Sonnedix is a Renewable Energy Producer (REP) with over a decade-long trajectory of sustainable growth. We develops, builds, and operates renewable energy projects for the long-term, with a focus on providing green, affordable electricity to our customers, and acting as a true social citizen there where it operates.

Tommy Atkinson

Chris Bolderstone

The often-forgotten renewable energy source, solar, is widely recognised as the cheapest and fastest to roll out. Whether at scale across a sunny desert, atop a warehouse or office roof, or covering a parking lot, solar panels are cheap, flexible, and powerful.

Isabel Murphy

Aaron Protheroe

Benjamin Southwold

Solar has so much to offer in the energy transition and, with battery storage technology advancing every week, harnessing the sun’s rays has never made more sense. Charging EVs, balancing the grid, powering homes – it’s all possible from the largest generator in the solar system.

But why are wind and hydrogen taking all the attention? This month, we speak to solar industry leaders to understand more about how the technology is being rolled out and where solar is changing lives.

Sonnedix, global renewable energy producer, is busy with solar projects around the world and is set to hybridize wind and solar in Chile to bring true cost effectiveness and reliability to local communities. In Italy, the company will roll out a number of exciting projects, adding significantly to the generating capacity in rural areas.

Enie.nl, the Dutch solar experts and certified B-Corp, is searching for expansion opportunities with its new solar carport product. Efficiently generating power from previously utilised sites, this innovator is at the forefront of the ‘renewables for everyone movement’.

In Kosovo, a market dominated by coal power stations, there is a concerted effort underway to embrace renewables and install a solar site at a previous ash dump, led by Kosovo Energy Corporation.

Octopus Electric Vehicles, the EV division of the UK energy company, is helping as many people as possible to enter the EV market by offering cars on a salary sacrifice scheme. A partnership with Wallbox sees bidirectional charging soon to become a reality, bringing residential solar panels into play for connected consumers.

Published by

Chris Bolderstone – General Manager

E. chris@cmb-multimedia.co.uk

Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX

+44 (0) 1603 855 161

www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© CMB Media Group Ltd 2022

Solar is such an important part of the mix, and could be rolled out at scale alongside alternative technologies. Tell us how your company is taking advantage of the sun, and if you have realised suitable benefits. We’re online at LinkedIn.

SONNEDIX

“The Reason we are Here? To Drive the Energy Transition Forward”

OCTOPUS EV

Delivering the Whole Package for a Cleaner, Fairer Future

SOLY

Solar Energy for Everyone – It’s Possible

DOVER FUELING SOLUTIONS

Embracing the Transition, Energizing the Future

MAXIMATOR HYDROGEN

Going the Extra Mile to Grow Footprint

NATIONAL GRID

At the Heart of a Transforming Energy System

BRITISHVOLT

Powering the Transition to a Carbon-Free Future

BOEING

Innovating and Leading for a Sustainable Future

GREENBACK RECYCLING TECHNOLOGIES

A Genuine Solution in the Quest for a Truly Circular Economy

66 72 78 84 94 100 108 114 122

DAIMLER TRUCK

Electrifying the Drive to Keep the World Moving

P2X SOLUTIONS

Building an Emission-Free Welfare Society

ACE AQUATEC

Accelerating Adoption of Responsible Marine Practices

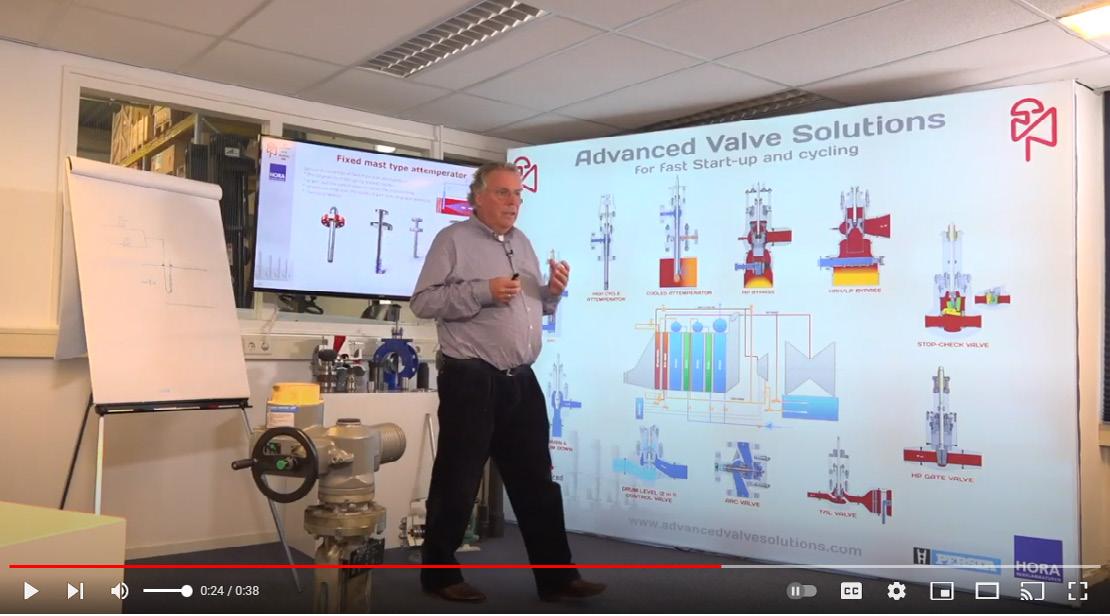

ADVANCED VALVE SOLUTIONS

Invaluable Valves at the Heart of Operations

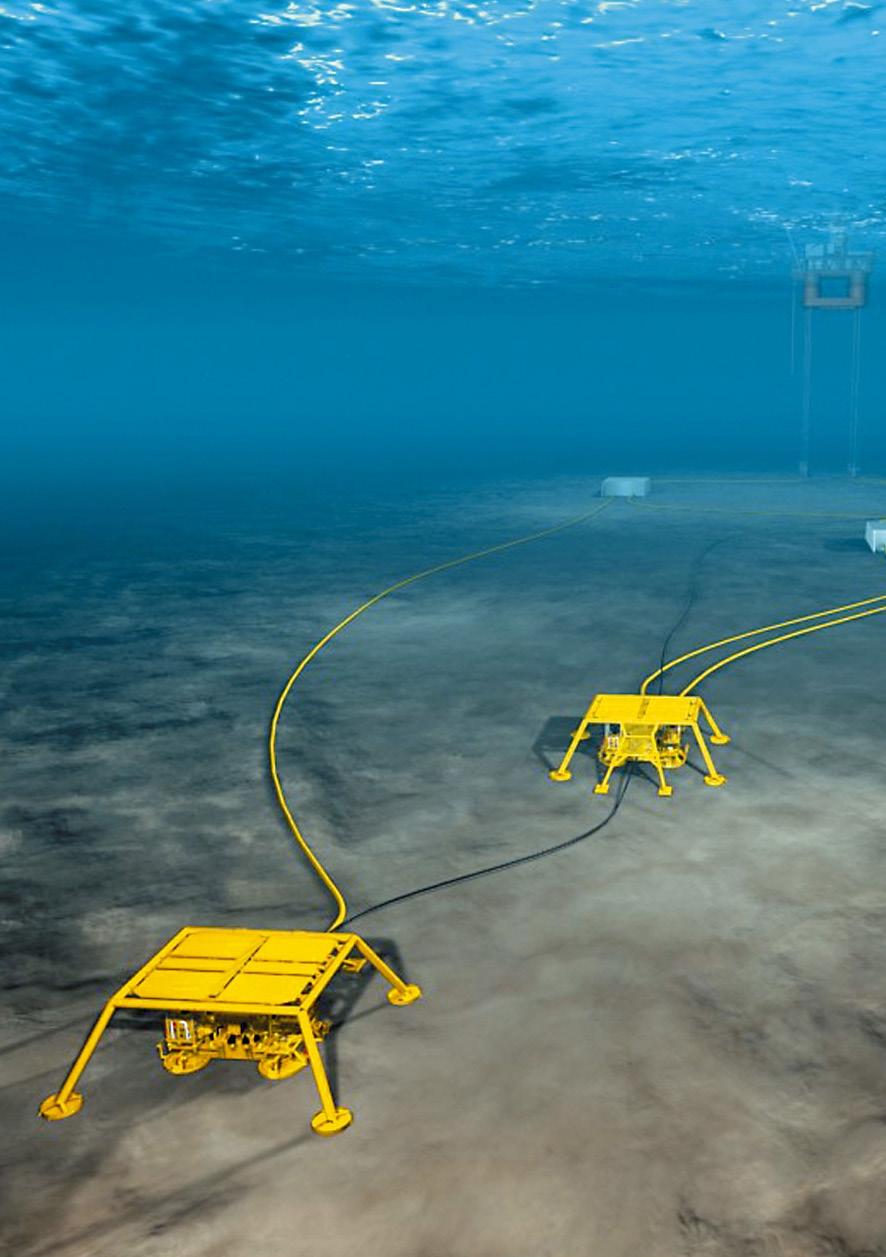

AGITO TECHNICAL DYNAMICS

Reliable Subsea Systems Through Comprehensive Simulation

ABERDEEN DRILLING SCHOOL

Trusted Scenario-Based Training from O&G Innovators

MORAY WEST

Renewable Energy to Power Scotland’s Future

NEOM

NEOM Creates the World’s Newest Wonders

KOSOVO ENERGY CORPORATION

Sustainable, Reliable and Affordable Energy Future

100

Axel Thiemann, CEO

Axel Thiemann, CEO

Sonnedix is a Renewable Energy Producer (REP) that develops, builds, and operates renewable energy projects, focusing on the provision of green, affordable electricity to customers around the world. With exciting projects underway, the company is looking forward to a period of long-term, sustainable growth as its pipeline materialises. “We want to tell our children that we at least tried to make a difference in this challenge we all face rather than hoping someone else would solve the problem,” he tells Energy Focus.

