PRODUCTION: Tommy Atkinson

With a number of exciting projects underway, and an impressive acquisition helping Harbour Energy to grow, diversify, and excel, Harbour Energy’s EVP North Sea, Scott Barr tells Energy Focus that a healthy company culture and a professional can-do attitude is helping drive the organisation forward.

//The UK’s energy transition is complicated and challenging. Moving to net zero by 2050 requires overhaul of multiple major industry sectors, and electricity generation is one of them. Carefully transitioning away from traditional fossil fuels towards modern, sustainable technologies requires long-term planning. Currently, the UK North Sea is expected to lose around 180 of its 284 active oil and gas fields by 2030 due to natural decline. 75% of the country’s energy needs are met by oil and gas, and to power the transition, the industry is essential. Existing fields must contribute their maximum potential, and productivity across the industry is vital. That is why industry leaders are diversifying, innovating, and pioneering new ideas and new ways of doing things.

“Where I think Harbour stands out as an organisation, both in the North Sea and globally,” opens Scott Barr, Harbour Energy’s EVP North Sea,

“is how we’re increasingly focused on effectiveness, efficiencies, and simplicity but also by embracing the opportunities of technology and innovation.”

Harbour Energy is the largest oil and gas producer in the North Sea - a diversified public company with long-term focus on value creation and sustainability. The company aims for safe, efficient, and responsible production of hydrocarbons to supply UK demand for energy.

The UK North Sea remains a legacy basin with oil and gas as well as established and emerging energies including wind, wave, and tidal opportunities. Across Europe, the North Sea has been centralised in strategy since the region began efforts to break away from Russian fossil fuels.

Investments continue to flow into energy infrastructure and innovation, and the North Sea’s potential is

unquestioned. For Harbour Energy, unlocking further long-term potential is about broadening exposure in a region it knows better than most.

Scott Barr - an industry veteran with 25 years’ experience across onshore and offshore activity, and a fellow and chartered engineer with the Institution of Engineering and Technology – is excited about Harbour’s pipeline. New projects, field extensions, carbon capture utilisation and storage (CCS), and major acquisitions are all progressing, with Barr relishing the challenge.

“We continue to progress high return, short cycle, infrastructure-led UK investment opportunities, supporting future production and cash flow,” he explains. “The start-up of production at Tolmount East, with first gas achieved on 4 December 2023, will increase future rates from the Tolmount area. The Leverett discovery, close to Harbour’s operated Britannia infrastructure, has

been successfully appraised with good flow rates achieved. The Talbot field is also on track to deliver first oil around the end of 2024 via the Harbouroperated Judy platform with all three development wells completed.”

Currently, Harbour boasts operated production hubs across the Greater Britannia Area, J-Area and AELE (Armada, Everest, Lomond and Erskine), as well as material non-operated stakes in flagship fields including Elgin/ Franklin, Buzzard, Catcher, and Clair. The bulk of production comes from the Central North Sea, with interests in the Southern North Sea, West of Shetlands, and the East Irish Sea.

Carbon capture is part of a longer-term strategy for the company which has committed to net zero by 2035. However, CCS remains in relative infancy as an industry and requires expert knowledge to build.

“Harbour’s involvement in developing the carbon capture,

transportation and storage industry is something we’re really proud of and excited by,” says Barr.

Busy with the Viking CCS project, alongside 40% shareholder bp, Harbour is looking to create a facility that can capture and store 10 million tonnes of CO2 annually by 2030. Close to the Humber region, populated by heavy

industry, Viking CCS has the potential to add £7 billion of investment across the full CO2 capture, transport, and storage value chain over the next decade.

