2-5 October 2023

Abu Dhabi, UAE

2-5 October 2023

Abu Dhabi, UAE

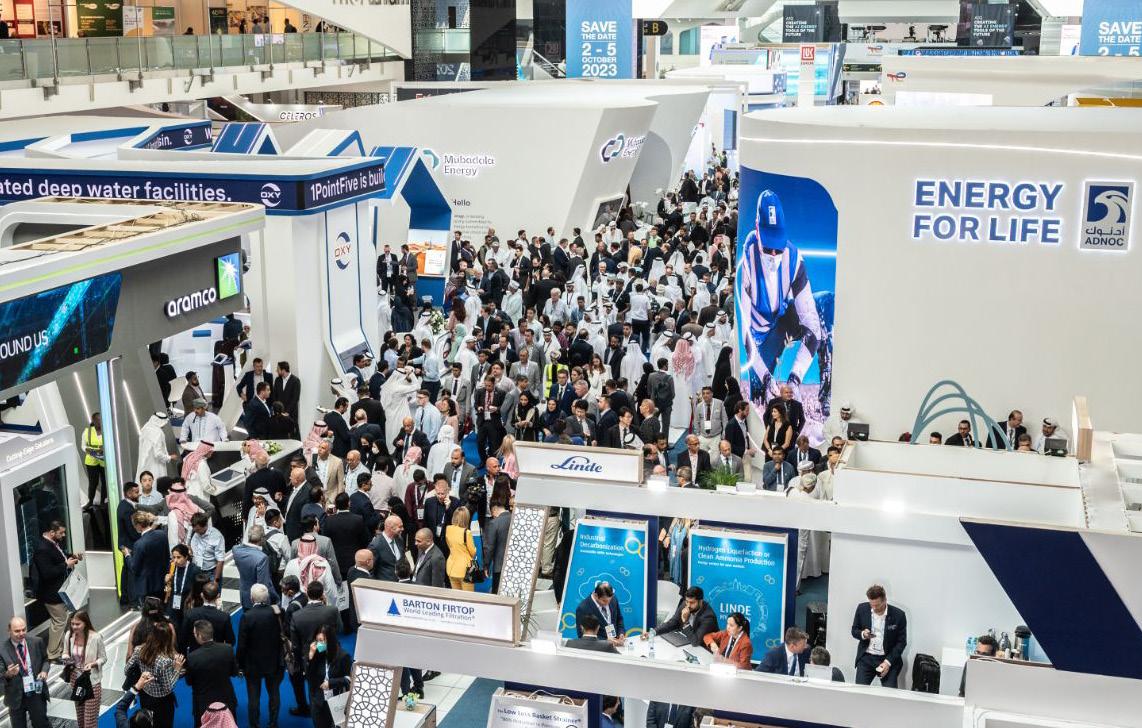

ADIPEC, the world’s largest energy exhibition and conference, brings together the ideas, ambition, technology and capital needed to accelerate the urgent, collective and responsible action that can decarbonise and future-proof our energy system.

160,000 Energy professionals

2,200 Exhibiting companies

54 NOCs, IOCs, NECs and IECs

15,000 Conference delegates

1,600 Conference speakers

350 Conference sessions

10

30 Country pavilions Conferences

Under the Patronage of H.H. Sheikh Mohamed Bin Zayed Al Nahyan, President of the United Arab EmiratesEDITOR Joe Forshaw

joe@energy-focus.net

PROJECT MANAGER Tommy Atkinson

tommy@energy-focus.net

PROJECT MANAGER David Hill

david@energy-focus.net

PROJECT MANAGER Chris Bolderstone

chris@energy-focus.net

PROJECT MANAGER Ekwa Bikaka

ekwa@energy-focus.net

FINANCE MANAGER Isabel Murphy

isabel@energy-focus.net

LEAD DESIGNER Aaron Protheroe

aaron@energy-focus.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Karl Pietersen

CONTRIBUTOR David Napier

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

An integrated, combined approach to renewable energy is taking centre stage as developers realise the potential of a linked tactic where solar, wind, and other technologies work in unison to achieve bigger, better, faster results.

Taking tools from different providers also drives cost competition and innovation as suppliers strive to be the best and grow their market share. It’s a highly beneficial model that is having great results.

Efficiency and reductions in emissions are key themes at this year’s ADIPEC conference, where Energy Focus is a media partner, and where the main topic will be decarbonising faster, together. All of the world’s biggest energy businesses will be in attendance and all will be showcasing their commitments to the future of energy. Lookout for our separate release on ADIPEC and some of the best companies that are exhibiting products and services that will truly revolutionise industry sectors.

Lamprell, the UAE-based rig builder and engineer, will be there talking about its shift in strategy, incorporating more renewable energy business with a new production line working on windfarm transition pieces. CEO Ian Prescott tells us more about this significant change.

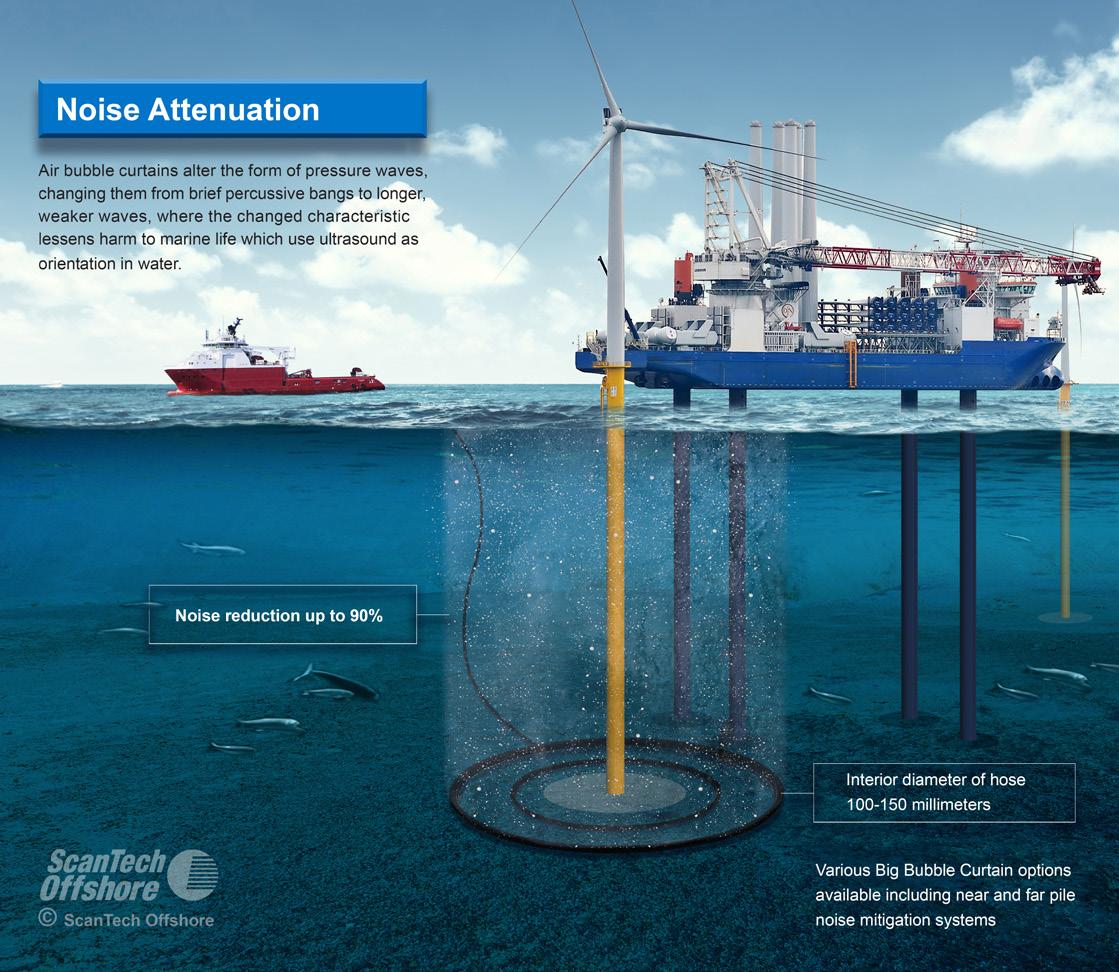

We also hear from the fantastic team at ScanTech Offshore, part of James Fisher and Sons, about a highly innovative new product that has been engineering specifically for the offshore wind market to protect sea life during construction.

Get in touch and tell us what your company is doing to bring together different ideas and technologies, and how you are rolling them out in a novel way. We’re online, as always, at LinkedIn.

Joe Forshaw EDITORPublished by

Chris Bolderstone – General Manager

E. chris@cmb-multimedia.co.uk

Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX ++44 (0)20 3097 1743 www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© CMB Media Group Ltd 2023

ADIPEC 2023

Decarbonise Faster, Together

LAMPRELL

Lamprell Reimagines with New Board and Management Team in Place

REFLEX MARINE Safety on the Seas, Guaranteed

UNIQUE GROUP

34 40 48

NEW OIL GENERATION

ECT Technology: Pioneering the Future of Heavy Oil Extraction with Sustainability in Mind

SCANTECH OFFSHORE (JAMES FISHER AND SONS)

ST3100 - Safer, Stronger, Smaller

SHELL On Track for Net-Zero Emissions by 2050

Can the world’s largest and most influential energy exhibition bring together the wide energy ecosystem to drive realistic, sustainable, fast transition and decarbonisation? Energy Focus looks at the key messages and hot exhibitors from ADIPEC - the most anticipated event of the year.

Since 1984, ADIPEC has been a leading platform for discussion, innovation, knowledge sharing, and progress in the energy industry. In that time, the world’s energy conversation has changed considerably. Fuelling the development of society with fossil fuels is a concept that has been and

is set to be gone, but the managed transition will take time. Renewable energy, closed loop systems, and driving down environmental impact is the new conversation – and the new source of opportunity.

In October, Abu Dhabi will again host the brightest, best, and biggest in energy from around the world, this

year focusing on the question – how can we decarbonise, faster, together?

To answer the call as best as possible right now is an unrivalled list of speakers from the global community. Nowhere else in history has a more impactful group of industry peers joined to make things happen.

Abu Dhabi, the largest of the

PRODUCTION: Sam Hendricks

United Arab Emirates, will hold the event with ADNOC (Abu Dhabi National Oil Company) the official host company.

“ADIPEC is a powerful global platform that can help present the possibilities of a more inclusive approach by welcoming the solutions and skills of the energy industry today,” said His Excellency Suhail Mohamed Faraj Al Mazrouei, Minister of Energy and Infrastructure United Arab Emirates.

“ADIPEC 2023 will be a progressive force for energy transformation and leadership,” said Tayba Al Hashemi, CEO of ADNOC Offshore and Chair of ADIPEC 2023. “It will unite the expanding and increasingly diverse world of energy and help us work together to transform, decarbonise and futureproof our industry, by accelerating the innovation and tangible actions needed to enable a lower carbon and higher-growth future for the world.”

While the nature of conversations around the world’s energy mix have changed, the mix itself has remained relatively constant. While decreasing slightly, coal still makes up almost 37% of total electricity generation (40% in 1971). Natural gas makes up 23% and nuclear 10.3% (13% and 2% respectively in 1971), with oil the only fuel to significantly decrease over the period (21% in 1971 down to 2% in 2019). Renewables have gained traction climbing around 3% to reach 26% of global generating capacity.

But in the UAE, the oftenoverlooked progress has been phenomenal. Abu Dhabi-based Masdar, established in 2006, is now one of the world’s most significant renewable energy companies, pioneering wind and solar around the world. The UAE is home to the world’s three largest and lowestcost single-site solar plants and the first

Arab country to operate zero-carbon nuclear power that will supply 25% of the nation’s electricity demand by 2024. Also an early adopter of hydrogen technology, the region hopes to be a leader in this fuel of tomorrow. Today, as one of the world’s top contributors to the energy transition, according to the Gren Future Index 2023, Abu Dhabi is an example to follow.

At ADIPEC, more than 160,000 people from more than 2200 companies will come together to define the future of energy. Guest speakers across the various conferences and sessions include Wael Sawan, CEO Shell; Patrick Pouyanné, CEO TotalEnergies; Dai Houliang, Chairman CNPC; Bernard Looney, CEO bp; Claudio Descalzi, CEO

Continues on page 10

Continued from page 8

innovation, utilisation of modern energy finance, and advancing progress in developing markets.

and accelerating the development of new technologies,” he said.