In Chile, at the Meseta de Los Andes solar project development site, 160 MW of green electricity will soon flow from a vast 250-hectare site, deep in the Valparaíso region, 80km north of Santiago. More than 2700 hours of sunshine blasts down here every year.

Glinting in the sun, solar panels in long rows will harness the abundant resource, creating clean and sustainable power, sent along a 15km 220kv transmission line to the Los Maquis substation. From here, power will flow to cover the needs of 180,000 Chilean homes, avoiding 160,000 tons of CO2 being released into the atmosphere. 386,750MWh of clean energy will be produced each year. It’s a major success story.

The project comes from leading international renewable energy producer Sonnedix. Currently, the company has 7.8 GW of total capacity around the world and is busy ramping up development to contribute to the energy transition in a big way.

Chile is a strong focus region for Sonnedix (the company already owns 15 operating plants in Chile, delivering more than 244 MW with a further 1GW in the pipeline – excluding the 160

MW in Los Andes), but the company’s reach is global - Italy, France, Germany, Poland, Portugal, Spain, USA, and Japan all host Sonnedix infrastructure.

CEO Axel Thiemann was in Chile recently overseeing this exciting and important project.

“I love visiting the sites,” he tells Energy Focus. “Seeing where investment goes is motivating and inspiring – it’s so much more than electrons and spreadsheets on a screen. Our sites are fascinating, they are so large that seeing the scale really drives the purpose around making the world a better place, and that is exciting.”

Established in 2009, Sonnedix saw the opportunity for solar energy to make a difference with the drastic decrease in cost of technology. The global rollout has been dramatic and solar is now widely accepted as a sustainable form of power generation.

“When we started, we were

focussed on France, Italy, and Spain – the European feed in tariff markets. Everything we did was subsidised and we believed in the future of renewable energy and the future of solar, but back then we were not competitive with conventional generation,” details Thiemann. “We faced various challenges that led us to a more global investment. Energy is a strategic sector, and every country makes their own decisions but even with renewables going global, the local pictures can change – doors open and close. We wanted to have a more global investment footprint early on and we moved into Japan, Chile, and Puerto Rico. We grew from there and we were lucky, finding supremely talented team members who worked very hard to get us to where we are today.”

Last year, the International Renewable Energy Agency found that modern, sustainable energy generating projects could deliver cost savings of $156 billion to emerging economies. An IREA report showed that 162 GW or 62%

// TODAY, MORE THAN TWO THIRDS OF PEOPLE LIVE IN PLACES WHERE WIND AND SOLAR ARE THE CHEAPEST FORMS OF GENERATION //

of total renewable power generation added in 2020 had lower costs than the cheapest new fossil fuel option. Renewable energy is undoubtedly the way forward when it comes to powering industrial, commercial, and consumer life, and Thiemann is happy that costs are aligning.

“Solar is one of the areas where a concentrated industrial support policy, with feed in tariffs and subsidies to bring scale, has been successful. Costs for solar PV panels have dropped by more than 90% from the very early days and solar is now cost competitive with conventional generation in most parts of the world,” he explains. “Today, more than two thirds of people live in places where wind and solar are the cheapest forms of generation. Not just cheaper than new build, but cheaper than running already existing conventional power plants. The decision is now whether to continue running an existing coal plant or whether to build a solar plant. That is really fantastic for the energy transition and supports our purpose.

“The reason we are here is to drive the energy transition forward, doing the best we can to provide cost efficient, green electricity –as much as we can,” he adds.

While many companies have been dashed by challenging economic conditions and uncertainty following the pandemic and local political instability, Sonnedix has remained concentrated on its vision, starting projects, and pursuing growth continuously.

Today, Sonnedix’s international credentials are on full display as it progresses developments around the world. Recently, the company acquired a 36 MWp operating solar plant in Spain. Sonnedix entered Portugal by acquiring a 262MWp PV portfolio under

development. A 14MWp PV plant was recently completed in Hirono, on Japan’s Pacific coast. Five solar PV projects will soon begin generating in Italy in Lazio and Piemonte, totalling 50MW. In October, the company announced the acquisition of its first solar and wind platform with 290MW operating in Chile. Earlier this year, the company entered the Polish market by acquiring a local developer. Along with a number of other exciting developments in 2022 alone, the company is increasingly active, always searching for new opportunities. Thiemann highlights Poland, Portugal, the UK, and Germany

our solar portfolio and preparing for the deployment of storage. It’s about the interplay between industry and regulation – as of today, it is not necessarily profitable yet to operate storage in many countries, but we see the need for it increasing as more renewable generation is deployed and we are confident that regulators will provide frameworks to allow this type of technology to take off.”

In October, Sonnedix acquired ARCO, one of the largest independent renewable power producers in Chile, entering the wind generation space. With this addition, Sonnedix reached over 1GW of total capacity in Chile.

as other areas where there has been recent success, and he expects European rollout to accelerate with a strong pipeline across the continent.

“In Italy, we just started new plant construction again – for the first time in more than 10 years. Development started more than two years ago, and it is now coming to fruition.

“We just started construction in Poland,” he adds. “It’s a small project, almost a proof of concept to make sure we fully understand the processes and interconnection requirements to move forwards with confidence on our almost 1GW development pipeline.

“Our largest project under construction currently is the site in Chile and we are looking forward to seeing that fantastic project complete early next year. There is a lot of activity, and we have a lot to be proud of. We have an amazing team that is driving us. There are a lot of firsts happening and we are hopeful that it will stay that way.”

For the CEO – a former electrical engineer with experience across consultancy and banking - a truly exciting proposition comes in the form of hybridisation of systems,

adding wind to solar, and integrating renewable energy systems to provide further certainty in supply.

“In some countries, we are reaching significant market share of renewable energy in the electricity supply, and we are looking at how to provide that energy when it is needed and not just when the sun shines or when the wind blows. That is where we want to focus so that we can be very competitive, and customer focused in all of the countries that we operate in.

“We recently moved into wind from our latest acquisition in Chile, because we believe that the next challenge will be to hybridise with mixed generation from wind, solar, storage, and potentially other technologies such as hydrogen, to provide baseload electricity,” he says.

“For now, we are a working with wind in Chile as the power markets there are one of the earliest liberalised globally and one of the most advanced. This is where operating wind and solar together makes sense today because they have a lot of resources with complex grids. In most parts of Europe, our primary focus today is growing

In Europe, the energy crisis, driven by natural gas supply uncertainty as a result of the Russia-Ukraine war, sees many countries worried about meeting demand with supply. While this is an opportunity for policy makers to invest in a renewable system of the future, there is no doubt that the transition must be managed. For Sonnedix, provision of cheap, green, and reliable power has been at the company’s raison d’être. Thiemann sees the company as uniquely placed to assist in the transition and provide certainty where there are challenges.

“We must be customer focussed and we must understand what our customers want,” he insists.

“We must navigate the energy crisis in Europe. What we’re seeing is dramatic and not sustainable from a humanitarian perspective. The energy price increases, partially driven by the war, are tough – and they come at the same time as inflation and interest rates were already rising, and the supply chains were tight partially as a late pandemic effect. The rapid and repeated regulatory actions to protect end customers, particularly from the energy price changes, are challenging. It is clear that the end customer must be

Continues on page 12

Sonnedix is a Renewable Energy Producer (REP) with over a decade-long trajectory of sustainable growth. We develops, builds, and operates renewable energy projects for the long-term, with a focus on providing green, affordable electricity to our customers, and acting as a true social citizen there where it operates.

Continued from page 12

protected, but it is very important that is done in a measured way, and we are seeing many unintended consequences from price caps, windfall taxes, and other market measures which combined with the uncertainty from inflation and interest rates, have the potential to set the energy transition back.

“At the same time, we believe that renewables can play a major role in mitigating the energy crisis and provide energy security. Today, we are the fastest to deploy new energy sources and the big blockers, on top of uncertain regulations such as permitting timelines – so we must figure out how we can streamline these processes and work with communities that we impact to ensure they get what they need, and we are the good neighbours that they deserve.”

Increasing inflation, increasing interest rates, and volatility in power pricing continues to shake up the industry in a big way. But the low-cost nature of solar makes it increasingly appealing, not just

in Europe but around the world.

“Even if our input costs go up, and our prices rise, we are still the cheapest producers. We will be able to sell our electricity as long as we develop and operate well. We are financially wellbacked, and we can weather short term issues,” explains Thiemann.

If solving an energy crisis, driving an energy transition, and building a sustainable business are the outcomes of current activities for Sonnedix, Thiemann is happy that the business is achieving its goals, but he reminds that customer satisfaction must never be overlooked.

“We will continue to build as much to allow coal and gas to be switched off so that we can drive the energy transition forward. Things are getting more complicated as it’s not easy to simply complete ‘more of the same’. It’s about understanding customers’ needs, providing them with whatever we can do to fit their requirements – and customers are not the only off-takers that need electricity, there’s also the grid operators and regulators that control how we interconnect

to the grid and what we need to provide. Our big focus is on interacting with all of them successfully.”

