As a leading manufacturer of starch, glucose and agri-products we offer a range of innovative, sustainable ingredient solutions.

Solutions of exceptional quality made from nonGMO maize sourced in South Africa for customers across the continent and around the world. Spanning industries and product categories as diverse as confectionery, prepared foods, alcoholic and non-alcoholic beverages, paper manufacturing, pharmaceuticals, building

EDITOR Joe Forshaw

SENIOR PROJECT MANAGER Sam Hendricks

SENIOR PROJECT MANAGER James Davey

PROJECT MANAGER Ekwa Bikaka

PROJECT MANAGER Christina Allcock

christina@enterprise-africa.net

PROJECT MANAGER Eleanor Sarbutt-King

eleanor@enterprise-africa.net

PROJECT MANAGER Jamie Waters

jamie@enterprise-africa.net

LEAD DESIGNER Aaron Protheroe

FINANCE MANAGER Samantha Lynn

samantha@enterprise-africa.net

CONTRIBUTOR Manelesi Dumasi

Timothy Reeder

Benjamin Southwold CONTRIBUTOR William Denstone

Published by Chris Bolderstone – General Manager E. chris@cmb-multimedia.co.uk

Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX +44 (0) 1603 855 161 www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/ or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

//The development of new industry sectors in South Africa is vital as people hunt for new skills in modern sectors, that will allow them to gain sustainable employment. Embracing digital and the Fourth Industrial Revolution is one thing, but driving skills development in much-needed sectors – where there is economic opportunity but lacking knowledge – is another. Thankfully, this idea is being embraced by some as they look to utilise existing infrastructure to pave the way for development.

At the Port of East London, run by Transnet National Ports Authority, new Port Manager Sphiwe Mthembu is hoping to increase capacity and efficiency but also create new sectors including a marine repair and rebuild industry by regenerating the back of port area.

The Department of Forestry, Fisheries and Environment (DFFE) began a campaign sometime ago to manage the process of recycling waste electrical and electronic material. This has resulted in the growth of ERA – the Ewaste Recycling Authority. From here, new strategies and plans are being put in place by producers all over the country as they look to assist in the mitigation of harmful e-waste. This new concept for South Africa promises economic development and new industry creation in the recycling space.

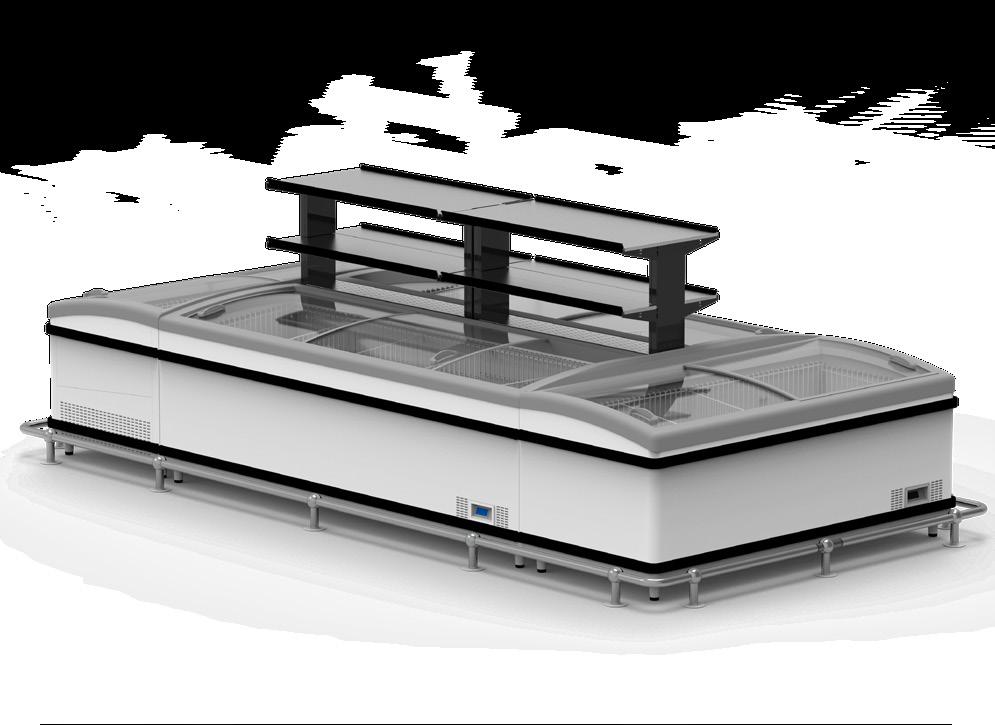

Concord Retail Solutions is looking at new refrigerant gases for its products, mainly CO2. While expertise in this area is still underdeveloped in SA, this is a company pushing to make the most of the opportunity as clients demand environmentally friendly products.

Barloworld is innovating in the financial space, listing genderlinked bonds on the JSE to fuel female empowerment schemes. Creating new ideas and succeeding in previously unexplored territories is the way to get ahead, and demonstrates real entrepreneurialism.

Get in touch and tell us how you and your business is pioneering. We’re online all the time.

Powering over 20,000 users across Africa, Caseware Africa (Caseware) is the global leader in auditing and financial reporting software and is used in over 170 countries worldwide. With four Cs of building business - Courage, Curiosity, Creativity and Culture - always guiding him, Theuns Holtshousen, Business Development Executive describes how Caseware is leveraging the value of collaboration and innovation to continually expand the reach and breadth of its unique, data-rich and insightful offering.

Established for over 30 years, Caseware is transforming the way in which auditing and accounting professionals work through quality products and services combined with state-ofthe-art infrastructure. “At Caseware, we specialise in financial reporting,

audit and analytics software and have come to be known as the undisputed leader when it comes to compliance,” outlines Business Development Executive, Theuns Holtshousen.

“Our offering to clients is a complete solution to ensure success consisting of software, implementation,

and training. Our world-class products are not only designed to deliver on our compliance promise, but ensure quality results, increased effectiveness, and improved profitability.” Caseware is a division of Adapt IT, a South

Continues on page 10

As global leaders in financial reporting software,

designed

and manage multiple compliance

single integrated

African company which provides leading specialised software and digitally-led business solutions.

The financial services division of Adapt IT is widely regarded as one of South Africa’s leading software houses. For more than 25 years, Caseware has specialised in the design, development and deployment of financial solutions for auditing and accounting professionals, providing a complete range of professional services and solutions from audit and accounting to tax and secretarial.

Caseware Africa services all Englishspeaking African countries. “Initially, Caseware Africa was founded as CQS in 1993, which was then acquired by Adapt IT in 2016. Over the last five years especially, we have gained significant market share in East, West and Southern Africa, and there are many other African countries into which we can still further grow,” Holtshousen says. “Malawi is an example of territory

which we have recently uncovered and is already yielding great growth.”

In addition to expanding its footprint across the African continent, Caseware is also very focussed on creating new offerings to help their customers solve new and additional problems, thereby enabling greater value and forming strong partnerships.

“We are a learning organisation first and foremost, and constantly challenge ourselves to be better than we were yesterday, to get more information and act more effectively and strategically. There is also a massive boon of the infrastructure offered by a bigger organisation, and the stability of diversity – the importance of which we very much have learned during Covid-19,” Holtshousen adds.

One of Caseware Africa’s latest product additions is its comprehensive, powerful Caseware IDEA® Data Analysis tool which enables faster, more effective external audits. “Data analytics is changing the game for audit, accounting and finance professionals

globally,” Holtshousen asserts, “and IDEA® is a very mature analytics solution that boasts great depth and capability, which can be bolted onto the audit itself as well as financial reporting.

“There has been an explosion in the amount of data available to auditors, and the beautiful thing about IDEA® is that it gives the ability to access absolutely all of the data at once, rather than just a sample as was the case previously,” he confirms, stressing the empowerment that is wrought upon accounting firms who employ such an intelligent analytics system.

“There is another aspect to this, and the old maxim that with great power comes great responsibility rings truer than ever, in the sense that what has been seen cannot then be unseen,” he unravels. “One need only consider the enormous scrutiny that the audit profession has come under in recent years, to realise that the auditor occupies a really quite powerful position. With IDEA®, auditing teams can increase their data coverage, by investigating a large number of items and potentially

covering 100% of the transactions.

