Integrated Solutions for the Hydrogen Revolution

ALSO IN THIS ISSUE: Exclusive Interview with NEUMAN & ESSER Managing Partner Alexander Peters, together with Managing Director Jens Wulff

Worley / Centrica Energy Storage+ / Alabama Shipyard / Heathrow Airport

At Deep Casing Tools we deliver simple, sustainable innovations designed to streamline your drilling, completion, and plug & abandonment processes.

Our unique solutions across the well life cycle including cutting-edge tools such as the TurboCaser, TurboRunner, MechLOK Drill Pipe Swivel, SelfLOK Flotation Device and the Rubblizer are engineered to navigate challenging wellbore environments, ensuring reliability and efficiency at every stage.

Learn more about how technologies from Deep Casing Tools are revolutionising global operations and saving operators time, money, and emissions across all projects, contact the experienced team today.

EDITOR Joe Forshaw joe@energy-focus.net

PROJECT MANAGER Tommy Atkinson tommy@energy-focus.net

PROJECT MANAGER David Hill david@energy-focus.net

PROJECT MANAGER Chris Bolderstone chris@energy-focus.net

ACCOUNT MANAGER Isabel Murphy isabel@energy-focus.net

LEAD DESIGNER Aaron Protheroe aaron@energy-focus.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Karl Pietersen

CONTRIBUTOR David Napier

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

EDITOR’S LETTER

Yet again hydrogen is the talk of the month. So much potential, so abundant, so obviously the next big thing – but not a lot to talk of in terms of actual project rollout?

Why is hydrogen production not ramping up as fast as many thought it would? And why is the hydrogen economy not taking off like a rocket ship?

Simply, the cost. There’s also the political will and perceived risk.

So, the biggest and best companies out there are working hard to come up with new solutions. Worley, global EPC, is trying to come up with an ‘off the shelf’ hydrogen production plant where the design is influenced by the supply chain to drive cost down as much as possible through standardisation.

Centrica Energy Storage+ is looking at localising production, transport, and storage in the largest industrial cluster in the UK to show that, as a combined system, technologies can work together to drive efficiencies.

Neuman & Esser, global manufacturer of compressors and electrolysers, is promoting the implementation of systems that are designed with both in mind. A compressor from one company will not always perfectly align with the electrolyser from another, and so early stage integrating is vital for a cost-effective system.

Read more from industry leaders across the hydrogen space and understand how exhilarating the industry is, while also being rather frustrating at the same time. And get in touch and tell us what your company is doing to move hydrogen along.

Published by

Chris Bolderstone – General Manager E. chris@cmb-multimedia.co.uk Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX +44 (0)20 3097 1743 www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher. © CMB Media Group Ltd 2024

We’re online at LinkedIn

Joe Forshaw EDITOR

NEUMAN & ESSER

Integrated Solutions for the Hydrogen Revolution

Shipyard Renaissance Fully Underway in Alabama 6 14 28 36 42 50 56

CENTRICA ENERGY STORAGE+

Storage Unlocks the Hydrogen Economy

WORLEY

Developing World Leading Standardised Hydrogen Production Plants

ZENOBĒ A New Era for Energy

DSA ARCHITECTS INTERNATIONAL

Sustainability Rooted at Foundational Level

HEATHROW AIRPORT

Transformational Sustainability Projects Pave Way for Aviation of the Future

ALABAMA SHIPYARD

NEUMAN & ESSER

Integrated Solutions for the Hydrogen Revolution

PRODUCTION: David Hill

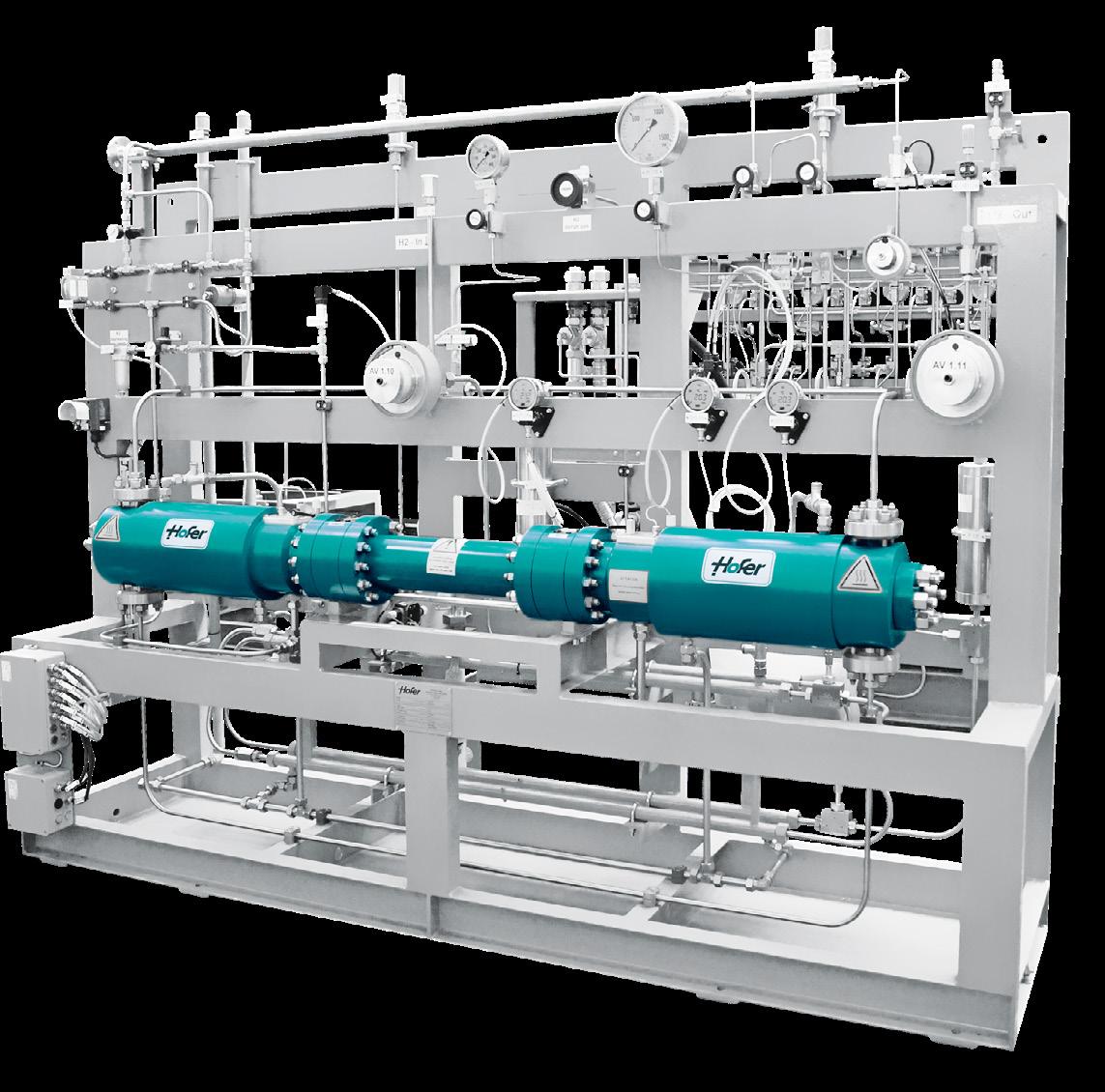

Compressors move energy and enable the transition to cleaner fuels of the future. But manufacturing compressors and electrolysers requires engineering of the highest level. NEUMAN & ESSER can deliver, and MP Alexander Peters together with MD Jens Wulff are confident about the company’s ability to drive a hydrogen revolution.

INDUSTRY FOCUS: ENGINEERING

//Germany’s NEUMAN & ESSER, a leading provider of compressor system solutions to global markets, is no stranger to energy transition. The company was established in Aachen in 1830 close to the Dutch and Belgian borders and was involved in the manufacture of machinery around the time of the industrial revolution in Germany. Brothers Johann Leonard Neuman and Friedrich August Neuman saw the obvious opportunities in the emergence of steam engines and air compressors used in the close-by

coal mines. The company thrived and built a reputation for excellence, but a second energy transition saw the advent of liquid fuels and gas, and a redesign was required to use air compressors for chemical parks and refineries. Again, NEUMAN & ESSER flourished, growing to become an industry leader. Now, as the modern energy transition continues, the fourthgeneration family-owned company is perfectly positioned to bolster green projects with compressors for hydrogen, biomethane, and LNG.

