Exclusive interview with BET Software General Manager, Michael Collins Betting Software Solutions Disrupting the Global Game Serioplast SA / Metos SA / Graaff Fruit / Dakri Cartons ALSO IN THIS ISSUE:

EDITOR Joe Forshaw

joe@enterprise-africa.net

SENIOR PROJECT MANAGER Sam Hendricks

sam@enterprise-africa.net

SENIOR PROJECT MANAGER James Davey

jamesd@enterprise-africa.net

PROJECT MANAGER Ekwa Bikaka

ekwa@enterprise-africa.net

PROJECT MANAGER Terry Hanley

terry@enterprise-africa.net

PROJECT MANAGER Eleanor Sarbutt-King

eleanor@enterprise-africa.net

PROJECT MANAGER Jamie Waters

jamie@enterprise-africa.net

LEAD DESIGNER Aaron Protheroe

aaron@enterprise-africa.net

FINANCE MANAGER Isabel Murphy

isabel@enterprise-africa.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

This month has been a continuation of the theme of South African businesses fighting hard against external factors to continue displaying inspiring stories of growth & innovation. Against a backdrop of global inflation pressures, with SA’s economy recording 6.3% overall inflation for the month (albeit with food price increases being markedly higher), as well as the ever-present looming spectre of load shedding with Eskom moving back to Stage 6, the country reported a 2.5% increase in manufacturing output year on year showing the resolve is far from beaten. We take a look at a number of companies reporting success stories despite these perennial challenges:

Our cover tells the remarkable story of BET Software and their transformation over 11 years from a tiny start up to competing with the best and most innovative software providers globally. Their GM Michael Collins lays out their vision to be the most innovative, leading software provider in Africa, and a front-runner in global markets.

Innovative PVC Compounds, a family run business, was hit hard by the Covid pandemic but a focus on essential industries during this time provided a platform for continued growth while maintain their core values and beliefs.

As well as the external pressures noted above, a changing climate provides a constant challenge for the crucial agriculture sector. METOS is a solution that is helping to revolutionise the field (pun intended) by providing farmers with tools to assist and improve their decision making.

Eagle Insurance head into their 50th year with a newly appointed permanent CEO – Sattar Jackaria, who tells us his plans for investment into technology and people to help the company remain the insurance partner of choice in Mauritius.

With rapidly declining fishing stocks along Africa’s East coast, Victory Farms have built an end to end protein platform with the goal of becoming the most sustainable fish farm in the world.

Published by

Chris Bolderstone – General Manager E. chris@cmb-multimedia.co.uk

Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX +44 (0) 1603 855 161 www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© CMB Media Group Ltd 2022

These challenges will be present for some time, please get in touch and tell us more about what your company is doing to ensure it continues to thrive. We’re always online at LinkedIn

EDITOR’S LETTER www.enterprise-africa.net / 3 Joe Forshaw EDITOR GET IN TOUCH +44 (0) 1603 855 161 joe@enterprise-africa.net www.enterprise-africa.net

4 / www.enterprise-africa.net 6 12 20 28 32 38 42 48 CONTENTS 12 BET SOFTWARE Betting Software Solutions Disrupting the Global Game SERIOPLAST SA Efficiency Tops Agenda for Global Manufacturer in Gauteng METOS SA Weather Data Game-Changing for SA’s Farmers GRAAFF FRUIT The Ideal Blend of Varietal Innovation and Farming Tradition DAKRI CARTONS Continuous Improvement Brings Corrugated Carton Perfection VICTORY FARMS Fastest-Growing Fish Farm Is Far from Floundering EAGLE INSURANCE Creativity, Integrity, and Innovation Ensure Mauritians Flock to Eagle INNOVATIVE PVC COMPOUNDS Flourishing Family Business Flying into Fresh Markets

54 60 66 70 74 78 84 88

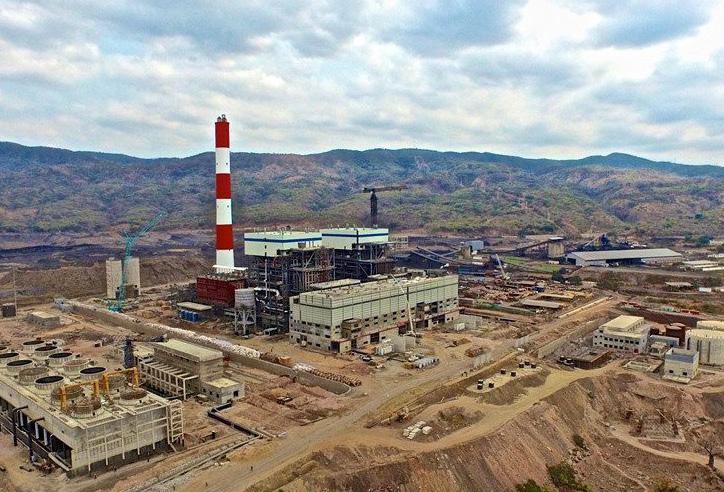

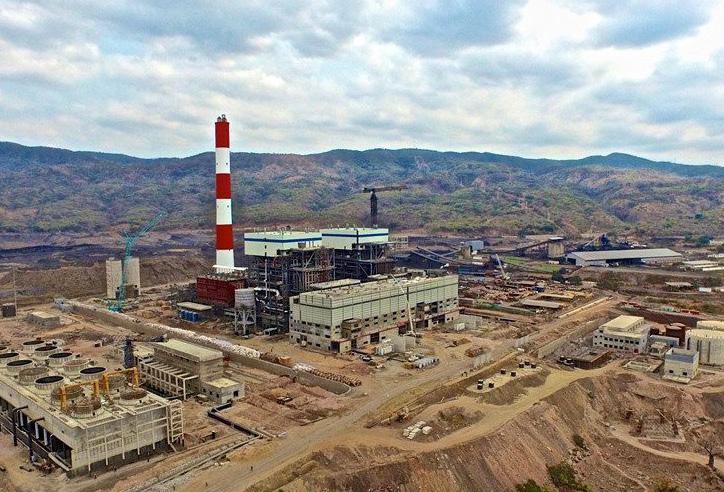

KANSANSHI MINING

Expansion and Enterprise Projects Approved at Cornerstone Copper Asset

BLENDCOR

Keeping Everything Running Smoothly

VISA SUB-SAHARAN AFRICA

Targeting the Last Billion Connections of SSA’s eCommerce Potential

DUBE TRADEPORT

Throwing A Spotlight on KZN’s Manufacturing Potential

FOSKOR

Proudly South African Phosphate Production

PRASA

Ensuring Rail Remains a Backbone of Public Transport

DEVMARK PROPERTY GROUP

Devmark Lets You Live Your Best Life

ZIMBALI LAKES

A New Chapter in the Zimbali Legacy

www.enterprise-africa.net / 5

20

BET SOFTWARE

Betting Software Solutions Disrupting the Global Game

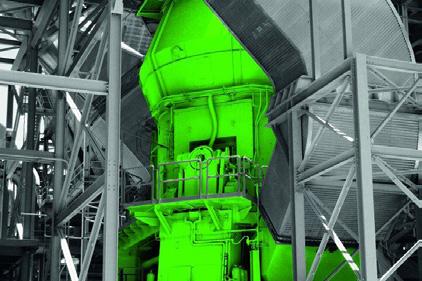

One of the most diverse betting software providers in sub-Saharan Africa with a rapidly growing international footprint, BET Software develops automated software systems to manage data seamlessly. “Our vision is to be the most innovative, leading software provider in Africa, and a front-runner in global markets,” opens GM Michael Collins, as the company and its talented team continues to disrupt the industry.

PRODUCTION: Jamie Waters

PRODUCTION: Jamie Waters

6 / www.enterprise-africa.net

Presenting: Michael Collins, General Manager

Presenting: Michael Collins, General Manager

largest bookmakers in South Africa. The tenacity and fearlessness of its team of a few developers allowed them to build a cutting-edge betting software system for South Africa’s leading bookmaker, constructed from the ground up, along with a range of other solutions. “We are now capable of rivalling the very best around the world,” GM Michael Collins asserts.

The quick evolution of the software development department resulting in its outgrowing its commercial parent, and since flying the Hollywoodbets nest. “This has allowed us to become the innovative, stand-alone software development house we are today,” Collins explains.

“We are one of the largest, most

PUSHING BOUNDARIES

It was in 2016 that the development team within Hollywoodbets - which BET Software has retained as a client - grew too large for an inhouse support function, and 25 team members were all transitioned into Betting Entertainment Technologies, leaving the Hollywoodbets base in June and moving into a new building in Umhlanga, at Tetford Circle.

By September, online customer migration, as well as Hollywoodbets retail transition over to SyX, an application billed as extraordinary in its ability to result large volumes of transactions in rapid time, was complete.

Five years later, all remaining

and cultivates - dedicated to refining their respective crafts and maintaining the incredible growth that has defined BET Software to date.

“We may be a well-oiled machine, but our people are far from cogs. Armed with an arsenal of learning and development programmes, various opportunities for growth and welldeserved incentives, our BET Software All-Star Army is well-equipped to push the boundaries of excellence,” GM Michael Collins furthers, linking this ethos to enabling the company to better serve both each other and clients. “It shows in everything – from what we develop and produce, to what we value and believe.”