“The power of analytics is really levelling up the sway and position of any financial professional and giving them a totally different seat at the leadership table. Access to this wealth of data and all these insights means that, they can be more effective in fulling their responsibilities and can make greater predictions on the practical implications of the insights that they gain, which I think is a great place for us and the sector to be in.

“Our mission statement is centred around empowering financial professionals with automated compliance, and we want to do this by creating solutions that make things as transparent as possible,” Holtshousen resumes. “This is the exciting part for me. As a product-driven business, we are placing a central focus on various compliance areas, and then turning to the richness of information and insights that resides in the data.”

With its many decades of expertise in helping auditors and accountants automate compliance, Caseware Africa has recently set out to transform

firms’ System of Quality Management (SoQM) management with a brandnew cloud-based app, SQM, designed by audit, data, and quality experts. “SQM helps audit and accounting firms implement their SoQM in compliance with the requirements of ISQM 1 that is becoming effective on 15 December 2022. SQM Quality is one of our proudest achievements to date, because it is our first global product,” Holtshousen beams.

“SQM supports multiple global quality management standards which enables network firms to acquire a single solution use across their global footprint. We continue to focus on delivering new and additional value to our customers,” he states. “SQM complements our existing audit and accounting solutions. What sets our offering apart, is that we support a variety of global compliance standards which have been developed by industry experts in quality management all across the world. Caseware Africa prides itself as being a leader in helping customers automate compliance.”

This is not Caseware’s sole distinguishing factor, Holtshousen details. “Another way in which we

stand out is in our maturity in diversity and transformation. Working on the African continent, on a daily basis we deal with such a variety of cultures and stories, and how we approach inclusion not only from an employee, but also from a stakeholder perspective to make space for everyone to feel safe is something that is part of our brand and of our DNA today.

“Software brands are well-known for their cultures, and ours is definitely part of our competitive edge - we are not only trying to build a business, but one with longevity that attracts customers for life,” is Holtshousen’s closing assessment, with Caseware secure, strong and stable. “We have a very strong leadership culture, and I believe that we are currently in a better position to perform than ever before. At Caseware we are building something not only of worth, but ultimately something that matters.”

Jamie Waters

As a leading supplier of world-renowned technology in printing, labelling, bar coding and more, Kemtek is a vital cog in South Africa’s retail, communication, advertising, manufacturing and packaging industries. The company brings innovative tech from around the globe to businesses in Southern Africa, making for improved performance and quality.

Graham Comins, Managing Director

Graham Comins, Managing Director

//Like most sectors of the South African economy, printing technology has received its share of disruption over the past decade. Those companies that have failed to keep up with trends, and have been unable to meet the quickly changing needs of customers, have fallen to the wayside. Today, clients want easy, instant, quality, and advanced systems that deliver solutions for a range of problems. In South Africa, declining spend on traditional print material, as well as a focus on digitisation, has fuelled change, but many have seen opportunity in this multimillion Rand industry.

Kemtek - the Johannesburgbased supplier of technology for printing, bar coding, labelling, additive manufacturing and more –has advanced its product portfolio to meet the needs of the modern customer, and is thriving as a result. “As technology has evolved, so have we – we are moving beyond technology to embrace and offer holistic business solutions that will deliver opportunities for growth,” the company says.

Working with top brands from all over the world, Kemtek brings unique technology to South Africa allowing for innovation and adoption of enhanced levels of quality. Whether 3D printing, scanning barcodes, labelling produce, or producing mass advertising campaigns, those that receive products and service from Kemtek can rest assured that they are working alongside one of the continent’s best.

But it hasn’t been easy for the company. Following a period of unprecedented turmoil in global supply

chains, catalysed by component and material shortages, getting products into the country and out to 2800 resellers, and then to clients, has made for a tough operating environment.

“A lot of things have happened in South Africa and there is an interesting story around what impact that has had on Kemtek,” smiles Managing Director, Graham Comins, former CFO who joined the company in April 2020.

“As a company, we are very focussed on technology products but we have three very different businesses. We also have a new business which is in its incubation phase at the moment.”

The supply chain crisis emerged as a legacy of the Covid-19 pandemic as shifts in demand, labour shortages, and structural macroeconomics turned traditional procurement upside down. Now, Russia’s war in Ukraine and fresh Covid-19 lockdowns in China add new challenges to the mix, causing further havoc for those reliant on a connected world.

“All of our businesses have reacted very differently to different events that have taken place. We are very proud to be the channel partner for HP Indigo Digital Presses and a lot of the finishing equipment that goes with that. We took a fundamental strategic decision a couple of years ago to move out of the older technologies

around flexographic and lithographic printing, and focus on digital and the products that support digital printing,” says Comins, highlighting the global boom in digital printing, which allows for faster, more efficient processes.

“With HP Indigo, we have a fantastic range of products, but because it is all Dollar-based, it can become very expensive very quickly in the South African market. With the volatility in the Rand, it affects our customers significantly. We have had to come up with some clever ways to price at the right point,” explains Comins.

Since September 21, the Rand has fluctuated wildly against the Dollar, now sitting significantly lower than it did last year resulting in constant planning and adjusting for the company.

Kemtek distributes to 2800 resellers, all over South Africa, and these resellers export to other sub-Saharan African nations, providing installations in Botswana, Angola, Zimbabwe, Mozambique, and soon, Mauritius. However, servicing machines and keeping the technology it supplies up to date is big business, and the

company faces challenges here that can only be overcome with great people and relationships.

“The global shortage of components has had an impact in terms of our ability to delivery and timelines to repair. Our principal suppliers are good at supporting us with that, but being stuck at the bottom end of Africa, we are often faced with delays as parts sit on aircraft or with courier companies for weeks. These are challenges we have to face and how we manage those sets us apart,” explains Comins.

Kemtek’s 136 people, working from bases in Johannesburg, Cape Town, Durban, Tshwane and Gqeberha deliver a carefully planned strategy that ensures customers are always serviced. For Comins, quality service delivery is paramount.

“Despite the issues we’ve had with supply chain issues and component shortages, we carry a lot of stock. We have always held stock and we have always recognised that you must have the stock to sell the stock. We have invested a lot of money into our inventory to ensure we carry a wide range. Generally, one of our differentiators is that we

give exceptional service and quick turnaround to our customers. The other thing we do is offer strong relationships with principals and OEMs. They recognise the skillset and strength that we have, and so they prioritise our needs,” he says.

“The partnerships that we have created go back a long way. Some of our suppliers like Datalogic, Honeywell, Epson, Sato, Argox – unless you’re in the industry, you might not know. Brother is a phenomenally good international brand and so we are very lucky to have those sorts of brands in our portfolio. Those brands bring credibility and that brings opportunity for us,” he adds. “By carrying those brands, you carry the same level of integrity. That

// WE HAVE ALWAYS HELD STOCK AND WE HAVE ALWAYS RECOGNISED THAT YOU MUST HAVE THE STOCK TO SELL THE STOCK //

creates a huge obligation around responsibility. We spend a lot of time and focus ensuring we can support those ranges properly. We have a great technical team and one of the things we do from an environmental viewpoint is try and fix products that are out there before we replace.”

Established in 1988, shifting through several iterations before becoming the Kemtek of today, the business has learned a lot and built a skillset that is unrivalled in South Africa. The company’s understanding of local needs, as well as its network of relationships, allow for a thorough understanding of what is required. Diversification underway right now to continue delivering into the future.

“We have an industrial 3D printing business, both selling equipment as the agent for global leaders, as well as a print bureau. There are other challenges that impact that business because the

SA environment is very different to Europe where additive manufacturing is becoming a very accessible and recognised method of prototyping and manufacturing of spare parts – it’s not like that here yet,” explains Comins.

“We have recently started a sustainability initiative where we look at water solutions. Water and power are major problems for South Africa and so we are looking at a number of different technologies around water including water from air technologies, especially for the coastal regions. Where there is high humidity, there is a product that is really cost-effective in terms of getting something into people’s homes for extracting and filtering water from air. We are also looking at other products around water treatment.

“Kemtek has diversified as we are trying to get to a point where if one business slumps, another will boom and we can hedge against dips in our markets,” he adds.

Right now, the company is busy

addressing some shortages in the supply chain around Auto ID and Bar Coding – a core offering for Kemtek. As local agents for labelling systems, orders have to be made far in advance to ensure availability. As supply issues bite, some chain stores have been prepared to use alternative solutions but for large national brands this is a big challenge. Thankfully Kemtek has delivered.