Key topics up for debate will include new technology, decarbonisation through

Thomas Storch, MD at Affinity Partners, reminds that 775 million people – predominantly in the global south – still live without access to electricity. Innovation is the key to the problem, but innovation costs money. “Because the private sector is often reluctant to invest in technologies that are not yet proven, government funding plays a critical role in bridging the financing gap

But government funding alone is not enough, and forming and rolling out public-private partnerships PPPs, while effective, takes time. “If we want to accelerate the energy transition, stimulating conversations and collaboration between the energy industry, the finance industry and global policymakers is essential. These dialogues have never been more important, as we increase our ambition to tackle the twin challenges of energy transition and energy security.

“Ultimately, while words and pledges can be impactful in signalling policy goals, finance and investment are the key drivers of a sustainable energy future,” says Storch.

Christopher Hudson, President of dmg events – organisers ofContinues on page 12

// IF WE WANT TO ACCELERATE THE ENERGY TRANSITION, STIMULATING CONVERSATIONS AND COLLABORATION BETWEEN THE ENERGY INDUSTRY, THE FINANCE INDUSTRY AND GLOBAL POLICYMAKERS IS ESSENTIAL //

Continued from page 10

ADIPEC – states that technology cannot be underestimated. “Critical to accelerating innovation in decarbonisation is technology. New and improved technologies will enable

industries and companies to reduce emissions, improve efficiencies, reduce environmental impact, and enhance production, collectively allowing us to stay within the 1.5⁰C warming threshold set by the United Nations.” Recognition that speed of progress

has to be increased is essential and this is why dmg events decided to highlight decarbonisation as such a strong theme for this year’s event.

“By platforming the collaborative and innovative technologies that will be integral to a secure, lower-carbon future, ADIPEC 2023 is contributing to the advancement of decarbonisation in support of the global energy transition for a brighter and more sustainable future for all,” says Hudson.

CEO at Uganda’s National Oil Company, Proscovia Nabbanja agrees that progress must hasten but focus must be shared with developing nations which face added pressure from around reducing emissions at the expense of their own development.

“Supporting an equitable energy transition through clean energy in the developing world is crucial

for combating climate change and achieving sustainable development,” she says. “These efforts contribute to poverty reduction, improved health, and inclusive growth. By investing in clean energy, developing countries can enhance energy security, decrease reliance on fossil fuels, create jobs, and foster economic growth. The international community, private sector, and governments must all play a role to support the energy transition in the developing world.”

Some of the world-leading companies demonstrating innovation at ADIPEC include Unique Group - expert in diving, buoyancy, unmanned surface vessels, and surveying – which is opening a new facility in Saudi Arabia to support growth in the Middle East, and Reflex

Marine – the leader in offshore crew transfer technology by crane – which is launching its latest product range with improved safety and technical performance. New Oil Generation will also be displaying its new method of enhanced oil recovery through exothermic chemical treatment, retrieving heavy oil with unique chemical reactions. Global majors, including bp and Shell, continue to diversify product portfolios and investments and both are now more exposed than ever before to renewable energy sources, both in upstream and across the supply chain. The landscape is complex and remaining close to the conversation is now more important than ever for those looking to grow in the ever-changing sector.

You can sign up to register for ADIPEC here. And you can

register as a delegate here.

This year, under the scorching desert sun, as the world continues its dynamic transformation towards sustainable energy solutions, ADIPEC stands as a beacon of hope, knowledge exchange, and collaboration, promising to unveil groundbreaking insights and innovations. Against a backdrop of rapidly shifting paradigms in the energy landscape, ADIPEC 2023 comes at a pivotal moment. As we navigate the complexities of an evolving industry, ADIPEC remains the compass that guides us toward a brighter and more sustainable future, driving the need to decarbonise faster, together.

Lamprell’s purpose has long been to provide best-in-class project services and solutions for the energy industry, and a recent reorganisation has resulted in an increased focus on the group’s strategy and part in renewables and the energy transition while it continues to support its core oil & gas business segment. The result is that Lamprell is doing its bit to best align with customer needs and enable optimum access to opportunities in its core markets.

//Lamprell enjoys more than 45 years’ experience in delivering world-class projects to the international energy industry, since its establishment in 1976. A leading provider of EPCI contracting services, the company drives strategy and growth through its renewables and oil and gas business units.

Underpinned by almost half a century of expertise, and staffed by more than 5,000 people through its primary facilities in Hamriyah, in the UAE, and those in Saudi Arabia, Lamprell has tirelessly established its reputation for delivering projects safely, to the highest standards of quality, on time, and to budget.

Lamprell has set about transforming its business to thrive in the energy transition, offering foundation fabrication and other services for the offshore wind sector alongside activities in its traditional oil & gas segment

including the delivery of modules, platforms and rig construction and refurbishment projects. “Over the years, we have gained a foothold in energy markets with significant barriers to entry,” explains CEO Ian Prescott, “and we continue to evolve the business to deliver more sustainable and differentiated solutions.” “The world around us is changing, and the way that we think about energy is changing, too.”

For a very long-established player in the Middle East, this represented a significant change in direction, Prescott underlines. “As with many other EPCI contractors, the company has been through some hard times in recent years,” he admits. “Lamprell failed to win sufficient business and ended up becoming financially distressed. Our major Saudi Arabian shareholders started acquiring Lamprell’s shares on

the open market, which were listed on the London Stock Exchange. They took a controlling interest in late August and then decided to delist with the process being completed in October last year.”

“Lamprell is now a private company, the shareholders have put in place a new Board of Directors, to reflect the new ownership structure, and the Board has in turn refreshed the management

// LAMPRELL CONTINUES TO ACTIVELY TARGET THE GROWING RENEWABLES INDUSTRY IN ITS TRADITIONAL MARKETS AS WELL AS NEW GEOGRAPHIES //

Ian Prescott, CEO

team with highly experienced individuals from the industry.”

“These are hugely exciting times, and we can all see the potential in the company; we are in fact starting to realise some of that potential already. We are under new ownership with new direction, have a new Board as well as new and energized management team, and we want to share that news far and wide.”

Extensive renewables experience has already allowed Lamprell to build several multi-purpose jackup vessels and hundreds of wind turbine substructures including jackets, suction buckets and piles, with a multi-billion dollar bid pipeline of renewables projects in the offing. The company is also currently delivering 62 transition pieces through its renewables production line. “A major part of the company’s new direction

was to invest in what we have called our ‘growing line’, a production line to cater for the serial fabrication of monopiles and transition pieces for the offshore wind sector,” Prescott adds. “Things like this are what make us, quite frankly, the best-kept secret in the Middle East, and certainly in the renewables sector. We have this capability, and we now want to share it with the Industry.

“We have revitalised the business development area of the Group,” Prescott emphasises, “and our pipeline is looking incredibly healthy. I doubt that there is a renewables project where we do not have some involvement in our addressable markets.”

In Lamprell’s oil & gas business, recent business development efforts have paved the way for the likes of the award in August by the National Petroleum Construction Company

(NPCC), for the fabrication, painting, and load-out of five offshore jackets and boat landings with an optional scope, including the supply and fabrication of grillage and seafastening of the structures.”

“With an overall fabrication weight of almost 14,000 tonnes, we are approaching this project with the same passion and determination that have fuelled our achievements in the past to ensure we deliver an outstanding project safely,” Prescott reiterates. “This is an important project award which serves as another indication of the progress Lamprell is making through its key strategic partnerships in the Middle East region.”

This is an interesting situation for Lamprell, Prescott stresses, in partnership with a competitor, but when the call came from NPCC,

Offer our customers top-tier equipment hiring solutions, all while ensuring affordability, and empower our skilled workforce to pave the way for a brighter future.

Lamprell was only too happy to assist. “We had the capacity, and were delighted to support this significant project. We are well underway with the engineering and have already done the first steel cut on the jackets; progress has been quite positive.”

Lamprell has in fact been a pioneer company in the renewables arena since the award in 2007 to build its first self-propelled multi-purpose vessel. By 2021, a total of 138 wind farm jackets, 90 suction buckets and 180 piles had been delivered for the East Anglia ONE, Moray East and Seagreen wind farms, while Lamprell also received the Middle East’s first green trade finance facility for the Seagreen project in 2021.

The group’s new state-of-the-

art renewables production line was called into service in 2022, this time in connection with Moray West offshore wind farm, to deliver 62 transition pieces, which Lamprell is currently executing. “This project is proceeding really well,” Prescott confirms, “and we are actually on the cusp of delivering the first batch of transition pieces as expected, on budget and with an outstanding health and safety record. We are also on track to meet the various forthcoming deliveries over the remainder of the year, ahead of the final batches within Q1 of next year.”

“Lamprell continues to actively target the growing renewables industry in its traditional European and UK markets as well as new geographies, including the USA, which continues to gain traction,” Prescott continues. “What sets us apart in particular is

the knowledge transfer that has taken place as we have redefined the business; everybody working on our renewables project and the production line today is a long-term Lamprell employee, employing the precision engineering which has always been our business and growing the knowledge share within the company.”

This deep well of knowledge and experience is part of what truly sets Lamprell apart, Prescott adds. “I have been hugely impressed by the people who we have within our business,” he beams. “This is the number one asset in any company like ours, and we have some incredible people. Over 1,000 of our total staff have been with Lamprell in excess of 15 years, a massive figure and a dedication which allows us to retain a lot of relevant, valuable experience to allow

us to execute these types of projects.”

A lot has been underway at Lamprell of late, and Prescott as CEO, in post since April this year, has hit the ground running. “I wanted to establish the new strategy for the company going forward,” he says. “We gathered together a broad-base spectrum of 15 employees for a strategy session which took place over two days, and the outcome of that was our key business pillars and fresh strategy to present to the Board. Each business pillar owner has presented a business case for expansion. Targets and goals have been discussed at length and presented. We are in the process of finalising this exercise, which has been the product of many long hours of work by our dedicated team, and getting the green light from the Board to proceed with the selected plans.”

Lamprell’s refreshed and reimagined direction coincides with the tremendous global growth in offshore wind, with an additional 200GW to be brought on stream by 2030 and a further 128GW by 2035. The positivity abounding at Lamprell has been mirrored in the evaluation of its work to date in this burgeoning field, Prescott shares. “The refreshing thing when we meet prospective renewables clients, who are a close knit group, is that when they talk to people who we are currently working with – such as Moray West’s owners, Ocean Winds, for example - the feedback is highly complementary. Now, increasingly, companies in Europe, and in the USA, where we have a number of opportunities, are looking at us to see what we can deliver,” Prescott reveals, and Lamprell

is unequivocally positioned to do so.

“We know that we are commercially competitive, and we have built a farreaching confidence around both the price and the quality of our product, all held together by an outstanding health and safety record - this is borne out of the oil & gas sector and improving day on day through the work with our renewables clients.” Prescott concludes. “We believe we can deliver a compelling offer and we are well placed to benefit from the many new prospects offered by the energy transition.”

