The MXT1296M1T provides various communication options, ISO 26262 functional safety support and flexible RF emission control

As the automotive market continues to demand larger touchscreens with more flexibility in size and shape, Microchip Technology Inc. is announcing a new maXTouch® touchscreen controller, that allows automotive designers to satisfy various and unique aspect ratios for touch displays in cars. This new offering includes additional functional safety support requested by OEMs.

The MXT1296M1T can reconfigure its driving and receiving touch channels to match the exact screen format, from 1:1 to 5:1 aspect ratio, including the popular 8:3 automotive aspect ratio. This feature enables the customer to efficiently use the number of touch channels available, without the need to select a larger, more expensive touch controller. Furthermore, customers can save additional development and validation time and resources by reusing a common PCB design to support different touch sensor aspect ratios. The MXT1296M1T is an industry first to enable the sensor channel reconfiguration by parameters. These settings do not require firmware modification, leading to lower design risk and faster time to market.

“As touch displays have become more popular in automotive user interfaces, car manufacturers are using various display formats and shapes to accommodate their interior design and emphasize their brand identity,” said Clayton Pillion director of the human machine interface business unit at Microchip Technology . “As the number one automotive touchscreen controller supplier, we know that products with enhanced diagnostic features are a significant advantage to customers who are designing with unique features and increasing ISO 26262 functional safety requirements in-mind.”

Microchip’s new maXTouch touchscreen controller offers two communication interfaces operating simultaneously, which allow a bridgeless connection to the back channel of the LVDS video link for touch information and a connection to a local microcontroller (MCU). The bridgeless topology reduces touch latency to improve the user experience. It also guarantees full compatibility with the maXTouch software driver, available for all major automotive operating systems,

including Linux®, Android™ and QNX®. When connected to an appropriate local MCU, the second interface offers:

• A redundancy link to the head unit through a CAN bus or 10BASE-T1S automotive Ethernet link for increased functional safety at the system level

• Local access and control of the maXTouch touchscreen controller’s features such as a capacitive keys report, live touch sensor diagnostics and raw data for external and custom post-processing

• Over-the-air and secure firmware update capability using Microchip’s TrustAnchor100 companion chip

The MXT1296M1T embeds various functional safety features to constantly check the integrity of the touch controller operation, as well as that of the connected touch sensors. The Failure Modes Effects and Diagnostic Analysis (FMEDA) and functional safety manual, dramatically ease the customer experience to design, build and certify a system for Automotive Safety Integrity Level B (ASIL-B) applications to the ISO 26262 standard.

Microchip Technology

https://www.microchip.com

3 | Most Versatile maXTouch® Touchscreen Controller Ever Offers Extensive Screen Format Flexibility

6 | Renesas Launches Automotive Actuator and Sensor Control MCUs for Evolving Edge Applications in NextGeneration E/E Architecture

Applications Drives Multiple Configurations; Integrates Analog Power Components to Reduce BOM Cost & Board Space

40 | Digi-Key, Seeed Studio and Machinechat introduce industry’s first private LoRaWAN-in-a-Box Solutions

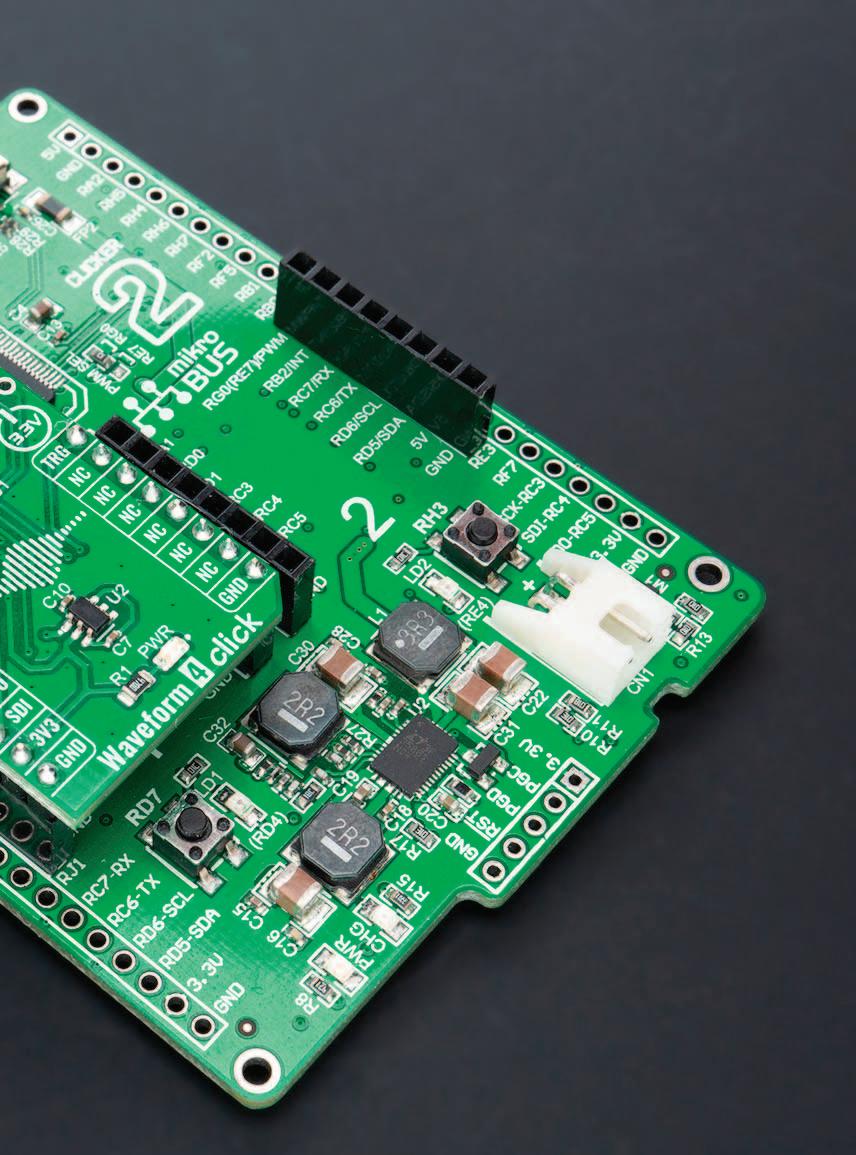

42 | Click: MIKROE adds high-performance signal generation for $109

43 | Round-the-clock accessibility

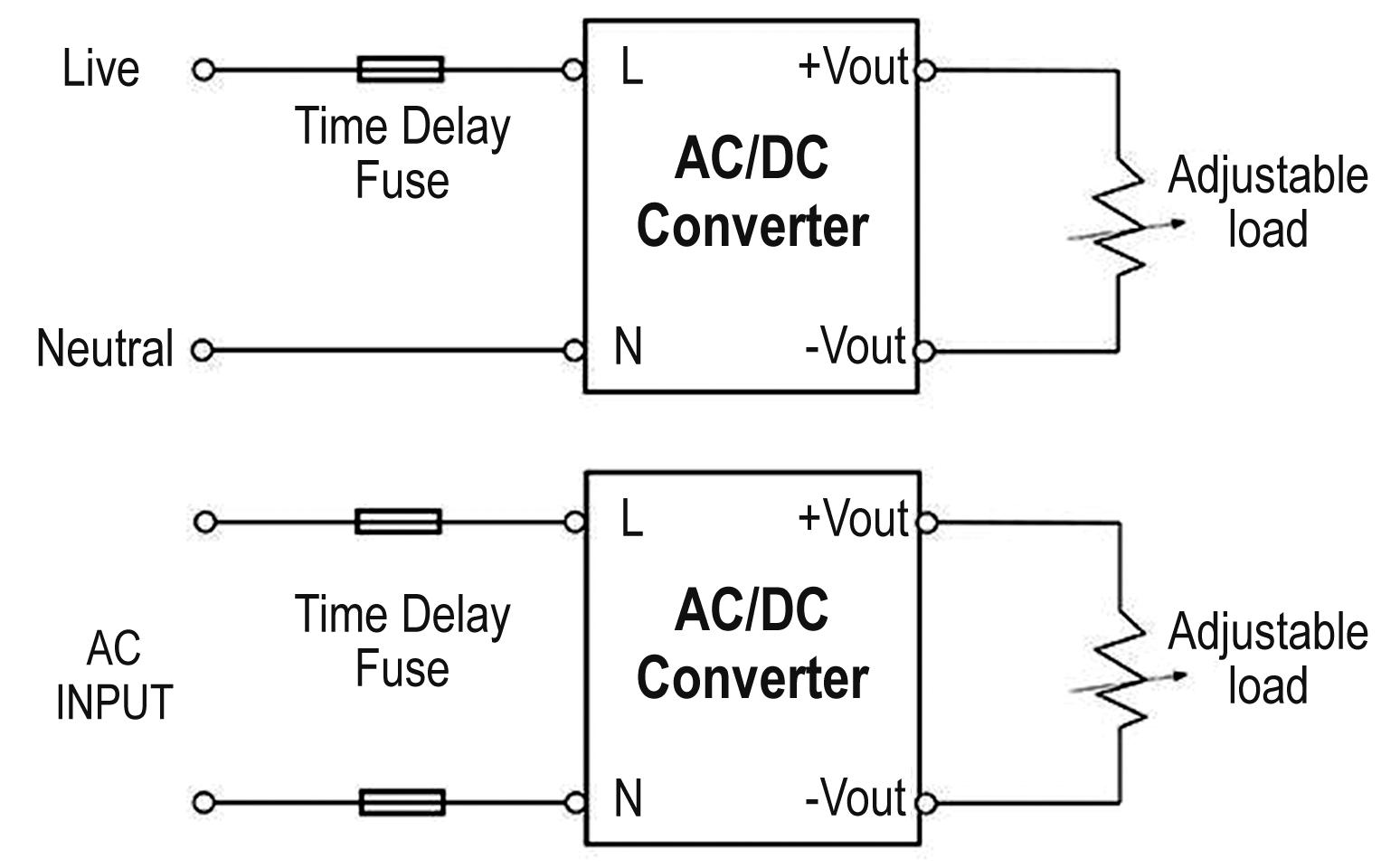

44 | Cost Effectively Meeting International Standards with Board Mounted AC/DC Power Supplies

47 | Verizon selects Infineon’s EZ-PD™ PAG1 AC-DC power solution for its 45 W USB-C fast wall charger

48 | Green Hydrogen - Myth or Reality?

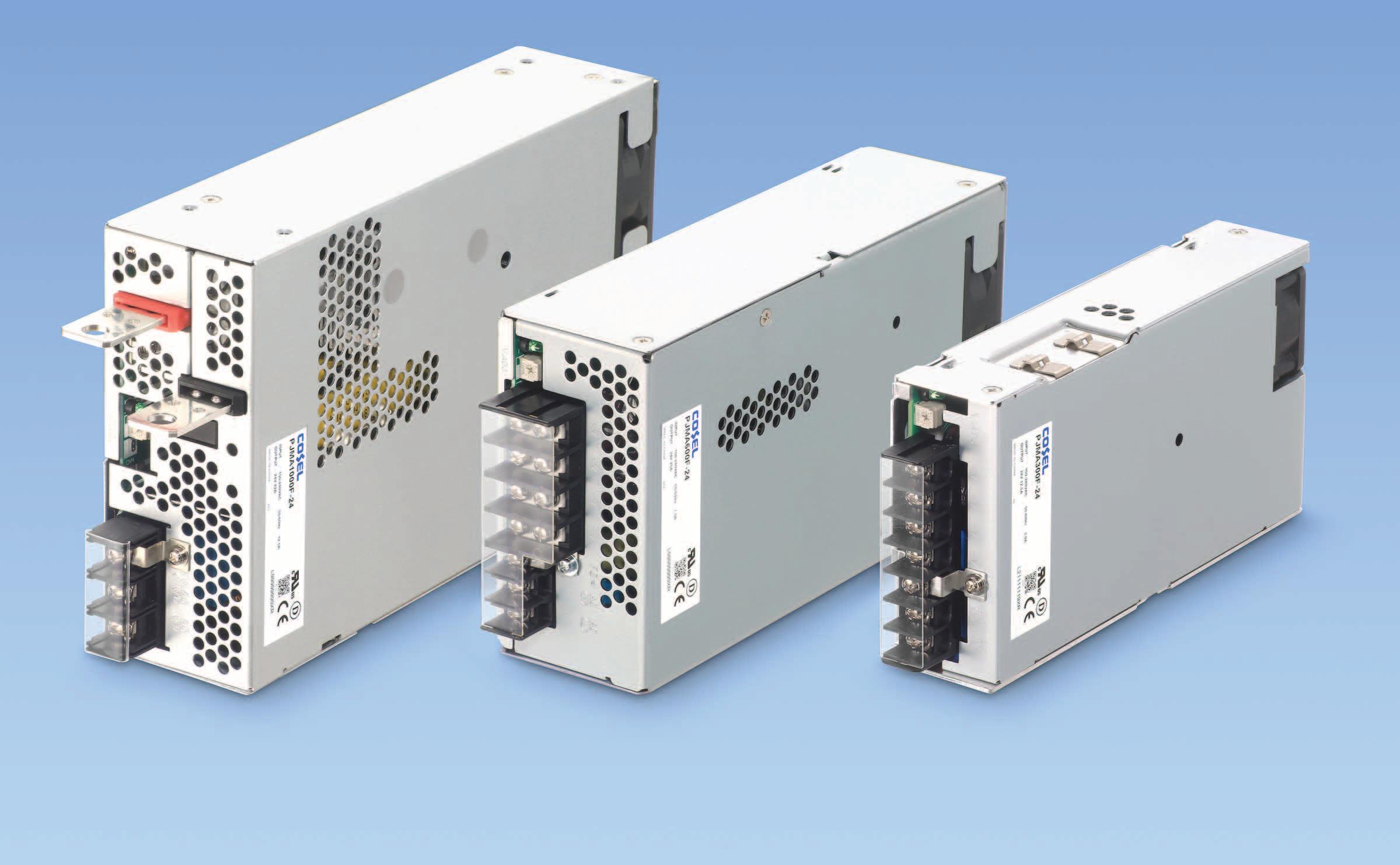

52 | COSEL’s adds a 300W to its robust and reliable PJMA series of power supplies for demanding medical applications

