of the infrastructure area of the Centrica family, Centrica Energy Storage operates the Easington onshore gas processing terminal in East Yorkshire and restarted gas storage operations at the Rough facility in the Southern North Sea in 2022, with a view to bolstering the UK’s energy security and helping to reduce consumer bills.

16 / www.energy-focus.net

INDUSTRY FOCUS: STORAGE

//“Energy is in our DNA,” opens international energy and services company Centrica. “From supplying the gas and coal that powered the industrial revolution, to becoming the market-leading energy services and solutions company we are today, we’ve been at the centre of the UK energy industry for over 200 years.”

Centrica is unique among energy companies in the UK and Ireland, in its operating across the entire energy value chain through a variety of distinct, but complimentary businesses, all of which have a common purpose, the organisation says: “helping you live sustainably, simply, and affordably.”

Formerly Centrica Storage Limited, a recent name change for this pivotal Centrica arm is designed to signify a change in ambition, Centrica Energy Storage (CES+) details. “We wanted

to keep storage in our name as it is at the heart of what we do now, and our plans well into the future,” the company stresses, “but we have larger ambitions outside of storage, including onshore and offshore hydrogen production and fuel-switching our existing operations to hydrogen to minimise our environmental impact.”

ROUGH READY TO ADD RESILIENCE

CES+ operates the Rough gas storage facility in the Southern North Sea, as well as the Easington onshore gas processing terminal in East Yorkshire, an onshore gas reception and treatment terminal, modified between 2011 and 2013 by CES+ to handle gas produced from the York field, at the time the largest known undeveloped gas reserve in the southern North Sea.

“This was the largest single

project within the Easington gas terminal in 20 years,” CES+ explains, “with the plant designed to handle 120 million cubic feet per day of gas, from the York field which will produce enough gas to meet the demands of half a million households.”

The Easington terminal processes gas from the Rough underground gas storage facility, located 18 miles off the coast of East Yorkshire, where storage operations restarted in 2022 following a dormant five years since 2017 to provide critical further energy security in the UK while cutting users’ bills. “Today, Rough provides more than half of the UK’s gas storage - 54 billion cubic feet (bcf) of gas - which is enough to provide the equivalent volume of gas to heat 2.4 million homes over winter,” CES+ states.

“The long-term aim is to turn

18 / www.energy-focus.net

Brokering - Offshore and Renewables Marine Logistics Software Sale & Purchase Vessel Valuations Make Waves Tel: +44 1224 74 77 44 chartering@seabrokers.co.uk www.seabrokers.co.uk The Global Shipbroker Seabrokers Chartering is an independent shipbroking firm focused on the offshore sector, renewable energy as well as aquaculture.

Controls, Automation & Instrumentation Services

Control & Distribution Systems

Wellhead Controls, Valve Actuation Controls, Hydraulic Power Units

Component Supply

Control Valves, Isolation & Block and Bleed Valves, Safety Relief Valves, Pressure Monitoring Equipment, Instrument & Pipe Fittings

Bespoke Engineering / Manufacturing Services

Service Support / Site Services

Control Component Repairs, Spare Parts Supply

CENTRICA ENERGY STORAGE

Supporting Centrica Energy Storage Ltd with Process Control

www.dycos.co.uk

info@dycos.co.uk

Rough into the largest long duration, low-carbon energy storage facility in the world, capable of storing both natural gas and hydrogen with the goal of bolstering the UK’s energy security,” CES+ adds, having last year made huge strides toward this objective in almost doubling gas storage capacity at the UK’s largest such facility.

At the time of reopening Rough for gas storage it was able to store approximately 30 bcf of gas for UK homes and businesses; this further investment in the facility has brought Rough up to the present 54 bcf capability in a major boost to the UK’s energy resilience. Despite diverse gas supplies through connections with Norway and other European countries, alongside three LNG import terminals, the UK has some of the lowest levels of gas storage in Europe at 12 days

average, or 7.5 peak winter days.

By way of comparison, Germany’s stands at 89 days, France’s at 103 days and that of the Netherlands at 123 days.

“The resilience of the UK’s

energy system needs to be substantially improved,” assessed Centrica Group Chief Executive, Chris O’Shea, of the significance of the development. “We are delighted to play our part by further expanding

www.energy-focus.net / 19

Ltd

Dynamic Control Solutions

INDUSTRY FOCUS: STORAGE

SPECIALIST SERVICES UNDERPINNED BY TECHNOLOGY AND GLOBAL MOBILITY

OCCMS’ long standing relationship with Centrica Storage at their UK onshore Gas Processing & Storage terminal, was formed to provide Completions & Commissioning oversight and execution support services. The high-level summary of the scope requirements are as follows:

• Execution oversight of handover from principal contractor.

• Commissioning Test Procedure development and implementation.

• FAT Support.

• Plan and execute pre-commissioning and dynamic commissioning.

• Technical delivery of processes and competence assessed personnel. Support handover to client operations for start-up and ongoing production.

During this project, OCCMS have safely delivered commissioning and completions services for Phases 1 to 4 at our client’s UK based terminal which receives separate and condition natural gas and associated liquids from two separate offshore fields to meet the required specification before transfer of natural gas into the national transmission system (NTS). The processing facilities consisted of an inlet area/separation, onshore compression, dewpointing, filtration and fiscal metering with associated utility and auxiliary supplies.

the UK’s gas storage capacity.

“Rough is not a silver bullet for energy security, but it plays a critical role in increasing capacity and supply confidence over the winter months.