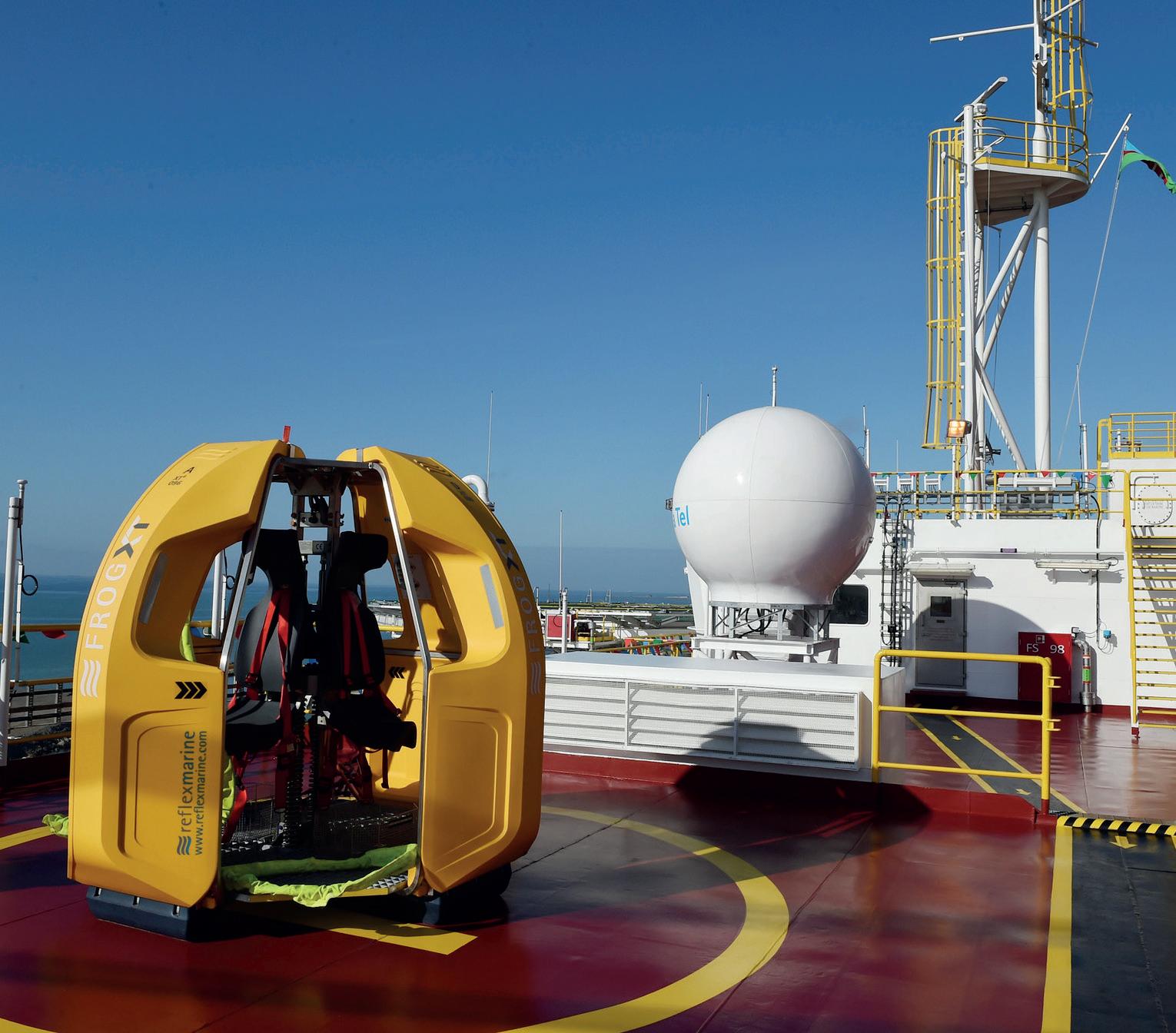

Reflex Marine is the leading designer, manufacturer, and marketer of crane-based crew transfer solutions in the offshore environment. COO Sandra Antonovic tells Energy Focus that the unending focus on safety will continue as the latest product updates are launched while the business looks to continue growing globally.

PRODUCTION: Tommy Atkinson

PRODUCTION: Tommy Atkinson

The perils of offshore work are well-documented. Waves, heat, cold, noise, hazardous materials, industrial equipment etc –the job is fraught with risk. But getting offshore to a vessel or rig should not be a threat. In few other careers is transport to work such a concern. But in the harsh offshore environment,

safety is always the priority as a commute is far from ordinary.

Typically, to get offshore for work on various energy installations or other sea-based infrastructure, helicopters of specially-designed crew transfer vessels are utilised. In deep water, far from shore this is often the only option. But when offshore, at an oil

field in the North Sea or at a windfarm in the Baltic Sea or at a gas well in the Persian Gulf, multiple installations make up the larger project and transfer or crew between platforms and vessels is essential. Helicopters are too expensive, and boats not logistically possible.

Reflex Marine, the Aberdeenheadquartered provider of crew transfer solutions, has designed and refined units for safe movement of people without the need for choppers or boats, and with human-wellbeing at the core. By utilising cranes to quickly and cost-effectively move people, clients can make significant savings while ensuring safety at all times.

“Most crew transfers are still done by crane,” explains Reflex Marine COO Sandra Antonovic. “Until fairly recently, crew would grab a rope hanging from a crane while the crane moves them across to another platform, hoping that they don’t let go and drop. The other option was a collapsible

basket which is a rope frame that hangs from a rope on a crane, again hoping that no one let’s go or slips.”

She highlights the scary scenes across offshore operations around the world where crew transfer was literally putting lives at risk. Employees would sometimes jump from the back of a vessel to a jetty at the base of a rig, with the waves pushing the vessel back and forward, bumping into the side of the structure. Scenes like this are not illegal but they are certainly not encouraged. This was the reason for the establishment of Reflex Marine in 1992.

“Statistically, helicopters are safe and there are very few accidents each year,” says Antonovic. “But it doesn’t seem like ‘very few’ if someone you know is in one of those accidents. We have not had a lost time incident, let alone a fatality, in 12 years. We are the only crew transfer option in the world

that has this safety track record.”

She adds that safety is the ultimate priority and everything else comes a distant second. For this reason, Reflex Marine has grown to become a global partner across multiple industry sectors, supporting more than 300 companies in 85 countries.

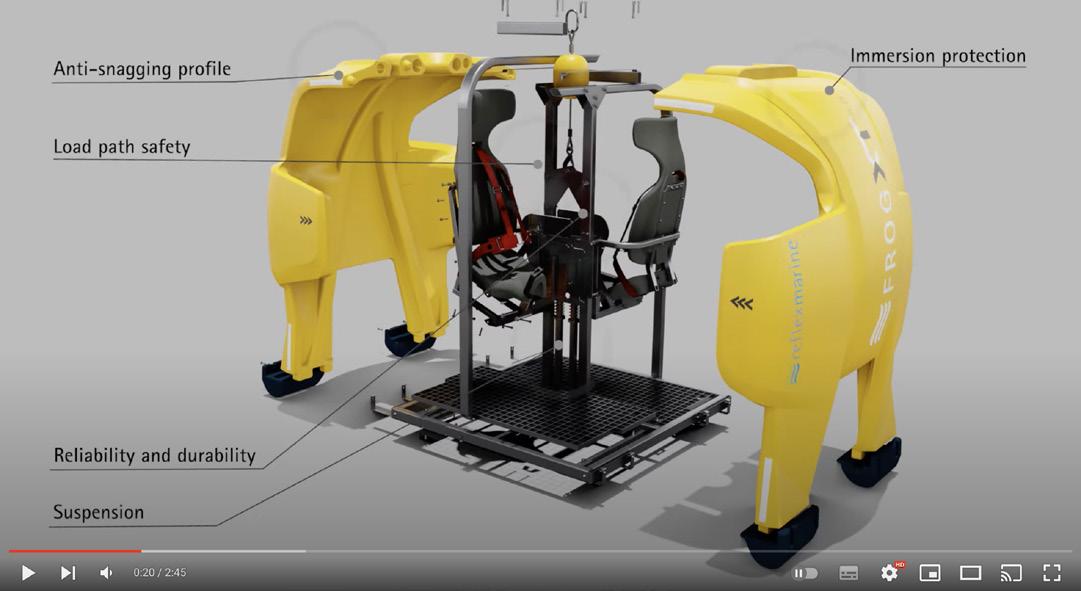

The product range is made up of the FROG, WAVE, STORM WORK, and other models. Each is a purposebuilt solution to move people and cargo offshore using a crane.

In Abu Dhabi, at ADIPEC, Reflex Marine will launch the latest iteration of one of its core products, especially popular in the Middle East. “We are promoting a new product which is an enhancement of one of our existing products. We are setting up an evening event for our clients and partners

and we are excited to showcase this product,” explains Antonovic.

The FROG, the first product in the company’s portfolio has been updated numerous times over the years. In 2013, a new model was released, capable of carrying four, six, or 10 people. Now, a fresh launch will see better materials and technologies that ensure safety and sustainability, while improving cost efficiency for clients who own.

“Internally, the focus is always innovation, research and development,” reminds Antonovic. “We are a forprofit company and we sell products, but we operate as a research and development department. We use revenue generated from sales to keep working on different new products and different solutions. We are constantly testing materials and theories, and we don’t have a large product portfolio because we spend around

20,000 hours designing and testing anything that goes into production. We particularly test the impact on the human body and the spine. We are always looking to make sure there are no injuries – not even bruises.”

Antonovic has used a Reflex Marine transfer system and likens it to a regular flight. You strap into a harness, you feel little motion, just a bump when the unit hits the deck, just like a plane landing. “It is very stable; you really don’t feel much.”

As well as being incredibly safe and

removing significant risk for operators, Reflex Marine saves cost where it is often unnecessarily be expended. “Helicopters are extremely expensive,” highlights Antonovic. “They make sense in deepwater, far from shore, where you want to take a medium-sized crew in the quickest possible time. Companies can pay tens of millions of dollars per year for helicopter transfer and there are a lot of circumstances where you don’t need helicopters and you can use a vessel and a crane.”

Safety seats, with hydraulic

suspension arms and heavy-duty harness belts, are surrounded by a high-strength buoyancy, supported by a stainless-steel structure. All components are standardised, and put together with ISO 9001:2015 certification.

“Inter-field transfer is difficult and there are often multiple installations where you need to move people. To use a helicopter here is extremely inefficient. Companies want a safe and cost-effective solution and helicopters cannot compete – especially considering weather limitations,” says Antonovic.

In the future, Reflex Marine will remain focussed on its innovative nature by constantly adapting and improving products as demands offshore change, always making the range stronger, safer, and more efficient. But Antonovic is keen on constantly increasing the

// WE ARE CONSTANTLY TESTING MATERIALS AND THEORIES, AND WE DON’T HAVE A LARGE PRODUCT PORTFOLIO BECAUSE WE SPEND AROUND 20,000 HOURS DESIGNING AND TESTING ANYTHING THAT GOES INTO PRODUCTION //

global footprint of the company. The former FMCG executive, with leadership experience in the finance and media worlds, has travelled extensively, understanding more about market potential and how Reflex Marine can support. Splitting the market into geographical segments, different products are in demand in different areas and diversifying risk by opening new sectors has been a key success for Antonovic.

“We have several markets that are equally important, generating equal levels of income - Europe, West Africa, the Middle East, Southeast Asia, and then slightly behind is the Americas,” she says.

“When the company was founded, the focus was only on offshore oil and gas as that was the general focus in the world. That has changed significantly, especially in the last 10 years, and we now have a very segmented market. We are still focussed on oil and gas, but we are now equally focussed on LNG and offshore wind.”

She adds that to mitigate against oil price crashes or energy industry turmoil,

Reflex Marine has differentiated itself to be a partner in industries away from energy. Navy, offshore civil engineering, fishing, marine research, and many more are key markets for the company.

“It has created sustainability for us as a company as it means we don’t depend on factors that we cannot control,” she explains. “Since 2015, we have added 30 more countries to our portfolio and we hope to continue building on this success.”

When Reflex Marine was founded three decades ago, there was an understanding that crew transfer is essential and that it would continue by crane. But the company could never accept that safety was neglected, and that nature has helped it grow to become a globally recognised organisation.

“There is now no need to move people with them hanging from a rope. We designed a product that transfers people by crane in the safest possible way, where they are as protected as possible,” states Antonovic.

The result? “From all the crew transfers that happen in the market

every year 50% is helicopters. We have around 10% of the global market. In offshore crew transfer by crane, you could say we are market leaders.”

Just one piece of the wider crew transfer universe, Reflex Marine’s products are expertly designed, manufactured, and marketed to overcome the challenges of clients. The brand has stood the test of time. The ongoing invention and development makes for a strong pipeline in the future. And the company’s people remain passionate about engineering safety.

To learn more about the newest enhancements in the product range, join Reflex Marine at ADIPEC where Antonovic and colleagues invite the industry to a product explainer, detailing how a partnership can make your operations safer.

Visit Reflex Marine at ADIPEC 2023, stand 8415.