7 | Microchip to Provide Silicon Carbide MOSFETs and Digital Gate Drivers for Mersen’s SiC Power Stack Reference Design

8 | Analog Devices’ People Counting Algorithm Ensures Efficient Space Utilization and Worker Safety

9 | Improved power density: alpitronic selects Infineon’s EasyPACK™ CoolSiC™ modules and EiceDRIVER™ X3 drivers for its 50 kW hypercharger

10 | How A2B Technology and Digital Microphones Enable Superior Performance in Emerging Automotive Applications

53 | Powerbox announces 700W power supply optimized for conduction cooling applications

54 | MicroSys puts Hailo AI performance on its SoM platforms with NXP S32G vehicle network processors

55 | SEGGER J-Link software now available for

18 | How rugged is rugged?

20 | The AI of Things

24 | Mouser Signs Global Distribution Agreement with Siretta to Deliver Leading-Edge IoT Mobile Broadband Technologies 26 | Trust platform provides security from concept to deployment

| Microchip Continues Expansion of Gallium Nitride (GaN) RF Power Portfolio

Implementation on MCUs

| Renesas Adds New Power Line Communication Modem IC Enabling High-Speed, Long Distance Communication, Expanding Practical PLC Applications

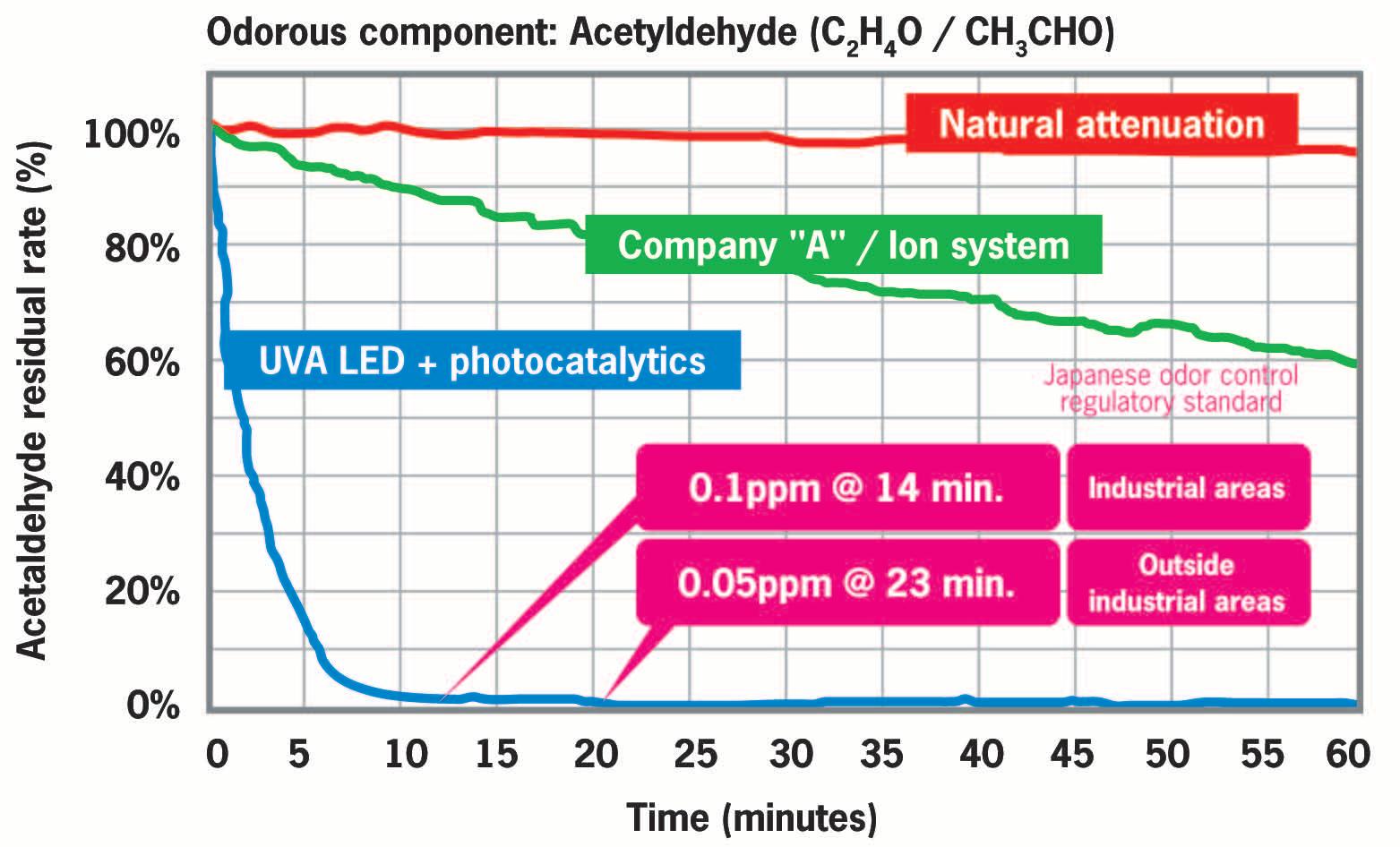

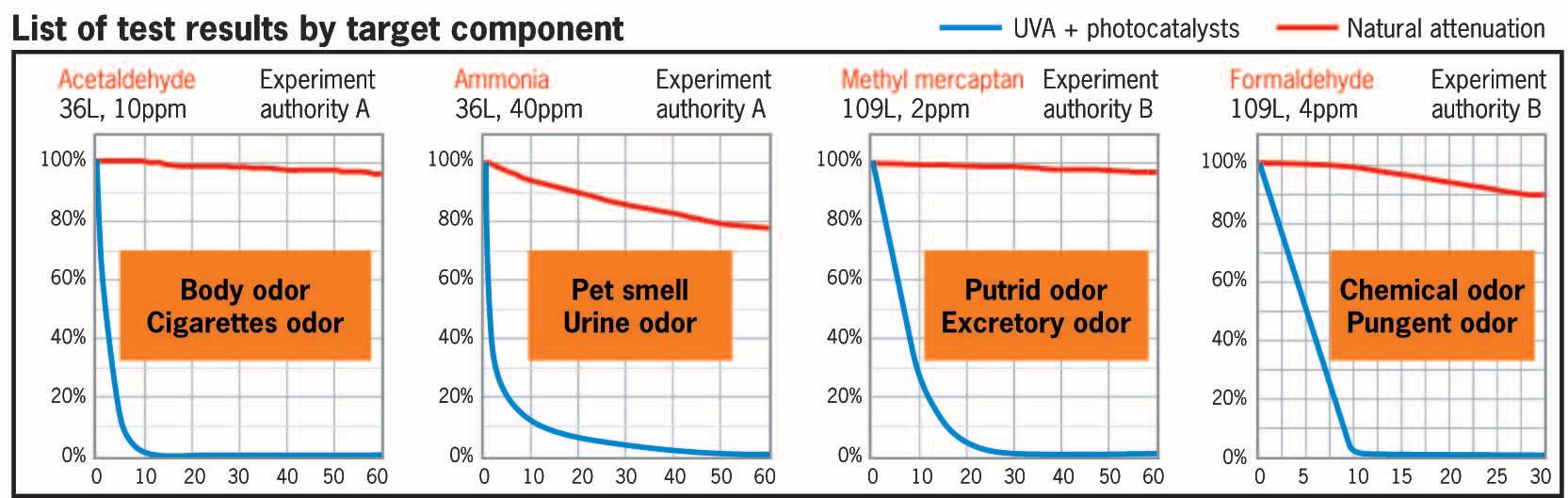

Rutronik Brings a Breath of Fresh Air

60 | Infineon and MCI supply sensors for air quality measurement to schools in Carinthia and Tyrol

