A corresponding ecosystem of support tools will help simplify motor control system development and accelerate time to market

A corresponding ecosystem of support tools will help simplify motor control system development and accelerate time to market

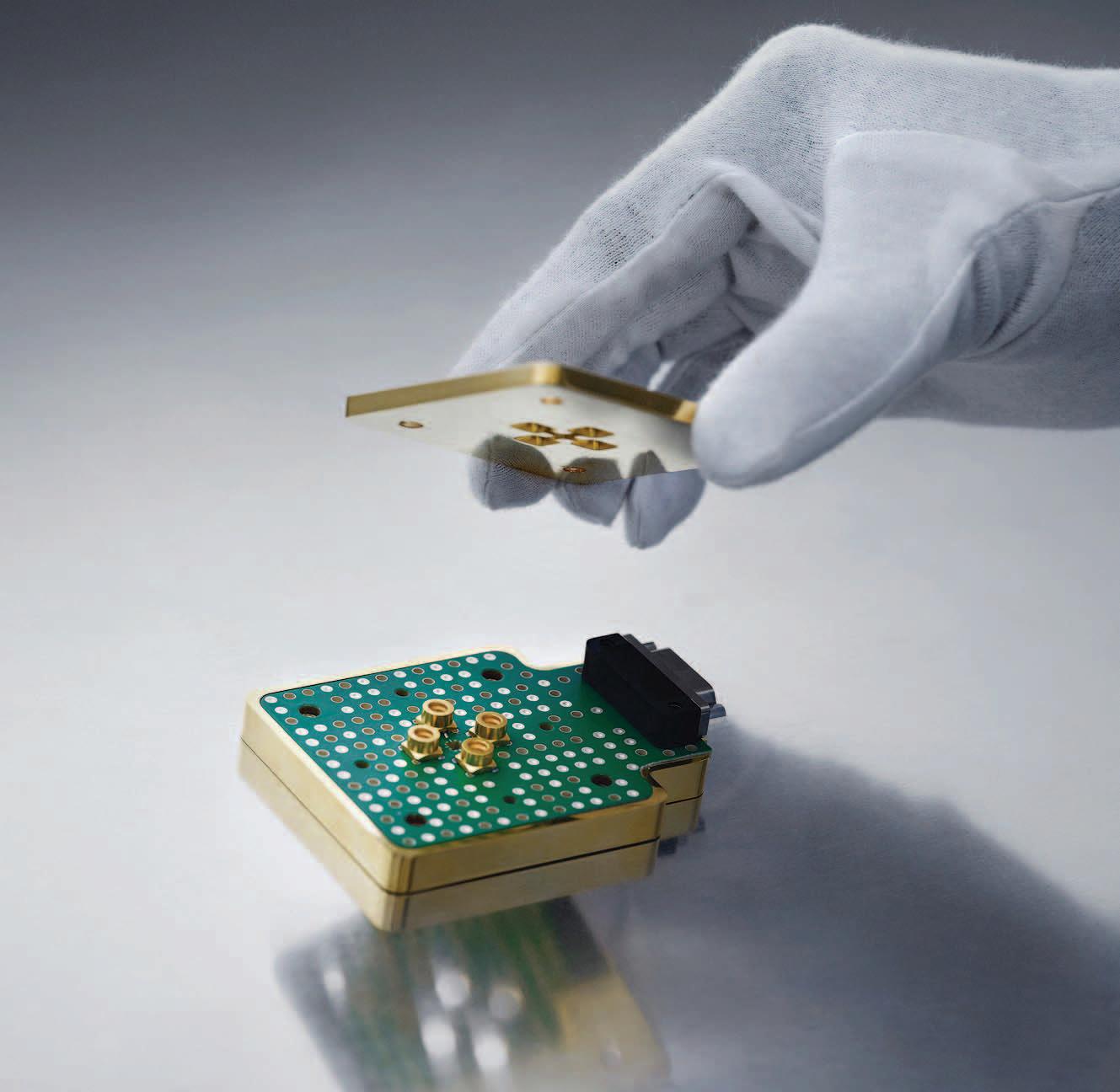

To implement efficient, real-time embedded motor control systems in space-constrained applications, Microchip Technology has launched a new family of dsPIC® Digital Signal Controller (DSC)-based integrated motor drivers. These devices incorporate a dsPIC33 digital signal controller (DSC), a three-phase MOSFET gate driver and optional LIN or CAN FD transceiver into one package. A significant benefit of this integration is reduction in component count of the motor control system design, smaller printed circuit board (PCB) dimensions and reduced complexity. The devices are supported by development boards, reference designs, application notes and Microchip’s field oriented control (FOC) software development suite, motorBench® Development Suite V2.45.

The integrated motor driver devices can be powered by a single power supply up to 29V (operation) and 40V (transient). An internal 3.3V low dropout (LDO) voltage regulator powers the dsPIC DSC, which eliminates the need for an external LDO to power the device. Operating between 70—100 MHz, the dsPIC DSC-based integrated motor drivers provide high CPU performance and can support efficient deployment of FOC and other advanced motor control algorithms.

An extensive ecosystem of motor control software and hardware development tools help make the design process faster and easier, reducing the customer’s time to market.

The dsPIC33CK Motor Control Starter Kit (MCSK) and the MCLV-48V-300W are two new dsPIC33-based integrated motor driver development boards that provide rapid prototyping solutions with flexible control options. The MCSK includes a dsPIC33CK low-voltage motor control development board, a 24V three-phase BLDC motor, an AC/DC adapter, a USB cable and other accessories. This cost-effective kit supports fast prototyping of motor control applications that operate between 12 and 48 VDC with up to 10 Amps of continuous current.

The MCLV-48V-300W development board enables fast prototyping of three-phase permanent magnet synchronous motors that are rated between 12 and 48VDC and capable of delivering up to 25A RMS continuous current per phase. This inverter board introduces a new modular concept where a separate dual-in-line module (DIM) is inserted into the board to configure it for a particular dsPIC DSC or MCU.

The motorBench Development Suite is a free GUI-based software development tool for FOC that accurately measures critical motor parameters, automatically tunes

feedback control gains and generates source code by utilizing the motor control application framework (MCAF). The latest version, v2.45, includes a powerful new feature called zero-speed/maximum torque (ZS/MT), which enables designers to eliminate Hall or magnetic sensors while maximizing the torque output from the motor, from start-up and at low speeds.

MPLAB® Discover now contains many dsPIC DSC-based MATLAB® Simulink® models supporting various motor control algorithms and development boards. Microchip also provides free device blocks for Simulink that can be used to generate optimized code from models for dsPIC DSCs and other Microchip MCUs.

The growing number of dsPIC DSC-based motor control reference designs now includes an automotive cooling fan, lowvoltage ceiling fan and a drone propeller controller. These reference designs shorten the time to market by providing a production-ready solution for various motor control applications. Typically, the board design files include schematics and a BOM, a board user’s guide and motor control source code that are available for download.

Microchip Technology

www.microchip.com

3 | Microchip Launches New dsPIC® DSC-Based Integrated Motor Drivers that Bring Controllers, Gate Drivers and Communications to a Single Device

6 | Pulsiv to deliver groundbreaking USB-C reference designs & finished modules with more than 95% average efficiency

7 | Infineon unveils high density power modules to enable benchmark performance and TCO for AI data centers

8 | Mouser to Inspire Innovation at Embedded World 2024

9 | Renesas Unveils Powerful Single-Chip RZ/V2H MPU for Next-Gen Robotics with Vision AI and Real-Time Control

10 | PIC & AVR MCUs are Making Edge Node Development Easy

13 | Microchip Expands its mSiC™ Solutions

14 | Power Integrations Launches InnoMux-2

16 | Meeting 5G communication and data center demands with advanced power management technology

22 |

Management

Managing Director - I onela G anea

Editorial Director - Gabriel N eagu

Accounting - I oana P araschiv

Advertisement - Irina G anea

Web design - Eugen Vărzaru

Contributing editors

Cornel Pazara

PhD. Paul S vasta

PhD. N orocel C odreanu

PhD. Marian Blejan

PhD. B ogdan G rămescu

30 | Opening smart locks via a smartphone

32 | New Adapter Board RAB4 from Rutronik System Solutions enables centimeter-precise positioning in real-time

34 | Getting started with Matter

36 | Ecodesign, Reuse, Repair, Prolonging Lifetime and New Technology − Is it the new paradox?

42 | Engaging Attendees and Showcasing Innovations

44 | Vector Offers Dynamic Load Management in Charging Parks

44 | TASKING at embedded world 2024

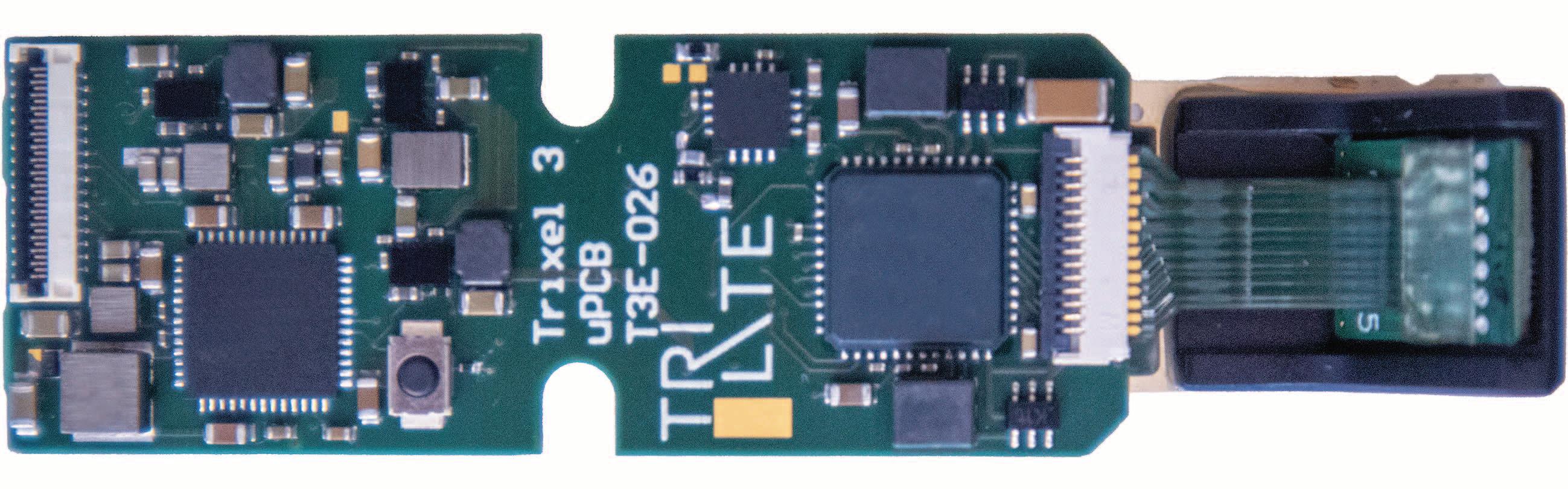

45 | TriLite announces availability of form factor engineering samples for Trixel® 3 Laser Beam Scanner (LBS), to accelerate development of AR use cases

46 | SemiQon announces successful testing and global shipping of its silicon-based 4-qubit quantum chip and ground-breaking transistors

47 | The goal: Fitting computer- on-modules with everything that application developers need

48 | Navitas GaN and SiC Technologies to Enable Next-Gen AI Power Delivery

48 | Shield enables Click boards to be added to Red Pitaya ‘Swiss Army Penknife’ engineering platform

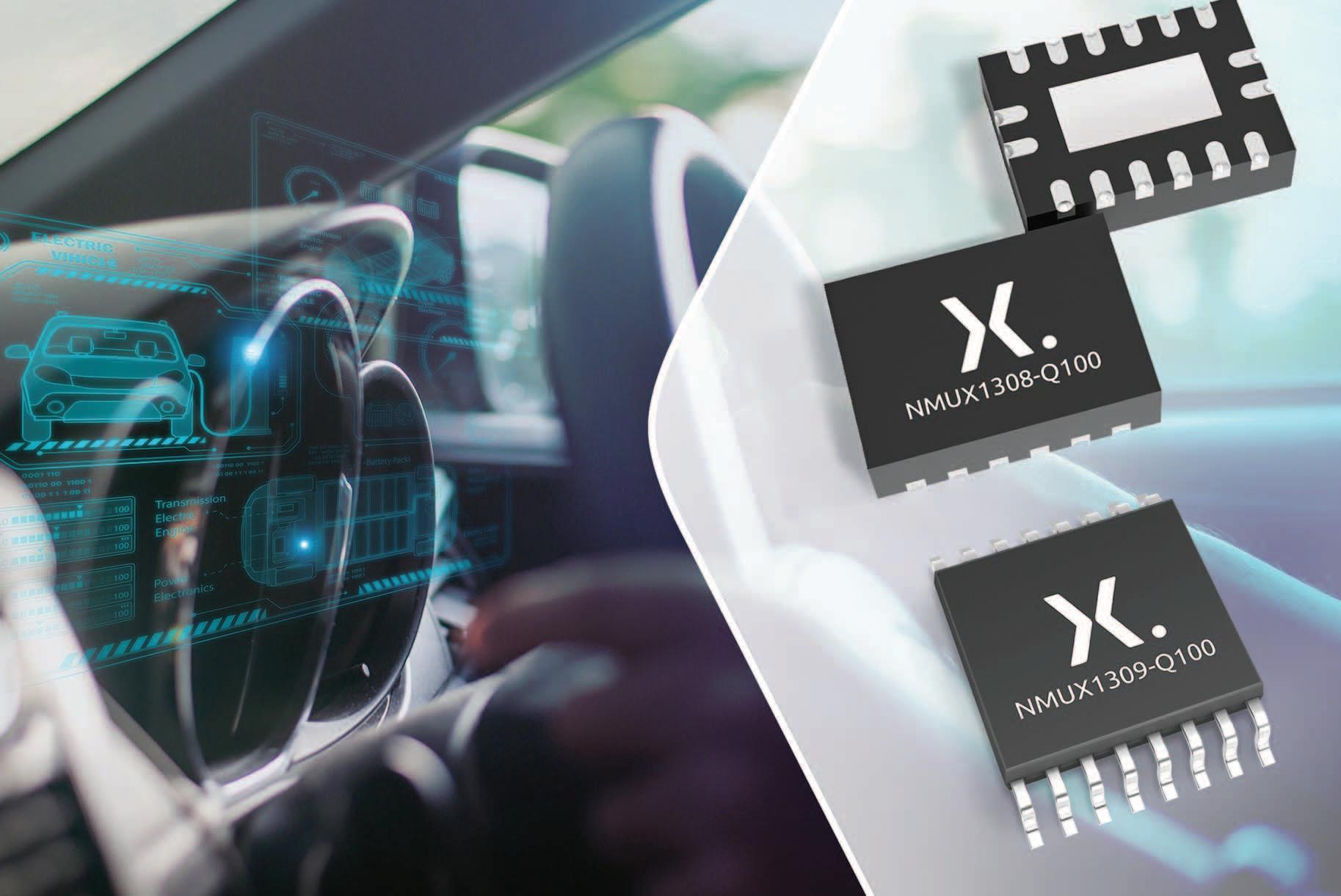

49 | Nexperia unveils Next Gen Low-Voltage Analog Switches

50 | Mouser Electronics Sponsors 2024 Global Create the Future Design Contest, Now Accepting Entries