“Rough can help our energy system by storing natural gas when there is a surplus and producing this gas when the country needs it during cold snaps and peak demand.” Rough will, equally, help keep prices down for consumers by balancing the UK’s gas market, injecting gas into the facility when there is excess supply and putting that gas back into the UK’s gas network when customers need it most, keeping prices lower at that point of peak demand; in November came the winter’s first release of stored gas at Rough into the UK grid.

“Customers are struggling with high energy bills which are driven by international energy prices,” O’Shea

During the initial period, various brownfield modifications were undertaken within the onshore plant and included, but not limited to, F&G system modifications which were updated to accommodate the changes within the gas plant.

Following this initial phase, additional gas compression, additional F&G, and methanol recovery and injection facilities were upgraded and or modified as part of the new Humber Gathering System (HGS) and included upgrading receiving facilities for the new Tolmount offshore field.

All construction completions and commissioning execution was controlled and managed through OCCMS’ ORBIT™ completions management system on premise with a dedicated database administrator at the clients facility.

The total onshore hours expended on life of project, including a small proportion for senior leadership oversight, are ~60,000 without a lost time incident, including during the Covid 19 pandemic. “This strong track record is demonstrable of OCCMS’ strong safety leadership & inherently positive behaviours which are prevalent throughout all levels of management and delivery teams alike” stated OCCMS’ Operations Director – Jamie Japp.

For further insights or information on how OCCMS can assist you with your Brownfield Projects, please contact us at: Aberdeen@occms.com

observed at the time. “Gas storage is vital to ensure the UK can manage demand effectively, keeping prices down, and I’m proud of the actions our team has taken over the last 18 months, including our decision to bring Rough back online, to underpin the UK’s energy security. However, we still have the lowest levels of energy storage of the world’s major economies with the ability to store fewer than eight days of peak winter demand and this leaves us susceptible to shocks in international markets,” he countered.

“Gas will continue to be used as a transition fuel for the foreseeable future and we stand ready to invest £2 billion to quadruple the size of the Rough field and make it the world’s biggest methane and hydrogen storage facility, bolstering the UK’s energy security, delivering a net zero electricity system by 2035,

creating 5,000 skilled jobs and decarbonising the UK’s industrial clusters by 2040,” O’Shea explained.

“This world class North Sea asset has the potential to help the UK economy return to a position of being a net exporter of energy once again.”

HYDROGEN TO HUMBER

A co-operation agreement between Centrica and Equinor to explore developing a low-carbon hydrogen production hub at Easington, looks set to further strengthen the region’s growing status as the UK’s foremost hydrogen super location. Under the plan, over the coming decade the Centrica-operated area could transition to a low carbon hydrogen production hub, massively supporting both the Humber’s decarbonisation ambitions

Continues on page 22

20 / www.energy-focus.net

The Safe and Timely Start-Up of our Client’s Assets Specialist services underpinned by technology and global mobility occms.com o mpl

INDUSTRY FOCUS: STORAGE

REWS INTEGRATED VESSEL MONITORING & COLLISION SOLUTION

Often difficult to envisage on a vast expanse of water; shipping accidents are all too common. In the past decade, the second most common cause of shipping incidents reported globally is collision (3,098). In the oil and gas industry particularly, a maritime incident can be catastrophic with detrimental environmental consequences.

The aftermath of these incidents is well documented, but there is a lesser-known theme behind the cause. Reports show that almost 96% of maritime accidents are caused by human error, with fatigue the top cited issue.

With the UK oil and gas workforce expected to decline from 120,000 to around 87,000 by 2030 (in line with production decline and decommissioning activities), significant pressure is placed on the fewer vessels and crews that are left behind. With fewer staff and crews often being placed on unfamiliar vessels, the risk of human error will likely increase.

Ultra provides an integrated collision avoidance monitoring solution, our Radar Early Warning System (REWS) directly improving maritime safety. By using multiple platform-based radar early warning systems the Ultra REWS monitors marine traffic, protecting offshore installations and avoiding maritime incidents.

REWS provides protection 24/7, 365 for one or more platforms with alarm data instantly available to operators strategically located at onshore control centres, on platform, or Emergency Response and Rescue Vessels (ERRV) that react to any incident.

ULTRA REWS:

• Proven radar early warning system (REWS)

• Round the clock monitoring, 365 days a year Integrated system with Radar, Automatic Identification System and CCTV for 360° surveillance

• Capable of protecting multiple assets from an onshore control centre

• VHF voice communications enables control centre operators to contact offshore assets and passing vessels

• 24/7 technical support and help line available

PROTECTING:

• Offshore assets from collision

• Subsea systems from fishing activity

• Man overboard

• 500m safety zone

• Emergency response coordination

Legal obligation to have a collision risk avoidance system Protection around renewable and new energy platforms

This technology is a step change in marine operation safety, providing a full audit trail for incidents, near misses, and learning opportunities. Operational costs are reduced by consolidation/sharing of ERRV and Guard Vessel fleets and removing thousands of personnel risk exposure hours, with potential for multi-client control-centre monitoring for maximum cost efficiency. Simply, offshore operators cannot afford to risk devastating collisions. Ultra REWS provides real-time vessel monitoring that improves marine safety, reduces offshore risks, cuts operational costs, and allows for informed decision making in the most challenging environments.

Continued from page 20

and UK’s achievement of net zero and hydrogen production targets.