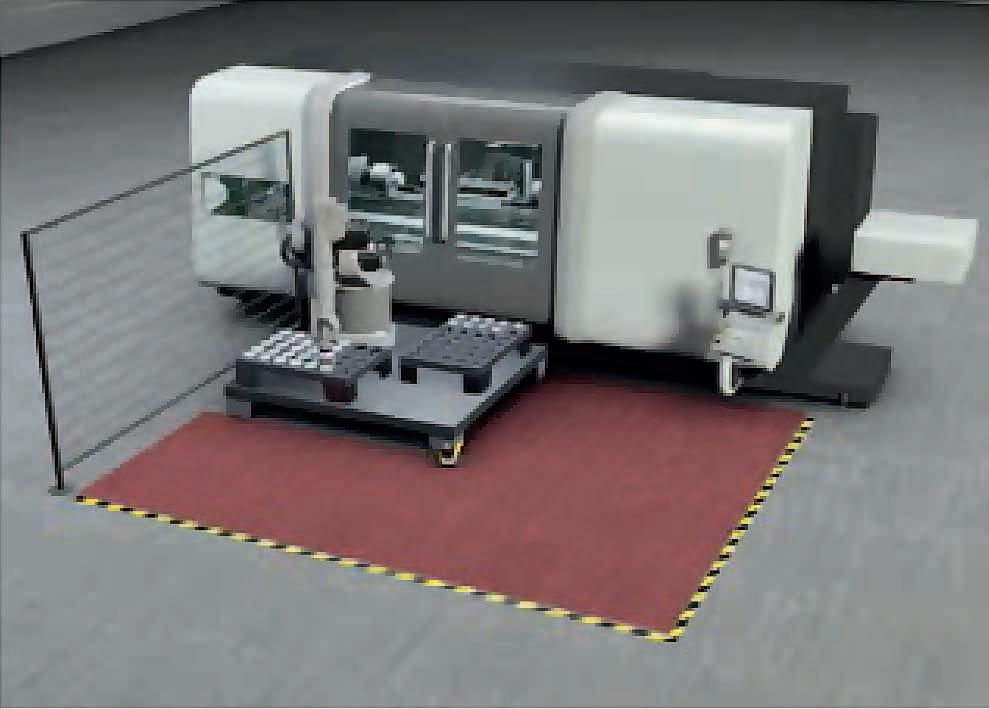

62 | Sensor solutions for robot working areas

|

Pineapple 38 | Renesas Programmable Smart Gate Driver for BLDC Motor

Management

Managing Director - Ionela Ganea

Editorial Director - Gabriel Neagu

Accounting - Ioana Paraschiv

Advertisement - Irina Ganea

Web design - Eugen Vărzaru

Contributing editors

Cornel Pazara

PhD. Paul Svasta

PhD. Norocel Codreanu

PhD. Marian Blejan

PhD. Bogdan Grămescu

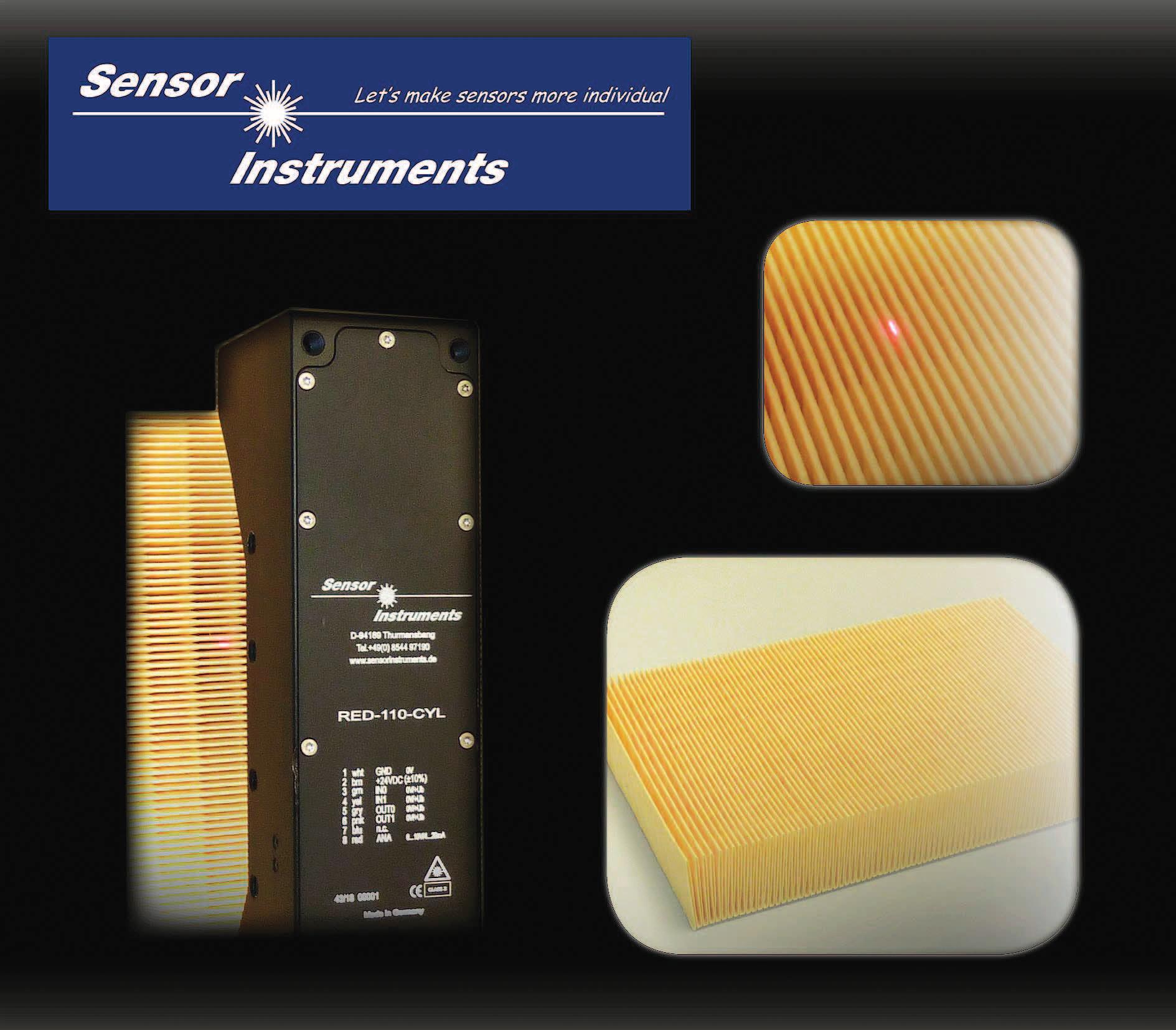

64 | Sensor solutions for pharmaceutical packaging

66 | Reliable object detection also with LED hall lighting

®

“Electronica Azi” is a registered trademark at OSIM - Romania, Registered position: 124259

ISSN: 1582-3490

Renesas Electronics Corporation announced two new microcontrollers (MCUs) designed for automotive actuator and sensor control applications supporting edge evolution in next-generation electronic and electrical (E/E) architecture. With the new RL78/F24 and RL78/F23, Renesas expands its RL78 Family of lowpower 16-bit MCUs and strengthens its broader automotive portfolio, offering customers highly reliable, high-performance solutions for systems ranging from actuators to zone control.

With E/E architecture extending to include zone and domain control applications, control mechanisms are evolving to accommodate body control for automotive systems such as lights, windows, and mirrors; motor control for engine pumps and fans; and multiple sensor control. Moving forward, high-speed and secure connectivity with zone and domain controllers will be mission critical for edge electronic control units (ECUs). Renesas’ next-generation RL78/F24 and RL78/F23 MCUs address changing technology demands for actuator and sensor control with enhanced security, rich connectivity, and functional safety capabilities. The new devices support the CAN FD high-speed communication protocol (RL78/F24) and

EVITA-Light security and are optimized for systems targeting ASIL-B levels under the ISO 26262 functional safety standard.

“Advances in E/E architecture add stress to the already heavy development burden, and there is high demand among our customers to efficiently develop actuators,” said Naoki Yoshida, Vice President, Automotive Digital Products Marketing Division at Renesas. “Our new actuator and sensor control MCUs build on our highly popular RL78/F14 and RL78/F13 devices and enable developers to reuse most of their existing software assets, reducing costs while continuing to accelerate the advancement of E/E architecture.”

The future of automotive systems design lies in a vehicle-centralized, zone-oriented E/E architecture, and that shift is sparking higher demand for more advanced functionality and better performance in actuator controller applications. The new RL78/ F24 and RL78/F23 MCUs deliver up to approximately 70 percent faster operating frequencies than the previous generation, which can more than double the performance in brushless motor control (BLDC) applications. Renesas also enhanced the hardware accelerator and timer functions for motor control and added a 12-bit A/D

converter, offering customers the enhanced functionality and performance levels they demand.

Key Features of RL78/F24 & RL78/F23 MCUs

• 40 MHz operating frequency

• Supports several connectivity interfaces, including CAN FD (RL78/F24), LIN, SPI, & I2C

• EVITA-Light support security functionality (support for AES-128/192/256 encryption algorithms)

• Pin compatible with the RL78/F14 and RL78/F13 MCUs with the same power efficiency

• On-chip flash memory capacity of 128 KB or 256 KB

• Package lineup ranging from compact 5 × 5 mm 32-pin QFN to 100-pin QFP

• Support for high temperatures up to 150°C

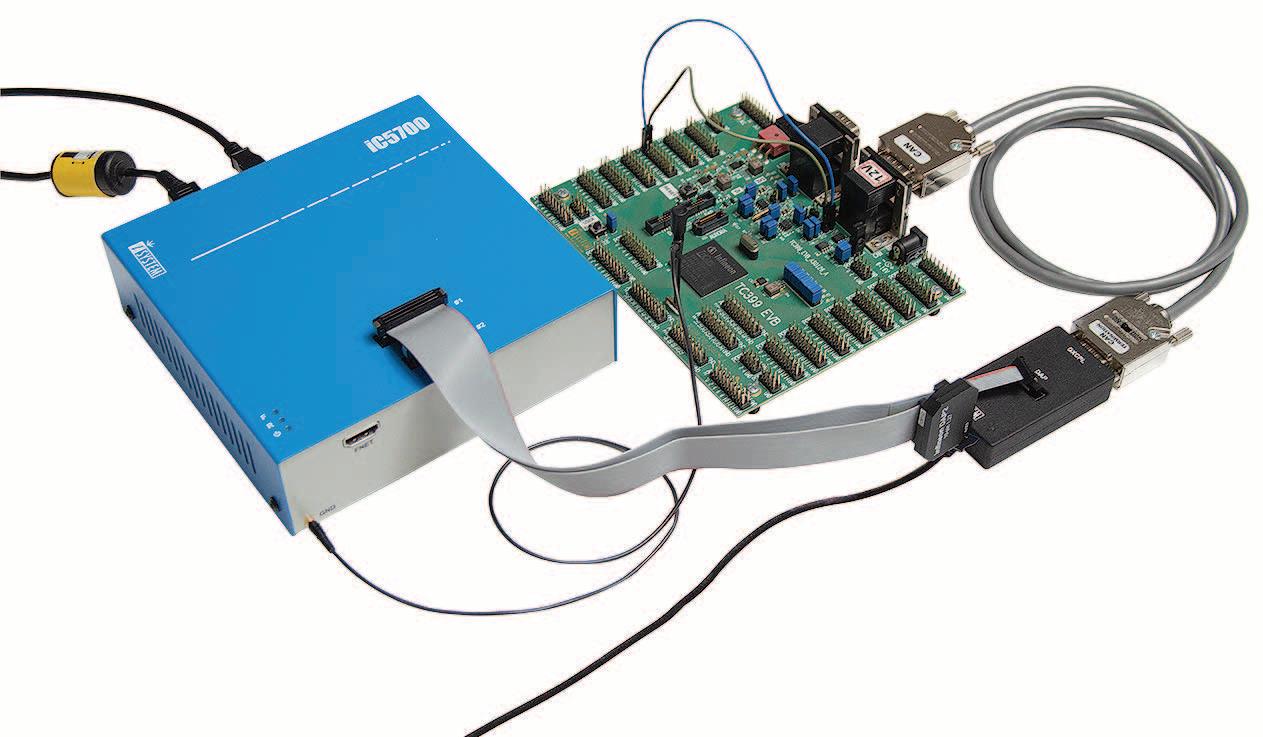

• RL78/F24 Target Board and RL78/F24

12V Motor Control Evaluation System

Starter Kit soon to be released for RL78/F24 (under development)

Samples of the RL78/F24 and RL78/F23 MCUs will be available starting April 2022, and are scheduled to enter mass production in the second half of 2023.

Renesas Electronics Corporation

https://www.renesas.com

E-mobility and renewable energy systems require power management solutions that drive performance and cost efficiencies in addition to speeding up development time. To keep pace with these requirements, Microchip Technology Inc. announced the collaboration with Mersen on their 150 kilovolt-ampere (kVA) threephase silicon carbide Power Stack Reference Design. Mersen is a global provider of power management solutions for numerous industrial sectors including e-mobility and energy storage.

Mersen’s three-phase SiC Power Stack Reference Design provides system designers with a complete, compact, high-power silicon carbide solution without the need for individual device sourcing, testing and qualification. The Power Stack Reference Design includes Microchip’s silicon carbide power modules and digital gate drivers and Mersen’s bus bar, fuses, capacitors and thermal management, optimally designed together in a single high-performance stack reference design. With Microchip’s 1200V MSCSM120AM042CD3AG silicon carbide MOSFET and AgileSwitch® 2ASC12A1HP digital gate driver, the Power Stack Reference Design enables engineers to rapidly develop high voltage systems using kits predesigned for their applications – reducing time to market by up to six months.

“Microchip customers will benefit from our collaboration with Mersen to provide silicon carbide MOSFETs and digital gate driver solutions,” said Leon Gross, vice president of Microchip’s discrete product business unit. “When power inverter designers can source a proven solution, they can avoid sourcing individual parts and reduce risk through reliability – and that helps avoid downtime. Designers now have an all-in-one evaluation system.”

The Power Stack Reference Design provides 16 kilowatts per liter (kW/l) of power density and up to 130°C Tj, peak efficiency at 98%, with up to 20 kilohertz (kHz) switching frequency. Utilizing Microchip’s rugged silicon carbide MOSFETs and AgileSwitch family of configurable digital gate drivers, the reference design enables engineers to select from 700V and 1200V options in currents up to 750A. Microchip also provides a choice in module construction including baseplate material, Direct Bonding Copper (DBC) ceramic material and die attach method.

“We worked closely with Microchip on the design and development of this silicon carbide Power Stack Reference Design given the availability of highly robust silicon carbide MOSFETs and compatible digital gate drivers from a single source,” said Philippe Roussel, PhD, vice president, Global Strategic

Marketing Executive Expert at Mersen “Thus, we can demonstrate our ability to optimize any inverter topologies from our customers, relying on our line of highly reliable bus bars, capacitors, fuses and cooling systems. The versatile Microchip silicon carbide line-up also gives us the capacity to extend these primary specifications to higher voltage, current and switching frequency to meet every customer’s operating point needs.”

In addition to the products in Mersen’s Power Stack Reference Design, Microchip is a provider of other silicon carbide power solutions including families of MOSFETs and Schottky Barrier diodes from 650V to 1700V, available in bare die and a variety of discrete and multi-chip module packages.

Microchip unifies in-house silicon carbide die production with its low-inductance power packaging and digital gate drivers enabling designers to make efficient, compact and reliable end products. These devices pair well with a comprehensive portfolio of microcontrollers (MCUs), analog and MCU peripherals, plus communication, wireless and security technology, providing system designers across many applications with proven total system solutions.