50 | Mouser Electronics Celebrates 60th Anniversary

51 | The SMTconnect 2024: Increased synergy effects between electronics production and power electronics

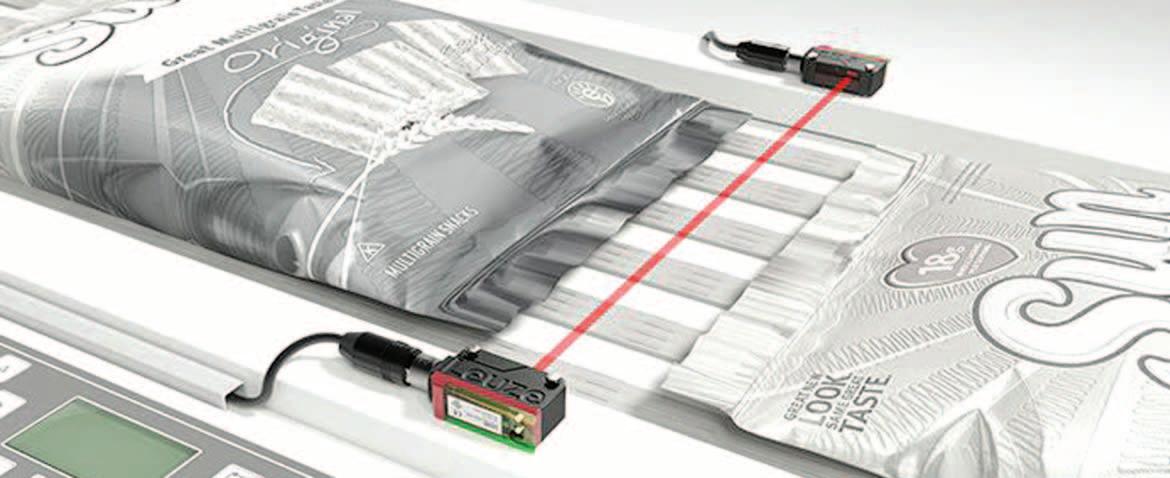

52 | Sensors with convincing cost effectiveness on conveyor lines and in the packaging industry

®

“Electronica Azi” is a registered trademark at OSIM - Romania, Registered position: 124259

ISSN: 1582-3490

Pulsiv to deliver groundbreaking USB-C reference designs & finished modules with more than 95% average efficiency

Pulsiv Limited, the Cambridge (UK) innovator of power electronics technology, is set to release a series of reference designs and assembled modules for USB-C applications that will deliver an average efficiency of more than 95%. This groundbreaking achievement, which minimises energy waste under all operating conditions, has been developed in collaboration with GaN leader, Innoscience and magnetics expert, Frenetic. Designs will be released throughout 2024 to support a new class of sustainable USB-C chargers, adapters, and in-wall sockets. The first 65W solution is expected to be announced towards the end of March 2024.

The front-end of the design utilises Pulsiv OSMIUM technology to efficiently manage the AC to DC conversion process with zero inrush current and no input voltage derating. Using an intelligent active valley fill approach, this patented method also enables the use of smaller system components compared to conventional designs. The DC-DC converter in the 65W variant is based on an industry standard QR flyback. However, when combining a Pulsiv OSMIUM front-end design with optimised magnetics from Frenetic, it is now possible to use an EQ20 core, which provides a 20% reduction in the flyback transformer size.

Frenetic CEO, Chema Molina comments: “By leveraging Pulsiv’s innovative OSMIUM technology, we’ve been able to highly optimise the magnetics to reduce size and drive the efficiency of the flyback transformer to a level we’ve not seen before.

This significant development will enable customers to achieve new levels of performance, size, and cost, and we’re excited to be part of such an innovative solution.”

The use of GaN components from Innoscience has helped to further minimise losses by lowering the RDS(on) and reducing parasitic capacitance, while also optimising the overall BoM cost.

General Manager for Innoscience EMEA, Denis Marcon adds: “We’ve successfully demonstrated that GaN technology is perfectly suited to improving the performance of power electronics designs. Pulsiv OSMIUM technology adds further benefits by significantly improving the overall average efficiency and reducing energy waste. I’m delighted that Pulsiv has selected Innoscience GaN e-mode devices (InnoGaN) for their 65W reference design.”

Pulsiv Chief Product Officer, Dr Tim Moore has been managing the roadmap of USB-C solutions and comments: “We are very excited to be bringing this game-changing technology to the market and deliver our mantra of ‘doing more while using less’. By achieving more than 95% average efficiency, it enables us to provide efficient in-wall USBC solutions that safely manage the critical thermal requirements. This enhances reliability, minimises overall size, and optimises cost to set a world-leading precedent in USBC power supplies.”

Pulsiv continues to demonstrate innovation by delivering cost effective, energy

efficient, and sustainable power electronics designs that benefit billions of devices. To accelerate and simplify the design process, three options will be offered:

Complete reference designs will be made available on the Pulsiv website where engineers can download a document package that includes a datasheet, schematic, bill of materials, and EMC test data.

Fully assembled, ultra-compact, and EMCcompliant finished modules will be produced by Pulsiv to demonstrate a sizeoptimised design and enable rapid prototyping of each reference design. They can also be easily integrated into end products without incurring any further design, development, or manufacturing costs.

Evaluation boards will be developed for customers who wish to test and/or adapt the design for their own requirements and will be stocked by a number of distribution partners. A datasheet with schematic, bill of materials, EMC test data, Gerbers, and PCB layout files will also be available.

To register your interest in this exciting new development and receive full product details upon launch, please click here: Register

https://pulsiv.co.uk

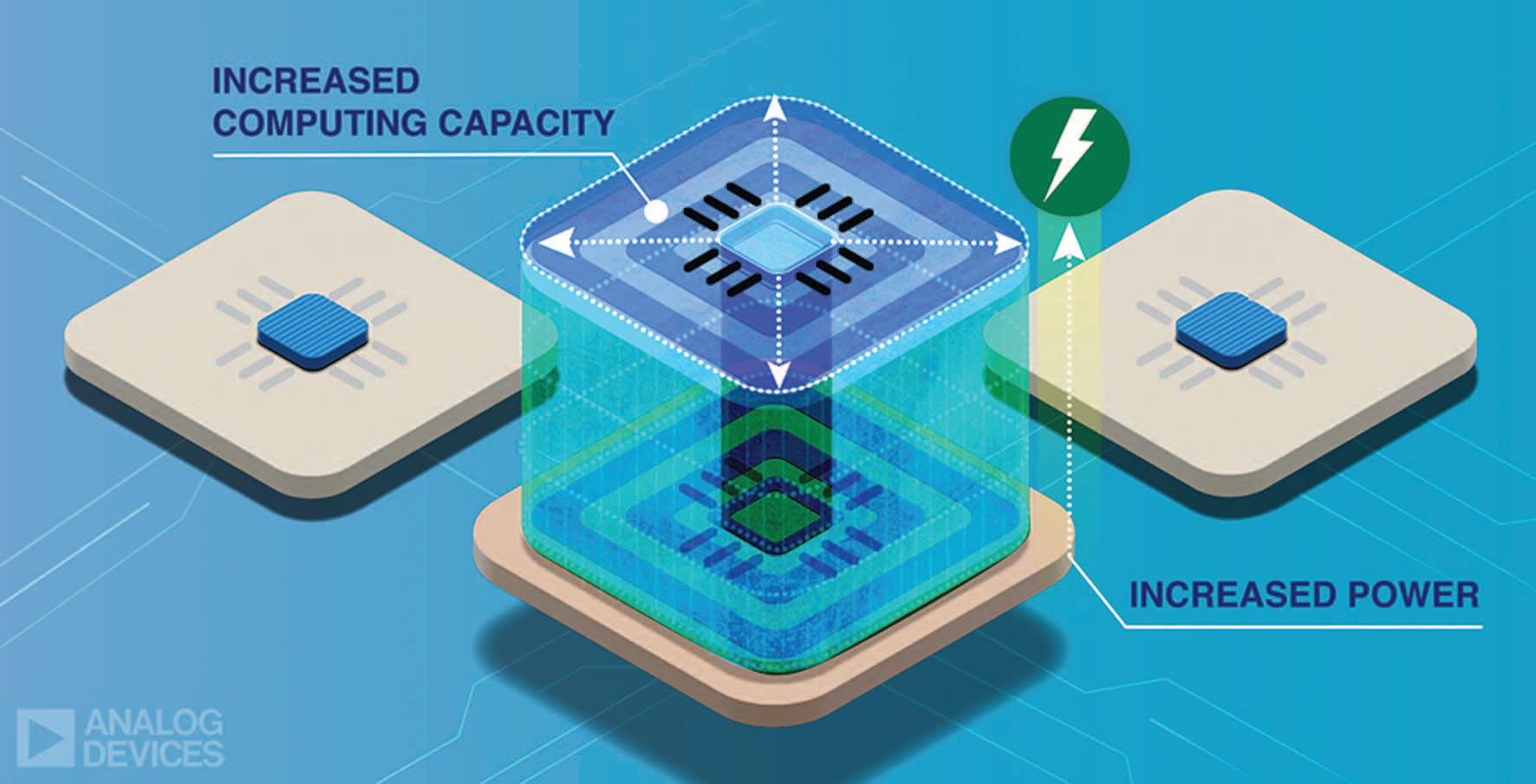

Artificial Intelligence is currently driving an exponential increase in global data generation, and consequently increasing the energy demands of the chips supporting this data growth.

Infineon Technologies AG launched its TDM2254xD series dual-phase power modules that enable best-in-class power density, quality and total cost of ownership (TCO) for AI data centers.

The TDM2254xD series products blend innovation in robust OptiMOS TM MOSFET technology with novel packaging and proprietary magnetic structure to deliver industry-leading electrical and thermal performance with robust mechanical design. This lets data centers operate at higher efficiency to meet the high power demands of AI GPU (Graphic Processor Unit) platforms while also significantly reducing TCO.

Given that AI servers require 3 times more energy than traditional servers, and data centers already consume more than 2 percent of the global energy supply, it is essential to find innovative power solutions and architecture designs that further drive decarbonization. Paving the way for the green AI factory, Infineon’s TDM2254xD dual-phase power modules combine with XDP TM Controller technology to enable efficient voltage regulation for high-performance computing platforms with superior electrical, thermal and mechanical operation.

Infineon introduced the TDM2254xD series at the Applied Power Electronics Conference (APEC). The modules’ unique design allows for efficient heat transfer from the power stage on to the heat sink through novel inductor design that is optimized to transfer current and heat, thereby allowing for a 2 percent higher efficiency than industry average modules at full load.

Improving power efficiency at the core of a GPU yields significant energy savings at scale. This translates into megawatts saved for data centers computing generative AI and in turn leads to reduced CO 2 emissions and millions of dollars in operating cost savings over the system’s lifetime.

“This unique Product-to-System solution combined with our cutting-edge manufacturing lets Infineon deliver solutions with differentiated performance and quality at scale, thereby significantly reducing total cost of ownership for our customers,” said Athar Zaidi, Senior Vice President, Power & Sensor Systems at Infineon Technologies

“We are excited to bring this solution to market; it will accelerate computing performance and will further drive our mission of digitalization and decarbonization.”

Infineon Technologies

www.infineon.com

Mouser Electronics Inc. will inspire innovation at this year’s Embedded World exhibition at the Nürnberg Messe in Nuremberg, Germany. From 9 to 11 April, the embedded electronics community will meet in person to learn more about the latest industry trends and collaboratively generate ideas and concepts for the future.

The Mouser booth will feature a retro 80s gaming kiosk where attendees can go head-to-head in the vintage stacking game, “Pick, Pack, Stack.” The booth will also have the highly popular “spin-to-win” game, giving visitors the chance to win a prize. Additionally, visitors have the chance to win a development kit from one of Mouser’s valued manufacturer partners through its online prize draw. Attendees can also relax and enjoy a freshly brewed cup of coffee, served by a robotic arm. Visitors to the booth will have the chance to talk with the customer service team, who will be ready to answer any queries and guide attendees through mouser.com.

Retro

– “Pick, Pack, Stack”

Step back in time with the retro stacking game – “Pick, Pack, Stack.” Relive the 80’s nostalgia at Mouser’s gaming kiosk as players compete head-to-head, guiding a mBot character to swiftly stack packages without letting them fall. Players will have to keep a watchful eye on the time as this game is a race against the clock. Those who successfully stack the packages in the fastest time will be featured on the arcade-style leaderboard, where

the top 10 players will be determined at the end of the exhibition.

Discover the perfect blend of technological innovation and taste with our cuttingedge autonomous coffee station! With the help of the NXP Semiconductors EdgeReady smart human-machine interface, ordering coffee becomes a breeze. Its advanced machine learning technology enables sophisticated face recognition and keyword spotting capabilities. Just a quick glance and a few friendly words are all it takes, and once the order is received, visitors can continue to be amazed as a sleek robotic arm serves up a freshly brewed, delicious cup of coffee.

Mouser’s customer service team will be at the booth to provide guidance on how to use a wide range of useful online services and tools that can support engineers through the design process. This includes the FORTE Intelligent BOM tool, the Price and Availability Assistant, ECAD design library, and Mouser’s helpful Conversion Calculators. The representatives will also be available to answer any questions regarding orders and delivery times.

Come along to the booth to play Mouser’s ever-popular “spin-to-win” game, where attendees have the opportunity to win a prize from a wide selection of high-quality gadgets and development tools.

Online Prize Draw

Mouser will also be holding an online prize draw for Embedded World 2024, where registrants can enter to win one of the development kits from some of Mouser’s valued manufacturer partners:

• Analog Devices Inc.