As a logical consequence,

NEUMAN & ESSER broadened its product portfolio by acquiring Brazilian electrolyser manufacturer HYTRON, bringing in its vast experience in hydrogen and established NEA|HYTRON electrolysers with PEM technology as a strong currency in the market. This allows for integrated end-to-end solutions across the full H2 value chain: From designing a hydrogen production plant with a tailored compression system through engineering, construction, and commissioning to digitally supported full-service

NEUMAN & ESSER

// WE ARE USING OUR 100 YEARS OF EXPERTISE IN COMPRESSION TO COMPRESS HYDROGEN. WE HAVE MORE THAN 2000 BIG COMPRESSORS RUNNING WORLDWIDE //

during operation customers may get everything from a single source.

With 1600 people around the world, and being present in 12 strategic country locations, the company is a globally active leader. In Germany, production sites in

ALEXANDER PETERS

Managing Partner& ESSER

Übach-Palenberg, Mülheim, Staßfurt and Wurzen are well-known for excellence, reinforcing the German reputation for world-class engineering.

Managing Partner of NEUMAN & ESSER, Alexander Peters points out that hydrogen is certainly an

JENS WULFF Managing Director

JENS WULFF Managing Director

& ESSER Deutschland

important industry for the company going forward, and its skills and expertise fit perfectly with the requirements of the industry.

“People must understand the holistic picture,” adds Jens Wulff, Managing Director of NEUMAN &

INDUSTRY FOCUS: ENGINEERING

ESSER Deutschland. “Many in hydrogen go and buy an atmospheric electrolyser and then they are surprised by a failure-prone compressor system. When looking at the big picture, people should strive to achieve system optimisation and not local optimisation. You must have a system that fits together correctly, and saving money on the electrolyser can lead to a bitter operational cost with downtime and inefficient production.”

Integrated solutions out of one hand for hydrogen production, transportation, storage, and utilization projects therefore make a major difference for those looking to decarbonise.

“We are using our 100 years of expertise in compression of hydrogen. We have more than 2000 compressors at all scales running worldwide for hydrogen compression across a range of applications, and we are now combining compression expertise with

electrolysis know-how,” says Wulff.

Peters adds: “As hydrogen becomes a more important part of the energy transition, our involvement will only increase.”

IMPLEMENTATION

In 2023, NEUMAN & ESSER announced a project near Magdeburg at the Osterweddingen industrial park providing compression, storage, filling, and transportation technology as well as consulting services for a hydrogen project led by the engineering and construction experts STREICHER Anlagenbau for ENERTRAG, a renewable energy provider. Power for a 10 MW NEA|HYTRON PEM electrolyser comes only from renewable sources and hydrogen will be utilised through the ONTRAS pipeline. Initially, two tonnes of green hydrogen will be produced daily, with the majority going to decarbonise long-haul transportation

in the heavy industry of the region.

Eight NEUMAN & ESSER compressors will be installed, with four feeding into the national gas grid and four used for trailer filling. All compressors have been designed for their respective use and are expected to integrate into the system seamlessly.

“Both the single-stage feed and the two-stage filling compressors are diaphragm compressors of the NEUMAN & ESSER brand NEA|HOFER and use the same proven compressor crankcase size. The diaphragm heads are of course adapted to the respective application,” says Area Sales Manager, Guido Harsch.

Wulff adds: “We can offer both compressor and electrolyser manufacturing as a highly tuned package. We can capture the best of both systems. Even if we don’t build the electrolyser, we are at least the compressor manufacturer with the best electrolyser knowhow. We know what electrolysers like and what they don’t –this is our strength.” This highlights the importance of integrating technology effectively, especially when it comes to hydrogen. A good showcase for this is the Green Hydrogen Trailer Filling system fed by a NEA|Hytron- 10 MW PEM Electrolyser. NEA supplies the entire system including buffer vessels, control systems and buildings.

In the Netherlands, this strength has been put to the test as NEUMAN & ESSER compressors are set to be utilised to inject hydrogen into salt caverns for storage. The gas must be purified and compressed significantly before injection into the cavern but overall, the process is relatively low cost.

Bigger and stronger is the aim of the industry as increased volumes will be pumped through pipelines and injected into storage sites around the world. Whether hydrogen or CO2 for CCS, there effective movement of gas through compressors is central in the energy transition.

“Salt cavern storage of hydrogen,

NEUMAN & ESSER

high-powered compressors for big ammonia plants – we have built a lot of these big compressors already,” says Wulff. “The demand for bigger compressors is there. High pressure, non-lubricated compressors, oil free, maintaining purity is a target for the next five years as big truck fuelling stations emerge, filling more than 500 trucks per day. We are currently executing projects for large scale H2 liquefaction in the US and for large scale H2 salt cavern storage in the Netherlands. Additionally, we are supporting various EPCs in the design and selection of green steel, green ammonia, and green methanol plants both on the electrolyser and the compressor side. “

To deliver at scale, the company calls on a world-class supply chain to support its activities. Quality is the key concern, and the procurement

department is always looking to build new relationships so that many options are available for each individual part. It sounds like standard good practice, but a lot of work is put into a strong supply chain strategy. It is paramount to work closely

with foundries and forgeries. Electric motors, drives, instrumentation programmable logic controllers (PLCs), heat exchangers, pressure vessels, and stacks for electrolysers are required.

The rectifier is also very important with its pumps for auxiliary systems,

INDUSTRY FOCUS: ENGINEERING

and other control instrumentation. The supply chain is vital and localisation in the procurement process has become a crucial element in recent times, following the disruption of the pandemic and the company’s global expansion.

For a fast-growing company standardisation is a must, but regulation makes it difficult to achieve with a company active on four continents. Flexibility and ingenuity have always helped to react to local content requirements or when it comes for example to different regulations around electrical manufacturing in the USA, Europe or Asian markets which are incompatible with each other.

GLOBAL EXPANSION

NEUMAN & ESSER has grown to a point where it is now a recognised authority on best practice in the hydrogen economy. This was evidenced in 2020 when Managing Partner Stefanie Peters was appointed as a member of the Hydrogen Council. Germany adopted a National Hydrogen Strategy which involves building 5GW of electrolytic capacity by 2030, a target that was doubled in 2023, now at 10GW.

“Investing in hydrogen is an investment in our future. In climate protection, in qualified jobs, and in securing the energy supply,” said Federal Minister of Economic Affairs Robert Habeck at the presentation of the National Hydrogen Strategy.

Many other countries have made public their hydrogen expectations, and many are progressing plans through pre-FEED and Final Investment Decision processes.

For Alexander Peters, Asia and Africa are the obvious choices for expansion because of the nascent markets and need for holistic integrated solutions, typically greenfield projects.

“We are going through the energy transition ourselves and we are assisting others with our adapted and newly integrated products and solutions for the energy transition,” he says. “We are well known in Europe and North America. We see Latin America as an area with room for improvement.

Asia and Africa especially are key focus areas, very important in the energy transition, converting wind and solar into hydrogen or green ammonia or green methanol as part of a clean energy supply.”

He highlights population figures as key considerations but is also

// WE ARE DOING MANY THINGS WITH LNG FOR MARINE AND WE ARE BUSY WITH AMMONIA AND GREEN AMMONIA AS A FUEL AND AS AN ENERGY CARRIER //

cognisant of the raft of risks that come with projects in new territories. “China is high risk and India is always looking for breakthroughs. Indonesia and the Philippines and Vietnam are doing good things. People are also looking for green ammonia projects for Australia, so the APAC region is exciting.”

Even where the company already has a strong presence, opportunities remain. “With our US Sales team, we have sold compressors for hydrogen liquefaction – which is very important for shipping hydrogen over long distances,” Peters adds.

“We are doing many things with LNG for marine and we are busy with ammonia and green ammonia as a fuel and as an energy carrier.”

With such exciting opportunities at its feet, this historic and successful

business is working hard to accelerate the energy transition, just as it has done in the past – using technology and engineering expertise to deliver innovation at scale. In the hydrogen and CCS spaces, NEUMAN & ESSER compressors are among the best available and, when paired with correct electrolysers and systems, the company delivers consistency.

“We are a plant engineering company, and we solve our customers’ mission critical challenges with reliably running and perfectly adjusted equipment,” Peters concludes.