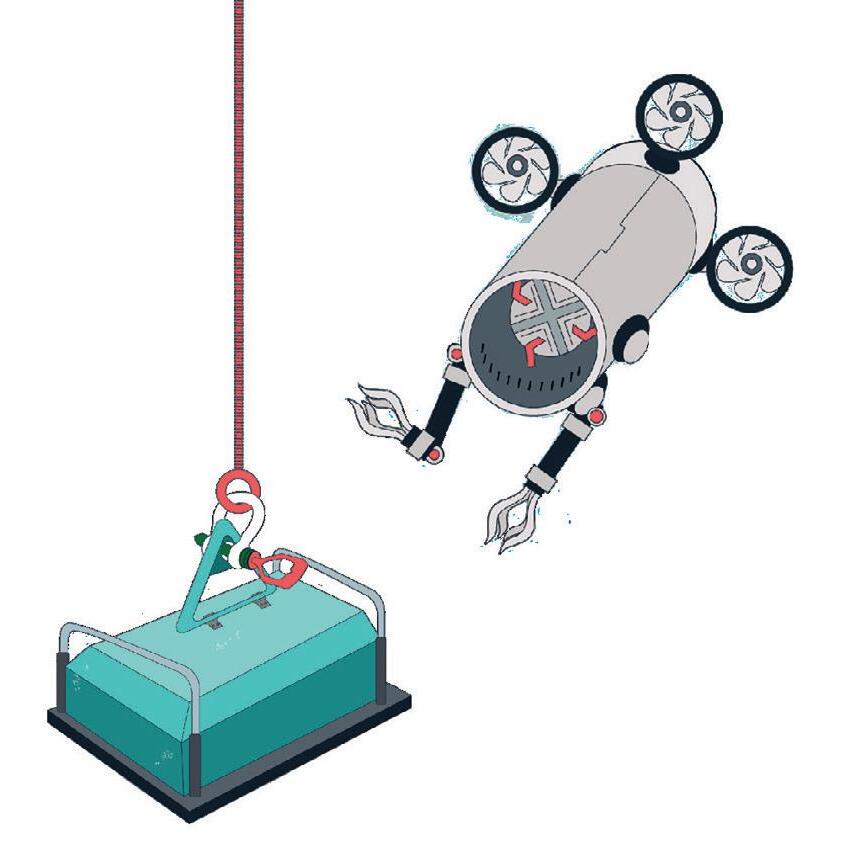

At Unique Group, a spirit of exploration endures after 30 years, as the company develops technology and engineering solutions to complex ocean and subsea challenges. COO Martin Charles tells Energy Focus that the company is expanding with a new facility in Saudi Arabia, supporting the Kingdom’s energy industry, while growing its vast product and service range around the world including an AI solution.

PRODUCTION: David Hill

PRODUCTION: David Hill

Martin Charles, COO

Martin Charles, COO

//When COO Martin Charles joined Unique Group 18 months ago, his vision was to build on the stellar reputation of the international subsea technology and engineering business. 18-months into his challenge and he is delighted with progress, amazed at how far the company has come in such a short span of time. Praising the “phenomenal team” for adopting a culture of continuous improvement, Charles is confident that the portfolio on offer will allow Unique Group to embed itself deep within client operations, becoming integral in projects that are so vital.

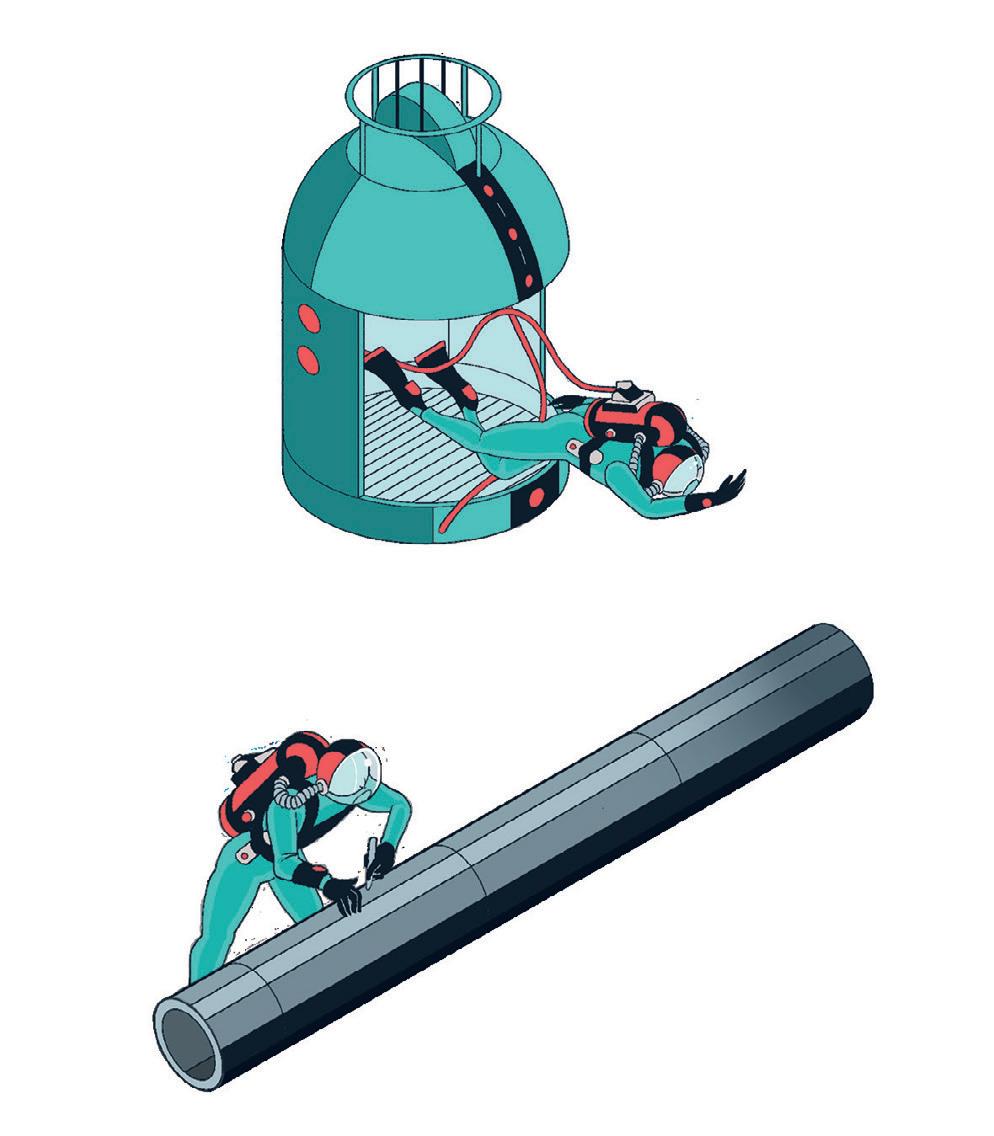

“We have four core lines of business that have been operating under Unique Group for 30 years, headquartered in the UAE. Those four core lines are Diving and Life Support Products, Survey Equipment, Unmanned Surface Vessels (USVs), and Buoyancy and Water Weights®,” he says.

All globally relevant and accessible, and all supported by strong Research

Gandhi since the establishment of the company in 1993. Initially, he saw the potential to build an electronic equipment company catering to the wider subsea industry with a major focus on oil and gas industry and began with three employees.

Today, the company is home to more than 600 experts and is certified by multiple global standards agencies.

“We have manufacturing sites in Cape Town and Sharjah for the diving business, and our Buoyancy and Water Weights® manufacturing site is in the Isle of Wight, UK. We operate out of four global regions, with 18 operational bases within these regions, and we are growing aggressively,” says Charles.

He highlights Saudi Arabia as a key market. “We are increasing our footprint by two thirds and looking to double the workforce.

“We moved into a new facility in August and that will support all four of our product lines which are growing in this region. From here, we will support

Unique Group acquired the facility in January and has spent time perfecting the space. A brand-new workshop area is complemented by state-of-the-art facilities, and Charles expects further investment as interest across the company’s products and services range booms.

“We will have a number of our USVs and a large survey division there. Buoyancy and Water Weights® is very active in Saudi Arabia, as is the diving division. We have secured a number of contracts recently and, as such, we need to invest in our diving facilities and stock holdings further,” he says, adding that Saudi Arabia and the Middle East are the strongest growth regions for the company right now.

Unique’s founder, Harry Gandhi, has always been keen on the region, seeing the growth potential and establishing the company in Hamriyah Free Zone, Sharjah, to take advantage of the major opportunities. “The Middle East represented the perfect place to set up an organisation. We started building the business in the Middle East, as we grew over time and became more successful, we started expanding to other global markets implementing the same business model,” he says.

Recent case studies prove the value of Unique Group products and services. The company was established to bring about change in the industry through excellence. “I envisioned a company that would stand out for its commitment to excellence, innovative products, and long-term client relationships.” says Gandhi.

In Qatar, during the pandemic, Unique Group was on hand to perform recertification and preventative maintenance operations on lifeboats. Performing in an offshore environment and requiring bespoke engineered solutions to make the recertification possible, Unique Group utilised a range of skills in its portfolio to delight the client, a large petroleum company.