Centrica and Equinor predict that the conversion of the Easington Terminal could produce an additional 1GW of low carbon hydrogen production, coupled with the roughly 200MW off-taker demand. Currently, up to one third of the UK’s overall gas supply enters via Easington, which is also Easington positioned close to some of the world’s largest

offshore wind farm developments, offering huge potential for both blue and green hydrogen production.

With the UK government having recently doubled its 2030 hydrogen production ambition to 10GW capacity, and at least half of this figure to come from electrolytic ‘green’ hydrogen, the area is a key location within the Zero Carbon Humber partnership which, it is intended, will provide regional hydrogen and CO2 pipelines between the area’s major energy producers and carbon intensive industries.

“The Humber is in a unique position to lead the way on industrial decarbonisation, and partnering with Centrica to potentially develop a new hydrogen hub at one of the UK’s most significant industrial sites could help to transform this region’s energy mix whilst preserving and creating jobs and skills,” Grete Tveit, Senior Vice President for Low Carbon Solutions at Equinor, expressed, restating Equinor’s ambitions to deliver nearly one fifth

Continues on page 24

22 / www.energy-focus.net

REWS Integrated Vessel Monitoring & Collision Solution

Number 1 defence solution for offshore assets in the North Sea; reducing risks and costs

Autonomously monitors marine traffic; protecting offshore installations and avoiding maritime incidents

Fully aligning with Marine Safety legal requirements

FIND OUT MORE Contact Phil Williams Business Development Manager E phil.williams@ultra-sss.com T 01489 557373 W www.ultra-ic.com

INDUSTRY FOCUS: STORAGE

Continued from page 22

of the national target by generating 1.8GW of hydrogen production within the Humber region by 2028.

“We are delighted to be working in partnership with Equinor to explore opportunities to deliver on our commitments to help the UK transition to net zero as hydrogen will play a key role in achieving this,” O’Shea agreed. “Like Equinor, Centrica is committed to investing in the Humber region, levelling up and de-carbonising industry to create a world leading, green energy-driven, economic hub.”

Mike Whitehead, President of the Hull & Humber Chamber of Commerce, succinctly encapsulated the value of this key partnership. “It’s fantastic to see these two major energy companies seeking to invest and explore ground-

breaking projects in this region, demonstrating our long-standing reputation as the UK’s Energy Estuary.

“Over the coming decades we will need this level of ambition to transition away from fossil fuels whilst creating jobs, boosting skills and attracting inward investment.”

GRAND, GREEN & GLOBAL AMBITIONS

Perfectly encapsulating the wider Centrica’s unbending green focus, the UK’s energy security was dealt a further aid via a deal with Repsol to see Centrica Energy purchase one million tonnes of LNG shipments between 2025 and 2027, to be delivered to the UK’s leading LNG import terminal and the largest in Europe, Grain, in Kent.

“I’m proud that Centrica is continuing to improve the UK’s

security of supply through this deal with Repsol,” O’Shea said. “When our security of supply is threatened, it is customers that lose out, so it’s reassuring that this agreement will ultimately help ensure that those on the front line of the energy crisis have some insulation from price fluctuations.

“Natural Gas is an essential transition fuel in the move to net zero and securing international agreements such as this will be vital if the UK is to reach its ambitious goals. Alongside the other steps we’ve taken to make the UK more resilient – through deals with Delfin Midstream and Equinor – our actions demonstrate our commitment to the UK consumer.”

Somewhat further afield, Centrica Energy, alongside leading renewable energy developer and fund manager Taaleri Energia and Lords LB Asset

Subsurface

24 / www.energy-focus.net

BETTER ENERGY TOGETHER A leading asset lifecycle and engineering technology company delivering sustainable solutions.

www.three60energy.com

Wells Subsea EPCC Operations Products & Solutions

// OUR AMBITIONS ARE GRAND, GREEN AND GLOBAL, AND WE BELIEVE THE FUTURE OF ENERGY MUST BE UNLIMITED AND CLEAN //

Management, a Lithuania-based fund manager, announced the signing in March of a Power Offtake Agreement for the Rokiškis and Jonava wind farms.

Generating 408GWh annually, the wind farms will produce green electricity equivalent to the consumption of approximately 197,000 households, consequently offsetting 123,000 tonnes of CO2e emissions every year.

Following on from its ambitious commercial strategy to expand the business across new borders and deliver on green growth ambitions, Centrica is working to support the application of merchant-based instruments and manage risks, the company explained, ultimately enabling long-term returns for investors who are bringing new green electricity into the grid.

“We’re excited to further build on our strong cooperation with Taaleri Energia, expanding our relationship beyond the Finnish, Swedish, and Norwegian markets to now include Lithuania as well,” furthered Kristian Gjerløv-Juel, vice president of renewable energy trading and optimisation at Centrica Energy. “Our commitment to delivering services and solutions that support the growth of sustainable energy systems across Europe is unwavering, and it’s fantastic to be on that journey alongside some of the leading developers and fund managers in the renewables industry.”

The agreement marks Centrica Energy’s first renewable power purchase agreement secured in Lithuania, a market that presents

Expert Well Examination Well Integrity Verification Engineering Consultancy

significant potential for the buildout, management, and optimisation of new renewable generation, and closely follows its first agreement in Estonia, bringing its portfolio of wind and solar assets under management in the Baltic states to a total of 168MW.

A key element of Centrica’s sustainable operating plan is the commitment to supporting every customer to live more sustainably, in its bid to become a net zero business by 2045 and help each of its customers to achieve same by 2050. “We are a leading renewable energy trading company,” the organisation resumes, “and our mission is to drive the green transition while offering sustainable and predictable energy costs for suppliers and off-takers. In short, we call ourselves energy movers by nature.”