The true power of Sonnedix, the spark that drives new ideas and fresh concepts, comes from the team. Around 500 people around the world work towards a united vision that permeates all cultures and geographies.

“There are a lot of things happening and luckily, we have good people that are driving this forward,” states Thiemann. “Everyone faces the same opportunities and challenges in the industry and what we have built is a great team that is engaged, dynamic, aligned with a purpose, and working very hard towards this.

“We have a long-term focus, while some of our competitors are owned by big financial players with a five-to-eightyear horizon which makes planning difficult if you think strategically. Our differentiator is our people. We are in an industry that is growing fast and is relatively new, competing in many parts of the world. Putting steel,

glass, silicon, copper, and aluminium together is not rocket science – but it’s not easy either – it is people that make it come to life. They develop, finance, build, and contract solar farms and drive it all forward. Having the right team in place is the ultimate secret behind our success,” he adds.

The company is highly distributed with teams spread from north to south and east to west, covering almost the entire map, and hoping for a larger presence in the future. Sonnedix employees take the vision of ‘powering a brighter future’ as a serious purpose.

“We have taken it as a challenge and used it as a strength by understanding how and why we work together and building a culture around that, with a sense that we work as one team. Working across time zones and cultural backgrounds is tough, from Chile to Japan to Italy, but is made possible by aligned in terms of our purpose,” says Thiemann.

This purpose is taking the company into the future in strong shape. Growth is in motion, and Thiemann – who joined the business 11 years ago, attracted by an organisation with a true

purpose – believes Sonnedix is looking at a long and sustainable trajectory.

“We are growing through multiple strategies,” he details. “We do early-stage development, we develop with partners, we buy latestage and operating projects, and we buy platform companies where it addresses a strategic need.

“In terms of growth,” he adds. “I believe we will continue to grow across all different avenues depending on what the opportunities look like in each country. We have more recently focused a lot more on development as an engine of growth, but I don’t think acquisitions will slow down. As newly developed plants come online, there is a whole new potential area for us to buy and free up capital for other developers to do more of the same.”

Importantly, any growth comes with more contribution to a global initiative – the energy transition. Net-zero by 2050 and ending reliance on fossil fuels in favour of clean, accessible, affordable, sustainable, and reliable energy sources are the goals set out by the United Nations. Sonnedix is playing its part.

“There is a long runway for growth in renewable energy. We are taking other sources of conventional

power offline, and we see much more electrification happening, from electric cars to replacing fossil fuel heating. We must achieve success in the countries we are in today and expand where it makes sense,” confirms Thiemann.

If Sonnedix can take its concept, like the Meseta de Los Andes solar project in Chile, and roll out in more countries, adding wind power and other energy sources to the mix, the full potential of the renewable energy sector will begin to be felt. With all OECD countries as potential targets, there remains so much opportunity to take ideas out of spreadsheets and onto sites.

Thiemann, who came into Sonnedix with a goal of taking action rather than waiting for others to do so, is passionate about future success and considers now the perfect time to flourish.

“As a company, clearly growth is our goal. Now that we are cost competitive, and the climate change has so much awareness, this is the right time to grow,” he smiles.

// THERE IS A LONG RUNWAY FOR GROWTH IN RENEWABLE ENERGY. WE ARE TAKING OTHER SOURCES OF CONVENTIONAL POWER OFFLINE, AND WE SEE MUCH MORE ELECTRIFICATION HAPPENING, FROM ELECTRIC CARS TO REPLACING FOSSIL FUEL HEATING //

Octopus Electric Vehicles (OEV) is opening up a new world of pure electrification. Offering car, charger and energy, Octopus presents the whole EV package and everything needed to hit the road, with a cost-neutral Salary Sacrifice scheme applicable to companies of all shapes and sizes sealing the deal to make EV adoption a real no-brainer.

PRODUCTION: David Hill

PRODUCTION: David Hill

to more than 300,000 chargers across the globe via our Energy Universe card.

For Octopus EV, helping customers transition to a greener and fairer world for future generations is crucialprimordial, in fact. Sister company Octopus Energy already supplies green energy to over 3.4 million UK homes and counting, with Octopus EV working tirelessly to do the same for the UK’s roads. “We couldn’t be good at what we do if we didn’t believe one thing,” the company insists. “We believe the eco-choice should be the easy choice, and while that sounds like a small thing, it’s not.”

Octopus Electric Vehicles reports that 30% of the UK’s carbon emissions comes from transport alone, and relays the rather terrifying news that air pollution is estimated to kill some 40,000 people every year. As the company points out, were this linked to, say, the water supply, the nation would rightly be in uproar. “But until recently, there hasn’t been a good alternative,” Octopus EV recognises, “and when not locked down, we’ve needed to get around - whether for work, to visit friends and family, or perhaps even get away for a holiday.

“Now, however, the car manufacturers have done something incredible, offering over 60 vehicles that

we can power with wind and sunshine. Tesla kick-started the revolution, doing for cars what Apple did for our phones, but this time with tech on wheels. Here at Octopus EV, we’re on a mission to help you discover them, and make it easy and affordable to make the switch.”

To achieve this, Octopus takes care of the whole package, assures CEO at Octopus Electric Vehicles, Fiona Howarth. “We source the car itself, an at-home charging point complete with a bespoke tariff for EV drivers, and rather than having our own public charging operator, we have integrated across over 450 different networks that give access

“Electric Universe simplifies public EV charging for drivers, helping accelerate the EV rollout by providing one card and app and its breadth of charge points is quickly expanding internationally,” Howarth unravels. At Octopus EV a range of over 65 fully maintained models all come complete with servicing and repairs to retain optimum condition, and can be ordered from the comfort of the sofa to be delivered free of charge. “In addition, we give customers the first 4000 miles free, and allow them to choose between a free home charger with Intelligent Octopus tariff credit, installed by an expert Octopus engineer, or for those without a driveway, exactly the same equivalent credit on the Electric Universe network.”

Intelligent Octopus is, quite simply, the smartest EV energy tariff on the road. It enables smart charging when it is cheapest and greenest for six hours every night at a superlatively low rate, saving up to 85% on fuel costs compared with petrol. In the UK, tariffs have arguably had more airtime in the last 12 months than over their lifetime to date combined, and as the world becomes greener, with electric vehicles proving to be the much-needed solution for zero emissions in the car industry, Octopus is well ahead of the rest.

“We have created affordable and

access to what we have come to call our ‘ultimate EV package’. We also sync the home chargers with Intelligent Octopus to charge EVs with the cheapest, greenest electrons available.”

Vehicle to grid (V2G) technology, enabling energy stored in Electric

Vehicles to be fed back into the network to bolster supply at times of peak demand, has provided Octopus EV with a UK first for next generation energy grid management, Howarth explains. “We’re looking to the future, where the worlds of electricity and cars come together, and we all have large batteries sitting outside our homes,” she explains.

“We’re excited to be pushing the boundaries of what EV charging can do,” states Wallbox, leading EV charging and energy management business.”

Redefining consumer relationships with the grid, world leading EV charging brand, Wallbox, is bringing industry-leading technology to the market so that everyone can be a part of the energy transition.

Already innovating for the EV network of the future, Wallbox supports efficient charging in over 110 markets globally and is compatible with the world’s leading automotive OEMs.

Currently, the company manufactures and installs a range of EV chargers for home, business, and public applications. Compact, connected, and controllable, Wallbox chargers are small but powerful.

In the future, Wallbox Head of Energy, Daniel Utges, expects these chargers to go beyond just fuelling vehicles, becoming sophisticated energy management devices to balance supply with demand.

“We are building technologies around Sirius, our energy management solution for home and business. It’s a brain that understands what is going on in your home or workplace.

Depending on the assets you have – batteries, electric cars and solar PV installations – it optimises your energy consumption,” he says.

This optimisation will include bidirectional charging, cost management, energy efficiency, and improved market access.

“EVs are batteries with wheels,” smiles Utges. “Our vision begins to look more real when we see hundreds of thousands of EV chargers around the world being able to charge and discharge, using our technology, at any point at any time.”

Wallbox created the EV charging standard to include features like PowerBoost and Eco-Smart. The former load balances the EV charger power with available power in the home and the other charges your car for free using available solar surpluses.

“With backing from Innovate UK, the UK’s national innovation agency, our experts are running a globally marketleading demonstration project for residential V2G called Powerloop, where our car batteries can be used to store green energy for when we most need it.”

The optimisation technology behind Powerloop takes signals

But it is bidirectional charging capability that Utges believes will truly democratise EV charging.

“Being able to charge the car but also discharge when you need it is a game changer. When you buy a car, standard batteries are 70-80kwh, and with this you can easily power your home for three or four days without any power from the grid. The result from our system would be charging the car when it is least expensive, or even free if you have PV solar surpluses, and then discharging when it is most expensive, allowing for big savings on the energy bill and making the energy transition available for everyone,” he says.

At Wallbox, where a culture of emissions reduction and net-zero is embedded above everything else, innovation is rife. “If you compare Quasar to the premium price against an inverter as well as a stationary battery with 7-10 kWh, Quasar is by far, a lot more cost effective giving you access to six times more battery from your car. We are proud of the work that we are doing and the adoption we are getting in the market. We are delivering a good product today and we are also investing a lot in the delivery of a great product for tomorrow,” says Utges.