Analog Devices, Inc. (ADI) introduced the ADI Eagle Eye™ ADSW4000 People Count algorithm for people detection and count in indoor spaces such as meeting rooms or office cubicles. The ADSW4000 is the first in a series of application-level software algorithms forming part of the ADI EagleEye platform that includes a hardware subsystem based on ADI’s Blackfin® embedded digital signal processor (DSP) and a set of application-level software building blocks enabling users to quickly develop their own people counting system. The ADSW4000 algorithm provides system edge node analytics that unlock insights to improve space utilization, people safety through distance monitoring, and energy efficiency of spaces within intelligent buildings.

• Download the ADSW4000 data sheet and order the evaluation platform: https://www.analog.com/adsw4000

• Learn more about the benefits of ADI’s EagleEye platform: People Counting Technology Analog Devices or for more information contact: support@analog.com

• Watch a video about the ADSW4000 algorithm: https://www.analog.com/en/education/education-library/ videos/6277728474001.html

• Learn about more ADI intelligent building solutions: Intelligent Building Systems and Technologies | Analog Devices

• Connect with engineers and ADI product experts on EngineerZone™, an online technical support community: https://ez.analog.com

ADSW4000 Key Features:

• People counting algorithm for indoor areas, such as meeting rooms or office cubicles

- Occupancy state

- Location of person (x and y coordinates)

• Zoned performance (multiple areas for larger coverage)

• Edge processing

- Metadata output over UART

- No captured images are transmitted

• Coverage area for optimal accuracy of 90%: 3 m radius

• Maximum coverage area (accuracy of 80%): 5 m radius

The ADI EagleEye platform enables a complete, end-to-end hardware and software solution to help solve occupancy challenges. Combining the proprietary ADI ADSW4000 algorithm and advanced Blackfin DSP enables efficiency of indoor space while maintaining security and privacy as images are processed but not transmitted from the edge node. From meeting rooms to cafeterias, and lobbies to open desk people counting, ADI EagleEye can solve workspace needs and maximize worker wellbeing and productivity.

Analog Devices

https://www.analog.com

Following the successful launch of the HYC150 and HYC300 of their hypercharger product line, alpitronic recently introduced the state-of-the-art and industryleading 50 kW DC electric vehicle charger HYC50. It is the first wall-mounted DC charger in this power range featuring two charging ports that allow fast charging of one vehicle at 50 kW or of two vehicles simultaneously at 25 kW each. This is made possible by using EasyPACK™ CoolSiC TM MOSFET 1B and 2B modules from Infineon Technologies AG in combination with the EiceDRIVER™ X3.

“We are committed to working closely with customers like alpitronic to help them realize unique designs enabling superior system solutions,” said Dr. Peter Wawer, president of the Industrial Power Control Division at Infineon. “In addition to comprehensive system expertise and many years of experience, we offer first-class solutions such as our portfolio of EasyPACK 1B and 2B modules with the latest 1200 V CoolSiC MOSFET technology to increase the efficiency as well as the power density. The devices can be flexibly combined with suitable drivers to meet the requirements of each customer and their individual project.”

“With Infineon’s CoolSiC EasyPACK modules in combination with a perfect matching driver IC, we were able to significantly improve the efficiency of our new hypercharger,” said Philipp Senoner, co-founder and managing director of alpitronic. “We are therefore very pleased to have Infineon as a reliable and competent partner at our side, providing a wide range of CoolSiC MOSFET, gate drivers and the necessary understanding of our specific requirements.”

By using the CoolSiC technology, the HYC50 achieves up to 97 percent efficiency and enables a bidirectional design. As a result, this hypercharger is suitable for vehicle-to-grid (V2G) operation. At the same time, the charger has a compact footprint of 1250 × 520 × 220 mm3 and weighs less than 100 kg. Its compact size makes the charger ideal for indoor wall mounting, though it can also be mounted flexibly on a pedestal outdoors. The charger supports the charging standards CCS1 and CCS2 with a capacity of 150 A, CHAdeMO with a capacity of 125 A, as well as GBT.

In this particular design, Infineon’s EasyPACK 1B and 2B modules, which include CoolSiC MOSFETs, a NTC temperature sensor, and PressFIT contact pins, were able to increase

power density by about 50 percent. In addition, by using CoolSiC technology, the noise level was significantly reduced from 65 dB to less than 50 dB.

Besides the necessary power devices, Infineon also provided the matching drivers. The X3 driver IC is particularly suitable for the modules in this design, offering a number of decisive advantages through its configurability and active and passive monitoring options. For instance, it enables additional sensor points for operational monitoring, with several gate drivers providing additional temperature points as well as gate voltage monitoring. Thus, the temperature and voltage can be adjusted exactly according to the requirements of the SiC MOSFETs, minimizing static conduction losses and avoiding overloads. Furthermore, the operating points in the field can be optimized by OTA (Over-theAir) updates – these can also influence the parameters in the gate driver.

The EasyPACK CoolSiC MOSFET modules will be available in the first half of 2022.

Infineon Technologies

https://www.infineon.com

This article about Automotive Audio Bus® (A2B®) technology explains recent advances in digital microphone and connectivity technologies. These innovations are enabling swift adoption of game-changing applications for future generations of vehicle infotainment systems.

Within the automotive in-cabin electronics segment, it’s becoming increasingly clear that the universe of audio-, voice-, and acoustics-related applications is rapidly expanding as car manufacturers attempt to differentiate their vehicles from the competition. Additionally, as average consumers become more tech savvy, their expectations related to both the driving experience and level of personal interaction with the vehicle are expanding significantly. Home theater quality sound systems are commonplace across all vehicle price points and are now being augmented by sophisticated hands-free (HF) and incar communications (ICC) systems. Additionally, active and road noise cancellation (ANC/RNC) systems, historically deployed in only the top-level premium

vehicles, are now making their way into more mainstream, affordable segments. Looking to the future, audible or acousticsbased techniques will become a critical component in Level 4/Level 5 autonomous vehicle engine control units (ECUs) as they attempt to detect the presence of emergency vehicles.

The common thread binding all these legacy and emerging applications is the dependency on high performance acoustic sensing technology such as micro- phones and accelerometers. And since nearly all emerging applications require multiple acoustic sensors like microphones (or mic arrays) to achieve the best system-level performance, a simple cost-effective interconnect technology is required to ensure that total system costs

are minimized. Historically, the lack of a microphone-optimized interconnect technology has been a significant pain point for car manufacturers, as each microphone would need to be directly connected to the processing unit using expensive and heavy shielded analog cable. These added costs – primarily in terms of actual wiring, but secondarily in terms of added weight and reduced fuel efficiency – have in many cases prevented the widespread adoption of these applications, or at least limited them to only the super-premium segments. Recent advances in both digital microphone and connectivity technologies are proving to be enablers to the swift adoption of game- changing applications in future generations of vehicle infotainment systems. A2B technology will make a difference.

Using a handheld cell phone while operating a vehicle is banned in most countries, while Bluetooth®-enabled handsfree devices have become standard equipment in almost all vehicles. A wide array of hands-free solutions is available, from simple standalone units containing a loudspeaker and microphone to advanced solutions that are completely integrated within the vehicle infotainment system. Until recently, most hands-free systems were implemented in a very similar fashion. They were comprised of only one (rarely two) microphone(s), and the associated microphone technology was the 50-yearold electret condenser microphone (ECM) type. The voice quality of the transmitted audio was often unsatisfactory, especially in simple standalone units where the distance between the microphone and the talker’s mouth could be rather large.

Communication quality could be improved if the microphone were mounted as close to the mouth as possible (for example, in the headliner of the vehicle). However, in this case, both front seats require individual microphones if the driver and passenger are to be equally supported.

A typical automotive ECM is a device that combines the ECM capsule with a small amplifier circuit in a single housing. The amplifier delivers an analog signal with a voltage level that allows transport over wires of several meters in length, as required in typical automotive installations. Without amplification, the original ECM signal would be too low for such a wire length, as the signal-to-noise ratio (SNR) would degrade too far due to electromagnetic interferences on the wire.

Even the amplified signal requires shielded wiring, which is typically a 2-wire cable with a bias (8V) that supplies the microphone device. Given such wiring requirements, it is obvious that the number of ECM devices used in mainstream vehicles is limited due to weight and system cost constraints.

One of the few advantages of ECMs is their built-in acoustic directionality, which is usually trimmed to a super- or hypercardioid polar pattern (a MEMS mic can also be made unidirectional but typically requires more complex acoustic designs).

Typically, 10 dB or more backward attenuation can be achieved, where “backward” means the direction toward the windshield, from which only noise (that is, no desired signals, such as the talker’s voice) originates. Having a higher sensitivity in the incoming direction of the desired signal is very beneficial to increase the SNR.

However, directional ECM capsules introduce unwanted side effects such as the high-pass characteristic where sensitivity decreases at lower frequencies. The 3 dB cutoff frequency of such a high-pass response is typically in the range of 300 Hz to 350 Hz. In the early days of HF technology, this high-pass behavior was an advantage because engine noise was present primarily at lower frequencies, so the engine sound was already attenuated through the microphone.

However, since wideband, or HD, telephony is available, this high-pass behavior starts to become a problem. In a wideband call, the effective bandwidth is increased from 300 Hz to 3400 Hz, to 100 Hz to 7000 Hz. The built-in high-pass filter of the microphone makes it necessary to amplify signals between 100 Hz and 300 Hz in the postprocessing unit, which would not be required if the microphone were to deliver better audio bandwidth in the first place.

Another disadvantage of ECM technology is the significant part-to-part variation in terms of sensitivity and frequency response. The relatively large manufacturing tolerance of ECMs may not present a problem for single microphone applications.

However, if more than one microphone signal is deployed in a small-spaced microphone array application, then tight matching between microphones is essential for optimal array performance. In such a case, ECMs can hardly be used.

Furthermore, from the physical size perspective, traditional ECM capsules are not generally suitable for small form factor microphone arrays.

Microphone arrays have experienced widespread applicability including in vehicles because they can provide similar, often superior, directionality performance when compared to traditional ECMs.

Spatial information regarding sound impact directions can be extracted from the microphone signals using two or more suitable microphones grouped in an array. This class of algorithms is often referred to as beamforming (BF). The name beamforming is borrowed from an analogy with phased array antenna technology, where a radio “beam” is formed from the emission of an antenna array focused in a certain direction using a simple, purely linear filter and sum algorithm. Although there is no such beam in a microphone array, the term beamforming has also become very common in the field of microphone signal processing, where it covers a much wider range of both linear and nonlinear algorithms that enable higher performance and greater flexibility than the simple linear beamforming process.

In addition to the BF processing, a raw microphone signal almost always requires postprocessing because every HF microphone captures both desired voice signals and disturbances in the environment such as a car cabin. Wind, road, and engine noise deteriorate the SNR, and signals being played by loudspeakers – usually referred to as loudspeaker echoes – are additional sources of unwanted signals. In order to reduce such disturbances and improve voice quality, elaborate digital signal processing techniques are required, often referred to as acoustic echo cancelling and noise reduction (AEC/NR). AEC removes the loudspeaker sound from the microphone, which otherwise would be transmitted as an echo of the voice of the person speaking at the other end of the line. NR reduces constant driving noise while increasing the SNR of the transmitted signal.

Although elaborate specifications (for example, ITU-T P.1100 and P.1110) that define many performance details of an HF system have been published by the International Telecommunication Union (ITU), the subjective impression of the communication quality in a call from an operating vehicle can be unsatisfactory if the AEC/NR processing is of substandard quality. Together with the previously mentioned BF algorithm, the bundle of AEC/NR/BF enables a wide array of new applications, all related with some level of digital audio signal processing. To support these applications, a new generation of microphone technology overcoming disadvantages of traditional ECMs is demanded.

Microelectromechanical systems (MEMS) technology is swiftly becoming the new industry standard for microphones, as it offers many advantages over traditional ECMs. First and foremost, MEMS enable a much smaller form factor sound sensor than existing ECM capsules. Additionally, integrating a MEMS sensor with an analogto-digital converter (ADC) in a single IC results in a digital microphone that delivers signals ready for AEC/NR/BF processing.

Analog-ported MEMS microphones without an integrated ADC are also available, but they share many of the same disadvantages as analog ECMs and even require more complex amplifier circuitry than ECMs if operated on the traditional 2-wire analog interface. It is only with an all-digital interface technology that the interference and SNR problems inherent to analog wires can be significantly alleviated. Also, from a production perspective, MEMS are preferred because MEMS mics can be produced with a much tighter specification variance than ECM capsules, which is important for BF algorithms. Lastly, with MEMS IC microphones, the manufacturing process is greatly simplified because automated mounting techniques can be utilized, which reduces overall production costs. From an application perspective, the smaller form factor is the largest advantage, and, due to very small sound-entry portholes, MEMS mic arrays can be made virtually invisible. The porthole and the sound channel to the sensor require great care in terms of design and production quality.