“We are devoted to being up to

date on energy advances to help our clients and using current energy forms as transitionary tools towards a new energy reality. Our ambitions are grand, green and global, and we believe the future of energy must be unlimited and clean.

“We see our ultimate role as the switch that accelerates the green transition by leading the development of a sustainable symbiotic energy market.”

Read more about Centrica Energy Storage in the upcoming edition of Energy Focus and hear exclusively from MD Martin Scargill.

www.energy-focus.net / 25 CENTRICA ENERGY STORAGE

WWW.CENTRICA.COM

info@cdint.co.uk | 01224 636420

PACE CCS

Pace Drives Momentum in CCS Network Rollout

PRODUCTION: David Hill

Capturing carbon dioxide from industrial processes and storing it safely and permanently in sedimentary rock formations deep under the ground is a concept that is gaining momentum globally. Pace CCS is the industry leader in the design of CCS networks – taking CO2 from emission site to underground well - and MD Matt Healey tells Energy Focus that the company is on a strong growth path.

26 / www.energy-focus.net

INDUSTRY FOCUS: CCS

//The decarbonisation problem facing engineers around the world is easy to explain but very difficult to solve. Innovation and pioneering thinking are essential, and collaboration across industry spheres is already helping to build a model for the future. But the work is extremely challenging. How do we take carbon dioxide from industrial processes, remove it from emissions and store it so that its environmental impacts are mitigated? Enter Pace CCS, a company founded in 2017 but switching to a sole carbon capture and storage (CCS) focus in 2020.

In 2022, global energy-related CO2 emissions reached new heights of more than 36.8 Gt. The amount of CO2 in the atmosphere was higher than ever, at 417.06 ppm. And in CCS, just 30 projects were operational with 164 in various stages of development at the end of 2022.

Pace CCS is dedicated to moving the industry forward through inventive design, clever engineering,

and technology adoption that ensures quality performance.

“We are a multi-disciplinary engineering design consultancy, specialising in CCS. We are truly global, we have offices in London, Kuala Lumpur, and Houston,” says Matthew Healey, Managing Director at Pace CCS.

Capturing and transporting CO2 from emission source, and storing in, typically, depleted oil and gas wells is a complex task. The industry is nascent, and best-practice is still being established despite the concept being proven. There is plenty of text available on how to perform CCS, but Pace looks to rearrange, reconfigure, and revolutionise to help grow a required industry with its own ideas and ecology.

MORE EXPERTISE

“We are forward thinking, we value the future of CCS, and we believe the model for CCS is still being developed,” says Healey. “We want to be part of creating an ecosystem that is separate from oil and gas or midstream. We are

doing new things for a new industry.”

An engineer with experience across the energy industry, Healey had his eureka moment with CCS in 2018. Today, the business has grown to a home of 50 highly experienced people with multimillion dollar turnover.

“I had been working in the energy industry for a long time. An opportunity came up in 2017 to provide services to one major client in a niche area so Pace was established. In 2018/19, we started to pick up early work in the CCS space. I have been out there as, essentially, a salesman for a longtime and you know when you’re on to something that people want.”

He says it was immediately obvious that CCS designs from Pace were appealing in the market. The team analysed market opportunities and saw that the market would be essential for decarbonising economies, with business and industry hoping for 400 Mtpa of carbon captured by 2030.

“We made a strategic decision to drop oil and gas work altogether and

28 / www.energy-focus.net

Matthew Healey, Managing Director

focus entirely on CCS. We bumped along through the pandemic, but we predicted that work would come. Those forecasts turned out to be accurate and we are predicting a very good year this year.”

The range of low carbon activities that are replacing fossil fuels of the past are complemented by CCS. In most cases, CCS projects lock CO2 away deep underground in

// WE ARE FORWARD THINKING, WE VALUE THE FUTURE OF CCS, AND WE BELIEVE THE MODEL FOR CCS IS STILL BEING DEVELOPED //

geological formations, permanently. The capacity of storage strata, the way CO2 reacts with its surroundings while in storage, the technology to ensure permanence, and long-term operation and maintenance of a storage site are all key considerations for project stakeholders, but the work of Pace is about transporting carbon dioxide to the storage site through dedicated pumps, compressors, pipelines, and other technology sets.

At capture stage, technology diverts flue gas at large emitting sites using chemical compounds such as amine. Separation chambers then split the gas before nitrogen and water vapours are safely released. CO2 is then compressed to liquid form before being injected, safely, more than 1000m below ground into porous rocks in a reverse of oil and gas extraction that we recognise as safe today.

Within Pace, engineering

expertise is abundant and this is what separates it from others in the space.

“We have worked on more projects, and we have more experts than anyone,” says Healey, highlighting the fact that the company has contributed to various industry standards including ISO 27913 (carbon dioxide capture, transportation and geological storage) and a comprehensive Hazard Analysis document for CCS projects (Hazard Analysis for Onshore and Offshore Carbon Capture Facilities and Pipelines) for the Energy Institute “Our unique selling point is our experience and expertise,” he adds.

COLLABORATIVE EFFORT

Currently, Pace is putting its knowledge to use, partnering in multiple projects as the industry expert. Following success in December 2022, when the company was awarded £180,000 in Net Zero Technology Centre (NZTC) funding,

www.energy-focus.net / 29

PACE CCS

INDUSTRY FOCUS: CCS

// YOU KNOW WHEN YOU’RE ON TO SOMETHING THAT PEOPLE WANT //

and the exploration of problems with CCS pipeline corrosion, a number of notable milestones have been achieved.