ADALM-PLUTO Active Learning Module

• BeagleBoard BeagleV®-Fire Single Board Computer

• Infineon Technologies PSoC™ 62S2 Wi-Fi®Bluetooth® Pioneer Kit

• Nordic Semiconductor Thingy:91™ Multi-Sensor Prototyping Platform

• NXP Semiconductors MCX-N9XX-EVK Evaluation Kit for MCX N94x MCUs

• onsemi NCN26010XMNEVK Industrial Ethernet Evaluation Kit

• ROHM Semiconductor BM2SC123FP2EVK-001 Reference Board

• Silicon Labs SiWx917 Wi-Fi 6 + Bluetooth®LE 5.4 Pro Kit

• STMicroelectronics

STM32H573I-DK Discovery Kit

• Texas Instruments BEAGL-PLAY-SBC BeaglePlay® Single-Board Computer

The Embedded World 2024 online prize draw is open for entries from 4 March 2024 until 3 May 2024. To enter the prize draw and to discover more about what Mouser will be exhibiting at Embedded World, visit https://emea.info.mouser.com/embeddedworld-2024-en (English)

Mouser Electronics www.mouser.com

New Generation AI Accelerator with 10 TOPS/W Power Efficiency Delivers AI Inference Performance of up to 80 TOPS Without Cooling Fan

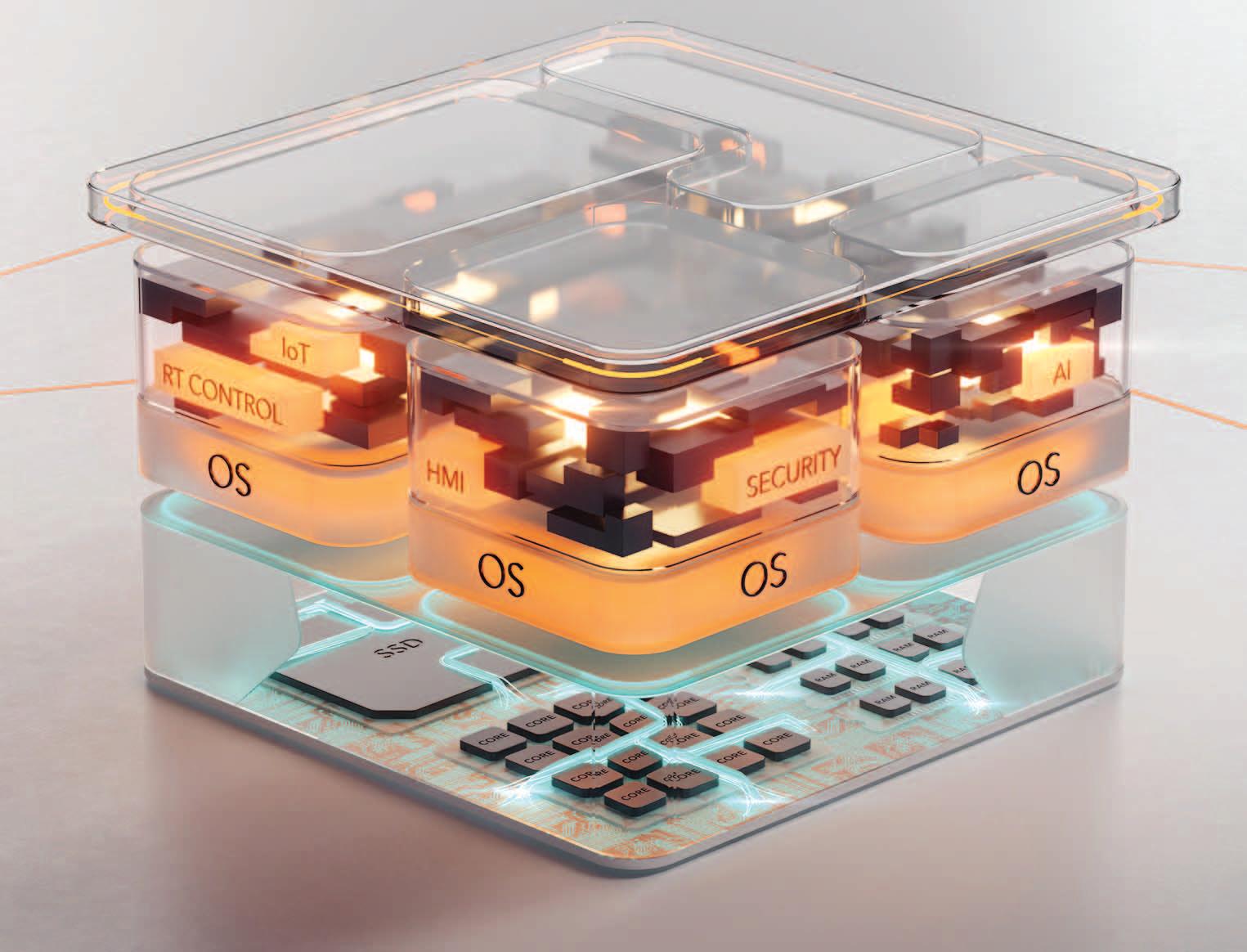

Renesas Electronics expanded its popular RZ Family of microprocessors (MPUs) with a new device targeting high-performance robotics applications. Offering the highest levels of performance within the family, the RZ/V2H enables both vision AI and real-time control capabilities.

The device comes with a new generation of Renesas proprietary AI accelerator, DRP (Dynamically Reconfigurable Processor)AI3, delivering 10 TOPS/W power efficiency, an impressive 10-fold improvement over previous models. Additionally, pruning technology employed in the DRP-AI3 accelerator significantly improves AI computing efficiency, boosting AI inference performance up to 80 TOPS. This performance boost allows engineers to process vision AI applications directly at edge AI devices without relying on cloud computing platforms.

The details of the new DRP-AI3 acceleration technology were recently presented at the International Solid-State Circuits Conference (ISSCC 2024) in San Francisco.

The RZ/V2H incorporates four Arm® Cortex®-A55 CPU cores with a maximum operating frequency of 1.8 GHz for Linux application processing, two Cortex-R8 cores running at 800 MHz for high-performance real-time processing, and one Cortex-M33 as a sub core.

By integrating these cores into a single chip, the device can effectively manage both vision AI and real-time control tasks, making it ideal for demanding robotics applications of the future. Since the RZ/V2H consumes less power, it eliminates the need for cooling fans and other heat-dissipating components. This means engineers can design systems that are smaller in size, less expensive, and more reliable.

Renesas has applied its proprietary DRP technology to develop the OpenCV Accelerator that speeds up the processing of OpenCV, an open-source industry standard library for computer vision processing. The resulting speed improvement is up to 16 times faster compared to CPU processing. The combination of the DRP-AI3 and the OpenCV Accelerator enhances both AI computing and image processing algorithms, enabling the power-efficient, real-time execution of Visual SLAM used in applications such as robot vacuum cleaners.

To accelerate development, Renesas also released AI Applications, a library of pretrained models for various use cases, and the AI SDK (Software Development Kit) for rapid development of AI applications.

By running these software on the RZ/V2H’s evaluation board, engineers can evaluate AI applications easily and earlier in the design process, even if they do not have extensive knowledge of AI.

Winning Combinations

Renesas has developed the “Visual Detection Single Board Computer” that uses camera images to identify its surroundings, and to determine and control its movements in real-time. This solution combines the RZ/V2H with power management ICs and VersaClock programmable clock generators to support power-efficient industrial robots and machinery. Its efficient design eliminates the requirement for an additional cooling fan, keeping the solution BOM and size down. These Winning Combinations are technically vetted system architectures from mutually compatible devices that work together seamlessly to bring an optimized, low-risk design for faster time to market. Renesas offers more than 400 Winning Combinations with a wide range of products from the Renesas portfolio to enable customers to speed up the design process and bring their products to market more quickly. They can be found at renesas.com/win.

Renesas Electronics

www.renesas.com

When designing robust edge nodes, the embedded system designer often has four considerations at the forefront of their mind: Sensor Interface | Low Power | Physical size | Security. Microchip Technology offers microcontrollers (MCUs) with a wide input voltage range from 1.8 to 5.5V making them invaluable in noisy environments as all signals can be lifted out of the background noise, the ability to source or sink up to 50mA on individual GPIO pins, as well as Industrial (-40°C to 85°C) and Extended (-40°C to 125°C) temperature ranges. Let’s take a closer look at those four considerations in order.

Sensor interfaces come in several common varieties. Commonly, the embedded system designer uses: Analog sensors which output a continuously varying voltage or current, Digital sensors which can use logic levels or data streams such as serial communications, Variable Pulse Width Modulation (PWM) such as throttle position sensors, or Time of Flight sensors used in range sensing. Let’s look at some of those in more detail.

Having the option to choose between Discrete analog vs on-chip integrated analog means the user can select the right analog tool for the job.

By using a larger process technology on our silicon wafers, this means the on-chip analog peripheral is far less susceptible to crosstalk as well as inductive or capacitive noise that increases as manufacturers move to much smaller process technologies.

Microchip’s integrated on-chip analog peripherals are configurable just as the user would configure any other peripheral.

By having peripherals integrated the user can also read them as inputs, for example the user might want to know what the inputs of the comparator are during a particular stage of the program.

Let’s look at some of those analog peripherals starting with op-amps.

• Integrated Op-Amps

Microchip’s integrated op-amps have the associated passive circuitry on-chip as well, such as the internal resistor ladder allowing programmable gain to be set and even changed during runtime. Furthermore, the op-amp configuration can also be changed during runtime meaning the user can switch between inverting, non-inverting, unity gain (voltage follower), and custom discrete configurations during runtime, giving far greater flexibility than using discrete hardware alone, while minimizing the costs associated with discrete hardware. Usually when using discrete hardware, the designer is forced to design their mixed signal application to handle worst-case scenarios and thus some performance sacrifices have to be made. However, using integrated analog peripherals allows the user to build some intelligence into their application, where the embedded system can change op-amp gain, configuration or even cascade them on the fly. This means the user can design their application to optimally handle each different scenario, while taking advantage of the lower power consumption of peripherals when compared to software-centric solutions. It needs to be said that the integrated opamp is not a “magic bullet”, and as such they won’t always be the most suitable for every possible application. For example, if the user finds themselves developing an application where they need superior analog performance, dual-supply configuration, or a specialty variant then they should look at Microchip’s wide range of discrete op-amps. This is a perfect case of choosing the right tool for the job at hand.

• Analog to Digital Converter (ADC) with enhanced features

Microchip’s enhanced ADC peripheral features include hardware functions that traditionally were only available using software-centric drivers, such as accumulation, burst modes, averaging, window comparison, and filtering. As always, these ADC peripherals can use external reference voltages, but they can also use multiple different internal reference voltages along with auto-conversion triggering.

This results in the user having access to the hardware functions that can be used while the CPU is in low-power modes. For example, the user can configure an ADC window comparison that only wakes the CPU when

the input signal is outside that window so that the CPU can process that input signal appropriately. This means the CPU sees far fewer wakes and results in significant power savings, vital in low-power applications. This has the added benefit of reducing system and therefore sensor noise, since digital components such as clocks and PWM can be disabled when not in use.

Usually when an embedded system designer starts developing an application they will attempt, as much as reasonably possible, to coalesce their sensors and devices around a single voltage domain. This is to reduce the added complexity, increased propagation delay, and associated Bill of Materials (BOM) and PCB real estate costs associated with using level shifting circuitry.

• Multi-Voltage I/O

Multi-Voltage I/O (MVIO) allows the user to set up one full I/O port using a second voltage domain between 1.62V and 5.5V. The MVIO peripheral uses only 500nA when in use, making it ideal for low-power applications. All digital behavior in serial protocols (I2C, SPI, USART), PWM, and GPIO all just work on the second voltage domain with input Schmitt Trigger levels being scaled according to the second voltage domain. Additionally, the second voltage rail can be divided down to be available for input to the ADC as a voltage reference.

• Configurable Logic Cell (CLCs)

The user can configure this peripheral as one of several different logic configurations, which dependent on the device includes the following gate configurations: AND, NAND, AND-OR, AND-OR-INVERT, OR-XOR, OR-XNOR. The user can also select from the following latches and flip-flops: S-R latch, J-K Flip-Flop with Reset, Clocked D-latch with Set and Reset, Transparent D latch with Set and Reset.

The user can leverage Microchip’s graphical configuration tools to create custom peripherals more easily for their application requirements.

This could be something as simple as a button debouncer, or more involved such as a hardware driver for WS2812B Individually Addressable RGB LEDs which combines SPI, PWM, and CLC to create a custom driver peripheral.

Traditionally the drivers for these Individually Addressable LEDs, which use a custom communications protocol, are software driven requiring a high-speed system clock, and result in a heavy CPU load. However, by using Core Independent Peripherals (CIPs), the system clock can be reduced, the CPU can spend more time in lower-power modes or even be used to run other tasks concurrently.

Using CIPs also gives the user increased responsiveness compared to using a CPU. This is because peripheral propagation delay tends to typically be in nanoseconds, while interrupt or other latency due to software-centric processing tends to be orders of magnitude greater.

Microchip 8-bit MCUs offer three lowerpower (sleep) modes: Idle, Standby, PowerDown, as well as a Configurable Standby mode where peripherals can be configured as on or off. With all peripherals off and in Power-Down mode the AVR-DB consumes only 700nA, making it ideal for ensuring long battery life in low-power remote sensing edge node applications.

The user can utilize the AVR Event System to pass signals between peripherals without waking the CPU. This results in predictable response times between peripherals, which allows for autonomous peripheral control and interaction, and synchronized timing of peripheral actions. The integrated CIPs are also highly interconnected so that signals can be directly routed between peripherals, making the transfer of data between peripherals much simpler to achieve all while using less power than in a software-centric design.

Microchip’s range of 8-bit PIC and AVR MCUs come in a variety of packages for your design needs, including PDIP, SOIC, SSOP, VQFN, and TQFP. This gives you flexibility when developing your final PCB design. However, be aware that the maximum current rating of the MCU may be limited by the device package power dissipation characteristics.

In recent years there has been a shift away from sensor nodes that do all their processing in the cloud, and towards edge nodes that do most or all of their processing locally before sending the results to the cloud.

This reduces the ongoing costs associated with cloud services by reducing the frequent bidirectional data transfers and computational processing, as well as the increased sensor node power usage by having frequent larger data transfers due to sending raw unprocessed data to the cloud.

Embedded systems designers can pair up a lower power 8-bit MCU that is used for directly interfacing with sensors, with a more powerful 16- or 32-bit device that can be used for the heavier computational load and increased memory requirements associated with more complex and secure communications stacks. By reducing the overall number of data

transfers between the edge node and the cloud service, both the ongoing cloud costs and battery usage can be significantly reduced. Additionally, by leveraging a second, more powerful MCU into their design, engineers can even perform Machine Learning (ML) at the edge, making their system design far more powerful for uncovering patterns in data and yielding useful insights.

Designers can also take advantage of Microchip’s secure elements including the ATEC608B which uses the ECDSA (Elliptic Curve Digital Signature Algorithm) sign-verify authentication for the Internet of Things (IoT) market, making it ideal for robust sensor edge nodes.

By using on-chip integrated peripherals, the user can reduce their PCB design complexity, saving valuable PCB real estate while reducing the total number of components in their BOM.

This is further simplified using graphical software tools MCC/Melody and Harmony to configure the peripherals and system. These can be used to get up and running quickly as they offer a high-level view of the MCU and peripheral features.

This means the user can significantly reduce the amount of time they spend studying their MCUs datasheet.

This is ideal for designers when evaluating new or perhaps unfamiliar peripheral features and generates usable code that can be used in production, or as a handy reference for people who want to develop their own drivers. All MCU and MPU products offered by Microchip can be programmed through MPLABX IDE which runs on Windows, MacOS and Linux using our range of compilers including XC8, XC16 and XC32. The designer can debug their application without leaving the IDE and can use Data Visualizer to connect to the Data Gateway Interface (DGI), serial ports, as well as outputting information in a terminal, or graphically plot data values over time. Data Visualizer can also be used with the Microchip Power Debugger which has two independent measurement channels, can deliver up to 100mA at 1.6V to 5.5V to power the target device, and can measure down to 100nA in the high-resolution channel. This makes the Power Debugger ideal for optimizing low-power applications required to run on a battery for years.

The device datasheet and other useful documentation can be accessed through MPLABX under the Kit Window. Each device datasheet covers a family of devices, allowing the viewer to compare devices within a family to identify the devices that best meet their design requirements. Such requirements include memory, RAM, the type of and number of instances of peripherals, including supported serial protocols and Configurable Logic Cells (CLC). If using a PIC or AVR Curiosity Nano development board, the user can also access the Curiosity Nano Hardware User Guide, GitHub code examples, schematics, and the Altium project files from the Kit Window.

for Programming and Debugging

Microchip offers a variety of hardware tools to evaluate an MCU, such as the Curiosity Nano development boards, which can be used with the Curiosity Nano Base board to allow easy use of any daughter boards using MikroBUS sockets. This makes developing a prototype or proof of concept much easier. Then when the designer starts developing a custom PCB for their application, they can program and debug their application using the PICKit programmer debugger.