If the acoustic seal is not tight, noise from the inner structure may reach the sensor and leakage between two sensors may degrade the performance of the BF algorithm. Different from typical ECM capsules that can be designed and manufactured to be either omnidirectional or directional, MEMS microphone elements are almost always manufactured to be omnidirectional (that is, they have no intrinsic directionality of sound reception). As such, MEMS microphones are phase-true omnidirectional sound pressure sensors that deliver ideal signals for advanced BF algorithms, where attenuation directions and beam widths can be user-configurable via software.

As a rule, it is very important that all signal processing modules are grouped in an integrated algorithm suite. Processing latencies would needlessly increase, and overall system performance would be degraded if functional blocks were implemented in isolation from one another.

For example, a BF algorithm should always be implemented together with the AEC and, optimally, from the same provider. If the BF algorithm introduces any nonlinear effects on the signal, the AEC will most certainly produce unsatisfactory results.

Ideal results of digital signal processing can best be achieved by an integrated algorithm bundle that receives uncorrupted microphone signals.

Standard linear BF and ADI-proprietary algorithms are compared below in detail in order to fully understand the performance potential of advanced BF algorithms. The plots in Figure 1 show three different BF algorithms regarding polar characteristics and frequency response in both in-beam and off-beam directions. A standard linear supercardioid algorithm based on a 2-mic array serves as the benchmark (black curves).

The benchmark curve shows the maximum attenuation in the typical zeroangle directions (that is, maximum offbeam attenuation) and a “rear-lobe” at 180°, where off-beam attenuation is lower. The resultant rear-lobe is a tradeoff with beam width in a linear algorithm. A cardioid beam (not shown) has its maximum attenuation exactly at 180°; however, its receptive area is broader than a hyper- or supercardioid configuration. Beams with less significant rear-lobes and higher off-beam attenuation can be achieved with nonlinear algorithmic approaches, with the red curve showing an ADI-proprietary 2-mic algorithm of this class (microphone spacing: 20 mm).

With two omnidirectional microphones in an array, there is always a rotational symmetry of the beam shape. In other words, the attenuation at X° in the polar plot is the same as at 360° – X°. This assumes that the 0° to 180° line of the polar plot is equivalent to the imaginary line connecting the two microphones. The 3-dimensional beam shape can be imagined by rotating the 2D polar plot around this microphone axis. Asymmetric beam shapes without rotational symmetry or more narrow beams require at least three microphones arranged in a triangle.

For example, in a typical overhead console installation, a 2-mic array can attenuate sound from the windshield. However, in such an orientation, a 2-mic array cannot distinguish driver from passenger. Rotating the array by 90° would make such driver/passenger distinction possible, but the noise from the windshield would not be distinguishable from sounds inside the cabin. Both windshield noise attenuation and driver/passenger differentiation are only possible using three or more omnidirectional microphones configured in an array. An exemplary polar characteristic of a respective ADI-proprietary 3-mic algorithm

is given by the green curve in Figure 1 where the microphones are arranged in an equal- sided triangle with 20 mm spacing.

Polar plots are computed with band-limited white noise arriving at the microphone array from different angles. The audio bandwidth is limited to 100 Hz to 7000 Hz, which is the wideband (or HDvoice) bandwidth of state-of-the art cell phone networks. Figure 2 compares the frequency response curves of the different algorithm types. In the in-beam direction, the frequency response of all algorithms is, as expected, flat within the desired audio bandwidth. The off-beam frequency responses are computed for the off-beam half-space (90° through 270°), confirming high off-beam attenuation over a wide frequency range.

The relationship between array microphone spacing and audio bandwidth vs. sample rate is worth further discussion. Wideband HD-voice uses a sample rate of 16 kHz, which is a good choice for speech transmission. There is a huge difference in voice quality and speech intelligibility between the current 16 kHz wideband sample rate and 8 kHz, which was used in earlier generations of narrow-band systems. Driven by speech recognition providers, there is growing demand for even higher sample rates, such as 24 kHz or 32 kHz. And specifications can be found where the sample rate of the voiceband application should be as high as 48 kHz, which is typically the primary system audio sample rate.

The underlying motivation is to avoid any internal sample rate conversion. However, the additional computational resources required to support these high sample rates cannot be justified by a tangible audible benefit, so 16 kHz or 24 kHz are now widely accepted as the recommended sample rates for most voiceband applications.

High sample rates are problematic for BF applications because spatial aliasing occurs at frequencies equaling the speed of sound divided by twice the microphone spacing. Spatial aliasing is undesirable because BF is not possible at such aliasing frequencies. Spatial aliasing can be avoided in a wideband system (16 kHz sample rate) if the microphone spacing is limited to 21 mm or less. Higher sample rates require smaller spacing to avoid spatial aliasing. However, overly small mic spacing is also undesirable because microphone tolerances and especially intrinsic (non-acoustic) noise of the microphone sensors can become an issue.

Signal differences between the microphones of an array get marginal if the spacing is small and disturbances such as intrinsic noise and sensitivity deviations between the microphones can overwhelm the signal difference between microphones. In practice, microphone spacing should not be less than 10 mm.

A 2B technology has been specifically developed to simplify the connectivity challenge in emerging automotive microphone and sensor-intensive applications. From an implementation standpoint, A2B is a single-main, multiple subnode (up to 10), line topology. The third generation of A2B transceivers that is currently in full production consists of five family members – all offered in automotive, industrial, and consumer temperature ranges. The full-featured AD2428W, together with four feature-reduced, lower cost derivatives –AD2429W, AD2427W, AD2426W, and AD2420W – comprise ADI’s latest family of pin-compatible, enhanced A2B transceivers.

The AD2427W and AD2426W offer reduced (subnode only) functionality and are primarily targeted for microphone connectivity applications such as hands-free, ANC/RNC, or ICC.

The AD2429W and AD2420W are entrylevel A2B derivatives that offer significant cost advantages relative to their full-featured counterparts and are particularly well-suited for cost-sensitive applications such as automotive eCall and multi-element microphone arrays. Table 1 shows a feature comparison among the thirdgeneration A2B transceivers.

The AD242x series supports daisy-chaining a single main plus up to 10 subnodes over a total bus distance of 40 m with up to 15 m supported between individual nodes. A2B’s daisy-chain, line topology is an important advantage over existing ring topologies as it relates to overall system integrity and robustness. If one connection of the A2B daisy chain is compromised, the entire network does not collapse. Only those nodes downstream from the faulty connection are impacted by the failure. And A2B’s embedded diagnostics can isolate the source of the failure, signaling an interrupt to initiate corrective action.

A 2B’s main/subnode line topology is inherently efficient when compared to existing digital bus architectures. After a simple bus discovery process, zero additional processor intervention is required to manage normal bus operation. As an added benefit of A2B’s unique architecture, system latency is completely deterministic (a 2-bus cycle delay, which is less

than 50 μs) irrespective of the audio node’s position on the A2B bus. This feature is extremely important for speech and audio applications such as ANC/RNC and ICC, where audio samples from multiple remote sensors must be processed in a time-aligned fashion.

All A2B transceivers deliver audio, control, clock, and power over a single, 2-wire, UTP cable. This reduces overall system cost for a variety of reasons.

• The number of physical wires is reduced relative to traditional implementations.

• The actual wires themselves can be lower cost, lower weight UTP as opposed to more expensive shielded cables.

• Jumper wires Most importantly, for particular use cases, A2B technology offers a bus power capability that delivers up to 300 mA of current to audio nodes on the A2B daisy chain. This bus power capability eliminates the need for local power supplies at the audio ECU – further reducing total system costs.

The total 50 Mbps bus bandwidth delivered by A2B technology supports up to 32 upstream and up to 32 downstream audio channels using standard audio sample rates (44.1 kHz, 48 kHz, etc.) and channel widths (16-, 24-bit). This pro- vides significant flexibility and connectivity to a wide range of audio I/O devices.

Maintaining a completely digital audio signal chain between audio ECUs ensures that the highest quality audio is preserved without introducing the potential for audio degradation via ADC/DAC conversion. System-level diagnostics are an essential component of A2B technology. All A2B nodes have the capability to identify a variety of fault conditions including opens, wires shorted together, reversed wires, or wires shorted to power or ground. This capability is important from a system integrity standpoint because, in the case of opens, wire shorts, or reversed wire faults, A2B nodes are still fully functional upstream of the fault. The diagnostic capability also provides for the efficient isolation of system-level failures, which is critically important from the dealer/installer standpoint.

The recently announced, fourth generation of A2B transceivers, AD243x, builds upon the existing technology foundation by increasing key functional parameters (node count increased to 17, bus power increased to 50 W) while adding an additional SPI-based control channel (10 Mbps) that provides an efficient software over-the-air (SOTA) capability for remote programming of intelligent A2B-connected nodes. The new features provided by the AD243x family make it well-suited for LED-fitted microphone nodes in superpremium microphone architectures.

From a single voice microphone to a multielement BF mic array for HF communication, from ANC to RNC, from ICC to siren sound detection, microphones have found more and more applications in the automotive industry. In accordance with the technology and market trend, almost every single new vehicle that hits the road today is equipped with at least one microphone module for HF communication. Premium and luxury cars may come with six or more microphone modules that are necessary for realizing the full potential of BF, AEC, ANC, RNC, ICC, and so on, where digital MEMS microphones present clear advantages. The growing microphone count presents one significant challenge to vehicle infotainment engineers - how to simplify the connecting harnesses and minimize their weight.

In the previously mentioned example, an HF microphone signal often prefers to have a rising frequency response shape (that is, sensitivity decreases with decreasing frequency) to remove the low frequency noise content inside the cabin. This is a helpful and very effective technique to improve the speech intelligibility delivered by a voice microphone.

On the contrary, an ANC microphone requires sufficient sensitivity level at low frequencies as the main purpose of the ANC algorithm is to reduce the low frequency noise. Thus, to share the same microphone in two applications in an analog system, the signal coming from the microphone needs to be fed into different circuits for proper frequency filtering. In this case, one or multiple ground loops may form, which can cause significant noise issues.

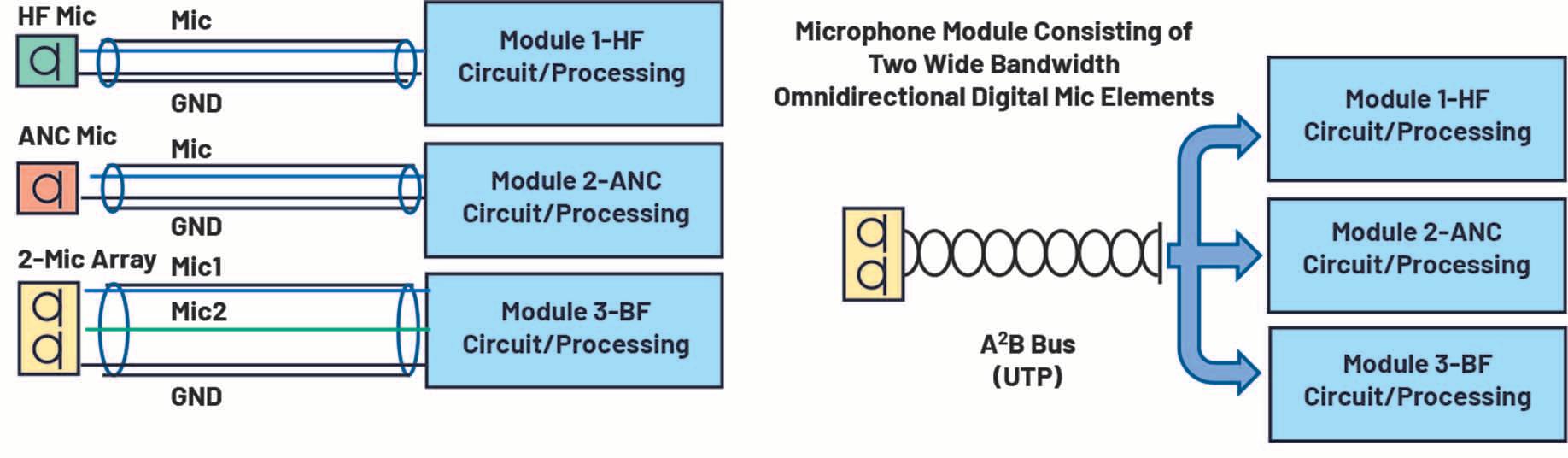

application block (HF, ANC, and BF) requires dedicated microphone(s) and separate harnesses for connecting to the corresponding functional circuit(s). This leads to four separate microphone elements and three sets of harnesses (a total of seven wires plus shielding). In contrast, because sharing signals is easily supported by the digital A2B system, the number of microphone elements can be potentially reduced from four to two. In this specific example, a single micro- phone module consisting of two wide bandwidth omnidirectional microphone elements can be used to provide two channels of acoustic signals that cover the needs of all application blocks. Once these two channels of signals reach the center processing unit (for example, the head unit or amplifier) through a simple UTP wire, they can then be shared and digitally processed to support HF, ANC, and BF applications.