At its root, this is a formidable

8 / www.enterprise-africa.net

to use on all events from bets being struck to settled. “We facilitate every one of these types of mechanisms,” Collins says, “including integrations with third parties, to our main marketplaces of South Africa and Mozambique.”

Zimbabwe, Zambia and Kenya are also gaining traction for BET Software, Collins shares, with local development arms established within those territories.

RED HAT

Collins pinpoints the company’s strategic partnerships with some major cloud service providers as a key differentiator for BET Software, and in particular the association it enjoys with Red Hat, whose

this in the traditional sense,” he relays, “as we do not use a traditional cloud provider like Azure or similar - we have actually built our own private cloud

our own distributed cloud network across multiple data centres in South Africa, into which we are developing. That gives us a lot more control over

www.enterprise-africa.net / 9

INDUSTRY FOCUS: TECHNOLOGY

costs, and the way in which we move data around distributed data centres, without it being a service that we are looking to other providers for.

“The partnership with Red Hat was key to achieving that, as they had to build it from scratch. This was not something to which they were accustomed either - someone telling them to install the Red Hat operating system onto bare metal, not part of

a pre-built cloud - but it allows us to ensure that we bring the services closer to clients around the country, locally.

“It also means that if we need to go into other cloud services, like an AWS, for example, it is simply a case of provisioning a node in a cloud platform that would then link directly into our own.”

Of all the work ongoing at BET Software currently, Collins explains, this is potentially the biggest and most important. “It takes us from a single point of failure to a distributed type of environment - we are no longer held against one monolithic structure to distribute everything,” he clarifies, which he reveals is pivotal to every company like this.

“Distributed architecture, rather than the monolithic structures of the past, should be at the forefront of all of their minds,” Collins affirms. “Although monolithic has its place,

and it does make troubleshooting a lot easier, as a company gets bigger it becomes a catastrophic point of failure that you have to spend a lot of time trying to avoid; with distributed architecture failure is limited to much smaller segments of the business, so such catastrophes can be mitigated.”

CSI

“Ubuntu is at the heart of everything we do. And that is why we are intentional about leaving a lasting social justice footprint. When BET Software started, we found that some learners and schools in the Durban area lacked access to computer labs, or their computers were outdated or non-functional. This shortfall that schools were experiencing posed huge challenges,” says Collins. That’s where BET Software stepped in.

“We assist in developing learners’ technological skills. We facilitate their

10 / www.enterprise-africa.net

// WE WANT TO ENABLE OPERATORS TO BE ABLE TO TRANSITION BETWEEN PLATFORMS WITH FAR MORE EFFICIENCY AND EASE //

growth by providing a solid foundation that allows them to excel in their future careers in a technologically-driven world. We have seen a sustainable and meaningful impact as a result of our work. Learners have become more confident,” Collins adds.

BET Software’s CSI initiatives also include a graduate and bursary programme. The company’s “Dare To Dream” bursary programme provides funding to ICT students at accredited tertiary institutions around the country, and the graduate programme offers work experience to graduate trainees, with the goal of absorbing them into the company.

VISION

BET Software’s ethos and values centre around disruptive innovation, accountability and authenticity and integrity. “Further to these, we embrace collaboration, diversity

and empowerment,” Collins stresses, and when it comes to his vision for the company’s future, there are a few essential elements which he wishes to tick off.

“First of all, we want to enable operators to be able to transition between platforms with far more efficiency and ease, rather than feeling beholden to one singular betting platform as they currently are.

“At the moment it is almost impossible, because people are locked into a platform; the likes of monday. com allow people to try 20 different project management cloud offerings before they settle on something that they like, and we see no reason why it should be any different with the betting platform provider as an operator.

“Our overarching vision,” Collins closes, “is to create software as a service for the industry, whereby it is also possible to choose certain components

from several platforms. For example, if someone wants to choose horse racing from us because we are the leader, but we are terrible at sports betting, they can build up a portfolio that encompasses their choice of the best of breed for each different element.

“It could be the death knell for us, because we could be rubbish at everything,” Collins wryly smiles, but there is little chance of that: the ability to forge close relationships with customers and provide leadingedge betting platforms, as well as 24/7 support, customisation, and optimisation that surpasses customer expectations makes BET Software truly the ace in the hole.

Content sponsored by BET Software

WWW.BETSOFTWARE.COM

www.enterprise-africa.net / 11

BET SOFTWARE

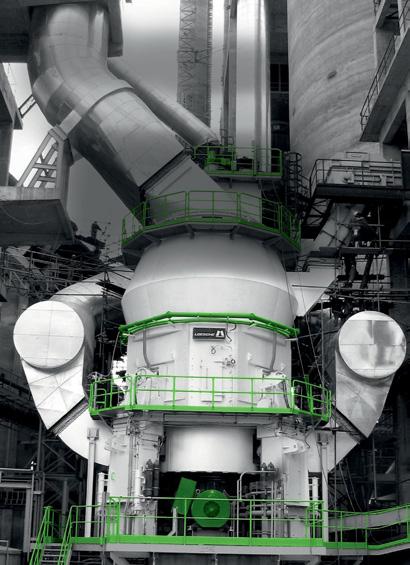

SERIOPLAST SA

Efficiency Tops Agenda for Global

Manufacturer in Gauteng

“We are Serioplast, and we produce globally, with the best possible quality and at the lowest possible price. We don’t only make bottles: we also design and engineer our own machines and our own moulds; we operate as contract manufacturer, and we recycle post-consumer plastic in order to bring it back in the production loop. In all we do our industrial processes and organization are flexible, scalable, and easily replicable. In South Africa, the company is a strategic partner for some of the biggest manufacturers on the continent and Director Kelvin Mills is excited about the position of the regional division as his team strives for excellence in production across all areas.

PRODUCTION: Eleanor Sarbutt-King

PRODUCTION: Eleanor Sarbutt-King

12 / www.enterprise-africa.net

INDUSTRY FOCUS: MANUFACTURING

//Approaching the end of its first decade in South Africa, expert manufacturing business

Serioplast is perfectly positioned for growth alongside its key customers. A global leading maker of plastic products for the FMCG industry, Serioplast is headquartered in Italy with 34 plants in 16 countries, and more than 2050 employees.

First opening on the continent in 2011 with a plant in Tunisia, Serioplast hit sub-Saharan Africa in 2014 when it realised the need to be closer to its key client, Unilever.

Tasked with establishing a modern, efficient, and productive plant was industry veteran Kelvin Mills. His

career had spanned engineering and production in metal and plastics, and he had worked across operations, sales, and management for big name brands.

He was at a conference in Germany in 2012 when the senior leadership team from Serioplast approached him.

AHEAD OF EXPECTATION

“I already knew they were setting up in SA – it was the worst kept secret - and we began talking,” he smiles.

“I became MD of Serioplast SA, and we set up the plant in a greenfield operation. Initially, we were supposed to be onsite at Unilever, but they advised that in time, they would probably require the space for further

expansions. We found a site next door and within a year we had built the factory and installed the machines. We created an aggressive plan, and everyone said it could not be achieved.”

The company did not just achieve its vision, it got up and running before the deadline, and had bottles moving into Unilever before the deadline.

“We installed a new machine every two weeks until we had 15 machines, and in the first year we supplied 140 million bottles,” Mills emphasises.

In South Africa, Unilever manufactures a large range of FMCGs. Serioplast products globally, hold cleaning materials, personal care products, food and drink, and

14 / www.enterprise-africa.net

Image: Michele Picolo

host of other goods. The company operates to ISO quality standards and supports some of the world’s best recognised brands.

Procter & Gamble is also a key client of Serioplast in South Africa and the conglomerate’s range of household products is well-suited to the output from the plant in Boksburg.

“We supply rigid packaging to Unilever and Procter & Gamble. We are hoping to get some more customers online asap and we are busy validating bottles for them currently,” says Mills, adding that growth with new customers is not the main aim for the business.

“We don’t go out looking for business,” he states. “We don’t have sales reps locally. We do have key account managers in Italy that take care of our key customers, but we do not actively

go and search for new clients. Our footprint of machinery is high-volume, and we produce a huge amount of bottles each year. We would need major companies to come on board as clients, and we would then also need to be able to continue satisfying our major clients, so we don’t hunt for new business.”

Instead, growth comes through efficiency. After initial establishment of the plant in 2013/2014 Mills and colleagues were tasked with commissioning new technology for producing closures for one of the major home care products that Unilever produces. Previously, closures were shipped to South Africa to make up the final product. It was inefficient and costly. Localising production would provide competitive advantage, Localizing

remains one of Unilever’s drivers.

“Until last year, we only did bottles but we installed the injection moulding machinery to add closures to our portfolio. We now produce around 230 million units out of the SA plant annually,” he highlights.

OPTIMISE & IMPROVE

In his second stint with the company, Mills left to help establish local production of the globally popular Bio-Oil brand from Union Swiss. He was approached by the leadership team at the helm of that business expansion because of his technical knowledge and understanding of the South African landscape.

During this time, progress at Serioplast stalled and the plant’s stellar performance had dipped. A

SERIOPLAST SA www.enterprise-africa.net / 15

Image: Davide Locatelli

INDUSTRY FOCUS: MANUFACTURING

struggling local economy and various other macros issues compounded the situation and Serioplast went against strict internal policy to get Mills back before tasking him with reintroducing global best practice to the Gauteng site.

