PRODUCTION: David Hill

Lhyfe, a green hydrogen production company that is staunchly committed to the energy transition, is responsible for many world firsts across the industry. Soon, it will begin with several new projects, building significant production facilities that will be able to offer green hydrogen at scale for clients across all industries. Luc Graré, Head of Central and Eastern Europe at Lhyfe, talks to Energy Focus about nurturing experience and knowledge that others simply don’t have.

//Led by science, the hunt for the sustainable fuel of the future – one which can power home and industry for centuries to come, without an entire overhaul of existing infrastructure – is centring around hydrogen. While there will always be a mix, swapping out fossil fuels for a zero-emission alternative that is abundant and powerful and storable is already underway. Hydrogen offers an almost perfect option –plentiful, high-energy density, zero direct CO2 emissions, and able to be used at industrial scale. Importantly, hydrogen is already proven. It has been used for power generation since the 19th century. For real decarbonisation efforts, hydrogen is the frontrunner. But it’s not easy to convince investors. After all, fossil fuels are in use now; they are working today; they are generating returns at scale; and they are doing so safely. Environmental

impact aside, fossil fuels used for power generation are reliable and efficient.

European green hydrogen production company Lhyfe –established in 2017 by Matthieu Guesné – set about changing perceptions. Starting small and scaling carefully, the company has dedicated all of its knowledge and expertise to creating highly efficient and safe hydrogen production plants that can supply green hydrogen for industry, mobility, and more, in various useful packages. It has taken a lot of investment and a number of faithful leaps, but Lhyfe is now recognised as an industry leader and its work has furthered the reputation of hydrogen as a fuel of the future.

Luc Graré, Head of Central and Eastern Europe at Lhyfe, tells Energy Focus that the company is demonstrably committed to the energy transition and is creating a lasting legacy through the green hydrogen production plants

it owns and operates. He says that major projects are underway or in the pipeline, and the team – more than 200 spread across 11 countries – is one of the most ambitious in the world.

GREEN BY DEFINITION

“We are only active in green hydrogen and that gives a maximum focus - it has to work,” he smiles. “We don’t look at other things because they are easier or they are seen as low hanging fruit. We have 100% focus on green hydrogen and we do it at European scale. That means we can take advantage of economies of scale and repeat successes across multiple countries.”

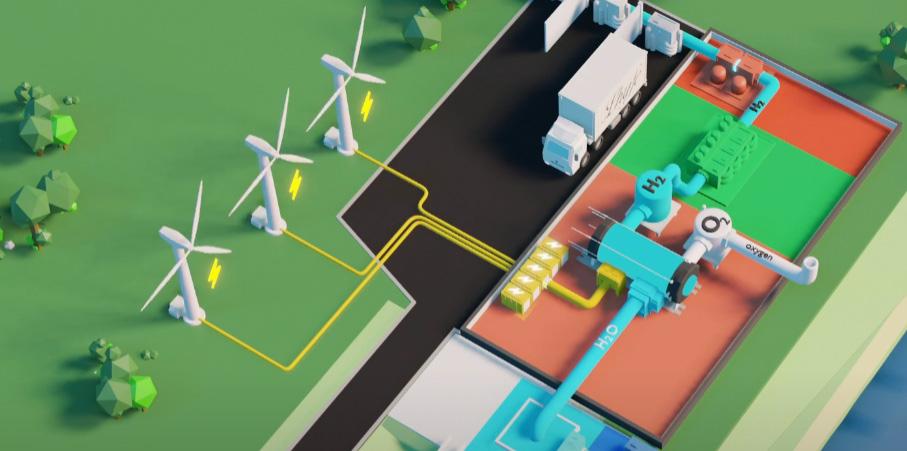

Green hydrogen, as opposed to blue or grey hydrogen, is produced using renewable energy sources (typically wind or solar) to power an electrolyser which separates water molecules, creating hydrogen and oxygen at the anode and cathode.

It’s now simple science, but it costs money. However, many are willing to front the cost to ensure environmental progress, but it is critical that green hydrogen meets the new definition outlined by EU lawmakers. This means hydrogen production must be powered by renewable electricity.

“It is green, it is renewable – it is made through electrolysis. Solar or wind energy powers the electrolyser,” explains Graré.

“We invest in production plants which we then own and operate. We sell the hydrogen to different offtakers across industry and mobility.”