Embracing the challenges around net zero, Centrica –the UK’s leading vertically integrated energy business – is underway with multiple projects to deliver the hydrogen economy of the future, starting in the country’s largest industrial cluster around the Humber. Decarbonising here will be a major triumph for those involved in the energy transition. Marting Scargill, MD at Centrica Energy Storage tells Energy Focus more about progress in the northeast.

MARTIN SCARGILL MANAGING DIRECTOR

MARTIN SCARGILL MANAGING DIRECTOR

INDUSTRY FOCUS: STORAGE INFRASTRUCTURE

Arapidly changing energy industry is moving at such a pace that many stakeholders are left behind. Consumers, companies, governments – all have faced shocks over the past five years. The energy market, and all of its sub-sectors are volatile, characterised by risk, innovation, original thinking, and uncertainty.

Against this backdrop, it’s hard to plan. For energy giant Centrica, adapting and changing in nimble fashion is no easy feat. With over 21,000 employees, more than two centuries of history, 10.3 million customers, and a vertically integrated portfolio of companies that operate across the entire value chain, keeping up with a changing market is challenging.

But Centrica has positioned itself as a pioneer. Not a follower, but a creator

of change. Intentionally doing things differently to achieve new outcomes as it embraces the net zero journey ahead.

Centrica Energy Storage (CES+) is part of the infrastructure division responsible for long duration energy storage within the group. Responsible for the reopening of the Rough gas storage facility, and operation of the Easington Gas Terminal, this vital business is busy planning for long-term energy security, that meets net zero requirements, at an affordable level.

“We have so many things going on. We have big ambitious plans,” smiles MD Martin Scargill

HYDROGEN STORE

Traditionally, CES+ (rebranded to include the + in 2023) has been a gasfocused business, and the company is now looking beyond the horizon

towards 2050 and UK Net Zero. This means hydrogen production and storage are within Scargill’s remit, and he is pushing hard for project progress. Hydrogen offers so much as an energy carrier – abundant, emission-free, powerful – and so it is an obvious choice when it comes to decarbonising at scale, especially in industrial areas like the UK’s northeast and Humber regions.

Longer-term, Scargill believes that CES+ facilities can be used as part of the emerging hydrogen economy, kickstarting major economic opportunities through hydrogen while at the same time furthering UK energy security and affordability.

“The long-term ambition is to use Rough as the UK’s largest hydrogen store,” he says. “But, at the moment, the hydrogen economy is not moving at the

The Global Shipbroker

pace that people thought it could. Our proposition to government is to have a hydrogen-ready redevelopment project shovel ready for this year. We have moved that into front end engineering design (FEED) this year, and that is a significant commitment from Centrica without certainty, to showcase our belief in the value of storage to the UK.”

Currently, Rough is the largest energy storage site, capable of storing 54 billion cubic feet of gas – half of total UK storage capacity. Balancing the system when demand is high, Rough was a diamond in the UK energy system for decades before closure in 2017. In 2022 the facility was reopened, before a doubling of capacity project was completed in 2023.

“We are pleased with what we have been able to do,” says Scargill adding that Rough has been very reliable,

filled to capacity last year. “For energy security and keeping bills down, we did everything we could. We filled it to the max by October, and we have been producing that gas back to the system from November. It continues to do its

Controls, Automation & Instrumentation Services

Control & Distribution Systems

Wellhead Controls, Valve Actuation Controls, Hydraulic Power Units

Component Supply

Control Valves, Isolation & Block and Bleed Valves, Safety Relief Valves, Pressure Monitoring Equipment, Instrument & Pipe Fittings

Bespoke Engineering / Manufacturing Services

Service Support / Site Services

Control Component Repairs, Spare Parts Supply www.dycos.co.uk

job, and we set some very high targets for our teams to keep it as reliable as possible. We are very pleased with that.

“In terms of expansion, we are at the limit of what we can do with the infrastructure that we have. We

INDUSTRY FOCUS: STORAGE INFRASTRUCTURE

SPECIALIST SERVICES UNDERPINNED BY TECHNOLOGY AND GLOBAL MOBILITY

OCCMS’ long standing relationship with Centrica Storage at their UK onshore Gas Processing & Storage terminal, was formed to provide Completions & Commissioning oversight and execution support services. The high-level summary of the scope requirements are as follows:

• Execution oversight of handover from principal contractor.

• Commissioning Test Procedure development and implementation.

• FAT Support.

• Plan and execute pre-commissioning and dynamic commissioning.

• Technical delivery of processes and competence assessed personnel.

• Support handover to client operations for start-up and ongoing production.

During this project, OCCMS have safely delivered commissioning and completions services for Phases 1 to 4 at our client’s UK based terminal which receives separate and condition natural gas and associated liquids from two separate offshore fields to meet the required specification before transfer of natural gas into the national transmission system (NTS). The processing facilities consisted of an inlet area/separation, onshore compression, dewpointing, filtration and fiscal metering with associated utility and auxiliary supplies.

During the initial period, various brownfield modifications were undertaken within the onshore plant and included, but not limited to, F&G system modifications which were updated to accommodate the changes within the gas plant.

Following this initial phase, additional gas compression, additional F&G, and methanol recovery and injection facilities were upgraded and or modified as part of the new Humber Gathering System (HGS) and included upgrading receiving facilities for the new Tolmount offshore field.

All construction completions and commissioning execution was controlled and managed through OCCMS’ ORBIT™ completions management system on premise with a dedicated database administrator at the clients facility.

The total onshore hours expended on life of project, including a small proportion for senior leadership oversight, are ~60,000 without a lost time incident, including during the Covid 19 pandemic. “This strong track record is demonstrable of OCCMS’ strong safety leadership & inherently positive behaviours which are prevalent throughout all levels of management and delivery teams alike” stated OCCMS’ Operations Director – Jamie Japp.

For further insights or information on how OCCMS can assist you with your Brownfield Projects, please contact us at: Aberdeen@occms.com

are looking for opportunities, but we are around 54bcf right now but we think we could get it to around 58bcf. The facility is nearly 40 years old and that is why we are looking to develop new infrastructure that can quadruple capacity at Rough. We would be delighted to sanction something this year if the economic certainty is provided.

“It’s a big platform and it’s busy. We have around 100 people there at any time,” he says of the atmosphere on site, 18 miles off the East Yorkshire coast, 20 minutes in a helicopter. “We are investing all the time in terms of extending the life of the facility. For its age, it is in really good condition, but we must keep on top of everything. We are always upgrading, replacing, and

repairing. The team is always busy.”

THE CENTRE PIECE

Planning is well underway to build new infrastructure around Rough, modernising the facility and enabling it to become a centrepiece of the hydrogen economy of the future.

Continues on page 20

INDUSTRY FOCUS: STORAGE INFRASTRUCTURE

REWS INTEGRATED VESSEL MONITORING & COLLISION SOLUTION

Often difficult to envisage on a vast expanse of water; shipping accidents are all too common. In the past decade, the second most common cause of shipping incidents reported globally is collision (3,098). In the oil and gas industry particularly, a maritime incident can be catastrophic with detrimental environmental consequences.

The aftermath of these incidents is well documented, but there is a lesser-known theme behind the cause. Reports show that almost 96% of maritime accidents are caused by human error, with fatigue the top cited issue.

With the UK oil and gas workforce expected to decline from 120,000 to around 87,000 by 2030 (in line with production decline and decommissioning activities), significant pressure is placed on the fewer vessels and crews that are left behind. With fewer staff and crews often being placed on unfamiliar vessels, the risk of human error will likely increase.

Ultra provides an integrated collision avoidance monitoring solution, our Radar Early Warning System (REWS) directly improving maritime safety. By using multiple platform-based radar early warning systems the Ultra REWS monitors marine traffic, protecting offshore installations and avoiding maritime incidents.

REWS provides protection 24/7, 365 for one or more platforms with alarm data instantly available to operators strategically located at onshore control centres, on platform, or Emergency Response and Rescue Vessels (ERRV) that react to any incident.

ULTRA REWS:

• Proven radar early warning system (REWS)

• Round the clock monitoring, 365 days a year

• Integrated system with Radar, Automatic Identification System and CCTV for 360° surveillance

• Capable of protecting multiple assets from an onshore control centre

• VHF voice communications enables control centre operators to contact offshore assets and passing vessels

• 24/7 technical support and help line available

PROTECTING:

• Offshore assets from collision

• Subsea systems from fishing activity

• Man overboard

• 500m safety zone

• Emergency response coordination Legal obligation to have a collision risk avoidance system

• Protection around renewable and new energy platforms

This technology is a step change in marine operation safety, providing a full audit trail for incidents, near misses, and learning opportunities. Operational costs are reduced by consolidation/sharing of ERRV and Guard Vessel fleets and removing thousands of personnel risk exposure hours, with potential for multi-client control-centre monitoring for maximum cost efficiency. Simply, offshore operators cannot afford to risk devastating collisions. Ultra REWS provides real-time vessel monitoring that improves marine safety, reduces offshore risks, cuts operational costs, and allows for informed decision making in the most challenging environments.