“Our main focus is to optimise current installations,” he explains. “We have gone through an aggressive turnaround, and we are consolidating…… The next step will be to look at additional finer improvement projects, which the

team embrace and execute with passion. The improvements that we see definitely gives the team a great sense of accomplishment

For this efficiency drive, Serioplast SA calls on its group (SGS) for input. Serioplast Global Services in Italy helps to drive positivity and influence the internal construction of its own machinery. By understanding the needs of the client in a deep and meaningful way, Serioplast is able to create equipment that keeps output high and costs down.

“The level of output of finished goods is substantial – the Seriomac machines we use are top of the range,” says Mills.

“Machinery is a big part of it,” he adds. Besides our own Seriomac Blow-moulding machines, we also have injection moulding machines, injection stretch moulding, auxiliary equipment, compressors, chillers, material feeding systems etc. and they all have to be accurate and top of the range. it’s all about achieving our KPIs. If equipment is not calibrated properly, it will put

16 / www.enterprise-africa.net

// WE ARE ALWAYS UNDER THE CRUNCH. THERE IS ALWAYS A TARGET FOR COST SAVING OR REDUCING WEIGHT OR INTRODUCING RECYCLED MATERIAL – WE ARE ALWAYS WORKING ON SOMETHING THAT WILL RESULT IN IMPROVEMENT //

Image: Alejandro Vecchiettini

us out and that is not acceptable.”

Thankfully, Mills is a seasoned leader and stives to meet KPIs. Data is king and is used to drive improvements in the required areas. Mills is also responsible for the plant in Egypt which has recently achieved 220 million pcs output per year, growing from just 23 million bottles in 2020. In the future, he will likely become responsible for Tunisia and Australia as a result of the triumph in South Africa.

PROBLEM SOLVERS

It is not an easy job to guide a successful, large-scale manufacturing operation in a slow economy that is dragged by loadshedding. Contributing 12% of GDP and 42% of formal employment in the country in 2019, manufacturing is a critical sector. But in

1975, manufacturing was responsible for 25% of GDP, and the current power crisis is putting many businesses, and jobs, at risk of adding to the decline. For Serioplast, it’s about continuing to hit KPIs and understanding why they’re in place. The local challenges are yet to cause major disruption.

“We are always under the crunch. There is always a target for cost saving or reducing weight or introducing recycled material – we are always working on something that will result in improvement,” says Mills.

“We have been fortunate in that we have not been that impacted too badly by loadshedding, and we feel lucky to be in the industry space in the east of Johannesburg which has avoided major commotion.”

To ensure the company is

prepared for the future, a rooftop solar PV installation is being discussed, and a back-up generating solution is being planned. Solar would not provide enough energy for the entire operation to go off the grid, but it would be a strong sign of commitment to the group’s larger sustainability pledges. “It is one step closer to being self-sustainable,” smiles Mills.

Demonstrating true resilience, even through one of the most challenging times in living memory for businesses – when many SA manufacturers were lost – Serioplast stepped up to achieve strong results. None of the 138 employees were lost, and the company provided a much-needed service in route to market for its client’s products.

“When Covid hit, our volumes actually increased because of a

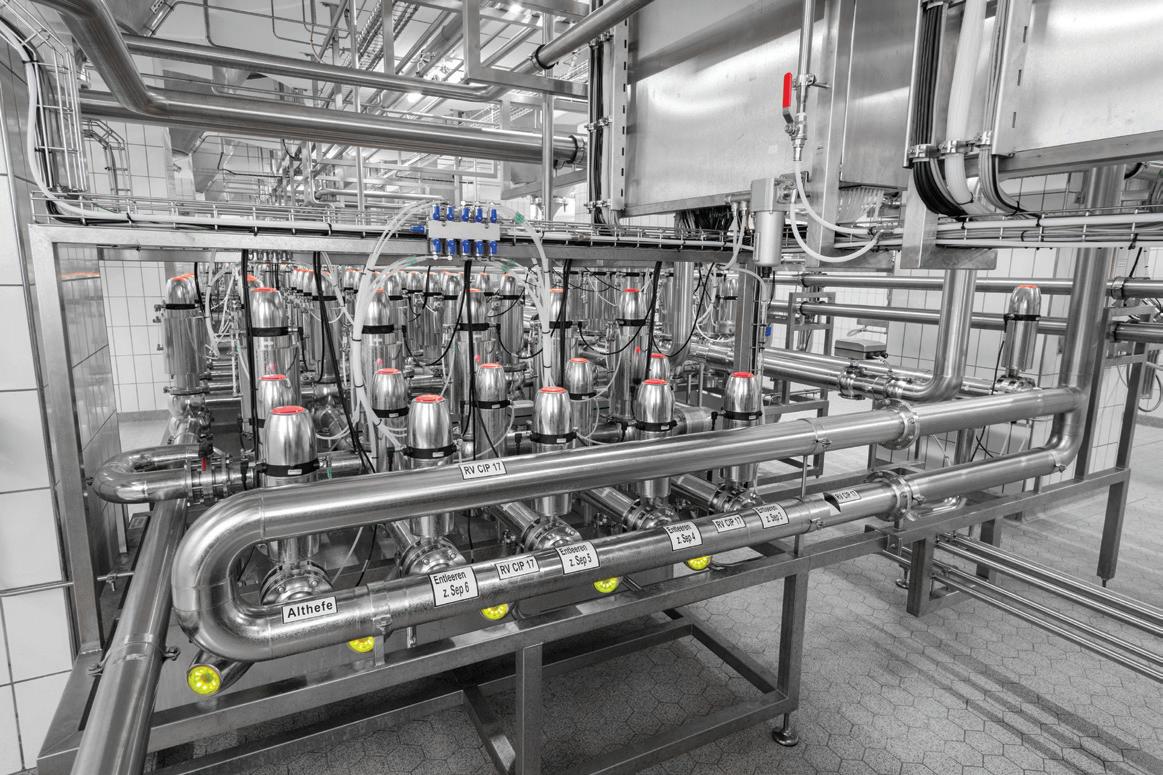

PRODUCTS

Pipes

Pipe Unions

Bends

Tank Fittings

Ball, Butterfly & Leakage Valves

Single & Double Seat Valves

Installation Accessories

Sight Glasses

SERVICES

Specialised fabrication

Plant modifications

Plant installation

Valve services

Plant maintenance

Skid building

Plant improvements & upgrades

Specialist procurement

SERIOPLAST SA www.enterprise-africa.net / 17

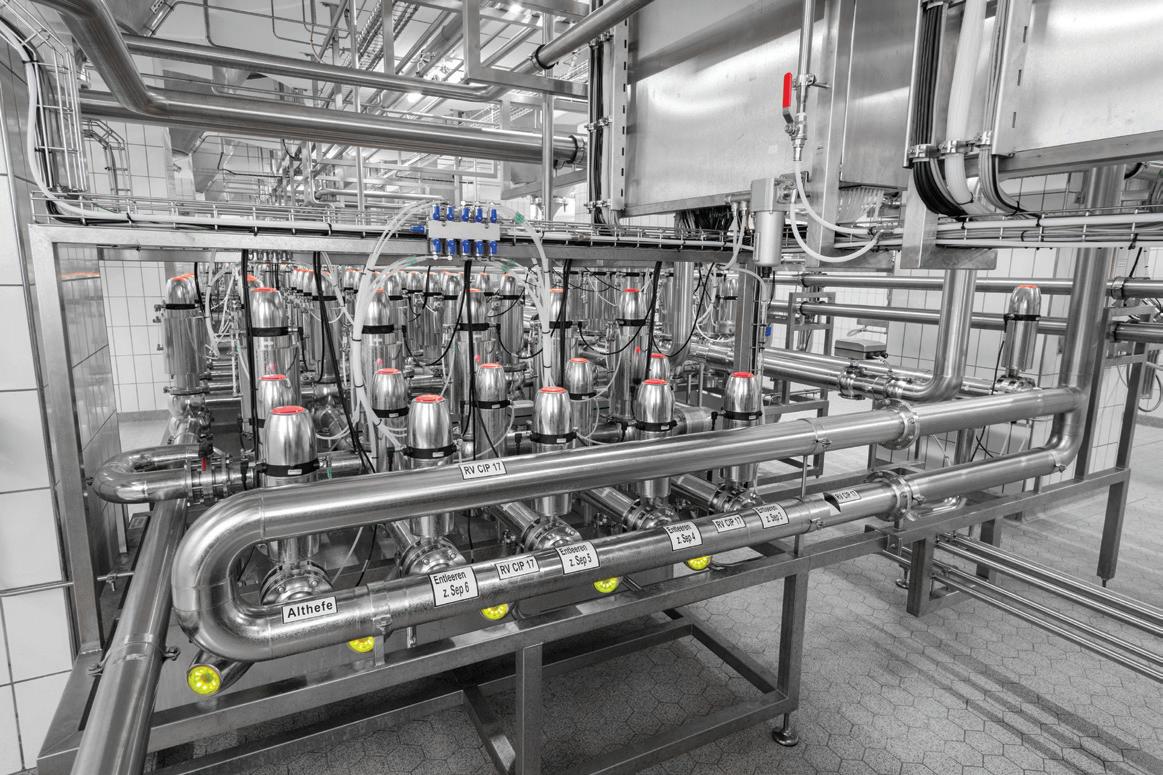

industries STAINLESS STEEL

OF 1 Delphi St, Eastgate, Sandton, 2090 www.bcgstainless.co.za 011 452 9888 info@bcgstainless.co.za

to the food, chemical, beverage and pharmaceutical

SUPPLIERS

SOLE AGENT & DISTRIBUTOR IN SOUTH AFRICA AND SUB-SAHARAN AFRICA FOR KIESELMANN & GUTH VENTILE

BCG Stainless Steel Services is a leading supplier of Hygienic stainless steel valves, fittings and accessories to the South African and Sub-Saharan Processing industries.