By using Microchip’s range of 8-bit PIC and AVR MCUs, embedded system engineers and designers can more easily and quickly develop robust low-power sensor edge nodes than ever before while making fewer compromises. Designers can leverage a powerful suite of Core Independent Peripherals (CIPs), including creating custom peripherals, while using hardware functions that traditionally required power consuming CPU intervention, all while remaining in a lower power (sleep) mode. With PIC and AVR MCUs, Microchip makes development of remote sensing, cloud connected and ML nodes easier than ever!

■ Microchip Technology www.microchip.com

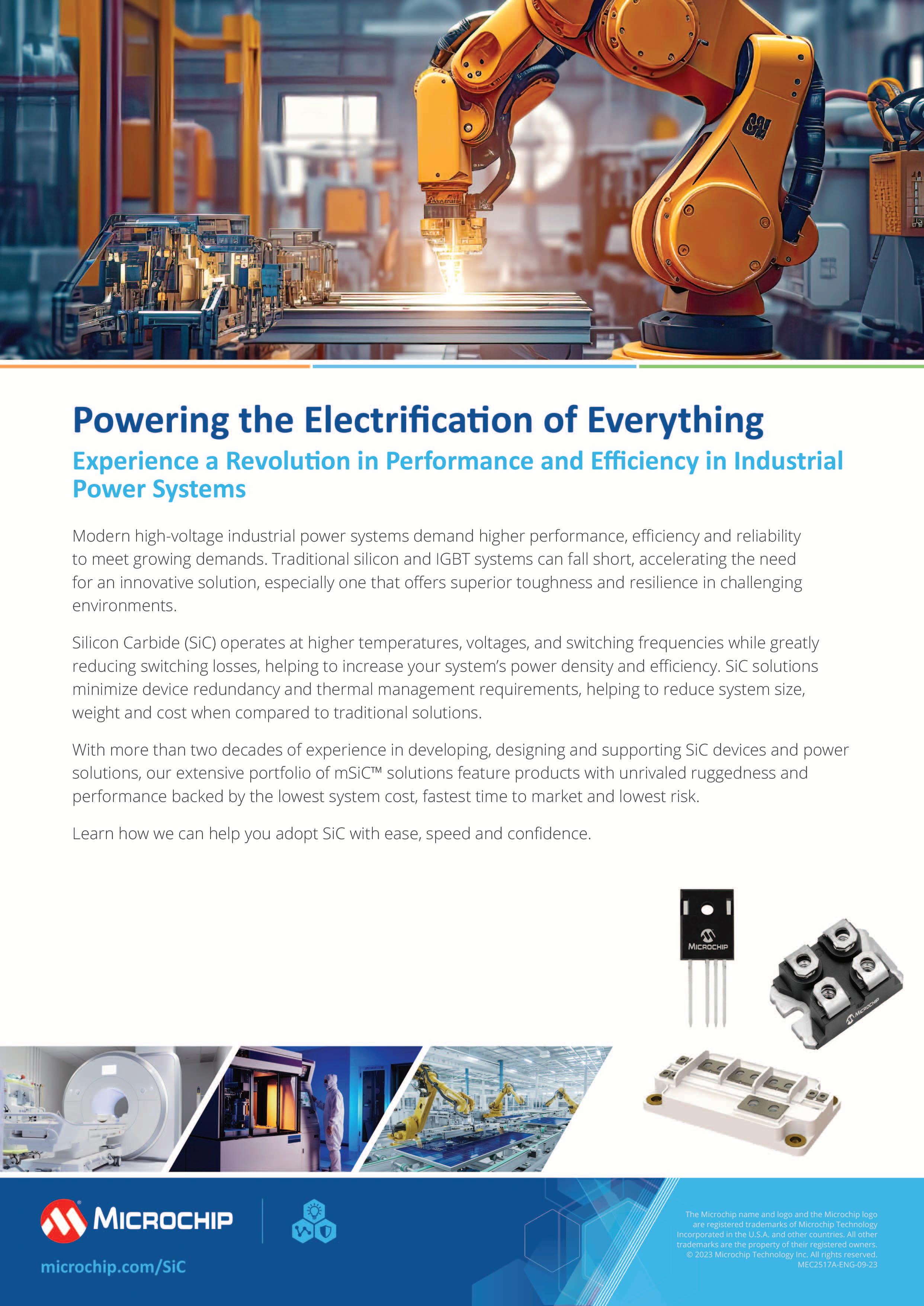

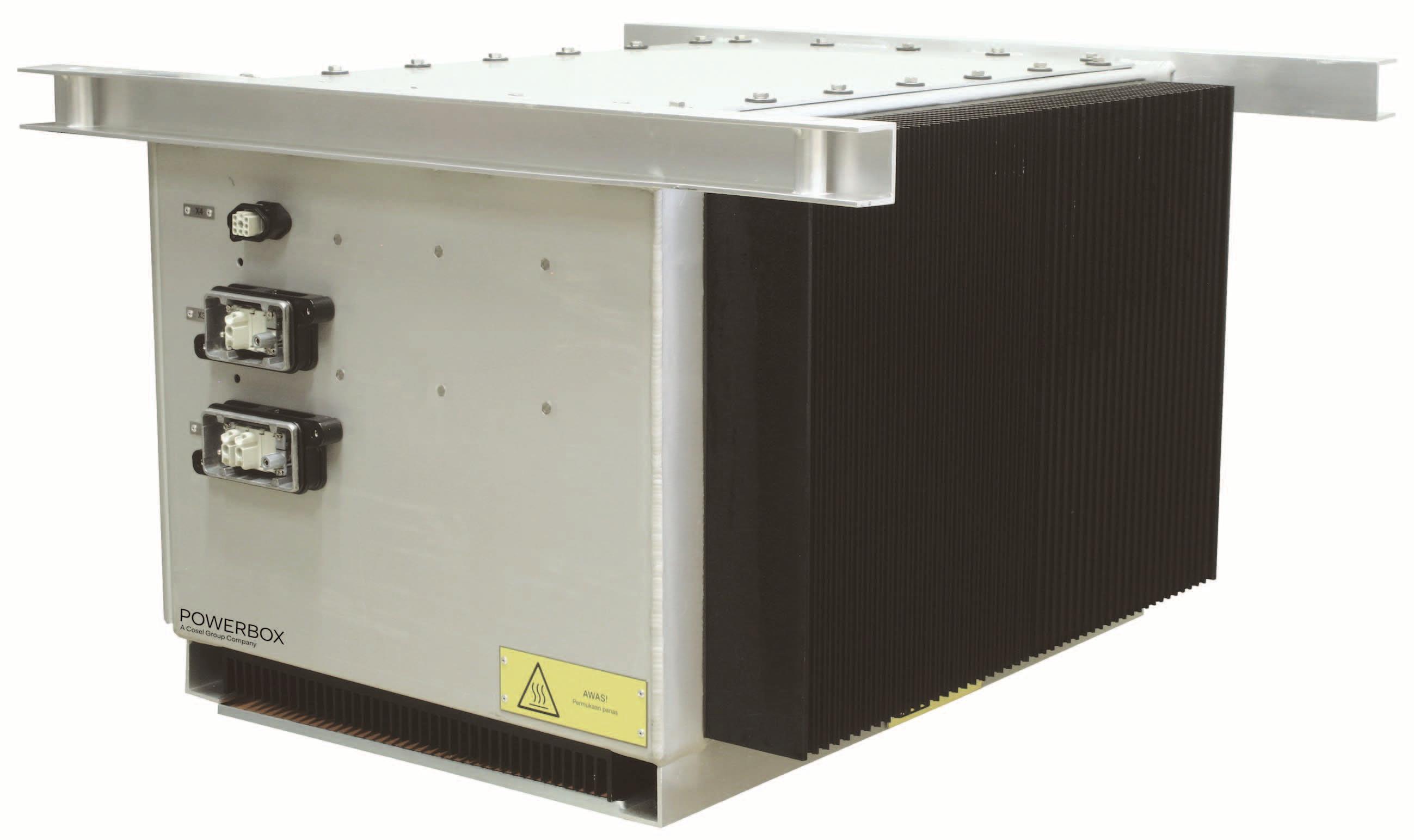

THE HIGHLY INTEGRATED 3.3 KV XIFM PLUG-AND-PLAY DIGITAL GATE DRIVER IS DESIGNED TO WORK OUT-OF-THEBOX WITH HIGH-VOLTAGE SIC-BASED POWER MODULES TO SIMPLIFY AND SPEED SYSTEM INTEGRATION

The electrification of everything is driving the widespread adoption of Silicon Carbide (SiC) technology in medium-to-high-voltage applications like transportation, electric grids and heavyduty vehicles. To help developers implement SiC solutions and fast-track the development process, Microchip Technology introduces the 3.3 kV XIFM plug-and-play mSiC™ gate driver with patented Augmented Switching™ technology, which is designed to work out-of-the-box with preconfigured module settings to significantly reduce design and evaluation time.

To speed time to market, the complex development work of designing, testing and qualifying a gate driver circuit design is already completed with this plug-and-play solution. The XIFM digital gate driver is a compact solution that features digital control, an integrated power supply and a robust fiber-optic interface that improves noise immunity. This gate driver has preconfigured “turn-on/off” gate drive profiles that are tailored to optimize module performance.

It incorporates 10.2 kV primary-to-secondary reinforced isolation with built-in monitoring and protection functions including temperature and DC link monitoring, Undervoltage Lockout (UVLO), Overvoltage Lockout (OVLO), short-circuit/overcurrent protection (DESAT) and Negative Temperature Coefficient (NTC). This gate driver also complies with EN 50155, a key specification for railway applications.

With over 20 years of experience in the development, design, manufacturing and support of SiC devices and power solutions, Microchip helps customers adopt SiC with ease, speed and confidence. Microchip’s mSiC™ products include SiC MOSFETS, diodes and gate drivers with standard, modified and custom options. For more information about Microchip’s SiC portfolio, click here The 3.3 kV XIFM plug-and-play mSiC gate driver is now available for purchase.

■ Microchip Technology | www.microchip.com

New GaN-based ICs combine AC-DC and DC-DC stages into a single power converter; cut power system losses by up to 50 percent

Power Integrations, the leader in highvoltage integrated circuits for energy-efficient power conversion, today announced the InnoMux™-2 family of single-stage, independently regulated multi-output offline power-supply ICs. InnoMux-2 ICs consolidate AC-DC and downstream DCDC conversion stages into a single chip, providing up to three independently regulated outputs for use in white goods, industrial systems, displays and other applications requiring multiple voltages. Elimination of separate DC-DC stages slashes component count, reduces PCB footprint and increases efficiency by as much as 10 percentage points compared to traditional two-stage architectures. Efficiency is aided by the ICs’ 750 V PowiGaN™ gallium-nitride transistors, zero-voltage switching (without an active clamp) and synchronous rectification.

Roland Saint-Pierre, vice president of product development at Power Integrations said: “Most modern electronic systems rely on multiple internal voltages to operate various functions such as computing, communication

and actuation function – typically heat, light, sound or motion of some kind. But losses in each conversion stage are compounded, degrading system performance and generating heat. The InnoMux-2 IC overcomes this challenge by providing up to three independently regulated voltage outputs or two voltage output and a constant current output from a single stage, achieving a compact and efficient power sub-system with low component count.”

InnoMux-2 ICs deliver up to 90 watts of output power with accurate regulation of better than ±3 percent across the full input line, load, temperature and differential current step conditions. Total power system efficiency (AC to regulated low-voltage DC segment) is above 90 percent; the advanced InnoMux-2 controller also manages light-load power delivery, avoiding the need for pre-load resistors and reducing no-load consumption to less than 30 mW. This conserves power for necessary functionality in applications subject to the 300 mW allowance for standby usage under the European energy-using product (EuP) regulations

InnoMux-2 devices leverage Power Integrations’ thermally efficient InSOP™24 and InSOP™28 packages with PCB cooling, so no heatsink is required.

Device options include dual- and threeoutput constant voltage (CV); optionally, one output may be dedicated to constant current (CC) drive, suitable for powering LEDs in displays or for high-speed charging of an internal battery.

Typical applications include TVs, monitors, appliances, networking, home and building automation, LED emergency lighting and industrial power supplies.

Pricing for InnoMux-2 IMX2174F devices starts at $1.11 for 50,000-unit quantities.

For further information, contact a Power Integrations sales representative, or visit power.com.

Power Integrations www.power.com

Devices

Perched atop a 25 meter mast on the edge of the Mojave Desert, a 5G radio transceiver is exposed to searing heat. The smaller and lighter the radio components and the more efficient the radio’s electronic systems, the less heat they generate and the easier to keep the system cool and functioning. At a data center spread out over 1000 acres, banks of servers are executing millions of searches and high demand workloads to feed an ever-growing information hungry world. The technology demands fast transitioning high currents, with very high power component densities that maximize efficiency to rapidly deliver content.

Across the advancing communications world, the most challenging applications for today’s power electronics face the technical hurdles of size, weight, and power (SWaP). Almost every application seems to be getting smaller and lighter while demanding more power.

The need to optimize SWaP is driving the power electronics industry in many new ways. Power management technology is playing a significant role in the innovation of today’s data center and communication industry.

With sustainability and cost reduction as the goal, technology leadership means higher system efficiency is the target.

With more advanced process technologies being used in communications systems comes lower operational voltages and significantly increased currents, which challenge system efficiency.

Methodologies beyond pure silicon development need to be considered for these next generation systems. This is where ADI is poised to bring advances.

On the wireless side, the emphasis is on maximizing power density and getting to as small a solution as possible to reduce the overall size of 5G applications or provide flexibility to incorporate additional capabilities or functionality. Operating in a smaller space translates to functioning more cost effectively and more efficiently.

Possible options and advances in wireless communications technology are endless. ADI’s deep domain knowledge spans across industries and technologies, providing perspectives and solutions to meet these systems’ growing demands.

Insights include alternative ways of system packaging to impact size, weight, and power that produce a smaller footprint, lower component count, and smaller board area impact.

Reducing the board’s size has the added value of freeing up space to include new technologies or additional functionality such as artificial intelligence (AI) and speech recognition.

Lower noise systems require less shielding; less shielding requires less weight and smaller size.

Electronic technology products require a variety of voltages and currents to operate. Efficient power conversion is key to a well-run system. This means high frequency switching power conversion is needed. A drawback to high frequency switching is the generation of electromagnetic noise interference (EMI) in the RF range. This EMI interference can disrupt the function of highly sensitive devices such as the RF transceiver embedded in a 5G network. ADI’s Silent Switcher® series of power converters operate at high frequency while maximizing efficiency—generating the industry’s lowest electromagnetic interference (EMI). This results in a more robust communication link in cellphone network equipment.

The 5G radio installation is responsible for delivering cell and internet service worldwide, allowing workers, friends, and family to stay in touch. The promise of a globally connected future will undoubtedly have a massive impact on how the world’s population will live, learn, work, and play. Fifth generation wireless technology will require significant advances in power electronics to achieve this goal. And, reliability will be critical, as lives may depend upon it.

Many 5G applications are mission critical and always on. Healthcare workers and emergency responders rely on technology for critical communication and incident alert management.