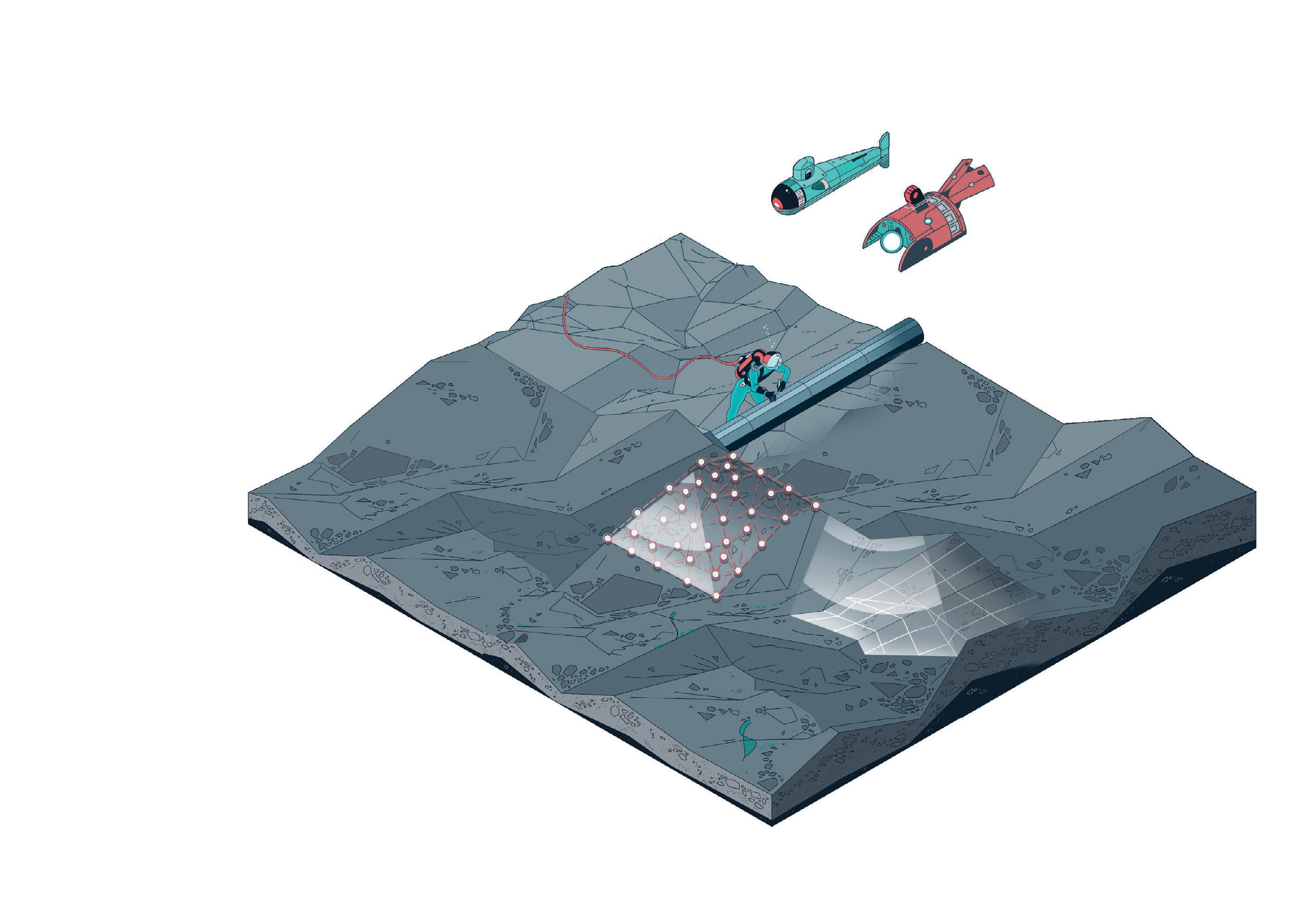

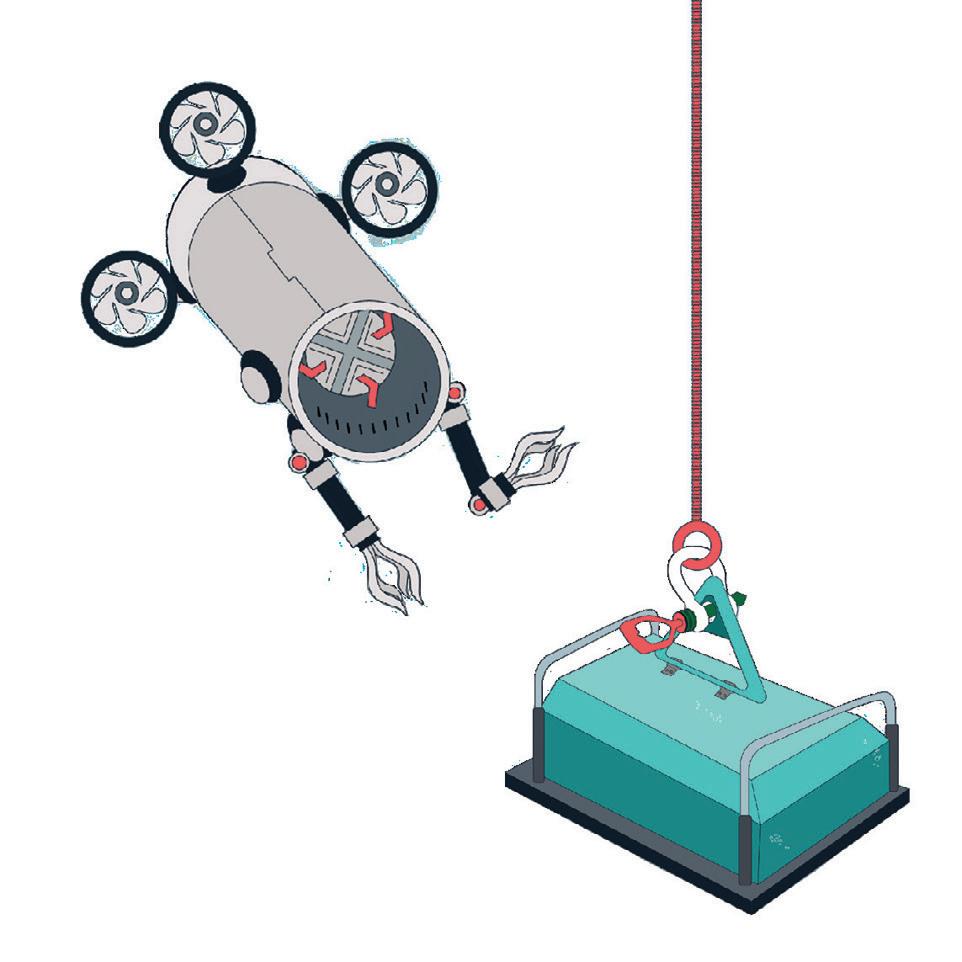

Uni-Pact, one of Unique Group’s leading USVs, is a small and light unmanned solution (length 3 m, beam 1.6 m, draft 0.45 m and weight 412 kg) that is adaptable for various applications. It can be used to support a wide variety of nearshore projects, such as hydrographic surveys, data harvesting, UXO (unexploded ordnance) surveys, coastal and harbour monitoring and mapping, habitat mapping, seabed mapping and classification, data harvesting and survey of freshwater reservoirs where the use of petrol and diesel engines is prohibited.

The Australian Institute of Marine Science (AIMS) partnered with Unique Group to perform a carbon-conscious bathymetric survey at Cape Ferguson in April 2022 for an upcoming jetty extension project. The goal was to acquire bathymetry data for seabed modelling. Unique Group’s Uni-Pact USV was selected as the autonomous survey vessel to meet the client’s requirements.

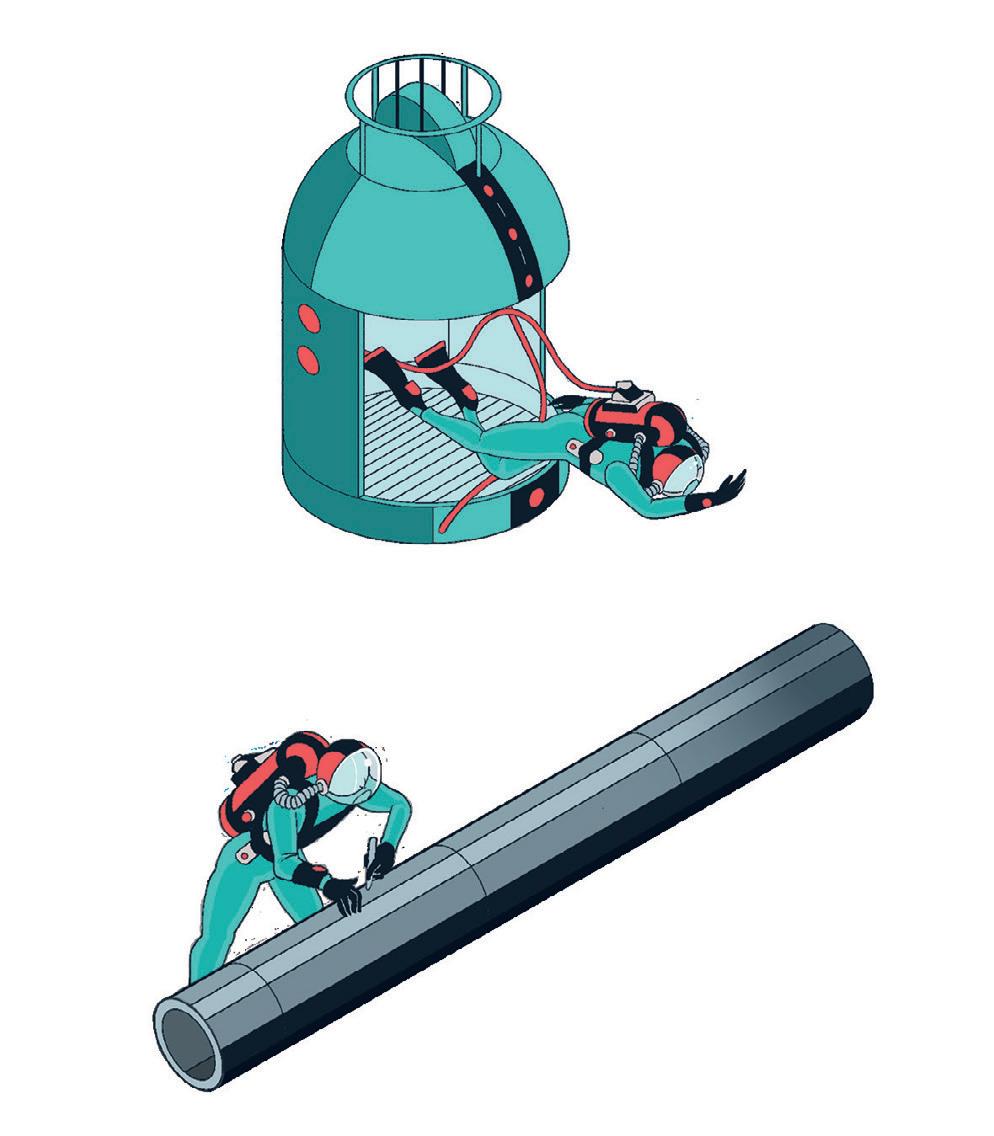

In Dubai, Unique Group worked on the deepest dive pool in the world, supplying two 316L stainless steel

static wet bells – comprising a pressure vessel, a control panel and supply and monitoring umbilicals – and installing underwater. The company also completed the surface control system, with everything completed to IMCA and ASME standards. The company’s Buoyancy and Water Weights® division recently completed a 1760 MT load test on a derrick crane in the UAE, using 18 Water Weights® and Seaflex WaterLoad bags of capacity 35t, 100t and 110t - the largest water bag available on the market. Another UAE project saw Unique group safely place 1200m HDPE piping on the seabed composed of silt, gravels sand, and sandstones using concrete sinkers. The cost savings and efficiency provided by an integrated approach from the Unique Group buoyancy and Water Weights division and engineering personnel left the client delighted.

“The solutions we can achieve for our clients by delivering synergy and turnkey solutions, looking at cost and environmental impact, are remarkable. We have that global

footprint, and we are well-positioned to tap into resources and strong intelligence-base,” says Charles.

“Seeing our products and services make a significant impact in the industry brings immense satisfaction,” adds Harry Gandhi.

Expertise across multiple sectors is a key strength for Unique Group. Charles – a mechanical engineer with history in executive management, and subsea products and services across offshore wind and oil and gas - is eager for the company to further entrench cross-division projects activity and knowledge sharing in a bid to offer more to customers.

“Our distinct lines of business and the synergies we can leverage across those lines is a differentiator,” he says. “We have very different, bespoke expertise to tap into across the range. Our agility around that – all inhouse capability – combined with our decision making is exceptional.

“We are driving mobility through

our HR teams,” he adds. “With the advent of improved communications, and a transparent approach, we are moving people around different parts of the world, maintaining their work environment with Unique while being linked into various initiatives and progress plans, we have in place.”

For Harry Gandhi, creating an environment where people can thrive and deliver their best work has always been a core focus. When he started the company alongside just two colleagues, his approach was to create a culture of loyalty which in turn has led to substantial growth and client satisfaction.

“We have always strived to provide the best, and the continued support of our team has been instrumental in helping us achieve our goals. Together, we have overcome challenges and celebrated victories, and I am truly grateful for the strong

bond we share as a team.” he says.

There have been challenges along the way, he says. “We navigated the complexities of regional legislations and regulations, ensuring compliance and maintaining a knowledgeable team to support operations across multiple countries. Finding the right talent has been another hurdle, but through investment, acquisitions, training, and fostering a positive work culture, Unique Group has attracted top talent and ensured a commitment to quality and technical expertise.”

This expertise is helping the company to continue on its growth path, with multiple sectors now recovering following a Covid-slump. Diving and Life Support related products and services, and the medical technology Hyperbaric Oxygen Treatment Chambers have been particularly strong, and Charles is happy with the way forward in

these two industries where Unique Group provides products that truly live up to the company name.

“Diving and Life Support is an interesting division right now,” he says. “Since the pandemic, we have seen some excellent growth and lots of opportunities in traditional oil and gas, renewables, and defence. We have seen this market come back very strongly. We are in the middle of development of a significant project for the Indian navy with built-in-India dive support vessels where we are delivering the full saturation dive system. We are using lots of new technologies and new developments on this project and for this market. There is a lot of IP around that which we expect to leverage across global markets.”

The company’s order book in the medical technology space is also

Continues on page 32

Continued from page 30

exciting with multiple applications for medicinal enhancement using Unique Group dive chambers. “That market was really challenged through the Covid period, but we are seeing it come back with strength across all our sectors,” says Charles.

“We have a number of product developments and solutions that will be taken to the market later this year. In September, we have launched a state-of-the-art generative AI chat solution – Aquila Subsea, which is set to revolutionise the industry by providing instant and accurate responses to a wide range of queries related to marine survey, empowering survey engineers and researchers to swiftly understand manuals, troubleshoot issues, and access critical information.”

Aquila Subsea marks a monumental leap forward as the first-ever generative AI chat solution tailored specifically

for the subsea survey industry. By harnessing the power of artificial intelligence, Unique Group is delivering an unparalleled value addition to survey engineers and researchers, facilitating rapid resolution of technical challenges. With its comprehensive repository of manuals, data sheets, and manufacturer’s information, the AI platform guarantees precise and reliable solutions for queries of all complexities, providing access to a Knowledge Repository with over 10,000 Survey Equipment solutions. Unique Group is excited to announce that limited signups to access Aquila Subsea are now open.