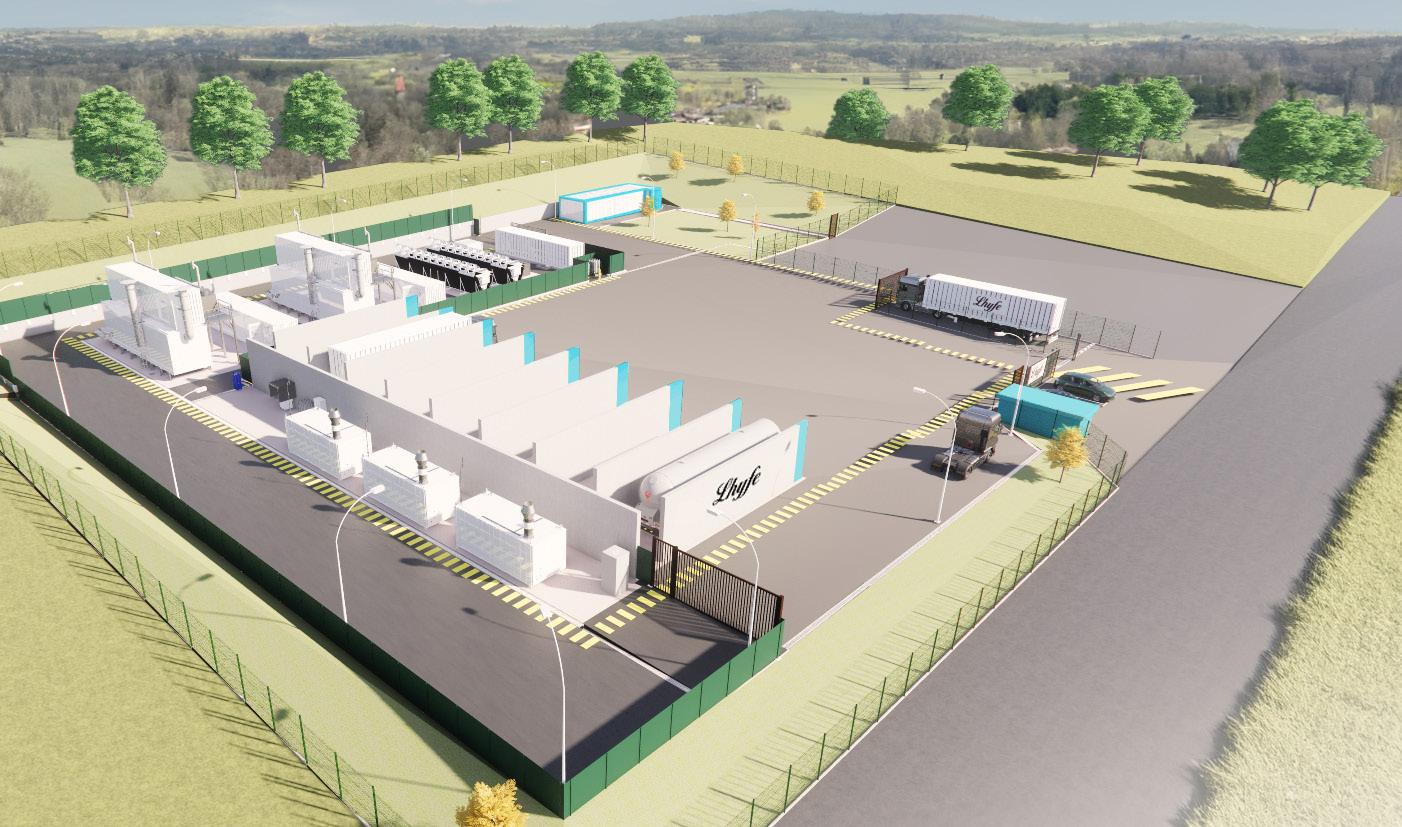

Demonstrating its industry leading capabilities while satisfying growing demand for decarbonisation and reliability, Lhyfe is investing in green hydrogen production plants that are both innovative and proven. The

company has projects in its pipeline across Europe and has experimental ideas at advanced stages to further improve and advance the industry.

Graré highlights Germany as a forward-thinking nation when it comes to hydrogen policy,

focused on industrialisation through decarbonisation while remaining globally competitive.

But the first stages in scaling are underway in France, where small projects are being used to build knowledge and experience,

removing risks and developing robust business cases.

“We are busy with a project in France where we have approval from IPCEI (Important Projects of Common European Interest) as part of their subsidy project funding of €149 million to build a 100MW plant in Le Havre. We will produce green hydrogen there in 2027,” explains Graré.