The need for on-demand data and storage by businesses and consumers is increasing exponentially. To meet these demands, a significant increase in power will be required by data centers. This means efficient power conversion is a critical factor in managing the power demand on our already strained power grid system. Improvements in power management technology are necessary as some data centers consume as much electricity as a small city of 80,000 people.

“ADI brings added value by providing high density, fast response solutions to power the advanced ASICs, CPU, and GPU, which are needed to process all this data,” said Gary Sapia.

Application specific integrated circuits, custom designed for a particular use, are the biggest power consumers.

For the same amount of power, ADI’s solutions help by reducing power conversion losses and lowering heat dissipation.

When you search a picture—say “all dogs with flat noses,” the search engine goes out, crunches the information, and finds it very rapidly from a selection of perhaps two billion choices. This effort requires a special heavy duty processing engine, searching an enormous database that employs artificial intelligence (AI). All these operations require a network of machines to ramp up very rapidly to perform the task, resulting in a rapid spike in power.

Spiking power means spiking current. It’s similar to pushing the pedal of your car’s accelerator—the fuel injector opens up and sprays gas into the engine, taking you across the finish line. When clicking search, you are essentially pushing the accelerator, fueling many servers with power.

McCormick School of Engineering and Applied Science Northwestern University.

These machines need lots of current to execute your request—and they need it now!

To manage current demand in a very short period of time requires special systems that operate with high efficiency and very high bandwidth. ADI’s monolithic integration and proprietary coupled inductor technology allows meeting these stringent requirements while delivering superior efficiency and reducing power consumption.

3 Microseconds (THE TIME IT TAKES FOR ANALOG DEVICES’ POWER MANAGEMENT TECHNOLOGY SOLUTIONS TO SUPPLY HUNDREDS OF AMPS AND LET THE GATEWAYS OPEN. THESE SOLUTIONS PROVIDE A VERY FAST TRANSIENT RESPONSE.)

Whatever your vantage point, wherever you look, the need to reduce size, weight, and power remains a constant for data centers and for all of the communications industry. ADI’s system of circuitry and connectivity products includes integrated circuits (ICs) that manage system information control, data collection and translation, high accuracy data sensors, RF radio solutions, and high efficiency power conversion.

All this packaged as discrete reference designs and in highly integrated application specific module systems solutions known as μModule®.

Data centers, social media companies, connected device manufacturers, cloud service providers, and search engine giants strive to achieve challenging sustainability goals.

The five major U.S. tech companies, affectionally known as FAANG, run hyperscale data centers - super-efficient information factories, each with up to 2.5 million servers.

For almost a decade, they’ve been streamlining computing processes, switching to renewables, and investigating better ways to cool their facilities. These data juggernauts self-imposed a special responsibility to minimize their usage of the planet’s resources.

With the advent of 5G and the requirement for high data rate systems, the processing power of data centers is growing through the roof.

Innovations

Power can make up more than half of a typical data center's costs, with 30% to 40% of that figure attributed to building cooling systems. It makes sound financial and business sense to reduce power consumption when the bill for electric power and cooling the systems continues to be a significant part of the operational expense.

Inefficient power systems produce heat. Therefore, a more efficient power system will require less energy to operate, less space to devote to cooling systems, and less money devoted to fans, heat sinks, and other forms of thermal management. Reducing a data center’s power consumption helps the communications businesses to operate more effectively and sustainably. ADI’s technology can help make FAANG servers more efficient and use less power.

Communications companies powering extremely high current devices no longer rely on reaching power-saving targets with off-the-shelf components. They leverage breakthrough materials and small modules to provide them with new pathways toward smaller and lighter 5G radios. ADI offers tailored solutions to fit customer requirements while considering four vectors of intelligent power management to achieve aggressive power-saving goals.

Size matters equally in a sprawling data center and on the top of a 5G radio mast. Smaller electronics circuits using less metal, plastic, and other resources help technology leaders attain their sustainability targets.

Server system form factors are standard throughout the industry. Increasing ASIC throughput performance requires significant increases in power. Given unchanging size constraints, can engineers increase throughput capacity (the processing of information)?

The answer: ADI engineering makes this possible by providing the highest power density solutions in the industry— adding value with advanced integration and proprietary magnetics, delivering more power at greater efficiency and in less space. Essentially, through ADI innovation, more computing capacity can be packed in the same volume.

A conventional power circuit that down converts an input bus voltage to systemlevel voltages may contain as many as 30 separate components.

By combining these circuit elements into a single μModule device, equipment manufacturers can shrink the footprint of the power circuit, place it closer to the load, simplify the design, and optimize the system performance.

As process technology improves, system voltages get lower and current requirements increase in a nonlinear manner. This dramatic increase in current across the power distribution network (PDN) resistance create losses that significantly impact system power efficiency and power dissipation in the form of heat. As we well know, power loss increases with the square of the current.

Our biggest challenge is to reduce this loss. This is where ADI’s μModule technology meets the challenge head on.

AI or smart power provides the data center operators the ability to monitor power usage and shut down or power up the server racks on-the-fly as needed to conserve energy. Facilities without smart system management may end up with servers being on, unnecessarily, during off peak hours. By using ADI’s smart system management, data center operators can realize up to 25% power savings while reducing electricity bills.

Data centers require enormous amounts of power to operate. Monitoring and controlling this power for failure is critical for safety and reliability. ADI’s intelligent hot swap technology sets the industry standard in providing the needed system monitoring and control that insure safe reliable data center operation.

Hot swap ensures the input current is controlled in a safe manner, preventing component stresses that can cause system failures and component lifetime per-

Improvements in circuit and magnetics design, packaging, and integration are also shrinking the power system in wireless and wired communications equipment. μModule® technology, pioneered by ADI, offers the industry’s highest power density solutions, as multiple power components, making up a complete power solution, are packaged inside a single, surface-mount substrate.

To drive peak operating efficiency, smart system management is required to effectively manage and control the power systems.

5G radio and data center server systems can benefit from new technology today, which enables operators to incrementally improve efficiency and reliability over time by applying insights gained from operational data.

formance degradation. In the event of a fault, hot swap alerts the system and attempts to limit the condition or perform an immediate shutdown to prevent a catastrophic failure, such as a fire.

Hot swap’s intelligent technology manages voltage and current at the rack mounted board level, enabling the safe installation of a backup board (or line card) without the need to power down the entire rack or system.

This allows for the reliable servicing of individual units and minimizes service interruptions - saving time and cost.

ADI’s intelligent hot swap solution is an advanced technology that ensures systems operate in an efficient, safe, secure, and reliable manner, which are critical parameters for any high power data center system.

Mobile phone and internet data services are how most of the world stays connected and informed. The sheer scale of these technologies has a monumental impact, both environmentally and financially. That’s why innovations in power management technology that have the potential to enhance sustainability with increasing efficiency are so valuable.

Creating sustainable solutions that consume less energy is growing in importance across applications. Power semiconductors are central to that objective. But technology is just a starting point.

ADI is committed to making it easier for power electronics system designers to bring safe and reliable data centers and communication innovation to the market as well as reach the goal of a sustainable future that will benefit the planet and its global population.

■ Analog Devices www.analog.com

About the authors

Gary Sapia, received his Bachelor of Science in Engineering from Texas A&M University, with advanced technology courses in power electronics and RF system design. He has over 28 years of experience focused on the design and development of analog systems, including power conversion and high frequency solutions for the communications and GPS markets. Prior to joining Analog Devices, Gary spent 18 years as a field applications engineer at Linear Technology (now part of ADI), focused on Cisco and other prominent Bay Area networking companies.

Andrea Pizzutelli, holds a Ph.D. in information technology and an electrical engineering Laurea degree from Politecnico di Milano in Italy. He has 15 years of experience developing integrated power conversion products and has held various positions focusing on data center, telecommunications, and notebook markets. Andrea has also co-authored multiple scientific papers and holds numerous U.S. patents.

Engage with like-minded members and ADI technology experts in our online community, EngineerZone®. Expand your network, ask your tough design questions, share your expertise, browse our rich knowledge base, or read about new technologies and the engineers behind them in one of our blogs.

Visit https://ez.analog.com

The healthcare industry has been adopting greater use of digital technology over the last couple of decades. The COVID-19 pandemic helped accelerate this evolution. The remote access to healthcare necessitated by the pandemic highlighted several other benefits, such as more efficient healthcare delivery and continuous patient monitoring. Technological advances have spawned the Internet of Medical Things (IoMT), where networks of patients with portable and/or wearable medical devices and sensors, and the corresponding healthcare systems and providers, are connected through the Internet.

Author: Rolf Horn Applications Engineer DigiKeyContinuous blood glucose levels and heart monitors are examples of devices that have gained widespread acceptance. IoMT devices help automate data transfer, thereby reducing human error. Advances in predictive data analytics and artificial intelligence (AI) make IoMT devices even more powerful by enabling data-driven diagnostics with early detection of abnormalities, greater patient self-engagement, and reduced healthcare costs.

Security:

The sensitive nature of the medical information being transferred requires a high level of security. The Advanced Encryption Standard (AES) and Elliptical Curve Cryptography (ECC) can encrypt and decrypt data transfer using secure keys and hence authenticate the data.

Keys based on a true random number generator (TRNG) in the device help in the secure generation of these keys. Spoofing attacks can be minimized with the use of device identification using unique physically unclonable functions (PUF) within the semiconductor device. Secure boot-up hardware protocols, as well as tamperproof mechanisms that prevent access to protected regions of the device memory help enhance device security.

Wearable and portable devices typically run on battery power. Low-power communications protocols such as Bluetooth LE 5.x, power-saving modes when the device is not active, and an efficient architecture that optimizes operational performance versus power consumption are some essential features that can maximize battery life.

Rich feature set in a small size

Small and light devices enable their use in wearable and portable medical applications. New applications such as smart tooth implants require tiny form factors. The System on Chip (SoC) concept provides a high level of multi-functional integration onto a single chip. This can include a peripheral feature set that provides high-speed analog and digital sensing, measurement, data transformation, and communication. Other essential requirements include wireless connectivity, high-speed data processing with large flash and RAM memory, precision low-frequency/low-power clocks and timers, DC/DC voltage regulation, etc.

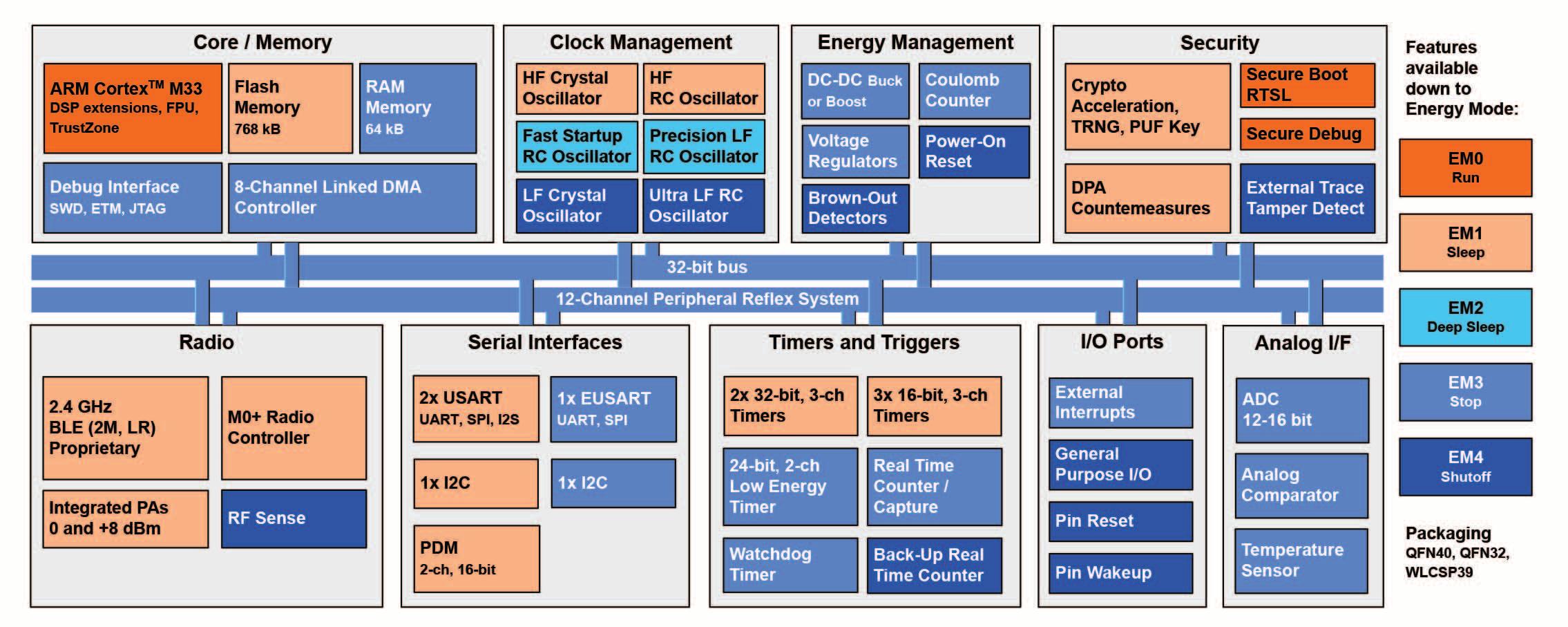

Silicon Labs EFRBG27 wireless Gecko SoC family for IoMT applications

In March 2023 Silicon Labs aannounced the release of a new family of secure, energy friendly devices that expand their Wireless Gecko portfolio. This includes the BG27 series of Bluetooth LE SoC devices ideally suited for IoMT applications.

A block diagram showing the rich feature set included in the BG27 SoCs is shown in Figure 1. Some details on the key features are listed below:

The 76.8 MHz, 32-bit ARM Cortex® M33 RISC core with DSP instruction and floating-point unit allows for high-performance signal pro cessing capability at 1.50 Dhrystone MIPS/MHz. It includes the ARM TrustZone security technology. The flash memory is 768 kB, while the data memory is 64 kB of RAM. The Linked Direct Memory Access Controller (LDMA) allows the system to perform memory operations independent of the software, hence reducing energy consumption and software workload.

The EFR32BG27 includes an Energy Management Unit (EMU) that manages transitions of the energy modes (EM0 to EM4) of the SoC. With the EMU, applications can dynamically minimize energy consumption during program execution. EM0 mode provides the highest number of features, such as enabling the CPU, radio, and peripherals at the highest clock frequency. Peripherals can be disabled in the low-power active modes EM2, EM3. Voltage scaling is used by the EMU when transitioning between energy modes to optimize energy efficiency by operating at lower voltages when possible. EM4 is an inactive, lowest power state that allows the system to wake up into the EM0 mode.

DC/DC Conversion:

The EFR32BG27 family includes both buck and boost mode onchip converters that can supply the required internal 1.8 V. The boost mode devices, such as the EFR32BG27C230F768IM32-B , have the ability to operate down to 0.8V, allowing single cell alkaline, silver oxide, and other low-voltage battery operation.

The boost converter can be shut down using a dedicated BOOST_EN pin, hence saving system battery power during storage and shipping. In this mode, the maximum current draw is only 20/50nA, depending on the powering of certain pins. In the buck mode devices, such as the EFR32BG27C140F768IM40-B, a maximum 3.8 V can be supplied externally. An on-chip supply monitor signals when the supply is low enough to allow the regulator to be bypassed and extend the range to 1.8 V.