Success in supporting these varied industry sectors sees Unique Group rely on a diverse and widespread supply chain which is thoroughly vetted and examined to ensure efficiency as well as environmental impact. The company is

ambitious for continuous improvement and has adopted consciousness of environmental impact as a core value.

“We take it seriously,” confirms Charles, referring to the nature of the company’s work and its environmental effect. “Our focus on products and services such as unmanned surface vessels support our aims of delivering environmental enhancements to support turning our industry greener than it has been.”

He says that the supply chain spend is “enormous” and this is part of the driver behind an enhanced quality management system focus. Ultimately, Unique Group must deliver cost effective solutions for projects and clients, and this is not about being low cost – “It’s about quality and timing,” says Charles.

“We are looking at expanding our supply chain and elevating it within the group to drive focus and visibility,” he adds. “We want to improve terms

and deliverables to be lean across the business. We have a range of initiatives going on and we are always focused on continuous improvement.”

The enhanced quality management system, which Charles champions as game changing within UG, is encouraging efficiency with every decision. “We are delighted at the uptake and the trend identification and outputs from the system that is supporting driving change,” he says. “It’s all about operational excellence – improving schedules and terms,

driving out waste, enhancing quality, and improving solutions and cost for our clients is a significant step change that will deliver real improvements through 2023 and beyond.”

In the Buoyancy and Water Weights® division, supporting green energy is a key focus and innovation is underway to ensure the company is a strong partner to the wind energy industry. By providing floatation devices for power cables and floating wind facilities, Unique Group calls on its core competencies but is adapting for new scenarios. As well as building on the green energy effort, these initiatives also support efficiency and risk reduction strategies.

“We have some solutions that we are really eager to present to the market. It is a genuine attempt to be part of the energy transition through the products and services that we have right now, with a step change.” says Charles.

In just 18 months, the COO has enjoyed a fast pace and an agile environment as well as embracing the clear opportunity for synergy across the group. Through this, clients have

been delighted and the company’s reputation – started by Harry Gandhi in 1993 – has been advanced. Earlier this year, the company also announced the appointment of Sahil Gandhi to the position of Chief Executive Officer (CEO), succeeding Harry Gandhi, who will now assume the position of Chairman of the Group. With Sahil at the helm, Unique Group is poised to achieve even greater success and drive innovation in the subsea technology sector. The future is equally as exciting as the past 30 years.

“We are still looking at organic developments, and we have some great innovations underway right now, but we also have an eye on the M&A marketplace to complement our existing services and platforms,” Martin Charles concludes, adding that Unique Group will always go beyond the conventional to deliver for clients and create a positive impact.

// WE HAVE SECURED A NUMBER OF CONTRACTS RECENTLY AND, AS SUCH, WE NEED TO INVEST IN OUR DIVING FACILITIES AND STOCK HOLDINGS FURTHER //

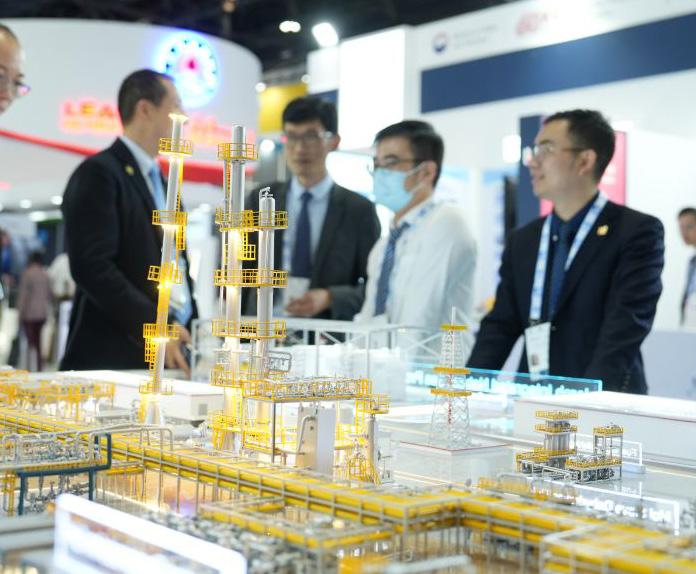

Qatar-based New Oil Generation, a joint venture between a Czech R&D company specializing in ground-breaking Exothermic Chemical Treatment (ECT) technology and industrial visionary Muhammad al-Misned, is spearheading a transformative approach to sustainable and efficient heavy oil extraction. Their mission is to revolutionize the oil industry by emphasizing profitability and sustainability through the implementation of advanced ECT technology.

PRODUCTION: Tommy Atkinson & New Oil Generation

PRODUCTION: Tommy Atkinson & New Oil Generation

As conventional oil resources diminish worldwide, the significance of vast heavy oil reserves as a future energy source is escalating. Heavy oils now account for approximately 70% of all liquid oil estimates. With conventional Enhanced Oil Recovery (EOR) methods, extraction of these resources has been a challenge, if not a hindrance in terms of profitability, efficiency

and sustainability. Most of the EOR methods increment the environmental footprint, rendering entire extraction operations questionable. Despite the odds, New Oil Generation is introducing a game-changer.

The underlying principle behind thermal EOR methods is to reduce viscosity by introducing heat into the reservoir. However, these methods typically require steam generation on the surface and subsequent injection into the reservoir, resulting in significant energy consumption. Furthermore, they entail high capital investments in steam generation infrastructure, specialized well completion, and terrestrial steam pipelines with heat insulation. This accumulates not only costs, but also carbon footprint with all the necessary construction.

Enter New Oil Generation—a research and development and oilfield service company specializing in innovative EOR technologies. Their ground-breaking ECT technology offers an alternative solution that eliminates the need for further infrastructure development, minimizing the environmental footprint while maximizing profitability. As co-founder, Muhammad al-Misned explains, “ECT provides a comprehensive solution for oil producers facing economic, technological, and environmental feasibility challenges in heavy oil extraction.”

“We use our own in-house developed technology that utilizes binary mixtures of chemicals injected into the wellbore. This thermochemical stimulation generates heat, nitrogen

// HEAVY OILS NOW ACCOUNT FOR APPROXIMATELY 70% OF ALL LIQUID OIL ESTIMATES //Muhammad al-Misned, Co-founder

gas, and pressure in the reservoir, thereby reducing oil viscosity and increasing reservoir pressure,” Jakub Hodinář, the Czech co-founder and brain of the operations details. “Unlike conventional EOR technologies, ECT employs chemicals that generate substantial heat directly within the

reservoir, resulting in minimal energy losses and a reduced carbon footprint in terms of energy and water usage. One of the key advantages of ECT technology is its elimination of the need for surface facilities and steam generation, leading to improved energy efficiency, cost-effectiveness,

and reduced environmental impact.”

New Oil Generation uses a computer-driven modular platform with surface pumping system and command and control unit with integrated sensors on the bottom hole assembly. This technology set-up is mobile, easily and rapidly deployable anywhere, thus not aggravating environmental impact of the upstream operations.

ECT technology aligns perfectly with the oil sector’s increasing focus on sustainability and environmental protection. As Jakub Hodinář highlights, the industry faces growing pressure to adopt cleaner technologies and address greenhouse gas emissions and water scarcity concerns. ECT meets these challenges head-on by

// ONE OF THE KEY ADVANTAGES OF ECT TECHNOLOGY IS ITS ELIMINATION OF THE NEED FOR SURFACE FACILITIES AND STEAM GENERATION, LEADING TO IMPROVED ENERGY EFFICIENCY, COST-EFFECTIVENESS, AND REDUCED ENVIRONMENTAL IMPACT //

providing a high level of environmental protection without further depleting water resources. The binary mixture used in ECT is specifically designed to be environmentally safe, without any dangerous chemicals or residues.

ECT represents the new generation of Enhanced Oil Recovery methods—a green technology

combining environmental responsibility with technological advancements and robust production impact.

The overall efficacy of ECT has quickly gained recognition, challenging established steam-based thermal EOR methods such as SAGD and CSS.

ECT technology has garnered interest from National and International Oil Companies (NOCs and IOCs) across various territories. Its applicability is not limited by technical constraints, allowing for implementation anywhere in the world where heavy-oil extraction, low recovery factor and decreasing production is an issue.

New Oil Generation has dedicated significant efforts and expertise to advance ECT technology, transforming it into the preeminent state-of-the-art tool for EOR of heavy crude oil reservoirs. With more than 15 years of research, development, and field-testing, ECT has proven its efficacy and safety. They offer comprehensive EOR services, including reservoir and well analysis,

// LIKE IN PRECISION AGRICULTURE, YOU HAVE TO KNOW WHERE, WHEN AND HOW YOU NEED TO USE YOUR LIMITED RESOURCES TO KEEP YOUR REQUESTED PRODUCTION RATE WITH LOWEST COSTS //

field deployment of ECT technology and operational management, posttreatment monitoring, consulting, and evaluation. The latest SmartFieldTM ECT solution enables even a long-term technology deployment combined with subsurface data collection, evaluation and more precise EOR operation planning. “Like in precision agriculture, you have to know where, when and how you need to use your limited resources to keep your requested production rate with lowest costs. SmartFieldTM ECT gives you both the knowledge and capability to plan costs, act just-in-time and effectively,” sums co-founder Muhammad Al-Misned.

ECT provides a compelling alternative to traditional thermal

EOR methods, ensuring the highest possible recovery factor sustainably. Muhammad al-Misned encapsulates its value, stating, “ECT offers heavy oil producers using simple, unsophisticated extraction technologies the opportunity to improve efficiencies across the board. High level of mobility of our technology means low and flexible operational costs for our clients. Removing the steam from the stimulation process brings long term sustainability and effectivity of production even in regions with extreme lack of water resources. No waste of water, no greenhouse gas emissions during operations anymore. This is exactly what the world public, company

shareholders and investors expect from the new generation of upstream technologies. We did our job well.”

ECT technology is set to reshape the heavy oil extraction landscape, providing a sustainable, cost-effective, and environmentally friendly solution for maximizing production and minimizing the industry’s environmental footprint. New Oil Generation’s commitment to innovation and efficiency makes ECT the optimal choice for heavy oil extraction in the 21st century.