The French company built its first production plant in France in 2021 – a small scale 1MW facility designed as a pathfinder project for the company to develop best practice. “We learned how to operate, what are the issues, how to debug, and how to build in efficiency,” he says. “Today, we are building six projects, three in France and three in Germany. Each in France is 5MW and one of the German builds is 10MW.

Our strategy is certainly to scale up.”

Understanding the risks, and then developing plans to mitigate them, is critical in the process. The engineering involved in even the smaller projects is on a scale not seen by many, and Graré highlights Lhyfe as one of the only companies to boast such experience.

“Many companies in the market announced big plans like 200MW or 500MW but they have never built anything small. How can this work when you don’t understand the risks? How can you discuss with the bank? You have to go through the industrial roadmap to learn. In Le Havre, we will build a 100MW plant, but before that we will have several smaller projects already coming online which will fill us with experience.”

In Germany, in the south of the country, Lhyfe is building a significant

project capable of delivering 3.2 tonnes of hydrogen for clients across multiple industries. “Our 10MW project in Schwäbisch Gmünd is under construction today,” details Graré.

Germany presents many opportunities for Lhyfe, and beyond Schwäbisch Gmünd there are significant plans in the pipeline. Lubmin, in the German north, is an exciting location for Lhyfe for a number of reasons. On the coast, facing the Baltic Sea, close to German connections with Denmark and Poland, Lubmin was previously agreed as the landing site for the Nordstream pipeline project brining natural gas from Russia to Europe. But with Russian ties severed and business relations strained, the region now sits somewhat forgotten.

“There is a lot of capacity there,”

Hiperbaric, on the way to becoming the leader in Hydrogen Compression

Hiperbaric, world leader in the development of highpressure industrial equipment, has doubled its hydrogen compressor business in Europe. Specifically, the company based in Spain, has generated a business portfolio of about 30 new hydrogen equipment to different customers, both sustainable mobility and industrial. In this way, it aims to become the European leader in high-pressure hydrogen compression.

The company offers complete and advanced containerized Hydrogen compression solutions of up to 1,000 bar / 14,500 psi for sustainable and decarbonized mobility and industry storage.

The basic way to densify hydrogen is to compress it at very high pressure. For this reason, Hiperbaric has developed a range of H2 compressor units with a plugand-play solution, adaptable to any level of production and demand.

It is safe, efficient, and reliable equipment, capable of compressing hydrogen with an inlet pressure range from 20 bar to an outlet pressure up to 500 or 1.000 bar. This wide range of inlet and outlet pressures allows it to be positioned both in the production stage, being able to be fed directly from an electrolyzer, or a medium pressure storage tank (such as tube trailers at 200 bar).

Hiperbaric has an agreement with Lhyfe to supply renewable hydrogen compressors that the company is implementing in projects in France and Germany for renewable generation, compression and filling of hydrogen at high pressure.

Hiperbaric is the global leader in high pressure technologies (up to 6,000 bar) for different sectors for more than 25 years and has 1,000 water compressors installed in 50 countries on five continents. “With our experience in high-pressure applications, we intend to be part of the solution for a sustainable energy transition and contribute our Hydrogen High-Pressure Compression Technology to the hydrogen value chain,” says Andrés Hernando, CEO at Hiperbaric.

For more information visit Hiperbaric.com

says Graré adding that the area is also the home of a decommissioned Soviet nuclear power plant and therefore a large substation.

“The available infrastructure makes it a very interesting site,” he continues. “We will build an 800MW plant to be operational in 2029 and the hydrogen can enter the network for supply across Germany. There is a huge substation still there as the nuclear plant was, at the time, the largest in Europe. The substation is intact and that is why lots of offshore wind energy comes online there. Access to pipeline networks, alongside access to the substation infrastructure is why we decided to build there, after FID and approval processes are complete.”

The project in Lubmin will come off the back of a 200MW production facility set to go up in Delfzijl in the Groningen region of the Netherlands in 2028. Again, Lhyfe will use all of the experience developed to date to create a highly sustainable and efficient site that can be truly green, using renewable power from the Dutch North Sea. From here, the connection into Germany can be easily made via pipeline. In Germany, more than 7000km of pipe network is set to be dedicated to the transport of hydrogen as former gas pipes are converted as a result of a drop in consumption of natural gas.

“We have the experience to know how things will work and that project will be connected to the hydrogen backbone network across the Netherlands through Gasunie. It will also connect into the German network and that means we can produce hydrogen in the north of the Netherlands, using power from offshore wind, and we can deliver that all the way to Germany,” Graré explains.