The bypass mode also allows the system to go into the EM4 energy-saving mode. A Coulomb Counter block is integrated into the DC/DC converter. This includes two 32-bit counters that are used to measure the number of charge pulses delivered by the DC/DC converter, enabling accurate battery level tracking to enhance user safety.

Bluetooth 5.x networking:

Bluetooth Low Energy (LE) wireless protocol is supported by this SoC family. The radio receiver uses a low-IF architecture consisting of a low-noise amplifier and an I/Q down conversion. The automatic gain control (AGC) module adjusts the receiver gain to avoid saturation for improved selectivity and blocking performance.

The 2.4 GHz radio is calibrated at production to improve image rejection performance. The family includes a range of transmit powers from 4 dBm to 8 dBm. RF noise mitigation includes operation of the DC/DC converter in soft switching mode at boot, and DC/DC regulating-to-bypass transitions to limit maximum supply slew rate and mitigate inrush current.

The RFSENSE block allows the device to remain in EM2, EM3 or EM4 energy-saving modes and wake up when RF energy above a specified threshold is detected.

DigiKey, a leading global commerce distributor offering the largest selection of technical components and automation products in stock for immediate shipment, has launched season 3 of its “Farm Different” video series, sponsored by Analog Devices, Inc. (ADI) and Amphenol Industrial.

Season 3 features three episodes that provide a look into the future of farming to determine what innovations will power the next generation of global food production. The series explores how robotics and autonomous vehicles are coming to the farm and also dives deeper into the integral data necessary to identify local strategies, maximize yield and help farmers sustainably feed the planet.

“The agricultural community has never backed down when facing sustainability challenges,” said Josh Mickolio, supplier business development manager at DigiKey. “Navigating reduced labor pools, unpredictable weather and rising costs threatens growth in production and the survivability of small and large farming operations alike. This season highlights the fertile future of smart farming, showcasing solutions that leverage the creativity, ingenuity and resilience this industry is known for.”

“With factors such as population growth and climate change, the future will require us to achieve much more with far less, and technology has a key role to play in precision agriculture,” said Tzeno Galchev, marketing director at ADI. “Our technology is helping enable efficiencies across the board. This includes smart edge applications like livestock management and tracking that use our ultralow power technologies, all the way to automating, electrifying, and navigating the machinery that feeds the planet using our inertial measurement units, connectivity, and battery management solutions.”

“In the realm of agriculture innovation, our connectivity solutions are at the heart of empowering farmers to ‘Farm Different,’ ushering in a new era of precision, efficiency and sustainability,” shared Mark Cunningham, general manager at Amphenol Industrial. “At Amphenol, we are committed to enabling the transformation of agriculture, where technology and data converge to cultivate a brighter future for farming.”

To learn more about the video series, sustainable production and how DigiKey is supporting the rapidlychanging agricultural sector, please visit the DigiKey website.

■ DigiKey | www.digikey.com

Security: The EFR32BG27 family of SoCs includes a range of security features, as shown in table 1.

The Secure Boot with the Root Of Trust and Secure Loader (RTSL) authenticates trusted firmware that begins from immutable read-only memory (ROM). The cryptographic accelerator supports AES and ECC encryption and decryption. It also includes Differential Power Analysis (DPA) countermeasures to protect keys. The TRNG harvests entropy from a thermal source and includes start-up health tests for this source, as required by the NIST SP800-90B and AIS-31 standards, as well as online health tests as required for NIST SP800-90C. The debug interface, locked when the part is released in the field, has a secure unlock function that allows authenticated access based on public key cryptography.

True random number generator (TRNG)

On the hardware side, an External Tamper Detect (ETAMPDET) module enables detection of external tampering such as unauthorized enclosure opening. It can generate an interrupt to warn the software and allow system-level actions to be taken.

Rich peripheral set: The SoCs include hybrid analog-to-digital converters that combine both SAR and Delta-Sigma techniques. The 12-bit mode can operate at speeds of up to 1 Msps, while the 16-bit converter can operate at up to 76.9 ksps. The analog comparator module can use internal or external references and can also be used to sense the supply voltage. SPI, USART and I2C serial communication modes are all supported. The Real Time Clock and Capture (RTCC) module provides 32-bit timekeeping down to EM3 power modes and can be clocked with the internal low-frequency oscillator.

Secure boot with root of trust and secure loader (RTSL)

Secure debug with lock/unlock

DPA countermeasures

Anti-tamper

Secure attestation

Secure key management

Symmetric encryption

Public key encryption - ECDSA/ECDH/EdDSA

Key derivation

Hashes

External tamper (ETAMPDET)

Using TrustZone

Using TrustZone

• AES 128-bit/192-bit/256-bit

- ECB, CTR, CBC, CFB, CCM, GCM, CBC-MAC, and GMAC

• p192 and p256

• ECJ-PAKE p192 and p256

• SHA-1

• SHA-2/256

The Low Energy Timer (LETIMER) provides 24-bit resolution and can be used for timing and output generation when most of the device is powered down, allowing simple tasks to be performed with minimal power consumption. The Peripheral Reflex System (PRS) is a signal routing network that allows direct communication between the peripheral modules without involving the CPU. This reduces software overhead and current consumption.

Low footprint packages: One of the devices in the EFR32BG27 family is the EFR32BG27C320F768GJ39-B. This device comes in a wafer-level chip scale package (WLCSP) with dimensions of just 2.6 mm x 2.3 mm and can be run in either buck or boost regulator modes. The rest of the family comes in either QFN32 4 mm × 4 mm, or QFN40 5 mm × 5 mm packages in specific regulator modes of either buck or boost.

Conclusion

The EFR32BG27 provides industry-leading energy-efficient processing capability and low-energy Bluetooth connectivity. These small form factor SoCs, that include a variety of security features, are ideally suited for IoMT applications.

■ DigiKey

www.digikey.com

Author: Prabhath Horagodage Senior Staff Product Management Renesas Electronics

Author: Prabhath Horagodage Senior Staff Product Management Renesas Electronics

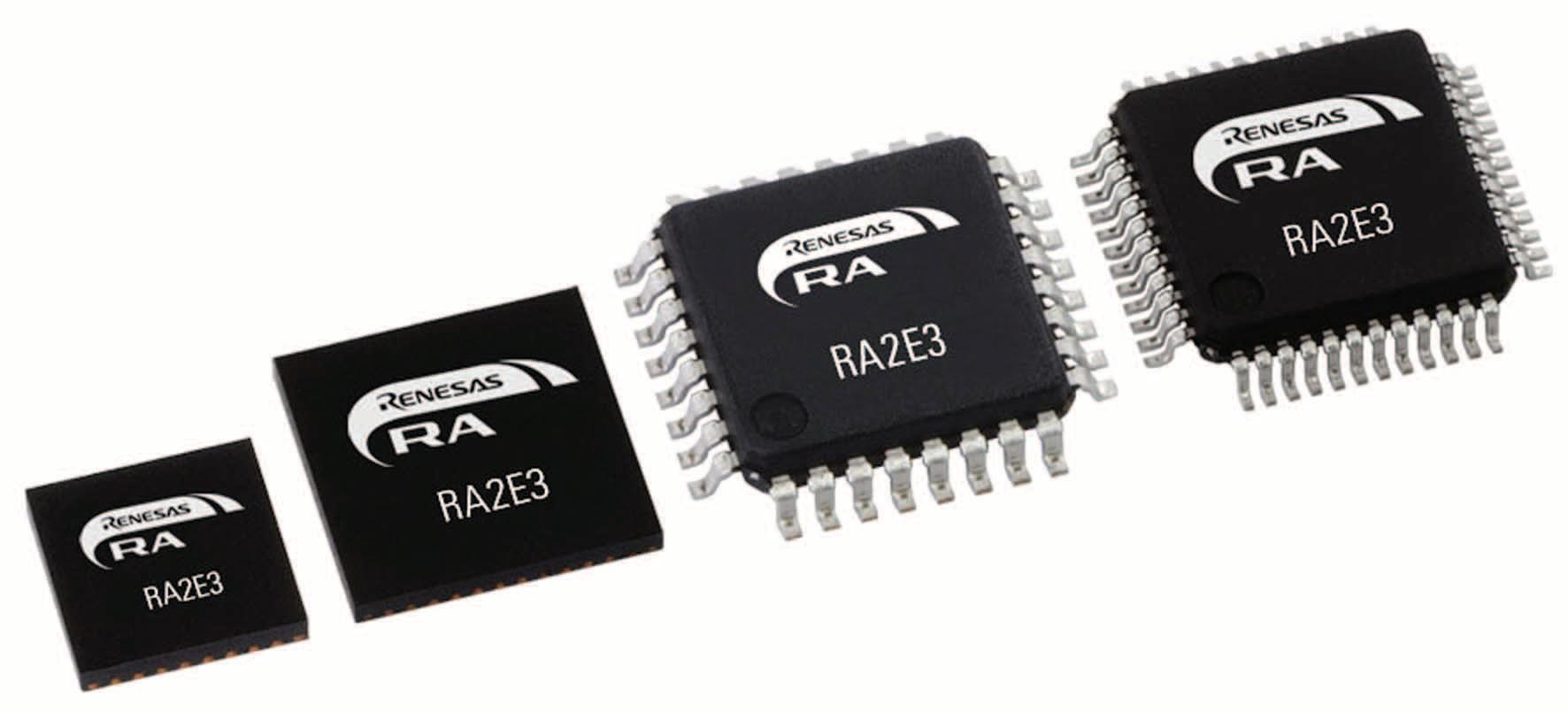

Microcontrollers are used for a variety of purposes. Some applications require high speed, high performance, and continuous full operation, while others require only partial operation at specific cycles. Renesas has been studying these use cases for a number of years and designed the extremely power-efficient RA2E3 to allow designers various means of reducing the MCU power consumption with its power-saving functions. This allows microcontroller-based electronic products to be power efficient and environmentally friendly as expected by end users.

RA2E3 provides four main power-saving functions which can be used either separately or in combination:

1. Three different low-power operating modes

2 Four different power-control modes

3 Switching the clock frequency to an appropriate speed

4. Stopping unnecessary modules for a specific duration

RA2E3 provides the following three different low-power modes:

1. Sleep mode

2 Software Standby mode

3 Snooze mode

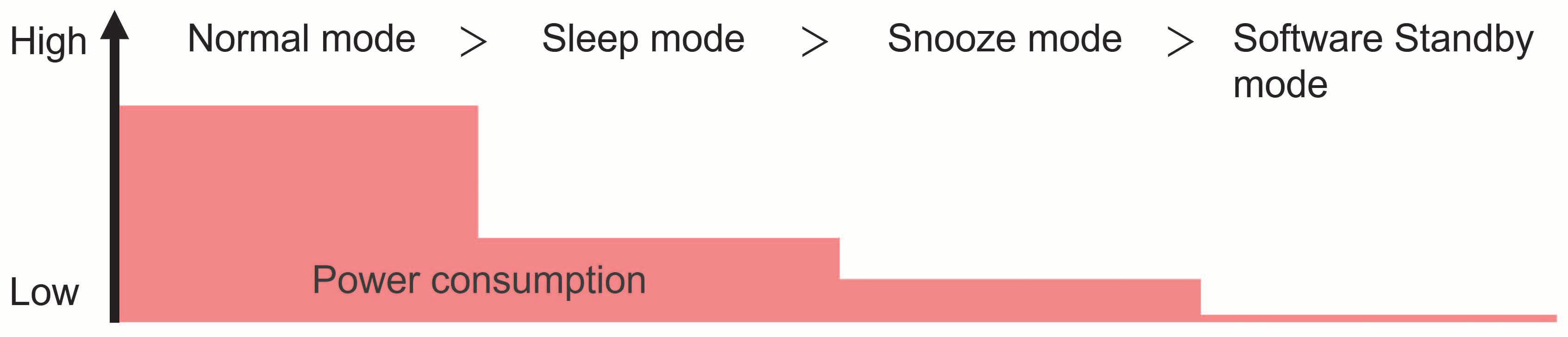

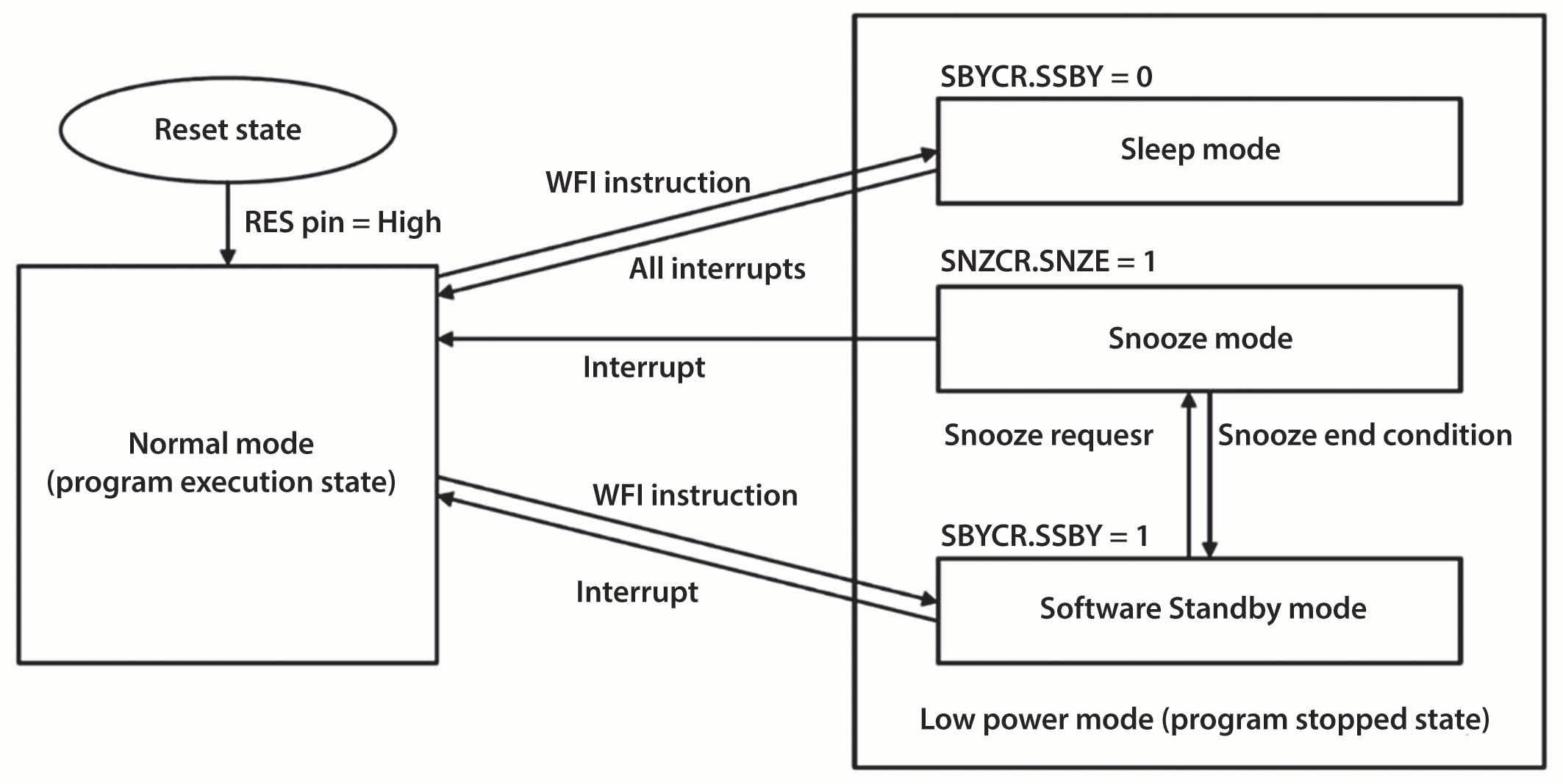

The MCU can be programmed to be transited among these modes automatically when the required conditions are satisfied.