Continued from page 18

In a nutshell, Centrica sees a system that produces hydrogen at sites onshore around Easington, transports it for use in the heavy industries of the Humber and northeast region,

before excess being pumped back offshore to Rough for storage. At the same time, storage could be developed onshore at other existing infrastructure sites, and other sectors can be connected through a pipeline network. Ultimately, these projects

will fuel decarbonisation efforts as Centrica, its customers, its supply chain as the country pursues net zero.

“The storage project at Rough is the centre piece for us in the northeast

Continues on page 22

INDUSTRY FOCUS: STORAGE INFRASTRUCTURE

Continued from page 20

Humber region, but the challenge with hydrogen is that there is not enough being produced,” Scargill explains, “our idea being that we could have up to 1GW of hydrogen production at Easington. We could have that as green or blue or a mix, depending on how national strategy develops.”

As a concept, onshore production with offshore storage at volume makes sense in the northeast. The Humber Industrial Cluster is the

“WE

biggest CO2 emitter in the UK with two large oil refineries and an integrated steelworks operation alongside other heavy industry applications.

“In the Humber, 12 million tonnes of CO2 per year need to be removed. There is an opportunity there for us to look at building green hydrogen production capacity, perhaps later supplementing with blue. That is a 50/50 JV with our strategic partners at Equinor.”

In November 2022, the two companies signed a co-operation

agreement to develop a low-carbon hydrogen production hub at Easington, securing existing jobs, creating new jobs and developing skills while moving away from fossil fuel reliance.

“Under our rebranding as part of our future hydrogen strategy, we want to take forward hydrogen production projects for Centrica and our business unit. We are going to be submitting a number of projects into the next hydrogen allocation rounds and that is a positive development for us as we are leading Centrica’s hydrogen production and storage businesses,” says Scargill, adding that the vision goes beyond decarbonising its own operations and supports customers also navigating emission reduction journeys.

“It is needed in industry, and it is needed to keep the lights on when the wind is not blowing and

the sun is not shining. Our area, in the Humber, with the best geology for storing hydrogen in salt caverns or in gas fields, has everything we need. The demand, the geology, the skilled workforce, the businesses that want to invest – it’s all here.”

Currently, the company and other stakeholders are waiting for a clear investment case, with long-term certainty, to be positioned by both industry and government. While the engineering side of hydrogen production is not new, the technology required for green hydrogen is yet to be deployed at scale and so is relatively expensive while the sector develops. In the UK, the government has already opened various project avenues for those interested in building out new infrastructure. Hydrogen Allocation Rounds (HAR) promote funding

CENTRICA ENERGY STORAGE

mechanisms to support low carbon hydrogen production, and Centrica has been active within HAR1 and HAR2.

“Industry has continually requested some form of intervention from government to allow investors to be able to have sight of a return in a nascent market. There is so much upfront capital required to build these things, and then an uncertain market,” says Scargill.

The vision for hydrogen in the UK, as part of its Energy Security Strategy, is to realise 10GW of low carbon hydrogen in construction or production by 2030, with at least 50% being green.

VITAL CONNECTIONS

Before the end of this decade (as close as 2026 according to some reports) connecting pipelines will start to be developed across the

northeast to connect industrial clusters. 100km of pipes will be rolled out in what National Grid has labelled ‘Project Union’.

Eventually, 2,000km of pipeline will bring hydrogen to other sites around the country following the example from the Netherlands where hydrogen network infrastructure is set to start operating in 2027.

“We now have the hydrogen

“THE DEMAND, THE GEOLOGY, THE SKILLED WORKFORCE, THE BUSINESSES THAT WANT TO INVEST –IT’S ALL HERE”

INDUSTRY FOCUS: STORAGE INFRASTRUCTURE

“HYDROGEN

STORAGE UNLOCKS THE WHOLE HYDROGEN ECONOMY AS

YOU CAN THEN BALANCE

SUPPLY AND DEMAND FLUCTUATIONS BETWEEN PRODUCERS AND OFF TAKERS, ULTIMATELY MAKING THE SYSTEM CHEAPER”

production business in with the storage business and we want to build a leading UK hydrogen production, storage, distribution hub in the Humber to help decarbonise industry while storing hydrogen for use when required. The modern system requires flexible, dispatchable, low carbon power and that is the way we will have the system balanced in the future,” details Scargill.

“We have big storage at Rough, and we are certain that it will eventually play an important role in the UK, and we think we could even access export markets. In the short term,

the government have been pushing ahead with the hydrogen storage business model for smaller sites. We have fantastic salt strata – the best in the country – in East Yorkshire, and that is where the government is initially comfortable supporting projects around hydrogen storage. Hydrogen storage unlocks the whole hydrogen economy as you can then balance supply and demand fluctuations between producers and off takers, ultimately making the system cheaper.”

Scargill, an engineer by training and seasoned business leader, is confident that the first UK hydrogen

Leading Energy Transformation.

- supporting CES+ and the UK transition to clean energy.

the wells expertise to deliver a sustainable Carbon Zero future

The world’s largest independent well and reservoir management company, providing a uniquely integrated service trusted by leading operators and suppliers across the globe.

ecosystem will emerge from the Humber and a system could be running by as early as the end of the decade.

GREEN INVESTMENTS

Across the wider Centrica business, so much is happening as the company looks to provide security of supply, at an affordable rate, in line with environmental expectations and net zero goals. The group developed a People & Planet Plan which looks to support customers at all times while promoting sustainability.

“We are now investing £600-800 million per year over the next five years

CENTRICA ENERGY STORAGE+

© SGS Société Générale de Surveillance SA. (2024) SGS24-715

Valve Management

Trusted valve maintenance from a leading provider

With technical expertise across more than 400 different valve manufacturers gained over more than 125 years we can supply refurbishment, certification and overhaul for all your valve needs giving a cost effective and reliable service to our customers.

CONTACT US: 0151 350 6666 ukenquiries@sgs.com sgs.com

on energy transition infrastructure,” highlights Scargill, speaking of the group’s green-focused investment plan, launched in 2023. “We want to invest in the UK and Ireland, we want to invest in energy security, and we want to invest in low carbon assets that keep the lights on and bills down.”

Success here does not come through one single project but an integrated approach including customers and suppliers. “Energy transition is a huge task,” he admits.

“There are so many things being worked on at the same time. Developing the business models and

bringing things forward takes a long time. We have voiced our opinion that things might not be ambitious enough at times. We must decide where to spend money – every penny counts, and we get that we must show value for money. When the Department for Energy Security and Net Zero takes all these schemes to Treasury, there is understandably a discussion about affordability and value for money, and that is where the speed of deployment is determined. We’re confident that our projects will unlock clean growth and inward investment that is good news for the regional and national economy.”

Alongside the focus on natural gas and hydrogen, the company is also actively engaged with partners around CCS to ensure emissions that continue will eventually find a safe forever home deep underground.

Industry commentators mostly agree that, alongside renewable energy and hydrogen, CCS is essential in a net zero strategy for the Humer Industrial Cluster.

“Centrica majority owns Spirit Energy and through that we have a facility in Morecombe Bay where we can store a billion tonnes of CO2 and we have a license for that,” says

“WE WANT TO INVEST IN THE UK AND IRELAND, WE WANT TO INVEST IN ENERGY SECURITY, AND WE WANT TO INVEST IN LOW CARBON ASSETS THAT KEEP THE LIGHTS ON AND THE BILLS DOWN”

INDUSTRY FOCUS: STORAGE INFRASTRUCTURE

Scargill. “We are pursuing that project, and we will be looking keenly at the expansion process for projects in the Humber region to see when the Humber gets a connection to a CO2 store as that will allow all of the emitter projects to connect into the system and reduce emissions.”

Many modern systems, including hydrogen and CCS, are being developed to be less labour intensive and cheaper to maintain. This means engineering complexity out of

machinery and moving infrastructure onshore where possible. Rough is an example – a facility built to be manned, more than 40 years ago. In the future, Centrica and others will look to have smaller, simplified systems in place, easily controllable from a central location, and with minimal scheduled maintenance.