INDUSTRY FOCUS: MANUFACTURING

lot of the bottles we make are for disinfectant and antiseptic detergent products - everybody was disinfecting everything,” Mills remembers. “After Covid, we settled back to where we were before, and we are thankful that it hasn’t hit us in a big way. Currently there is a big price war and there are new players in South Africa who are aggressive in the market. That pressure transfers to us. Even when the volumes are there, the bottom line might not be what it used to be,” he says reiterating the need for efficiency.

Ensuring the entire team understands this need for efficiency, and guaranteeing they

are able to achieve is something Mills is passionate about.

“We can still further improve, and we want to grow the team and set everybody up for success,” he says. “Often businesses are quick to blame but they haven’t set individuals up for success. I want to give people a global vision and a global understanding of how the business operates. I want to join to the dots between the various departments so that people can take ownership. The more they know, the more they understand, the more they can take ownership – and that drives motivation. That is the next phase in improving this business.”

He explains that by regularly developing fresh KPIs, and equipping employees to meet and exceed those targets, the company is proving its importance within the group.

“Educating people around these KPIs and the reason they are important will allow for more of an understanding on growth and where we need to focus our attention. We have a dashboard that displays where the South African business is and how it fits into the global operation and currently it looks really good. If we achieve all KPIs, we are running a very good business – we don’t guess, everything is meticulously calculated.”

18 / www.enterprise-africa.net

// THE MORE THEY KNOW, THE MORE THEY UNDERSTAND, THE MORE THEY CAN TAKE OWNERSHIP – AND THAT DRIVES MOTIVATION. THAT IS THE NEXT PHASE IN IMPROVING THIS BUSINESS //

Image: Walter Carrera

Togetherness in the workforce –striving for achievement of vital targetsis one of the attributes that has allowed Serioplast to thrive in South Africa.

Mills describes the team as a ‘happy family’ that understands why they do what they do and works within clear boundaries that allow for strong focus.

“People are the main challenge in any business,” he adds. “It’s always

about getting the right team. The saying about ‘you’re only as good as your team’ is absolutely 100% true.”

Going forward, streamlining inputs and embracing new normals across customer and supply chain will keep the team busy. With so many different grades of raw material, a constant focus on sustainability, and a need from clients for flexibility, Serioplast must remain agile.

“Years back, a customer would ask for a bottle and say it must be HPDE. We could then decide on the grade and give the best product. Now, our customers are dictating the grades they want, and trials, tests, and approvals are essential – it’s much more complicated.

“Supply of that approved raw material could be more complicated, especially during Covid. Supply chain sometimes stressed meaning we at times have to scramble,” says Mills.

Our main customers are growing consistently, and always innovating with new ideas. With this as a base, Serioplast remains buoyant.

“We produce globally, with the best possible quality and at the lowest possible price,” the company says of its commitment to clients.

In an ever-changing industry, economy, and environment, it pays to partner with the best, and Serioplast is an example to follow in South Africa. Mills is confident about the way forward: “It has been nearly 10 years, and we have already done so much more than people ever thought possible. I would certainly say we are bullish,” he concludes.

SERIOPLAST SA www.enterprise-africa.net / 19

WWW.SERIOPLAST.COM

// IF WE ACHIEVE ALL KPIS, WE ARE RUNNING A VERY GOOD BUSINESS – WE DON’T GUESS, EVERYTHING IS METICULOUSLY CALCULATED //

Image: Alejandro Vecchiettini

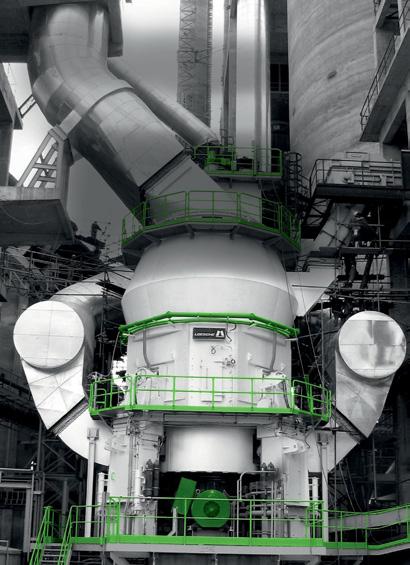

Weather Data Game-Changing for SA’s Farmers

“We can’t control the weather, but we can change how we respond to it,” says Marketing Portfolio Lead: Ag-Tech and Services at WinField United South Africa. She explains that by using a METOS® weather station and associated software, farmers can develop highly effective and reliable plans to mitigate against negativity in the field. A growing brand with a strong value proposition, METOS® SA is the leading the way in SA’s agri-tech space.

PRODUCTION: Eleanor Sarbutt-King

PRODUCTION: Eleanor Sarbutt-King

20 / www.enterprise-africa.net

METOS SA

INDUSTRY FOCUS: AGRICULTURE

//South of Cape Town, in the coastal town of Hermanus, where the cool ocean wind blows across the beautiful Hemel-enAarde Valley, and the sun-drenched vineyards, wine producers are using new technology to plan their annual farming schedules. “It has helped us

immensely when it comes to making the correct decisions when it comes to spraying,” says Pieter Willem Eksteen of Bartho Eksteen Wine Estate.

The equipment is a world-class weather station and associated technology from Pessl Instruments, supplied by METOS® South Africa. The

weather stations are sophisticated, innovative, and even in the sometimes hard South African conditions. Designed in Europe by specialists with knowledge of agriculture, science and data, the system is a comprehensive tool that helps farmers to make decisions with greater efficacy, increasing output and farming environmentally and economically more sustainably..

Johan Stephan of Stephan & Son

Potatoes in Sandveld, north of Cape Town, is using the same technology to plan irrigation and spray schedules, driving efficiency across the farm.

“We have access to accurate, sitespecific weather data instead of having to rely on estimates,” he says.

Pessl has been developing and manufacturing the hardware in Austria for 38 years. Today, the tech is distributed under the METOS® brand all over the world. Since 2019,

22 / www.enterprise-africa.net

Carina Olivier, Marketing Portfolio Lead: Ag-Tech and Services WinField United South Africa

METOS® in South Africa has been part of the WinField United South Africa group, a diversified agricultural network of businesses helping the country’s farmers to thrive.

“Weather technology has grown a lot. Before IoT, there was manual equipment and someone had to go out, at the same time, in the same place, every day, to take measurements,” says Carina Olivier, Marketing Portfolio Lead: Ag-Tech and Services at WinField United South Africa.

“METOS® weather stations are fully automatic, running from a solar panel with a backup power battery. It runs on cellular network towers – it can log every 15 mins and then sends the data through to the cloud every hour.. Technology has made it possible to have more accurate and automatic readings for the farmer’s convenience.”

WEATHER TECH

Deployment of METOS® weather stations is a game changer for farmers in southern Africa. The climate is changing and traditional methods of managing fields are no longer providing enough info to build a thorough plan. Rainfall patterns, sunshine hours, disease spread, natural disaster predictions – wherever there is a need for weather data on a hyperlocal basis, a METOS® weather station can provide support. Already prized by the University of Stellenbosch following the successful EUREKA Climate Smart Agriculture project – in which 200 weather stations have been installed across the Western Cape – METOS® infrastructure is becoming essential for modern agri operations.

“It helps the farmer in real time to plan for when is best to spray,”

explains Olivier. “Most agricultural products are applied using water as a medium and there are a lot of environmental factors that can influence the efficacy of that application,”

Too hot with low humidity and the droplets can evaporate. Strong winds and the droplets blow away. Heavy rains and the crop protection products can be washed away. A precise plan is vital.

“All of this needs to be accounted for and it can become quite laborious – farmers don’t want to sit there crunching numbers. That is where the Field Climate platform comes into play. It takes all these environmental factors and provides a very nice, easy to read graph to show exactly when is best to spray,” she details.

Pairing a state-of-the-art weather station with easy-to-use software, at a good price, with the backing of

METOS SA www.enterprise-africa.net / 23

INDUSTRY FOCUS: AGRICULTURE

international quality standards, is a winning recipe, and METOS® SA has seen significant growth – even in tough economic conditions - since gaining Pessl distribution rights five years ago.

“We are living in a very fast changing world with the climate, and we see it – especially here in the Western Cape where we have been hammered by unexpected rain patterns,” says Louise Duminy, Brand Manager WinField United South Africa. “This hardware is truly world-class and you get constant country-wide support with it. It is hyper-localised and it can tell you exactly what to expect on your farm. With changing weather patterns, and confirmation of El Niño, farmers can understand how the pattens are going to change so that they can plan ahead. It is such a help for people who have, in the past, been

guessing what nature will do. It gives so much better insight and that is because the hardware is incredible. We use technology in everything we do, and this is for the farmer to do the same.”