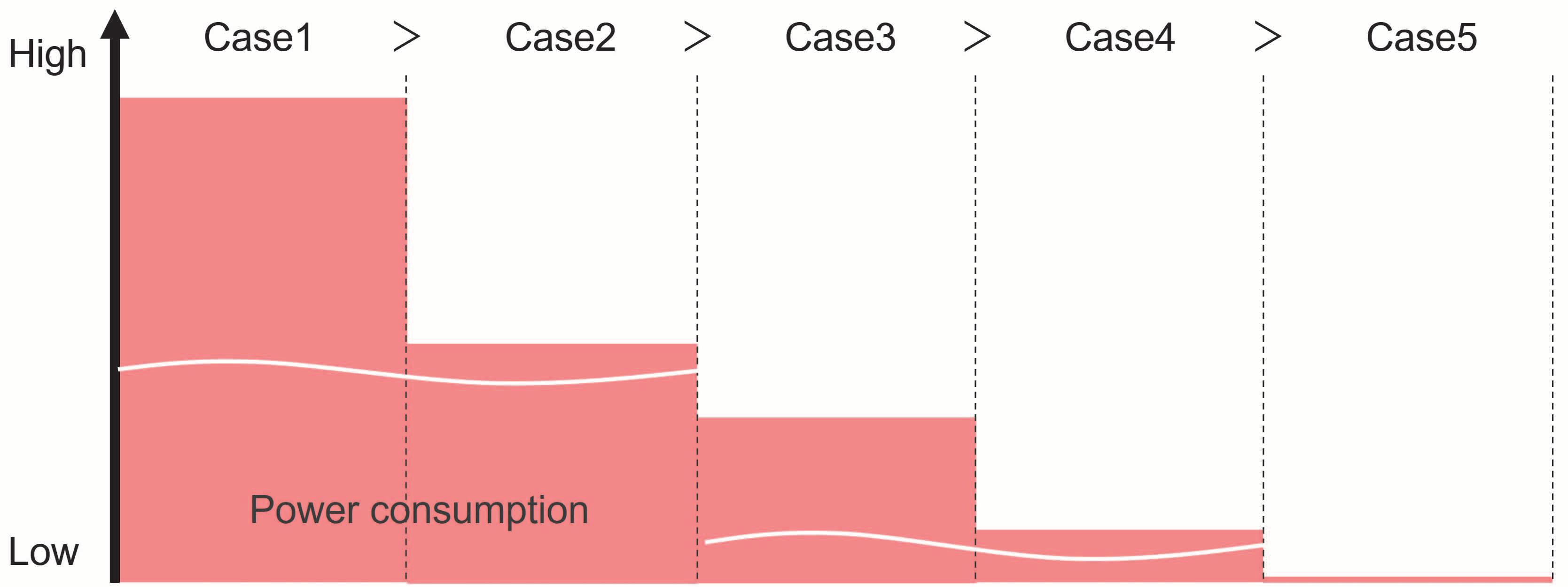

The maximum supply current in the Normal mode with a certain condition (high-speed clocks, all peripheral clocks are enabled, etc.) is 12mA while the typical supply current in the Software Standby mode in a certain condition (all SRAMs are on, all peripheral modules are stopped, etc.) is 0.25μA. Supply currents in Sleep mode and Snooze mode lay between those in Normal and Software Standby modes based on the conditions like number of operating modules, clock frequency, etc. Power consumption in each mode can be roughly compared as in Figure 1. The transition method among low-power modes is depicted in Figure 2.

Sleep mode – in this mode, the CPU stops operating but the contents of its internal registers are retained. Other peripheral functions and oscillators do not stop by default, but the user can set up whether they are to be stopped or not.

For example, if the user needs to execute A/D conversion for a certain period in fast mode but CPU intention is not required in that period, the user can program MCU to enter Sleep mode with a high-speed conversion clock at the start of the A/D conversion and return to Normal mode when the A/D conversion is completed.

In this example, the user saves unnecessary CPU power consumption during that period. Refer to the RA2E3 hardware manual for more details about entering into, operating in, and canceling the Sleep mode.

Software Standby mode – in this mode, the CPU, most of the peripheral functions, and oscillators stop. However, the contents of the CPU internal registers and SRAM data, the states of on-chip peripheral functions, and the I/O ports are retained.

Software Standby mode allows a significant reduction in power consumption because most of the oscillators have stopped. For example, if an MCU needs to wait for an external input like IRQ interrupt to initiate a specific operation and no other operation is required during that waiting period, the user can program the MCU to stay in Software Standby mode until the input is received, saving most of the unnecessary power consumption. Once the input is received, the target operation can be executed in Software Standby mode or after transit to either Snooze or Normal mode as required. It is possible to return to Software Standby mode again after the completion of the target operation and wait for the next input.

Direct transition to the Normal mode form Snooze mode can be made, however.

Let’s look at an example using the UART in Snooze mode. Before starting the UART communication, the MCU can stay in Software Standby mode saving power. When it starts to receive the UART data, the MCU can transit to Snooze mode and continue receiving data without waking up the CPU, unnecessary peripheral functions, and oscillators. Once the data receiving is completed, the MCU can return to Software Standby mode again and wait for the next UART data. Refer to the RA2E3 hardware manual for more details about entering into, operating in, ending and canceling the Snooze mode.

Refer to the RA2E3 hardware manual for more details about entering into, operating in, and canceling the Software Standby mode.

Snooze mode – in this mode, the CPU stops operating but the contents of its internal registers are retained. Operation of most peripheral functions and oscillators are selectable. As depicted in Figure 2, direct transition to Snooze mode from Normal mode or Sleep mode is not allowed. Transition to Snooze mode should be made through the Software Standby mode.

There are four power-control modes which are defined mainly based on the maximum operating frequency and the operating voltage range. The current consumption of memory (Flash/RAM) is reduced by controlling the memory reading speed according to the power-control mode. Users can select the power-control mode as it meets the appropriate operating frequency and power consumption. Power-control modes can be used in Normal, Sleep, and Snooze modes. Power consumption in each mode is shown in Figure 3.

High-speed mode – in this mode, the maximum operating frequency and voltage range during flash reading are 48MHz and 1.8V to 5.5V respectively. The maximum supply current in this mode with a certain condition (operating in Normal mode, all peripheral clocks are disabled, CoreMark code executing from flash) is 4.80mA.

Middle-speed mode – in this mode, the maximum operating frequency and voltage range during flash reading are 24MHz and 1.8V to 5.5V respectively. However, the maximum operating frequency is 4MHz when the operating voltage is 1.6V to 1.8V. The typical supply current in this mode with a certain condition (operating in Normal mode, all peripheral clocks are disabled, CoreMark code executing from flash) is 2.60mA.

Low-speed mode – in this mode, the maximum operating frequency and voltage range during flash reading are 2MHz and 1.6V to 5.5V respectively. The typical supply current in this mode with a certain condition (operating in Normal mode, all peripheral clocks are disabled, CoreMark code executing from flash) is 0.30mA.

Subosc-speed mode – in this mode, the maximum operating frequency and voltage range during flash reading are 37.6832kHz and 1.6V to 5.5V respectively. The typical supply current in this mode with a certain condition (operating in Normal mode, all peripheral clocks are enabled, etc.) is about 5μA.

The frequency division ratio can be selected for the system clock (ICLK). When a high-speed clock is not required, the user can switch to the appropriate lower-speed clock and save power consumption. Clock division ratios are 1, 2, 4, 8, 16, 32, and 64.

The lower the frequency, the lower the current consumption. But in terms of power performance (mA/MHz), 48MHz is the most efficient (100μA/MHz = 4.8mA/48MHz).

In general, for applications that require higher calculation processing and CPU performance, lower power consumption can be achieved by setting the frequency higher and shortening the CPU processing time in Normal mode.

On the other hand, for applications like control systems, current consumption can be reduced by setting the frequency to a lower value in Normal mode.

For example, the typical supply currents when the ICLK is 48MHz, 32MHz, 16MHz, and 8MHz are 4.80mA, 3.45mA, 2.05mA, and 1.40mA respectively under the condition of following power-saving functions. Low-power mode: Normal mode, Power-control mode: High-speed mode, Module stopping : all the peripheral clocks are disabled.

The clock division ratio 1, 2, 4, 8, 16, 32, and 64 can be selected for the peripheral clocks (PCLKB, PCLKD) too.

Power consumption can be saved by stopping non-operating modules or their clocks with the following register settings:

• Operation of DTC, I2C, SPI, SCI, CAC, CRC, DOC, ELC, AGT, GPT32n, GPT16n, POEG, ADC120 modules can be stopped by the setting of the MSTPCRn (n: A, B, C, D) registers

• Register R/W clock for RTC, WDT, IWDT can be stopped by the setting of the LSMRWDIS register

• Operating clock for MPU, Debugging, BPF can be stopped by the setting of the LPOPT register

• 8KB out of 16KB of SRAM can be powered off in Software Standby mode by the settings of PSMCR register

More power savings can be achieved using the power-saving functions in combination. The table details five cases that are just a few examples among the many possible combinations.

For additional information on the ultra-low power RA2E3 MCUs: www.renesas.com/ra2e3

■ Renesas Electronics

www.renesas.com

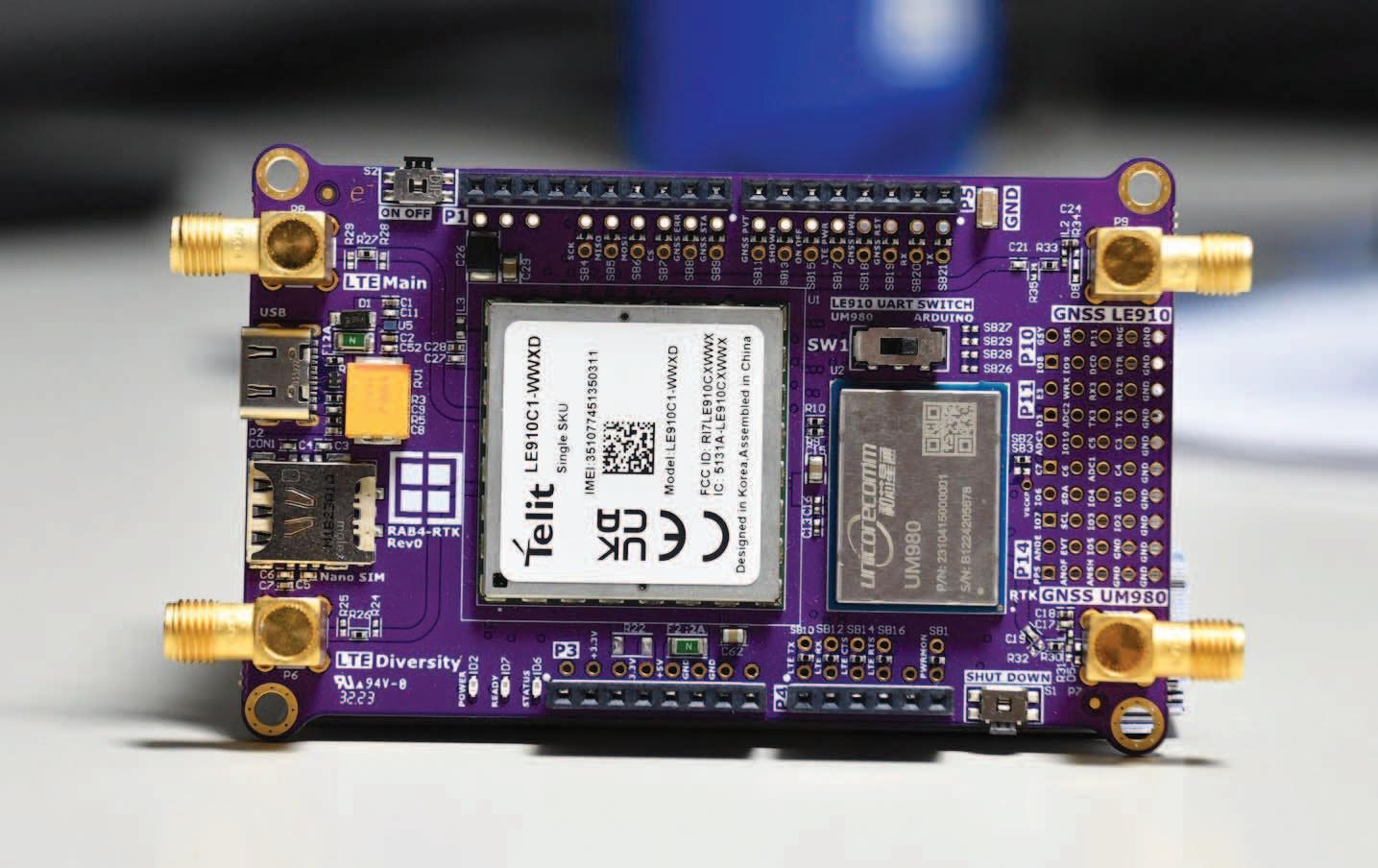

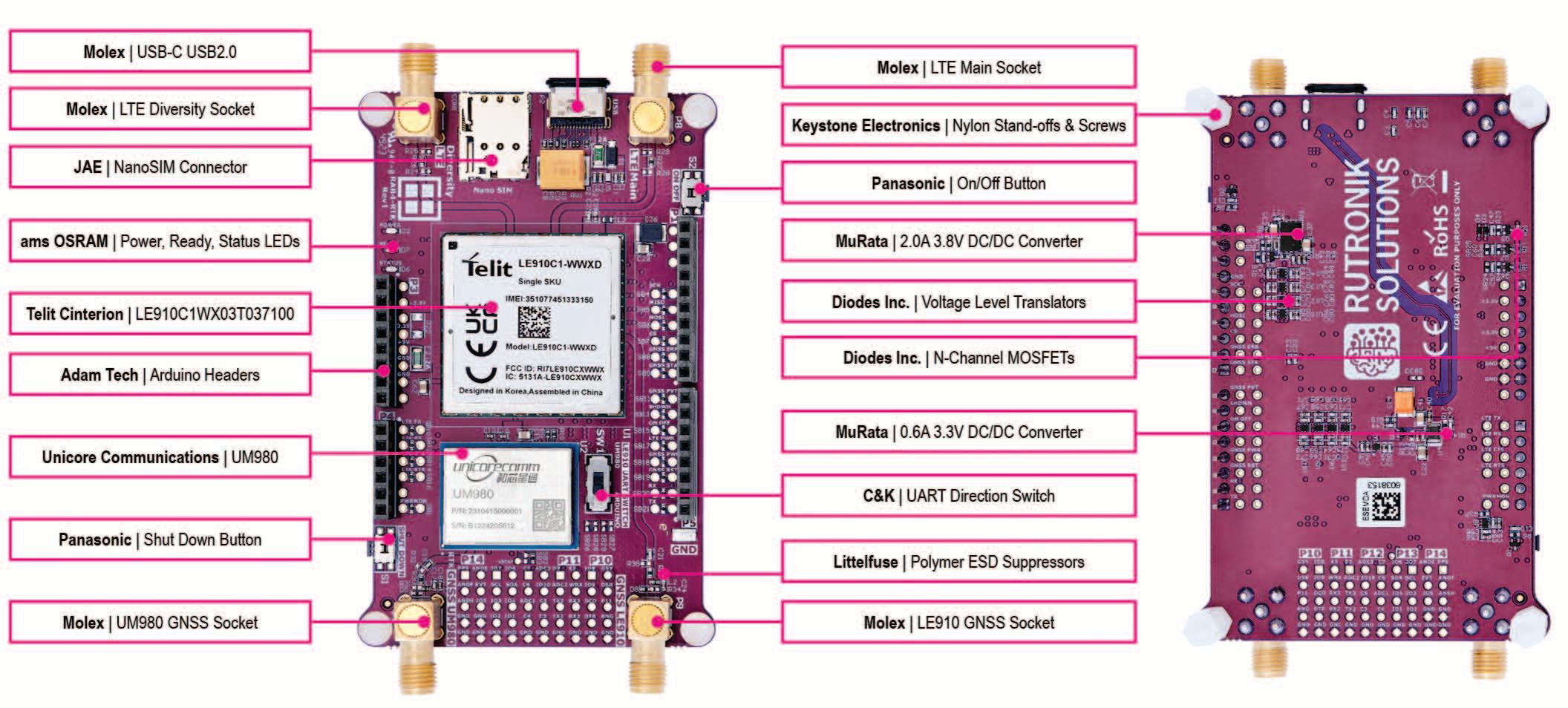

Author: André Becker, Field Application Engineer Semiconductor & Wireless Central Europe Rutronik