In March 2023, the company teamed with ABB to develop CCS infrastructure that can be adopted at lower cost for clients. By utilising digital twin technology developed specifically for the industry, clients will be able to virtually replicate concepts and scenarios to familiarise with processes, allowing for informed decision-making.

“While companies can see the benefits of CCS, there is still a

reluctance to make the investment without clear knowledge of how things will work on the ground, at every stage of the process,” says Healey.

In June 2023, the company partnered with deepC Store to develop the CStore1 project, a floating CCS hub off the coast of Australia. CO2 from various energy and industrial processes in Japan would be delivered by ship to the site before being injected into wells.

August 2023 saw a Joint Industry Project from the NZTC and other industry players in which corrosion of CCS networks is again being studied with the goal of reducing cost over the longer-term.

At the end of the year, the company announced that it would work with Hafnium Labs to build the world’s first reliable digital twin software for full chain CCS

networks – essential in driving down cost and spreading understanding of how the networks behave.

Knowledge of how CO2 acts throughout the process is vital. Impurities present after capture can influence water solubility and create corrosive effects in liquids at higher temperature points. This is important information leading some CCS projects to explore the use of alternative ideas that avoid the use of methanol and triethylene glycol (TEG), currently the main impurities present in CCS networks.

TECHNOLOGY COOPERATION

A partnership has also been built alongside John Crane, one of the world’s leading providers of engineered technology. John Crane pioneers mission-critical products, services, and

30 / www.energy-focus.net

PACE CCS

solutions that enable the energy and process industries to achieve efficient, sustainable operations. Its portfolio includes technology critical in CCS and across the wider energy transition. Healey describes the relationship as mutually beneficial as Pace looks to bring best-in-class technology to projects, and John Crane looks to enable the energy transition by supporting relevant developments.

“It has become clear that there is plenty of crossover,” Healey says. “Our partnership here is a clear example of the value we can bring – a knowledge base that is supported by engineering ability.

“Carbon dioxide comes with its own challenges, especially with increasing volumes and in the case of new capture and storage applications. The partnership has been really

helpful for us, taking learnings around what they are doing and liaising with clients around technology.”

René Leven, Segment Leader, Hydrogen and CCUS, New Energy Solutions at John Crane, is also enthusiastic about the collaboration.

“We supply the critical components in rotating machinery such as mechanical seals, high performance couplings and filters. John Crane has delivered solutions with reliability and sustainability at the core for more than a century, and we’re committed to strengthening every link in the value chain for new, growing industries like CCUS and hydrogen,” Leven says. “To do so, it is important to look at all the details. There are so many critical elements that enable this technology. It’s not only dry gas seals, separation seals and

power transmission couplings, but also aspects such as efficient compression and pumping. This has led to interesting discussions with Pace CCS.”

As an engineering technology company, John Crane is interested in evaluating how mechanical seals perform in new emerging CO2 operating conditions. Pace has deep knowledge on the process side and the pair have already learned a lot together about optimal seal selection. The focus is on reducing and eliminating CO2 leakage through CCS networks by use of, or development of, state-of-theart equipment. According to Leven, there are commercial risks associated with incorrect technology selection.

“We want to make sure that we provide the right technology to ensure a safe and reliable operation, especially for new CCS projects. It is a

www.energy-focus.net / 31

INDUSTRY FOCUS: CCS

// WE HAVE FREEDOM AROUND HOW AND WHERE PEOPLE DO THEIR WORK – WE ONLY CARE ABOUT WHAT THEY DO

no-brainer: You can’t have CO2 leaking straight back into the atmosphere right after you capture it,” he says.

“You must have the right selection of products,” Leven adds. “An example is integrally geared compressors that traditionally use floating carbon ring seals even though more sophisticated technology is available. At higher pressures, floating carbon rings leak significant amounts of CO2, which can increase emissions at a time when curbing them has never been more critical. This also poses a commercial issue. CCS initiatives are expensive in terms of the energy and money

that goes into them. If you have significant amounts leaking after capture, then it is very wasteful.”

John Crane has long pioneered the use of dry gas seals in CCS. Used mainly in compressors and highperformance CO2 pumps, John Crane’s market-ready dry gas seals maximise reliability and sustainability. The company’s portfolio includes Type 2812 and Type 28VL, which are used in high-pressure and supercritical CO2 pump applications respectively.

“We are advocating the use of dry gas seals in all CO2 compressors, as they leak much less compared to floating carbon rings,” says Leven. “However, especially at medium- and higherpressure stages, dry gas seals offer clear advantages and are technically superior. We already see some manufacturers switching to dry gas seals in countries where regulations are getting tighter.”

Through all the mechanical elements in a CCS network, Pace and John Crane advocate for the development and deployment of

dedicated technology. This technology should apply lessons learned from previous oil and gas applications while addressing the unique dynamics of energy transition projects, Leven says.

“We design the process that connects emission source to geological storage and it cannot be done without the right technology from companies including John Crane and others. All details have to be examined and reimagined; we can’t simply accept that because it works in oil and gas it will work in a CCS network,” says Healey.