“This will mean offshore can be unmanned and will just be pipes,” says Scargill who worked offshore earlier in his career. “People only

“ULTIMATELY THAT WILL REDUCE BILLS FOR PEOPLE. DECARBONISING THE UK’S LARGEST INDUSTRIAL CLUSTER IS ALSO OUR TASK AND WE ARE LOOKING AT HYDROGEN PRODUCTION AND STORAGE IN THE LONG-TERM”

need to go offshore for intervention campaigns on short day trips. Ultimately it would create more jobs as we maintain the onshore equipment as the industry grows.”

IN A GOOD PLACE

With so much happening, now is an extremely exciting time. For CES+ and the wider group, there is a missiondriven culture which is deep-rooted, and the solutions being developed internally will have a big impact on the net zero journey. With more than profits on the line, the company has an all-important mandate and is making strong progress.

“We’re in a good place and we have turned the business around,” says Scargill who joined Centrica in 2007. “We were almost entirely focused on the downstream market

but our new Chief Executive has changed our strategy to realign with the energy transition and maintain a degree of vertical integration between various market segments. Through the energy crisis, we saw the successful companies were those that had assets to back their positions.”

“WE NEED A BALANCE OF TECHNOLOGIES TO GET THIS RIGHT AND THAT IS WHY WE ARE INFLUENCING WHEREVER WE CAN TO DRIVE THE INDUSTRY”

Right now, CES+ is nimble and flexible, and this is encouraging and motivating for the industry, and for customers. The Centrica group is ambitious and healthy, and this makes for a real force when it comes to navigating challenges – certainly not a business being left behind.

“We have the best long duration energy store in the UK and our challenge is to grow its capacity, and that is our primary focus,” says Scargill. “Ultimately that will reduce bills for people. decarbonising the UK’s largest industrial cluster is also our task and we are looking at Hydrogen production and storage in the long-term. In the meantime, while that market develops, we can provide energy security by having more storage on the system.

We are importing more energy

than ever – 40% last year. And we need to embrace long duration energy storage for security of supply and price. As we move further in the energy transition, we need to keep the lights on and balance the grid, and that is not a challenge we have faced in the past. There is certainly a bright future for our assets as we play our part in Energising a Greener, Fairer Future, but we need more than Rough for the UK. We need a balance of technologies to get this right and that is why we are influencing wherever we can to drive the industry,” he concludes.

WORLEY

Developing World Leading Standardised Hydrogen Production Plants

PRODUCTION: David Hill

By standardising the design and process around hydrogen production plants, Worley is looking to cement its position as a world leader in EPC for the growing hydrogen industry. As more projects move from concept to FEED, pre-FID and beyond, the need for a programme approach to drive down cost is essential. SVP Global Hydrogen, Chris Gill explains more for Energy Focus.

Chris Gill, SVP Global Hydrogen

Chris Gill, SVP Global Hydrogen

INDUSTRY FOCUS: HYDROGEN

//Europe’s largest renewable hydrogen production plant is emerging from the ground. Shell announced a Final Investment Decision (FID) in 2022, expecting hydrogen production to begin in 2025. The 200MW electrolyser will be located on the Tweede Maasvlakte in the Port of Rotterdam and will produce around 60,000 kg of renewable hydrogen per day. The plan is to take green electricity produced through an offshore wind farm to power the electrolyser before distributing hydrogen via a new hydrogen pipeline to partially decarbonise activity at the Shell Energy and Chemicals Park Rotterdam. Named Holland Hydrogen 1 (HH1), the project is one of just a few globally to progress to implementation. Hydrogen is the fuel of the future and, because of its green potential, many plans are in development. But

because the industry remains in infant stages, costs are still prohibitive.

Worley, a global professional services company of energy, chemicals and resources experts, is supporting the delivery of the HH1 project and is looking to lead the way in the design and construction of hydrogen production plants around the world.

According to the International Energy Agency (IEA), challenging economic conditions combined with mixed government policies and lacking sight of returns for investors has slowed the progress of low carbon hydrogen rollout, even with interest in the industry remaining strong.

Worley is aiming to add value to driving standardisation across projects, removing complexities from processes, and taking a programme approach where levelized costs can be reduced for international players

looking to deploy across multiple sites.

“It’s nascent, it’s expensive, in most cases the business cases don’t hang together very well, and people are struggling to commit to long-term offtake agreements because of the price of the molecule,” says Chris Gill, SVP Global Hydrogen at Worley.

“Without long-term offtake agreements, you can’t finance the project. Nearly all projects are reliant on subsidies and the subsidy money is not flowing all that freely – someone has to pay a green premium in all of this.”

PROJECT PROGRESS?

Shell’s HH1 is important as it paves the way for others to follow. It demonstrates that what has been designed can be built and will work, and it shows that value can move through the chain. In Saudi Arabia, the NEOM Green Hydrogen project – the world’s

WORLEY

largest - has also received a FID and will produce 600 tonnes of carbon-free hydrogen per day by the end of 2026. A 30-year offtake agreement is in place and major companies are involved.

For Worley, seeing ground broken is significant and gives confidence that the hydrogen economy has certainty.

“There is a general agreement that this is the direction of travel, and it is what needs to happen,” explains Gill of attitude in the industry. “But there is always reticence and people want to see something that has been built first. We have been working with several customers to assist with innovative plans. Proof of concept is still required for customers, but we do have a number of customers who are already excited about moving forward.”

While only a few standardised, renewable projects have progressed significantly on a global scale, Worley is extraordinarily busy. The company boasts skills in abundance and is laden with engineering and project capability from its historic involvement across energy, oil and gas, chemical, and other process industries. At the same time, the Worley team is expert in attracting finance and implementing highly successful projects that achieve goals.

“We’ve advanced several projects and have independently undertaken efforts to introduce our inaugural product to the market,” says Gill. “While we don’t have a full range of ‘products’ readily available, we’re actively working on it and are progressing in pre-FID phases on a number of standardised projects.

“As we grow in the market, we’ll achieve more volume in the supply

// THERE IS A GENERAL AGREEMENT THAT THIS IS THE DIRECTION OF TRAVEL, AND IT IS WHAT NEEDS TO HAPPEN //

chain and that will iterate. We expect the product development cycle to then reduce costs while improving efficiency.”

Competitors are also busy with more than 40 countries around the world making it clear publicly that hydrogen is part of the longer-term energy mix. Thanks to Worley’s long history working in tandem with downstream and chemical and integrated energy companies, there is a clear advantage. “I think we are a little further ahead than most because of the traditional work we have been doing in the hydrogen space with a number of our traditional customers,” says Gill.

Currently, significant project details remain closed in terms of media coverage, but Gill confirms that Worley is active with global organisations in traditional energy, power and utility, and private equity to develop, with more than 470 hydrogen projects at various stages.

“We’re engaged in multiple

hydrogen projects for a global customer, showcasing how customers adopting a programmatic approach facilitate faster standardisation. These projects are backed by solid balance sheets and secured offtake agreements. It’s essential for project economics to align for approvals, and customers like these are pivotal in propelling the industry forward.

“We are working with a number of utility customers –those with renewable portfolios looking to convert electrons into molecules – who have programme approaches and we are active across a number of different scopes.”

STANDARDISATION

As the industry advances, Worley sees its value add as a unique ability to drive down cost by offering standardisation solutions across. To achieve this, the company is actively engaging the supply chain to create simple and

INDUSTRY FOCUS: HYDROGEN

LEADING THE NET ZERO TRANSITION WITH HYDROGEN

Honeywell solutions cover the entire value chain when it comes to the reduction of carbon dioxide through the use of hydrogen.

Worley and other contractors around the world are busy developing the future of energy, investing in hydrogen to fuel the progressive energy transition. It’s a challenging but exciting adventure and requires innovation at every stage to pave the way for the low-carbon foundations of tomorrow.

Partnering with Honeywell to develop advanced control and automation systems, Worley is focused on delivery and cost-efficiency for the industry.

Together, the companies have developed the Worley Repeatable Accelerated Package (WRAP) scope, focused on green hydrogen production.

“It is now starting to move from predesign into project sourcing and execution,” says Tim Cook, EMEA EPC Sales Director at Honeywell.

Currently, both companies are looking at providing an ‘off-the-shelf’ solution for a major international energy business keen on green hydrogen usage in the production of sustainable aviation fuel.