“Firstly, it’s all about quality,” says Comins. “Everything we do, product or service, is quality focused. Kemtek’s name is attached to products, being a distributor, so we look at build quality, support, spare parts, availability, and opportunities in the SA market. We always take the local environment into consideration so we require products to be more flexible and robust.”

The global printing market is expected to grow from $311.53 billion in 2021 to $322.43 billion in 2022. The African printer technology market is expected to exceed $235.3 million by the end of 2031. To ensure it aligns itself with this industry growth, Kemtek is looking to grow in all markets in which it operates and take advantage of any opportunities that arise.

“This company has always had a very entrepreneurial nature and we encourage new ideas. We are very keen on trying new things and working out how to make them successful. That mentality continues to this day,” explains Comins.

“Last July, there were riots in KZN and the following months were extremely busy as businesses tried to restart and needed to replace their point-of-sale equipment, and they had to restock their shelves with new products which all required new labels to be printed. We had a fantastic opportunity there.”

During this turbulent period, as the country emerged from strict lockdowns, Kemtek – designated as an essential services provider and allowed to trade during lockdown

– also thrived in ancillary sectors.

“We have a local ribbon plant and we buy jumbo rolls of thermal ribbon which we split into different sizes. It’s agnostic in terms of the label printers it can go into and we have grown a significant market share here. We cut every size, even for competitor products, so any customer can buy from us. We have nine ribbon machines, with a great team, and we bring in world-class products from Europe and the Far East and we split and sell here,” details Comins.

In 3D printing, a market set to hit $62.7 billion globally by 2028where Kemtek already boasts a strong presence – the company has bolstered its portfolio. “Around six months ago, we became an agent and started bringing in the Creality range of 3D printers. That has given us a lot of growth. We have tried a number of brands, but Creality has a great name in the SA market,” highlights Comins.

Industry, universities, and government are driving a 3D printing industry in SA, with a number of designers, prototypers, and SMEs enhancing interest in the technology. Away from additive manufacturing, Kemtek continues to enhance its range, always focusing on product quality, regularly bringing the world’s best to South Africa.

“We have just launched a new

To establish a sustainable and fair WEEE collection and recycling system that works to meet Producers’ environmental compliance obligations in a manner that meets our collective aspirations for our country, planet, and people.

Electrical and electronic equipment;

Electrical goods;

Electronic consumer goods;

industrial goods;

product for a colour label printer, a Rebo Systems colour technology that is very well suited to the SA market. We are about to launch another Epson colour press,” says Comins. “The nice thing for us is that we have team members who specifically go and hunt out new technologies from around the world. They build relationships, bring demo units in, and test the market. We understand opportunities before starting to distribute.”

Staying ahead of the disruptors in the market, often by partnering with them, is essential for Kemtek. Fortunately, the company has been doing this for decades and is the go-to for most in the country to understand new trends.

“The changes we’ve seen, especially on our print side, have been fast. We have seen a decline in sales of

commercial presses and a massive increase in labels and packaging –especially on the digital print side.

“The SA environment is unique in that there are lots of different challenges and whichever way you go, you end up with lots of different consequences around the decision you’ve made,” says Comins.

Almost always, the outcomes of Kemtek’s strategies are positive, both internally and externally. As this burgeoning industry provides so much scope for growth, this is a company perfectly positioned to thrive.

have a really diverse set of opportunities,” smiles Comins.

South Africa’s ERA Ewaste Recycling Authority has contributed to building a legal framework around which a green eco-system can be formed, where producers of electrical and electronic equipment contribute to recycling products at the end of life. It’s a demanding problem to tackle but CEO Ashley du Plooy is happy to lead the charge. He tells Enterprise Africa more about the long-term vision for this relatively new organisation.

//South Africa already faces a major problem with electronic waste (e-waste) – one which is set to exacerbate without intervention. Research suggests that each South African generates 6.2 kg of e-waste annually, with less than 13% being recycled. Often comprising harmful materials that are toxic in the environment (lead, barium, lithium, cadmium, mercury, nickel and more), e-waste is also infamous for organic compounds such as flame retardants, chlorofluorocarbons, polycyclic aromatic hydrocarbons (PAHs), polybrominated diphenyl ethers (PBDEs), and polychlorinated dibenzo-p-dioxins and furans (PCDD/ Fs). According to medical journal, The Lancet: “These environmental contaminants pose severe threats to both the health of human beings and the environment.”

The increasing nature of this challenge is dramatic. Volumes grew by 21% globally over the past five years, and as economies embrace more digital solutions and adopt more technology, electronic usage and therefore e-waste is rising quickly.

In South Africa, recycling is not popular and organisations still struggle to encourage recycling of traditional waste materials. E-waste is more difficult and more expensive, but there is opportunity. As well as harmful toxins, there are valuable materials found in electronics. Gold, silver, copper, platinum, palladium, iron and aluminium are all reasonably easy to recycle from phones, laptops, televisions and other electrical devices.

In 2014, the Department of

Forestry, Fisheries and Environment (DFFE) formed a Steering Committee, from around 120 producer and recycler delegates, to consult with the sector in the formulation of a national Industry Waste Management Plan for the Electrical and Electronic Equipment (EEE) sector, and by 5 May 2021 Extended Producer Responsibility (EPR) regulations were finalised and published. Chair of the initial Steering Committee and CEO of ERA Ewaste Recycling Authority,

Ashley du Plooy, tells Enterprise Africa that there is now clear legislation in place to encourage and enforce responsible e-waste recycling.

His frustration, however, is that few producers of electronic products have registered as EEE Producers with DFFE as required by the EPR Regulations or signed up for ERA membership, a situation that must change.

“We estimate that there are between 3000 and 6000 producers of EEE in the South African market. Technically, there should have been between 3000 and 6000 registrations. Currentlythere are only 129 registered producers, so the compliance rate is exceptionally low. There is a pipeline of 200-300 other producers that have since registered after the deadline date in November.”

By 2030, some industry experts expect that the world could produce around 75 metric tonnes of e-waste as this fast growing waste stream continues to snowball. Recognition of the problem is essential, and taking steps to address the issue is equally as important.

While somewhat complicated in terms of legal structure, the fundamental mission and process for ERA members is simple: become a member and register as a producer, join a producer responsibility organisation (PRO), collect and report your relevant market data, and pay your levy.

The payment of the EPR levy, which is higher for those that produce more, is one of many factors that have slowed membership uptake to date.

Since 2014, the government has been clear that collecting money to address e-wate, from somewhere in the value chain, would be inevitable. The first concept was to apply a ‘Producer Pays’ principle. “Simply, those producers who are responsible for certain waste streams would have to take care of the waste generated at the end of life of those products,” says du Plooy.

ERA lobbied hard to avoid a blanket-type levy application through a previously proposed Industry Waste Management Plan and instead encouraged government to adopt an appropriate system based on Section 18 framework of the National Environmental Management Waste Act 59/2008 which allows for producers to set their levy, collect, and apply the levy through a PRO.

Today, ERA has 38 registered members, made up of some of the largest electronic manufacturers in South Africa. The likes of Defy, Isuzu, Oracle, Smeg, Dell, Tarsus, Philips, Huawei, Brother and more are all active participants in the development of e-waste solutions. But even with some of the more prominent companies on side, there is much still to do.

“There is a big concern about who is complying and who is not.

There is a concern that compliance among a small number of producers will create price distortions and make compliant producers non-competitive in the market,” says du Plooy.

“We are concerned that a lot of producers of EEE function in other markets where they understand the EPR initiative (the EU is very strong on this).

“We would like to get the message through to those in governance in companies trading in South Africa, and those in government trade missions where these companies are based, that they have the choice – take a disrespectful position towards the African continent and the SA government or comply.”

But paying a levy, despite legislation, is not easy. The economy in South Africa is shrinking again, posting a contraction of 0.7% in 2022’s second quarter. Public purchasing

// REGISTER AS A PRODUCER, JOIN A PRO, REPORT YOUR DATA, AND PAY YOUR LEVY –THESE ARE THE FOUR STEPS THAT EVERY PRODUCER OF ELECTRONICS MUST TAKE //

power is decreased as inflation bites, and manufacturers continue to be blighted by power outages. Often, a levy is unaffordable and unappealing despite forming fundamental parts of company ethos and a major part

of product - and therefore a good value proposition – for others.