MULTI APPLICATION

Global warming is fuelling a large reduction of productive agricultural land in Southern Africa. Researchers suggest that over the next century usable land will decrease by a further 12%, on top of a more recent decline. Population

growth continues, and a long-term food production supply/demand crisis is looming. Clear and concise data around temperatures, weather patterns, and other measurables is not only of interest to farmers. Researchers and scientists are excited about analysing deep and meaningful info to help create plans for the future.

“A farmer can see what is going on the farm and gain forecasts to plan for the week ahead. But since the network also logs the data in real

24 / www.enterprise-africa.net

// IT LEARNS SO THAT IT CAN BECOME MORE ACCURATE FOR THE AREA WHERE IT IS INSTALLED. COMBINING FORECAST MODELS WITH ON THE GROUND MEASUREMENTS IS WHAT MAKES IT UNIQUE //

Short Courses

time and keeps a historic record, it can be of value to research and other entities who want to study and create climate models,” details Olivier.

“We can provide universities or research centres with weather data and we are also looking to expand our market to banks, insurance companies, and anyone that can use the data for risk mitigation.”

She highlights the highly intuitive system on which the software is built as a real differentiator for METOS®. Alongside the weather stations themselves, the program is instructed to give highly accurate output.

“Pessl Instruments has an global partnership with Meteoblue – the world’s leading forecast provider – and it uses a multi-learning model where it determines which of their 17 different

weather forecast models is the most suitable for that specific location to ensure data is as accurate as possible. It also uses the data collected by the weather station to, over time, compare what was the weather prediction was and what actually happened. In this way, it learns and calibrates itself so that it can become more accurate for the area where it is installed. Combining forecast models with on the ground measurements is what makes it unique.”

There has been interest from researchers who see the weather stations as perfect tools for monitoring smart city developments. As metros look to technology to make environmental improvements to air conditions, water management, and more, this type of proven technology is well-suited.

“Meteoblue in collaboration with

Pessl already does this worldwide,” says Olivier, “and this could be particularly applicable in South Africa. Weather stations could be installed across cities, in parks, on bus stops, by rivers, to collect data on temperature, wind and other climatic parameters. This can help mitigate risks from floods, storms, and other challenges.”

Others in the industry that provide weather station hardware often lack the quality of supporting software, and developers of clever programs often create without the hardware in mind. Having the whole package available together and being able to empathise with farmer in the field, sets METOS® apart.

“Pessl is focussed on agriculture and how it can bring value to the farmer. The software and all the technology and AI

www.enterprise-africa.net / 25

Introduction to

Introduction

cga@sun.ac.za sun.ac.za/cga +27 21 808 4935

/ Advanced Earth Observation

to Geographic Information Systems

INDUSTRY FOCUS: AGRICULTURE

installed 200 weather stations as part of that project. The other 250 is stations we put in place to establish our own network,” details Olivier. In total, METOS® SAhas around 1000 weather stations active across southern Africa.

that they have built into the systems is of major value,” declares Olivier. “Other weather station providers , might be focused on scientific data recording, which is beneficial to a university, but it can be difficult for a farmer to use that data without actionable insight. We give the farmer tools that are easy to use and understand and can assist in quick decision making.”

EUREKA CLIMATE SMART AGRICULTURE PROJECT

Demonstrating the power of weather station coverage across the Western Cape, the Climate Smart Agriculture

project set into motion by EUREKA – a JV between the University of Stellenbosch, Pessl, Metos SA, and TerraClim – shows the vast difference in microclimate between regions that sit very closely together. Complex terrain means that intelligence is required to make effective and accurate decisions while temperatures in SA are at the highest level in 138 years.

“It is focussed on the agricultural production areas. We have a large footprint in the Western Cape after a project funded partially by the SA and Austrian governments and the private entities themselves and we

“TerraClim ingests the data and studies historic climate- and terrain data to amongst other things, determine what would be the best cultivar of grape to be planted on a specific block. It looks at different aspects such as quality and the amount of yield that could be achieved. This is helpful to the industry on a larger scale so that farms can undertake longer-term planning and hindsight analysis,” she adds.

Another value added for farmers – who can purchase a weather station outright or gain one on a lease arrangement with Metos SA – is the disease models produced by the system.

26 / www.enterprise-africa.net

// WE GIVE THE FARMER TOOLS THAT ARE EASY TO USE AND UNDERSTAND, AND CAN ASSIST IN QUICK DECISION MAKING //

The station identifies environmental factors and calculates the risk of a certain disease developing in the field, based on the pathogen’s biology. Temperature and moisture condition measurements help to calculate a risk which allows farmers to plan sprays correctly and ensure crop is protected during a time of high-risk. METOS® SA

ALWAYS A MARKET

The South African economy continues to teeter on the edge of recession, registering GDP decline in one quarter and slim growth the next. In the agricultural space, where work is seasonal and often reliant on export, an unpredictable economic environment has made life difficult for some farmers. But Olivier is confident that METOS® technology will not drop down the list of priorities as people try to cut costs.

“Everybody needs to eat,” she says. “There is always a market for food That is why we get tremendous support from government entities around the world. These weather stations can help farmers to work sustainably which contributes to food security and the economy. 21% of SA’s workforce is employed in agriculture. If we can’t farm sustainably then those jobs will be on the line. The system also plays a role in helping South Africa and Africa to export food.”

She adds that the data being compiled currently does sometimes make for difficult reading. Weather patterns are changing – drought is common, and temperatures continue to soar. The price of doing business in agriculture will increase, and methods will change. But, again, utilising technology to make the best decisions will be essential.

“It is a complex system but when compared to the value of crops and the value of food in the long-term, along with the inputs you can save, the value of the system is much larger than the price of the individual parts.”

In the future, the valuable complex system could be manufactured locally. Creating jobs and keeping money in the

Climate Smart Agriculture: Getting Ahead of the Curve

economy, METOS® SA is keen on local production to bring the value chain to South Africa. “Certain international funding entities are looking at investing in Africa and African agriculture,” says Olivier. “One of the options we are exploring is to put up a production plant in Africa so we can manufacture locally which will reduce import costs, allowing us to provide products and services at a more cost-effective price. We hope to see progress with this in the next two to three years.”

This will help to drive further roll out, and the snowball effect will mean total coverage and unparalleled information collection for the benefit of all who require consistent weather data.

“With our growing network and the projects, we have been implementing, farmers are realising the need for accurate and hyperlocal data in their

operations. When we kicked off with this is 2019 in SA, it took a lot more for me to convince a farmer why they need this. Now, they approach us and they tell us they need a weather station. The brand is in a good place, the SA weather network is in a good place, and I can only see it growing exponentially from here,” Olivier enthuses.

Proof of the value delivered by METOS® SA is highlighted by Eksteen in Hermanus and Stephan in Sandveld who both agree that their partnership with METOS® SA has improved how they farm through the use of clear and concise weather data.

METOS SA www.enterprise-africa.net / 27

For food and economic security info@terraclim.co.za www.terraclim.co.za WWW.METOS.CO.ZA

The Ideal Blend of Varietal Innovation and Farming Tradition

With family farming roots running deep, Graaff Fruit is a third-generation business bringing customers around the world healthy, tasty, natural products from its 220ha Lushof farm.

“Graaff Fruit is a company entrenched in traditional values, with contemporary ideas,” it sums up, of the dual driving forces behind its provision of some of South Africa’s finest fruits.

With its name coming from the Roman goddess of fertility, the Ceres Valley is renowned for producing some of the best quality fruit in the world and ideal for the cultivation of an array of vegetables and fruits like cherries, peaches, apples, plums, pears, nectarines, and apricots.

In 1968 the Graaff family purchased the Lushof farm in the Warm

Bokkeveld area near the town of Prince Alfred Hamlet, barely north of the Ceres Valley in the Western Cape. Robert Graaff later became the first member of the Graaff family to live on the farm, moving over in 1997 and beginning farming there the following year.

Today, Graaff Fruit packs in excess of 25,000 tons of fruit annually. Delecta, the South African exporter

of deciduous and citrus fruit in which Graaff Fruit now holds a 63.5% share, exports more than five million cartons of produce from 120 suppliers to 35 countries.

PARTNERSHIP WITH NATURE

Since the outset the farming area has almost tripled in size, from the original 80ha under production to

PRODUCTION: Timothy Reeder

28 / www.enterprise-africa.net GRAAFF

//

FRUIT

INDUSTRY FOCUS: AGRICULTURE

its current 220ha, with a medium chill climate and high summer temperatures combining to produce good sugar levels, all underpinned by a healthy supply of water received from mountain runoff through local irrigation schemes. “Today under the guidance of [GM] Danie Viljoen and his team,” Graaff details, “we

produce apricots, peaches, nectarines, plums, pears and apples here.”

At Romansrivier, near Wolseley in the Breede River Valley, Graaff Fruit also produces stone fruit under nets, an additional measure which helps to mitigate the challenges presented by the climate and protect the trees and fruit from wind damage. “As our storage dam is situated higher than our orchards, we are able to irrigate our orchards by gravitational flow which ensures a very low carbon footprint,” Graaff Fruit adds.