Even the smallest changes and slightest improvements can have a marked difference in the energy transition. With Wallbox, your gateway to the new grid, you can take advantage of best-in-class tech, while reducing emissions; all while saving money.

Find out more at www.wallbox.com/shop

www.wallbox.com

from the market, assessing when the grid needs energy from the vehicle and when it can use the battery to store energy. It then tells the two-way charger when to charge and discharge to the grid.

“Octopus Powerloop reinvents home energy,” Howarth beams, “allowing electric cars store green energy in the middle of the night and give it back to the grid at peak times to reduce our reliance on fossil fuels. We started running this project more than four years ago, and now we have over 100 Nissan Leafs with bi-directional chargers, charging

and discharging back to the grid.

“These are the first cars to operate in the National Grid’s balancing mechanism, which is a massive milestone in creating a smart energy system that matches up renewable energy with the batteries on our driveways for storage, and being able to aggregate it and offer it back to the grid when it is needed most while being compensated for it as well.”

The EV market is set to explode with growth, with 230 million EVs forecast to be on the roads globally by 2030. The UK currently has around 465,000 EVs, with the government setting forth

intentions for a tenfold increase in charge points by 2030. When it comes to the future of Octopus EV, Howarth delivers an unequivocal vision with equal parts conviction and excitement.

“We want to help tens, even hundreds of thousands of people to make that switch to EV, and continue to make it as hassle-free, beneficial and enjoyable to do it. These are two things we at Octopus ultimately want to bring together - the ease of adoption, while being the best energy supplier for EV drivers. We are well on the road to greater electrification of our society, and moving full-steam ahead to help accelerate the transition to a cheaper, greener energy future.”

// WE ARE MOVING FULL-STEAM AHEAD TO HELP ACCELERATE THE TRANSITION TO A CHEAPER, GREENER ENERGY FUTURE //

Milan and Patrick van der Meulen, Founders © Soly

Milan and Patrick van der Meulen, Founders © Soly

Dutch solar business, Soly, is making solar available for everyone, encouraging more and more to remove emissions from the atmosphere. Growing fast, this exciting young business is thriving because of its purpose driven approach. Milan van der Meulen talks to Energy Focus about an exciting new product which will open up new spaces for clean energy generation.

The Netherlands plays an important role as a hub for global energy trading. A European centre of innovation, the country has set ambitious plans for its own transition, aiming for 100% of electricity to be sourced from renewables supplies by 2050. But today, even with the best intentions, the country faces major challenges. A result of the Russians invasion in Ukraine is that the Netherlands will provide exemptions for export credits for fossil fuel energy projects, something which would have otherwise stopped by the end of this year. The Netherlands energy mix remains heavily bogged in fossil fuels. According to the IEA, key energy sources for the country over the past decade are natural gas, oil, and coal, with nuclear, biofuel and waste, and renewables like wind and solar making up a negligible percentage of total consumption. It’s an inconvenient truth that must be addressed.

Prime Minister, Mark Rutte, said at the recent COP27 summit that the

private sector has a significant role to play in the country’s energy transition. Milan van der Meulen, Founder at Soly – the Groningen-based certified B-Corp solar energy specialist – agrees and is doing everything possible to encourage uptake in the renewables space.

The concept behind his business, established with brother Patrick in 2012, was the painful concept presented in the 2006 documentary film An Inconvenient Truth.

“When I was 13, Patrick was 16, our father almost forced us to watch this documentary about global warming,” van der Meulen tells Energy Focus. “We watched it several times and we became a bit intoxicated with talk of climate change. We knew then that we would have to start careers in the industry of sustainability or renewable energy.”

Committed to finding solutions, the brothers quickly settled on solar as a problem solver. Quick to roll out, using affordable and established technology, and implementable for individuals, solar

was the obvious choice for rapid impact.

“Creating large solar or wind parks, you have to rely on other parties, but putting solar panels on your home is something you can make happen alone,” smiles van der Meulen.

Importantly, the young business took a digital-first strategy allowing potential customers to communicate and organise online, streamlining interaction. “We were young and digital-minded. We quickly gained a scalable position, and we grew fast.”

Equally as crucial in the company’s speedy expansion was choosing reliable partners and technology suppliers. This enabled Soly to offer residential customers a new solar installation alongside a full guarantee, protecting them from financial shock.

“If the system failed to deliver the amount of power that we expect, then we would compensate. Consumers were completely safe on their investment, and that was how we differentiated ourselves. We were also the first company in the Netherlands to offer a rental or lease product to the Dutch

consumer. In the current time, that is very important with people paying big money for electricity. Now, they can switch to solar and pay a monthly fee that is much lower and the rental proposition has become very big.”

Because of the innovation and dedication to change displayed within the company, growth over the past decade has been substantial. Today, the company is home to more than 100 employees and oversees operations across the Netherlands, Belgium, Germany (Q1 2023), South Africa, with

an appetite for expansion into new geographies. Both residential and B2B markets are serviced, and the early ambition of the business remains at the heart of everything that happens. Making solar energy available to everyone is the single focus for Soly, and van der Meulen explains about an exciting new product that will further the company’s healthy ambition.

“In the B2B space, we are active with SMEs and we have a

very good solar carport product, the ZonneCarport. Many big solar companies are building large installations on rooftops, but we have many car parking spaces that are not being utilised. We came up with a solar carport product that can be used to charge EVs. That is a product that is new for us and we are proud of,” he says.

“We encountered a company that wanted to produce solar energy but the rooftop was not ideal to

// WE WERE ALSO THE FIRST COMPANY IN THE NETHERLANDS TO OFFER A RENTAL OR LEASE PRODUCT TO THE DUTCH CONSUMER //Solar Carport in Zuidhorn, Westerkwartier © Soly

carry the weight. They had a large parking lot and we tried to use that as a solution. We partnered with engineers to develop the product, it’s very implementable right now and we have a number of projects underway.”

Solar installations need space, but the Netherlands is a small country with much of the urban space already taken. However, taking the ‘it’s possible’ approach to every challenge, Soly optimises space with energy producing assets. Construction is movable, flexible, and tailored to specific energy requirements. It keeps EVs charged and shaded, and people dry.

“We were focused on creating a solution for open parking spaces where there are only cars. We wanted to cover with solar panels and we developed our carport to do so. In hotels or similar spaces, there are large car parks that are not utilised and our carport allows for guests to charge their EV while keeping out of the rain.”

In the Netherlands, Soly has

built a partnership project with the Westerkwartier municipality where surplus energy produced from a solar carport in Zuidhorn, at the rear of the town hall, is supplied directly into households. The project is home to 1121 solar panels with a capacity of 521 kWp. “It’s a new way to find spaces for the production of solar energy,” adds van der Meulen.

The ZonneCarport is just one aspect of a significant development journey that the company is on. Westerkwartier municipality is already considering the next site for carport rollout, and residential installations continue to boom in popularity. For Soly, recent investment combined with its mission-driven nature is encouraging year-on-year growth.

“Right now, our growth is exponential. In the second half of this year, we have seen a strong growth curve and we expect next

year to experience the biggest growth we have seen as a company so far,” says van der Meulen.

“We have around 22,000 households that have switched to receive their energy from us. This year, Shell Ventures together with the largest pension fund in the Netherlands, ABP, partnered with our company. That really helps us to enter new markets and there is a big expansion strategy underway. Each week we are increasing the number of installations and we are growing rapidly.

“We have a complete digital and self-service customer journey. From start to finish, the homeowner does everything online and there is no physical interaction apart from the installation. It’s a very efficient model,” he adds.

To achieve such success in a turbulent commercial environment, against the backdrop of economic slowdown and war in Europe, demonstrates the strength at the core

of Soly. Even through 2020 and 2021, where many companies struggled with balancing cost and income, Soly pushed forward, sticking to its purpose of switching to nature as an energy source, and trusting the sun – our largest energy supplier.

“We had some Covid problems,” admits van der Meulen. “It did not impact our direct operations but it did create obstacles in the supply chain. You must be innovative to come up with solutions. Because of the amount that we install, we tend to see manufacturers prioritising us and that allows us to

keep going. Smaller installers are often left out by manufacturers, and that is a problem. We had to manoeuvre through these challenges but we are now reasonably secure in our supply chain.”

When difficulties around sourcing a unique inverter component came up, Soly took a pragmatic position and did not delay. It quickly scoured the industry and negotiated with a new supplier that had available stock before sending a truck to Poland to collect. “You have to be smart,” smiles van der Meulen.

Covid challenges aside, this bright and innovative organisation is doing all the right things. Investing in the energy transition, helping others to do the same, providing innovative funding and interaction models, and committing to sustainability through B Corp accreditation, there is an open market ahead of Soly.

“We have experienced so much organic growth and we saw such a big increase in demand recently,” says van der Meulen. “The demand is much bigger that what can currently be delivered, and that increases

delivery time for the end customer.

“Internally, we are exploring other European markets where we do not see this model a lot, and we are looking at growing further in the markets where we are already present.”

Clearly, Soly is answering the call for private sector involvement in the Dutch energy transition. Actively looking to drive impact, the future is sunny for Milan van der Meulen and team. In 2021 alone, the company avoided 66 million kg of CO2 being released into the atmosphere through the installation of 32,500 solar panels. Van der Meulen hopes to roll out the ZonneCarport at scale, and is on the hunt for opportunities.

“Our carport product is unique and we are looking for companies that find it attractive so that we can build new partnerships,” he concludes.