“Since we were awarded two additional carbon storage licences by the North Sea Transition Authority (NSTA) in September 23, the Viking project has continued to make

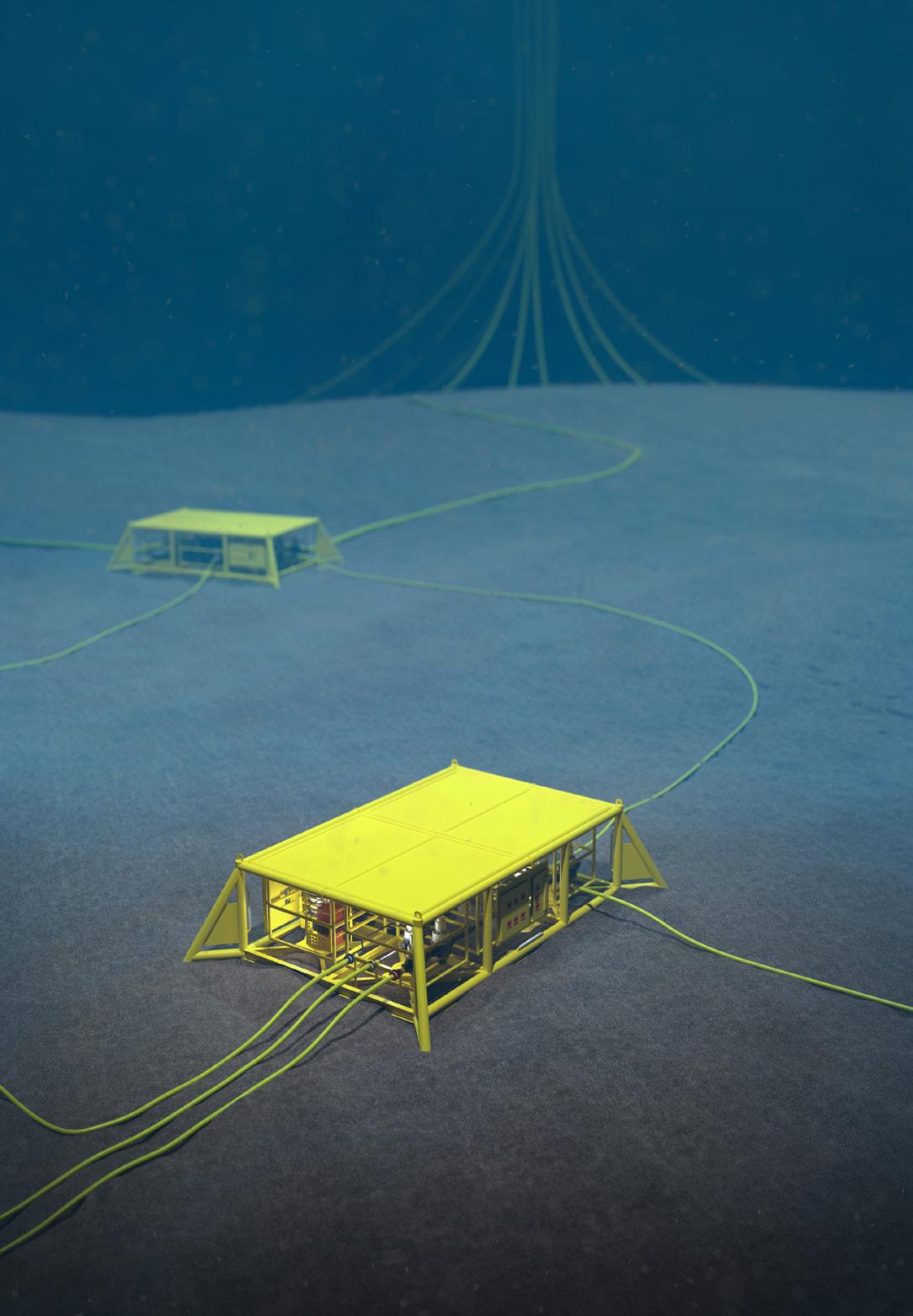

J+S Subsea is busy supporting Harbour Energy and other major operators across various global operations, offering a full package when it comes to subsea infrastructure design, manufacture, and maintenance.