“We are proud of our Romansrivier nature reserve which is managed in co-operation with CapeNature and seeds from plant species growing in the reserve have been sent to the Millennium Seed Bank in the UK.”

The purchase in 2012 of the very large Rietfontein farm, situated in the golden Triangle in the Koue

Bokkeveld just 50km north of Ceres, added a significant apple portfolio to Graaff Fruit’s productions in a region blessed with very high winter chill units and mild summers. The farm has abundant water supplies, and presents considerable opportunity for future expansion.

Graaff Fruit takes nothing for granted in the fortune it has been granted in the many advantages to its various locations. “We believe in preserving what Mother Nature provides,” it commits. “We are in partnership with nature. With our roots firmly grounded in Africa, we also feel a strong sense of social responsibility towards our community and our country. It influences the way we farm, invest, and do business.”

“Graaff Fruit is committed to supporting methods that are sustainable, that minimise wastage

30 / www.enterprise-africa.net

// GRAAFF FRUIT IS COMMITTED TO SUPPORTING METHODS THAT ARE SUSTAINABLE, THAT MINIMISE WASTAGE AND THAT PRESERVE THE ENVIRONMENT //

and that preserve the environment.”

Chiefly producers of top quality stone, pome fruit and table grapes as well as onions, Graaff Fruit has today have achieved complete vertical integration and involvement in the entire supply chain through intellectual property management, nursery, production, packing, shipping, and marketing the product.

CONTEMPORARY IDEAS

South Africa is among the foremost fruit producing countries in the world and more than 50% of its agricultural exports number fruit, contributing 2.5% to the country’s GDP. Apples have been produced commercially in South Africa since the 1880s and have been exported from South Africa to the UK since the 1890s, while pears topped the export charts from as early as 1910.

Consequently, there are basketfuls of acquired knowledge and wisdom around this ancient art to deploy, which Graaff Fruit expertly combines with the best of modern innovation and ideas. “We are driven by progressive innovation and have a welldefined company culture of providing our customers with the best possible fruit in every aspect,” it explains.

Graaff Fruit is always prepared to extend its reach in pursuit of the best, too. “We travel abroad annually in search of new cultivars that would be suitable for the South African

climate and soil and this keeps us at the forefront of varietal innovation. We have tested hundreds of new varieties on our trial orchards, including a trial orchard under net, and this process is ongoing from year to year.”

“Our philosophy is to maintain relationships with all breeders in order to make the best variety choices for our needs.”

“We position ourselves as leaders in our field by remaining on the forefront of the latest developments and technology in our farming sector,” the company furthers, which it achieves by keeping itself keenly abreast of trends within the industry and regularly consulting various specialists who are world leaders in their fields.

Known for its unbending standards and its glorious marriage of historic knowledge with the best

of modern technology, Graaff Fruit is at the root of some of the best deciduous fruit in South Africa; equally, it stresses, it is a caretaker, of both the environment and its people, who it recognises are firmly at the backbone of the organisation. “We continuously nurture good working relationships with our staff members, maintain ethical practices and work towards continual improvement of their living standards,” the company resumes.

“We realise that our business would not exist without them and that healthy worker relations lead to a healthy business.”

GRAAFF FRUIT www.enterprise-africa.net / 31

WWW.GRAAFF-FRUIT.COM

// WITH OUR ROOTS FIRMLY GROUNDED IN AFRICA, WE ALSO FEEL A STRONG SENSE OF SOCIAL RESPONSIBILITY TOWARDS OUR COMMUNITY AND OUR COUNTRY //

DAKRI CARTONS

Continuous Improvement Brings

Corrugated Carton Perfection

PRODUCTION: Eleanor Sarbutt-King

An organisation recognised as a foremost producer of corrugated carton in Mauritius, Dakri Cartons is a custom packaging solutions company with more than 30 years’ experience in the industry. Continuous improvement and innovation represent the cornerstones of Dakri Cartons’s method, outside-the-box thinking which consistently entails upgrades and new products galore.

32 / www.enterprise-africa.net

INDUSTRY FOCUS: MANUFACTURING

//Creating both standard and custom packaging for businesses in the Indian Ocean region, since 2015 Dakri Cartons’ factory has been relocated in Petite Rivière, Mauritius. A leading specialised corrugated carton

manufacturing company on the island, Dakri Cartons also imports and sells biodegradable food packaging products, including packaging boxes made from Kraft paper.

The company specialises in the production of die-cut and regular slotted boxes, with various degrees of print and graphic design, as well as a large proportion of a variety of boxes that are used in the food industry; for example, small perforated die-cut boxes for cherry tomatoes and grapes which are sold in supermarkets, and a variety of boxes like these for various products

which were previously packed in plastic bags or plastic boxes. They also produce a variety of cake boxes and pizza boxes. With the seismic shift away from plastics and a market that was historically dominated by polystyrene, Dakri Cartons has seized the opportunity to create alternatives now being sold in Mauritius, Reunion Islands and the Seychelles.

PACKAGING PILLAR

“Dakri Cartons aims to provide you with sturdy and dependable carton packaging for your needs,” states Dakri Cartons. “We use corrugated sheets

34 / www.enterprise-africa.net

// THERE IS NOT A LOT MADE OF CARDBOARD THAT WE CANNOT MANUFACTURE //

in our box manufacturing process, a tried-and-tested material which is resilient and malleable, and which has become the benchmark for standard and customised carton boxes.

The company has evolved into a pillar of the carton manufacturing industry in Mauritius.

With its core business in the provision of corrugated cardboard and food packaging, Dakri works with and produces for major international beverage companies and the textiles, alcohol and food industries, especially can packaging for the foremost tuna brands.

“There is not a lot made of cardboard that we cannot manufacture,” Dakri summates.

“Now we are setting our sights on the coastal countries

of Africa, wherever there is good access to a port,” he relates. “This is really important to us; as we are a cardboard factory in the middle of the Indian Ocean, the further inland we have to deliver the product, the less competitive we are naturally going to be, with the addition of freight and transport costs.” CEO Nazir Dakri reasons.

“Another of the core strengths of being located on an island like Mauritius: while it is a very small market, it is equally very diverse, and the requirements of each customer are vastly different. We have therefore had to design the factory to be inherently flexible, to be able to make small to medium, as well as large, runs, in any type of format or print variation according to what the client requires.”

SPECIALISED SOLUTIONS

“We do not make standard products, as such; we make custom, specific products branded specially for the customer at hand. Currently we are targeting very specialised businesses, and above all we want to produce the packaging for the wine industry,” Dakri

DAKRI CARTONS www.enterprise-africa.net / 35

// DAKRI CARTONS HAS EVOLVED INTO A PILLAR OF THE CARTON MANUFACTURING INDUSTRY IN MAURITIUS //

Celebrating 35 Years of Excellence! Congratulations to the Dakri Cartons team

INDUSTRY FOCUS: MANUFACTURING

reveals. “Mainly the boxed wines that are used by restaurants and bars.”

Interestingly, Dakri describes that, for Dakri Cartons, the best way to stay ahead of the chasing pack is by focusing on introspection and self-improvement, rather than

being overly concerned by what its competitors may be doing around it. “We feel that we have so much to learn and develop ourselves, it is so much more interesting to focus internally, and try make us our own competitor.

“I borrow the mindset I use when doing triathlons: of course, yes, there is competition, but it boils down to how well we have trained and mastered each aspect of, in this case, the business, and every small step has to be better than the previous year. If that work has been done right, and diligently, and techniques and principles and traits have been applied, you cannot

be anything other than the best in the field at the end of that year.”

It is an interesting proposition; if the importance is placed merely on overtaking the perceived ‘leader’, and then no more is done to excel, is a business, or an individual athlete, to borrow Dakri’s analogy, not severely limiting its own potential? “This is why we exclusively set our own personal bars, not those based on someone else’s expectations,” Dakri answers.

CONTINUOUS IMPROVEMENT

Dakri Cartons’s machinery and processes are subject to similarly stringent enhancements. “We make

36 / www.enterprise-africa.net

// WE MAKE USE OF CUTTING-EDGE MACHINERY, AND KEEP UP TO DATE WITH TECHNOLOGY //

use of cutting-edge machinery, and keep up to date with technology,” Dakri outlines. “To stay in the lead in our industry, we must consistently produce high-quality carton, and we keep standards high by constantly improving our carton production techniques.”

Perhaps naturally, this drive for continued and sustained improvement translates to the opportunities for uplift available to the company’s staff. “We are very employee-centric; we believe firmly in learning and education alongside continuous improvement as core and fundamental for us.

“We often find gaps, particularly on the technical side, with those coming to work for us and we have to fill those gaps ourselves through training and raising the standards, and continually reinforcing these. This has made a huge difference, I have remarked, raising confidence and the willingness to take responsibility and risks, and thus bringing greater reward, while knowing what the limits are and what is too far.”

It has a big effect on employee retention, Dakri confirms, but is double-edged: “It is also extremely useful in weeding out those who do not share the company’s values with regards to growth and continuous improvement,” he says. “Over time, I hope that we will gain a reputation that means that only people who want a career and to progress and grow are wanting to work with us.

HIREFOUR FORWARDING CO LTD

Freight forwarding service is to provide transportation by sea of full load container from Port Louis to port destinations chosen by customers.