“We are busy across multiple sites, at various stages, and we are in the middle of design before Final Investment Decisions happen later in the year,” says Cook. “Worley do the process design first and then they look at the control and automation systems, and that is where we get involved. We work across renewable energy, through the electrolysers to purification and compression – that is where our WRAP is successful. We provide control and safety systems, and we are looking at temperature, pressure, flow, and various other parameters. We take in a lot of data and control the process based on that data.”

Honeywell has set up a demo station at Worley HQ in the Hague. From here, where more than a year of engineering and design has gone into a concept without commitment from an official customer, Honeywell is displaying how standardisation is key in driving down the prohibitive cost of green hydrogen.

“We are putting remote input/output in the field instead of having cabinets dotted around a site. Also, CCTV, alarm systems, fire and gas systems, building protection systems – we can bring all of that together.

We can offer a fully integrated, standardized solution resulting in significant cost reduction. Applied over multiple installations for large multi-site programs, this can offer further increased savings,” explains Cook.

Investing now offers Honeywell first mover advantage in an industry expected to boom over the next decade. Longer-term, the company is already planning systems that could allow for centralised control over a global network of hydrogen production sites, expected to come from current energy majors.

“Between Worley and Honeywell, we believe we can make these projects attractive and investible.

“Hydrogen is not new, but green hydrogen is novel. It’s all about making it cost effective against grey hydrogen. Budgets are tight, everything must be efficient – no waste, no spare capacity, no contingency. Solutions must be perfect and that is why we have spent so much time working these things out,” concludes Cook.

“It has been great working with Honeywell as our Main Automation Contractor partner over the last year as part of the Worley solution helping to reduce the levelized cost of hydrogen production. I am looking forward to all that hard work maturing into projects soon,” says Chris Gill, Worley VP of Hydrogen.

Learn more about Honeywell’s enablement of the hydrogen economy today

minimal solutions around their area of expertise, while working within a functional Worley brief. Gill says that this must be done across Capex and Opex if the hydrogen economy is to reach a self-sustaining position.

“In Capex, we are trying to standardise the asset and remove complexity. An important part of that

is to make it supply chain led.” He gives the electrical example, where Worley has a key strategic supply chain partner. “Rather than us designing several different motors or electrical drivers, we are asking the supply chain to come up with the easiest way to do things so that you have the simplest electrical arrangement. We think that

will lead to more economical assets.”

For Opex efficiency, the embedding of digital solutions is vital. Utilising digital solutions across appropriate digital platforms allows for operators to get better outcomes from assets over the asset lifecycle. “This challenges

Continues on page 34

DIGITALLY UNLOCKING POWER TO X

End-to-End Digital Solutions for Power to eChemicals

INDUSTRIAL CYBER SECURITY

RENEWABLE HYDROGEN LOOP

HONEYWELL EXPERION® PKS

Infinitely Scalable, Fault Predictive, HIVE®

INTEGRATED DIGITAL TWIN

Grid to Gate Power and Process Digital Twin

INTELLIGENT OPERATOR COCKPIT

AI Enabled Suite for Future Ready Operation

SAFETY & SECURITY

Fire and Gas Detectors Gas Cloud Imaging

PLANTWIDE OPTIMIZATION

Optimizing LCH and Derivatives in Realtime

WORKFORCE COMPETENCY

Competency, Safety and Productivity

HYDROGEN PASSPORT

Realtime Carbon Intensity Management

ADVANCED ALARM MANAGEMENT

Operations and Worker Safety

EQUIPMENT EFFECTIVENESS

Predictive Asset Performance Management

LEAN&MODULAR EXECUTION

Design, Integration, Implementation, Construction, Testing & Commissioning Modular, Flexible and Scalable Deployment

INDUSTRY FOCUS: HYDROGEN

assumptions in the business case to enable it to take off,” Gill adds. With standardisation across the planning and implementation process, positive relationships with suppliers are essential. There must be shared vision and there must be a willingness to advance the industry and not simply a quest for short-term profit. The company works closely with most manufacturers of electrolysers

and has invested R&D capability in creation of solutions at industrial scale to fit around electrolyser OEM scope.

Honeywell is one of Worley’s control and automation partner, using its unmatched global presence to develop simplified, but above all safe, solutions in hydrogen production facilities.

“We work very well together, they get our vision, and they share that vision. We have a number of common

customers and so collaboration makes a lot of sense,” states Gill. “Ultimately, standardisation will reduce the levelized cost of the product. If we get this right the pie will be bigger because projects will go through FID and get to implementation, and we will hopefully get a bigger share of the pie.”

MARKET LEADERS

Gill is keen on involvement in projects far and wide, but stresses that producing green hydrogen for use in the energy industry is by no means easy. The level of funding and skill required to bring about progress is significant. “The challenge of how to put projects together and the challenge of standardisation and commercials, combined with process experience, is where the common middle ground is,” he says, adding that the company has some of the best minds in the industry working on solutions every day.

“If it was easy, everyone would do it. We have a number of industry gurus and people who really know

their stuff. Our teams attract different, younger talent. We appeal to people who want to be in clean energy, and they feel good about being in clean energy. It’s a magnet for talent and requires a different way of thinking and a different way of doing things, and that is great. From a development and retention point of view, it’s a real positive. When we started moving in this direction, I was quite surprised by the number of people who came and asked to be part of it.”

Part of the industrial gas space for 16 years, Gill started out with BOC, looking after operations in Korea. He then ran his own business for four years before joining Worley, responsible for downstream chemicals. He became MD for Spain, Sweden and Belgium in 2019 and then demonstrated a good understanding of traditional customers and knowledge of how industrial gas companies work before taking over the hydrogen business. “The hydrogen molecule has been used for a long time and industrial gas companies are front a centre in that. They went

through a process of standardising assets 20 years ago,” he says.

Through his career, he is confident that the hydrogen space has certainly seen progress, but more needs to be done to advance hydrogen as part of a strategy to achieve net zero by 2050 and reduce emissions by 45% by 2030, according to the Paris Agreement

“Have we seen progress? Yes, absolutely. I have been in this role for four years and when I started, 20MW was a big green hydrogen project. 500MW or 1GW is now a big project. The scale of the projects has increased, and we have seen projects develop to the point where the business cases work. We are seeing projects get through FID and HH1 is a good example – we are building it now. Is it enough to meet 2030 targets in which hydrogen is part of the solution? No.”

As more projects advance through the challenging stages with the help of Worley, and the hydrogen economy makes material progress, the company’s standardisation efforts will continue to drive down cost and improve

efficiency, allowing more countries, companies, and people to take advantage of carbon-free, clean, safe, and innovative hydrogen production to fuel the world of the future.

“We want to be one of the key market leaders in the space. It’s in the sweet spot in terms of what we do and we want to be a go-to provider of solutions in the hydrogen space,” says Gill.

In the short term, Worley is busy in Rotterdam with Shell HH1. And in the medium term, teams around the world are continuing to pioneer in the industry, bringing thought leadership and engineering excellence to solve problems that others cannot. Gill is embracing the challenge and enjoying the collaboration.

“It really is very exciting,” he concludes.

ZENOBĒ

A New Era for Energy

PRODUCTION: David Hill

Balancing the grid with battery storage solutions, allowing for renewable energy to be utilised when the sun goes down, when the wind doesn’t blow, Zenobē is bringing together engineering, finance, and innovation to build the energy system of the future. Wasting green energy is no longer an option, and Zenobē is making moves to eliminate the practice across Scotland for good.

INDUSTRY FOCUS: STORAGE

//Often described as ‘long-term’ or ‘far off’ or ‘for the next generation’, the idea of net-zero is intimidating. In the UK, the goal is for all greenhouse gas emissions to be equal to the emissions removed from the atmosphere by 2050. The energy sector is a big player here, responsible for significant emissions through the utilisation of fossil fuels. Making the switch is daunting. Embracing renewable energy, developing new technologies, harnessing digital capability, and innovating solutions – while vital – costs money.

But some are investing. Some are committing, and some are taking the leap, aiming for a brighter and more sustainable future. International

power, technology, and finance experts, Zenobē, believes that a net-zero society is within reach.

Founded in 2017, the company has become the leading battery storage operator in the UK and has grown its presence across Australia, New Zealand, and Benelux. “We’ve raised c.£1.8 billion in debt and equity funding. We have c.730MW of grid-connected batteries live or under contract and c.1,000 electric vehicles with strong ambitions for the future,” the company states.