PROBLEM SOLVING CULTURE

Pace is furthering development of a dedicated CCS industry by developing its own software. Few dedicated programs exist that are CCS-focussed and not reworks of oil and gas software. Used in predictive forecasting around thermodynamic performance across pipelines, wells, compressors in industrial processes, software from Pace surrounds earlystage design, and this can influence

32 / www.energy-focus.net

//

Strengthen Every Link in Your CCUS Value Chain

Accelerate decarbonization with John Crane, the trusted choice for about 50% of the world’s CCUS sites.

• Proven CO2 Compression

• Advanced Pump Sealing

• Equipment and Process Filtration

procurement later in the process.

“The future CCS marketplace brings challenges and we position ourselves to solve problems that clients will have,” reiterates Healey.

The innovation and enthusiasm to forge this exciting and essential new industry comes from a Pace team that has been built to excel. Healey, an experienced engineer, recalls his own history working for engineering consultancies that he labels ‘not good to work for’ and his mission has been to create an environment within Pace that gives engineers freedom.

“We have a very happy team,” he smiles. “When we started the company, it was about creating a good company to work for. I have put a lot of effort into doing the right things and using behavioural psychology to create a company that frees

engineers to do what they’re best at.

“We have great retention, and we know that others want to poach our engineers,” he adds. “We have freedom around how and where people do their work – we only care about what they do. We trust that people want to do the best for the project and we create an environment that helps them do that. It has been very successful and we are proud of that. We deliver good work, and we have happy clients. We have a great record of getting enquiries for a small project and turning that into many years of successful partnership.”

The extent of, and number of, partnerships that Pace has developed is another distinguishing factor for the company. Alongside unrivalled expertise and experience, the collaborative approach to product, service, and industry development has

helped Pace to carve out and maintain pole position in a rapidly changing and expanding market. As CCS booms in the UK, and around the world, Pace will remain a pillar in the industry. Some suggestions expect the rocks under the North Sea could absorb 22 billion tonnes of CO2 and the UK could boast 78 gigatonnes of storage nationally. With other regions showing signs of even further potential, and with pressure ramping up for countries and industries to decarbonise, Pace is the company that will engineer solutions that maximise the obvious high-value opportunities.

www.energy-focus.net / 33 PACE CCS

WWW.PACECCS.COM

HARBOUR ENERGY

Healthy Ambition & Safety Excellence Boost Harbour

PRODUCTION: Tommy Atkinson

With a number of exciting projects underway, and an impressive acquisition helping Harbour Energy to grow, diversify, and excel, Harbour Energy’s EVP North Sea, Scott Barr tells Energy Focus that a healthy company culture and a professional can-do attitude is helping drive the organisation forward.

34 / www.energy-focus.net

INDUSTRY FOCUS: OIL & GAS

//The UK’s energy transition is complicated and challenging. Moving to net zero by 2050 requires overhaul of multiple major industry sectors, and electricity generation is one of them. Carefully transitioning away from traditional fossil fuels towards modern, sustainable technologies requires long-term planning. Currently, the UK North Sea is expected to lose around 180 of its 284 active oil and gas fields by 2030 due to natural decline. 75% of the country’s energy needs are met by oil and gas, and to power the transition, the industry is essential. Existing fields must contribute their maximum potential, and productivity across the industry is vital. That is why industry leaders are diversifying, innovating, and pioneering new ideas and new ways of doing things.

“Where I think Harbour stands out as an organisation, both in the North Sea and globally,” opens Scott Barr, Harbour Energy’s EVP North Sea,

“is how we’re increasingly focused on effectiveness, efficiencies, and simplicity but also by embracing the opportunities of technology and innovation.”

Harbour Energy is the largest oil and gas producer in the North Sea - a diversified public company with long-term focus on value creation and sustainability. The company aims for safe, efficient, and responsible production of hydrocarbons to supply UK demand for energy.

The UK North Sea remains a legacy basin with oil and gas as well as established and emerging energies including wind, wave, and tidal opportunities. Across Europe, the North Sea has been centralised in strategy since the region began efforts to break away from Russian fossil fuels.

ROBUST PROJECT PIPELINE

Investments continue to flow into energy infrastructure and innovation, and the North Sea’s potential is

unquestioned. For Harbour Energy, unlocking further long-term potential is about broadening exposure in a region it knows better than most.

Scott Barr - an industry veteran with 25 years’ experience across onshore and offshore activity, and a fellow and chartered engineer with the Institution of Engineering and Technology – is excited about Harbour’s pipeline. New projects, field extensions, carbon capture utilisation and storage (CCS), and major acquisitions are all progressing, with Barr relishing the challenge.

“We continue to progress high return, short cycle, infrastructure-led UK investment opportunities, supporting future production and cash flow,” he explains. “The start-up of production at Tolmount East, with first gas achieved on 4 December 2023, will increase future rates from the Tolmount area. The Leverett discovery, close to Harbour’s operated Britannia infrastructure, has

36 / www.energy-focus.net

Scott Barr, EVP North Sea

HARBOUR ENERGY

been successfully appraised with good flow rates achieved. The Talbot field is also on track to deliver first oil around the end of 2024 via the Harbouroperated Judy platform with all three development wells completed.”

Currently, Harbour boasts operated production hubs across the Greater Britannia Area, J-Area and AELE (Armada, Everest, Lomond and Erskine), as well as material non-operated stakes in flagship fields including Elgin/ Franklin, Buzzard, Catcher, and Clair. The bulk of production comes from the Central North Sea, with interests in the Southern North Sea, West of Shetlands, and the East Irish Sea.

Carbon capture is part of a longer-term strategy for the company which has committed to net zero by 2035. However, CCS remains in relative infancy as an industry and requires expert knowledge to build.