Besides freight forwarding, the company acts as purchasing agent for its clients. The goods required by them are purchased in Mauritius from various suppliers with a zero rated invoice. The list of goods may vary from poultry feeds, plastics, minerals, hardwares, motors or even vehicles. Goods are placed in company’s store until stuffing is done in container before transporting to maritime agency.

Tel: (230) 240 6841/240 6088

E-Mail : hirefour.forwarding@intnet.mu

“We are introducing the Kaizen principle, a system of continuous improvement, to rally the engagement of all employees. It encourages them to think of how they can improve their working conditions, while also thinking of the positive impact of these changes on their colleagues”, he adds, with the Japanese philosophy of ‘good change’ involving employees at all levels of the company working together to improve the manufacturing process. Continuous improvement, for Dakri, also relates to Dakri Cartons’ footprint, he reveals. “What I want to do now is take Dakri Cartons international. I would like to set up factories in the better countries in Africa - those that have a demand for the product, and a hunger and entrepreneurship to export. If they are aligned with those elements, we will look to open there.” Reunion

Island

features highly on Dakri’s wish-list, offering an already-established, stable market and a potential great reduction in lead time.

“Every year, we are continuously improving every aspect of the business, meaning that there is always so much underway here,” Dakri closes; the company’s new print-ondemand service and exciting potential e-commerce entry are just two more of its current ventures. “Penetrating the African market would arguably be the biggest deal, though,” he closes.

“Our three decades of experience and service have earned us the trust of major business leaders in Mauritius, Reunion, and the Indian Ocean region; now we want to take our excellence in a box as far and wide as we can.”

DAKRI CARTONS www.enterprise-africa.net / 37

Consolidation | Packing | Transport

IKS Building, Old Marine Road, Port Louis, Rep of Mauritius

WWW.DAKRICARTONS.COM

// OUR THREE DECADES OF EXPERIENCE AND SERVICE HAVE EARNED US THE TRUST OF MAJOR BUSINESS LEADERS //

VICTORY FARMS

Fastest-Growing Fish Farm Is Far from Floundering

Based in rural Roo, Homa Bay, Kenya, just seven years since its founding, Victory Farms is already the largest producer of fish in East Africa and is now on a mission to feed two billion Africans and provide affordable, accessible, and healthy protein to people across the land.

Established in 2015 with its base near Lake Victoria, Kenya, Victory Farms is already subSaharan Africa’s fastest growing fish farm and specialises in the supply of tilapia to the Kenyan market, with a production capacity of 10,000 metric tonnes. The company is, in turn, vertically integrated with breeding facilities and a sales depot in Nairobi.

Having been incepted against a backdrop of rapidly declining wild fish catch in Lake Victoria, increasing demand for protein and high levels of undernourishment, Victory Farm now uses the very best global aquaculture practices to deliver healthy and fresh tilapia into low-income Kenyan neighbourhoods daily. Several small business and entrepreneurs

PRODUCTION: Jamie Waters

38 / www.enterprise-africa.net

//

INDUSTRY FOCUS: AGRICULTURE

to AFN. “The traditional way of doing aquaculture is also very inefficient and that’s the way that’s practiced almost everywhere in Kenya and East Africa.

“We saw an opportunity to build an end-to-end protein platform,” he adds by way of resolution. “It’s really a science-driven and tech-enabled platform significantly disrupting traditional businesses through the use of technology.” Identifying the high, but unmet, demand for fish in the East African market and deficit being filled by Chinese-sourced fish of varying quality, Rehmann and co-founder Steve Moran set out to produce quality tilapia to supply across Kenya and subsequently expand to other East African countries.

carbon neutral fish farm, as it sets about building commercial tilapia farms that can provide affordable, accessible and healthy protein to millions of people in East Africa.

QUITE A CATCH

According to the United Nation’s Food & Agriculture Organization (FAO) fish feeds over 200 million Africans, and in most regions of the continent, with East Africa a prime example, supply annually falls short of demand - primarily because fishing rates are unsustainable.

A study published in the Marine Ecology Progress Series Journal reveals that fish stocks along the coast of East Africa are depleting at an alarming rate, with 70% of the reefs below sustainable levels.

Victory Farms reveals a 90% decline in tilapia, the most popular freshwater fish, as the human population surges and unsustainable fishing practices abound. “The problem is the wild catch cannot keep up and it isn’t going to bounce back, at least not for a long time,” explained Joseph Rehmann, CEO and co-founder of Victory Farms,

In recognition of the efficacy of its combination of indoor fish farming, on-base farming and lake farming using deep-water cages in the provision of a consistent supply of fish, Victory farms last year raised $5 million in equity funding to expand its operations into Rwanda, Tanzania and the Democratic Republic of Congo (DRC).

The round, led by two angels - MD of Bain Capital Ed Brakeman and Hans den Bieman, Director of Sealand Aquaculture - came after the commercial fish farm secured a mezzanine debt investment from the ag-focused social impact investor AgDevCo in 2021, and from private equity firm DOB Equity in 2020. Then, in April this year, Victory Farms successfully completed a $35 million Series B round, to not only fund the expansion of its operations in Kenya and Rwanda, but pave the way for potential entry into Ethiopia, Uganda, and Tanzania, too with its climatesmart, profitable, scalable solution to Africa’s nutritional security challenges.

“Our regional growth will expand access to a healthy and nutritious protein alternative for Africa’s mass consumer,” Victory Farms enthused. With tilapia being the most environmentally and financially efficient protein solution for Africa, investment of this kind in sustainable African aquaculture is

40 / www.enterprise-africa.net

FEEDING FOR PROSPERITY

Novatek Animal Feeds is the largest animal feed producer in Zambia and has been in operation since 2008. With two production facilities, one located in the capital city Lusaka and the other on the Copperbelt Province, Mpongwe, Novatek is strategically located with a large retail and distribution network to serve farmers all over Zambia. Novatek strive to be the leading supplier of technologically advanced animal feed products in Zambia and is also the only feed producer with an ISO 22 000 Food Safety Management System Certification.

NOVATEK AQUAFEEDS

Novatek Animal Feeds Zambia produces a variety of fish feeds products that ranges from hatchery to out-grower feeds and includes crumbles and pellets for both ponds and cage systems. We supply fish feeds to most of the southern African countries and East Africa such as Kenya at Victory Farms, Rwanda, Uganda, Congo DR and Tanzania.

We are also commencing delivery of our fish feeds into West Africa, especially for the Catfish to be accompanied by Tilapia. Our fish feeds are certified under DQS Quality Systems and ISO 22 000.

Quality feed for Africa from Africa

central to reducing reliance on imports and delivering food to millions, all while supporting local agriculture industry.

NETTING SUCCESSES

At the outset of the freshly-founded company some eight years ago, the decision was taken to create a pipeline of qualified workers for their fish business in Homa Bay County. “The aquaculture industry was small and couldn’t provide a big talent pool of trained professionals. We had to focus on training first,” Rehmann expounds. “Pioneering was the hardest part.”

To fulfil the demands of a business which involves fish feed production, breeding, hatchery, processing, cold chain distribution and retail, the founders instituted a college hire programme called Graduate Aquaculture for Learning

and Training (GALT); it has already, to date, seen 40 trainees graduate, half of whom now work at Victory Farms in a true vindication of the training investment. “They are the future of aquaculture in East Africa,” Rehmann proudly announces.

With the founding duo bringing decades of experience of business and aquaculture acumen and technical skills, the company’s staunch dedication to upskilling its workforce and having now mastered the art of fundraising, over the years the business has grown from the 100 tonnes of fish it was producing to, in 2022, 7,000 tonnes and 10,000 tonnes expected this year; the plan is to use the recent funding to further scale Kenya’s production capacity to 20,000 tonnes annually.

“Kenya has the opportunity to be the world leader in tilapia

production,” Rehmann goes on, “and our fundraising enables us to deploy capital into research and development to understand how to substitute foreign feed ingredients with local ingredients which has a massive multiplier effect on job creation.”

“We are also exploring investment opportunities in Uganda, Tanzania and Ethiopia for the next few years,” Rehamnn rounds off, and while there may be plenty of other fish in the fiercely competitive Kenyan fish farming sea, Victory Farms, listed among the top 100 SMEs in Kenya by Business Daily and KPMG in 2022, looks set to enjoy top billing for the foreseeable.

VICTORY FARMS www.enterprise-africa.net / 41

Feel free to reach out to us and we will be glad to do business with you. We are here to serve you. Contact us: National Sales Manager: +260978 779 017, +260971 252 522 salesmanager@novatek.co.zm

VICTORYFARMSKENYA.COM

Creativity, Integrity, and Innovation Ensure Mauritians Flock to Eagle

Eagle Insurance is one of the leading insurance companies in Mauritius and provides comprehensive insurance solutions across a broad range of sectors. Its newly-appointed CEO Sattar Jackaria, an actuary by trade, explains that although Eagle Insurance has been transacting all classes of short-term insurance business for nearly half a century whilst earning a solid reputation along all these years, it cannot afford to sit on its laurels amidst the stiff competition on the island. He further stresses that Eagle Insurance needs to continuously improve its offering through further investment in technology, upskilling & empowering of its staff, developing new product features but more importantly, delivering an irreproachable customer service in order to keep it firmly on its perch.