In 2020, an exciting and innovative company focused on the subsea engineering industry was borne out of the management buy-out of Systems Engineering and Assessment Limited, a Cohort Group business. The new business, J+S Subsea, has since proved its ability across multiple projects and with many different partners in the offshore energy sector.

“Our growth in the last three years has been phenomenal and it’s not just turnover, it’s the calibre of people we are attracting,” says MD Phil Reid.

Part of that growth has been a strong relationship with listed independent oil and gas company, Harbour Energy. Harbour has assets across the UK North Sea and J+S Subsea has become important in the effective maintenance and upkeep of various subsea resources. The company handles design, engineering, operational support, and maintenance of subsea equipment, and has built a strong reputation for excellence.

“We were recently awarded a £1m+ contract for the supply of full subsea infrastructure for a new well that is going in. Half of the equipment is going in during 2024 and the other half in 2025,” explains Reid.

“We were awarded that contract because of our delivery schedule. Moving from a concept to delivering exactly what they needed – several weeks before tier ones could – is what is appealing about us.”

J+S Subsea makes use of its Legacy Locker – a portfolio of capital equipment that has been refurbished or reengineered to allow for continued operations on site, while not costing the earth. It is focused on avoiding scrapping of useful materials and embracing the circular economy.

good progress, with the Planning Inspectorate accepting for examination our application for the Development Consent Order for the onshore pipeline in November. Late last year, we were also delighted to announce Cory Group’s exclusive commercial agreement with the Viking CCS project – which marked a really significant milestone in developing the CO2 shipping sector in the UK as well as real progress on how the captured CO2 emissions from dispersed sites

“Recently, we received a message from Harbour looking for some hydraulic hoses on a Sunday afternoon and we turned that around in 24 hours. We had a team in on the same night, manufacturing equipment to be on a dive vessel the next day,” says Reid, adding that other pieces for Harbour have been found in the Legacy Locker, reducing lead time and cost significantly.

Another recent project saw J&S deploy its full skillset from design to manufacture, supply and then maintenance and operation when it delivered a complex system to an operator in Canada. Taking a FPSO off-field, electrical resistance had to be maintained and J+S stepped in to deliver the required subsea battery systems. At the same time, the company has been busy developing an innovative control module which is going though qualification.

“When we have the control system through qualification, we will be challenging the tier one companies and that is exciting,” smiles Reid.

As J+S grows, the ability and skillset within the company will develop allowing for the successful delivery of bigger and more complicated projects, and this is where Reid sees J+S Subsea adding real value.

“We want to be a one stop shop,” he concludes.

www.jands.co.uk | +44 1224 773435 | info@jands.co.uk

around the UK can gain access to high quality storage,” Barr adds.

Harbour is also busy with the Acorn CCS project in Scotland where it holds a non-operated 30% stake. CO2 can be transported, using existing oil and gas infrastructure, and stored deep under the North Sea, permanently.

“Acorn also received an additional two storage licences in the same licensing round in September. And finally, just before Christmas the UK Government announced its ‘CCS Vision’, which

provides more clarity on the process for emitter sequencing to CCS projects, which is a really significant step forward for projects like Viking and Acorn.”

Through 2024, Barr is hopeful that energy around CCS will continue as the industry proves its ability to contribute to sustainability goals.

“I think all round we’re seeing some

Continues on page 8

J+S Subsea provides proactive, responsive and cost-effective solutions for design, engineering, operational support and maintenance of subsea equipment, primarily related to the Subsea Production Control market.

J+S Subsea can provide a range of solutions to fulfil all your Subsea Energy Controls needs. We can provide service and support whether you need to refurbish your existing equipment, deliver critical components or design, assemble and test a new system.

Our vision is to enhance subsea operations by delivering cutting-edge technology that is efficient, safe and environmentally sustainable. Our team of skilled engineers and technicians are dedicated to pushing the boundaries of Subsea Engineering. From concept design to installation, J+S Subsea delivers tailor-made solutions that meet the unique challenges of each individual project.