Currently, the majority of truly green electricity in Europe is generated through wind infrastructure (15%). As this share increases with the number of wind farms going up aggressively,

Reciprocating piston compression technlogy of up to 500 - 1,000 bar

Effective cooling thanks to piston compressor innovative design

Safe and reliable solution thanks to the venting system

green hydrogen producers are looking at further improving efficiency by pairing production facilities with green electricity generation on the same site. This is no easy task and that is why Lhyfe is busy exploring options through pilot projects on the ocean.

“In Germany, there is 8GW offshore wind capacity and, after many years, it has still not been made clear how we can bring all the gigawatts produced in the north, in the sea, down to the south,” says Graré. “It is not only the case in Germany – we also see it in Scotland where offshore wind fails to supply a totally congested grid network. A solution is needed as the German government wants to add another 60GW of offshore wind capacity. Same in Scotland, Ireland, and the Netherlands. It will not work by bringing power across the land

because it is so congested. The only solution is to directly produce hydrogen at sea from electricity generated at sea, bringing the hydrogen to land via pipeline before transporting energy as hydrogen to different customers. We are investing a lot in how we can produce green hydrogen at sea and we have completed a lot of tests in the Atlantic in our project, Sealhyfe.”

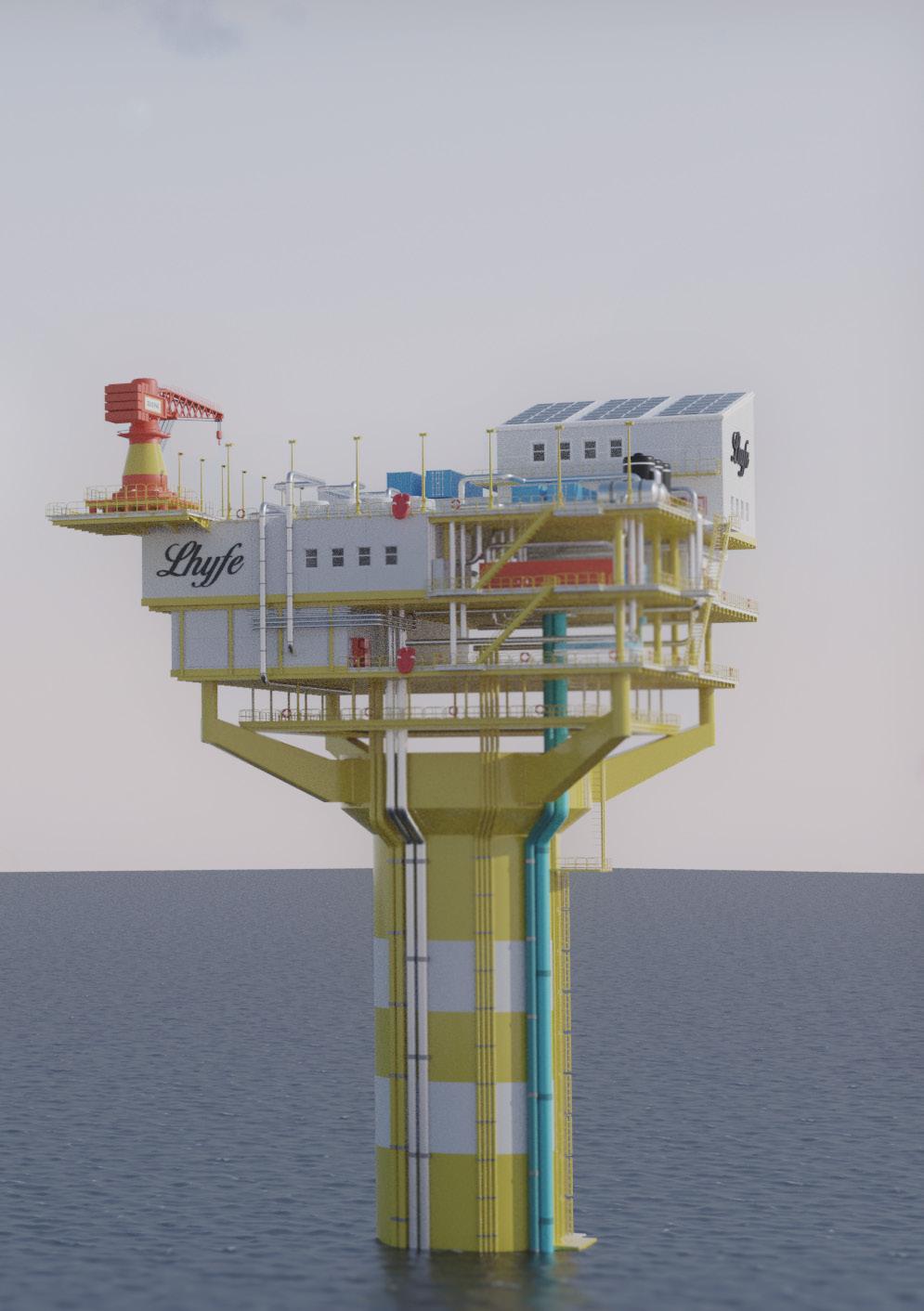

Lhyfe positioned an electrolyser capable of 1MW production in a remote location, on a floating barge connected to an offshore wind turbine.