Content sponsored by Soly

// OUR CARPORT PRODUCT IS UNIQUE AND WE ARE LOOKING FOR COMPANIES THAT FIND IT ATTRACTIVE SO THAT WE CAN BUILD NEW PARTNERSHIPS //

Dover Fueling Solutions is redefining what’s possible through performance and innovation. The global expert in the provision of advanced customer-focused technologies, services, and solutions in the fuel and convenience retail industries, DFS is assisting in the green energy transition while embracing digital technology to drive fuel retail business. DFS VP of Business Development, Kurt Dillen tells Energy Focus more about progress in this quickly changing industry.

PRODUCTION: Rob Fenton

PRODUCTION: Rob Fenton

//COP27 has highlighted again the speed of innovation and reinvention required if society is to avoid climate disaster and take a greener path forward. Importantly, governments continue to adopt new pledges that will mean change for business, and those that are able to adjust and take part in a transition will be those that thrive.

In the UK, for example, all new HGVs sold need to be zero emission by 2040. Conventional petrol and diesel cars and vans will be banned from sale by 2030, and even hybrids will be restricted from 2035. Clearly, from a transport perspective, the transition is gathering pace. Whether its electric vehicles (EV), hydrogen power, or another form of fuel, the industry must adapt to a new environment.

Investing in EVs or another fuel source is just the first step for consumers, but for businesses there

must be ancillary roll out. A network of fueling stations must be updated, new types of fuel must be developed, infrastructure must support consumers, and companies must be able to thrive

Kurt Dillen, VP Business Development at Dover Fueling Solutions (DFS),

has a vision of how the network of the future will look and the company – a world leader in technology and services for the fuel and retail space – is constantly innovating alongside its customers to achieve growth.

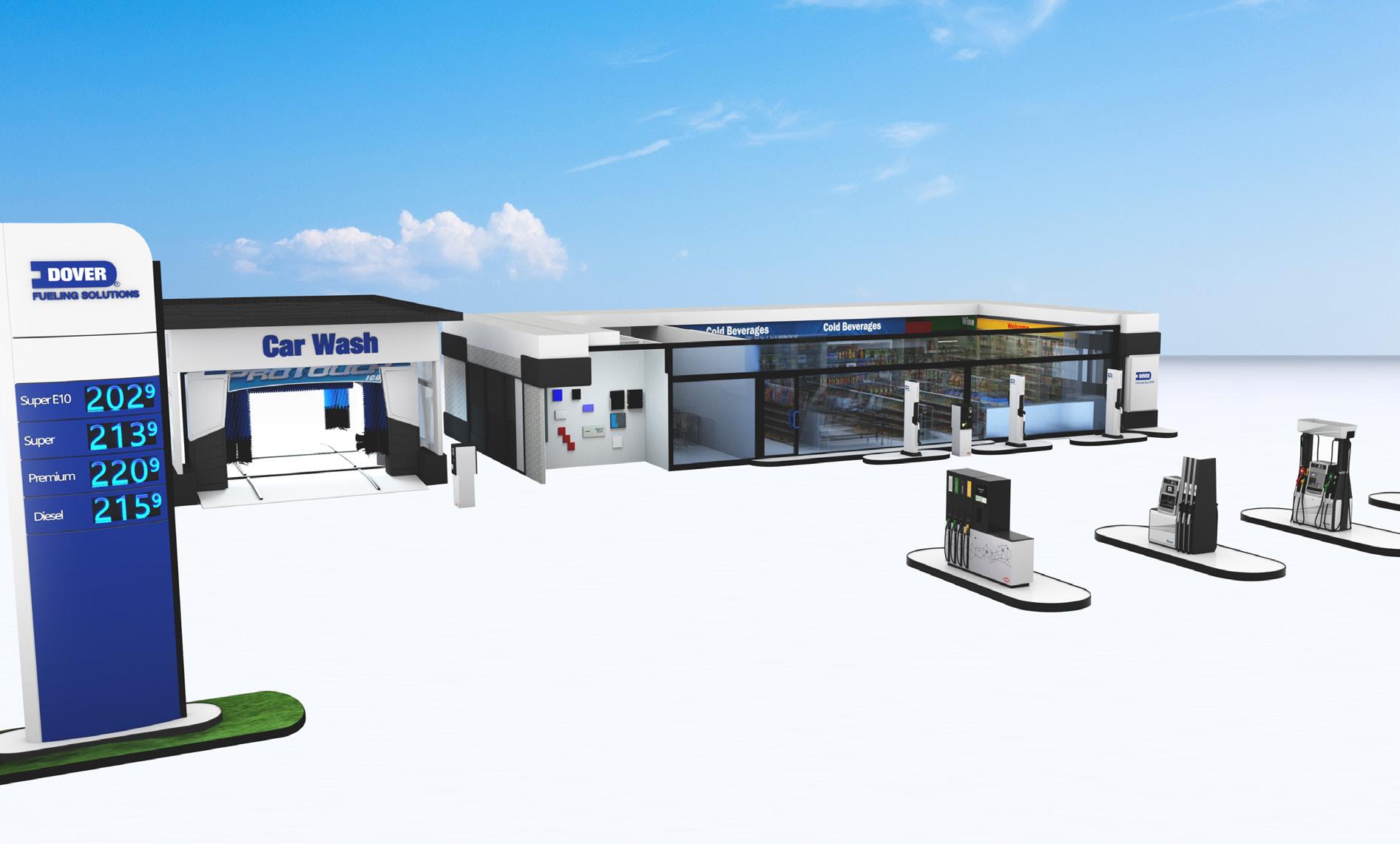

“In the future, you will wake up

and your phone will tell you that your car needs charging. Your phone will then direct you to the nearest charging station while ordering you a sandwich and coffee. When you arrive, your car will charge quickly while you collect your favourite food, and tech at the station will recognise you and your car, taking payment automatically. There will be no queues, there will be no waiting,” he smiles.

An industry veteran of 35 years, Belgium-based Dillen explains that DFS is made up of some of the best brands globally including Tokheim, Wayne, Fairbanks, ProGauge, OPW Fuel Management Systems, ClearView, AvaLAN Networks, and more recently LIQAL. Since 2016, these inventive players dominate the sectors in which they operate, allowing the group to drive change. “We have a presence in all regions around the world and we are operational globally with factories in the USA, Brazil, Europe, India, and China. We have development resources all around the world, in every region and every time zone,” he says.

As the automotive sector is transformed, change in the fueling network will come in three lanes: Digitisation, energy source, and retail focus. The entire experience will shift and DFS will be at the heart of this switch, globally.

“We have Tokheim, Wayne, and OPW FMS within our portfolio and they have all been in existence for more than 125 years,” says Dillen. “Now is a dynamic time as the transition towards other energies and technologies is underway.

“There is transformation with technology. The traditional dispenser that moves fuel from a big tank to a small tank in your car has been around for hundreds of years and it works, but there is major innovation around payments, smart data, loyalty. Data is money as data gives knowledge. With knowledge you can improve your business. The second transition underway is in clean energy and EVs. Electric cars are already on the road, and trucks, buses, and heavy duty vehicles are now also converting.”

Embracing change, DFS is already busy innovating to bring improvement, both in terms of customer journey and experience, and environment.