“Harbour’s involvement in developing the carbon capture,

transportation and storage industry is something we’re really proud of and excited by,” says Barr.

Busy with the Viking CCS project, alongside 40% shareholder bp, Harbour is looking to create a facility that can capture and store 10 million tonnes of CO2 annually by 2030. Close to the Humber region, populated by heavy

industry, Viking CCS has the potential to add £7 billion of investment across the full CO2 capture, transport, and storage value chain over the next decade.

“Since we were awarded two additional carbon storage licences by the North Sea Transition Authority (NSTA) in September 23, the Viking project has continued to make

www.energy-focus.net / 37

INDUSTRY FOCUS: OIL & GAS

J+S MAKING WAVES IN OFFSHORE ENERGY

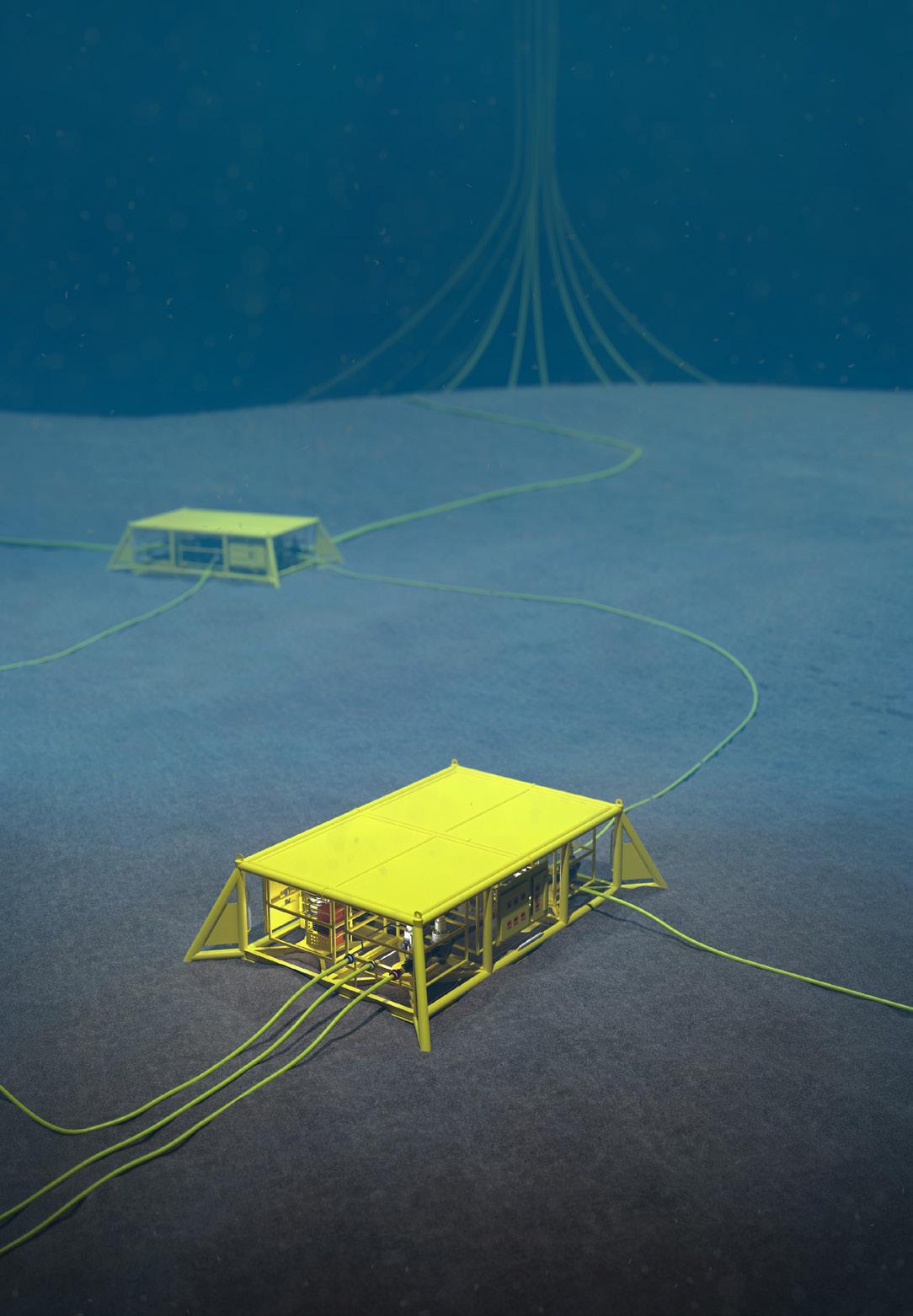

J+S Subsea is busy supporting Harbour Energy and other major operators across various global operations, offering a full package when it comes to subsea infrastructure design, manufacture, and maintenance.

In 2020, an exciting and innovative company focused on the subsea engineering industry was borne out of the management buy-out of Systems Engineering and Assessment Limited, a Cohort Group business. The new business, J+S Subsea, has since proved its ability across multiple projects and with many different partners in the offshore energy sector.

“Our growth in the last three years has been phenomenal and it’s not just turnover, it’s the calibre of people we are attracting,” says MD Phil Reid.

Part of that growth has been a strong relationship with listed independent oil and gas company, Harbour Energy. Harbour has assets across the UK North Sea and J+S Subsea has become important in the effective maintenance and upkeep of various subsea resources. The company handles design, engineering, operational support, and maintenance of subsea equipment, and has built a strong reputation for excellence.