Zenobē is also the number one owner and operator of e-buses in Australia and New Zealand, and are quickly expanding into light commercial vehicles and truck, while powering 25% of the UK e-bus market.

Clearly, Zenobē views the energy transition and decarbonisation as an opportunity and not a hurdle. This is a company proving that there are returns to be had when making clean power accessible.

PROJECTS WITH PURPOSE

At the start of 2023, the company gained £235 million project finance debt from a consortium of banks to begin its ambitious plans in Scotland, starting at Blackhillock. The 300 MW site is home to the first battery storage facility in the world that can provide Stability Services using a transmissionconnected battery. The first 200 MW will go live this year with the next 100 MW due in 2026. Bringing the finance

Emerging technologies need pioneers who

set the standards.

SMA LARGE SCALE ENERGY SOLUTIONS

Stabilize the future energy supply with our cutting-edge integrated power plant solutions, featuring advanced grid-forming capabilities. Capitalize on new business opportunities and shape the energy transition.

and engineering capability together to deliver such a project is what separates Zenobē from others in the industry.

“Securing this first of its kind financing structure is another landmark for Zenobē and our mission to accelerate the grid’s uptake of renewable energy affordably and reliably,” said co-founder Nicholas Beatty. “This follows the successful arrangement of a private placement to debt finance our existing and pipeline fleet business last year. As lead advisor, NatWest has been instrumental in developing a debt facility that enables us to deliver grid-scale battery storage projects in Scotland and presents a significant growth opportunity for our business to deliver more of these projects across the UK and elsewhere.”

Recently, other major battery storage projects have been initiated

in Scotland, as the company looks to support the National Grid with its uptake of renewable power. The country has committed to netzero by 2045 and is keen to make the most of the abundant natural resources available, including wind, solar, and tidal generation.

WISHAW

At the end of 2023, Zenobē opened a new site in Wishaw, North Lanarkshire, with a transformational 50 MW battery storage system that has the capacity to store enough wind power for 130,000 households for two hours. This reduces waste in the renewable energy industry allowing consumers to save while driving overall efficiency. When the network has limited capacity, and no storage solution, windfarms can turn off turbines – curtailment

– wasting large amounts of green power. In 2023, the UK wasted more than 2200 GWh which could have been used to power all homes in Glasgow and Edinburgh for a full year.

Clearly, battery storage is a critical component in the renewable energy rollout. This is why Zenobē has committed £750 million to create pioneering projects across Scotland, reinventing the way the

// BATTERY STORAGE IS ESSENTIAL IF THE UK IS TO IMPROVE ITS ENERGY SECURITY AND BRING DOWN COSTS FOR CONSUMERS //

INDUSTRY FOCUS: STORAGE

grid interacts with its new wind partners, spinning away off the coast and across the countryside.

“The Wishaw site inauguration represents a significant milestone for Zenobē and Scotland’s renewable energy ambitions as we seek to double Scotland’s storage power capacity,” said co-founder, James Basden.

“Battery storage is essential if the UK is to improve its energy security and bring down costs for consumers. By capturing and storing excess energy with sites like Wishaw, we can power homes, buses and trucks with energy that would otherwise have been wasted. Our recent successful capital raise provides the funding and Wishaw going live is the first step in this

journey. We are pleased to work with our partners Fluence, Centrica, H&MV and Santander UK to deliver this project that will enable even more clean, renewable energy to flow safely and reliably through the electricity network to power homes and businesses in the wider Glasgow area and beyond.”

In January 2024, two significant announcements came when the company finalised a project finance debt structure to support Scottish rollout before beginning construction of the exciting Kilmarnock South battery project.

The new debt backing of £147 million is structured by NatWest and is supported by a range of infrastructure banks. It comes following success at

the company’s 300 MW Blackhillock site near Inverness and is an upscaling after the project was upsized with larger energy capacity. Importantly, sites like Kilmarnock South and Wishaw will pass on estimated savings of £41 million over the next 15 years, by reducing wastage and stopping wind farm curtailment.

Kilmarnock South is particularly exciting for the company because of its scale. The project will stop 3.4 million tonnes of CO2 entering the atmosphere and has a 300 MW capacity that can store renewable energy, brining Scotland closer to energy autonomy. Again, the project is designed to reduce wasted green energy.

“Reaching this significant milestone demonstrates Zenobē’s commitment

THE PERFECT EPC PARTNER IN COMPLEX ENERGY SOLUTION PROJECTS

H&MV Engineering, a multi-disciplinary engineering firm with offices across Europe and Asia, boasts substantial expertise across engineering and design, high voltage systems, independent connections provision (ICP), infrastructure and asset management, and training and development.

H&MV, established in 1997, was onboarded in Zenobe’s recent project to connect a new battery energy storage system (BESS) to the transmission system in Scotland. The BESS, in Keith, Moray, will provide stability and security of supply to the region between Aberdeen and Inverness, as Scotland looks to further its renewable energy ambitions. A 300MW/600MW project, and the first to provide the full suite of active and reactive power services, this development will be the largest transmission connected battery in Europe when commissioned.

“The client required a competent contractor with both ICP and high voltage experience to deliver electrical and civil design, civil construction, electrical installation, and commissioning works in order to complete connection,” says UK Managing Director, Nigel Taylor.

H&MV, recognised for being adaptable and flexible, was appointed as the Principal Designer and Contractor under CDM 2015 Regulations, taking site and project management responsibilities.

“Our scope included design, procurement, supply, installation and commissioning of the 275 and 33 kV electrical network required to connect the BESS to the transmission network. Commissioning and testing were in compliance with, and approved by, SSE. H&MV completed all associated earthing as well as protection schemes, interlocking, controls, and metering systems,” details Taylor.

H&MV Engineering worked hand-in-hand with Zenobe, coordinating delivery of the BESS to site, including a number of heavy infrastructure packages such as the Power Conversion System, 33 kV transformers, containerised batteries, HVAC and fire suppression system, while liaising with landowners, the planning office, and local community.

“The award of this ground-breaking project reflects the confidence that Zenobe has in H&MV Engineering’s ability to deliver critical and complex projects,” said Taylor.

Contact H&MV Engineering today to discuss your project requirements. www.hmvengineering.com | +353 61 357 496 | H&MV Engineering

to stopping the waste of wind power by doubling Scotland’s battery storage capacity,” said Basden at the start of construction. “Kilmarnock South will enhance the country’s position as a

leader in delivering energy that is cost-effective, clean and efficient. This is an important moment as we bolster the UK’s energy infrastructure and help to ensure that every household feels the benefits of sustainable, affordable electricity.”

Kilmarnock South performs a similar function to a power station for the local substation but without the waste, and without the greenhouse gas emissions. In 2025, the project will come online and balance the grid using green energy from wind farms including Viking and Beatrice.

Alongside these significant projects, Zenobē is also busy investing fleet charging solutions for bus operations in Oxford, investing in relevant fleet management software in South Africa, supporting development and rollout of electric concrete mix

vehicles in Birmingham, and finding new uses for second-life batteries. This is a business not looking at the distant future, content with being all voice and no action. Zenobē is doing things now – taking action, utilising money, and building commitments that make net-zero a reality. The team is motivated and, thankfully, the size of the problem is only matched by the level of ambition and optimism. Encouraging more to follow is the next step for policy makers and regulators.

DSA ARCHITECTS INTERNATIONAL

Sustainability Rooted at Foundational Level

PRODUCTION: Tommy Atkinson

A leading architectural practice, with offices around the world, DSA Architects International is recognised for its excellence when it comes to sustainability and energy efficiency. These principles have been at the heart of the company’s designs for decades and will continue to drive projects in the future. Recently, DSA has collected prestigious awards and certifications for its work around sustainability. MD DSA Architects Middle East, Peter Davison explains more.

DSA Africa - Canopy by Hilton Seychelles

DSA Africa - Canopy by Hilton Seychelles

INDUSTRY FOCUS: ARCHITECTURE

//In 2023, Mike Scott, Group MD at DSA Architects International (DSA), told Energy Focus that the company had developed a culture of sustainability. “Designs that fully consider the use of eco-friendly materials, energy conservation and waste reduction are always our goal,” he said.

A long history (est. 1985) and an ambitious strategy make this mantra more important than ever before as the company, and the world, advances projects at an increasingly fast rate. In just the last 12 months, the company has been awarded a number of projects where sustainability that incorporates world-class design is the key focus.