Returning to dock in November 2023, the pilot showed production stats just as high as on land facilities, and the ability to operate in rough, remote environments, while utilising advanced technology, was extremely positive.

“We needed to test the impact of the seawater environment when

producing hydrogen, but also if it’s possible to run such a plant remotely,” says Graré. “This kind of structure on the sea would not have people all the time, and travelling offshore to these structures is very expensive. We had a lot of positive outcomes from this test, and we are busy preparing the next scale for offshore hydrogen production which will come in Ostend in Belgium. That project, called HOPE, will be operational in 2026 and we will produce 10MW from a jack-up rig, bringing hydrogen to land via a very innovative flexible pipeline. On land, we will compress and then transport in tube trailers. It is subsidised by the EU and the Belgian government.”

HOPE has been selected by the European Commission to receive a €20 million grant as part of the Clean Hydrogen Partnership. Lhyfe and its partners also received €13 million from the Belgian government with the eventual goal of producing four

tonnes of hydrogen every day at sea. If developmental progress continues, the company will become the world leader in a vital industry sector, claiming first-mover advantage and opening up opportunities for green hydrogen production the likes of which has never been seen before.

One of the key challenges for Lhyfe and others involved in green hydrogen production is sourcing reliable electricity supply from legitimately green sources. The demands of producers of green power are monumental, and this drives the continued rollout of projects all over the world. Green hydrogen production can require more than 53 kWh of electricity to create just one kilogram of hydrogen. That kilogram can hold around 40 kWh of usable energy. Buying power in volume is essential.

“We have to look at economies

of scale,” admits Graré. “There is large demand in the market and there are opportunistic companies that want to make green hydrogen through signing PPAs for renewable power. But we have several plants in several countries and we buy renewable energy in a portfolio which creates economies of scale with one large portfolio rather than many small deals. We are expanding so we look to sign more and more PPAs at a lower rate with prices coming down. This means that the average across the total portfolio is coming down. That is undoubtedly what differentiates us from others.”

Across its procurement process, Lhyfe is focused on quality and longevity in relationships. The company is technology agnostic and able to design plants of different sizes in different locations with proven methods and a verified international supply chain. Because it has garnered a reputation as a go-to name in green

hydrogen, Lhyfe is often approached by industrial companies to discuss construction of production facilities on site. “That onsite production is a facility that we would own and operate on the site of the customer,” says Graré.

This approach can make a lot of sense for the big emitters and is likely the direction of travel for major industrial customers under pressure from stakeholders to address sustainability challenges and remove fossil fuels, replacing with green alternatives.

“The most important industry to target right now is the steel industry,” says Graré. “It is a big CO2 emitter that needs to be decarbonised. We have signed a MoU with steelmaker UGITECH to show our commitment to that industry. We are also working with the fertiliser industry which is another big emitter, and more sectors

that could embrace green hydrogen.”

Usable green hydrogen remains a relatively scarce resource, with little production at scale operational. As more production comes online – with the EU targeting 10 million tonnes of annual production by 2030 – the industry will continue to boom but right now there is need to be efficient. For this reason, Lhyfe has again been innovative, developing a hydrogen trading platform, a Marketplace, which it launched at Hannover Messe in April.

“It is enormously innovative,” Graré lauds. “This is like Air BnB for hydrogen. If you have too much, you can use the Marketplace to offload. It brings buyers and sellers together and that is innovative - no one has ever done this before.”

The Marketplace will be delivered across Lhyfe’s Heroes digital platform dedicated to green hydrogen,

developed entirely inhouse.

By being proactive in the energy transition and adopting the ideas of tomorrow, Lhyfe is a company that is doing more than most to deliver tangible results. Sustainable energy from a renewable source, endless in potential, and developed and delivered through proven and dependable channels – it’s what governments, industry, and the general public is calling for. The question now is not about how it is done but more about how quickly Lhyfe can scale. Graré is enthusiastic.

“It’s a very, very exciting time. For some renewable hydrogen is the future, for us it is now”, he concludes.