“The big bugbear for producers is handing over the large cheque,” admits du Plooy. “So the key hook on which producers hang their non-compliance is that there is no guarantee that free riders will be dealt with. Given the low uptake in the beginning of the first phase, there is a feeling that there are too many producers who are not compliant, and the prospect of a legal sanction or consequence is not very high.”

But this will change as time goes by. Penalties can include fines, cancellation of registration or even imprisonment. To date, the sector has been largely unorganised and, as more clarity is installed around responsibility and process, the prospect of reprimand becomes more real.

“Given the fact that there is now a pipeline of 200-300 producers who have registered late, there has been

no indication as to whether there will be sanctions, but the government has stated that full levies must be paid by late registrants. Now, there is the question about the level of compliance. Those that have come forward and want to comply are feeling that those who have made absolutely no attempt should be the focus of corrective action,” says du Plooy.

The varying degrees of compliance, even among the ERA members, is a challenge for du Plooy and team. Within this relatively fresh concept, should there be a universal approach to noncompliance (and compliance)? How does ERA know which companies are acting responsibly, which are keen to work together, and which are actively avoiding the legislation altogether? The system must be wholly inclusive, and this brings new sets of challenges for producers in a business environment

THERE IS A CONCERN THAT COMPLIANCE AMONG A SMALL NUMBER OF PRODUCERS WILL CREATE PRICE DISTORTIONS AND MAKE COMPLIANT PRODUCERS NONCOMPETITIVE IN THE MARKET //

Defy

Nestle DG Store

NSE South Africa Solar Africa

Solareff

Pinnacle Micro Sithabile

Smeg Asbis

Axiz Vega

Miele

Home Appliance

HP South Africa Philips Domestic Appliances

Obscure Kemtek Imaging Systems

HPE Baker Hughes

Mustek Inhep Electronic Holdings

Tevo Huawei

Rectron Liebherr

Dell Hellermann Tyton

Roche Diagnostics Brother

which often means operations are already stretched. This is why ERA is planning for the long-term.

“We want to build a sustainable base for extended producer responsibility over a decent period of time,” says du Plooy.

“After joining a PRO and participating in the planning of the scheme, producers must report their market data so that we can build a picture of the total electronic output. We can then set appropriate targets for wate collection and recycling.”

This is where companies face challenges. They must work their way through often large product portfolios, categorise, confirm weight, and collect all relevant data. Previously, government wanted producers to detail toxicity of materials, categorise by dimensions and more, but ERA

To establish a sustainable and fair WEEE collection and recycling system that works to meet Producers’ environmental compliance obligations in a manner that meets our collective aspirations for our country, planet, and people.

a) Electrical and electronic equipment;

Electrical goods;

Electronic consumer goods;

Electronic industrial goods; and

Lighting.

opted for a streamlined approach in the early stages. Weight and existence of focus materials that require special treatment to recycle are the key focus points for now. All of this information feeds into the setting of levies and is of course under heavy scrutiny from members and industry observers.

“There are those that will come in and say they know they need to comply and ask what needs to be done, before doing it,” smiles du Plooy. “Then, there are some that have registered with

us as a means of cover and they want to wait for everyone to be onboard before they work effectively. Then we have those that undertake constructive engagement with us. It is not easy for a lot of companies - sometimes they have listings of more than 6000 products which they then need to categorise into a basket of goods before detailing average weights of everything and classifying focus material.

“We are meant to set certain conditions for the incorporation of

recycled materials into products and the recyclability of electronic products, but those are highly sophisticated metrics and for a sector that has never organised itself, it is virtually impossible at this stage.

We are at the beginning of a new dispensation in the management of electronic waste and, like most other PROs in our position, we are taking a very cautious approach to ensure we do not introduce distortions or perversions, which is easy to do when people are rushing to comply,” du Plooy explains.

“From an ERA point of view, when compared to the five registered EEE PROs, our governance, approach, and methodology, places us in a unique position. We have opened ourselves up to nominations for Board members from the sectors that we represent as required by the regulation. We are the only association to follow that process and, from the beginning of our consultation in 2021, we have put or plans and levies on the table. We have only been able to finalise our plan with any degree of certainty

in the first quarter of 2022,” he says, adding that producers are beginning to offer significant feedback; taking various positions, suggesting tweaks to the framework, asking for a complete overhaul, and reversing the system to collect levy from consumers.

“It’s a mindset change and any change takes time, but we will get there. We want to install confidence in the market that we have the right governance in place, the right systems in place, and the financial ability to manage e-waste effectively,” du Plooy reassures.

While the major impact of ERA will be felt over an extended period of time, there have already been strides forward. In Ghana, a thriving industry has been developed, where waste electronic gear is dismantled and upcycled, with previously discarded materials being given new life within a circular economy. South Africa could follow a similar path – a site has been established by the Uni of Johannesburg

and Gauteng Department of e-Government (GDeG) in the province - but ensuring waste streams from commercial and public sources are managed correctly is the first step.

“We have refined our methodology and we now take a sectoral approach, linked to our focus on strong governance,” says du Plooy. “The legislation states that PROs like ERA should follow a consultative approach to formulating EPR Plans and setting EPR levies and we have taken a sectoral approach. We have a strong presence in the ICT sector where we have around 90% of the ICT distribution network within ERA. Through that, we have on our board the CCO of a listed company. Then we have a strong focus on the large domestic appliance sector where have the chairperson of the South African Domestic Appliances Association on the board. We also have a Director of one of the leading brands as a result of our approach –we tackle a sector, take a consultative approach in setting the levies, create an understanding around what needs to

happen, and we then encourage that sector’s participation on our board.”

Importantly, ERA remains a non-profit organisation and this is vital in ensuring longevity and sustainability. Du Plooy is clear that this is status is essential to ensure that no conflict arises between its members’ commercial activities and the ERA work. “We see ourselves as a developing bureaucracy that will be able to ensure that we grow a legitimate and effective space for extended producer responsibility,” he says.

Johannesburg-based Kemtek Imaging Systems has started its journey with ERA. This advanced tech supplier works with electronic machinery from some of the world’s best manufacturers and supports a country-wide footprint. Registered as a member, the company is busy preparing its market data so that it can pay the levy, with the support of ERA.

For similar companies, and electronics producers around the country, the path forward is becoming

clearer. Electronic waste is a growing problem that must be dealt with effectively. Producers have been identified as those that must pay levies to ensure waste is managed correctly. The message from ERA to its members and to the wider industry is clear: “Register as a producer, join a PRO, report your data, and pay your levy – these are the four steps that every producer of electronics must take,” states du Plooy.

The organisation has established its position between producer, collector, and recycler, and the consumer will soon have easy access to knowledge around those that are compliant. A 2021 study from Simon-Kucher & Partners (developed for the COP26 United Nations Climate Change Conference) showed that consumers purchasing decisions are driven, more than ever, by sustainability. Many, especially in younger generations, will pay more for goods from sellers with sustainable brands. Clearly, there is now a commercial driver of

responsible practice around recycling. Those that are able to demonstrate to a keen public that they are part of the solution and are fully compliant, will undoubtedly reap rewards.

“Companies must invest, innovate and transform their business models now to protect their longterm profitability and viability. The rise of sustainable disruptors and increasing consumer awareness will all serve to drive the expectation for affordable sustainable alternatives,” said author of the study, Shikha Jain.

Eventually, ERA hopes to represent producers responsible for 50% of the electrical and electronic equipment in South Africa, and these companies will be sending a clear message to the market – WEEE must be correctly managed, we are willing to do so, and we are collectively investing in a cleaner and more sustainable South Africa.

Eleanor Sarbutt-King

Economic activity at the Port of East London is to get a jump start through new investment which will see it expanded significantly to accommodate bigger vessels, more technology, and new industry sectors. Connecting the port to the wider logistics network of the country is the goal of Port Manager Sphiwe Mthembu who shares his ambitious goals with Enterprise Africa.

//A significant manoeuvre is underway at the Port of East London as Transnet National Ports Authority targets considerable growth from South Africa’s premier river port. Underutilised and threatened by a lack of diversity in its client base, this strategic and well-connected port has all the potential to become another gateway to Africa, driving economic activity across the Eastern Cape.

In August 2022, TNPA appointed Sphiwe Mthembu as Port Manager, tasking him with building long-term plans for the port including the introduction of new technology, attracting new customers, boosting capacity, and connecting the port to the rest of the region like never before.