PRODUCTION: Eleanor Sarbutt-King

PRODUCTION: Eleanor Sarbutt-King

42 / www.enterprise-africa.net

EAGLE INSURANCE

Sattar Jackaria, CEO

Sattar Jackaria, CEO

INDUSTRY FOCUS: INSURANCE

//Having started operations in January 1974, Eagle Insurance has notched up nearly half a century in this most competitive of Mauritian markets and built up an extensive portfolio of customers, from private individuals to SMEs and large corporates.

“Our specialist position in the market allows us to bring significant benefits to our clients. With an unparallel blend of expertise and experience, we are able to offer tailor made and innovative insurance solutions to our clients,” explains CEO Sattar Jackaria.

“Being in the services industry and insurance being quite a complex field, one of the key ingredients to be a

leading insurer is to have a passionate and highly experienced workforce that will go the extra mile to meet the needs of the client. It goes without saying that you also need to have the financial muscles to meet the claims when they arise. Eagle Insurance is proud to boast a strong balance sheet that is managed judiciously and protected by a panel of trustworthy reinsurers with whom it has forged strong relationships. In addition, Eagle Insurance is privileged to have IBL as its main shareholder, the largest conglomerate on the island.” Based on its sound practices and operational excellence, Eagle Insurance prides itself on delivering a high level of customer service to meet its clients’ evolving and more demanding requirements.

OPERATIONAL EXCELLENCE

Eagle Insurance has historically been providing insurance to mainly businesses. These businesses usually use brokers to advise them on their insurance requirement and help them choose the best offering on the market. By virtue of this legacy, Eagle Insurance has established close working arrangements with most of the brokers on the island, to better meet the needs of businesses, with policies ranging from building insurance to employee benefits like personal accident and health insurance - the full spectrum of what a business should take out as insurance protection. “We have earned the trust of most brokers and their clients alike” Jackaria reveals.

44 / www.enterprise-africa.net

TYSERS – A PROUD SUPPORTER OF EAGLE INSURANCE

Tysers is delighted to extend its congratulations to Sattar Jackaria, newly appointed CEO of Eagle Insurance Limited (EIL), and wishes him great success in his new position.

We are proud to have supported EIL for more than 30 years and offer a full suite of classes to accommodate all of Eagle’s insurance and reinsurance requirements. Tysers has provided insurance services to the African continent since the mid-1970s. Our acquisition of broking firm RFIB in 2020 increased our footprint and further enhanced our client offerings and capabilities in the region. Today, we work with both domestic and international insurers in the Mauritian and African markets and have the capacity, knowledge, and expertise to advise on all aspects of our clients’ insurance and reinsurance needs.

Client-first philosophy at our core

First established in 1820, Tysers has a client-first philosophy at our core. This client-centric approach, combined with a forward thinking and nimble approach to insurance and reinsurance, has stood the test of time and we have grown from a broker with less than 100 employees in the 1980s to today’s leading independent Lloyd’s broker with over 1,000 experienced and talented employees.

Our services continue to evolve as we embrace technology and enhance our offerings to better protect our clients’ businesses.

Headquartered in London, the premier insurance market, we have offices and associates around the world and trade in 140 countries across the globe. We provide creative and custom-made solutions to meet the specific needs of our global client base for consulting, broking and placing risks, technical wordings and claims handling; placing our business with Lloyd’s and other top-rated carriers.

Tysers, part of the AUB Group

In 2022 Tysers became part of the AUB Group, an ASX200 listed group comprising insurance brokers and underwriting agencies operating in 520 locations across Australia and New Zealand. Visit AUB Group for more details. The combination of AUB and Tysers creates a leading, international insurance broking group with a huge depth of expertise and capabilities with vast product offerings and specialisms.

For more information, please visit Tysers.com.

EAGLE INSURANCE www.enterprise-africa.net / 45 Tysers Insurance Brokers Limited is authorised and regulated by the Financial Conduct Authority. Registered Office: 71 Fenchurch Street, London, EC3M 4BS. Registered Company No. 2957627 England. TYSERS IS PROUD TO HAVE SUPPORTED EAGLE INSURANCE FOR OVER 30 YEARS tysers.com linkedin.com/company/tysers

INDUSTRY FOCUS: INSURANCE

As a testimony to this specialist expertise on the corporate market, Eagle Insurance is the market leader on the marine side. “We are the market leader on the marine side. This includes cargo and hull insurance taken out by businesses. Moreover, we have leveraged on this expertise to create a policy for those wanting to insure their own personal pleasure craft.”

Moving forward, Jackaria stresses that the focus would be on consolidating this corporate market segment as well as to use this expertise to develop its presence on the individual market.

“In order to take the business to its next phase of growth, we need to strengthen our positioning on the corporate segment but at the

same time adapting our processes to cater for individuals” while remaining aligned with the broader Eagle Insurance vision, Jackaria divulges.

“We will strive to be the insurance partner of choice for businesses but also for individuals by customising our products and services to their needs.”

PROXIMITY AND PROMPTNESS

Formally appointed in July 2023, following an interim period, Jackaria, a seasoned professional with more than 20 years’ experience in the financial services sector coupled with a deep understanding of the local insurance landscape, is well-positioned to take Eagle Insurance forward.

Strong leadership qualities and the ability to foster positive team

spirit across the company were additional corollaries that served to make Jackaria the ideal man for the job. “For the past 7 years at IBL, I was entrusted to define the strategy and of the different businesses within

46 / www.enterprise-africa.net

// AT EAGLE INSURANCE, OUR PEOPLE AIM TO DELIVER THE SAME LEVEL OF SERVICE TO ALL OUR CLIENTS IRRESPECTIVE OF THEIR SIZES OR IMPORTANCE //

its financial services cluster and to drive them forward. I am humbled to take on this new challenge at Eagle Insurance” he offers by way of context.

“Over the last three months, I have enjoyed working closely with the team internally to fine tune our strategy,” he says.

“We have also consulted with those who we service, and what has emerged is our closeness, proximity and promptness to respond to queries and settle claims that collectively differentiate us.”

A flat organisational structure is behind the ability for Eagle Insurance to establish a close working relationship with its stakeholders. “At Eagle Insurance, our people aim to deliver the same level of service to all our clients irrespective of their sizes or importance.

We have found that this humility has helped to respond to the needs of our clients promptly and efficiently.” What comes across in all that Jackaria describes is the core Eagle tenet of putting people first, ensuring that staff, clients, intermediaries, and any other stakeholders are firmly at the centre.

RAISING PROFILE

“Within the corporate segment, Eagle Insurance is well-known” he admits. “However, if you were to ask the layperson in the street to name an insurance company on the island, Eagle would not be the brand enjoying top billing in most cases - even unknown by many.”

“If we wish to really make an impression on the individual market , first and foremost we need to

work on our brand recognition, our visibility, and our value proposition. We are going to focus a lot of energy and resources on this area over the course of the next few years.

“Recruitment and human resources are equally high on the agenda,” Jackaria wraps up. “With the shortage of experienced staff within the industry on the island, a true employee value proposition to entice the best of this current generation will therefore be crucial. Implementing these two fundamental aspects of the strategy will help business flow naturally and, in turn, keep Eagle Insurance aloft and soaring above the rest.”

EAGLE INSURANCE www.enterprise-africa.net / 47

WWW.EAGLE.MU

INNOVATIVE PVC COMPOUNDS

Flourishing Family Business Flying into Fresh Markets

PRODUCTION: Eleanor-Sarbutt-King

Durban-based PVC manufacturing business, Innovative PVC Compounds, is family-founded and family-run. It is this family experience that has built deep trust internally and externally. Operating differently from most family set ups, the business will soon gain international quality certification, boosting global growth ambitions. The Directors talk to Enterprise Africa about strategy and growth.

Running a successful family business takes a clear vision, time, commitment, strategic efforts, and great patience, all of which Innovative PVC Compounds has proven is not only very much possible but a pleasing experience. The Siddiqi family has built a strong and reliable brand

that instils trust within the internal team as well as customers near and far.

Innovative PVC Compounds is a compounder of a wide range of PVC (Polyvinyl chloride) compounds which are formulated, developed, and delivered from its base in Durban, KwaZulu-Natal.

48 / www.enterprise-africa.net

//

INDUSTRY FOCUS: MANUFACTURING

members working in the business since inception or soon thereafter.

The production facility is headed by an accomplished Production Manager who specialises in plastics processing. Management is formed by three key areas – Finance, Operations and Procurements, and Sales and Marketing – all of which are led by family members within their relevant departments. The passionate and zestful nature of the IPC team allows for the business to grow with ambition and purpose, serving customers with the best customer service and quality compounds.

COLLECTIVE VISION

“When we talk about the future and vision of the company, we see it as a collective approach working with everyone’s strengths,” Saná, Marketing

Director says. “Mubeen, the CEO, who also happens to be my father, has extensive experience in the PVC compounding industry, and how the market works – that is our foundation. Saalick, a highly qualified Industrial Engineer, and my brother, oversees all operations and procurements. Alongside our Production Manager Bheem Singh Verma who is an Engineer specialising in plastics processing, they ensure the business runs efficiently and effectively. Rumaisa, my mother, who has taken over the chairmanship of the board of directors has a well versed and overall knowledge of the industry due to the family being in the business for the last 28 years. She also brings in the CSR element to all areas of the business, with her extensive background in social responsibilities.