PRODUCTION: Joe Forshaw & Aaron Protheroe

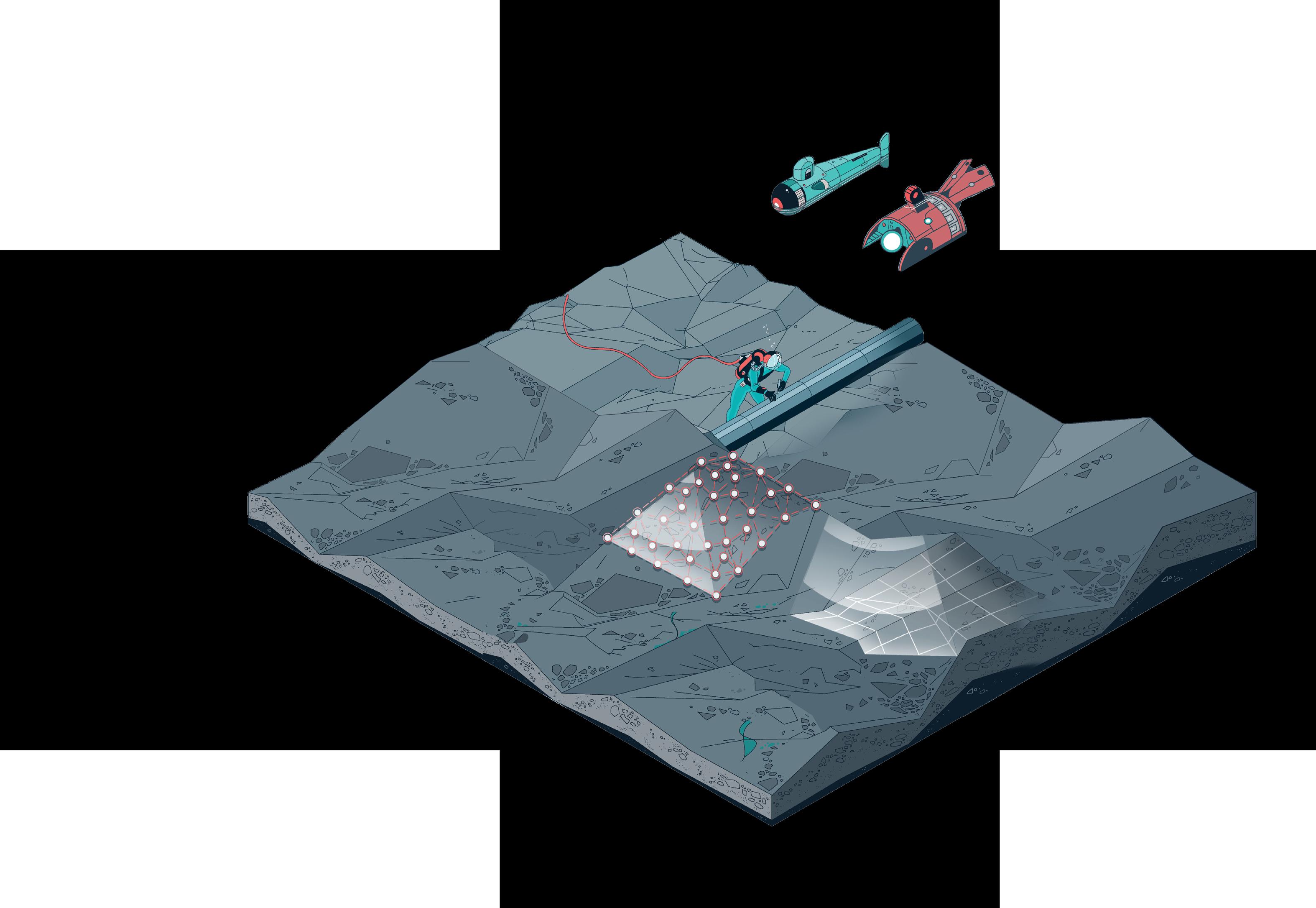

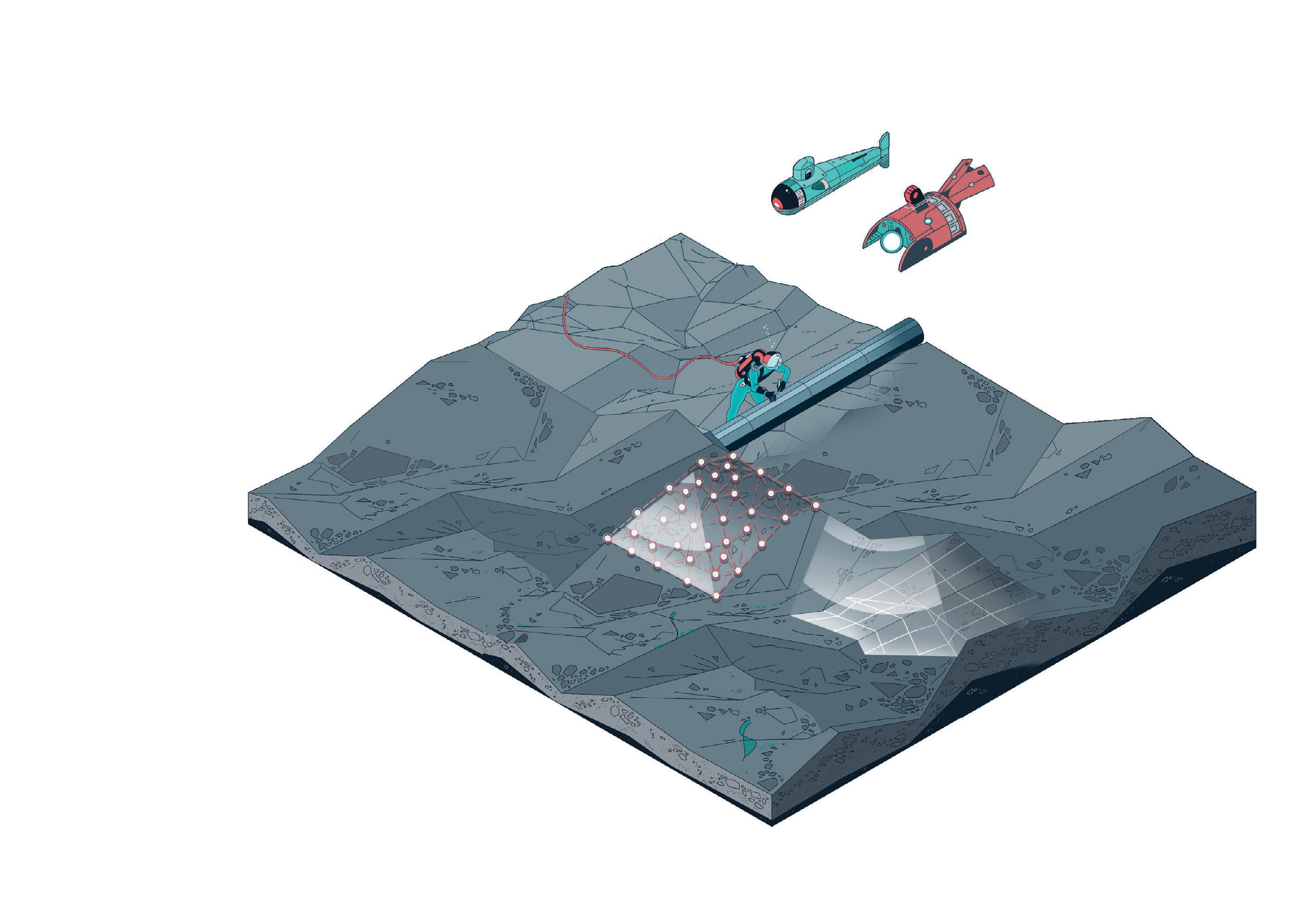

A world-class innovation from ScanTech Offshore is helping to double capacity while more than halving the footprint on a vessel as the company launches its ST3100 air compressor which delivers Class Zero, oil free air for big bubble curtain applications around offshore wind farm developments. VP of North America, Barry Craig tells Energy Focus about expansion in the growing US market.

The potential of offshore wind as a green energy source is unmatched. The IEA suggests that worldwide, offshore wind could provide around 36,000 TWh of electricity each year – close to the total projected global demand for electricity in 2040. The industry is expected to become a US$1 trillion (£800 million) sector in the coming decades, and world-leading economies including the US are set to realise the booming potential of the wind energy market. In 2018, US electricity demand was

4,011 TWh but the potential of offshore wind was calculated at 8,086 TWh. Turbine technology is getting bigger and cheaper, and regulation is paving the way for sustainable rollout.

In the US, where 30GW is targeted by 2030, less than 0.5GW is currently installed, but that is changing. Project developers are continuing to search for exciting opportunities and a robust supply chain is being developed.

From north to south, all the way down the US East Coast, offshore wind farms are proposed or already

planned. To ensure the public benefit from not only the green energy that will come, the Jones Act enforces the deployment of local vessels and workforce (where possible) to carry out construction activities.

James Fisher and Sons, headquartered in the UK, and its subsidiary ScanTech Offshore, has an existing operation in Houston, Texas, and recently expanded to Providence, Rhode Island to further support the nascent US offshore wind industry. It is also expected in 2024 that further

expansion of supporting facilities will be opened across the North-East Coast of the US. These operational bases will provide in-country support of ScanTech Offshore’s world-class bubble curtain air delivery packages.

In 2018, ScanTech Offshore – a company with a strong history in well-test and support for the oil and gas industry – diversified and entered the renewables market, exploring opportunities for the deployment of its specialist air compressor units. Through bespoke technology which was carefully engineered to be powerful but stackable on a vessel, ScanTech Offshore air compressors quickly became recognisable across the energy sector as a reliable, premium product.

Engineers at ScanTech Offshore sites in Aberdeen and Great Yarmouth quickly saw the potential of air compressors in wind energy, supporting the idea of the bubble curtain – a barrier that surrounds the piling of wind turbine foundations with bubbles to attenuate noise and protect marine wildlife. Air is sent down a hose to a flexible hose system, which is pre-laid on the seabed with special

nozzle openings that release bubbles in strategic column formations.

A high flow of compressed air is required to create a well-formed and effective bubble curtain. Not as simple as pumping gas down a tube, the air that goes into the water must be Class Zero ‘clean air’ and must be moved in huge volumes at pressure. To create the force, ScanTech Offshore stacks up multiple compressor units alongside its SeaSentry system, which ensures air is contaminantfree and leaves no negative environmental impact in the water.

Prior to ScanTech Offshore, bubble curtains delivered the volume of compressed air by installing many industrial-style air compressors that required a large footprint on a vessel (up to 30 air compressors on a single vessel). This resulted in the need for the deployment of larger vessels (typically PSVs) in order to install the required compressed air volume needed to support an effective bubble curtain.

The typical compressor types being deployed were either not stackable due to the inability to stack or issues resulting in overheating due

to the types of vessels often available in the market to locate the equipment.

ScanTech Offshore successfully entered the market in 2018 by providing the market-leading bubble curtain specialist - HydroTechnik Lubeck - a ‘stacked solution’ that effectively reduced the footprint allowing for a larger portion of available vessels to be considered to support certain offshore campaigns. This was achieved by deploying ScanTech Offshore’s containerised ST1600 (1600cfm / 45m3/min) model air compressor that had been proven to be a durable and reliable compressor from supporting high-value well test support contracts in the oil and gas sector for over 25 years.

ScanTech Offshore has supported numerous Big Bubble Curtain (BBC) projects spanning from the UK, and Europe to Asia deploying the ST1600 compressors with great success. However, during this time, it was clear to ScanTech Offshore that the market needed a truly purpose-built solution that would eliminate the most common challenges experienced when installing a large spread of diesel-

driven air compressors on a vessel with confined space constraints.

Previously, compressors would give off undesirable levels of heat whilst working on ships with high sides, as the heat from machinery would struggle to escape. Temperatures became uncomfortable for personnel and led to increased maintenance for machinery. It became clear that future projects may even require larger volumes of compressed air to support an effective bubble curtain, due to challenging environmental conditions (such as strong sea currents) and the increasing size of the foundations (requiring more noise attenuation).

HydroTechnik approached ScanTech Offshore for a solution that

would provide further deck space savings allowing for even higher volumes of compressed air to be installed on a single vessel but also “fit for purpose” whilst working on vessels with high sides. Finally, the new system needed to be capable of supporting projects in deeper water –capable of producing a higher working pressure was of critical importance.

After refinement and much testing, ScanTech Offshore developed the ST3100, a 20ft CSC / DNV2.7-1 containerised air compressor with a Caterpillar engine and original radiator technology that can deliver 3100cfm and capable of working pressures of up to 200 PSI, providing the air required to a create a bubble curtain that reduces noise by up to 90%. Importantly, the ST3100 delivers more than double the power compared to previous air compressors, whilst taking up half the footprint, even when equipment

is not stacked. When stacked (as per the design) the footprint savings are much greater providing up to 3-4 times more compressed air on the same footprint as some of the alternative solutions available in the market.

Testing and learning in 2018 through to 2022, several major projects were undertaken as ScanTech Offshore eyed eventual rollout in the US. “Even during the initial learning in Europe and Asia, we instantly saw that the market needed a purpose-built solution and not just a compressor. It had to be reliable,

“WE INSTANTLY SAW THAT THE MARKET NEEDED A PURPOSEBUILT SOLUTION AND NOT JUST A COMPRESSOR”ScanTech Offshore Great Yarmouth

and it had to be designed first and foremost with the safety of personnel in mind,” says Barry Craig, VP of North America at ScanTech Offshore.

He says that on an oil rig, compressors are stacked in a uniformed position and the heat generated can escape. But on the back of a vessel, the heat has nowhere to go, and the result was increased maintenance in addition to the need to take additional measures including sea water cooling for the units when working in higher ambient countries such as Asia.

“We spent 18 months on the design work, and we looked at many different options to maximise every aspect, from power to emissions.”

Caterpillar engines were chosen because they were familiar and proven in the harshest environments that ScanTech Offshore support, this paired with ScanTech Offshore’s vast experience with the engines made them the ideal choice. The engines also offer Stage V / EPA Tier Four Final emission standards – required for compliance in both the European and US markets. There is also no need for additives, meaning no storage of diesel exhaust fluid (DEF) on a vessel. Pairing with compressor technology

from Sullair, the offering was almost complete, but ScanTech Offshore still had to develop the solution to deal with the high temperatures.