This is not a trivial task for traditional analog systems. At a minimum, an analog microphone requires a pair of two shielded wires (ground and signal/ power), pins, and connector cavities for interconnection. The amount of wires is always twice the number of microphone modules in the system. Meanwhile, the total weight of the harness could increase even more rapidly depending on the wire length that is needed for connecting each microphone module. One simple way to mitigate this problem is to reduce the number of microphones used in the system by sharing a microphone signal among multiple applications. For example, the same microphone signal could be used in HF communications and as an error signal in the ANC system. However, different applications may require different microphone characteristics.

As a digital bus with daisy-chaining capability, A2B technology together with the digital MEMS microphone provide a wellsuited solution for interconnecting and/or sharing multiple microphone signals demanded by audio, voice, noise cancelling, and other acoustic applications that are rapidly expanding in vehicles. Consider an imaginary while exemplary case where a car application calls for an HF microphone module, an ANC microphone module, and a simple array microphone module consisting of two microphone elements for BF, and all three modules are integrated around the overhead console area. Figures 3a and 3b show how such a design may be realized with the traditional analog and the digital A2B systems, respectively. Since the analog system cannot easily accommodate microphone sharing, each

Although the example illustrated in Figure 3 may not represent a real situation, it clearly demonstrates the benefits of the A2B technology over the traditional analog technology. A digital audio bus system like the A2B technology addresses the challenge of automobile manufacturers to offer new audio and acoustic- related concepts that enhance user experience and allows these concepts to be brought to the market for faster implementation. Indeed, many applications that are either new to the automotive market or previously difficult to implement have been made possible by the commercialization of A2B technology. For example, as a leading automotive audio solution provider, Harman International has developed a family of digital microphone and sensor modules that takes advantage of the A2B system to enable various automotive applications.

Figure 4 shows some common automotive A2B microphones and sensors and how they can be used on a vehicle. These sensors include single A2B microphones and multi-element microphone arrays for ANC and voice communication, A2B accelerometers for RNC, externally mounted bumper A2B microphones, and rooftop A2B microphone arrays for emergency siren detection and acoustic environment monitoring.

Enabled by these A2B microphones and accelerometers, more and more application solutions requiring multiple sensor inputs are currently under development to further enhance the user experience in the automotive industry.

Vehicle architectures of the future will become increasingly more dependent on

high performance acoustic sensing technology such as microphones and accelerometers. A completely digital approach including sensor, interconnect, and processor provides significant performance and system cost benefits. Analog Devices and Harman International are partnering to deliver cost-effective solutions that create value and differentiation for their end customers.

Analog Devices

https://www.analog.com

Visit https://ez.analog.com

About the authors

Contact Romania:

Email: inforomania@arroweurope.com

Mobil: +40 731 016 104

Arrow Electronics | https://www.arrow.com

Ken Waurin is a strategic marketing manager at Analog Devices, where he has overall responsibility for Automotive Audio Bus (A2B) technology. Since joining ADI in 1996, he has held product management, business development, tactical, and strategic marketing roles that span multiple technology areas including DSP, MEMS, converter, video, and connectivity. His primary focus is on automotive infotainment and emerging applications driving vehicle differentiation such as premium audio, road noise cancellation, and in-vehicle zonal communications. He can be reached at kenneth.waurin@analog.com

Dietmar Ruwisch is a senior audio technologist at Analog Devices. He studied physics in Münster, Germany, and received his doctorate in 1998 with a thesis on artificial neural networks. Since then his key area has been audio signal processing, where he holds several patents. His focus is on improving the quality of audio communication - whether between humans or with a machine - and the corresponding processing of microphone and microphone array signals. He can be reached at dietmar.ruwisch@analog.com

Yu Du is a senior principal acoustic engineer at Harman International Industries. He holds both a B.S. and M.S. degree in vehicle engi- neering from Tsinghua University (Beijing, China) and received his Ph.D. in mechanical engineering from Virginia Tech (Blacksburg, Virginia). His R&D experience extending over more than 20 years in various fields of acoustics includes structural acoustics, active and passive vibration and noise control, MEMS transducer design and simulation, hearing science, and acoustic signal processing. His current work at Harman focuses on advanced microphone and sensor technology development for automotive applications. Dr. Du is a member of The Acoustical Society of America (ASA), The Audio Engineering Society (AES), and The American Society of Mechanical Engineers (ASME). He currently serves on the AES Technical Committee for Automotive Audio.

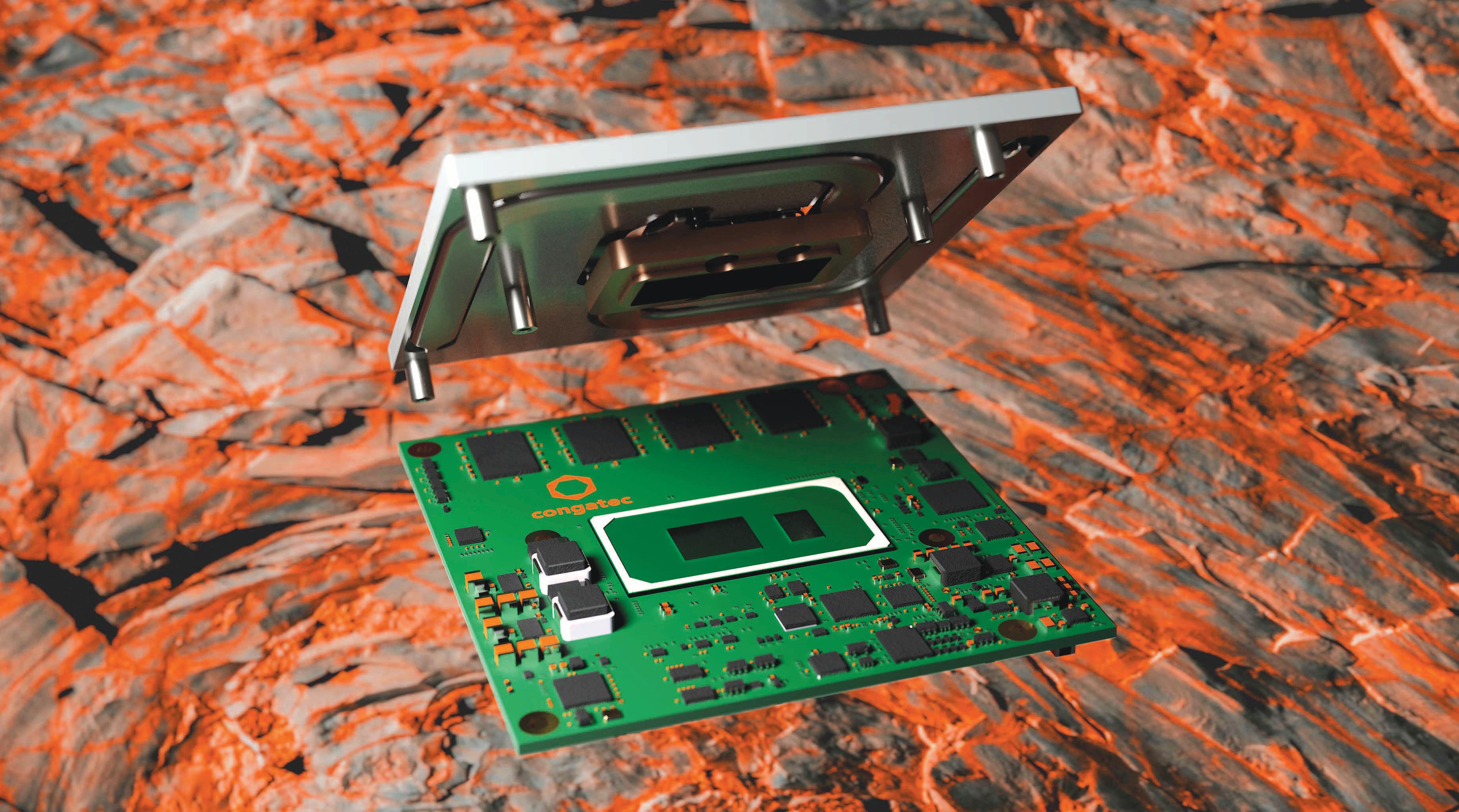

congatec COM

Express modules with 11th generation Intel Core processors are predestined for harsh environmental conditions

Most standard Computer-on-Modules use SO-DIMM connectors to integrate the main memory. Since the main memory is often customized for the specific application, this modular approach works well for module manufacturers and their OEM customers. However, the resistance of such connectors to shock and vibration is limited.

Author: Zeljko Loncaric, Marketing Engineer

Author: Zeljko Loncaric, Marketing Engineer

Although lever arm and mass are not so large, even comparatively small vibrations can impair the functional reliability of the RAM when standard memory modules are used. Applications exposed to high shock and vibrations therefore require more robust designs.

In the rail cargo sector, for example, vibrations of around 0.002 g2/Hz at frequencies from 0 to 350 Hz are common. Vibration levels experienced in jet aircraft are significantly higher at 0.01 g2/Hz with frequencies up to 2000 Hz. For systems deployed in trucks, levels even reach up

to 0.02 g2/Hz. And turbine engines, such as those used in wind turbines, pose higher demands still, stressing components with up to 0.03 g2/Hz.

Developers of such and many other mobile and stationary automation systems exposed to shock and vibration are therefore looking for better solutions to connect the main memory. For instance, memory manufacturers have added screw holes at the far end of their SO-

DIMMs to attach the RAM modules securely so that shock and vibration are no longer a problem.

But such technology does not have many takers that is why rugged SO-DIMMs with mounting holes have been mass-produced, which makes them more expensive. In addition, they are also more complex mechanically and hence more expensive to assemble. Lastly, they also require additional mounting holes on the boards, which further increases production costs. The best solution therefore is to avoid all these add-ons and simply solder the memory directly onto the module. This reduces the bill of materials for components, makes production more cost-effective and, most importantly, ensures ruggedness. And there is yet another distinct advantage of soldered memory: Cooling is easier than with conventional memory connectors. First, because the PCB on which it is soldered has better heat dissipation, and second, because the heat sinks of rugged Computer-on-Modules are specially designed for the respective ruggedness requirements and can be equipped with a heat-conducting connection for cooling hot spots such as the main memory.

congatec recently introduced new Computer-on-Module solutions based on the very latest 11th generation Intel Core processors with soldered RAM. These COM Express Type 6 Computer-on-Modules comply with the ETSI EN 300 019-1-7 and IEC 60721-3-7 specifications for portable and non-stationary telecom equipment and have been tested for commercial 7K3, 7M2 and industrial 7K4, 7M2 environments. This class also applies to nonweather protected locations in moderate outdoor climates and transfers between these conditions. For example, where equipment may be exposed to direct sunlight, radiant heat, ambient air movement, condensation, precipitation, and water from sources other than rain and ice.

In terms of shock and vibration, these modules are suitable for use in demanding transport and mobility applications up to offroad and rail vehicles. In addition they can withstand continuous operation in extreme temperatures (-40°C to +85°C), high humidity and heavy mechanical

stress due to shocks and vibrations and meet all requirements for fire protection. Typical customers for the new range of Computer-on-Modules based on the Tiger Lake microarchitecture are OEMs of trains, commercial vehicles, construction equipment, agricultural vehicles, self-driving robots and many other mobile applications in demanding outdoor and off-road environments. Shock and vibration resistant stationary devices are another important application area as digitization requires critical infrastructure protection (CIP) against earthquakes and other mission -critical events. All these applications can now benefit from super-fast LPDDR4X RAM with up to 4266 MT/s, which congatec offers in graded versions with 32, 16, 8 and 4 GB as standard variants. Depending on the requirements, the highest-performance modules can also be equipped with smaller memory or lower-performance variants based on the Intel Core i3-1115G4E with more than 8 GB RAM. In-band error correction code (IBECC) for single failure tolerance and high data transmission quality in EMIcritical environments corroborate the ruggedness of the modules.