DSA Architects International was founded in Johannesburg when Ridler Shepherd Low Architects opened its doors. Over the past three decades, the company’s scope and scale has changed dramatically and now, operating across strategic locations globally, with their offices in Dubai, Riyadh, Johannesburg, Lisbon, Belgrade, Kochi, and Hyderabad, DSA Architects

International is a global powerhouse when it comes to sustainable, striking, solutions-based design.

In 2023, the company was named among the top 100 Architects and Designers by the Luxury Lifestyle Awards, claiming another top spot after scooping titles for Best Luxury Hotel Architecture for DoubleTree by Hilton Jeddah in Saudi Arabia, 2021; Best Luxury Hotel Architecture for Jumeirah Gulf of Bahrain Resort in Bahrain, 2022; and Best Luxury Architect Studio in Saudi Arabia, 2023.

The multifunctional team, with offices around the world, design to deliver. Utilising architectural, design, planning, engineering, and construction skills that others simply cannot, this is a business doing more for sustainability than most in the industry.

SSID

In Dubai, where the newbuild luxury property market continues to boom unlike anywhere else in the world, DSA Architects was busy with a prestigious project for the Swiss International

Scientific School in Dubai (SISD). This project was a milestone for DSA, promising to make the most of the company’s skillset. Following strict Swiss engineering and design principles that encourage sustainability and energy conservation, the project is impressive and boasts strong green credentials.

“Construction was carried out over what we call phases. Phase one and phase two were 10 months each inclusive of a three-month re-design period. We were indeed faster than normal due to materials and construction methodology that we used,” explains Peter Davison, MD DSA Architects Middle East.

“One of the unique items was that DSA oversaw the design and construction of the first Minergie standard building in the MENA region. In other words, our project boasted novel developments in both the design, build, and delivery of a low energy consumption built environment. Additionally, we used

Continues on page 46

FOUNDER & MANAGING DIRECTOR

Green Vision Consultants

Green Vision Consultants was founded in 2020 by Ahmad Alayaly, an Emirati national with over 25 years of professional experience in the government sector of Dubai, United Arab Emirates. His progressive vision and concern towards improvement of the built environment has emerged him to assemble a team of specialists to deliver sustainable waste management and wayfinding & signage design projects in the UAE, as well as other GCC countries and the MENA region as a whole, expanding all the way to executing projects worldwide.

Wayfinding & Signage Design

Wayfinding Strategy & Planning

User Flow & Circulation Analysis

User Type Identification

User Behavior Analysis

User Experience Management

Signage Graphics & Technical Design

Location / Placement Plans & Drawings

Existing Signage Design Review & Validation

Construction Supervision

Green Vision Consultants is a Dubai based multi-disciplinary design consultancy firm specializing in design and planning of Wayfinding & Signage, Waste Management and Sustainable Design Consultancy services.

Our team of professionals consists of industrial designers, environmental engineers, architects, project managers and strategists with extensive expertise in the field of wayfinding & signage design, waste management, and sustainable design of the built environment.

We share a common goal of making the world a better place by proposing sustainable design solutions to our clients for their projects in various sectors.

As the company's name states, OUR VISION IS GREEN, and we provide sustainable design solutions with high consideration of environmental impact in every decision we take.

Waste Management Design

Waste Management Strategy & Planning

Identification of Waste Generators

Classification of Waste Types

Calculation of Waste Volume Generation

Waste Routes Analysis

Waste Flow Management

Waste Equipment Identification

Waste Room Design & Specifications

Sustainable & Environmental Solutions

Existing Design Review & Validation

Construction Supervision

Sustainability Consulting

Understanding of Client’s and Project’s Sustainability Requirements

Guidance on Compliance Documentation

Required from Each Discipline

Energy Modeling and Simulation

Life Cycle Assessment (LCA) and Embodied Carbon Calculations

Development of Sustainable Design Strategy & Solutions

Sustainability Specifications

Implementation of Sustainability Framework and KPIs

INDUSTRY FOCUS: ARCHITECTURE

Continued from page 44

our skill in designing buildings that are fit for purpose, well ordered, legible and of course highly functional.”

Minergie is a Swiss certification for building standards and is focused

on the reduction of CO2 emissions and associated costs in the built environment. Established in 1998 in Basel, certifications are now globally present with new projects and buildings going up all over the world.

DSA embraced the Minergie principles and helped make the SISD the first certified business in the Middle East. Foremost in the design process was thermal isolation through the use of glass and white surfaces.

“Our goal is for the students to feel up-lifted,” says Davison.

“We used thermally insulated wall construction (called a Jehan Wall), consisting of polystyrene core and shotcrete to either side of the surface, along with plaster to external wall faces only.

“Our windows are high specification Argon gas filled double glazed units, with all external

aluminum works thermally broken thus avoiding any heat transfer,” he adds.

As an international boarding school, the building had to include live, work, play environments under one roof, and this is a challenge for architects.

But DSA has completed projects of this nature, separately and integrated, many times through its portfolio.

“The buildings have a human scale, so for example the circulation spaces are generously proportioned for a greater sense of comfort and well-being. Additionally, the use of white surfaces ensures generous ‘daylighting’ and aids teaching clarity,” explains Davison.

“Our environmental impact was improved by reducing time in the construction period. By using waterproofing ‘additives’, rather than ‘post’ water proofing in the conventional way, we saved valuable time,” he added, reminding of the company’s

community focus, ensuring buildings are suitable for their local surroundings physically and functionally.

In terms of energy efficiency, solar is an obvious choice in Dubai with more than 3500 monthly sunshine hours on average. Rooftop solar and solar carports have been deployed, expecting 30,680 megawatt-hours of clean energy over a 25-year lifespan. Alongside other green energy and sustainability initiatives, the result is a building that drives home a deep focus on using the building for better.

“The roof system was managed through a layered propriety insulated and waterproofed roof build-up system.

“Internally all the lighting is LED and therefore low heat generating. We also connected these to motion sensors limiting the operational runtime to activity time only.

DSA ARCHITECTS

All air handling units utilized are DC type in lieu of AC units’ due to low heat generation capabilities,” states Davison.

AFRICAN EDGE

In Africa, DSA has designed a number of high-end hotels for international brands. Attracting tourism to the continent has long been a goal of governments and the private sector with tourism’s unique ability to create large numbers of sustainable jobs, quickly. With the likes of Hilton, Radisson, and Six Senses trusting DSA to turn ideas into reality, the DSA brand is in a good place.

In Zambia, the Mosi-oa-Tunya Livingstone Resort on the banks of the Zambezi River in the country’s south – owned by Radisson Blu –received an EDGE green building

certification thanks to proactive energy efficiencies initiatives.

Close to Victoria Falls, the hotel is unique in its design and Radisson has intentionally opted for a sustainability focus to allow the local environment to thrive. Longer-term, the group hopes to realise 150 hotels in Africa by 2025.

“The hotel’s commitment to sustainability is evident in its 20% increase in energy efficiency, water reduction, and use of sustainable building materials. These efforts have not only helped the property achieve EDGE certification but also align with Radisson Hotel Group’s award-winning Responsible Business Program. By signing the UNESCO Sustainable Tourism Pledge, the resort has demonstrated its dedication to promoting environmentally friendly practices within the hospitality

INDUSTRY FOCUS: ARCHITECTURE

// WE ARE COMMITTED TO DELIVERING EXEMPLARY CONCEPT, DESIGN, APPROPRIATE STATE OF THE ART TECHNOLOGY AND SERVICE, THEREBY REINFORCING OUR STANDING AS A LEADING INTERNATIONAL ARCHITECTURAL CONSULTANCY //

industry,” the company said.

In the Seychelles, well-known as a paradise of the Indian Ocean but with a famous African welcome, energy security is a must as the country’s government has called for 15% renewables by 2030 to combat the heavy influence of diesel generators.

When Hilton Hotels decided that the beautiful Anse La Mouche beach front would be the perfect location to open a new property, DSA was

engaged to design something special. Under Hilton’s boutique lifestyle brand Canopy, the Seychelles location was its first Resort Hotel property worldwide.

“Drawing inspiration from its breathtaking surroundings, this stunning resort offers 120 locally inspired guestrooms, 70 branded residential apartments, a retail village, and other exciting facilities to cater to every guest’s needs,” the company says.

Designed with contemporary

charm and local flair in mind, regional conditions were also taken into consideration. Construction was a challenge because of the local topography and demanding brief.