“We came up with a unique heat rejection system that has been incorporated into the compressor unit that allows it to be stackable, reducing footprint drastically, and ensuring that the ambient conditions around the machinery and on the vessel are maintained well within safe working limits for personnel. Furthermore, the solution providing additional value through automated refuelling and reduced need for personnel amongst other things.”

With extensive and successful trials conducted on the ST3100 solution, the team took the units to the US market and successfully supported the first commercial scale offshore wind farm on the East Coast of the US. The ST3100 solution ensured our client could deploy their own specialist vessel for the project, negating the need to deploy a much larger vessel to the project at a greater cost.

Alongside the cost-effectiveness proven in the US, the ST3100 did the job underwater, reducing decibels from construction activity significantly,

protecting whales, dolphins, porpoises, and other sea life. On the deck, the heat from the units was completely mitigated thanks to the clever system designed by ScanTech Offshore.

The process of evolution from compressor for oil and gas, to allnew specialist designed product for renewables was a journey for ScanTech Offshore. “We had to go into it almost with our eyes closed to learn – what do we actually need on these vessels to make it safer, more efficient, and maximise performance? At the end of the day, this is all about uptime,” says Craig, adding that downtime can cost millions of dollars per day. “The value of us providing what we do is critical. Everything stops if we’re not providing compressed air to the bubble curtain effectively.”

The offshore project in the US provided engineers and offshore teams with a significant amount of data to display to the market. The on-deck and beneath the surface excellence displayed on this key project in the US was the perfect case study to demonstrate the full value that the ST3100 solution offers.

Craig moved to Rhode Island in 2022, with plans to deploy the ST3100 technology along the East Coast of the US, supporting their key clients and partners in each state. Following the successful deployment on the recent US project, it has set the business up as a well-established player for the future projects expected in region.

Now a proven part of the growing supply chain, ScanTech Offshore hopes to ramp up US involvement substantially. “We want to be the number one supplier for sure. We have taken the design which we built in the UK, and we’ve taken it across the pond with a leading EPCI to do the work on the US East Coast, and it’s been very successful,” says Craig.

Already secured on two large projects for the next two years, local manufacturing will begin imminently with the US renewable pipeline now beyond 51GW – enough to power 20 million homes.

“We focused on the US because it is an emerging market and it’s good to be in emerging markets at the start,” says Craig, adding that the importance of local procurement is vital. “We already had our facility in Houston with a team which has

successfully supported operations in the US for over a decade. The same team even supported operations on the first US offshore wind turbines off Block Island, RI. Today, with the expanding offshore wind ambition demonstrated by the US, we also have plans to replicate and expand our offering up and down the East Coast to support the upcoming projects.

“We will work collaboratively with key partners in region to ensure our air delivery packages can support the projects and bring a huge amount of added value through our innovative technology. We are working with our partners on methods to improve efficiency and reduce cost in an effort to further boost the sustainability of the offshore wind industry.”

Craig, pays tribute to the James Fisher and Sons plc board who backed the move during an unpredictable time, following the pandemic and global supply chain challenges, providing investment and continuing to support the team at ScanTech Offshore.

“We are now set to enter phase 3 of our build programme where equipment will be assembled out of our Houston facility. The

units being built will probably be working on renewable based projects for the next decade at least. We will build the compressors in America, with 100% US content.”

The US market is different to the European sector and one of the challenges is vessel size and availability. The Jones Act means that locally flagged vessels, manned by local people, must be used in offshore construction, and this can mean big changes in cost as projects look to move up in size. To help here, ScanTech Offshore always had the footprint of the compressor in mind and Craig says that making it as small as possible without compromising on power was the goal.

“We want to give a solution that widens the selection process for a vessel that can be used and allow vessels to potentially complete other tasks as there would be spare deck space,” he hopes.

“When we look at the vessels available here, there’s not a huge number of large vessels and the availability of vessels is not great because the oil and gas market

is up. The day rate jumps from vessel to vessel and can easily be $10,000 - $15,000 a day if you need to jump up to the next class.”

“In some circumstances, ScanTech Offshore technology has the potential to even to reduce the need for two vessels,” reiterates Craig.

The US offshore wind developers have been strict in saying you must comply with the highest level of tier emissions, and you must use US-flagged vessels. We looked at the market and how it might work, and we believed that the ST3100 could make an impact there more than anywhere else in the world by reducing the footprint and allowing for a wider variety of Jones Act vessels to be deployed. If a competitor tried to stack the equipment, then you’d get the same issue of heat not escaping and ambient temperatures rising beyond what you would want for people or machinery. The ST3100 not only stacks but conforms to the slim profile that US vessels typically have ensuring there is no dead

space when installing equipment.

The added bonus for ScanTech Offshore equipment is the certification that boosts confidence. Everything is rated for offshore work – DNV 2.7-1 certified and CSC approved, using the correct grade of steel, easy to transport and crane like any other container. “We give validation that everything is fit for purpose and designed to be on a vessel and designed to be at sea,” says Craig.

“Previously, industrial compressors had been chained to the back deck of a vessel, and no formal certification such as CSC were being met. With the ST3100, walkways are clear, and units can be craned from vessel to vessel if required,” he adds.

On-ship, with temperature levels low, and you are automatically informed if maintenance issues could arise via remote telemetry installed on all units (creating reports for the client at the same time). ScanTech Offshore engineers are thrilled with the performance of the ST3100 units to date. Craig reports that, ultimately, they continue to do the job.

“I speak with our team on the project, and they say they have never seen so many whales, ever. The number of whales off the East Coast of the US is phenomenal. The project we recently supported was stopped several times in the name of animal welfare. We hear of in excess of 100 whales at a time in a single area and that is not something our team sees often. So, I think you can see why they’ve adopted the highest levels of mitigation possible.”

The wind energy market will grow exponentially in the coming decades and Craig is excited to be part of a solution for the future. In the US, new vessels are on order or under construction, new facilities are being erected, domestic skills development programmes are being rolled out, and the American Clean Power Association (ACP) expects 83,000 jobs to be created in offshore wind by 2030.

“With the rapid expansion of offshore wind globally across multiple geographies, it highlights the necessity to build and support locally in order to be successful,” says Craig.

Typically, sound detection buoys are placed at 750m distances from a construction site and operations must not exceed the agreed threshold in the environmental permit which is critical to comply with at all times. The bubble curtain helps to achieve this by altering the characteristics of the sound waves as they pass through the bubbles.

“There’s nothing that gets close to it in terms of noise reduction,” confirms Craig. “A 15-18-decibel reduction is enough to make a real impact as sound behaves differently in water. This can equate to a 90-95% noise reduction which provides a clear benefit for marine life.”

Other noise abatement technologies can be used alongside the bubble curtain to protect marine life and, as long as conditions are suitable, the local underwater populations will remain well protected

as activity ramps up. However, time after time it has been shown that bubble curtains are the most effective technology to attenuate noise during pile driving activities.

“It’s phenomenal, it has been a massive team effort from the offshore teams feeding in the information to our engineering team doing a lot of testing. We’ve just finished a big job, one of the first in the US and it has been a great success. You can do all the simulations, but until you prove it in the field, it’s only as good as your theory.”

Going forward, ScanTech Offshore is well-placed for expansion in the US and harnessing potential in the Blue Ocean economy, and Craig hopes that the wider James Fisher and Sons team, which has already supported over 17GW of renewable construction and development around the world, can

assist as the nation ramps up effort to green its generating capacity.

“We’ve already secured a further two major projects on the East Coast of the US for major international wind energy businesses. Our pipeline here is extremely exciting for at least the next three years, complementing our already prominent Europe and Asia business lines.

He adds further assurance that if you engage with ScanTech Offshore, or the wider James Fisher Group, you will get a partnership that achieves results.

“We’ve all been offshore, and we’ve seen the failings of our customers, competitors or even our own. That’s what differentiates us, and that is why we are successful.

“Our units are brand new; they’re not going to have been in anybody else’s hands, and they’re not going to

be rented out without our people.”

Truly a leading product for a burgeoning market, ScanTech Offshore’s ST3100 is an enabler of the green energy transition in the US. All EPCI companies and fleet owners should be considering the significant efficiencies that the system offers. Asked if he is expecting competitors to flood the market with similar products anytime soon, Craig remains confident.

“By the time they do, we will likely be on to the next innovation by working closely with our partners and clients as we all strive to further improve efficiency.”

As Shell continues to power progress across various energy sectors, its clear goal is to advance the energy transition, shaping the world of tomorrow for the better by investing in low-carbon technologies that drive value and performance. CEO Wael Sawan is confident about the company’s ability and ambition.

//The famous yellow and red of Shell, adorned across energy infrastructure around the world, is perhaps the most recognisable brand in the history of the energy industry. Hailed as an innovator and reliable supplier of liquid fuels for decades, the company was known for world-leading oil, petroleum, and associated chemical products. Where you saw the yellow and red scallop, you knew a premium range was close.

But changes in the world have forced Shell into a fresh manoeuvre. As a globally relevant business, the requirement for addressing climate change, global warming, pollution, and human impact on the planet has ramped up significantly.

Pressure from shareholders, governments, and customers has seen a strategy shift within Shell. Prioritising renewable energy for

the future, and transitioning away from traditional oil and gas, the company is refocusing while ensuring continued value creation. Now, the yellow and red pecten conjures the image of a brand that is integrated, diversified, and active in change.

In September 2022, Ben van Beurden stepped down as Shell CEO, and Wael Sawan former-Director Integrated Gas, Renewables and Energy Solutions took over. Perhaps a symbol from the business around its future intentions, bringing in an executive from a renewables background.

“We want to be a net-zero emissions energy business by 2050,” highlights Sawan.

Employing multiple strategies, the group is looking to reduce its emissions which have been mapped using the Greenhouse Gas Protocol – a globally recognised accounting standard for

measuring emissions. Scope 1, 2 and 3 emissions are problematic, and drivers of climate change, and Shell produces a lot. But the company is reducing its emissions across all areas, with Sawan driving ambitious targets for the coming years.

In 2020, before Sawan took over at the top, the company was busy in the UK market, completing a power purchase agreement (PPA) to supply households with energy from the Dogger Bank wind farm. This power generation monster is located off the coast of Yorkshire and is the world’s largest, with a capacity of 2400MW. Shell’s offtake agreement saw it deploying 480MW.

“Offshore wind will play a key role in the UK’s transition to a low-carbon future,” said Rupen Tanna, Director at Shell Energy Europe. “Power is a growth priority for Shell. This long-term

agreement will enable us to supply more clean power to our customers, while supporting the development of one of the most ambitious renewable power projects in the world.”

Shell was forced to exit the retail energy markets in the UK, Germany, and the Netherlands due to poor returns. But the company’s focus and strategy around renewable energy did not change. “We continue to look at opportunities to invest in offshore wind generation, including innovative wind technologies such as floating wind,” the company states.

With a strong history of managing complex, challenging projects in the North Sea, Shell is perfectly positioned to advance wind energy. MarramWind and CampionWind will be innovative floating offshore wind

farms, delivered by a partnership of Shell and ScottishPower. “This is another step in helping to provide more, cleaner power to homes and businesses,” said Hessel de Jong, former-Shell General Manager Europe for Offshore Wind.

At the end of 2022, Shell

announced that it had, in partnership with Eneco, won a bid to develop a 760MW wind power plant at the Hollandse Kust (west) VI site, 53km off the coast of Ijmuiden. The JV labelled Ecowende will eventually supply 3% of Dutch electricity

demand with green energy.

Sawan was in charge of renewable for the company at the time and highlighted the contribution of offshore wind to the company’s vision. “With Ecowende, we will take a huge step in growing our offshore wind portfolio while making a positive contribution to biodiversity. Through this project we can profitably accelerate the large-scale roll-out of offshore wind in the Netherlands and beyond. This fits well with Shell’s Powering Progress strategy to deliver more and cleaner energy to our customers, at home, on the road and at work.”

Ecowende will take a new approach to wind farm construction and will place towers further apart to allow channels for birds to fly through, innovative foundation techniques to protect marine wildlife, and encouraging natural reefs on the seabed to promote biodiversity.

Adding further diversity to the portfolio, Shell has made acquisitions that have bolstered its exposure to multiple alternative energies. In August 2022, the company announced completion of its acquisition of Sprng Energy, a solar and wind supplier to distribution companies in India. With significant GW under management, and more in the pipeline, the company was a perfect fit for Shell as it tripled its renewable capacity.