The value package also includes rugged mounting options for the COM and carrier bundle, active and passive cooling options, optional conformal coating for protection against corrosion from moisture or condensation as well as sulfur protection, a list of recommended carrier board layouts and – for maximum reliability – shock and vibration resistant components for the extended temperature range. This impressive technical feature set is complemented by a comprehensive service offering that includes shock and vibration testing for custom system designs, temperature screening and high-speed signal compliance testing, as well as design-in services and all necessary training to simplify the use of congatec’s embedded computer technologies.

The Computer-on-Module concept in a nutshell: https://www.youtube.com/watch?v=2iPhK_nunJw&t=4s ►congatec

https://www.congatec.com

There has been an explosion in the number of Internet of Things (IoT) devices in the last decade, in markets ranging from medical devices to home and building automation to industrial automation. These are devices such as wearables, sensors, appliances and medical monitors – all connected, collecting and sharing massive amounts of data. A new forecast from International Data Corporation (IDC) estimates that there will be 41.6 billion connected IoT devices, or “things”, generating 79.4 zettabytes (ZB) of data in 2025.

Author: Kavita Char Renesas ElectronicsA key driver for this explosion in IoT is ubiquitous wireless connectivity that allows things to be connected to each other and to the internet. This hyper-connectivity has a lot of advantages such as automated control, easy communication between devices and sharing of data.

Elements of AIoT

It also allows collection and sharing of massive amounts of data that can be harvested and used to make intelligent decisions. As the number of connected devices grows, so does the amount of data that is generated. IDC forecasts that the amount of data generated by these devices will

see a compound annual growth rate of 28.7% over the 2018-2025 forecast period. Artificial Intelligence (AI) is the next logical step in making IoT even more useful. Intelligence can be built into IoT end devices to enable them to not only collect and share data but also to analyze it, learn from it and make decisions and act on it, without any human intervention. A combination of AI and IoT (AIoT) creates “intelligent” devices that learn from the generated data and use these insights to make autonomous decisions. New AI technologies are enabling intelligence on the edge and are significantly reducing the need for, and costs associated with cloud analytics. AI is expected to be the technology that helps IoT reach its fullest potential.

AIoT allows computation to move closer to the data. AI technologies, running on edge devices, can automatically process and analyze data generated by sensors and other IoT devices – such as temperature, pressure, humidity, vibration or sound – and use this information to make decisions and trigger actions.

In the past, AI applications have mainly run in the cloud due to complexity of the machine learning models. However, there are some applications that cannot run in the cloud due to lack of reliable and high bandwidth connectivity or when the application is such that it needs the models to be run at the device itself. These could be applications that need fast, realtime operation, which precludes the use of the cloud due to its latency. Examples of such applications are virtual assistants, industrial control, face recognition or medical devices that need quick real-time responses and cannot tolerate the latency of the cloud connection. Additionally, there might be concerns about security and privacy of data, driving the need to store and process data on the local device. Cloud connectivity and services can also be expensive and can drive up the cost of the devices or services associated with its use.

AI at the edge, therefore, provides advantages of autonomy, lower latency, lower power, lower requirement for bandwidth, lower costs and higher security, which make it more attractive for new emerging applications and use cases. Increased compute capability on the edge devices enables AI capability. AI finds use in many IoT applications such as vibration analysis, voice processing, image classification and computer vision, which need a combination of DSP compute capability and inference using machine learning.

1.The AI-enabled edge device market will be the fastest-growing segment within the AIoT

2.There is growing adoption of AI technologies in IoT end devices and companies are moving from cloud-based AI to edge AI to reduce latency and cost and enable real-time monitoring.

3.An analysis from Deloitte predicts sales of edge AI chips to exceed 1.5 billion units, representing annual unit sales growth of at least 20%.

AI in IoT offers a whole slew of benefits to users and organizations such as true intelligent automation, a richer user experience, deeper business insights and operational efficiencies.

Here are a few of these benefits:

AIoT can process and detect patterns in real-time operational data that are not

‘AI’ IN IoT - MARKET DRIVERS & TRENDS AIoT allows users to convert raw IoT data into useful insights that the system can learn from and that can drive decision making. MarketsandMarkets forecasts that the global AI in IoT market size will grow from USD 5.1 billion in 2019 to USD 16.2 billion by 2024, at a Compound Annual Growth Rate (CAGR) of 26.0% during the forecast period. According to MarketsandMarkets, the major factors expected to drive the market are the need to efficiently process huge volumes of real-time data being generated from IoT devices to gain valuable insights, real-time monitoring, enhanced user experience and reduced maintenance cost and downtime.

4 Gartner predicts that by 2022, more than 80 percent of enterprise IoT projects will include an AI component, up from only 10 percent today.

5.A lot of technology companies in the IoT space are investing significantly in AI in order to deliver new “intelligent” products, increase business efficiency and use data to drive business insights and enhance customer experience.

6.Venture capital funding and acquisitions of AI-focused IoT start-ups is growing fast.

7.Vendors of IoT platforms such as Amazon, IBM, Microsoft and Oracle, are integrating AI capabilities on their major general-purpose and industrial IoT platforms.

visible to the human eye and can use that data to set operating conditions in realtime, that result in optimal business outcomes. AI can thus help to optimize production processes and improve workflow resulting in increased efficiency and reduced operational costs.

AI can help institutions to use data to identify risks in a timely manner and use these insights to optimize their processes to increase safety and reduce loss and make better informed business decisions. Applications where AI can help to reduce risk include predicting mechanical faults on airlines and detecting safety risks on a factory floor.

AI and the ability to process and draw insights from large amounts of data, has opened up new technologies that did not previously exist such as voice recognition, face recognition and predictive analysis. These newly created capabilities can be used in many applications such as use of robots in delivery services or for disaster search and rescue operations, smart video doorbells, voice based virtual assistants and predictive maintenance for vehicles or building automation systems, amongst others.

In manufacturing, unplanned downtime of machinery resulting from equipment breakdown can be very disruptive to business. Predictive maintenance can help in predicting equipment failure by analyzing data from machinery and scheduling maintenance proactively, resulting in reduced incidence and costs of unplanned downtime.

AIoT enables new and advanced level of solutions that can transform businesses, enrich the user experience and increase safety and security. Here are some applications that benefit from AI:

Agricultural AIoT

Agriculture is one of the key segments that can benefit from AIoT.

Robots

Robots, in manufacturing as well as consumer products, are examples of applications that are very well suited for AI. Robotic vacuum cleaners have sensors that gather data on the environment and use AI to make decisions on how to traverse a space. Similarly, robots used in manufacturing, package/food delivery or search and rescue operations in disaster areas, use AI to sense complex (and sometimes hostile) environments and adapt their responses accordingly. Robots, with ability to recognize faces and human emotions, have also been used in retail environments to direct traffic and enrich the shopping experience.

Industrial automation

Computer vision with AI can be used to improve quality control on the assembly line and help with anomaly detection. AI can also help with predictive maintenance of the machinery to avoid downtime, improve machine life and reduce manufacturing costs. Robots can be used on the manufacturing floor or warehouses to move packages around, assist in the assembly line, inspect product quality and perform repetitive, high precision tasks.

In the retail environment, AIoT helps to tailor the shopping experience and provide personalized recommendations based on customer intelligence, demographic information and customer behavior.

By bringing analysis and decision making to the edge, AI helps to reduce volume of data that needs to be transferred to the cloud and hence reduce costs related to cloud connectivity and services.

AI is used to create an intelligent system that adjusts parameters based on weather conditions, water usage, temperature and crop/soil conditions. The data from sensors is analyzed to make optimal decisions on crop choices, fertilizers, irrigation and pest control. AI helps farmers in enhancing their yields, do seasonal forecasting and weather prediction for crop planning and utilizing resources in the most optimal way. Computer vision with AI is used to monitor crops and large farmlands to identify problem areas and generate alerts when needed.

Autonomous or self-driving vehicles combine IoT and AI to navigate through traffic, respond to changing traffic, weather or road conditions or predict the behavior of pedestrians. AI can also be used to gauge the condition of the vehicle based on collected usage data and provide predictive recommendations for maintenance.

AIoT can help companies to reduce their energy costs and make the buildings energy efficient by adjusting lighting and climate control based on building usage and user preference data.

Predictive maintenance (using diagnostic data on health of the building systems) allows repairs and maintenance when they are needed rather than on a schedule, thus helping companies save on costs. They can also provide alerts on potential system failures before they happen and help to tune the systems for optimal performance. AI can also be used for automated access control using camera sensors.

AIoT can open up new ways to create more efficient cities, maintain city infrastructure, and improve public services for communities. This can be done by gathering and analyzing data from multitudes of sensors and IoT devices and extracting actionable insights that can be used to make adjustments in real-time. Practical applications of AI include waste management, public services such as parking management, traffic management and smart lighting. As an example, drones can be used to monitor traffic in real-time and the data can be used to adjust traffic lights or lane assignments in order to manage and reduce traffic jams, all without intervention by humans. Similarly, sensors attached to waste bins can alert the operators to pick up the garbage only when the bins are full, thus helping to reduce costs.

AI finds application in fleet management by using predictive maintenance, with real-time monitoring of the fleet and proactive maintenance of the vehicles based on data collected from GPS trackers and sensors. AI also helps fleet operators with real-time navigation to reduce fuel costs, tracking vehicle maintenance, and identifying unsafe driver behavior.

AI can help retail in two ways. AI and predictive analytics help to collect and analyze large amounts of data and use that information to help retailers forecast and make accurate, data-driven business decisions. AIoT can use customer intelligence, demographic data and behavioral analytics to provide personalized recommendations to shoppers and improve store operations, product placement strategy, customer service and overall user experience. Retail robots can help to direct traffic and improve the customer experience.

AIoT in healthcare can be used for diverse applications, such as detecting and diagnosing diseases by analyzing imaging data, remote monitoring of patient’s information via sensors and raising alerts when anomalies are seen, predictions of a patient’s risk of diseases by analyzing EHRs (electronic health records) and predicting drug interactions. In addition, robotic surgical systems can perform or assist in very complex and high precision surgeries and make minimally invasive surgery possible.

It utilizes Deep Neural Network (DNN), a multilayered network that is particularly suited for applications involving image classification, voice recognition or natural language processing. The e-AI tools embedded in the Renesas e2 Studio Integrated Development Environment convert NN models into a form (C/C++ based) that is usable by the MCU and assist in embedding the pre-trained NN model on the target MCU.

‘AI’

AIoT is enabling new applications and use cases and will help IoT reach its fullest potential.

Renesas has a comprehensive family of Arm based MCUs capable of running AI applications. Renesas is working closely with ecosystem partners to bring end-toend AI solutions in predictive analytics, vision and voice applications, amongst others. Applications using these capabilities span market segments such as industrial automation, smart homes, building automation, healthcare and agriculture.

Renesas’s “e-AI” (embedded AI) solution uses the popular NN models - Caffe developed by UC Berkeley and TensorFlow from Google.

Applications of AIoT can be found in markets as diverse as smart cities, industrial automation, medical, agriculture and smart homes. We will continue to see a rise in new applications that will incorporate AI in IoT end points, and more and more manufacturers will make AIoT an area of significant investment.

►Renesas Electronics www.renesas.com

Mouser Electronics, Inc. announced it has entered into a global distribution agreement with Siretta, a leading global manufacturer and developer of Internet of Things (IoT) products, software, and complete end-to-end solutions. As part of the agreement, Mouser Electronics becomes an authorized distributor of Siretta’s advanced mobile broadband technologies, including its lines of SNYPER network signal analysers, high-speed QUARTZ industrial routers, and ZETA modem starter kits - all designed for a variety of IoT, industrial, and transportation applications.

The Siretta SNYPER-LTEM (GL), now available from Mouser Electronics, is a high-performance, multi-language network signal analyser dedicated to surveying LTE Cat M, LTE Cat NB IoT, and 2G/GSM Global networks. The powerful SNYPER summary page displays percentage thresholds to determine the most suitable mobile network operator (MNO) available and the performance of a “preferred” MNO can be evaluated against the other networks.

Siretta’s high-speed EU industrial routers include the QUARTZ-LTE dual-port LTE routers (EU) and the QUARTZCOMPACT single-port 4G/LTE routers (EU), which enable industrial IoT applications to transfer large amounts of data over a cellular network. Both routers offer upload speeds up to 50 Mbps, with fallback to 3G/UMTS or 3G communication (respectively), should 4G/LTE be unavailable.

The QUARTZ-LTE router enables fast downloads up to 100 Mbps, with dual SIM backup, dual-port Ethernet capabilities, and Wi-Fi or GNSS asset tracking/management options. The QUARTZ-COMPACT router offers download speeds of up to 150 Mbps, a single SIM slot, 10/100 Ethernet LAN port and serial port for serial-to-IP transfers, which can be swapped out for an optional GPS. Both routers contain QUARTZ software (which offers support for VPN security) and function across the European (EU) 4G/LTE bands. The routers provide a robust industrial design and strong resistance to EMI and are ideal for applications requiring local or remote communications.