Currently, the Port of East London is home to various cargo handling facilities across automotive, containers, dry bulk, liquid bulk, and breakbulk,

as well as a ship repair resource. But the port’s big brother in Durban, and its sister in Cape Town, as well as its neighbour in Gqerbha are currently all favoured for size and efficiency reasons.

Mthembu – an accidental maritime expert – is looking to

quickly reinvigorate the port with ambitious expansion plans.

“Our aim is to get the port operating and functioning at full capacity,” he says.

“The port is currently limited when it comes to accepting deep draught vessels. Our draught at the entrance level is around 15m and that limits us. The exco plan is to widen and deepen the entrance, and that is part of the project that will be happening between now through the next decade - the studies have started already.”

The next decade will see the port become a construction site as the entrance is deepened and widened, new facilities are added, and – importantly – rail connections established. Currently, the port – which sits at the mouth of the Buffalo River on South Africa’s eastern shore – sees trucks collect and drop off containers after a journey through the city centre. This leads to congestion and challenges around road maintenance. Transnet has made no secret that it would like to see more cargo railed around the country, and moving materials from the Port of East London onto the country’s rolling network would provide a benefit.

“Our Managing Executive has announced that Transnet has given R4.3 billion to invest in the port for the

next decade. As part of that, we will be looking at port development plans that are in the process of approval. They earmark directly to creating capacity in terms of technologies where we are looking at partnering with the private sector to bring those technologies,” explains Mthembu.

“These technologies may include ship-to-shore or ship loaders attached to our silos – it depends on customer requirements and demands. The grain elevator that we have is geared to connect to that type of technology, but the challenge currently is the fact that we have low capacity on the rail side but we will be engaging with our sister company to understand how they can assist the port to ensure logistics function well.”

Currently, a Transnet Freight Rail line connects East London to Gqerbha, – the Cookhouse-Blaney branch line –which was reopened in 2021 after R26 million investment to bring FMCG and other products onto the tracks and off the roads. The idea is to connect the East London IDZ to Gqerbha, reducing time and cost for businesses.

The Port of East London would benefit immensely from a further connection, allowing for easier transfer into the IDZ and further.

“For a port to be connected in the modern day, you need railroad and

Mercedes-Benz South Africa has a rich manufacturing heritage of over six decades in South Africa.

Our manufacturing operations in East London, Eastern Cape, are efficient, environmentally conscious, state-of-the-art and award winning.

The investment of Mercedes-Benz South Africa is testament to our commitment to drive the socio-economic development of the East London region and local supply chain partners. We manufacture the C-Class sedan to over 80 markets worldwide and do so sustainably by protecting the environment and the climate. This is why as a company, we also bear social responsibility and focus all our corporate social responsibility on education, youth empowerment and community upliftment in the Eastern Cape.

As the inventor of the automobile, not only do we face up to the challenges of the future; we also want to set benchmarks for tomorrow’s sustainable mobility by building on our legacy of efficient, flexible and sustainable operations which positively impact on the communities.

For more information visit: https://corporate.mercedes-benz.co.za/

multimodal systems that will allow the supply chain to function from hinterland, bringing cargo to the port. This will remove trucks from the road and will stop damage to the roads.

“We are open to any operator that wants to come in and ship break bulk cargo. We want to bring all the players together – TFR, the customer, the municipality – so that we can understand how to increase rail capacity. This is our short-term goal,” insists Mthembu.

Widely respected for its success in the global automotive industry, the Eastern Cape is home to hundreds of organisations across the sector, employing thousands of people.

This success is largely down to the location of the region’s ports and their efficiency. In 2021, South Africa exported almost 300,000 vehicles with ports in Gqerbha and easily-accessedDurban handling the majority of the volume. This is where Mthembu sees significant opportunity for expansion.

In 2021, the Port of Durban was once again criticised by commentators for slumping competitiveness as its capacity is challenged.

Transnet announced in September that expansion plans had been approved, but in the short term this means there will be spill over.

“Port of East London is driven by the operation of Mercedes-Benz South Africa (MBSA) and it plays a big role in most industries in this region. The volume of containers that move in this supply chain are headed for the MBSA manufacturing facility. The connection of the port is linked to the MBSA plant

// WE WILL BE INCREASING THAT CAPACITY TO SEE IF WE CAN ACCOMMODATE OTHER OEMS LOOKING TO GET INTO THE EASTERN CAPE BY PUSHING UNITS THROUGH THE PORT //

and then you have the supply chain activities. That is a worry for the port. If the supply chain breaks down, the port is directly impacted. We are moving into a strategy which will see us diversify and we are looking at the other big sector – liquid bulk - that sector is productive,” highlights Mthembu.

“We will be increasing that capacity to see if we can accommodate other OEMs looking to get into the Eastern Cape by pushing units through the port. In the next three to 10 years, we will have capacity that will enable us to handle two OEMs.

“We will also be increasing the berths on the car terminal side to assist with increasing that capacity. The terminal will then be able to handle two vessels simultaneously. We are looking to begin planning with OEMs or cargo owners to bring bulk operations to

the West Bank. It’s all about increasing capacity at the port,” he adds.

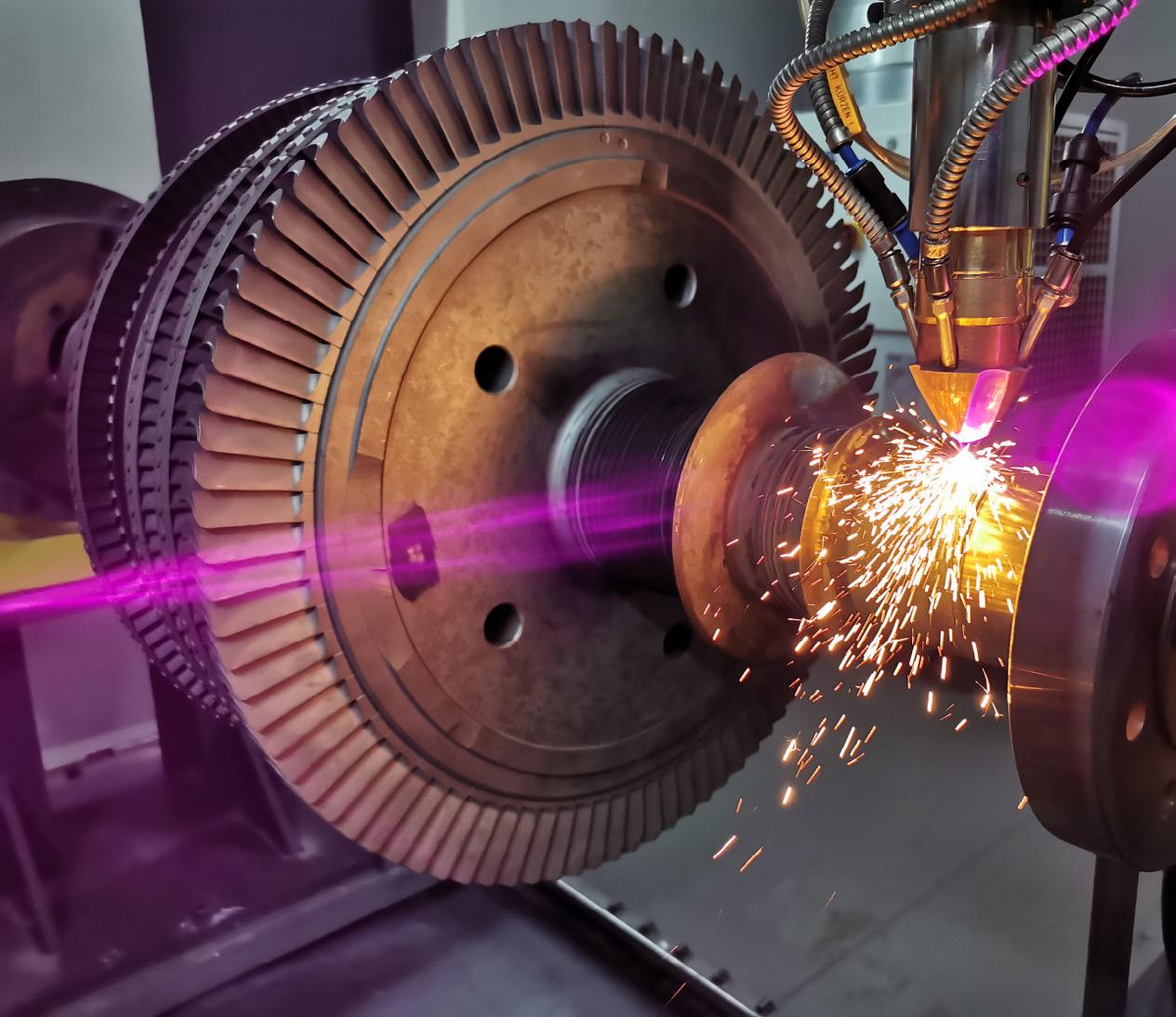

On site, there is space available in both the back of port area, and on the dry dock. Ambitious Mthembu doesn’t only want to increase existing business here, but is keen on the idea of building an entire industry in marine ship repair that will bring significant economic impact in the long term. Soon, a study will be initiated, exploring the viability of a fully-fledged maritime repair and engineering offering from the Port of East London.