Dive into a new era of subsea excellence with us, where sustainability is more than a principle - it’s a commitment. We’re reshaping the subsea landscape by integrating sustainable practices and innovation. From efficient subsea equipment to responsible waste handling, our approach minimises our impact on the environment. Join our journey to redefine subsea operations with a focus on a greener future.

At the heart of the company’s commitment to achieving net zero, is the pioneering Legacy Locker initiative. This forwardthinking initiative embraces the principles of the circular economy, offering a portal for the reuse, refurbishment, and recycling of subsea equipment. Beyond unlocking capital tied up surplus equipment, the Legacy Locker users, enhance their environmental footprint by identifying opportunities to minimise waste and promote sustainability.

Continued from page 6

good momentum, but the onus is now on us and the Government to keep that going this year.

“I have to mention some of the work we’re involved in to innovate and create sustainable approaches,” he goes on. “One trial project we are involved in works to try and harness wave power to provide low-carbon power to offshore installations. It’s a demonstrator project called Renewables for Subsea Power which is working to develop a wave energy converter that can harness wave energy to provide low-carbon power to subsea equipment via a subsea battery, as well as help power an autonomous underwater vehicle (AUV) used for subsea inspections. It’s really exciting stuff with a lot of potential.”

This £2 million collaborative project sees giants from the energy

and engineering industries come together off the coast of Orkney to demonstrate a battery energy storage system (BESS) for use in harsh, underwater conditions, utilising renewable energy to provide reliable electricity supply to subsea equipment.

Delivering on its promise of reducing emissions and achieving net zero by 2035, Harbour is also hard at work with various projects to reduce flaring and integrate efficiency-driving technology across operations.

“Protecting the environment and supporting the energy transition are central to the sustainable success of Harbour,” reiterates Barr. “We continue to work towards our sustainability goals by reducing our emissions, investing in CCS, and implementing quality offsetting where necessary. In addition to our endorsement of the World Bank Zero Routine Flaring Initiative, the North

Sea Transition Authority (NSTA) expects the UK oil and gas industry to reduce flaring and venting emissions to the lowest possible levels and achieve zero routine flaring and venting by 2030. This can be a challenge on existing assets as flaring often is an integral part of design, so significant modifications are required to achieve this. We have ongoing flare reduction engineering studies to help us map a pathway to eliminate short and longer-term routine flaring and to reduce non-routine flaring events.”

In 2023, Harbour commissioned flare reduction engineering studies to map a pathway to elimination of short and longer-term routine flaring, and to reduce non-routine flaring events across its North Sea business. “This study,” says Barr, “is one example of how Harbour’s North Sea business is supporting broader ‘net zero by 2035’ goals and meet the company’s

*Combining

wholesale supply & engineering services can provide efficiency savings and productivity gains for our clients (i.e- our integrated contract with Harbour Energy)

sales@drondickson.co.uk

commitment to the World Bank Zero Routine Flaring initiative by 2030. We have detailed emissions reduction action plans (ERAPs), for each of our assets that detail our portfolio journey toward these commitments. We also have recently participated in the Innovation and Targeted Oil and Gas (INTOG) licensing round as part of our decarbonisation efforts.”

Another feather-in-the-cap for the company and its sustainability initiatives is the ongoing success with decommissioning. A challenging and complex part of the life of a field, but essential across the industry, Harbour has a sterling record in the North Sea.

To date, Harbour has a 10-year programme which will have seen

145 wells plugged and abandoned, 38 platforms removed and recycled and over 1,500 kilometres of pipeline flushed, cleaned, and made safe.

Going forward, the journey for Harbour is exhilarating. It continues to search for opportunities to extend the life of existing assets, and it embraces the addition of a major new portfolio following the company’s proposed acquisition of upstream assets from Wintershall Dea in December 2023 (subject to regulatory and shareholder approvals). Valued at $11.2 billion, the acquisition includes a number of Norwegian North Sea assets and, in total, added around

1.1 bnboe of 2P reserves at c.$10/ boe and more than 300 kboepd of production at c.$35,000/boepd.