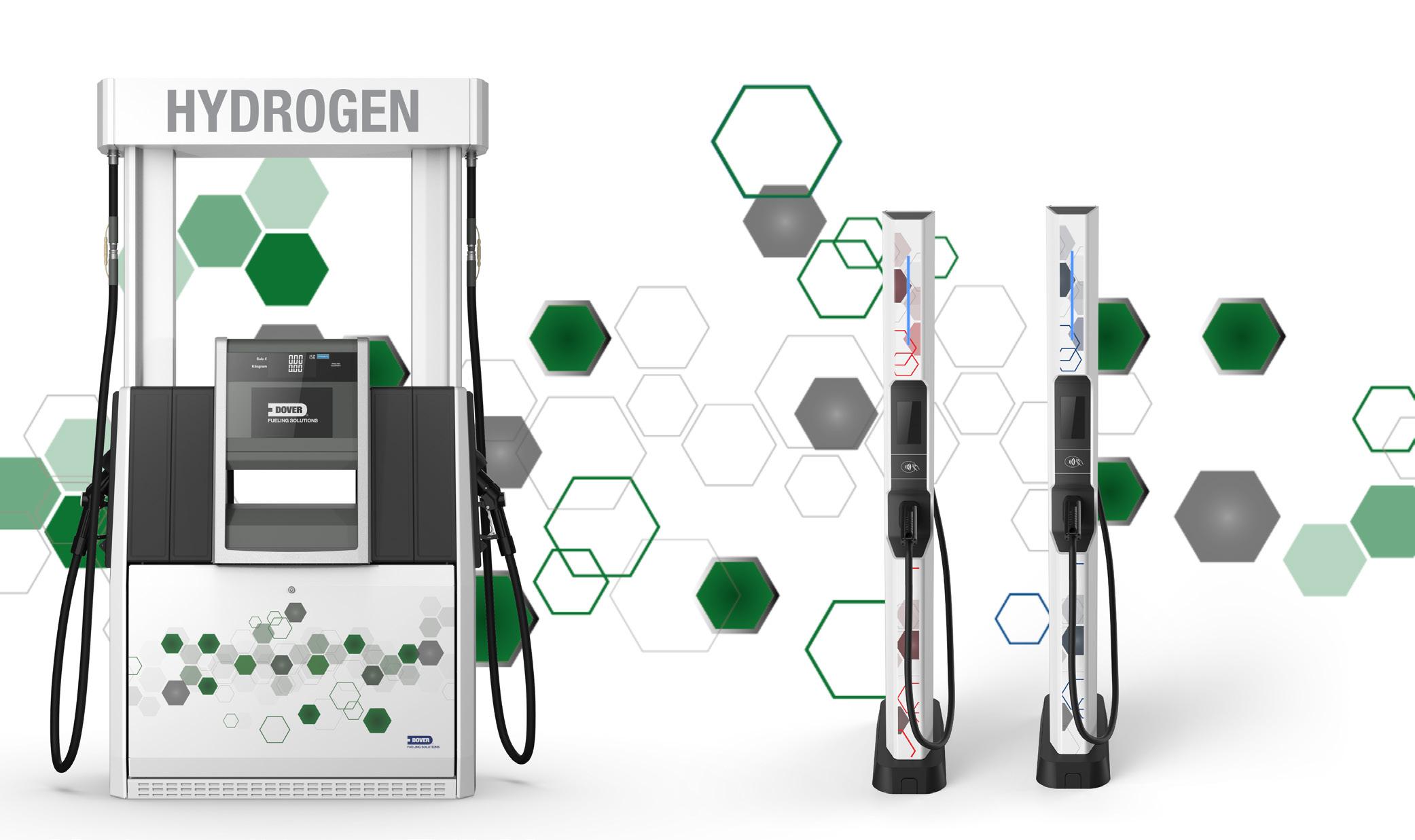

In October, the company displayed its all-new hydrogen dispenser at the 2022 Hydrogen Technology Expo in Bremen, Germany. With digital interface, intuitive user experience, reliable performance, and low cost of total ownership (TCO), the DFS Hydrogen dispenser is an essential element for fuel stations looking to support the green energy movement.

In September, DFS announced an exciting new high-powered ultrafast charging system for EVs in Europe – the Power UX™ 180 EV Charging System. Compact and powerful, the system can be placed on any forecourt, and in different locations, allowing for more EVs to charge at one time. 100km of range should be achieved in just 10 minutes of charging, and installation is suitable for fuel station, workplace, or high traffic environments. Launched at international mobility trade fair, eMove 360, in Germany, the Power UX™ 180 EV Charging System is an enabler of the energy transition.

“DFS is committed to offering products and solutions that support our customers diversified energy

requirements,” said Soren Powell-Holse, Product Marketing Director of EMEA.

“In the last two years, we have become very interested in the clean energy transition,” agrees Dillen. “Europe is ahead and China is moving fast, and the US is slightly behind. The plans from European governments and the rules being put in place for a clean environment provide massive growth potential in that area. Our engineers have to develop new technologies, new solutions, new devices, and that makes

it very interesting for all the people in our company. We are now innovating and developing new technologies for the future, and that is exciting.

“We have a big project in Europe. We are releasing a complete range of new products, where we have merged ranges from Tokheim and Wayne, selecting the best of the best, simplifying our supply process. It’s about optimising operational efficiency and optimising performance of our products,” he adds.

Away from refueling, digital solutions remain a big opportunity for expansion. Again, it’s all part of a smooth customer journey – the way people pay, what is quickest, what is cheapest, how is data stored and processed securely. Multiple DFS brands have software and systems that contribute to a growing digital footprint, and Dillen is keen to push this in the future.

“We have been investing heavily in solutions and cloud technology as we see that offering having great value for our customers. They need to know what is going on at their sites and they need to know who is buying and when, and this is why we need data. We invested in our own DX cloud for which we partnered with Microsoft Azure as a cloud provider. All the technologies we can

// OUR ENGINEERS HAVE TO DEVELOP NEW TECHNOLOGIES, NEW SOLUTIONS, NEW DEVICES, AND THAT MAKES IT VERY INTERESTING FOR ALL THE PEOPLE IN OUR COMPANY //

provide are now linked with the DFS cloud to provide data and information.

“We are launching the DX cloud technology globally with features around stock management, advertising opportunities, and POS capabilities. More and more data and application handling will happen in the cloud. It’s not just the dispenser, it’s everything that is happening in the shop, in the car wash, on the forecourt – all the components are becoming smarter, and everything is connected to the cloud. It’s a journey for our customers and our company so we are eager to do this.”

Customers are happy to engage with DFS when it comes to updating forecourts and supplementing technology thanks to the historic brands that stand behind the blue and white façade.

At every turn in the road, with every innovation, DFS has stood behind its customers, keeping consumers moving. Traditional fuel pumps from the group have been installed all around the world, adorning sites from New York to Beijing and Cape Town to Reykjavik. Currently, Dillen estimates there to be 750,000 fueling stations worldwide, which the company splits into thirds across its Americas, EMEA, and Asian markets.

“We are active in all countries around the world and we have solutions and market share for everyone. Our biggest markets are North America and Europe,” he explains.

“We are the market leader in Europe for fuel dispensing, and we are the market leader for solutions. With POS and payment devices, looking at Europe, we are very strong. We see growth opportunities in Africa with a fast-growing population and we are already a market leader there. We are the number two player in the US and we are one

of the two major players in the world. In Latin America, we are the market leader. In Asia, we are strong in China.”

The Dover Corporation, owner of DFS, is a NYSE-listed multinational with more than 24,000 employees across 17 operating companies, generating around $8 billion. This powerful position allows for a customer-centric focus that few can match. It also allows for the swift overcoming of industry and economic hurdles.

“The last few years have been amazing, and many people are surprised about that because of COVID,” smiles Dillen, talking about a purple patch for DFS since the start of 2020 where many companies struggled in tough

market conditions. “COVID did have an impact on the business, but the fuel business has been seen as essential. Our focus was always around our need to provide fuel and energy to the people. Because of this, we were not interrupted. Globally, we didn’t slow down and investment into dispensing and solutions continued.”

He highlights a major operation in the USA which helped the company to flourish, utilising its extensive reach in the digital space, updating technology to make life easier for consumers.

“We have been delivering fantastic growth and we had one sector that was fantastic. In Europe, we have been paying with EMV (Europay, MasterCard, and Visa) chip cards for a long time, but the US was behind. We had to upgrade the entire network, all stations, with EMV card capability. That’s around 120,000 stations that needed upgrading – average around six payment devices per site – that is a lot of business. This gave us a tailwind as it

// WE ARE ACTIVE IN ALL COUNTRIES AROUND THE WORLD AND WE HAVE SOLUTIONS AND MARKET SHARE FOR EVERYONE //

“The technology evolution is never standing still but now, with new energies, the industry has never been so dynamic, and we have to develop many things. The industry and the government don’t know how the picture will look in 2030, but we are working towards the targets and that is very interesting,” states Dillen.

The challenges that have been felt by the business include supply chain issues that emanate from the pandemic and other economic factors. Cost, timings, and logistical issues are seemingly unabating as manufacturers hunt for reliable chains.

example, we will step in and assist to help buy whatever we can and help solve problems. We can bring our size to get priority in component supply.

“Shipping is an issue and it remains hard work,” he adds. “We have been lucky and we have not stopped production because of any shortage, but it is a lot of work and requires new solutions every day.”

needed to be done before a deadline.”

When it comes to the instore experience, DFS is a frontrunner and, as the model changes, so too will its offerings.

“2022 is the year where supply is our biggest concern – it is difficult,” admits Dillen. “We are specialised in supply and we work very closely with our suppliers to ensure success. If a supplier cannot find a component, for

Even with these difficulties, the innovative nature of the business has allowed it to thrive, remaining in demand as the unending need for energy increases. As the speed of the transition accelerates, DFS will support its supply chain and roll out solutions that support Net Zero aspirations set out at COP27, while keeping in mind the network of the future, whatever that might look like.

“We are involved in multiple

// THE TECHNOLOGY EVOLUTION IS NEVER STANDING STILL BUT NOW, WITH NEW ENERGIES, THE INDUSTRY HAS NEVER BEEN SO DYNAMIC AND WE HAVE TO DEVELOP MANY THINGS //

projects with multiple customers to bring these new energies to sites. In the future, we see gas stations becoming hubs for energy. Whether it’s traditional fuels, hydrogen, EV charging – the hub will be there offering everything required including new shops, quick service restaurants, other retail ideas, and it will become a place to gather while solving problems. It is making our industry super interesting

during this period,” says Dillen.

In the UK, it is predicted that EVs will outsell petrol and diesel by the end of 2022. Longer-term, hydrogen fuel systems will supplement EVs rather than replacing entirely, and most vehicles on the road are expected to be emission free by 2035.

“Our goal is to become product leaders in every region, for each part of our business,” says Dillen, speaking of DFS ambition for market leadership globally across all of the sectors it plays in. Currently so close behind another player, and only lacking in terms of market share in the USA, this is very achievable with so much change and disruption on the horizon.

“We are innovators and product leaders and we are investing a lot in development. We want to bring IP so we can offer the best solution to our cus-

tomers, so they can grow. We are investing a lot and supporting our customers in the transformation (digitalisation and energy), and we are customer centric. We think with our customers, and when they are successful and growing, we are happy. We exist to grow the business of our customers,” Dillen concludes.

DFS holds the vision of enabling the evolution of consumer experience in fueling and convenience retail, and right now that vision is being realised.