“We hope to have a strategy on which we can base operations to attract specifically ship repairers to dock and carry out ship repairs in the Port of East London.

“We will be engaging stakeholders so that we can communicate these plans and ensure they are aware of

and align with everything we do. The municipality is important here. One of the greatest things we want to do is create a back of port operation where people can come and set up warehousing or other operations to support port operations.

“Ship repair will be the first step in driving employment numbers and we will benefit from the spin offs that come from the Port of Durban. We hope that by the end of the year, our plans will start to bear fruit,” says Mthembu.

For Empangeni-raised Mthembu - a former engineer and packaging industry professional who turned to maritime following successful education where he is currently submitting PhD materials – who has also held senior positions at the Port of Durban, growth is very much

on the agenda following a worrying period through the pandemic where global logistics was challenged.

“Cargo wasn’t moving and some ships were being laid off. In South Africa, volumes fell drastically as ports were operating minimally. The movement of people was restricted and we ran with skeleton crews. It was a bumpy time. The ports have fixed costs and with that, although the country was closed, we still had to pay those costs. We did have some vessels coming through with essential goods and we relied on those. We were able to just about sail through, but it was difficult – both financially and emotionally. We put

plans in place to shield our employees and we soldiered on. We know our role in the South African economy and we wanted to do our bit to keep things moving,” he says of a time where the daily number of miles navigated by vessels globally dipped dramatically.

Turnaround times are excellent at the Port of East London and, despite capacity challenges, operations are efficient and effective. Clearly, this vital piece of national infrastructure has the ability to bring so much more than it already does to the local and national economy.

“I am of the view that this is a port that should be seen as one of the most

important assets for the country as it is the only river port in South Africa. Compared to other ports around the country, we are lacking behind and so we are very keen on improvements –building capacity, training employees, bringing in more ships, creating marine engineering, and developing back of port,” enthuses Mthembu.

Over the longer term, beyond the initial decade of future proofing, the Port Manager is keen for overhaul to unlock further productivity. Currently, the container terminal is located on the east bank of the Buffalo River – fed by the road that leads through the city. Ideally, the container terminal could be relocated to the west bank, where there is more space to create yards and include new technology. Being positioned on the west of the river would also create a link to the R72, reducing truck traffic through the metro area. Importantly, this could also open up access to the

// I AM OF THE VIEW THAT THIS IS A PORT THAT SHOULD BE SEEN AS ONE OF THE MOST IMPORTANT ASSETS FOR THE COUNTRY AS IT IS THE ONLY RIVER PORT //

nearby East London IDZ and create a location of choice for manufacturers.

“We are increasing capacity to see if we can attract another OEM, taking away the direct reliance on MBSA. We also want to target ship repairs. When you have ships coming for mechanical repair, you are not only bringing ships for cargo, you are also bringing ships for repair. We do have the facility but it is underutilised.

“As we grow with a new OEM, that will create jobs. As we add another industry around ship repair, that will develop expertise, and the industry will know that the Port of East London has these skills. We also want to bring bulk – grain, coal or manganese. When we are able to diversify like that, we will have managed to link the port to the hinterland and that is what creates jobs.

“We aim expand the automotive terminal, rebuild the container terminal, attract break bulk cargo, and expand liquid bulk. We will then be a fullyfledged and efficient river port. We have the capabilities to do that as we have a line from the port to Mthatha that is not utilised. There is a rail line that moves from the port, through the IDZ, all the way to Gqerbha – that line is not utilised. Strategically, we have to look at how we attract volumes to actively open these corridors and also attract cruise ships to contribute to the tourism industry,” details Mthembu.

Ultimately, the port’s primary aim is to facilitate trade and economic growth by providing and sustaining a reliable and cost-effective port supply chain system. With Mthembu’s ideas, and the backing of stakeholders as well as TNPA, this could be matched before the end of the decade, one step at a time.

“We want to position ourselves as the automotive choice for all the OEMs, even with PE close to us, we want to increase automotive as much as possible, despite being a multipurpose terminal.

“The main focus right now is widening and deepening the entrance, whilst focussing on rail allocations, allowing easy access to this beautiful river port,” he concludes.

Eleanor Sarbutt-King

By issuing the first ever gender-linked bond in Africa, Barloworld is setting a precedent around its ambitions for the future as it aims to significantly empower women across its operations. Group Finance Director, Nopasika Lila tells Enterprise Africa more about this exciting innovation.

//For leading industrial processing, distribution, and services company Barloworld, its 120th anniversary is not a time to look back but a preparative year, forward focussed, as it takes action rarely seen before to drive culture change internally.

Over the years, the company has achieved significant transformation milestones, but now further progress has been cemented in place as Barloworld commits to diversification and change within its leadership team and procurement spend.

On August 23, the company issued two gender-linked bonds on the Johannesburg Stock Exchange (JSE) with the goal of increasing the participation of women in the company’s structure and operations.

As part of a wider Environmental, Social, and Governance (ESG) scheme, this focus on female involvement has been warmly welcomed by the majority with many applauding Barloworld for innovation and leadership in advancing gender equity.

“Our view is that it takes deliberate action to be able to achieve

targets and contribute positively beyond our operations,” says Group Finance Director, Nopasika Lila. “If we don’t do so, it will not happen.”

By selling three- and five-year bonds on the JSE’s Sustainability Segment, Barloworld aimed to raise just under R1 billion. These funds would be used to fuel the company’s female empowerment initiatives, measured against overarching targets of achieving 50% representation at leadership level by 2025 and commitment of 15% of spend with suppliers to black-women owned businesses.

Lila - who joined Barloworld in 2019 having previously led the Eskom Pension and Provident Fund, and has held Board seats at enX, Nampak, and Basil Read – explains that whilst the concept behind the bond issuance is very simple, the mechanics and performance measurements were slightly more complicated.

“When you issue a vanilla bond you go to markets and ask for money

for a specific purpose. In this case our ask was somewhat nuanced. We were clear that the funds we are seeking will be used to ensure that we progress and grow in the areas that the general economy, as well as the business of Barloworld, has been challenged with. We wanted to actively contribute to our ESG agenda. Specifically, we said if it is women-focussed, then we need to have clear KPIs as everything would need to be measured,” she says, adding that reduced interest rates were negotiated as an added benefit to the achievement of the agreed targets and KPIs.

“If the agreed bond rates were at, say, 6% and we would achieve leadership of 50% female by 2025reviewed progressively - we would get a discount on the agreed rate – that is how we get the benefits.

“We also want to be deliberate to how we approach women-owned business in our supply chain. We ensure that 15% our procurement spend goes to women-led businesses. As we progress and do business, we now must hold true to those commitments

THEN WE CAN ACHIEVE TARGETS AND CONTRIBUTE. IF WE DON’T DO SO, IT WILL NOT BE ACTIONED //

and it will become our normal.”

The concept came from a discussion between two successful female leaders – Lila and Relebohile Malahleha, Barloworld’s Executive: Strategic Finance, and Treasury.

“Relebohile asked me one day why we couldn’t consider a genderlinked bond that could really give us a mark in terms of contribution towards our ESG targets. We started thinking about what it could look like, and how we could position and package it to the market,” Lila remembers.

“We started engaging more on it during the year, and it became a no brainer. We put a lot of thought into it and we knew we had to position it appropriately so that it makes sense to investors who were at the time not familiar with the Gender Linked Bond Framework and Principles.