“We were recently awarded a £1m+ contract for the supply of full subsea infrastructure for a new well that is going in. Half of the equipment is going in during 2024 and the other half in 2025,” explains Reid.

“We were awarded that contract because of our delivery schedule. Moving from a concept to delivering exactly what they needed – several weeks before tier ones could – is what is appealing about us.”

J+S Subsea makes use of its Legacy Locker – a portfolio of capital equipment that has been refurbished or reengineered to allow for continued operations on site, while not costing the earth. It is focused on avoiding scrapping of useful materials and embracing the circular economy.

good progress, with the Planning Inspectorate accepting for examination our application for the Development Consent Order for the onshore pipeline in November. Late last year, we were also delighted to announce Cory Group’s exclusive commercial agreement with the Viking CCS project – which marked a really significant milestone in developing the CO2 shipping sector in the UK as well as real progress on how the captured CO2 emissions from dispersed sites

“Recently, we received a message from Harbour looking for some hydraulic hoses on a Sunday afternoon and we turned that around in 24 hours. We had a team in on the same night, manufacturing equipment to be on a dive vessel the next day,” says Reid, adding that other pieces for Harbour have been found in the Legacy Locker, reducing lead time and cost significantly.

Another recent project saw J&S deploy its full skillset from design to manufacture, supply and then maintenance and operation when it delivered a complex system to an operator in Canada. Taking a FPSO off-field, electrical resistance had to be maintained and J+S stepped in to deliver the required subsea battery systems. At the same time, the company has been busy developing an innovative control module which is going though qualification.

“When we have the control system through qualification, we will be challenging the tier one companies and that is exciting,” smiles Reid.

As J+S grows, the ability and skillset within the company will develop allowing for the successful delivery of bigger and more complicated projects, and this is where Reid sees J+S Subsea adding real value.

“We want to be a one stop shop,” he concludes.

www.jands.co.uk | +44 1224 773435 | info@jands.co.uk

around the UK can gain access to high quality storage,” Barr adds.

Harbour is also busy with the Acorn CCS project in Scotland where it holds a non-operated 30% stake. CO2 can be transported, using existing oil and gas infrastructure, and stored deep under the North Sea, permanently.

“Acorn also received an additional two storage licences in the same licensing round in September. And finally, just before Christmas the UK Government announced its ‘CCS Vision’, which

provides more clarity on the process for emitter sequencing to CCS projects, which is a really significant step forward for projects like Viking and Acorn.”

NET ZERO BY 2035

Through 2024, Barr is hopeful that energy around CCS will continue as the industry proves its ability to contribute to sustainability goals.

“I think all round we’re seeing some

Continues on page 40

38 / www.energy-focus.net

Working in the subsea environment

J+S Subsea provides proactive, responsive and cost-effective solutions for design, engineering, operational support and maintenance of subsea equipment, primarily related to the Subsea Production Control market.

J+S Subsea can provide a range of solutions to fulfil all your Subsea Energy Controls needs. We can provide service and support whether you need to refurbish your existing equipment, deliver critical components or design, assemble and test a new system.

Delivering Bespoke, Cost-Effective Solutions

Our vision is to enhance subsea operations by delivering cutting-edge technology that is efficient, safe and environmentally sustainable. Our team of skilled engineers and technicians are dedicated to pushing the boundaries of Subsea Engineering. From concept design to installation, J+S Subsea delivers tailor-made solutions that meet the unique challenges of each individual project.

Riding the Wave of Innovation and Sustainability

Dive into a new era of subsea excellence with us, where sustainability is more than a principle - it’s a commitment. We’re reshaping the subsea landscape by integrating sustainable practices and innovation. From efficient subsea equipment to responsible waste handling, our approach minimises our impact on the environment. Join our journey to redefine subsea operations with a focus on a greener future.

At the heart of the company’s commitment to achieving net zero, is the pioneering Legacy Locker initiative. This forwardthinking initiative embraces the principles of the circular economy, offering a portal for the reuse, refurbishment, and recycling of subsea equipment. Beyond unlocking capital tied up surplus equipment, the Legacy Locker users, enhance their environmental footprint by identifying opportunities to minimise waste and promote sustainability.

t: +44 1224 773435 | e: info@jands.co.uk | www.jands.co.uk Site 7 Tumulus Way, Midmill Business Park, Kintore, Aberdeenshire AB51 0TG Registered in Scotland No : SC645331 THE COMPLETE SUBSEA SOLUTION Subsea UNDER CONTROL

INDUSTRY FOCUS: OIL & GAS

Continued from page 38

good momentum, but the onus is now on us and the Government to keep that going this year.

“I have to mention some of the work we’re involved in to innovate and create sustainable approaches,” he goes on. “One trial project we are involved in works to try and harness wave power to provide low-carbon power to offshore installations. It’s a demonstrator project called Renewables for Subsea Power which is working to develop a wave energy converter that can harness wave energy to provide low-carbon power to subsea equipment via a subsea battery, as well as help power an autonomous underwater vehicle (AUV) used for subsea inspections. It’s really exciting stuff with a lot of potential.”

This £2 million collaborative project sees giants from the energy

and engineering industries come together off the coast of Orkney to demonstrate a battery energy storage system (BESS) for use in harsh, underwater conditions, utilising renewable energy to provide reliable electricity supply to subsea equipment.

Delivering on its promise of reducing emissions and achieving net zero by 2035, Harbour is also hard at work with various projects to reduce flaring and integrate efficiency-driving technology across operations.