Author: André Becker, Field Application Engineer Semiconductor & Wireless Central Europe Rutronik

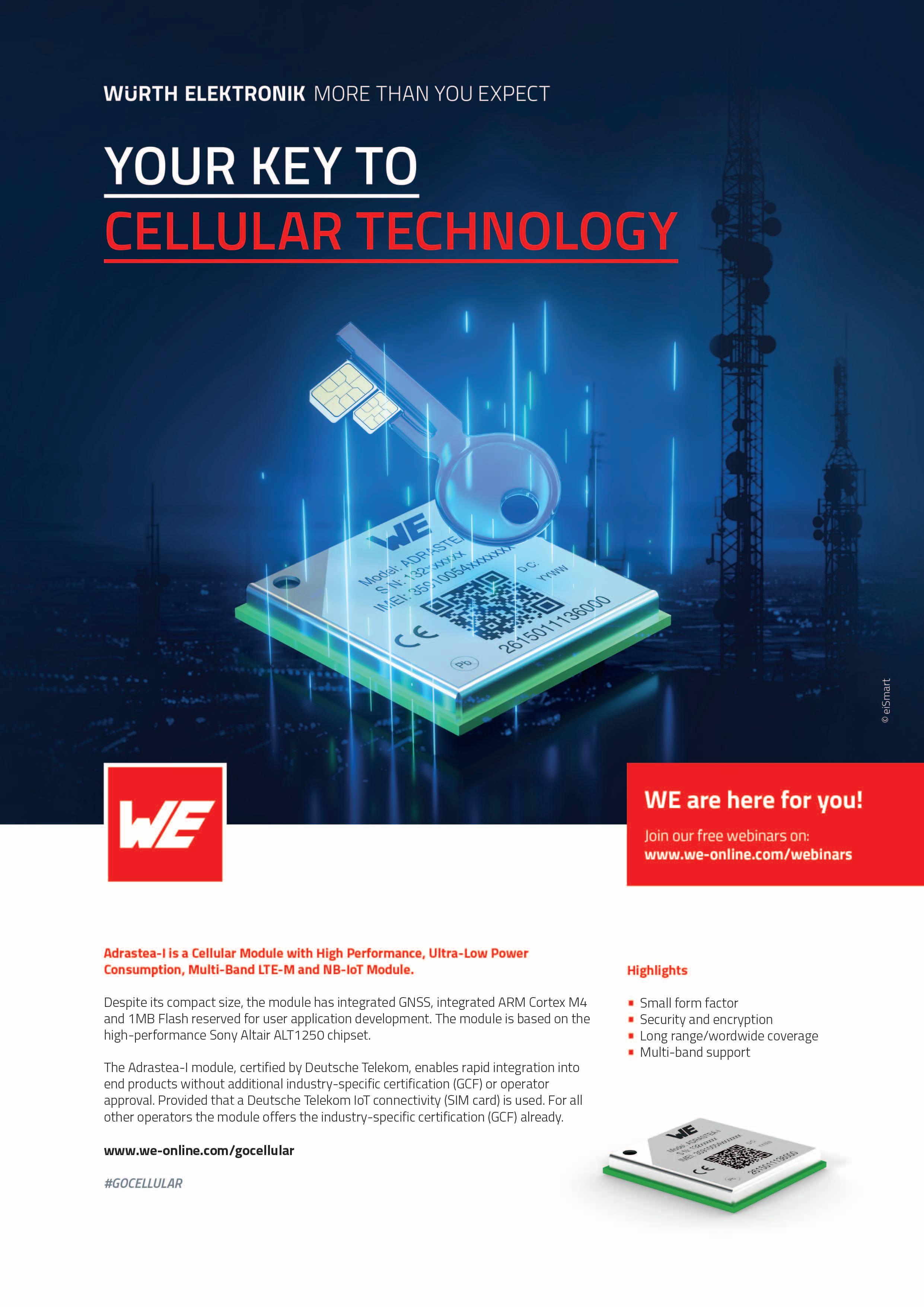

An electromechanical lock is called “smart” if it can be opened and closed by wireless communication with an electronic key. Mobile devices, such as smartphones, wearables, and other tokens, assume the role of a traditional key. Communication between the key and the lock is usually via Bluetooth, Wi-Fi, or near-field communication (NFC).

These smart locks allow secure and convenient access control by making physical keys outdated. New keys can also be conveniently managed, which is a big advantage in buildings with multiple locks. That is why smart locks are a rapidly growing segment in the IoT sector.

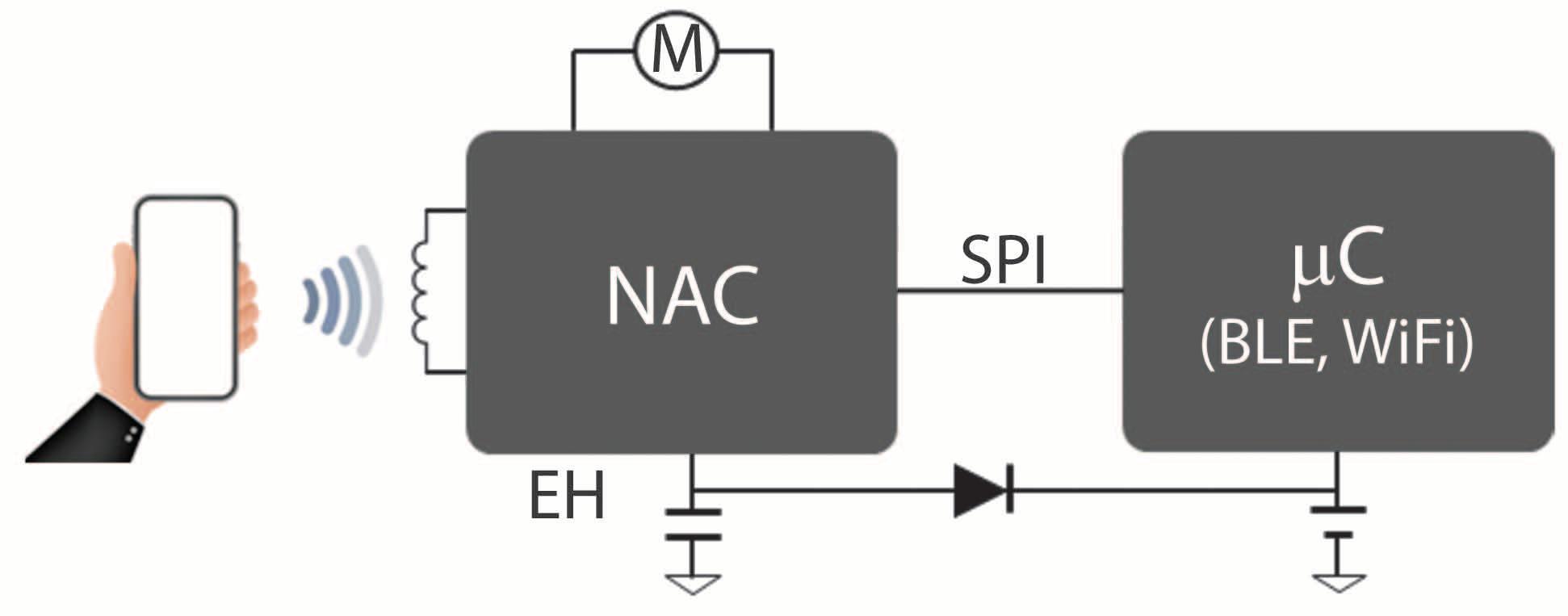

Smart locking systems are increasingly replacing traditional locks. For these innovative lock models, Infineon’s NAC1080 fits like a key in a lock, as it combines NFC, motor control, and energy harvesting in one chip. This eliminates the need for an additional power source, which obviously reduces costs.

For example, the market research and consulting firm Grand View Research put the global market at US$ 1.95 billion in 2022. It is expected to grow at a compound annual growth rate (CAGR) of 19.6 percent between 2023 and 2030, driven by a growing adoption of advanced communication technologies, convenience, and increased interest in advanced security systems.

Smart locks essentially consist of a traditional mechanical lock and an electronic control unit.

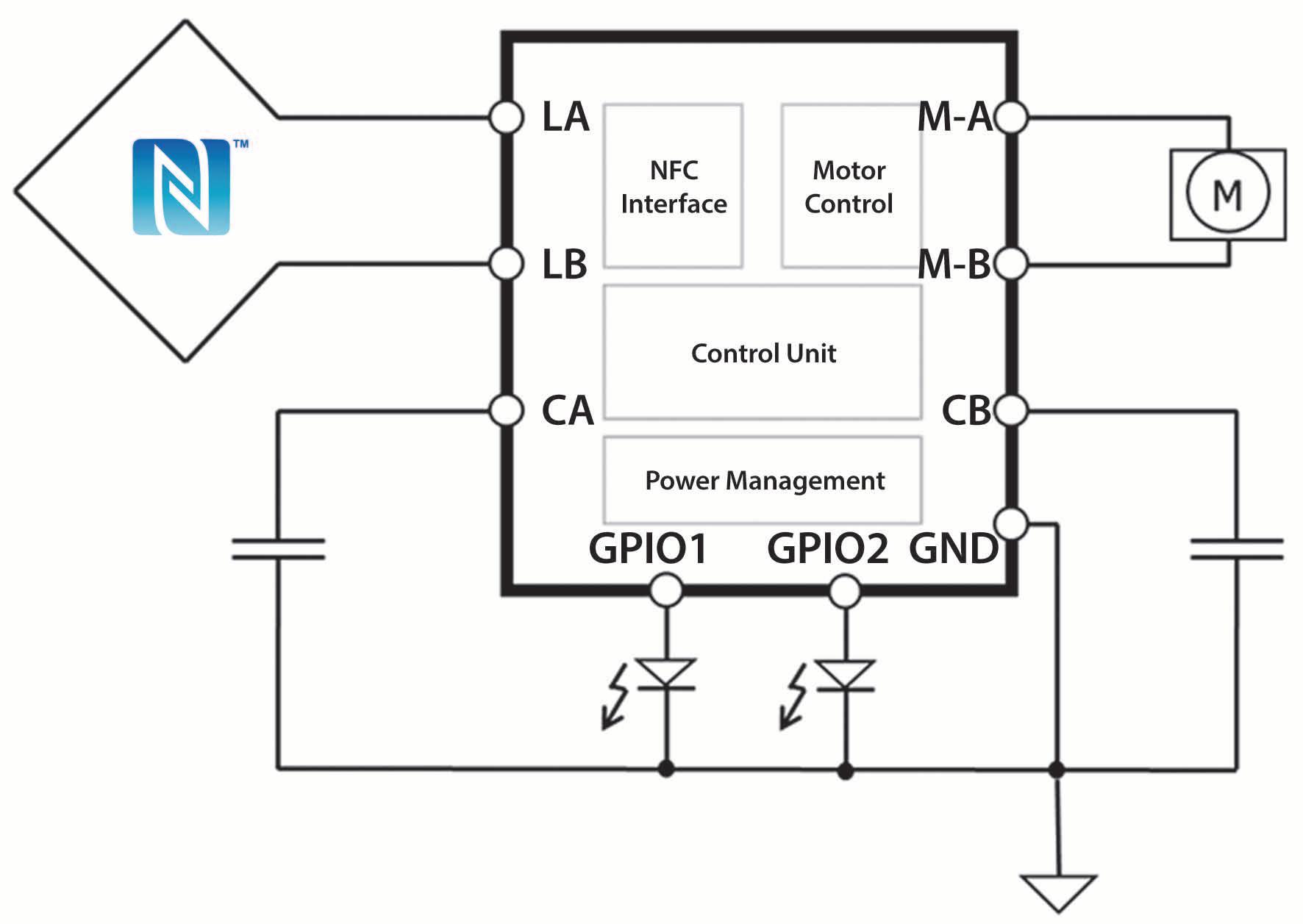

A microcontroller authenticates the user through a digital key exchange (e.g. via NFC) and passes the subsequently sent control commands to the motor drivers to lock or unlock a lock. Previous applications with an electrical power source operate as active participants in NFC communication. As a result, the motors that control the mechanical part of the lock are also supplied with electricity by this power source.

A smart lock based on Infineon’s NAC1080 NFC controller, which acts as a passive NFC participant, uses the voltage

induced by the active NFC participant for communication and to power the application, including the motor. With this energy (which is temporarily stored in the capacitor) and an integrated H-bridge driver, the NAC1080 can drive small motors in the milliwatt range (up to 250 mA load current).

The combination of passive NFC operation and a double-layer capacitor eliminates the need for an additional power source, such as batteries or accumulators, thereby reducing costs. The actual charging process takes only a few seconds and does not require an additional battery management system.

When the NAC1080 is accessed by the user, the AES128 symmetric encryption method with a random number generator provides the required security. A universal asynchronous receiver/transmitter (UART) or serial peripheral interface (SPI) can be used to read documented log files.

Microcontroller combines NFC interface and motor driver

This makes it possible to assign the operation of the hardware to the users at any time. The NAC1080 is based on a programmable 32-bit Arm Cortex M0 core operating at a CPU frequency of 28 MHz. It is available in DSO-16 (4 mm × 10 mm) and VQFN32 (5 mm × 5 mm) packages.

If the NAC1080 is integrated into larger locking systems and used as a passive component, it can continue to be used despite a power failure, empty batteries in the smart lock, or loss of keys.

Using an SPI interface, the NAC1080 can communicate with external devices.

An evaluation kit, included software libraries, and a cell phone app enable developers to carry out quick commissioning.