“We have had immense support from our Group CEO, Dominic Sewela and our Board to bring this whole idea to life,” she adds.

The success of this initiative has been felt far and wide. Internally, Barloworld was thrilled to overachieve on its target with the bonds being oversubscribed. Externally, there is a clear appetite in the market to support such programmes, and for other organisations this paves the way for ongoing ESG success with Barloworld setting the example.

Since the establishment of the JSE’s Sustainability Segment in 2020, more than R26 billion market capitalisation has been mobilised. This ESG-focussed segment perfectly feeds into the ethos of highperformance culture at Barloworld.

“ESG is integrated in our strategy, integrated everywhere in our business,” states Lila.

“That makes it easier for us as it is something that we have been living as Barloworld. We see it every day and we have live examples. At Board level we have already achieved 55% female representation and

at Executive Committee level we have 44% so we are getting there. It makes it real for everyone when you live by these examples.”

As the first of its kind, this Gender Linked Bond has been closely watched by all in the industry, keen to understand whether there would be attainment of the commitments. With the significant demand for the bond, and questions from other businesses on how to structure similar packages, Lila is confident the concept has been well-received.

“It has gone to plan,” she smiles. “Financiers have capital and sometimes they want to invest in something that is different. This may have been more complex but it is simple to understand. The ability to put forward our measurement criteria and then see things measured through the year, it makes it easy to comprehend.

“We had to answer questions about what would happen if we didn’t achieve the targets. The upside was

clear for when we do hit targets, but some investors wanted to know about the downside would be. It works both ways; investors will get the benefit of an increased rate should we not achieve on the committed targets.”

Valdene Reddy, Director of Capital Markets at the JSE was excited by the offering, hoping that more companies would follow. “I am thrilled that this listing happened in August, which in our country’s calendar is designated as Women’s Month. I am hopeful that the listing of this first-ever gender bond will encourage more companies to come to the JSE to list instruments that aim to close gender inequality,” she said.

As interest and appetite around Barloworld’s concept spreads, there have been proposals from Europe for the company to consider a similar

bond for European investors. The Luxembourg Stock Exchange requested an engagement with Barloworld, with the goal of eventually issuing a second gender-linked bond.

“That works perfectly for Barloworld because we operate in various countries and jurisdictions across Africa, Russia and Mongolia, and such funds would be utilised in our dollar-based businesses.

“We have received a lot of calls from companies in South Africa and aboard asking us to come and talk to them about the gender-linked bond. We certainly feel there will be a lot to come out of this.”

According to the World Economic Forum’s Global Gender Gap Report 2022, the world needs another 132 years to close the gap – multiple crises outbreaks have slowed progress and, in some circumstances, reversed gains. There is a real risk that positivity

will be eroded without a constant focus – globally – on this vital issue.

At Barloworld, transformative growth is entrenched beyond discussion. Action is being taken with much being accomplished. These stories are necessary to display what is possible when affirmative decisions are driven.

“ESG has been with us for a long time. My first experience with ESG was more than 20 years ago. It was spoken about as a concept, with no action or follow through,” says Lila.

South Africa ranks in the top 20 of 156 countries in its performance on gender parity, but its performance in terms of economic participation and opportunity sees it rank outside the top 90. More needs to be done and ESG will be an essential lever in this change.

“My share to young women is that it is not enough to be a woman, the expectation is that they also need to perform and excel in all that they do. When that is instilled in the minds of young people, they know they must work hard.

“We are creating a very solid foundation for young people to want

// IT IS NOT ENOUGH TO BE A WOMAN; THE EXPECTATION IS THAT WE NEED TO PERFORM AND EXCEL IN ALL THAT THEY DO //

to associate with Barloworld. We are represented across the world in different businesses, so there is room for people to develop,” she says.

120 YEARS.

“Our ESG success certainly filters through the business. Incidentally, we have a small group head office, with most Barloworld employees sitting at the operational level. it is therefore essential from a leadership perspective that these achievements filter into those divisions as that is essential for our targets being met,” says Lila

exist the next 120 years, we need to be conscious and ensure we contribute positively towards ESG matters.

“When we look at wealth creation for our shareholders, it is a long-term matter. We must look at long-term implications of our actions today so that shareholders are able to maximise going forward.”

THE NEXT 120

“Our KPI’s are in some ways linked to our earnings. This is tracked through the Barloworld Business System (BBS) which ensures that leader’s KPIs are embedded in their scorecards. Our entire organisation is aware of the fact that if KPI’s are not met this ultimately impacts the bottom line.”

Going forward, ESG strategies will continue to drive the direction of Barloworld as management embeds sustainability at the heart of operations.

“ESG stands out for us,” confirms Lila. “We are looking at a number of opportunities in this space. Barloworld has been around for 120 years. For us to remain relevant and continue to

With the organisation’s next set of results due soon, the Group Finance Director is confident that the focus on ESG and delivery of concepts like the gender-linked bond will result in a strong ethos of attainment.

“We are looking forward to issuing our results. We aspire to be an organisation that instils high performance through our BBS culture. The fact that we have women leading these businesses means that high-performance continues,” Lila concludes.

BEEN AROUND

ARE TO REMAIN

TO

“We unlock the power of food to enhance quality of life for everyone, today and for generations to come.” So begins the world’s largest food and beverage company, Nestlé, whose Head Office in South Africa represents the hub of an ESAR operation encompassing 23 country markets split into six clusters, where tackling hidden hunger and transforming lives and livelihoods remain pressing concerns.

//Present in 191 countries around the world and with more than 2000 brands ranging from global icons like Nescafé or Nespresso to local favourites such as Ricoffy to its name, Nestlé is steadfast in its drive to enhance quality of life and contribute to a healthier future. “We want to help shape a better and healthier world,” the company abridges. “We also want to inspire people to live healthier lives. This is how we contribute to society while ensuring the long-term success of our company.”

This is a commitment which dates right back to its foundations more than 150 years ago, when Swiss pharmacist Henri Nestlé created an infant cereal - ‘Farine Lactée’ - which saved the life of a child. The first Nestlé products then arrived in South Africa during the 1870s, with the company’s

presence in the country formally entrenched in July 1916.

“We constantly aim to push the boundaries of what is possible with food, beverage and nutritional health products to promote better health, greater accessibility and affordability, effortless preparation, protection of our natural resources and enjoyment,” Nestlé states. “We focus our energy and resources where unlocking the power of food can make the greatest difference and apply our expertise in nutrition, health and wellness to help people, families and pets live happier, healthier lives.”

Access to affordable nutrition is a global challenge, with an estimated three billion people unable to secure

adequate food. Micronutrients account for approximately 7% of the global disease burden, and play a key role in the growth and development of the whole family. A lack of micronutrients, otherwise known as hidden hunger, can lead to poor growth, sub-optimal brain development, and a heightened risk of contracting infectious diseases.

“That is why,” Nestlé responds, “we’re working to make high-quality food accessible and available and to address micronutrient malnutrition for the people who need it most.” The launch of NESTLÉ EVERYDAY is targeted specifically at helping to tackle micronutrient deficiencies in South Africa, in the form of an affordable fortified medium fat dairy powder drink which not only presents a viable solution to hidden hunger, but also builds immunity to help fight against micronutrient deficiencies.

In South Africa, studies have shown that adults are prone to zinc deficiency and that one in five children are stunted; addressing hidden hunger is thus a crucial step in ensuring the health and wellness of the whole family. “The introduction of NESTLÉ EVERYDAY into our stable of brands

for the South African family is a deliberate pivot from the business in East and Southern Africa,” comments Takudzwa Mupfurutsa, Business Executive Officer: Dairy at Nestlé ESAR, of the flagship product enhanced with locally sourced ingredients containing Calcium, Iron, Vitamins, and Zinc.

“We are driven to contribute to solving hidden hunger by bringing products that are affordable and accessible while boosting immunity and health for the whole family. NESTLÉ EVERYDAY is testament to that commitment, formulated through innovative and collaborative research with labs and communities.

“The COVID–19 outbreak emphasised the importance of strong immunity to help our bodies fight against infectious diseases, while the economic impact of the pandemic

for many families in emerging economies further hamstrung access to nutritious food to build immunity,” Mupfurutsa adds. “Therefore, we locally manufactured NESTLÉ EVERYDAY in South Africa, and we were intent on delivering an affordable product that suits all budgets, and is easily available

We live in challenging and uncertain times, which put pressure on us to deliver more and deliver instantly. But real, sustainable impact is not instant. It takes long-term focus, effort and patience. It takes partnership. It is a mindset; one that guides us at every point in our journey. At Ingrain, we are committed to realising lasting, positive impact. The kind that catalyses and sustains growth; leaving people and places better than we found them. Because we believe that enriching lives through everything we touch, makes sustainable impact possible.