The ZETA family of modems connect equipment to the LTE Cat 4, LTE Cat 1, LTE Cat M, and LTE Cat NBIoT networks and provide backward compatibility to the existing 3G/UMTS and 2G/GSM cellular networks.

►Mouser Electronics | https://www.mouser.com

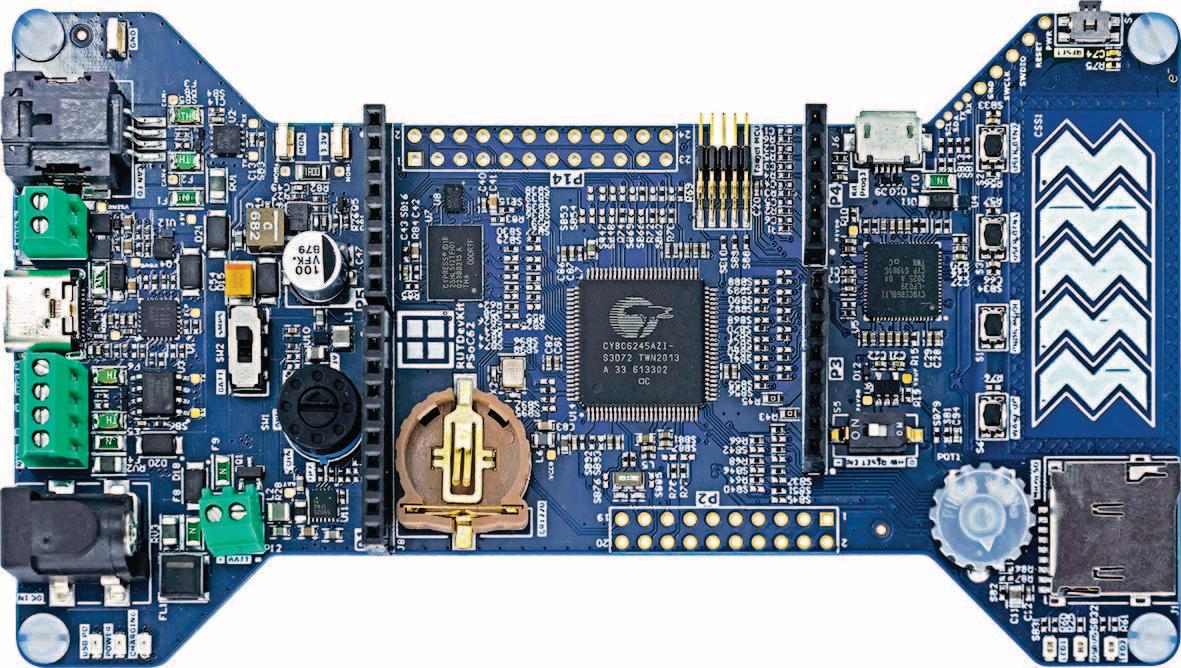

Infineon Technologies launched the company’s fifth-generation CAPSENSE™ capacitive and inductive touch sensing human-machine interface (HMI) technology. The next-generation CAPSENSE solution embedded in PSoC™ microcontrollers delivers higher performance and lower power consumption for demanding user interfaces in home appliance, industrial, consumer and IoT products. The enhanced HMI enables advanced solutions like proximity sensing with improved detection range, gesture detection and directivity, along with hover detection for tomorrow’s advanced touchscreens.

With ten times better performance and a tenth of the power consumption of previous generations, the new CAPSENSE technology allows designers to develop more intuitive user interfaces, while significantly reducing overall power consumption to meet the demands of battery-powered IoT devices. The latest CAPSENSE generation is ideal for home appliance and industrial applications including smart door locks, smart switches, thermostats, smart speakers, power tools, industrial touchscreens and other IoT devices. The new technology is also ideal for applications with larger touchscreens in industrial and home appliance products including induction cooktops, washer and dryers, refrigerators, ovens and more.

“As the leader in capacitive touch sensing technology nearing four billion units sold, we are excited to offer our fifth generation CAPSENSE technology to designers,” said Steve Tateosian, Vice President of IoT Compute and Wireless Business Unit of Infineon. “This new generation of CAPSENSE technology builds

Infineon’s 5th Generation CAPSENSE™ technology extends market leader-ship with improved robustness, reliability and lower power consumption

on our established leadership with an all-new ratiometric and differential sensing architecture. It provides improved noise immunity, and a robust and reliable HMI solution to perform even in the harshest environments with extreme electrical noises, and under extreme weather and temperature.”

Infineon’s proprietary CAPSENSE technology empowers designers to develop more advanced HMIs on tomorrow’s devices with various touch sensing user interface requirements. With the ultra-low power capabilities and the ability to fit in smaller form factors, this technology is also ideal for touch interfaces on wearables, hearables and smart IoT applications. The new CAPSENSE technology enables advanced HMI solutions like proximity sensing with improved detection range, gesture detection and directivity. A new, autonomous sensing mode, enables operation without a CPU reducing power consumption and a new ratiometric sensing architecture and differential signal path improves noise immunity and performance.

With Infineon’s CAPSENSE capacitive touch sensor interface, a user’s finger on the interface forms an electrical connection with embedded sensors. The sensors work with the PSoC device to translate data about the finger’s position into various system control functions. A single PSoC device can replace dozens of mechanical switches and controls with simple, touch-sensitive controls. CAPSENSE-based “button” and slider controls are more reliable than their mechanical counterparts because they are not prone to the environmental wear-and-tear that affects exposed buttons and switches. More information is available at: https://www.cypress.com/products/capsense-controllers.

Infineon’s fifth generation CAPSENSE capacitive sensing HMI technology embedded in PSoC 4 devices is available to lead customers today including support in ModusToolbox™. More information: https://www.cypress.com/products/capsense.

►Infineon Technologies | https://www.infineon.com

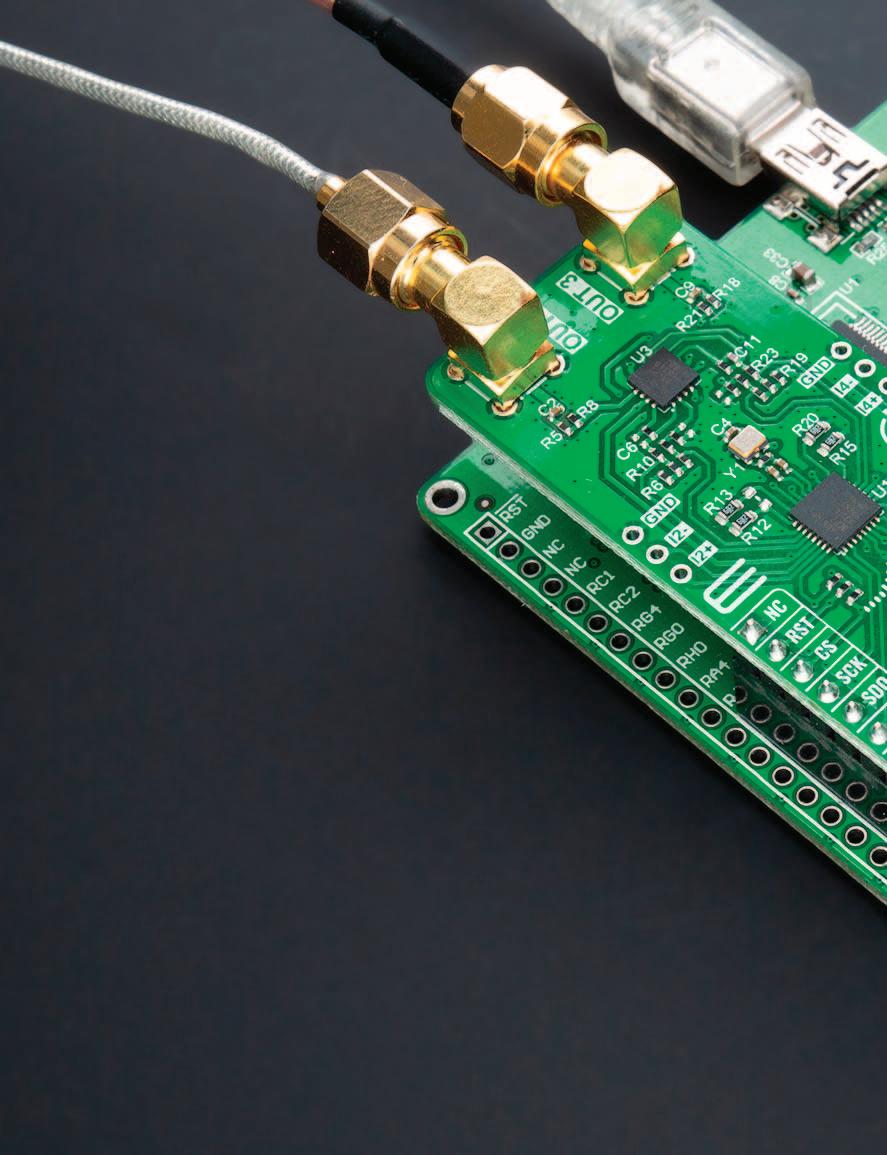

Analog Devices, Inc. announced a breakthrough RadioVerse® System-on-Chip (SoC) series providing radio unit (RU) developers with an agile and cost-effective platform to create the most energy efficient 5G RUs in the industry. The new SoC series provides advanced RF signal processing with expanded digital functionality and RF capacity that greatly improves 5G RU performance and energy efficiency. The SoCs are the newest addition to ADI’s RadioVerse ecosystem and combine its award-winning Zero IF (ZiF) architecture with significant advances in functional integration and linearization. ADI’s RadioVerse devices are the most widely used softwaredefined transceivers in 4G and 5G RUs worldwide.1

Demand for power efficient RUs is expanding rapidly as global network operators race to deploy 5G infrastructure. With the exponential growth of wireless demand, energy efficiency is a key metric for operators as they seek to reduce their carbon footprint while expanding network capacity. The new RadioVerse SoC series requires very low power compared to alternatives and implements advanced algorithms that deliver optimal RU system efficiency.

The ADRV9040 is the first in the new RadioVerse SoC series. It offers eight transmit and receive channels of 400MHz bandwidth and integrates advanced digital signal processing functions, including carrier digital up-converters (CDUC), carrier digital down-converters (CDDC), crest factor reduction (CFR) and digital pre-distortion (DPD). This expanded signal processing can eliminate the need for a field-programmable gate array (FPGA), thereby reducing thermal footprint, and total system size, weight, power, and cost. The SoC’s DPD algorithms were developed using advanced machine learning techniques and are optimized in close collaboration with major power amplifier (PA) vendors to ease the design burden and deliver best-inclass wide bandwidth performance. The algorithms are fully tested and validated across 4G and 5G use cases, including various PA technology types such as gallium nitride (GaN). In addition, the ZiF radio architecture simplifies RF filtering and signal chain components, reducing RU cost and development time for band and power variants designs.

Learn more about the ADRV9040 RadioVerse SoC at https://www.analog.com/ADRV9040

►Analog Devices | https://www.analog.com

Security is now a key requirement for embedded systems. The desire to connect devices to the internet to make it easier to control them and pull live data from their sensors brings with it a high risk of hacking. The hacking activity does not put at risk just individual devices but entire networks.

Author: Nicolas Demoulin, EMEA Marketing Manager – Secure Products Group

The direction is clear: vendors cannot go to market without an IoT product secure by design. The issue for device manufacturers as they look to harness the power of the IoT for their systems is the complexity of implementing effective and relevant security mechanisms. It is easy to see the fundamental need for authentication and encryption in these systems. But implementation has been much harder to achieve. There are multiple components, both software and hardware, that are needed to create a secure foundation for an embedded system.

A weakness in any one of them can easily lead to the hardware being compromised and loaded with malware that is used to attack an operator’s network or to leak sensitive data to cybercriminals. At the same time, many design teams are confronting for the first time the development difficulties presented by security concerns.

One of the core requirements for effective security is that each deployed device should have its own unique identity. A common flaw exploited by hackers is to have devices provide a common password or login for use by service and maintenance engineers.

The details of this login are often easy to guess and even if they are not they are usually easily obtained by a hacker. With this login, it is possible to gain access to not just one device but the entire fleet. Cybercriminals were able to create botnets – armies of identical computers used in denial-of-service attacks – through the use of simple automated scripts. The scripts identified and logged into each device of a certain type that had an internet connection.