// WE ARE INNOVATORS AND PRODUCT LEADERS AND WE ARE INVESTING A LOT IN DEVELOPMENT //

Mathias Kurras, CEO

Mathias Kurras, CEO

A foremost provider and developer of comprehensive system solutions for the entire hydrogen technology value chain, Maximator Hydrogen is a leader in the development, production, and delivery of highly reliable and modern hydrogen filling stations worldwide. As the number of stations worldwide continues to multiply, Maximator Hydrogen is harnessing its partnerships both internal and external to dominate key markets, not least the lucrative North American territory.

PRODUCTION: Rob Fenton

PRODUCTION: Rob Fenton

In the face of an abundance of obvious benefits linked to hydrogen fuel cell technology, car manufacturers have for years been engaged in a collective bid to crack the formula for successfully using the most abundant resource in the universe to power their vehicles. Hydrogen cars produce zero harmful emissions on the road, and refilling is very similar to filling up with petrol or diesel and is also almost as quick, with a brim-full

tank available in around five minutes. Historically, the lack of existing infrastructure has been cited as the biggest obstacle to a more widespread take-up, amplified as EV charging points have incessantly sprung up and the convenience of using hydrogen’s main competitor has in turn swelled and taken electric cars fully into the mainstream. With parent company Maximator GmbH, the world market leader in high-pressure technology, through abundant innovation and expertise, Maximator Hydrogen is poised to intervene, MD Mathias Kurras told Energy Focus earlier this year.

“We build hydrogen filling stations with passion and thus drive the future,” he outlines. “Our mission is to make hydrogen usable on a large scale and help infrastructure to become climate neutral.” Patience is

// WE BUILD HYDROGEN FILLING STATIONS WITH PASSION AND DRIVE THE FUTURE //

the previous record number lodged in 2020. In a continuation of the trend, concrete plans at the beginning of 2022 indicated that a further 252 refuelling station locations would be completed by the close of the year.

key, however, Kurras added - this is a marathon, after all, not a sprint. “We are fuelling the future; we know that in the end there will be hydrogen.”

“We have more than 130 years of experience behind our high solution competence in the field of machine and component construction,” detailed the man at the helm of this industry leader at the vanguard of a crucial movement. “The combination of this tradition, with a high degree of vertical integration

and sustainable innovations, allows us to develop the most suitable and efficient solutions with, and for, our customers, for the entire value chain of hydrogen technologies.”

The ubiquity of hydrogen refuelling stations worldwide has burgeoned exponentially over the last decade. At last count in 2021 the total stood at 685, an almost fourfold increase during the period with 142 hydrogen refuelling stations being placed into operation worldwide last year aloneagain more than ever before, shattering

Clearly then, the crucial and potentially era-defining takeaway is that the infrastructure for fuel cell cars is becoming more developed, and more widespread. Advancements in Spain and New Zealand are noteworthy, as both registered numerous new definite placement plans for the first time. Hungary and Slovenia were both new entrants, each with a hydrogen filling station; in total hydrogen is now currently available for purchase in 33 nations.

Maximator Hydrogen’s nascent Germany leads the way in Europe, already boasting more than 100

// WE HAVE MORE THAN 130 YEARS OF EXPERIENCE BEHIND OUR HIGH SOLUTION COMPETENCE IN THE FIELD OF MACHINE AND COMPONENT CONSTRUCTION //

allows us to plunge our full focus into this business and its many prospects, pursuing the dynamic growth in this sector,” Kurras detailed. “As well as the many years of expertise in the development and production of compression technologies, and key technologies from Maximator Advanced Technology, we also benefit from the know-how of around 700 hydrogen-relevant patents.

stations and set to triple this count by 2030 as it seeks to wean lorries and buses off fossil fuels and decarbonise its transport network. A standalone entity since 2019, Maximator Hydrogen’s work began

in earnest at the turn of 2022, with the purchase of some 400 traditional fuel stations in Germany to be converted into hydrogen sites.

“Unbundling the hydrogen segment from the Maximator Group

“We truly envisage the hydrogen compression market as being huge in the near future. Overall, technologywise we are the market leader worldwide, and in terms of the number of new hydrogen stations brought into service over recent years, we are leading the way in Europe.” Kurras went on to set forth the powerful partnerships Maximator Hydrogen is forging further afield, which include some giants of the industry.

Superior quality for maximum reliability

“A lot of neighbouring countries are now on our map,” he explained, “having delivered bus stations to Vienna and the Netherlands, and prototype refuelling stations to Sweden. We are looking now to step into the markets in Australia and the Middle East, while reinforcing an incredibly strong position in North America.

“We are delivering a lot of stations to Shell into the USA, and by the end of this year we will have provided up to 50 in California,” Kurras informs, and both the timing and placement is impeccable; of the 86 petrol stations in North America, 60 reside in California, with 11 new fuelling stations opening in the area in 2021. “In North America right now, we have one big customer as opposed to Europe where we have a lot of different clients,” Kurras says. “Besides this, in North America, we are entering a market where there are already a lot of cars, and therefore by this utilisation, rates of the stations are much higher.

“Right now, our ambitions are to make a successful market entry, with stations for passenger cars in California, and after that we are looking forward to also deploying very fast stations for heavy duty transport.” This does not come without its own series of challenges, Kurras clarifies, obstacles which are all of course greatly diminished through Maximator Hydrogen’s valuable affiliation with the larger group, Kurras qualifies.

“We receive a lot of input,” he states. “In all international markets

where the group already has a viable entity, whereby we can use this to determine feasibility and so enter the market ourselves. This in turn helps massively to keep the costs of our continuing internationalisation relatively low.” As a fast and efficient partner for the planning, construction, and operation of hydrogen infrastructure for road, rail and ship traffic, Maximator Hydrogen offers highly reliable and modern hydrogen filling stations from a single source.

As a number of mines begin to convert their huge trucks to using hydrogen, the off-highway section of the business is becoming another priority area for Maximator Hydrogen, Kurras furthers. “Besides the activities we are undertaking towards a bigger on-road station, this is the hottest topic within our company, which

www.weh.com

means that off-highway business is definitely a topic with a lot of focus.

“Our top priority is to actively shape the mobility revolution by providing the necessary infrastructure,” Kurras summarises. “All of it will be led by our latest and most highly efficient compressor generation, MAX Compression 2.0, which works with the same installation space and optimised energy requirements as its predecessor, but with up to five times the performance, this will enable us to be competitive in all markets, especially those with highly utilised stations.”

// OUR TOP PRIORITY IS TO ACTIVELY SHAPE THE MOBILITY REVOLUTION BY PROVIDING THE NECESSARY INFRASTRUCTURE //

© National Grid. Engineers at a substation

David Hill

As the largest electricity transmission and distribution business in the UK, National Grid is charged with delivering electricity safely, reliably and efficiently to both customers and communities alike, all while working towards a cleaner, greener energy future. “Through our regulated utility businesses in the UK and US we play a vital role in connecting millions of people to the energy they use,” the company proudly announces.

Through one of the world’s most reliable networks of cables, pylons and wires, National Grid has the vital task of transporting high-voltage, raw electricity produced from sun, water, wind and traditional fuels, balancing supply and demand to ensure homes and businesses in Great Britain are never without the electricity they need. “We own the high-voltage electricity transmission network in England and Wales,” it explains. “We’re responsible for making sure electricity is transported safely and efficiently from where it’s produced to where it’s needed.”

Unlike in the UK, National Grid’s gas and electricity businesses in the US supply energy directly to customers, owning and operating electricity distribution networks in upstate New York and Massachusetts, and transmission facilities and gas

distribution networks across the Northeast. “No matter what the weather, we’re here for our customers, delivering safe, reliable and affordable energy around the clock,” National Grid pledges.

“We have a pivotal role in the energy industry, and enable the innovation that is enabling the transition to a clean energy system.”

With climate change remaining the generation’s defining issue and time elapsing to take action and limit global warming, rapid, fundamental change is required from governments, society and businesses like National Grid. “We are continually seeking ways to make the energy system cleaner, while our National Grid Ventures and National Grid Partners divisions also enable innovations to help revolutionise and decarbonise the future of energy across electricity, gas and renewables.

“At National Grid, we’re committed to net zero for our own emissions by 2050, with a reduction of 80% by 2030 and 90% by 2040, enabling this by investing £30-35 billion over the next five years in the critical infrastructure and innovation needed to make net zero possible.

“£24 billion of this will go directly into clean energy solutions, making us one of the biggest

In the last six months, major financial services, energy, and infrastructure groups have engaged Tusker to provide a car benefits scheme to bolster long-term sustainability and ESG objectives. Over 300 companies have launched a Tusker scheme so far in 2022, many of whom have been motivated by a desire to reduce their carbon footprint.

Already popular with a variety of businesses for numerous reasons including staff retention and attraction, motivation, offering a sought after benefit and more, the increased sustainability offered by Tusker’s schemes have proved popular with many more companies in 2022. Tusker, as market leaders in the UK not only offer the scheme with the associated ESG benefits but also the ease of on boarding, where multiple teams are involved in a scheme’s set-up.

With traditional company car schemes, it can be difficult to restrict emissions across a policy, especially if employees take a car-for-car option. With a Tusker scheme, it is possible to restrict a policy to hybrid and electric vehicles only, although, thanks to the tax advantages offered by the low Benefit in Kind rates on hybrid and electric vehicles, most drivers opt for such vehicles anyhow.