With over 100 years of history, Ingrain now prepares to enter a new era - one inspired by our purpose of touching lives in pursuit of sustainable impact. As a prominent business within Barloworld’s Consumer Industries division, Ingrain is the largest producer of unmodified and modified starch, glucose and agri-products in SubSaharan Africa.

With a long-standing reputation of delivering quality through our four wet-milling plants across Gauteng and the Western Cape, we now position ourselves as a growth engine within Barloworld –throughout Africa and beyond.

Our innovative, sustainable product solutions touch millions of end consumers’ lives every day - providing essential ingredient solutions to a diverse range of industries.

We pride ourselves on sourcing only the highest quality, sustainable raw materials. All Ingrain products are made using non-GMO yellow and white maize, grown and harvested by South African farmers. We enforce strict protocols to ensure that we meet our customers’ requirements across domestic, regional and international markets - including Sub-Saharan Africa, Europe, the Middle East, South-East Asia, and Australasia.

This dedication to our customers means we can create customised solutions which address their specific needs. With our laboratories and dedicated field services

managers, we pride ourselves on the highest standards of product development, product formulation and problem solving.

At Barloworld and throughout Ingrain, we believe that by nurturing partnerships in an interconnected and interdependent ecosystem of sustainable impact, we unlock mutual growth.

Underpinned by Barloworld’s core values of integrity, teamwork, sustainability, excellence and commitment, we foster care and respect for all the lives we touch.

“Through greater partnering with customers for growth on the back of local sourcing in Africa, for Africa, we now see a tremendous opportunity to grow into the continent and beyond. It’s all about shared value. We can do things in a particular way, that will really make a positive impact in society.”

-Chris Wierenga, CEO, Barloworld Consumer Industries.Moving forward, we are committed to upholding quality on a granular level, without losing sight of the bigger picture: a unified network, powered by the ethos of sustainable impact. We recognise that together, we have greater impact. We grow together, reaching new heights - all while sowing the seeds that will sustain us for generations to come.

from both supermarket chains and spaza shops. We are proud that the final result also delivers exceptionally on taste, ensuring a delicious experience for the whole family.”

One of the most widely recycled materials in the world, aluminium is infinitely recyclable, saving enormous quantities of energy in its production and making it well-suited to the circular economy. Nestlé is continuing to drive science, technology and innovation to help meet its 2025 ambition to make 100% of its packaging recyclable or reusable in a first for the Starbucks® At Home by Nespresso® range, with the announcement of coffee capsules that are to be made

using 80% recycled aluminium.

“With every material we use to produce the capsules, we are committed to ensuring that none of our packaging ends up in landfill or as litter and aim to minimise the impact of our packaging on the environment,” explains Nicole Roos, Business Executive Officer for Beverages at Nestlé East and Southern Africa Region. “This includes advocating for adequate recycling infrastructure for coffee capsules regardless of the material used. In addition, aluminium can be re-melted and reused

infinitely, giving it a second life.”

The range is available across stores including Checkers, Pick ‘n Pay, Spar and Makro as well as convenient online platforms such as Takealot, Checkers Sixty60 and Pick ‘n Pay Online. Not only is this new initiative infinitely better for the environment, aluminium is also one of the best materials to retain freshness and protect the aromas of the coffee, providing an exceptional barrier to oxygen, light and humidity.

“By using 80% recycled aluminium, we demonstrate the recyclability of aluminium and want to encourage

// BY USING 80% RECYCLED ALUMINIUM, WE DEMONSTRATE ITS RECYCLABILITY AND IN TURN HELP TO DECREASE THE CARBON FOOTPRINT OF A CUP OF COFFEE //

Merchandisers ensure that our Principal’s products appear in the right store at the appropriate time and in the correct quantities.

Experienced staff stationed at all our independent traders, retailers and wholesaler channels ensure maximum shelf space, shelf occupation and on-going long standing relationships.

Order Administration and Warehouse Co-Ordination

Orders are captured and tracked from warehouse and distributors to our different traders and retailers

We have access to and continue to improve our IT infrastructure and resources to supply our clients with an effective service.

our consumers to recycle their aluminium capsules, helping in turn to decrease the carbon footprint of a cup of coffee. This is a key aspect of the Nestlé ESAR RE initiative that focuses on three key pillars RETHINK,

REDUCE and REPURPOSE to tackle sustainability issues”, Roos adds.

Nestlé is also wholly committed to the push to grow agribusinesses and encourage agripreneurship amongst young people in east and southern Africa, instituting the Nestlé Needs Youth (NNY) Agri Competition in partnership with the Branson Centre of Entrepreneurship South Africa. Capacity development, mentorship, and coaching support are all key to addressing the widespread skills gap in agriculture in Africa, accelerating the evolution of the sector and affording better efficiencies, improved processes, and cutting-edge technologies

“Many of Africa’s economies have an agrarian foundation from community all the way to national level and through this competition, we are looking to support and

encourage young people to participate in this economic sector,” explains Nestlé East and Southern African Region Head of Learning and Development, Desiree Zikalala.

“There are several transformative prospects in agriculture that desperately need young people to step in and lead, and we believe that the IGNITE Programme placements that are up for grabs will help facilitate those opportunities. We intend for the NNY Agri Competition to open further dialogue on young people in agriculture, and help build transformative networks that support agripreneurship, employment and employability.”

Astutely identifying a gap in the market six years ago, Africrest has become the fastest-growing property company specialising in office building conversions into middle income apartments and combines them with world-class facilities. Under a year ago the company was on the brink of completing its flagship Apollo conversion, whose success could not have been more comprehensive over the ensuing months and which has led to Africrest making the Sunninghill node its own.

//While the buy-to-let residential market may be languishing in the doldrums, Africrest and its innovative ‘Built-to-Rent’ model is thriving and over the last five years work has barely ceased for even a second. Beginning with an office conversion in Randburg yielding 36 apartments, its success has engendered growth resulting in residential developments worth around R2bn and a portfolio which, including commercial assets, is valued at R2.5bn. Africrest’s flagship project to date is the PwC head office building in Sunninghill, acquired from Attacq in October 2020. When Enterprise Africa spoke with Director Grant Friedman last year, he described the ‘perfect storm’ that brought together the company with the new office node of Sunninghill, where it was already busy on its Alpha development when it landed another 30,000m2 office building with no assurance that even one, let alone both, would let successfully.

This bravest of decisions was

vindicated entirely, Friedman reported, with Alpha’s rentals flying at upwards of 45 per month allowing Africrest to turn its attentions to what came to be known as The Apollo, and its 700 bachelor to two-bedroom units priced between R5000-R7000 a month. This was where Africrest was last year; The Apollo was on the brink of completion and more than 250 of the units had already been snapped up. Friedman shared with us the outline of the further 12,000m2 site Africrest had acquired just down the road in Sunninghill, putting the company on track for a total of 3000 apartments by the close of the year.

Established more than 15 years ago, Africrest’s original focus, Friedman outlines, was on buying dilapidated, C-grade buildings for next to nothing, to refurbish them and put in tenants who wanted to be in the heart of Braamfontein. A turning point for the business came with a small 36-apartment conversion

in Randburg, demand for which was almost double this number in the first week and the leases were snapped up at remarkable speed.

“Amid what was a sea of negative news at the time this building had filled up almost overnight and started generating solid rental. It was at that moment that we knew where the demand lay, and decided to follow it as far as it would lead us,” Friedman recounts, and thus began the real acceleration of the Africrest brand, into an innovative leader in converting office buildings into landmark, A-Grade, beautiful apartments and developing green-field communities. “Two years later, our residential business was dwarfing what we were doing within the office space, which had been our specialisation for over a decade.”

An emigration of similar outfits overseas after 2018 left Africrest with relatively little by way of true competitors, leading to what Freidman describes as, “a buying and building spree,” with one area in particular

catching the company’s entrepreneurial eye. “Sunninghill is a fairly new office node - only around 25 years old and exceptionally well-located in Johannesburg.” Freidman relays.