The deal is transformational for Harbour, catapulting the company to the top of the industry, becoming one of the world’s largest and most geographically diverse independent oil and gas companies.

“Our CEO Linda Cook has been clear that the strategy for Harbour is to look to grow and diversify our asset base internationally,” explains Barr. “That’s particularly been evidenced recently by Harbour’s proposed acquisition of substantially all of Wintershall Dea’s upstream assets which includes significant positions in Norway, Germany, Argentina, Mexico,

and Egypt as well an attractive portfolio of CCS projects in northwest Europe.

“We have a professional ‘can do’ attitude and one that is prepared to invest where we see opportunity.

“Here in the UK, we continuously work hard to maximise the value from our existing North Sea portfolio. This is a particular strength of Harbour’s – we are quite accomplished at extending an asset’s production life and extracting the maximising economic recovery from field,” Barr adds.

The Harbour Energy mantra of delivering efficiency, simplicity, and

technological innovation has been boosted by the recent acquisition and goes beyond hydrocarbon extraction and sale. There is now a corporate culture that must span operations, industries, and nations. Central in this, and a core focus that is implacable within Harbour, is the company’s commitment to operational safety.

In the Harbour Energy Trading and Operations Update for the year ending 31 December 2023, Linda Cook highlighted Improved safety

// WE CONTINUALLY WORK TO REDUCE RISK AND ENSURE THE SAFETY OF EVERYONE WORKING FOR US. HARBOUR HAS A STRONG SAFETY RECORD TO SHOW FOR THIS //

performance with total recordable injury rate of 0.7 per million hours worked (2022: 0.8), adding that safety would remain the focus for the future.

Barr - co-chair on the Decomissioning and Re-use Task Force, a part of the NSTA’s North Sea transition deal’s working groups - has worked hard to entrench safety deep in company culture.

“We’ve seen success from our strategy for a wide number of reasons, but the thing I always come back to is our operational and safety performance,” he says, constantly reiterating the magnitude and value of exemplary safety standards.

“This is always my absolute main priority and ensuring our people are kept safe and well, and raising awareness of potential dangers, particularly for colleagues working in hazardous locations offshore, is of

paramount importance to me and everyone in the company. Having started my career in an operational role and not losing my hands-on approach, I know only too well how important our attention and focus on major accident hazard prevention is. We continually work to reduce risk and ensure the safety of everyone working for us. Harbour has a strong safety record to show for this.”

Consistently communicating the company’s commitment to safety, and placing it – without doubt – as the key line of thought for all in the business is the way to reinforce standards.

“Onshore, offshore, wherever – reinforcing key messages with real world examples constantly so everyone always has that safety message at the forefront of their mind is important,” says Barr. “As you’d expect, we’re always looking at technical or

operational changes in the industry, but I think it is underrated just how effective it can be to make the time to talk to our colleagues about it and to remind ourselves of what happens when things go wrong.”

With more than 1800 employees worldwide, comprehensive internal communications can be challenging, but by putting a lot of effort into promoting a positive and inclusive work culture and prioritising the wellbeing and professional development of all employees, Harbour embeds values and behaviours deeply across all our learning and development processes. “Our performance management system has reinforced the strong culture that we are building,” says Barr.

This culture is delivering, and the recent acquisition will only strengthen and enhance the company’s ability to play a significant role in meeting

the world’s energy needs through the safe, efficient and responsible production. Harbour is without doubt one of the companies doing things differently, doing things better, and utilising the North Sea to its fullest.

“Oil and gas has always been an extremely competitive industry and that’s only getting more true as the North Sea basin matures further,” says Barr.

“We have worked extremely closely with all our stakeholders and regulators in what has been pioneering and paving the way for others,” he concludes.

Published by CMB Media Group

Chris Bolderstone – General Manager

E. chris@cmb-media.co.uk

Kiln House, Fuel Studios, Pottergate, Norwich NR2 1DX

T. +44 20 3097 1743

www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/ or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

©