Not only does this dramatically reduce the carbon footprint of the company car fleet, but it also brings financial advantages for employees on the scheme, who are able to save money on income

Paul Gilshan, CEO at Tusker comments, “We have seen a big rise in the number of companies for whom reducing their carbon output has become more of a priority and in offering the car benefit scheme, it not only supports their employees, but also helps achieve this objective. More people are able to drive an electric vehicle on our car scheme than if they were to organise a car independently thanks to the low benefit in kind tax the scheme attracts. It also helps employers retain staff, too, which is topical at the moment.”

// THE ENERGY TRANSITION IS ACCELERATING AND TO STAY AHEAD WE NEED TO CONTINUE EVOLVING AS A COMPANY //

A salary sacrifice green car scheme that is free, easy to set up and run, and gives your employees the opportunity to get a new electric vehicle.

So if youʼre looking for a great way to widen your benefits, look no further than our zero emission scheme.

Scan the QR code above to find out why leading energy & utilities customers in the UK work with us

businesses to low-carbon energy.

Also in 2022, National Grid launched North Sea Link, its fifth and latest interconnector which also happens to be the world’s longest subsea electricity cable, connecting the UK with Norway and capable of sharing enough clean electricity to power around 1.4 million UK homes. It has saved 800,000 tonnes of carbon, equivalent to taking 300,000 cars off the road or 1,900 return flights from London to New York, in the first year, paying off its carbon cost after only six months of operation.

green investors in the sector.”

As an energy transition pioneer, National Grid is wholly cognisant of the vital role it has in avoiding the worst of climate change. “The energy transition is accelerating and to stay ahead we need to continue evolving as a company; through a digital first approach, we’re transforming the clean energy landscape on the outside. We’re also working smarter on the inside, simplifying and standardising our systems and processes, so we do things once and

always in the most effective way.”

Over the past year, National Grid has notched up some impressive milestones on its path to making a net zero future a reality for everyone. It helped to connect the world’s largest offshore wind farm, Hornsea 2, to the electricity system in Great Britain, and constructed the world’s first T-pylon at its Hinkley Connection project in Somerset. The first new pylon design in Great Britain in nearly 100 years, 116 will come together to connect six million homes and

“North Sea Link is a remarkable feat of engineering and demonstrates how we can work with our neighbours to use every spare electron of green electricity to strengthen our energy supplies,” submitted Nicola Medalova, Managing Director Interconnectors for National Grid. “These vital energy superhighways will be a critical part of a cleaner, fairer and more affordable energy system, reducing our reliance on fossil-fuelled generation.”

UPGRADE, ADAPT, MAINTAIN

National Grid is to debut an innovative new way to connect customers to the high voltage network with the energisation of its first ‘grid park’, an efficient new way to connect renewables to the electricity transmission system, in Bedfordshire next year. The innovative first-of-itskind design connects three separate customers to the same new supergrid transformer, which is being installed at a new 33kV substation on the site of the existing 400kV Sundon facility.

The design has the potential to help expedite renewable power connections to the transmission network, boosting efforts to meet the country’s ambitious decarbonisation goals. EDF Renewables UK will be one of the first connections, which will see a 50MW battery connect to the grid as part of its nationwide Energy Superhub rollout. “Our first grid park build is an exciting development,” enthused Mark Beasley,

the project’s director at National Grid, “a proof of concept for a new way to connect low carbon generation in an innovative and cost-efficient way in the future – all of which bring benefits to consumers locally and nationally.

“When our first grid park goes live it will now play a key role helping us meet net zero targets in the future.” Over the last five years, National Grid

has invested £4.2 billion to upgrade, adapt and maintain the transmission network, with a further £7.1 billion projected over the next five. The first stage of a £130 million project to refurbish the existing overhead line network between Lincoln and Stevenage has been completed, seeing 1440km of new overhead line installed.

“Once complete, the new line will not only strengthen the existing infrastructure from Lincolnshire through to Hertfordshire but will also ensure the network is able to continue to transport increasing volumes of renewable power,” National Grid explained. Now, National Grid is trialling LineVision’s Dynamic Line Rating (DLR) technology for the first time in Great Britain, following successful deployment on its US networks.

The sensors and data analytics platform will highlight spare capacity on overhead power lines and allow the integration of more renewable power. In conjunction with the construction

of new infrastructure, the innovative technology forms part of National Grid’s work to upgrade and adapt the electricity network to meet increased demand and help deliver a net zero grid, concluded Lydia Ogilvie, Director of Network Strategy and Operations.

“To meet the increasing demand for electricity and deliver net zero, our network needs to grow, but at the same time we are continually looking at ways of expanding capacity on our existing infrastructure. I’m proud that National Grid is leading the way in using transformational and innovative engineering, integrating vital grid enhancing technologies like LineVision’s, to decarbonise and deliver world class reliability, at lowest costs for consumers.”

// NATIONAL GRID IS LEADING THE WAY IN USING TRANSFORMATIONAL AND INNOVATIVE ENGINEERING, INTEGRATING VITAL GRID ENHANCING TECHNOLOGIES //NATIONAL GRID © National Grid. T-Pylon Construction

Proudly British and passionately global, Britishvolt is on an unswerving mission to accelerate the electrification of society. Its overarching ambition is to create some of the planet’s most responsibly manufactured battery cells, primarily to power electric vehicles, and collaborations with academia, industry and private enterprise will help the UK to transition from fossil fuels to a low carbon, battery-based electric future.

The UK has been at the forefront of global investment in technology development and innovation since the industrial revolution. It is the ideal base for Britishvolt, with the development of current and future generations of battery technology pinpointed as of strategic importance to the country’s manufacturing sector, and key to sustaining its lucrative domestic automotive industry.

According to APC research, by 2030 the UK will need over 90GWh per annum of batteries for cars and light commercials alone, and represents over 11% of the total demand across Europe. British consumers bought more electric cars in 2021 than the previous five years combined, a trajectory set to only accelerate, Britishvolt is the UK’s foremost investor in battery cell technologies and associated R&D to develop homegrown intellectual property.

“The race to zero is an imperative for society, and batteries are core

to a successful energy transition,” Britishvolt stipulates, “and the move to a low carbon future will bring with it huge opportunities. Sales for electric vehicles continue to strengthen and domestic batteries are a vital ingredient in meeting this demand.”

“We do indeed have global ambitions,” the company states, “but the UK will always be where it all started.” Headquartered in the heartland of the UK automotive industry, the Midlands, with easy access to vehicle manufacturers as well as research partners at Warwick Manufacturing Group, also ideally situated on the best site in the UK is Britishvolt’s 30GWh battery Gigaplant, fully plugged into the national grid and ready to go.

“It is logical to build any battery cell manufacturing site as close to a renewable energy source as possible, in order to counter the energy intensity of the production process,” Britishvolt reasons, “and in Northumberland

renewable energy is plentiful; the entire area fully embodies the transition to a low carbon future.”

One of the UK’s biggest-ever industrial investments, and the largest in the North East of England since Nissan’s arrival in 1984, has enabled Britishvolt to power ahead with its historic plans with funding from the UK Government through its Automotive Transformation Fund. The ATF funding is critical to Britishvolt’s plans to build the £3.8 billion advanced technology battery cell Gigaplant, which will result in over 3000 skilled direct jobs onsite at full production, plus a further

// THE RACE TO ZERO IS AN IMPERATIVE FOR SOCIETY, AND BATTERIES ARE CORE TO A SUCCESSFUL ENERGY TRANSITION //

5000 in the wider supplier chain. Delight accompanied the confirmation of the funding, which will help propel the UK’s successful energy transition on the road to zero, for Isobel Sheldon OBE, Chief Strategy Officer, Britishvolt. “This is great news

for our plans to construct the UK’s premier battery cell Gigaplant in Northumberland,” she recognised. “The ATF’s grant funding is very important in proving that the UK Government is confident that we will deliver on our plans, and this will help to

generate further private investment.

“The Britishvolt Gigaplant will create both the jobs and the industry of the future, strengthening the UK’s technological base and playing a key role in helping the country reach its net zero target by 2050.”

Britishvolt’s private partnerships to date have been equally strong and important, not least in its selection of BTR as its key synthetic graphite and silicon oxide supplier, with processing powered on clean, renewable hydroelectricity. It followed securing a portion of its cobalt requirements from strategic partner Glencore and the announcement of a JV with Indonesia’s VKTR for nickel sulphate.

“Not only do we benefit from the technical expertise of BTR, now and in the future,” lauded Timon Orlob, Global COO, “but we also benefit from their global strategy concerning their manufacturing location and up-stream material plans.

“We were always committed to shaping global supply chains, and with this collaboration with BTR we are achieving that.” Britishvolt has strengthened a longstanding partnership by extending its

// THE BRITISHVOLT GIGAPLANT WILL CREATE BOTH THE JOBS AND THE INDUSTRY OF THE FUTURE AND STRENGTHEN THE UK’S TECHNOLOGICAL BASE //

contract with WMG, University of Warwick, to develop battery cell technologies and accelerate the route to market in a multi-millionpound deal. A two-year programme of work will assist with battery cell development and optimisation and help Britishvolt to ramp up availability for electric vehicles, and other applications, in the UK and beyond.

“The battery science, advanced

materials and cell prototyping expertise and capability at WMG has directly, and positively, supported our battery technology development programme,” explained Dr Allan Paterson, Chief Technical Officer at Britishvolt. “The relationship enables Britishvolt to continue to develop our products further, as we continually strive to deliver best-in-class, market-leading, cell technologies to our customers.”

WMG at the University of Warwick has worked with industry for the last 40 years, driving technology innovation to improve the productivity, resilience and sustainability of UK manufacturing.